Effect of Aging Time on Microstructure and Mechanical Properties in a Cu-Bearing Marine Engineering Steel

Abstract

:1. Introduction

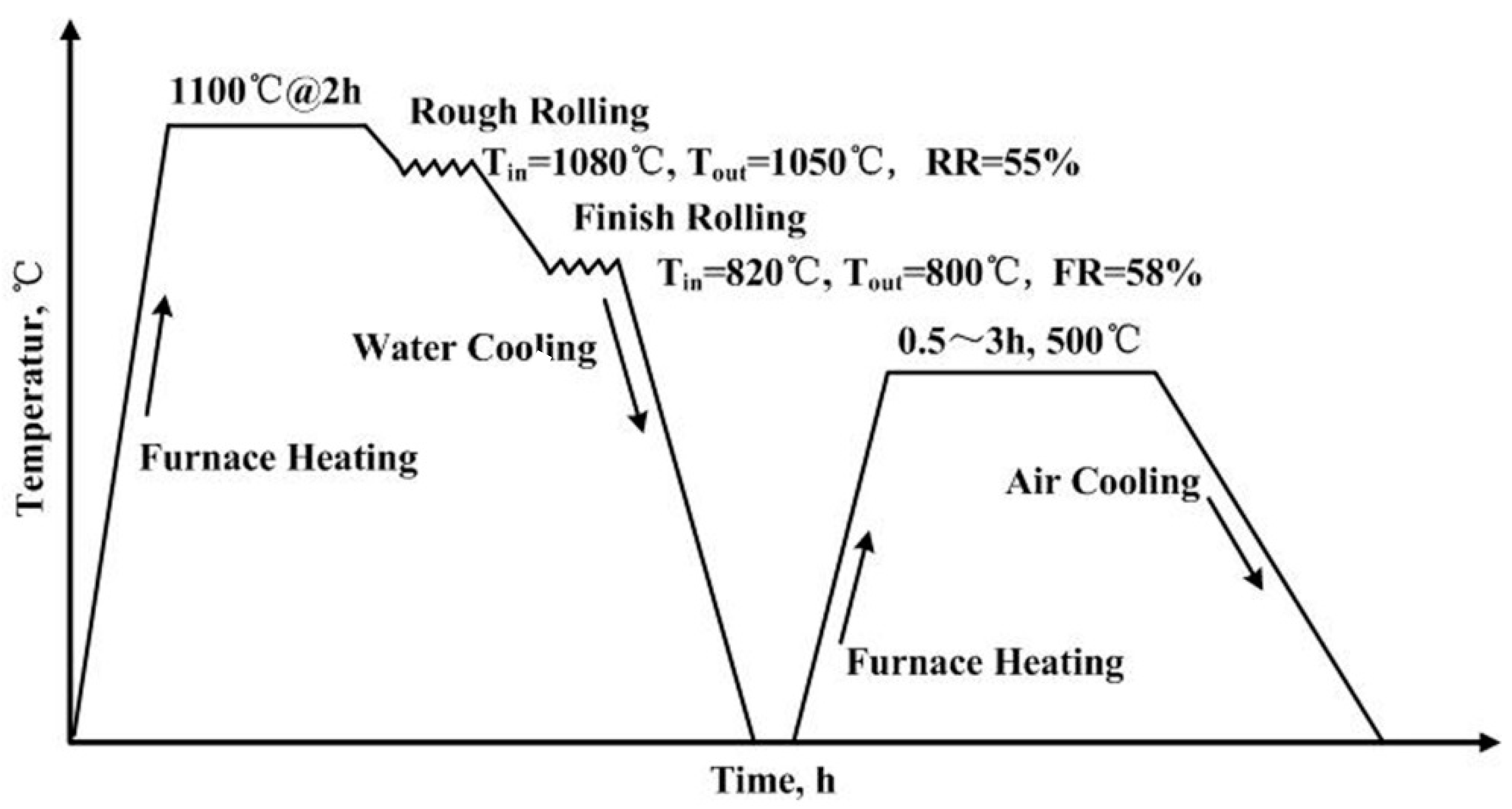

2. Materials and Methods

3. Results and Discussion

3.1. Microstructural Characterization by SEM

3.2. Microstructural Characterization by TEM

3.3. Tensile Properties

3.4. Low Temperature Impact Properties

4. Conclusions

- (1)

- The microstructure was characterized by polygonal ferrite and a small amount of bainitic ferrite in water-cooled condition. The structural recovery could be found during aging treatment, which became severe with the increase of aging time.

- (2)

- With an increase in the aging time, the structural transformation from twinned 9R Cu to stable fcc Cu could be confirmed by HRTEM, together with the coarsening of Cu precipitates.

- (3)

- Cu precipitate–dislocation interaction strengthening effects were calculated to be 232 and 199 MPa after aging at 500 °C for 1 and 3 h, respectively. The optimized samples could be obtained after a 1-h aging process where the yield strength, tensile strength and elongation showed high values of 755 MPa, 812 MPa and 26.3%, respectively.

- (4)

- Conversely, the low temperature toughness was destroyed by prolonged aging, which was caused by Cu precipitation. The CVN impact energy values decreased continuously when the aging process was prolonged due to the formation and coarsening of Cu particles.

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, Z.W.; Liu, C.T.; Wen, Y.R.; Hirata, A.; Guo, S.; Chen, G.; Chen, M.W.; Chin, B.A. Influence of aging and thermomechanical treatments on the mechanical properties of a nanocluster-strengthened ferritic steel. Metall. Mater. Trans. A 2012, 43, 351–358. [Google Scholar] [CrossRef]

- Das, S.; Ghosh, A.; Chatterjee, S.; Rao, P.R. The effect of cooling rate on structure and properties of a HSLA forging. Scr. Mater. 2003, 48, 51–57. [Google Scholar] [CrossRef]

- Ghosh, A.; Das, S.; Chatterjee, S.; Rao, P.R. Effect of cooling rate on structure and properties of an ultra-low carbon HSLA-100 grade steel. Mater. Charact. 2006, 56, 59–65. [Google Scholar] [CrossRef]

- Wen, Y.R.; Li, Y.P.; Hirata, A.; Zhang, Y.; Fujita, T.; Furuhara, T.; Liu, C.T.; Chiba, A.; Chen, M.W. Synergistic alloying effect on microstructural evolution and mechanical properties of Cu precipitation-strengthened ferritic alloys. Acta Mater. 2013, 61, 7726–7740. [Google Scholar] [CrossRef]

- Park, T.W.; Kang, C.Y. The effects of PWHT on the toughness of weld HAZ in Cu-Containing HSLA-100 steel. ISIJ Int. 2000, 40, 49–53. [Google Scholar] [CrossRef] [Green Version]

- Wei, L.Y.; Nelson, T.W. Influence of heat input on post weld microstructure and mechanical properties of friction stir welded HSLA-65 steel. Mater. Sci. Eng. A 2012, 556, 51–59. [Google Scholar] [CrossRef]

- Momeni, A.; Arabi, H.; Rezaei, A.; Badri, H.; Abbasi, S.M. Hot deformation behavior of austenite in HSLA-100 microalloyed steel. Mater. Sci. Eng. A 2011, 528, 2158–2163. [Google Scholar] [CrossRef]

- Deschamps, A.; Militzer, M.; Poole, W.J. Comparison of precipitation kinetics and strengthening in an Fe-0.8%Cu alloy and a 0.8% Cu-containing low-carbon steel. ISIJ Int. 2003, 43, 1826–1832. [Google Scholar] [CrossRef] [Green Version]

- Mulholland, M.D.; Seidman, D.N. Nanoscale co-precipitation and mechanical properties of a high-strength low-carbon steel. Acta Mater. 2011, 59, 1881–1897. [Google Scholar] [CrossRef]

- Isheim, D.; Gagliano, M.S.; Fine, M.E.; Seidman, D.N. Interfacial segregation at Cu-rich precipitates in a high-strength low-carbon steel studied on a sub-nanometer scale. Acta Mater. 2006, 54, 841–849. [Google Scholar] [CrossRef]

- Dhua, S.K.; Ray, A.; Sarma, D.S. Effect of tempering temperatures on the mechanical properties and microstructures of HSLA-100 type copper-bearing steels. Mater. Sci. Eng. A 2001, 338, 197–210. [Google Scholar] [CrossRef]

- Hwang, G.C.; Lee, S.; Yoo, J.Y.; Choo, W.Y. Effect of direct quenching on microstructure and mechanical properties of copper-bearing high-strength alloy steels. Mater. Sci. Eng. A 1998, 252, 256–268. [Google Scholar] [CrossRef]

- Ray, P.K.; Ganguly, R.I.; Panda, A.K. Optimization of mechanical properties of an HSLA-100 steel through control of heat treatment variables. Mater. Sci. Eng. A 2003, 346, 122–131. [Google Scholar] [CrossRef]

- Ghosh, A.; Mishra, B.; Das, S.; Chatterjee, S. An ultra low carbon Cu bearing steel: Influence of thermomechanical processing and aging heat treatment on structure and properties. Mater. Sci. Eng. A 2004, 374, 43–55. [Google Scholar] [CrossRef]

- Dhua, S.K.; Mukerjee, D.; Sarma, D.S. Influence of thermomechanical treatments on the microstructure and mechanical properties of HSLA-100 steel plates. Metall. Mater. Trans. A 2003, 34, 241–253. [Google Scholar] [CrossRef]

- Panwar, S.; Goel, D.B.; Pandey, O.P.; Prasad, K.S. Aging of a copper bearing HSLA-100 steel. Bull. Mater. Sci. 2003, 26, 441–447. [Google Scholar] [CrossRef]

- Liu, Q.D.; Zhao, S.J. Comparative study on austenite decomposition and Cu precipitation during continuous cooling transformation. Metall. Mater. Trans. A 2013, 44, 163–171. [Google Scholar] [CrossRef]

- Jung, J.G.; Jung, M.; Lee, S.M.; Shin, E.; Shin, H.C.; Lee, Y.K. Cu precipitation kinetics during martensite tempering in a medium C steel. J. Alloys Compd. 2013, 553, 299–307. [Google Scholar] [CrossRef]

- Wen, Y.R.; Hirata, A.; Zhang, Z.W.; Fujita, T.; Liu, C.T.; Jiang, J.H.; Chen, M.W. Microstructure characterization of Cu-rich nanoprecipitates in a Fe-2.5 Cu-1.5 Mn-4.0 Ni-1.0 Al multicomponent ferritic alloy. Acta Mater. 2013, 61, 2133–2147. [Google Scholar] [CrossRef]

- Monzen, R.; Iguchi, M.; Jenkins, M.L. Structural changes of 9R copper precipitates in an aged Fe-Cu alloy. Philos. Mag. Lett. 2000, 80, 137–148. [Google Scholar] [CrossRef]

- Bajguirani, H.R.H.; Jenkins, M.L. High-resolution electron microscopy analysis of the structure of copper precipitates in a martensitic stainless steel of type PH 15-5. Philos. Mag. Lett. 1996, 73, 155–162. [Google Scholar] [CrossRef]

- Monzen, R.; Jenkins, M.L.; Sutton, A.P. The bcc-to-9R martensitic transformation of Cu precipitates and the relaxation process of elastic strains in an Fe-Cu alloy. Philos. Mag. A 2000, 80, 711–723. [Google Scholar] [CrossRef]

- Thompson, S.W.; Krauss, G. Copper precipitation during continuous cooling and isothermal aging of A710-type steels. Mater. Trans. A 1996, 27, 1573–1588. [Google Scholar] [CrossRef]

- Lee, T.H.; Kim, Y.O.; Kim, S.J. Crystallographic model for bcc-to-9R martensitic transformation of Cu precipitates in ferritic steel. Philos. Mag. 2007, 87, 209–224. [Google Scholar] [CrossRef]

- Heo, Y.U.; Kim, Y.K.; Kim, J.S.; Kim, J.K. Phase transformation of Cu precipitates from bcc to fcc in Fe-3Si-2Cu alloy. Acta Mater. 2013, 61, 519–528. [Google Scholar] [CrossRef]

- Othen, P.J.; Jenkins, M.L.; Smith, G.D.W. High-resolution electron microscopy studies of the structure of Cu precipitates in α-Fe. Philos. Mag. A 1994, 70, 1–24. [Google Scholar] [CrossRef]

- Othen, P.J.; Jenkins, M.L.; Smith, G.D.W.; Phythian, W.J. Transmission electron microscope investigations of the structure of copper precipitates in thermally-aged Fe-Cu and Fe-Cu-Ni. Philos. Mag. Lett. 1991, 64, 383–391. [Google Scholar] [CrossRef]

- Perez, S.L.; Jenkins, M.L.; Titchmarsh, J.M. Evidence for deformation-induced transformations of Cu-rich precipitates in an aged FeCu alloy. Philos. Mag. Lett. 2006, 86, 367–374. [Google Scholar] [CrossRef]

- Feng, L.; Zhou, B.X.; Peng, J.C.; Wang, J.A. Crystal structure evolution of the Cu-rich nano precipitates from bcc to 9R in reactor pressure vessel model steel. Acta Metall. Sin. (Engl. Lett.) 2013, 26, 707–712. [Google Scholar] [CrossRef] [Green Version]

- Russel, K.C.; Brown, L.M. A dispersion strengthening model based on differing elastic moduli applied to the iron-copper system. Acta Metall. 1972, 20, 969–974. [Google Scholar] [CrossRef]

- Kong, H.J.; Xu, C.; Bu, C.C.; Da, C.; Luan, J.H.; Jiao, Z.B.; Chen, G.; Liu, C.T. Hardening mechanisms and impact toughening of a high-strength steel containing low Ni and Cu additions. Acta Mater. 2019, 172, 150–160. [Google Scholar] [CrossRef]

| Fe | C | Si | Mn | P | S | Ni | Cr | Cu | Al | N |

|---|---|---|---|---|---|---|---|---|---|---|

| Bal. | 0.005 | 0.2 | 0.7 | 0.01 | 0.004 | 2.5 | 0.5 | 2.0 | 0.03 | 0.005 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, M.; Xu, Y.; Wang, J. Effect of Aging Time on Microstructure and Mechanical Properties in a Cu-Bearing Marine Engineering Steel. Materials 2020, 13, 3638. https://doi.org/10.3390/ma13163638

Sun M, Xu Y, Wang J. Effect of Aging Time on Microstructure and Mechanical Properties in a Cu-Bearing Marine Engineering Steel. Materials. 2020; 13(16):3638. https://doi.org/10.3390/ma13163638

Chicago/Turabian StyleSun, Mingxue, Yang Xu, and Jin Wang. 2020. "Effect of Aging Time on Microstructure and Mechanical Properties in a Cu-Bearing Marine Engineering Steel" Materials 13, no. 16: 3638. https://doi.org/10.3390/ma13163638

APA StyleSun, M., Xu, Y., & Wang, J. (2020). Effect of Aging Time on Microstructure and Mechanical Properties in a Cu-Bearing Marine Engineering Steel. Materials, 13(16), 3638. https://doi.org/10.3390/ma13163638