Synthesis of Silver Nanoplates with the Assistance of Natural Polymer (Sodium Alginate) Under 0 °C

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation

2.3. Characterization

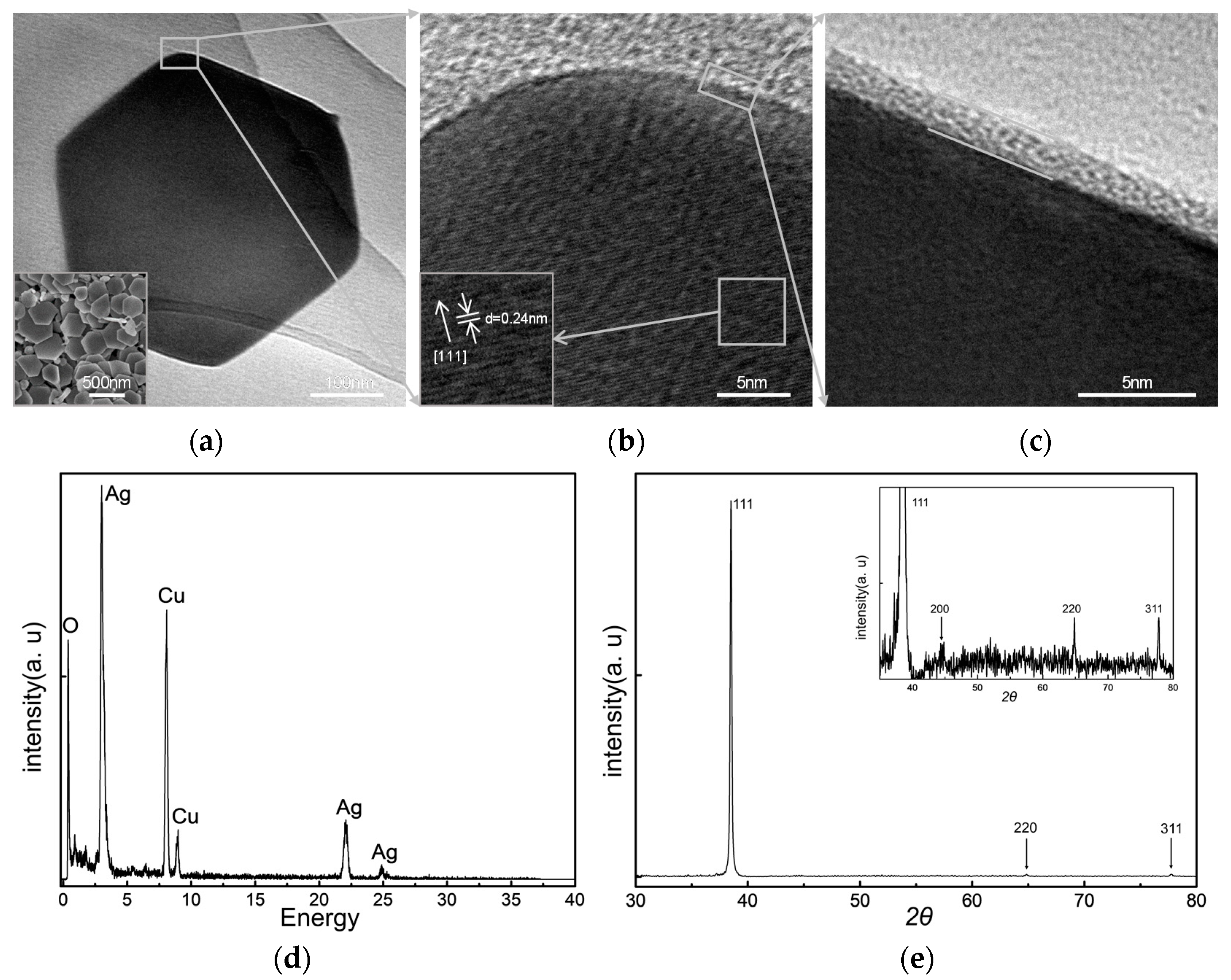

3. Results

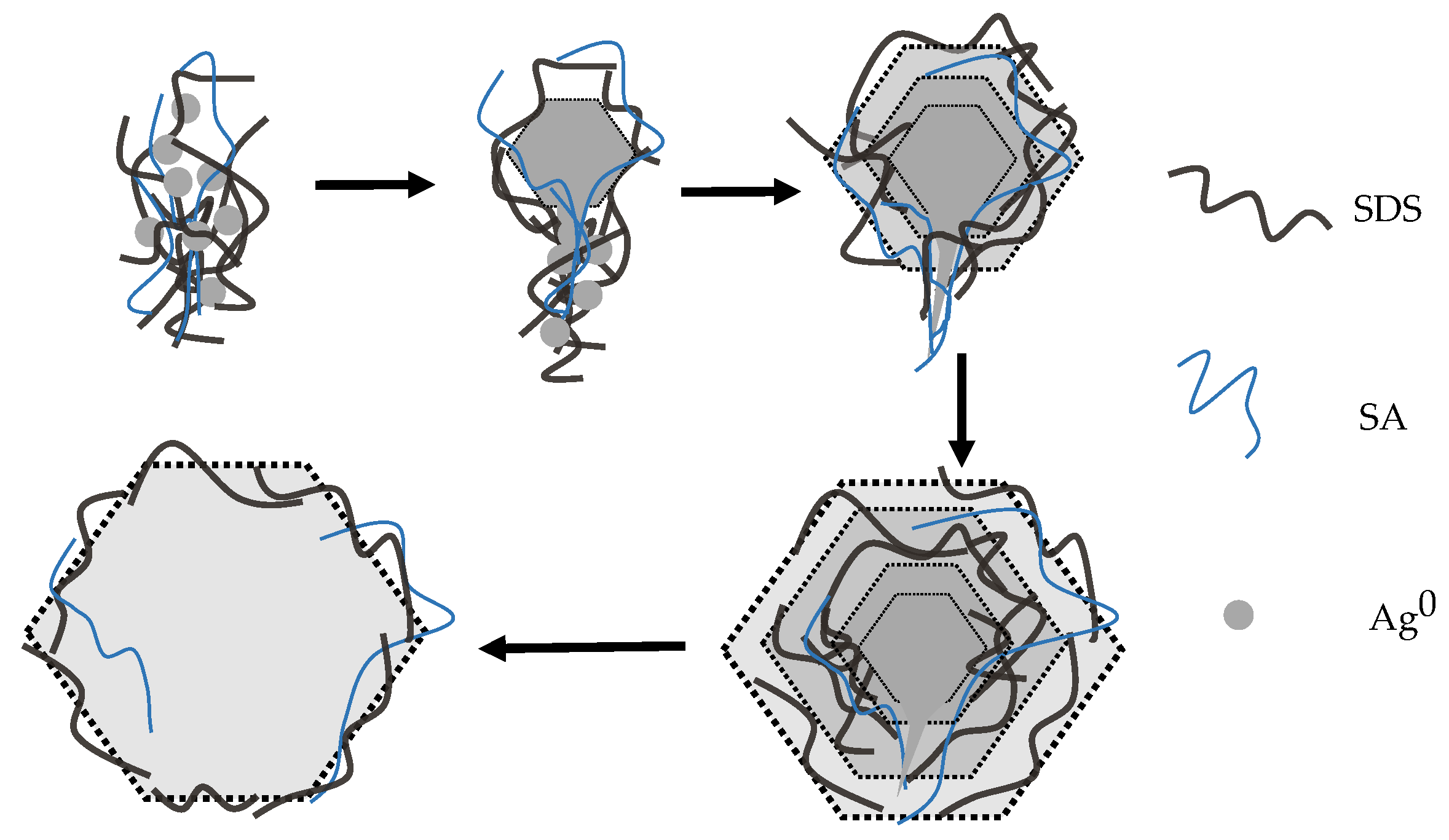

3.1. High-Yield Production of SNPs

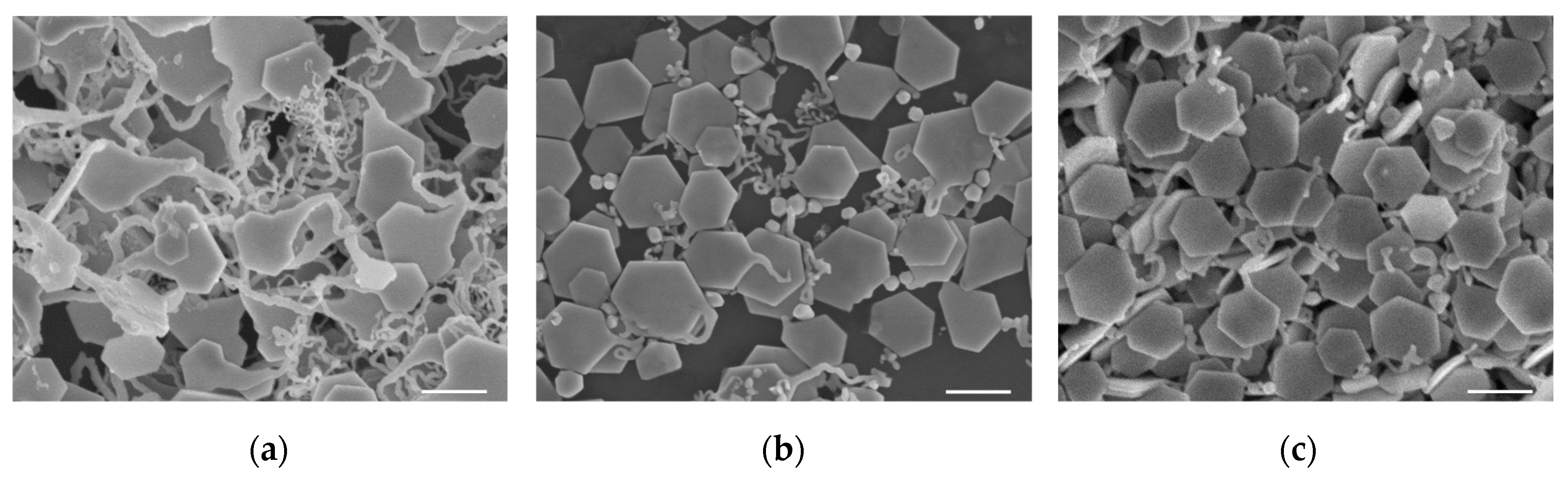

3.2. Time Controlling the Growth of SNPs

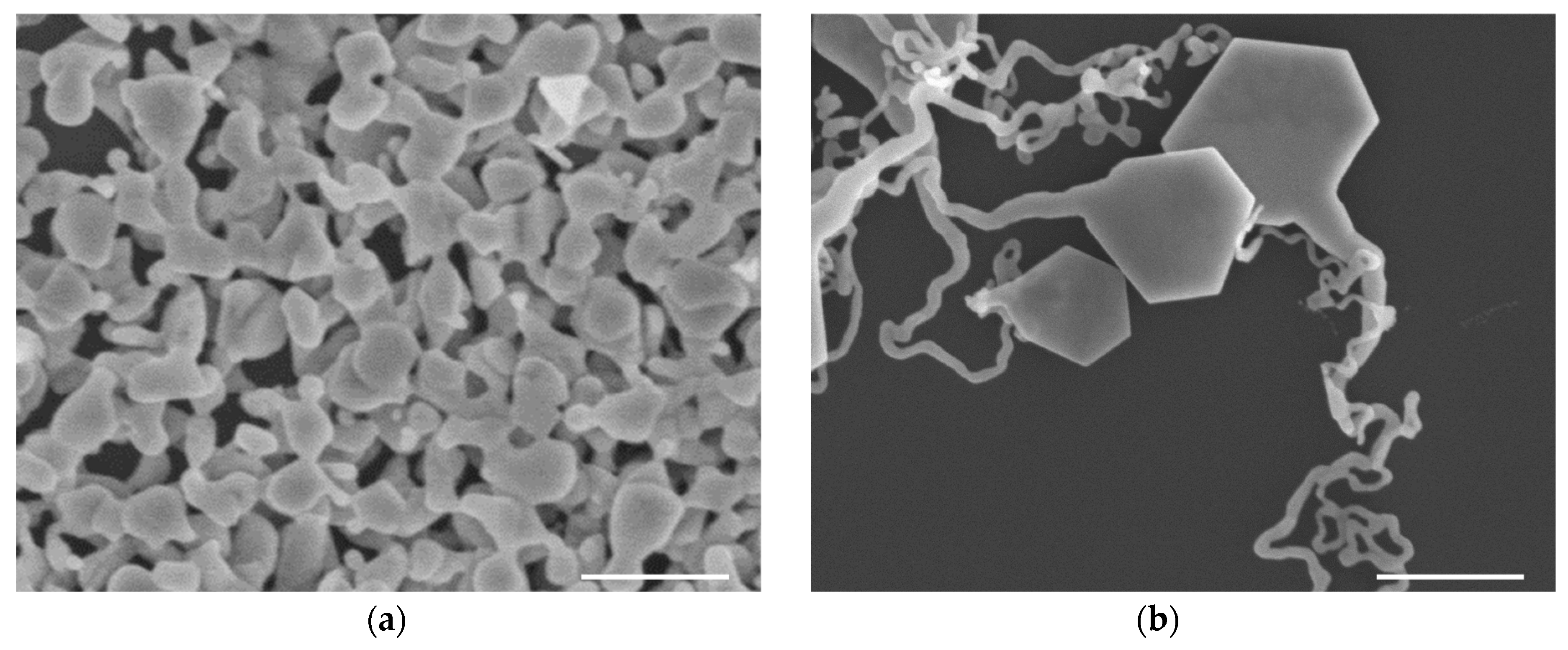

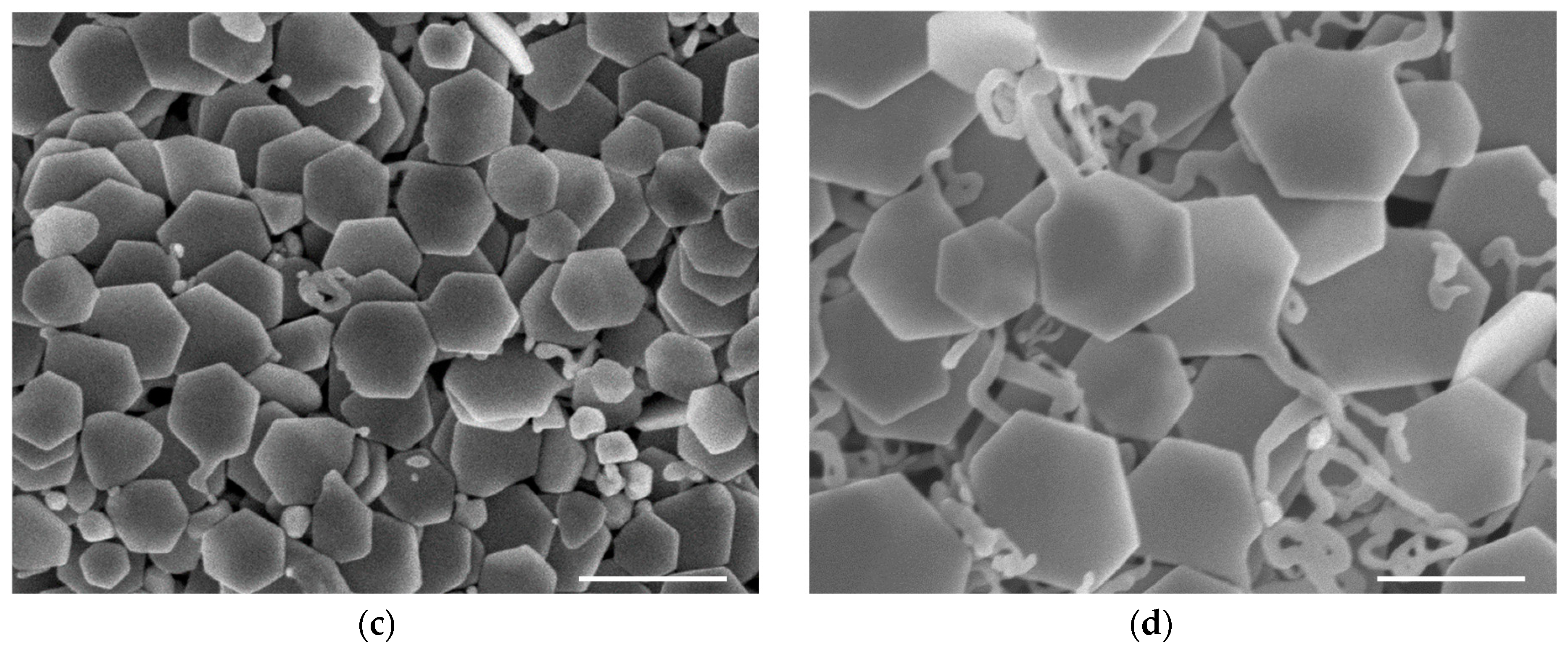

3.3. Morphological Changes in SNPs with Different Amounts of SA

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Deng, Q.; Kang, M.; Zheng, D.; Zhang, S.; Xu, H. Mimicking plasmonic nanolaser emission by selective extraction of electromagnetic near-field from photonic microcavity. Nanoscale 2018, 10, 7431–7439. [Google Scholar] [CrossRef]

- Zhu, S.; Fan, C.; Wang, J.; He, J.; Liang, E.-J. Surface-enhanced Raman scattering of 4-mercaptobenzoic acid and hemoglobin adsorbed on self-assembled Ag monolayer films with different shapes. Appl. Phys. A 2014, 117, 1075–1083. [Google Scholar] [CrossRef]

- Rossouw, D.; Couillard, M.; Vickery, J.; Kumacheva, E.; Botton, G. Fabry-Perot Plasmonic Resonances in Silver Nanowire Antennas Imaged with a Sub-Nanometer Electron Probe. Microsc. Microanal. 2011, 17, 766–767. [Google Scholar] [CrossRef][Green Version]

- Pourali, P.; Baserisalehi, M.; Afsharnezhad, S.; Behravan, J.; Ganjali, R.; Bahador, N.; Arabzadeh, S. The effect of temperature on antibacterial activity of biosynthesized silver nanoparticles. BioMetals 2013, 26, 189–196. [Google Scholar] [CrossRef] [PubMed]

- You, J.; Xiang, M.; Hu, H.; Cai, J.; Zhou, J.; Zhang, H. Aqueous synthesis of silver nanoparticles stabilized by cationic cellulose and their catalytic and antibacterial activities. RSC Adv. 2013, 3, 19319–19329. [Google Scholar] [CrossRef]

- Liang, H.; Wang, W.; Huang, Y.; Zhang, S.; Wei, H.; Xu, H. Controlled Synthesis of Uniform Silver Nanospheres. J. Phys. Chem. C 2010, 114, 7427–7431. [Google Scholar] [CrossRef]

- Wiley, B.J.; Sun, Y.; Xia, Y. Synthesis of Silver Nanostructures with Controlled Shapes and Properties. Acc. Chem. Res. 2007, 40, 1067–1076. [Google Scholar] [CrossRef] [PubMed]

- Gentry, S.T.; Levit, S.D. Stochastic Control: Transition from Differentiated to Undifferentiated Kinetic Growth in Ag Nanoprisms. J. Phys. Chem. C 2009, 113, 12007–12015. [Google Scholar] [CrossRef]

- Bastys, V.; Pastoriza-Santos, I.; Rodríguez-González, B.; Vaisnoras, R.; Liz-Marzán, L.M. Formation of Silver Nanoprisms with Surface Plasmons at Communication Wavelengths. Adv. Funct. Mater. 2006, 16, 766–773. [Google Scholar] [CrossRef]

- Bhattacharjee, G.; Bhattacharya, M.; Roy, A.; Senapati, D.; Satpati, B. Core–Shell Gold@Silver Nanorods of Varying Length for High Surface-Enhanced Raman Scattering Enhancement. ACS Appl. Nano Mater. 2018, 1, 5589–5600. [Google Scholar] [CrossRef]

- Pietrobon, B.; McEachran, M.; Kitaev, V. Synthesis of Size-Controlled Faceted Pentagonal Silver Nanorods with Tunable Plasmonic Properties and Self-Assembly of These Nanorods. ACS Nano 2008, 3, 21–26. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Jiang, Z. Facile fabrication of dendritic silver structures and their surface enhanced Raman spectroscopic properties. J. Chem. Sci. 2015, 127, 173–176. [Google Scholar] [CrossRef]

- Kusar, P.; Gruber, C.; Hohenau, A.; Krenn, J.R. Measurement and Reduction of Damping in Plasmonic Nanowires. Nano Lett. 2012, 12, 661–665. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Langille, M.R.; Mirkin, C.A. Synthesis of Silver Nanorods by Low Energy Excitation of Spherical Plasmonic Seeds. Nano Lett. 2011, 11, 2495–2498. [Google Scholar] [CrossRef] [PubMed]

- Mallikarjuna, N.N.; Varma, R.S. Microwave-Assisted Shape-Controlled Bulk Synthesis of Noble Nanocrystals and Their Catalytic Properties. Cryst. Growth Des. 2007, 7, 686–690. [Google Scholar] [CrossRef]

- Jana, N.R.; Gearheart, L.; Murphy, C. Wet chemical synthesis of silver nanorods and nanowires of controllable aspect ratio. Chem. Commun. 2001, 617–618. [Google Scholar] [CrossRef]

- Mukherji, S.; Bharti, S.; Shukla, G.; Mukherji, S. Synthesis and characterization of size- and shape-controlled silver nanoparticles. Phys. Sci. Rev. 2018, 4, 4. [Google Scholar] [CrossRef]

- Xia, Y.; Xiong, Y.; Lim, B.; Skrabalak, S.E. Shape-Controlled Synthesis of Metal Nanocrystals: Simple Chemistry Meets Complex Physics? Angew. Chem. Int. Ed. 2008, 48, 60–103. [Google Scholar] [CrossRef]

- Cobley, C.M.; Skrabalak, S.E.; Campbell, D.J.; Xia, Y. Shape-Controlled Synthesis of Silver Nanoparticles for Plasmonic and Sensing Applications. Plasmonics 2009, 4, 171–179. [Google Scholar] [CrossRef]

- Sun, Y.G.; Xia, Y.N. Large-scale synthesis of uniform silver nanowires through a soft, self-seeding, polyol process. Adv. Mater. 2002, 14, 833–837. [Google Scholar] [CrossRef]

- Chen, D.; Qiao, X.; Chen, J. Morphology-controlled synthesis of silver nanostructures via a solvothermal method. J. Mater. Sci. Mater. Electron. 2011, 22, 1335–1339. [Google Scholar] [CrossRef]

- Coskun, S.; Aksoy, B.; Unalan, H.E. Polyol Synthesis of Silver Nanowires: An Extensive Parametric Study. Cryst. Growth Des. 2011, 11, 4963–4969. [Google Scholar] [CrossRef]

- Zhou, S.; Li, J.; Gilroy, K.D.; Tao, J.; Zhu, C.; Yang, X.; Sun, X.; Xia, Y. Facile Synthesis of Silver Nanocubes with Sharp Corners and Edges in an Aqueous Solution. ACS Nano 2016, 10, 9861–9870. [Google Scholar] [CrossRef] [PubMed]

- Agnihotri, S.; Mukherji, S.; Mukherji, S. Size-controlled silver nanoparticles synthesized over the range 5–100 nm using the same protocol and their antibacterial efficacy. RSC Adv. 2014, 4, 3974–3983. [Google Scholar] [CrossRef]

- Wang, G.; Wang, G.; Liu, X.; Wu, H.; Fang, B. Copper Dendrites: Synthesis, Mechanism Discussion, and Application in Determination ofl-Tyrosine. Cryst. Growth Des. 2008, 8, 1430–1434. [Google Scholar] [CrossRef]

- Luo, M.; Huang, H.; Choi, S.-I.; Zhang, C.; Da Silva, R.R.; Peng, H.-C.; Li, Z.-Y.; Liu, J.; He, Z.; Xia, Y. Facile Synthesis of Ag Nanorods with No Plasmon Resonance Peak in the Visible Region by Using Pd Decahedra of 16 nm in Size as Seeds. ACS Nano 2015, 9, 10523–10532. [Google Scholar] [CrossRef]

- Tsuji, M.; Matsumoto, K.; Jiang, P.; Matsuo, R.; Tang, X.-L.; Kamarudin, K.S.N. Roles of Pt seeds and chloride anions in the preparation of silver nanorods and nanowires by microwave-polyol method. Colloids Surf. A Physicochem. Eng. Asp. 2008, 316, 266–277. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, W.; Wen, L.-P.; Chen, J.; Xia, Y. Facile Synthesis of Ag Nanocubes of 30 to 70 nm in Edge Length with CF3COOAg as a Precursor. Chem. A Eur. J. 2010, 16, 10234–10239. [Google Scholar] [CrossRef]

- Zhuo, X.; Zhu, X.; Li, Q.; Yang, Z.; Wang, J. Gold Nanobipyramid-Directed Growth of Length-Variable Silver Nanorods with Multipolar Plasmon Resonances. ACS Nano 2015, 9, 7523–7535. [Google Scholar] [CrossRef]

- Zeng, J.; Zheng, Y.; Rycenga, M.; Tao, J.; Li, Z.-Y.; Zhang, Q.; Zhu, Y.; Xia, Y. Controlling the Shapes of Silver Nanocrystals with Different Capping Agents. J. Am. Chem. Soc. 2010, 132, 8552–8553. [Google Scholar] [CrossRef]

- Xia, X.; Zeng, J.; Zhang, Q.; Moran, C.H.; Xia, Y. Recent Developments in Shape-Controlled Synthesis of Silver Nanocrystals. J. Phys. Chem. C 2012, 116, 21647–21656. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Liu, N.; Yu, H.; Wang, F.; Liu, L.; Lee, G.-B.; Wang, Y.; Liu, L. Silver nanostructures synthesis via optically induced electrochemical deposition. Sci. Rep. 2016, 6, 28035. [Google Scholar] [CrossRef]

- Zhu, J.-J.; Liao, X.-H.; Zhao, X.-N.; Chen, H. Preparation of silver nanorods by electrochemical methods. Mater. Lett. 2001, 49, 91–95. [Google Scholar] [CrossRef]

- Zhou, Q.; Zhang, J.; Saba, T.; Yue, Z.; Li, W.; Anderson, J.A.; Wang, X. Electric-Field-Assisted Facile Synthesis of Metal Nanoparticles. ACS Sustain. Chem. Eng. 2018, 7, 1271–1278. [Google Scholar] [CrossRef]

- Ren, Y.; Xu, C.; Wu, M.; Niu, M.; Fang, Y. Controlled synthesis of gold nanoflowers assisted by poly (vinyl pyrrolidone)–sodium dodecyl sulfate aggregations. Colloids Surf. A Physicochem. Eng. Asp. 2011, 380, 222–228. [Google Scholar] [CrossRef]

- Ren, Y.; Qi, J.; Wu, M.; Fang, Y. Controlled synthesis of gold nanosnakes assisted by poly (vinyl pyrrolidone)–sodium dodecyl sulphate aggregations. J. Exp. Nanosci. 2013, 8, 774–781. [Google Scholar] [CrossRef]

- Yang, J.; Zheng, H.; Han, S.; Jiang, Z.; Chen, X. The synthesis of nano-silver/sodium alginate composites and their antibacterial properties. RSC Adv. 2015, 5, 2378–2382. [Google Scholar] [CrossRef]

- Du, J.; Han, B.; Liu, Z.; Liu, Y.; Kang, D. Control Synthesis of Silver Nanosheets, Chainlike Sheets, and Microwires via a Simple Solvent−Thermal Method. Cryst. Growth Des. 2007, 7, 900–904. [Google Scholar] [CrossRef]

- Yang, J.; Xie, Y.-J.; He, W. Research progress on chemical modification of alginate: A review. Carbohydr. Polym. 2011, 84, 33–39. [Google Scholar] [CrossRef]

- Mahmoud, M.A.; El-Sayed, M.A.; Gao, J.; Landman, U. High-Frequency Mechanical Stirring Initiates Anisotropic Growth of Seeds Requisite for Synthesis of Asymmetric Metallic Nanoparticles like Silver Nanorods. Nano Lett. 2013, 13, 4739–4745. [Google Scholar] [CrossRef]

- Kirkland, A.I.; Jefferson, D.A.; Duff, D.G.; Edwards, P.P.; Gameson, I.; Johnson, B.F.G.; Smith, D.J. Structural studies of trigonal lamellar particles of gold and silver. Proc. R. Soc. Lond. Ser. A 1993, 440, 589–609. [Google Scholar] [CrossRef]

- Lim, B.; Camargo, P.H.C.; Xia, Y. Mechanistic Study of the Synthesis of Au Nanotadpoles, Nanokites, and Microplates by Reducing Aqueous HAuCl4with Poly (vinyl pyrrolidone). Langmuir 2008, 24, 10437–10442. [Google Scholar] [CrossRef] [PubMed]

- Xiao, D.; Wu, Z.; Song, M.; Chun, J.; Schenter, G.K.; Li, D. Silver Nanocube and Nanobar Growth via Anisotropic Monomer Addition and Particle Attachment Processes. Langmuir 2018, 34, 1466–1472. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, P.; Liang, Y.; Zhang, D.; Zhang, J.; Li, S.; Liu, W. Synthesis of Silver Nanoplates with the Assistance of Natural Polymer (Sodium Alginate) Under 0 °C. Materials 2020, 13, 3827. https://doi.org/10.3390/ma13173827

Yang P, Liang Y, Zhang D, Zhang J, Li S, Liu W. Synthesis of Silver Nanoplates with the Assistance of Natural Polymer (Sodium Alginate) Under 0 °C. Materials. 2020; 13(17):3827. https://doi.org/10.3390/ma13173827

Chicago/Turabian StyleYang, Pengfei, Yu Liang, Daxiao Zhang, Jin Zhang, Shijie Li, and Weiguo Liu. 2020. "Synthesis of Silver Nanoplates with the Assistance of Natural Polymer (Sodium Alginate) Under 0 °C" Materials 13, no. 17: 3827. https://doi.org/10.3390/ma13173827

APA StyleYang, P., Liang, Y., Zhang, D., Zhang, J., Li, S., & Liu, W. (2020). Synthesis of Silver Nanoplates with the Assistance of Natural Polymer (Sodium Alginate) Under 0 °C. Materials, 13(17), 3827. https://doi.org/10.3390/ma13173827