Investigating the Rheological Properties of Carbon Nanotubes/Polymer Composites Modified Asphalt

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Tests and Measurements

3. Results

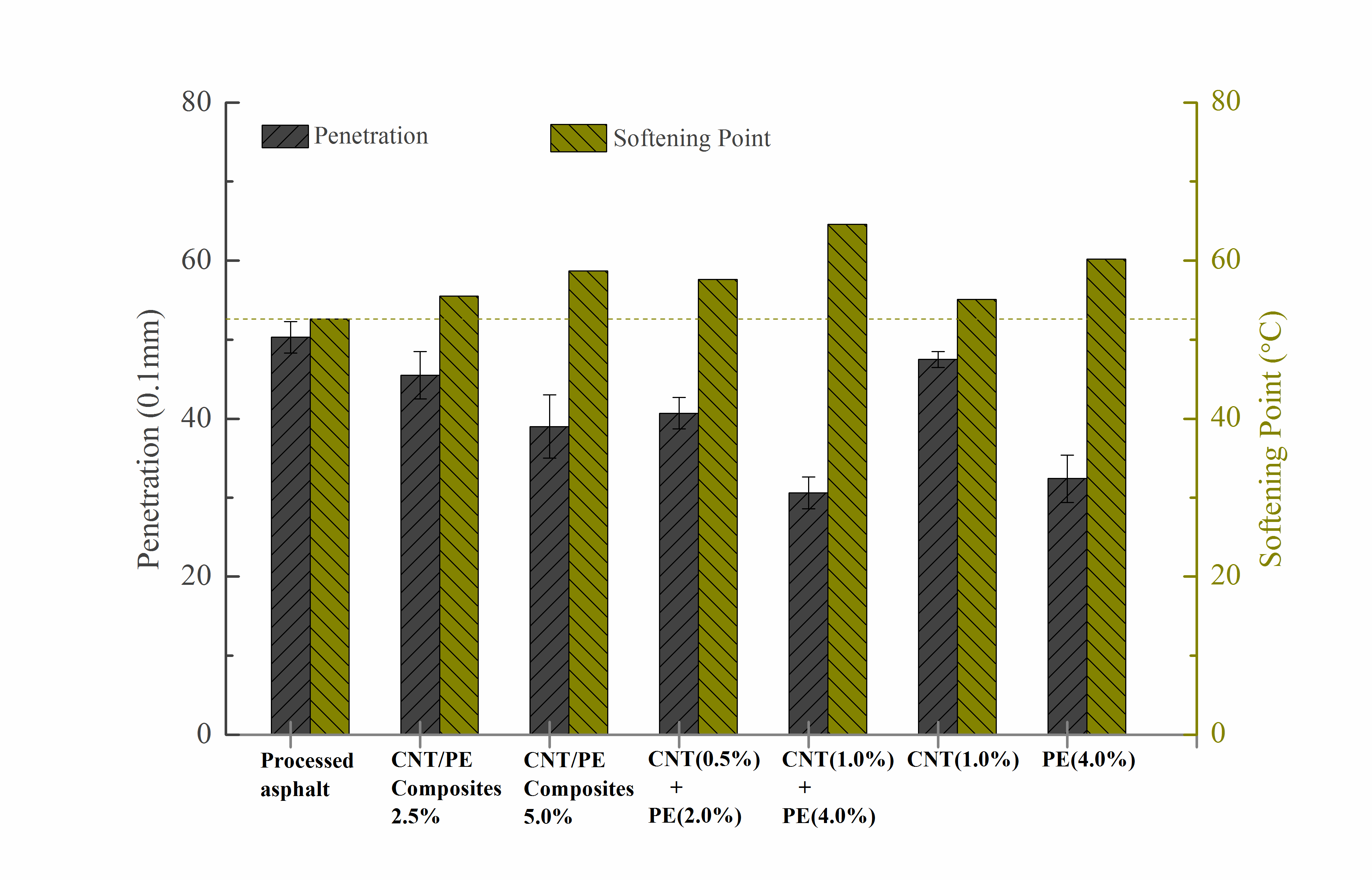

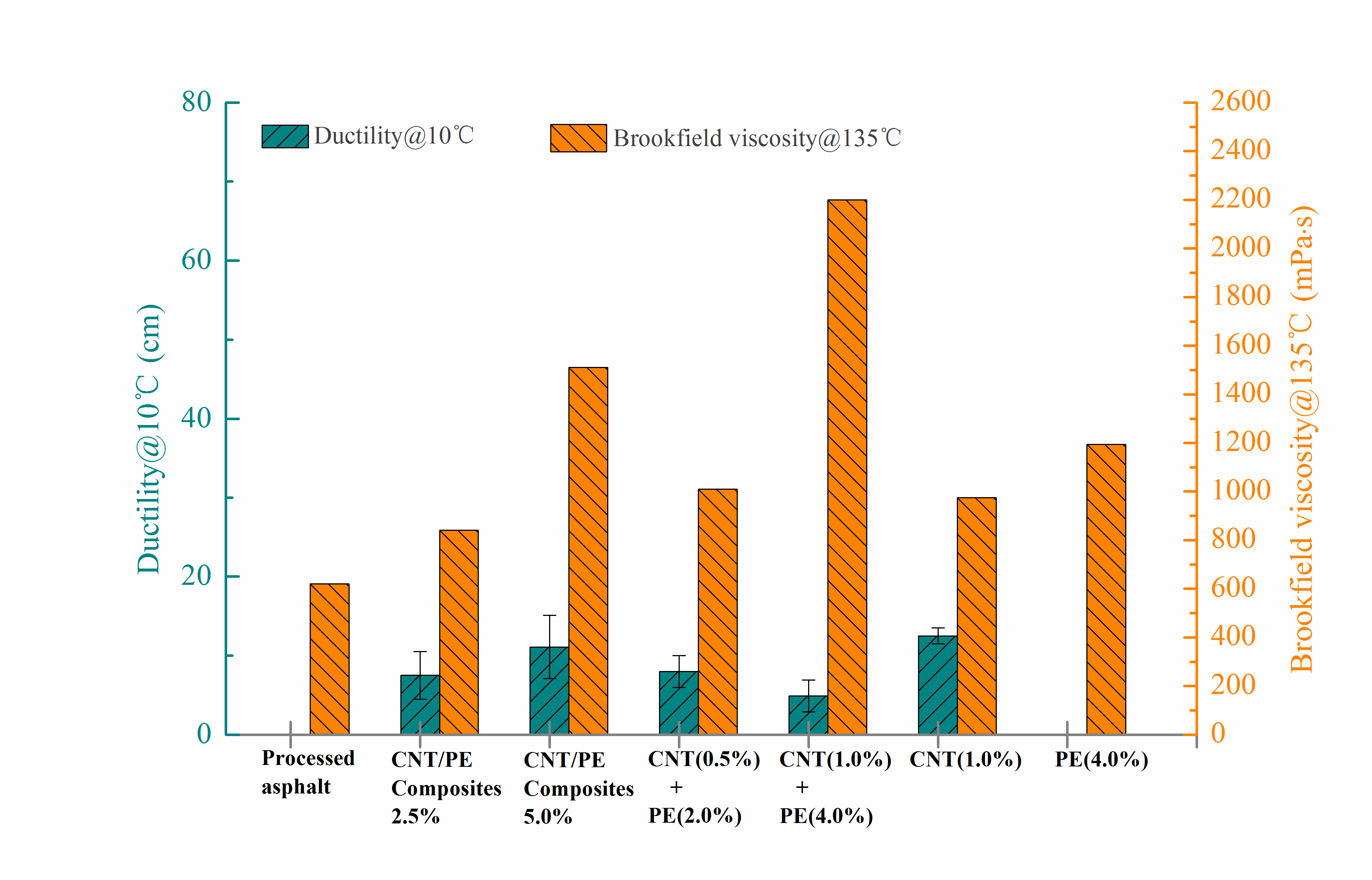

3.1. Conventional Properties

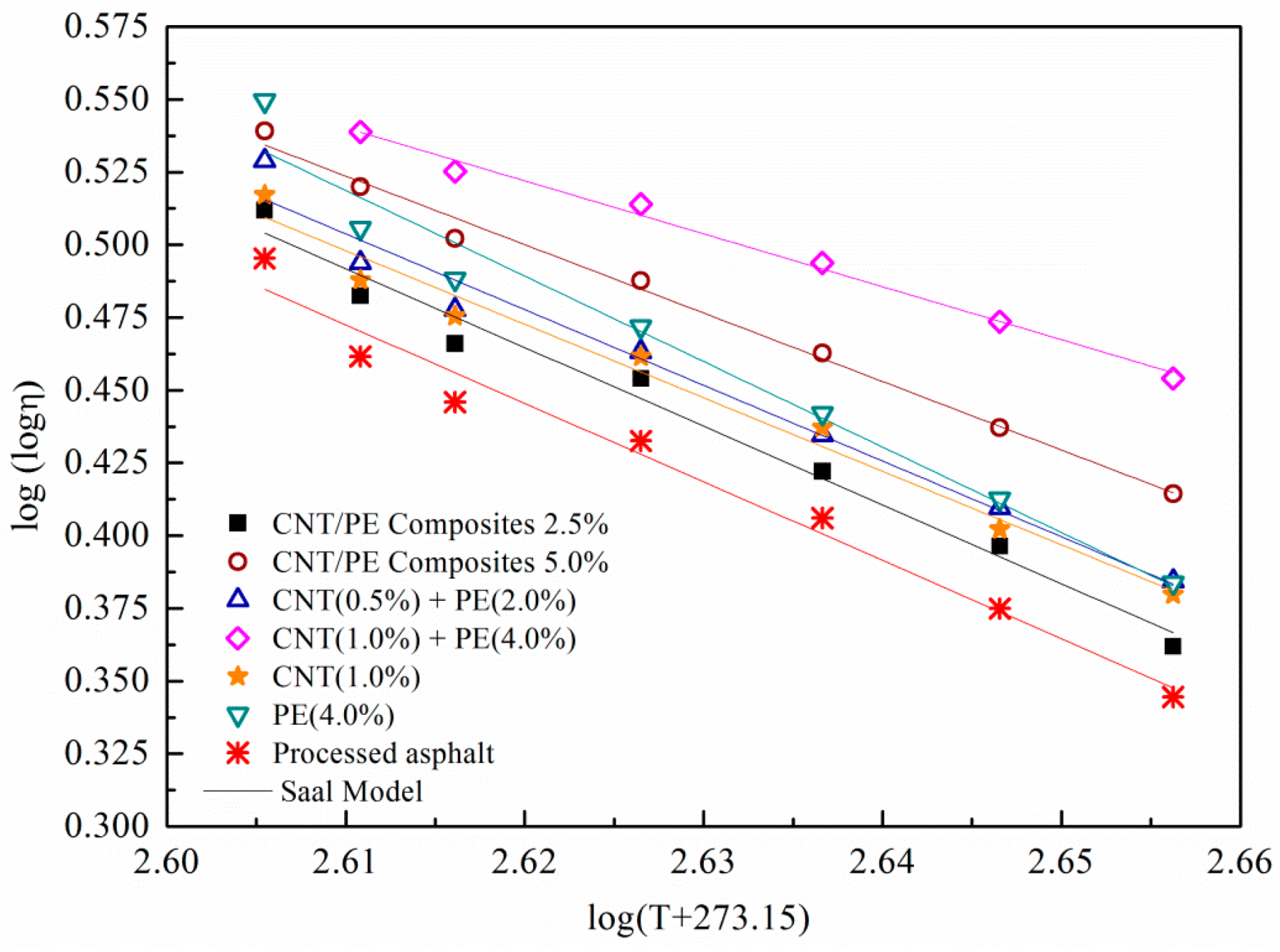

3.2. Viscosity-Temperature Property

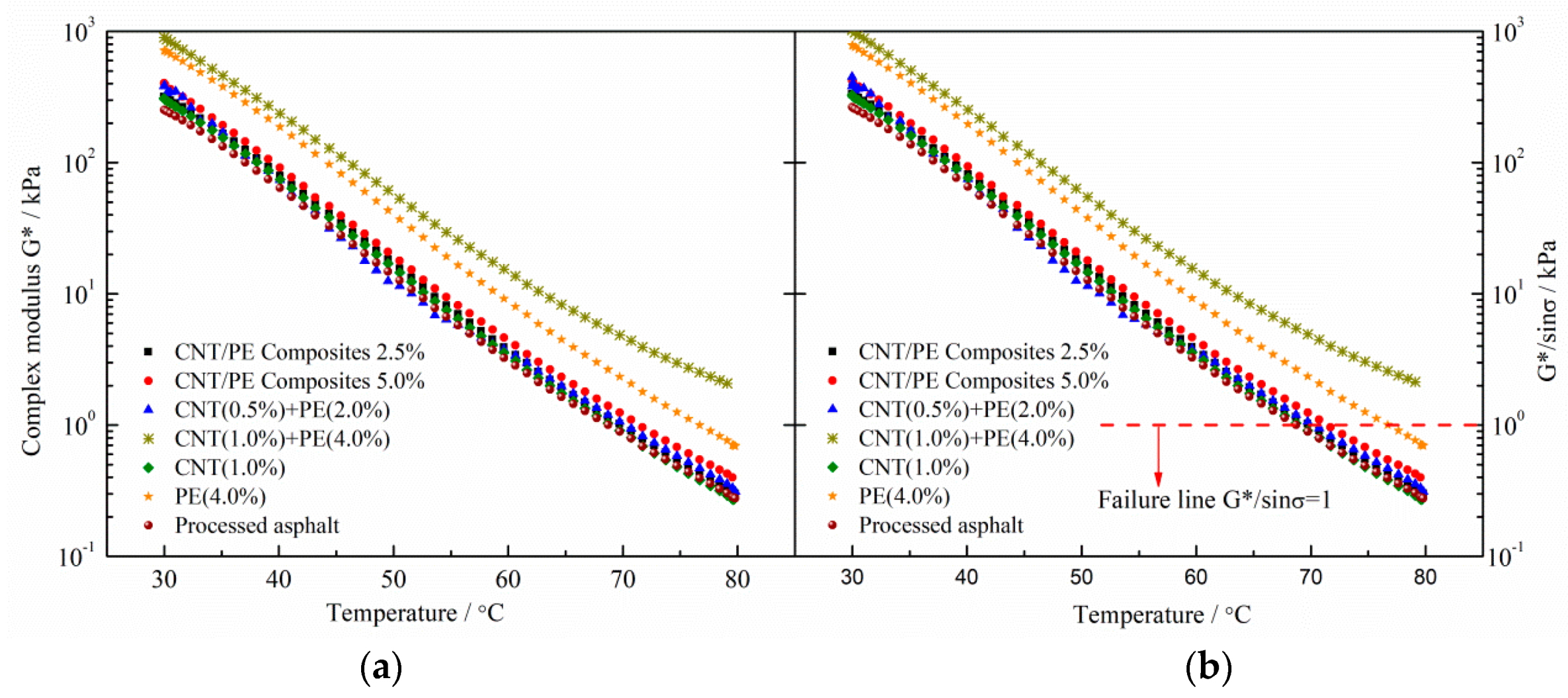

3.3. Dynamic Mechanical Properties Based on Oscillation Shear Test

3.3.1. Black Diagrams

3.3.2. Rutting Resistance Factor and Failure Temperature

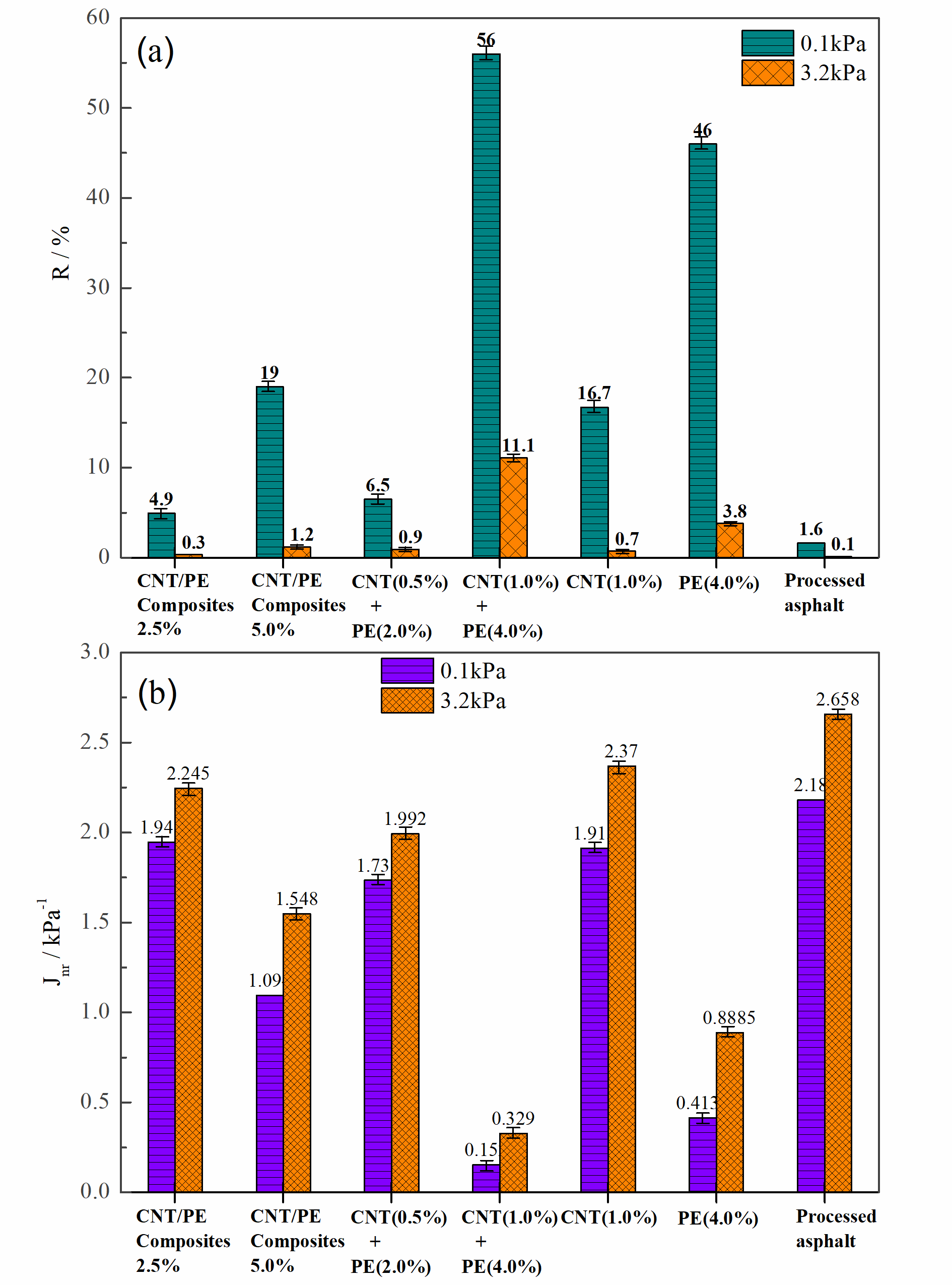

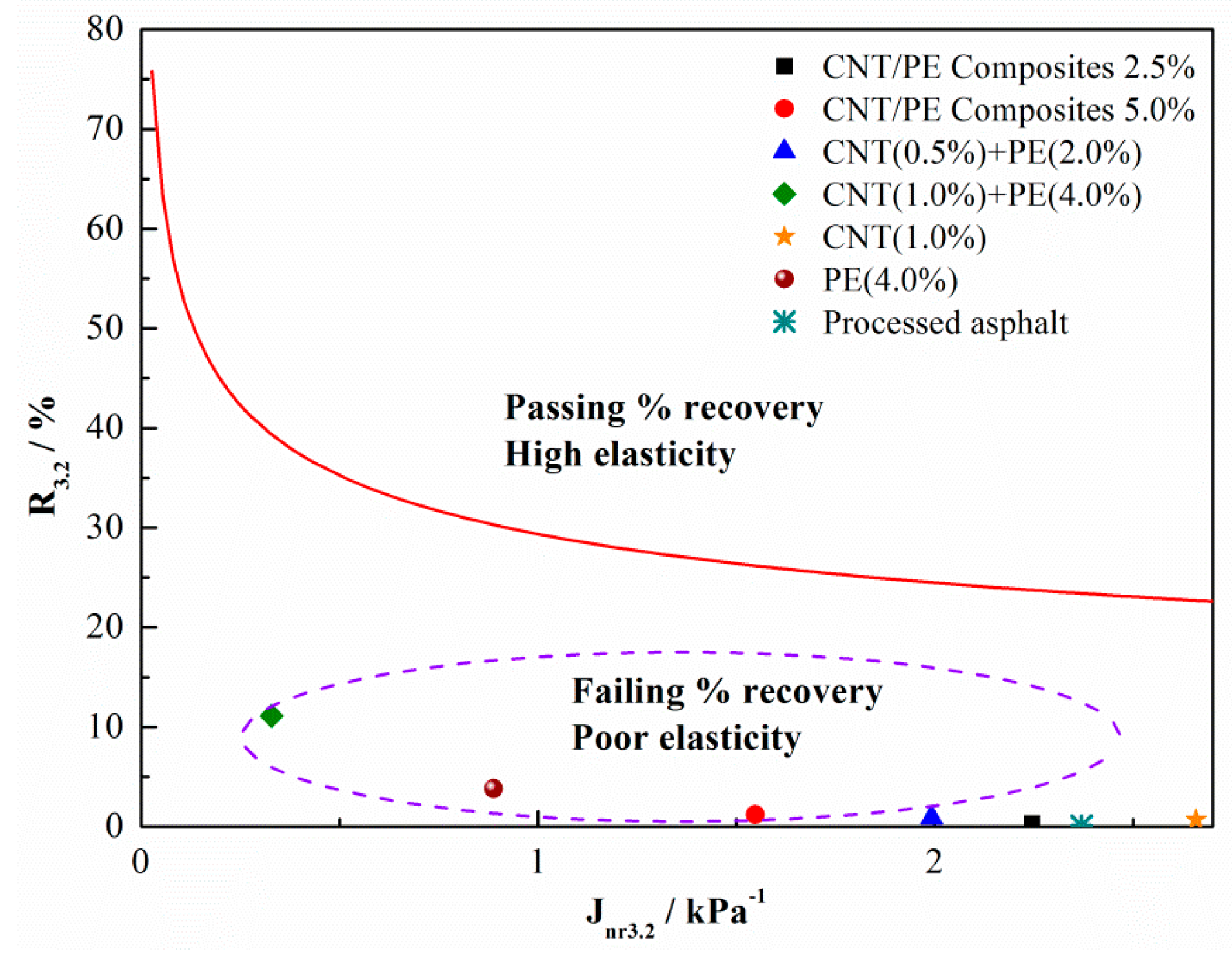

3.4. Creep and Recovery Behavior

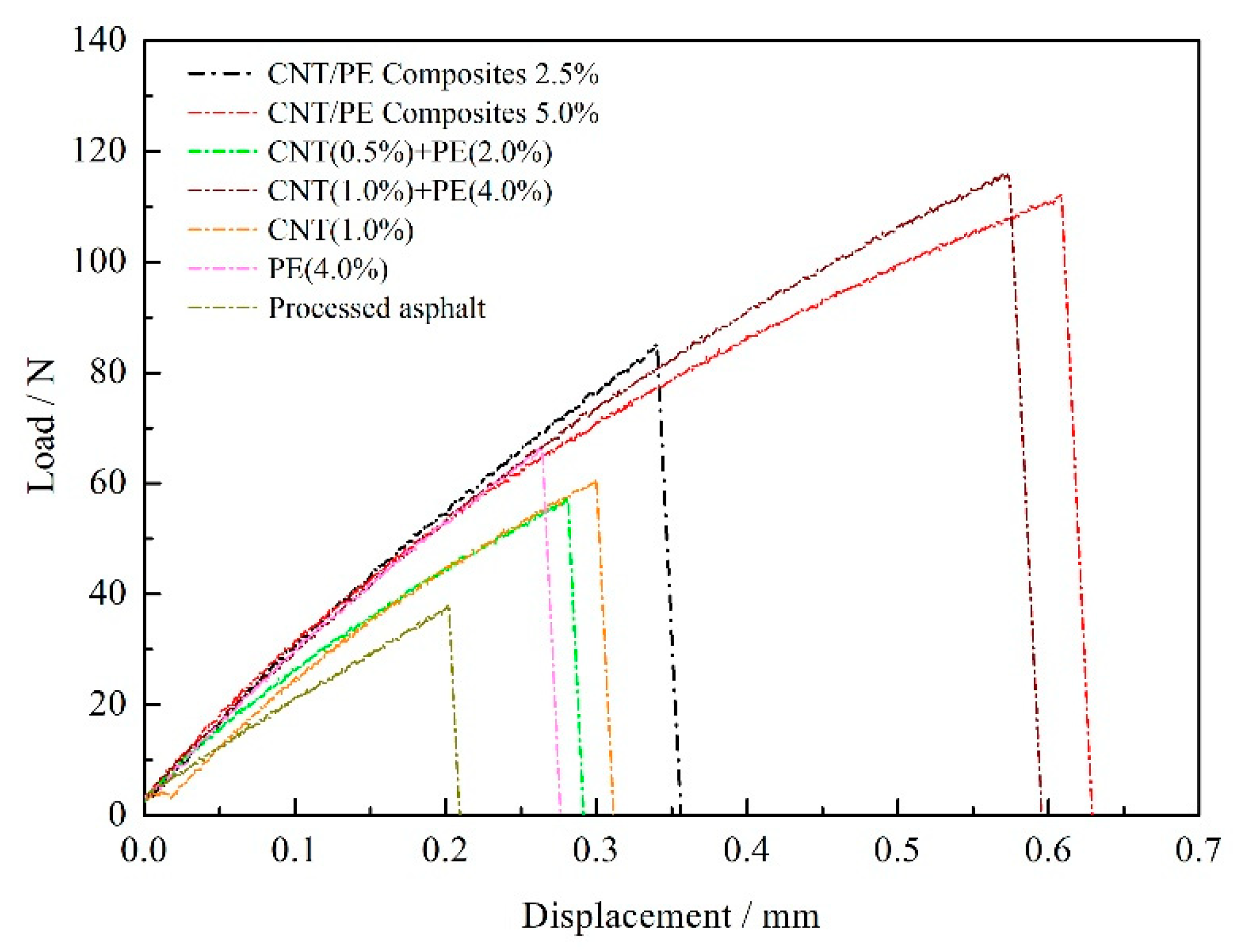

3.5. Low Temperature Fracture Behavior

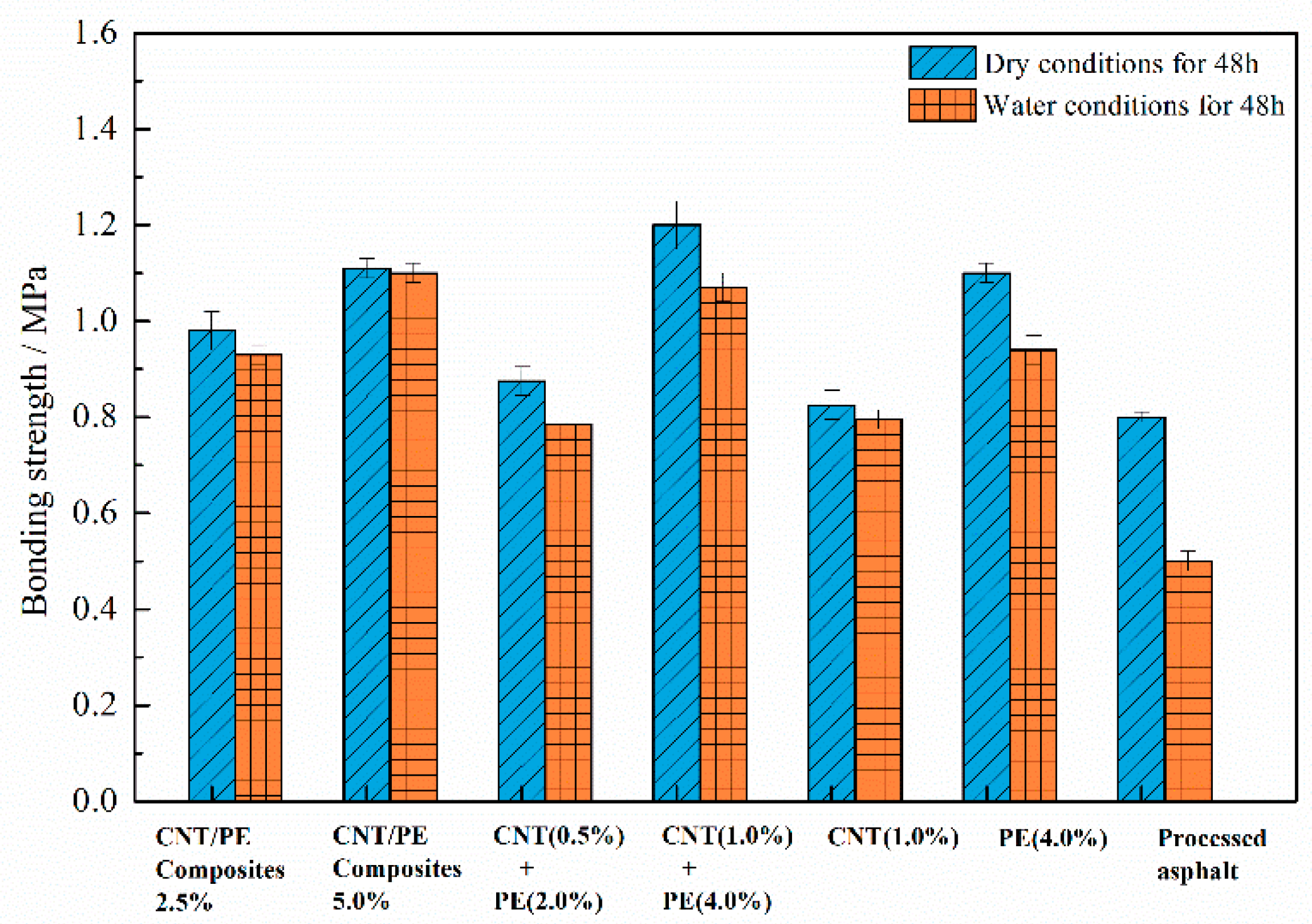

3.6. Aggregate-Binder Bonding Behavior

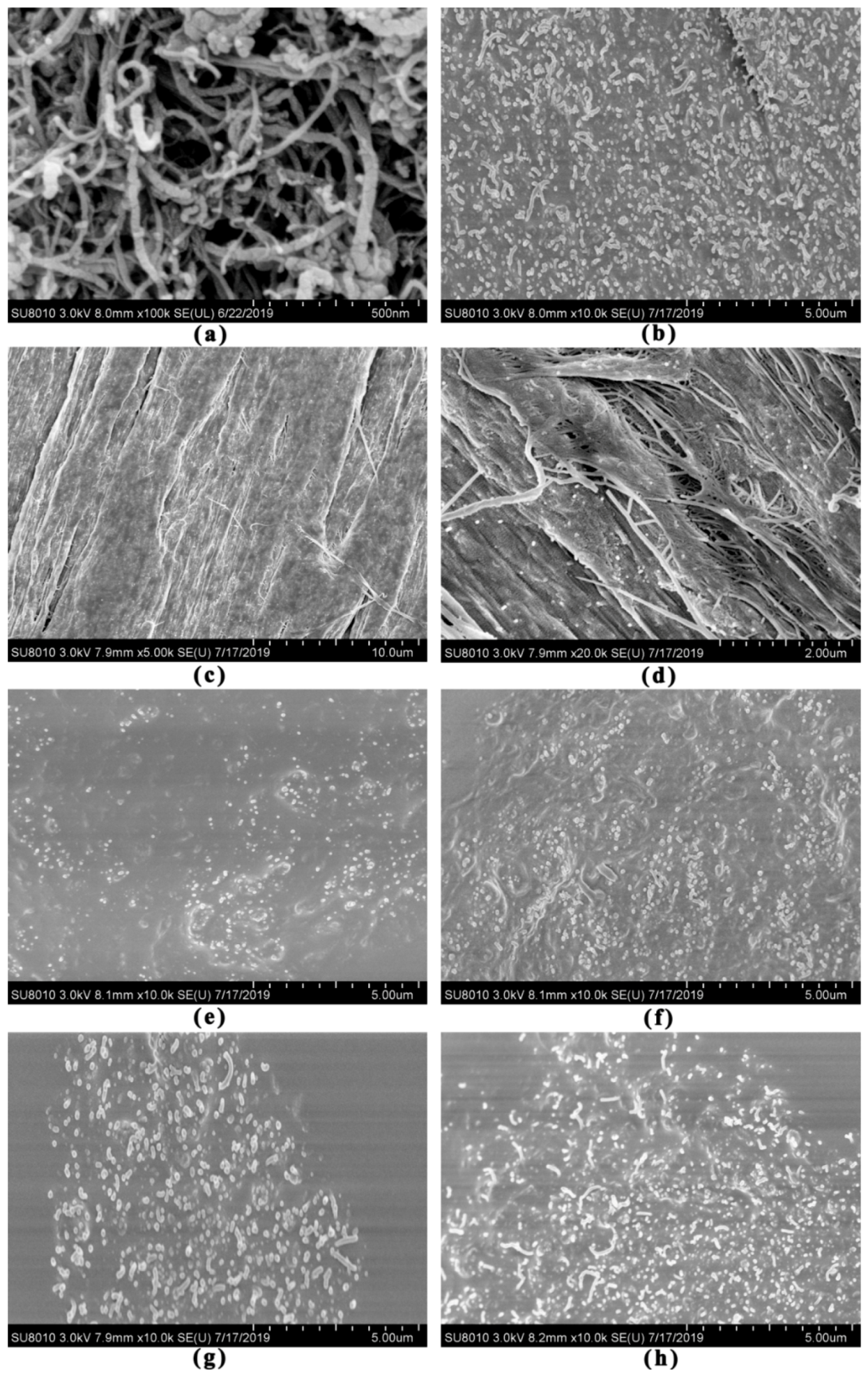

3.7. Micro-Morphology

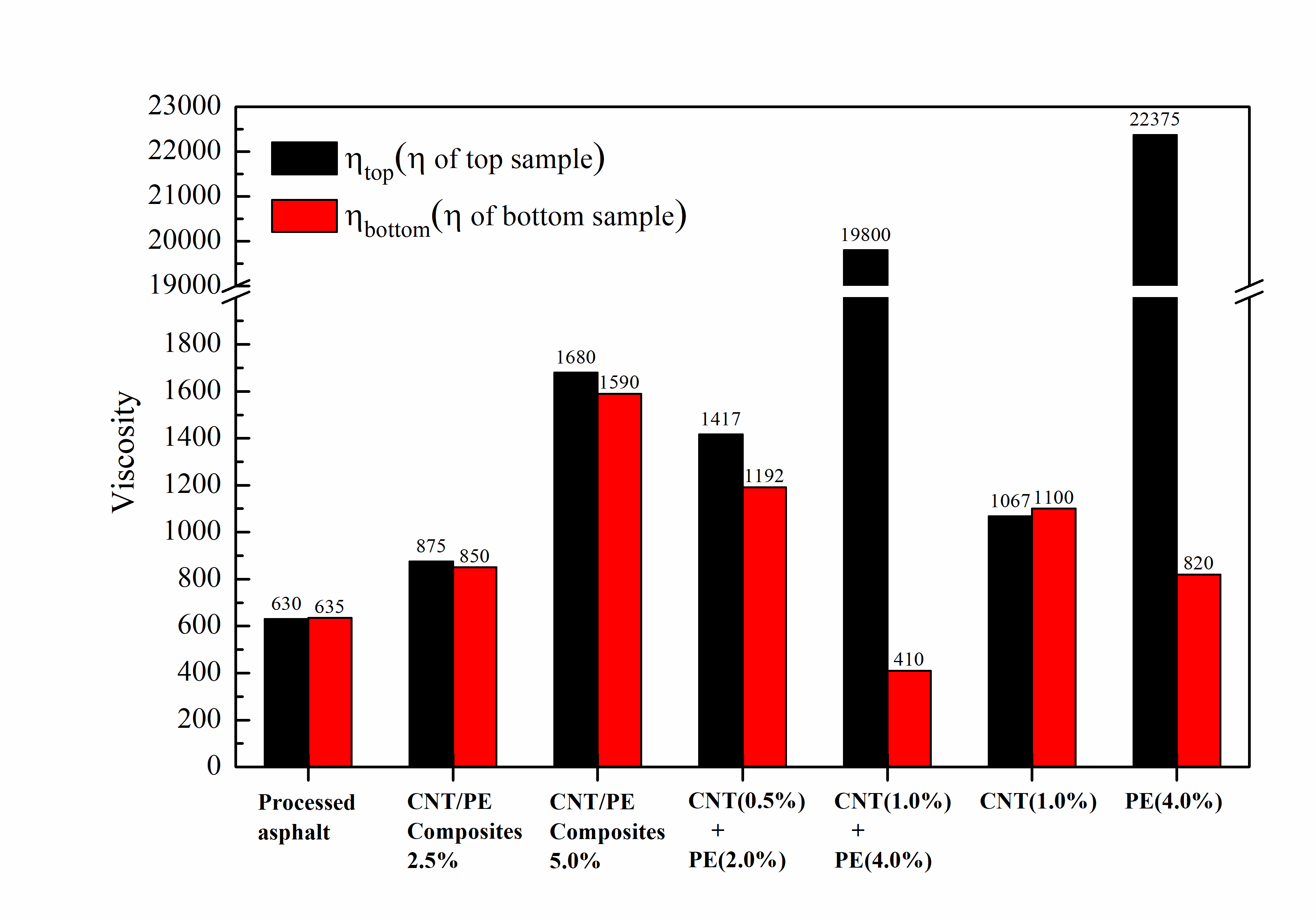

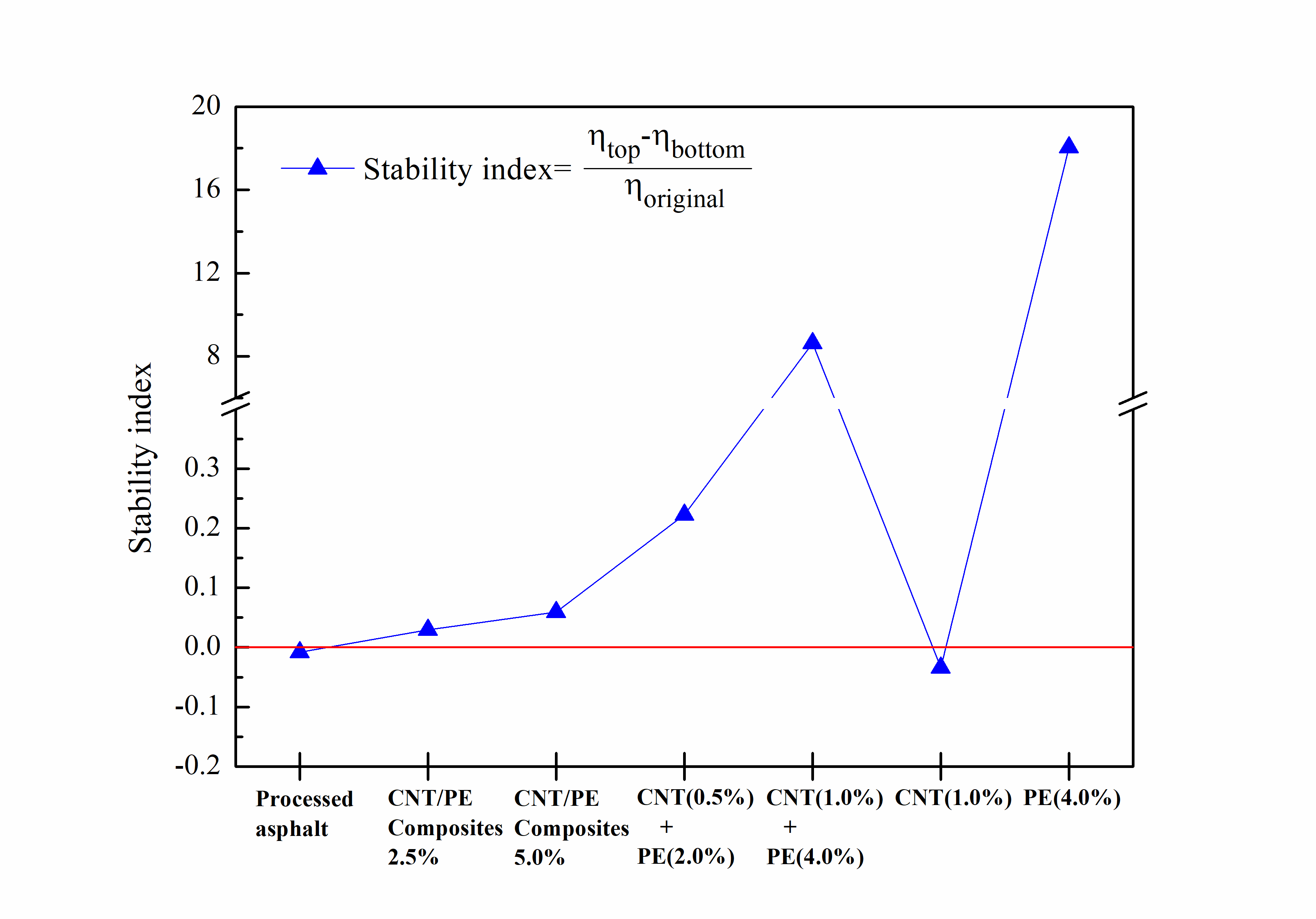

3.8. Thermal Stability

4. Conclusions

- The incorporation of CNT/PE leads to increased softening point, decreased penetration, and increased ductility of binder. Combined addition of CNT and PE into asphalt shows better physical properties than the melt mixing CNT/PE composite. In addition, the combined addition of CNT and PE significantly increase the viscosity of the modified asphalt in comparison to a single modifier, whereas the melt mixing CNT/PE composites lead to a lower viscosity compared to the combined method, indicating the improvement of workability.

- The combined use of CNT and PE shows a significant enhancement of high temperature performance of binder, which can be deduced by higher complex modulus, increased percent recovery, and reduced creep compliance. Whereas, the contribution of single CNT to high temperature performance of binder is limited (related to the dispersion of CNT in asphalt by high shear mixing), the reinforcement effect of CNT is more significant when combined with adequate PE. In terms of low temperature cracking resistance, the two types of studied CNT/PE modifiers benefit the cracking elongation of binder at low temperatures. Meanwhile, the CNT/PE composites outperform the combined addition of CNT and PE.

- The bonding behavior of the binder was improved by the CNT/PE modifiers. CNT/PE improves moisture damage resistance of modified asphalt. The CNT/PE melt mixing composites endow asphalt with better resistance to moisture damage in comparison with the combined addition method.

- From the prospective of micro-morphology, the dispersed CNT still remains dense and tends to stick together in CNT modified asphalt. Asphalt with CNT/PE composites formed an evenly dispersion system on the whole, since CNT is dispersed in PE melting matrix previously, high speed shear mixing is enough to result in fairly well dispersion of CNT/PE composites in asphalt. Notably, some CNT bridges on the interface between PE phase and asphalt for the two types of CNT/PE modified asphalt, which reinforces the adhesion of interface.

- The CNT/PE composites lead to the significantly improved storage stability of binder, while the storage stability of asphalt with combined CNT and PE is poorer than that of the binder with CNT/PE composites. The CNT/PE composites are recommended for asphalt modification due to its balanced performance (with better storage stability and lower rheological performance). Compared with PE modified asphalt, the incorporation of CNT in PE modified asphalt benefits storage stability. Last but not least, even though these results are positive, more investigations and further assessment of pavement, including performance of asphalt mixtures and road paving applications, need to be carried out. In any case, the conclusions in this work can be referred to by researchers in future.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Behnood, A.; Gharehveran, M.M. Morphology, Rheology and physical properties of polymer-modified asphalt binders. Eur. Polym. 2019, 112, 766–791. [Google Scholar] [CrossRef]

- Shah, S.M.R.; Zainuddin, N.I.; Min, Y.H.; Nasaruddin, N.A.I.; Sian, T.L. Reduction of optimum bitumen content in polyethylene modified bituminous mixes. Am. J. Civ. Eng. 2018, 6, 93–98. [Google Scholar] [CrossRef] [Green Version]

- Yao, Z.; Zhang, J.; Gao, F.; Liu, S.; Yu, T. Integrated utilization of recycled crumb rubber and polyethylene for enhancing the performance of modified bitumen. Constr. Build. Mater. 2018, 170, 217–224. [Google Scholar] [CrossRef]

- Brasileiro, L.; Moreno-Navarro, F.; Tauste-Martínez, R.; Matos, J.; Rubio-Gámez, M.D.C. Reclaimed polymers as asphalt binder modifiers for more sustainable roads: A Review. Sustainability 2019, 11, 646. [Google Scholar] [CrossRef] [Green Version]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Eur. Polym. 2014, 54, 18–38. [Google Scholar] [CrossRef] [Green Version]

- Fang, C.; Yu, R.; Liu, S.; Li, Y. Nanomaterials applied in asphalt modification: A review. J. Mater. Sci. Technol. 2013, 29, 589–594. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, A.N.; Amirkhanian, S.N. Influence of carbon nanoparticles on the rheological characteristics of short-term aged asphalt binders. J. Mater. Civ. Eng. 2010, 23, 423–431. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, A.N.; Amirkhanian, S.N. Long-term ageing influence on rheological characteristics of asphalt binders containing carbon nanoparticles. Int. J. Pavement Eng. 2011, 12, 533–541. [Google Scholar] [CrossRef]

- Amirkhanian, A.N.; Xiao, F.; Amirkhanian, S.N. Evaluation of high temperature rheological characteristics of asphalt binder with carbon nano particles. J. Test. Eval. 2010, 39, 1–9. [Google Scholar]

- Amirkhanian, A.N.; Xiao, F.; Amirkhanian, S.N. Characterization of unaged asphalt binder modified with carbon nano particles. Int. J. Pavement Res. Technol. 2011, 4, 281–286. [Google Scholar]

- Ziari, H.; Farahani, H.; Goli, A.; Galooyak, S.S. The investigation of the impact of carbon nano tube on bitumen and HMA performance. Pet. Sci. Technol. 2014, 32, 2102–2108. [Google Scholar] [CrossRef]

- Ziari, H.; Rahim-of, K.; Fazilati, M.; Goli, A.; Farahani, H. Evaluation of different conditions on the mixing bitumen and carbon nano-tube. Int. J. Civ. Environ. Eng. 2012, 12, 12–53. [Google Scholar]

- Ameri, M.; Nowbakht, S.; Molayem, M.; Aliha, M. Investigation of fatigue and fracture properties of asphalt mixtures modified with carbon nanotubes. Fatigue Fract. Eng. Mater. Struct. 2016, 33, 896–906. [Google Scholar] [CrossRef]

- Santagata, E.; Baglieri, O.; Tsantilis, L.; Chiappinelli, G. Fatigue and healing properties of nano-reinforced bituminous binders. Int. J. Fatigue 2015, 80, 30–39. [Google Scholar] [CrossRef]

- Santagata, E.; Baglieri, O.; Tsantilis, L.; Chiappinelli, G. Fatigue properties of bituminous binders reinforced with carbon nanotubes. Int. J. Pavement Eng. 2015, 16, 80–90. [Google Scholar] [CrossRef]

- Santagata, E.; Baglieri, O.; Tsantilis, L.; Chiappinelli, G.; Aimonetto, I.B. Effect of sonication on high temperature properties of bituminous binders reinforced with nano-additives. Constr. Build. Mater. 2015, 75, 395–403. [Google Scholar] [CrossRef]

- Santagata, E.; Baglieri, O.; Tsantilis, L.; Dalmazzo, D. Rheological characterization of bituminous binders modified with carbon nanotubes. Procedia Soc. Behav. 2012, 53, 546–555. [Google Scholar] [CrossRef] [Green Version]

- Goli, A.; Ziari, H.; Amini, A. Influence of carbon nanotubes on performance properties and storage stability of SBS modified asphalt binders. J. Mater. Civ. Eng. 2017, 29, 04017070. [Google Scholar] [CrossRef]

- Wang, P.; Dong, Z.J.; Tan, Y.Q.; Liu, Z.Y. Effect of multi-walled carbon nanotubes on the performance of styrene–butadiene–styrene copolymer modified asphalt. Mater. Struct. 2017, 50, 17. [Google Scholar] [CrossRef]

- Tsantilis, L.; Dalmazzo, D.; Baglieri, O.; Santagata, E. Effect of SBS molecular structure on the rheological properties of ternary nanomodified bituminous binders. Constr. Build. Mater. 2019, 222, 183–192. [Google Scholar] [CrossRef]

- Xin, X.; Yao, Z.; Shi, J.; Liang, M.; Jiang, H.; Zhang, J.; Zhang, X.; Yao, K. Rheological properties, microstructure and aging resistance of asphalt modified with CNTs/PE composites. Constr. Build. Mater. 2020, 262, 120100. [Google Scholar] [CrossRef]

- ASTM Standard D5. Standard Test Method for Penetration of Bituminous Materials; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- ASTM Standard D36. Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus); ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- ASTM Standard D113. Standard Test Method for Ductility of Bituminous Materials; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- ASTM Standard D4402. Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- El-Shafie, M.; Ibrahim, I.M.; el Rahman, A.M.M.A. The addition effects of macro and nano clay on the performance of asphalt binder. Egypt. J. Petrol. 2012, 21, 149–154. [Google Scholar] [CrossRef] [Green Version]

- Bokobza, L. Multiwall carbon nanotube elastomeric composites: A review. Polymer 2007, 48, 4907–4920. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.; Rodrigue, D. The effect of carbon nanotube orientation and content on the mechanical properties of polypropylene based composites. Mater. Des. 2014, 55, 653–663. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, J.; Zhu, H.; Xu, G.; Wei, J.; Gong, M. Influence of shear temperature on waste bio-oil modified crumb rubber asphalt. J. China Univ. Pet. 2018, 42, 162–169. [Google Scholar]

- AASHTO M332-14. Performance-Graded Asphalt Binder Using Multiple Stress Creep Recovery (MSCR) Test. In AASTHO Standard Specifications for Transportation Materials and Methods of Sampling and Testing, 34th ed.; AASHTO: Washington, DC, USA, 2014; Available online: https://global.ihs.com/doc_detail.cfm?&input_search_filter=AASHTO&input_doc_number=AASHTO%2C%20M332&input_doc_title=&org_code=AASHTO&document_name=AASHTO%20M%20332&item_s_key=00629852&item_key_date=851231&origin=DSSC (accessed on 2 September 2020).

- AASHTO TP 70. Standard Method of Test for Multiple Stress Creep Recovery (MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer (DSR); AASHTO: Washington, DC, USA, 2009; Available online: https://global.ihs.com/doc_detail.cfm?&input_search_filter=AASHTO&input_doc_number=AASHTO%2C%20TP70&input_doc_title=&org_code=AASHTO&document_name=AASHTO%20TP%2070&item_s_key=00496329&item_key_date=901231&origin=DSSC (accessed on 2 September 2020).

- Gong, M.; Yang, J.; Yao, H.; Wang, M.; Niu, X.; Haddock, J.E. Investigating the performance, chemical, and microstructure properties of carbon nanotube-modified asphalt binder. Road Mater. Pavement 2018, 19, 1499–1522. [Google Scholar] [CrossRef]

- Mohammad, J.K.; Ahmed, K.; Zhang, P.F.; Hashim, R.R.; Pesacreta, T. Microstructure and fracture morphology of carbon nano-fiber modified asphalt and hot mix asphalt mixtures. Mater. Struct. 2013, 46, 2045–2057. [Google Scholar]

- Das, D.; Satapathy, B.K. Designing tough and fracture resistant polypropylene/multi wall carbon nanotubes nanocomposites by controlling stereo-complexity and dispersion morphology. Mater. Des. 2014, 54, 712–726. [Google Scholar] [CrossRef]

| Items | Measured Values |

|---|---|

| Average diameter/nm | 10–20 |

| Tube length/μm | 5–15 |

| Purity/% | ≥92.0 |

| Ash content/% | ≤8.0 |

| Specific surface area (BET)/m2∙g−1 | 220–260 |

| Tap density/ g∙cm−3 | 0.01–0.06 |

| Metal content/ppm | ≤10 |

| Items | Measured Values |

|---|---|

| Density/g·cm−3 | 0.954 |

| Crystallinity/% | 86 |

| Melt point/°C | 130 |

| Melt flow index (MFI)/g·(10 min)−1 | 0.8 |

| Break elongation/% | >1000 |

| Break strength/kg·cm2 | 390 |

| Specimens | Absolute Value of m | n |

|---|---|---|

| CNT/PE Composites 2.5% | 2.700 | 7.558 |

| CNT/PE Composites 5.0% | 2.355 | 6.670 |

| CNT (0.5%) + PE (2.0%) | 2.604 | 7.299 |

| CNT (1.0%) + PE (4.0%) | 1.821 | 5.292 |

| CNT (1.0%) | 2.529 | 7.099 |

| PE (4.0%) | 2.690 | 8.193 |

| Processed asphalt | 2.711 | 7.516 |

| Specimens | Fatigue Temperature/°C |

|---|---|

| CNT/PE Composites 2.5% | 69.90 |

| CNT/PE Composites 5.0% | 71.50 |

| CNT (0.5%) + PE (2.0%) | 70.10 |

| CNT (1.0%) + PE (4.0%) | 87.50 |

| CNT (1.0%) | 68.95 |

| PE (4.0%) | 76.74 |

| Processed asphalt | 68.68 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, M.; Su, L.; Li, P.; Shi, J.; Yao, Z.; Zhang, J.; Jiang, H.; Luo, W. Investigating the Rheological Properties of Carbon Nanotubes/Polymer Composites Modified Asphalt. Materials 2020, 13, 4077. https://doi.org/10.3390/ma13184077

Liang M, Su L, Li P, Shi J, Yao Z, Zhang J, Jiang H, Luo W. Investigating the Rheological Properties of Carbon Nanotubes/Polymer Composites Modified Asphalt. Materials. 2020; 13(18):4077. https://doi.org/10.3390/ma13184077

Chicago/Turabian StyleLiang, Ming, Linping Su, Peizhao Li, Jingtao Shi, Zhanyong Yao, Jizhe Zhang, Hongguang Jiang, and Weixin Luo. 2020. "Investigating the Rheological Properties of Carbon Nanotubes/Polymer Composites Modified Asphalt" Materials 13, no. 18: 4077. https://doi.org/10.3390/ma13184077

APA StyleLiang, M., Su, L., Li, P., Shi, J., Yao, Z., Zhang, J., Jiang, H., & Luo, W. (2020). Investigating the Rheological Properties of Carbon Nanotubes/Polymer Composites Modified Asphalt. Materials, 13(18), 4077. https://doi.org/10.3390/ma13184077