Cryogenic Drilling of AZ31 Magnesium Syntactic Foams

Abstract

:1. Introduction

2. Material and Methods

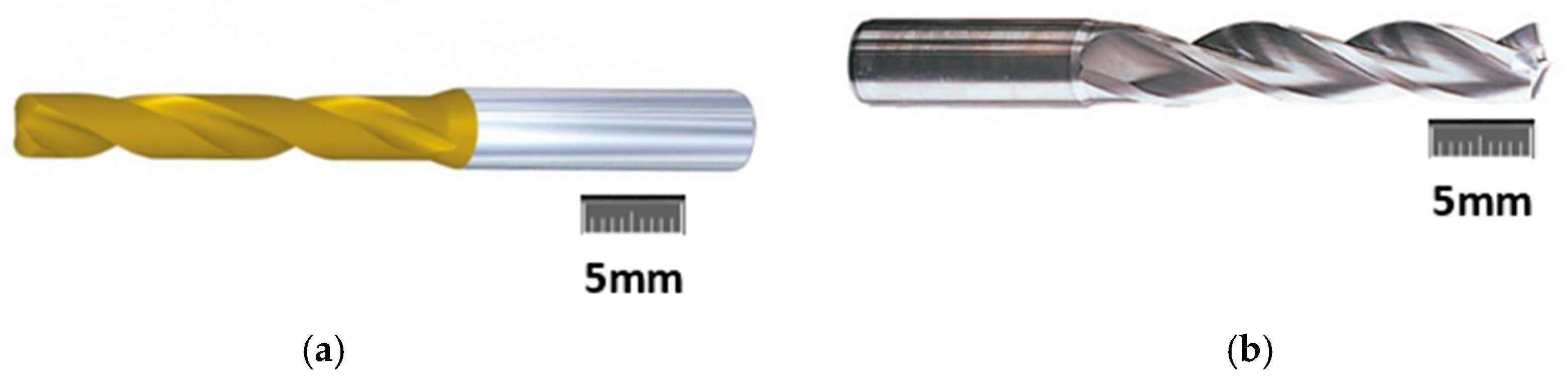

2.1. Cutting Tool

2.2. Cutting Conditions

2.3. Cooling Conditions

2.4. Surface Roughness, Burr, and Chip Morphology

3. Results and Discussion

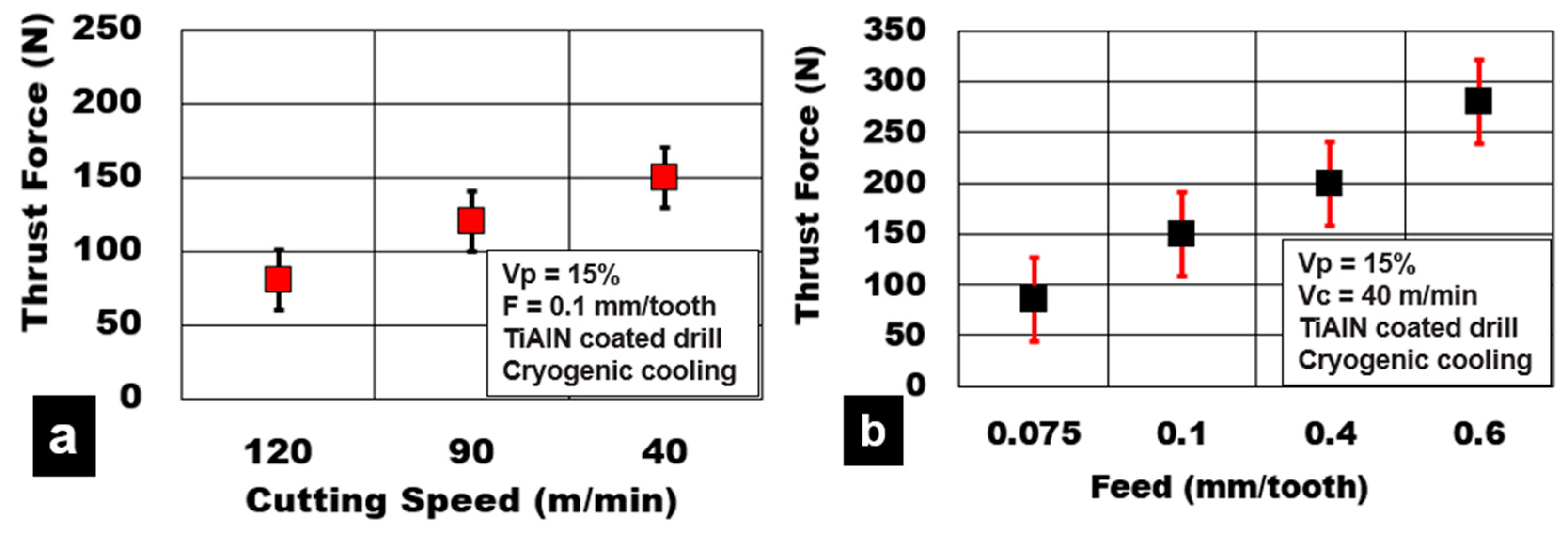

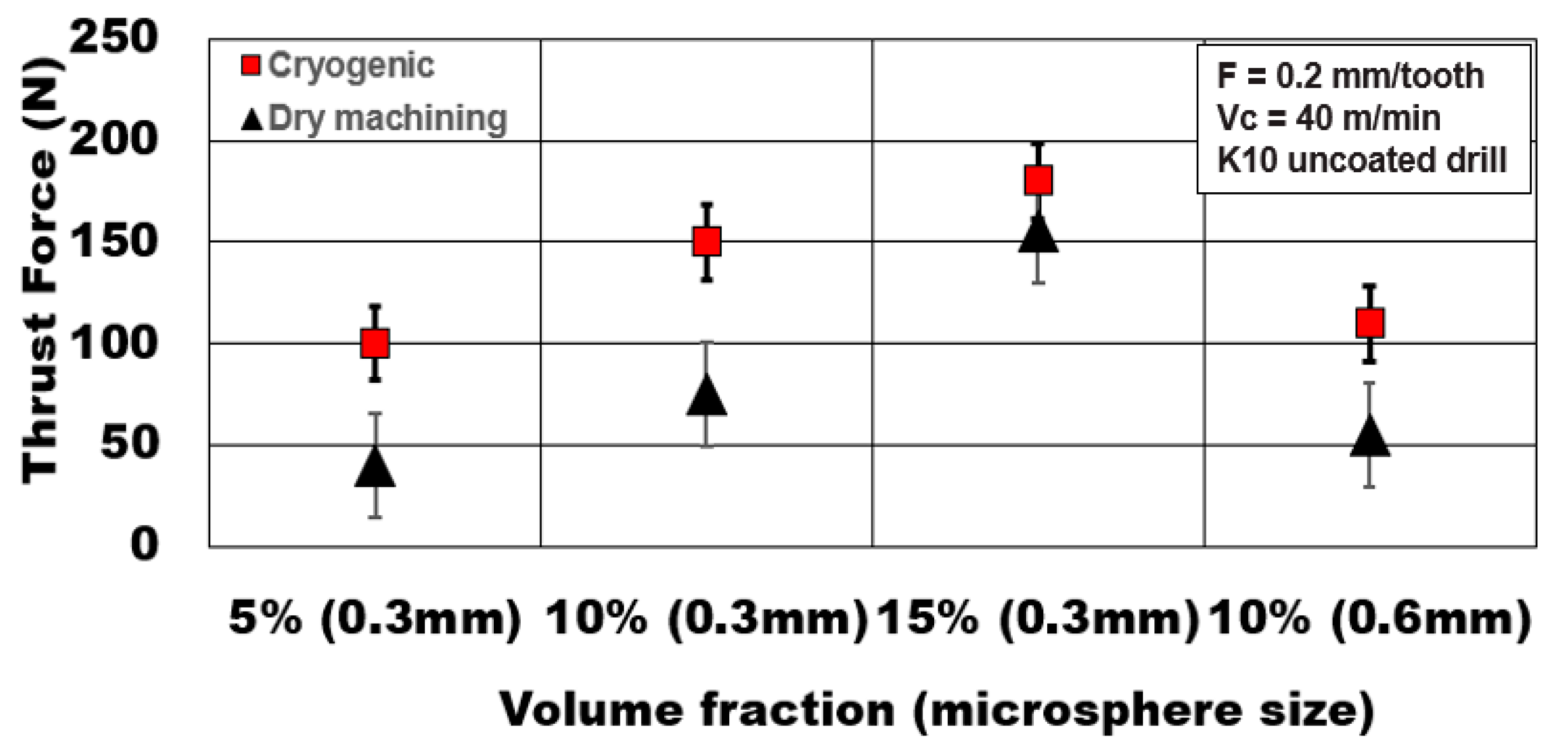

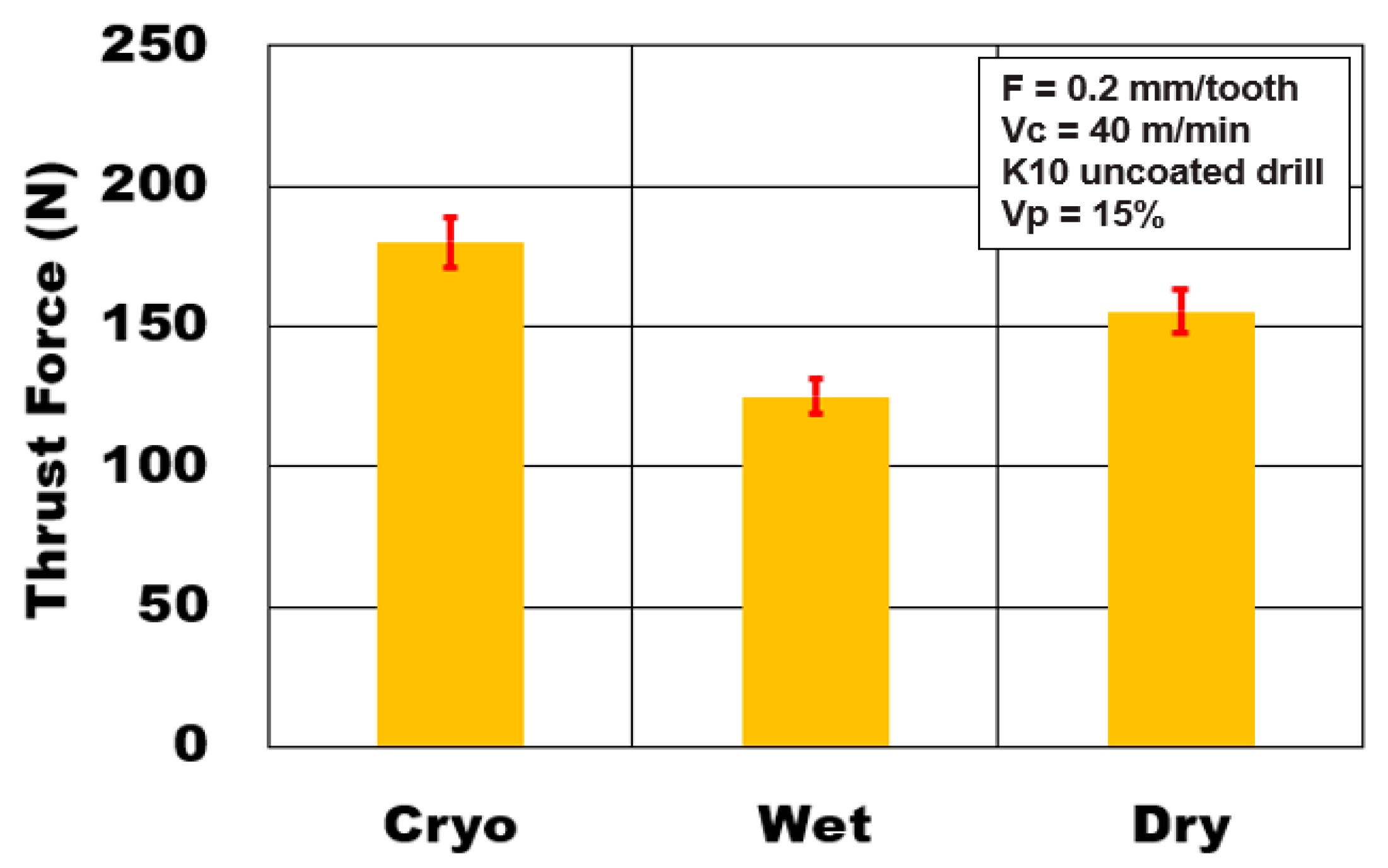

3.1. Thrust Forces

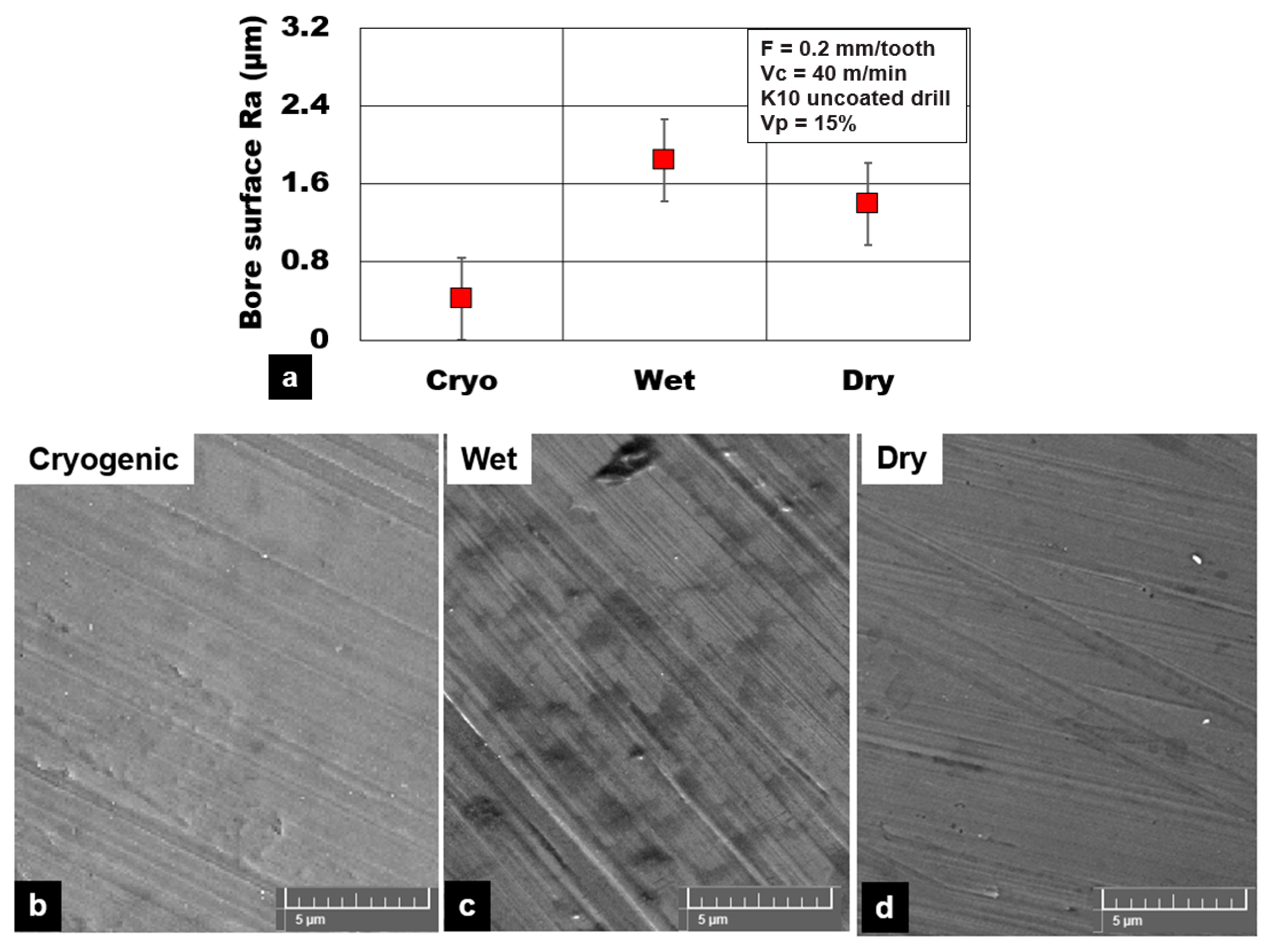

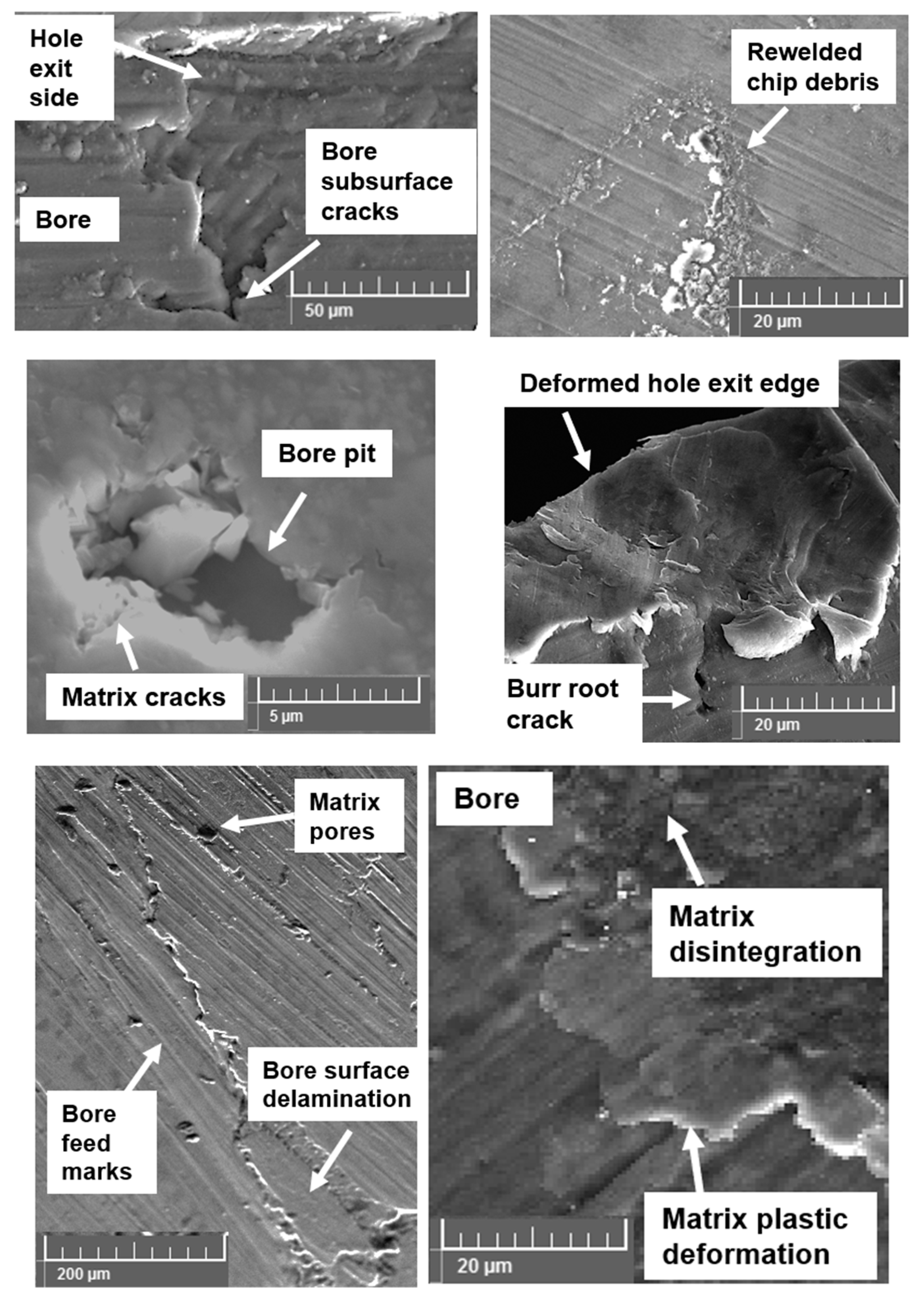

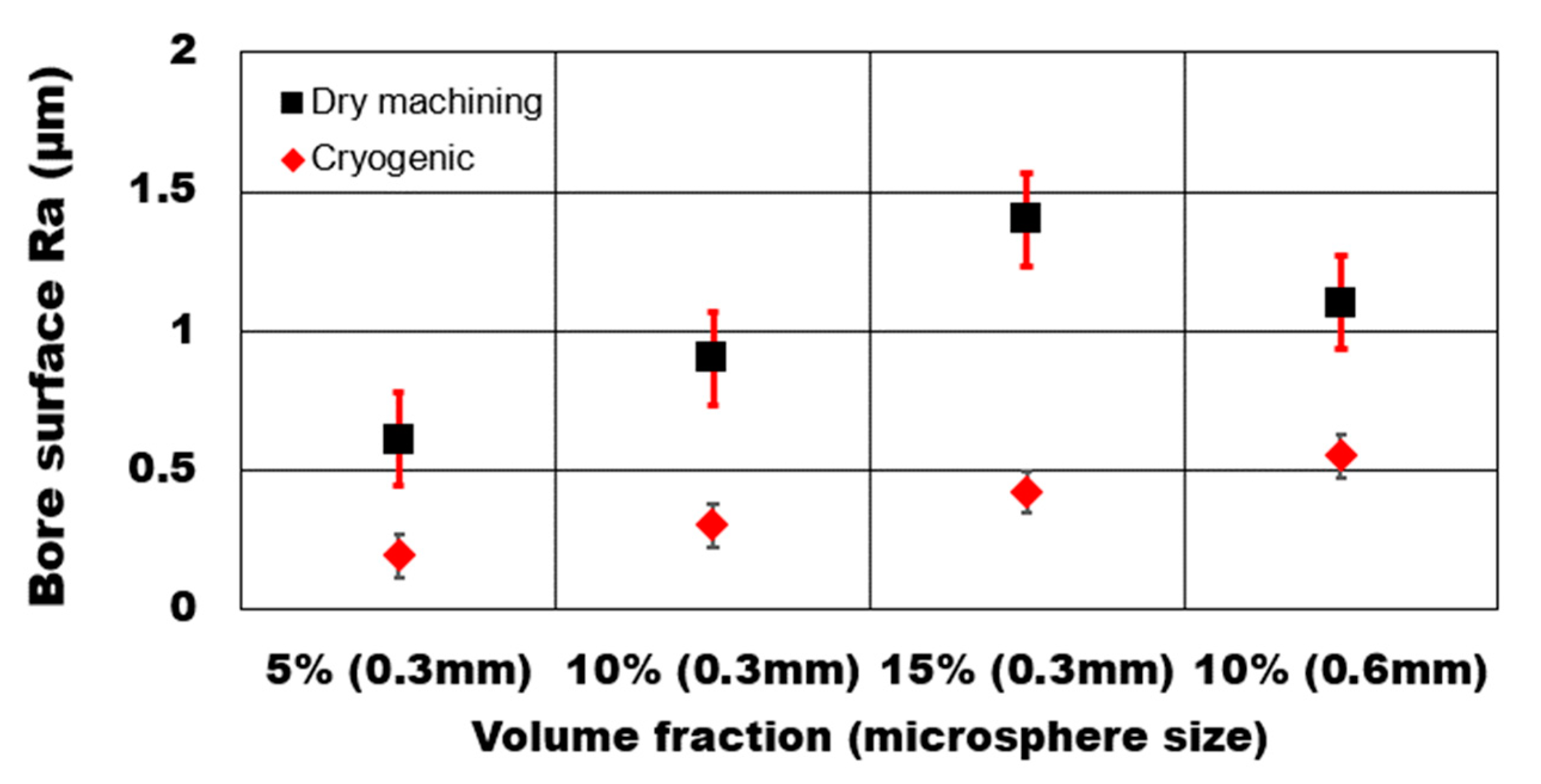

3.2. Surface Quality and Integrity

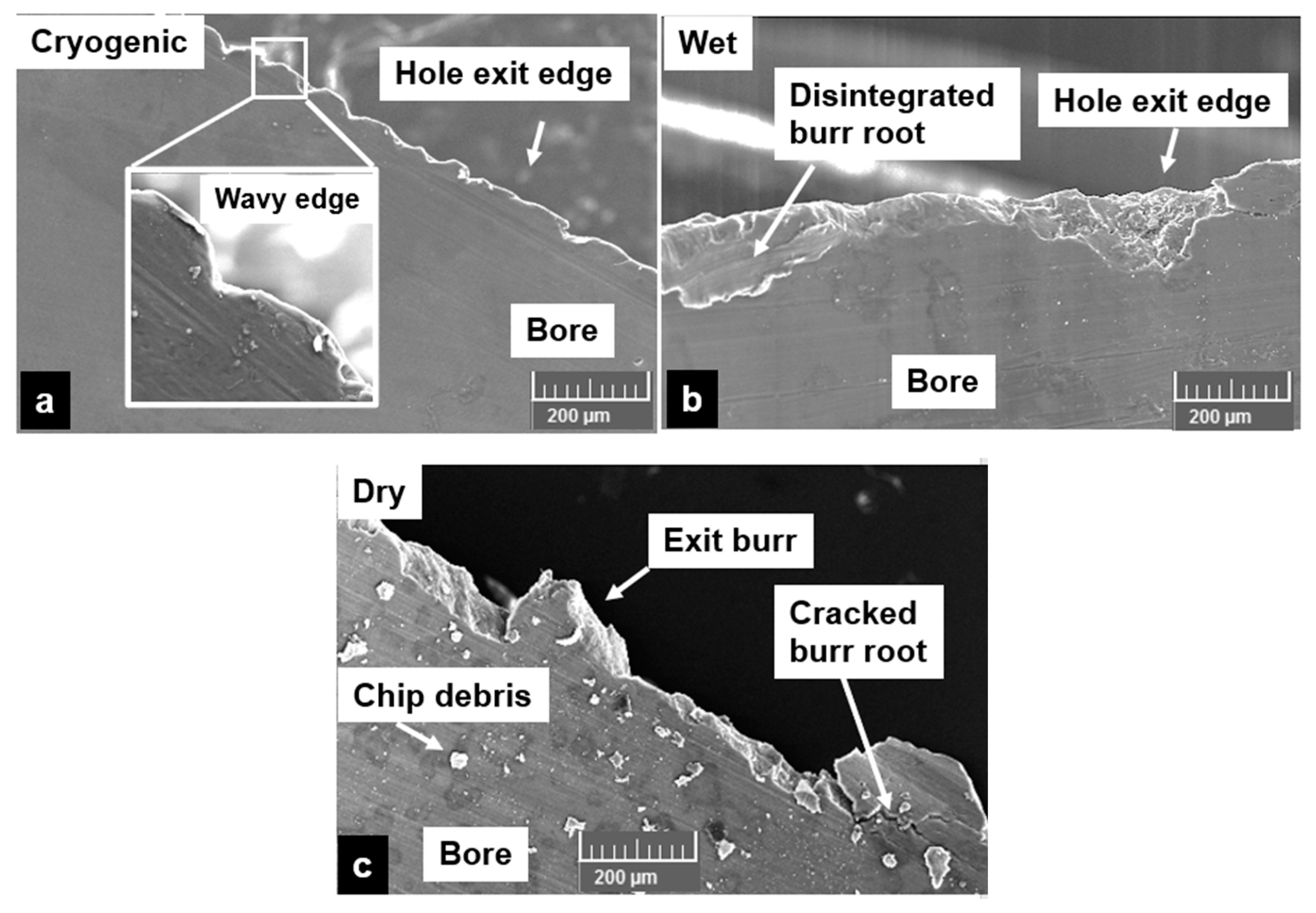

3.3. Burr Formation

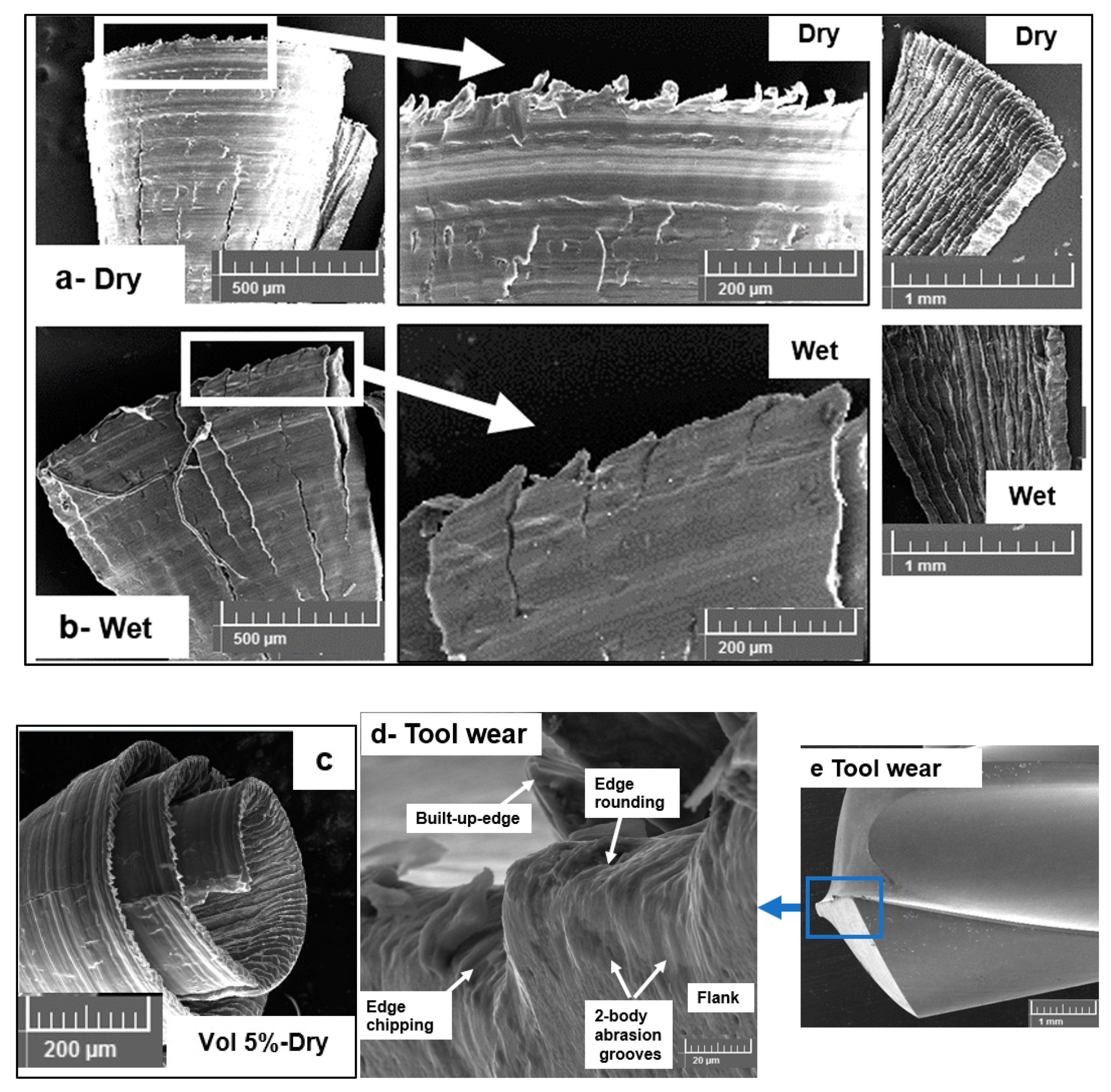

3.4. Chip Morphology

4. Conclusions

- Cryogenic drilling generated a 45% higher magnitude of thrust forces compared to dry and wet machining conditions while cutting AZ31-magnesium 15 vol% syntactic foam.

- Thrust forces during cryogenic machining increased by 250% due to an increase in feed/tooth (0.05 mm/tooth to 0.6 mm/tooth) and by 87% with decreasing cutting speed (120 m/min to 40 m/min).

- During cryogenic drilling, the higher the volume fraction of hollow alumina microspheres (15%) and the finer the average size of the microspheres (0.3 mm), the higher was the thrust forces by 45% and 36%, respectively.

- Cryogenic machining (0.42 µm) produced a 75% improvement in surface roughness (Ra) values compared to wet machining (1.84 µm) with minimal subsurface machining-induced defects.

- The surface roughness (Ra) deteriorated by approximately 125% with an increasing volume fraction of alumina microspheres (0.61 µm to 1.4 µm) under dry machining and cryogenic drilling (0.19 µm to 0.42 µm).

- Burr height reduction of 53% was achieved with cryogenic machining (60 µm) compared to dry machining (130 µm) and wet machining using Almag® Oil.

- In summary, cryogenic hole drilling of AZ31 magnesium syntactic foams reinforced with hollow alumina ceramic microspheres results in good surface quality and integrity compared to dry machining and wet machining conditions.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Parande, G.; Manakari, V.; Meenashisundaram, G.K.; Gupta, M. Enhancing the hardness/compression/damping response of magnesium by reinforcing with biocompatible silica nanoparticulates. Int. J. Mater. Res. 2016, 107, 1091–1099. [Google Scholar] [CrossRef]

- Cao, G.; Konishi, H.; Li, X. Mechanical properties and microstructure of Mg/SiC nanocomposites fabricated by ultrasonic cavitation based nanomanufacturing. ASME J. Manuf. Sci. Eng. 2008, 130, 1–6. [Google Scholar]

- Kumar, K.; Gill, R.S.; Batra, U. Challenges and opportunities for biodegradable magnesium alloy implants. Mater. Technol. 2018, 33, 153–172. [Google Scholar] [CrossRef]

- Dinesh, S.; Senthilkumar, V.; Asokan, P.; Arulkirubakaran, D. Effect of cryogenic cooling on machinability and surface quality of bio-degradable ZK60 Mg alloy. Mater. Des. 2015, 87, 1030–1036. [Google Scholar]

- Dinesh, S.; Senthilkumar, V.; Asokan, P. Experimental studies on the cryogenic machining of biodegradable ZK60 Mg alloy using micro-textured tools. Mater. Manuf. Process. 2017, 32, 979–987. [Google Scholar] [CrossRef]

- Outeiro, J.C.; Rossi, F.; Fromenti, G.; Poulachon, G.; Germain, G.; Batista, A.C. Process mechanics and surface integrity induced by dry and cryogenic machining of AZ31B-O magnesium alloy. Procedia CIRP 2013, 8, 487–492. [Google Scholar]

- Fiedler, T.; Al-Sahlani, K.; Linul, P.A.; Linul, E. Mechanical properties of A356 and ZA27 metallic syntactic foams at cryogenic temperature. J. Alloy. Compd. 2020, 813, 152181. [Google Scholar]

- Linul, E.; Marșavina, L.; Linul, P.-A.; Kovacik, J. Cryogenic, and high-temperature compressive properties of Metal Foam Matrix Composites. Compos. Struct. 2019, 209, 490–498. [Google Scholar]

- Khezrzadeh, O.; Mirzaee, O.; Emadoddin, E.; Linul, E. Anisotropic compressive behavior of metallic foams under extreme temperature conditions. Materials 2020, 13, 2329. [Google Scholar] [CrossRef]

- Linul, E.; Marșavina, L.; Vălean, C.; Bănică, R. Static and dynamic mode I fracture toughness of rigid PUR foams under room and cryogenic temperatures. Eng. Fract. Mech. 2020, 225, 106274. [Google Scholar] [CrossRef]

- Kannan, S.; Pervaiz, S.; Alhourani, A.; Klassen, R.J.; Selvam, R.; Haghshenas, M. On the role of hollow aluminium oxide microballoons during machining of AZ31 magnesium syntactic foam. Materials 2020, 13, 3534. [Google Scholar] [CrossRef] [PubMed]

- Gupta, N.; Luong, D.; Cho, K. Magnesium matrix composite foams—Density, Mechanical Properties, and Applications. Metals 2012, 2, 238–252. [Google Scholar] [CrossRef] [Green Version]

- Pu, Z.; Outeiro, J.C.; Batista, A.C.; Dillon, O.W.; Puleo, D.A.; Jawahir, I.S. Enhanced surface integrity of AZ31B Mg alloy by cryogenic machining towards the improved functional performance of machined components. Int. J. Mach. Tools Manuf. 2012, 56, 17–27. [Google Scholar] [CrossRef]

- Pu, Z.; Umbrello, D.; Dillon, O.W.; Lu, T.; Puleo, D.A.; Jawahir, I.S. Finite element modeling of microstructural changes in dry and cryogenic machining of AZ31B magnesium alloy. J. Manuf. Process. 2014, 16, 335–343. [Google Scholar] [CrossRef]

- Giraud, E.; Rossi, F.; Germain, G.; Outeiro, J.C. Constitutive Modelling of AZ31B-O Magnesium Alloy for Cryogenic Machining. Procedia CIRP 2013, 8, 522–527. [Google Scholar] [CrossRef] [Green Version]

- Koklu, U.; Coban, H. Effect of dipped cryogenic approach on thrust force, temperature, tool wear and chip formation in drilling of AZ31 magnesium alloy. J. Mater. Res. Technol. 2020, 9, 2870–2880. [Google Scholar] [CrossRef]

- De Agustina, B.; Berzosa, F.; Rubio, E.M.; Marin, M.M. Experimental study of magnesium drilling based on surface quality. Procedia CIRP 2019, 79, 74–78. [Google Scholar] [CrossRef]

- Davis, B.; Dabrow, D.; Ju, L.; Li, A.; Xu, C.; Huang, Y. Study of chip morphology and chip formation mechanism during machining of magnesium-based metal matrix composites. J. Manuf. Sci. Eng. 2017, 139, 091008. [Google Scholar] [CrossRef]

- Abdulgadir, M.M.; Demir, B.; Turan, M.E. Hybrid reinforced magnesium matrix composites (Mg/Sic/GNPs): Drilling investigation. Metals 2018, 8, 215. [Google Scholar] [CrossRef] [Green Version]

- Sun, F.; Huo, D.; Fu, G.; Teng, X.; Kannan, S.; Zhang, H. Micro-drilling of Mg-based MMCs reinforced with SiO2 nanoparticles: An experimental approach. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 234, 1473–1485. [Google Scholar] [CrossRef]

- Teng, X.; Huo, D.; Wong, E.; Meenashisundaram, G.; Gupta, M. Micro-machinability of nanoparticle-reinforced Mg-based MMCs: An experimental investigation. Int. J. Adv. Manuf. Technol. 2016, 87, 2165–2178. [Google Scholar] [CrossRef] [Green Version]

- Kheireddine, A.H.; Ammouri, A.H.; Lu, T.; Dillon, O.W.; Hamade, R.F.; Jawahir, I.S. An experimental and numerical study of the effect of cryogenic cooling on the surface integrity of drilled holes in AZ31B Mg alloy. Int. J. Adv. Manuf. Technol. 2015, 78, 269–279. [Google Scholar] [CrossRef]

- Kheireddine, A.H.; Ammouri, A.H.; Lu, T.; Jawahir, I.S.; Hamade, R.F. An FEM analysis with experimental validation to study the hardness of in-process cryogenically cooled drilled holes in Mg AZ31B. Procedia CIRP 2013, 8, 588–593. [Google Scholar]

- Bhowmick, S.; Lukitsch, M.J.; Alpas, A.T. Dry and minimum quantity lubrication drilling of cast magnesium alloy (AM60). Int. J. Mach. Tools Manuf. 2010, 50, 444–457. [Google Scholar]

- Kaynak, Y.; Gharibi, A. Progressive tool wear in cryogenic machining: the effect of liquid nitrogen and carbon dioxide. J. Manuf. Mater. Process. 2018, 2, 31. [Google Scholar] [CrossRef] [Green Version]

- Hong, S.Y.; Ding, Y.; Jeong, W.-C. Friction and cutting forces in cryogenic machining of Ti-6Al-4V. Int. J. Mach. Tools Manuf. 2001, 41, 2271–2285. [Google Scholar]

- Joshi, S.S.; Ramakrishnan, N.; Ramakrishnan, P. Microstructural analysis of chip formation during orthogonal machining of Al/SiCp composites. ASME J. Eng. Mater. Technol. 2001, 123, 315–321. [Google Scholar]

- Zhang, H.; Kong, X.; Yang, L.; Wang, Y.; Chi, G. High-temperature deformation mechanisms and constitutive modeling for Al/SiC/45 metal matrix composites undergoing Laser-Assisted machining. Mater. Sci. Eng. A 2015, 642, 330–339. [Google Scholar] [CrossRef]

| Avg Bubble Size (mm) | Al2O3 | Fe2O3 | CaO | SiO2 | Na2O | Bulk Density (Kg/m3) |

|---|---|---|---|---|---|---|

| 0.3 mm, 0.6 mm | 99.7 | 0.006 | 0.013 | 0.026 | 0.27 | 1700 |

| Property | TiAlN-PVD Coated | Uncoated |

|---|---|---|

| Flutes | 3 | 3 |

| Shank type | Straight | Straight |

| Drill diameter (mm) | 5 | 5 |

| Shank diameter (mm) | 6 | 6 |

| Grade | TiAlN Multilayer fine grain grade: KC7325 | Solid carbide K10 |

| Point angle | 140° | 140° |

| Helix angle | 30° | 30° |

| Flute length (mm) | 20 | 35 |

| Experiment Conditions | ||

|---|---|---|

| Matrix | AZ31 | Magnesium |

| Reinforcement | Hollow Alumina | Microsphere syntactic foam |

| Bubble volume fraction | (Vol %) | 5%, 10%, 15% |

| Cutting speed | m/min | 40–120 |

| Feed per tooth | mm/tooth | 0.05, 0.2, 0.4, 0.6 |

| Hole depth | mm | 5 |

| Cutting insert | Kennametal™ | TiAlN PVD coated K10 uncoated carbide |

| Cooling method | Cryogenic, Wet and Dry | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kannan, S.; Pervaiz, S.; Jahan, M.P.; Venkatraghaven, D. Cryogenic Drilling of AZ31 Magnesium Syntactic Foams. Materials 2020, 13, 4094. https://doi.org/10.3390/ma13184094

Kannan S, Pervaiz S, Jahan MP, Venkatraghaven D. Cryogenic Drilling of AZ31 Magnesium Syntactic Foams. Materials. 2020; 13(18):4094. https://doi.org/10.3390/ma13184094

Chicago/Turabian StyleKannan, Sathish, Salman Pervaiz, Muhammad Pervej Jahan, and DoraiSwamy Venkatraghaven. 2020. "Cryogenic Drilling of AZ31 Magnesium Syntactic Foams" Materials 13, no. 18: 4094. https://doi.org/10.3390/ma13184094

APA StyleKannan, S., Pervaiz, S., Jahan, M. P., & Venkatraghaven, D. (2020). Cryogenic Drilling of AZ31 Magnesium Syntactic Foams. Materials, 13(18), 4094. https://doi.org/10.3390/ma13184094