Age Hardening Characteristics of an Ultra-Low Carbon Cu Bearing Steel

Abstract

:1. Introduction

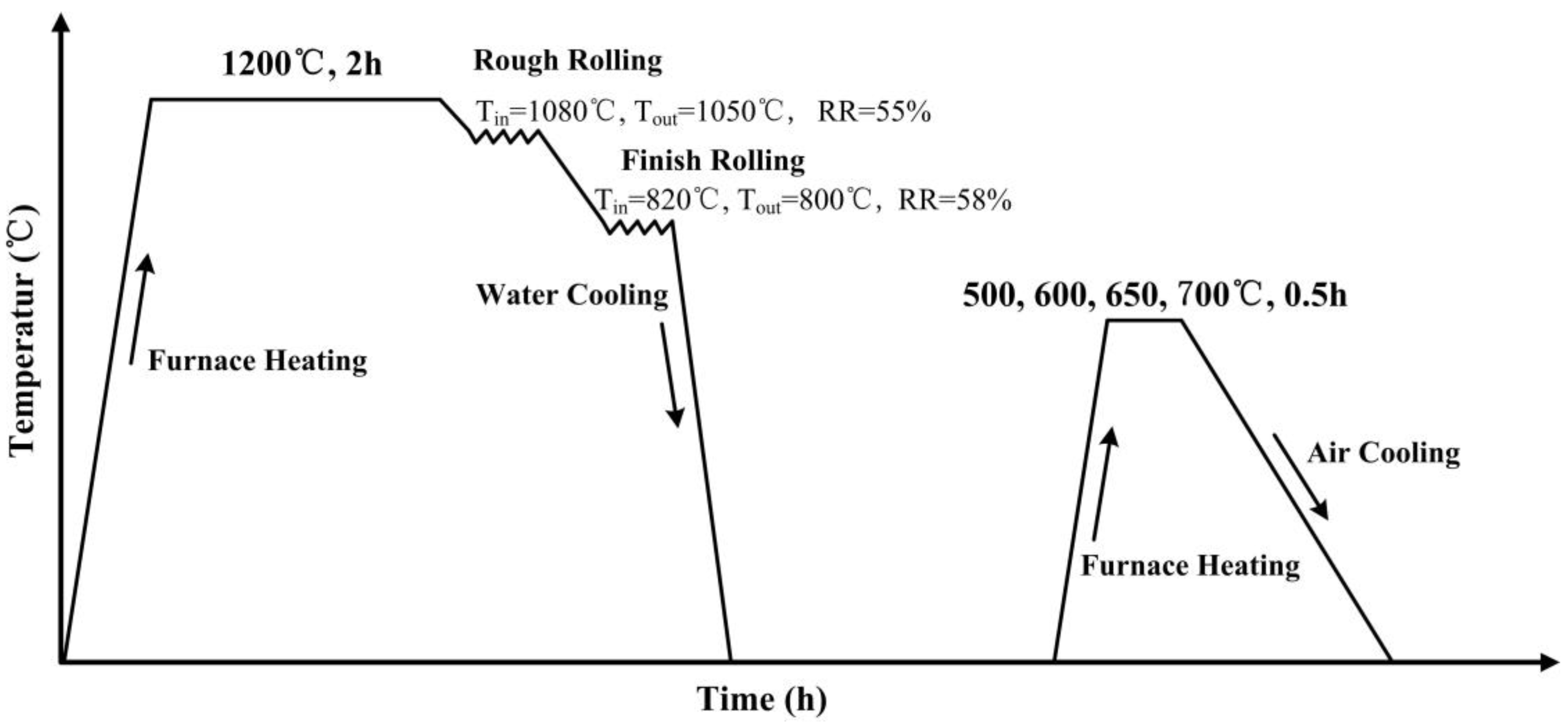

2. Materials and Methods

3. Results

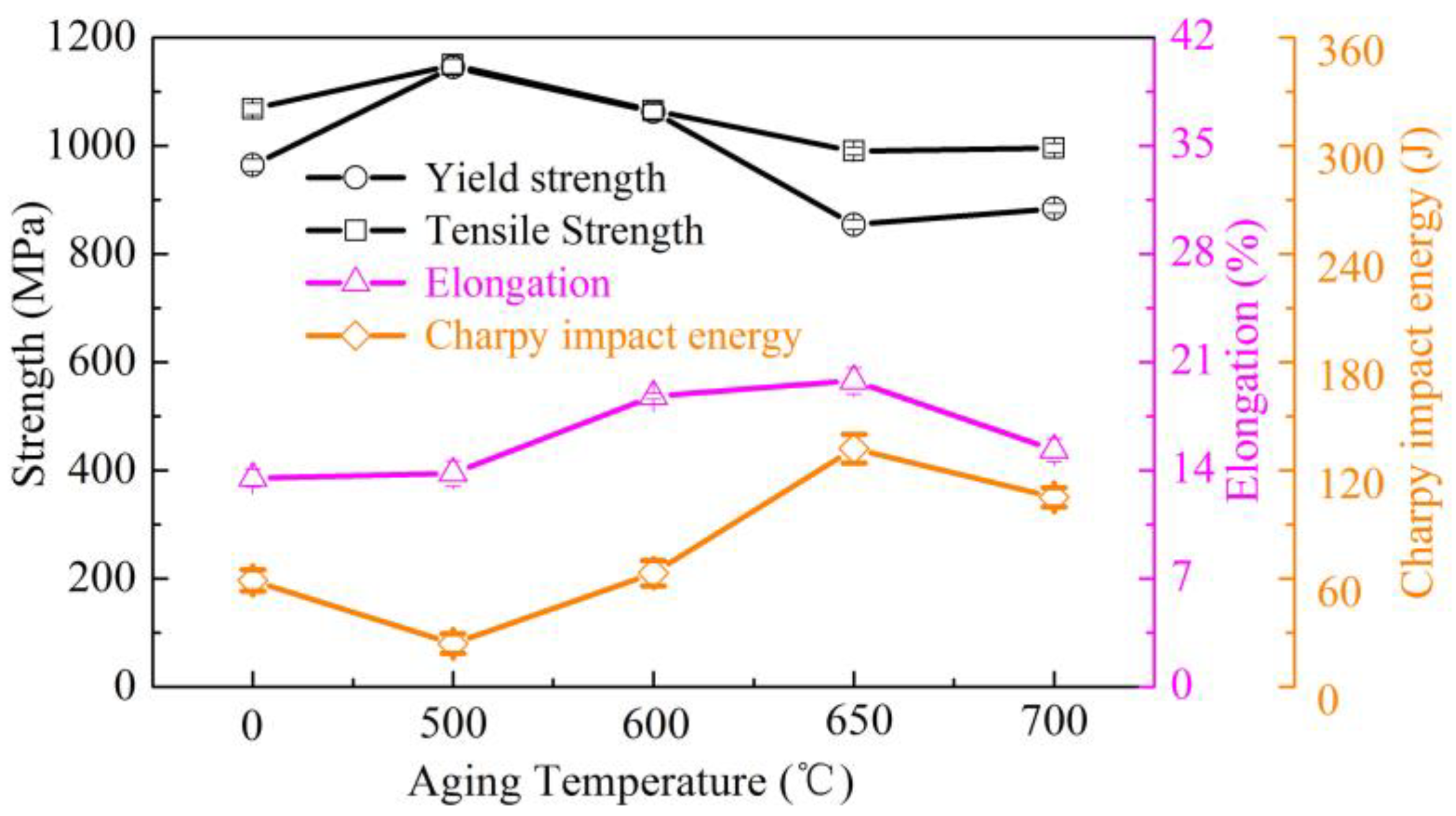

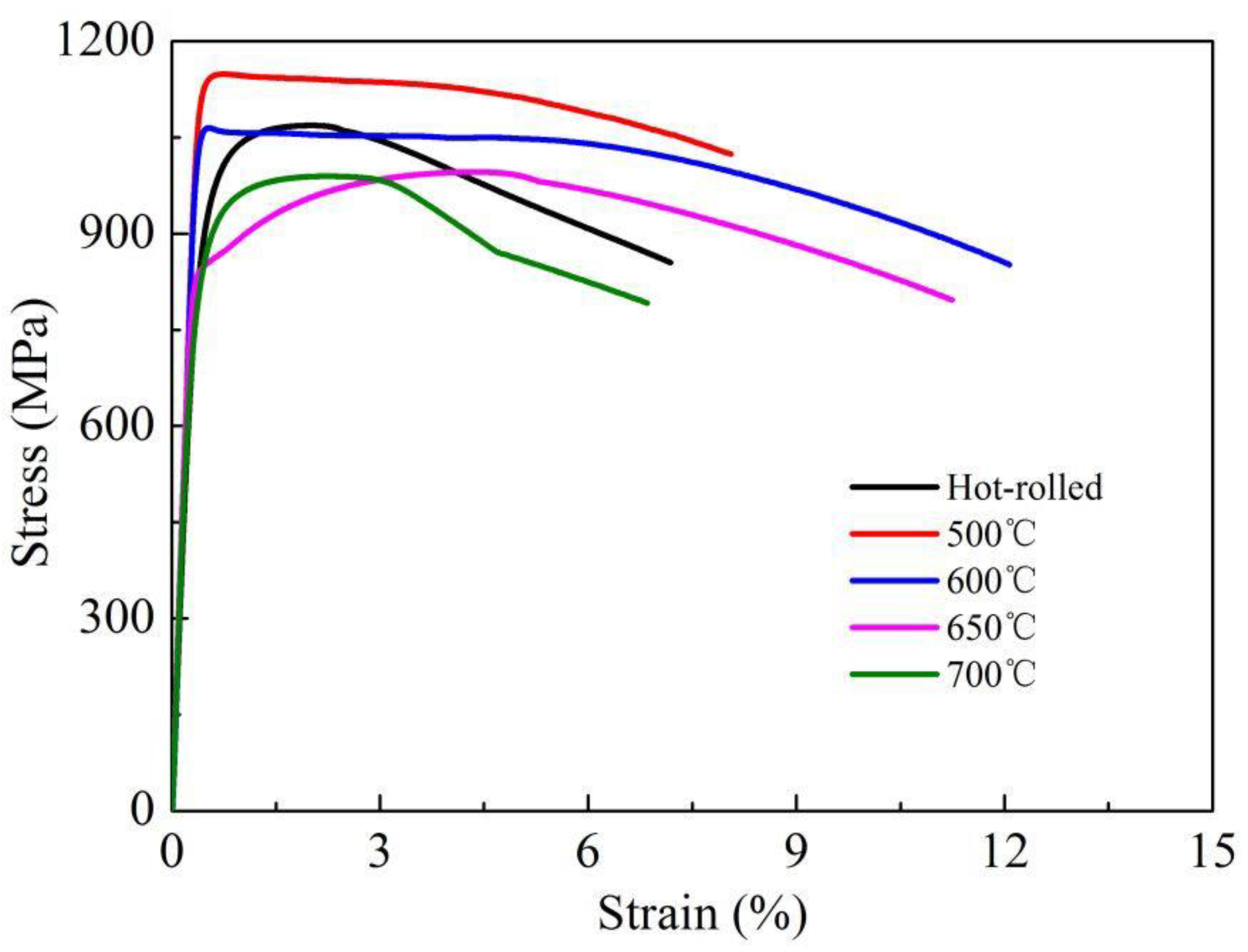

3.1. Mechanical Properties

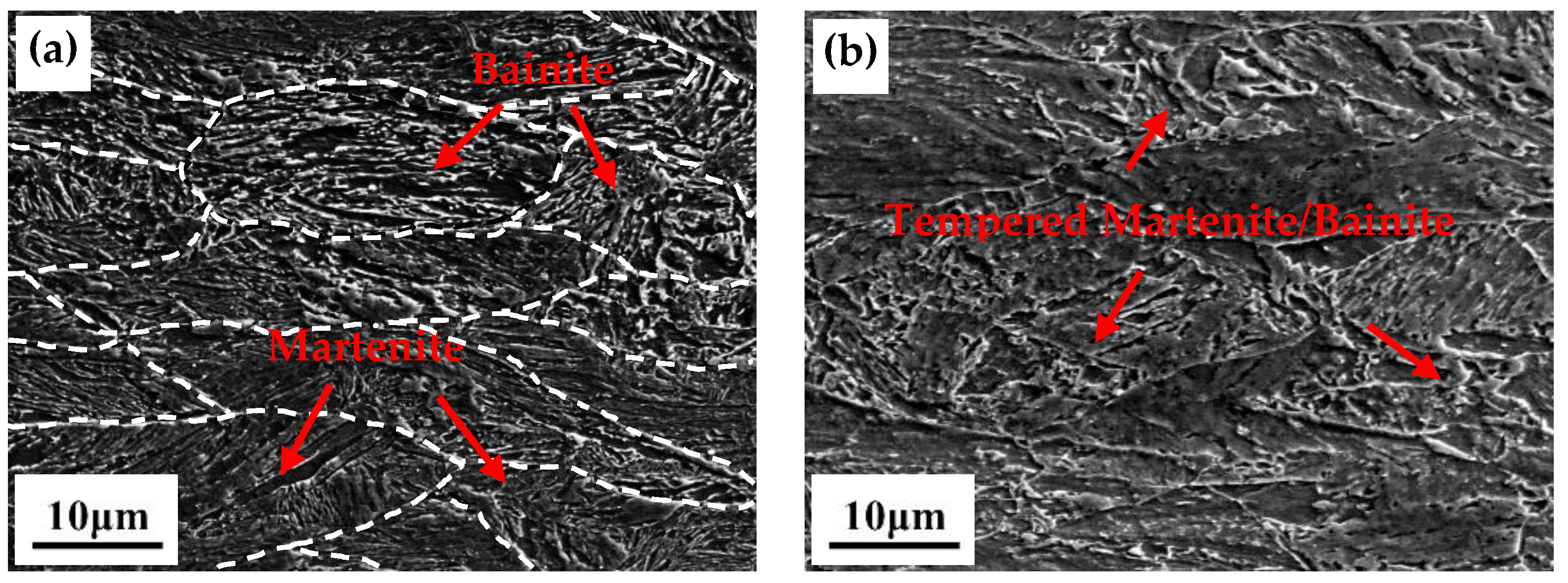

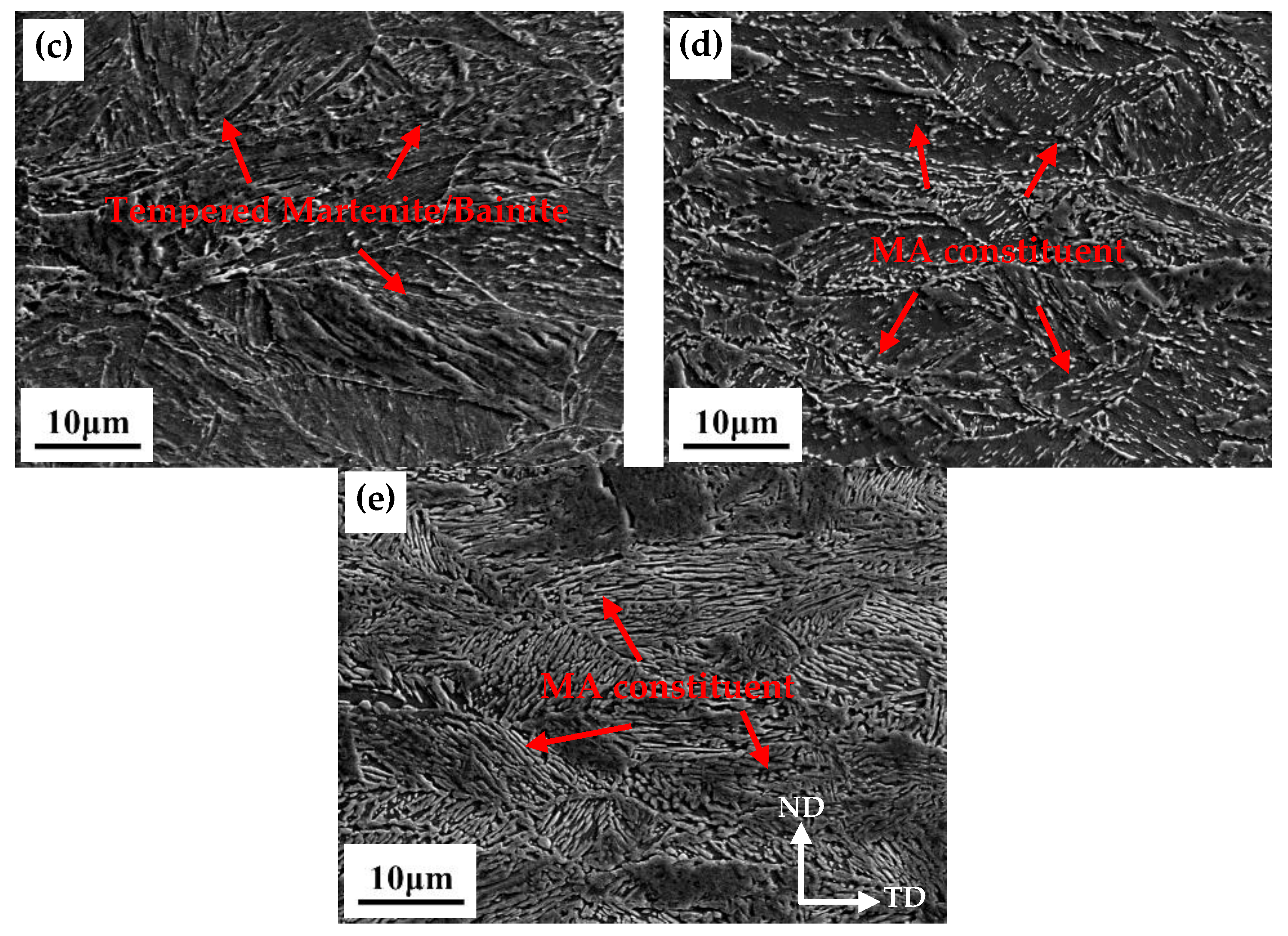

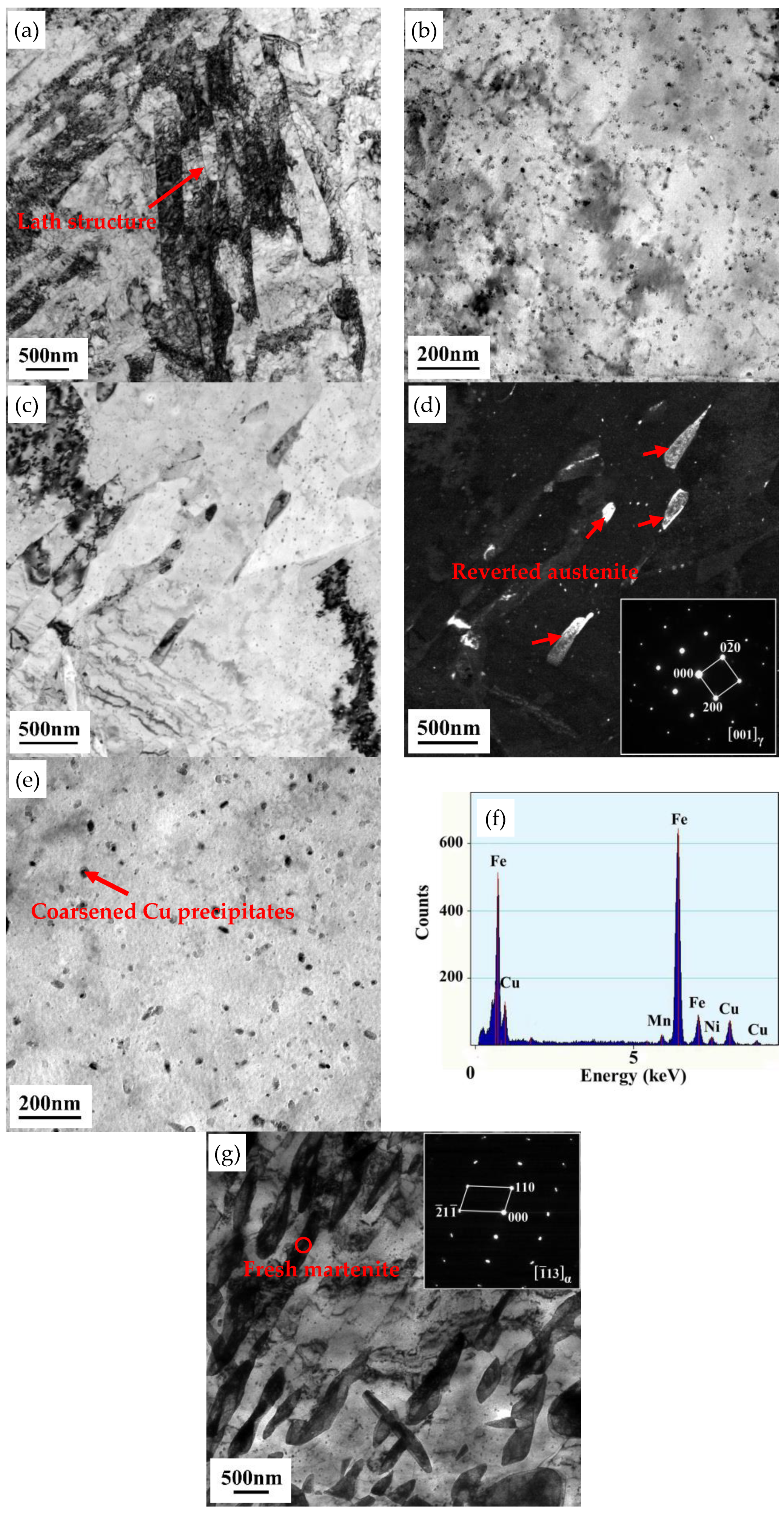

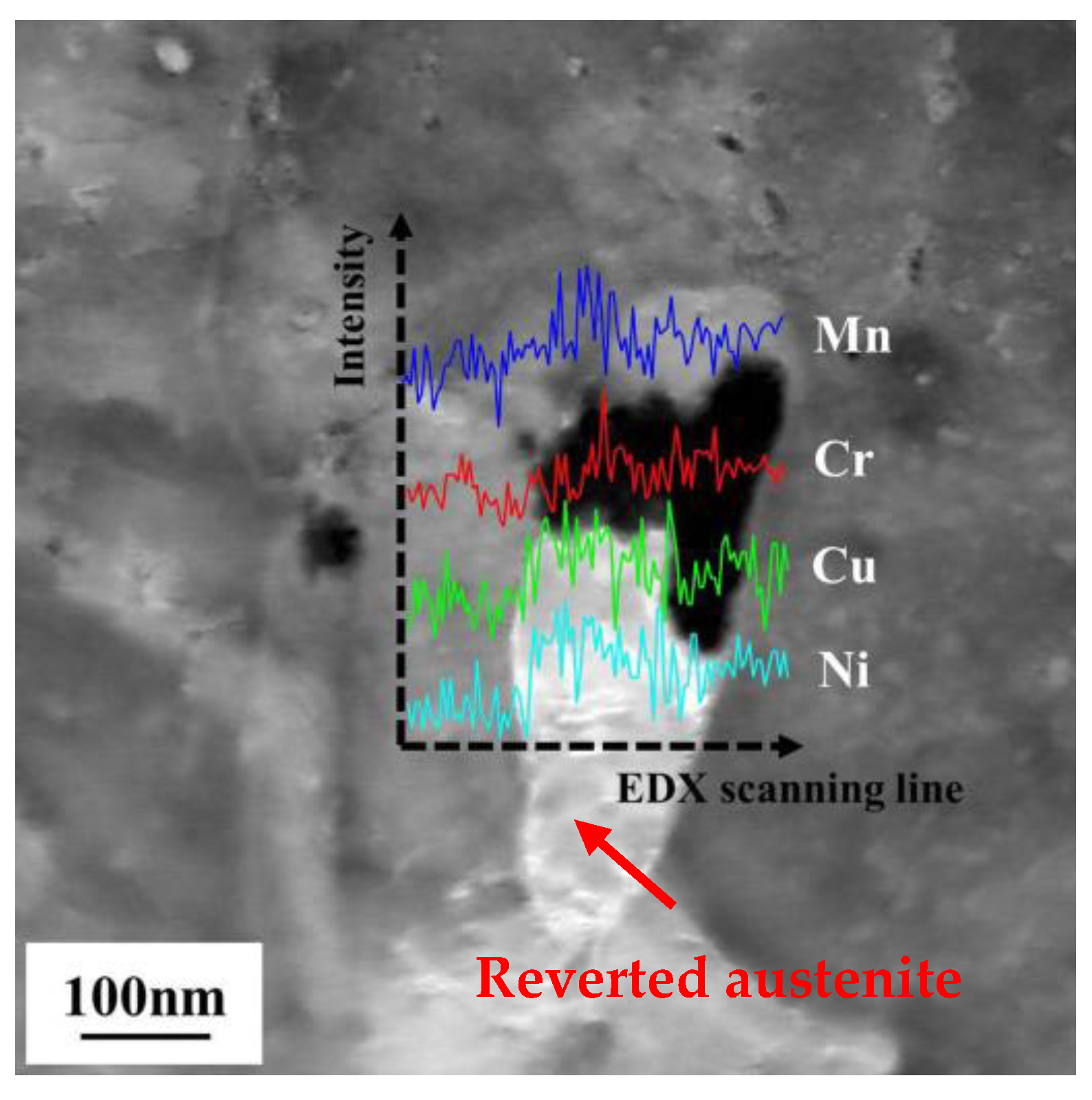

3.2. Microstructural Characterization

4. Discussion

4.1. Effect of Processing on Microstructure

4.2. Effect of Processing on Mechanical Properties

5. Conclusions

- Water-cooled steel exhibited a lath bainite/martensite structure and the lath structure was continuously recovered during the aging process. The formation and coarsening of Cu precipitates increased with aging temperature.

- After aging at 650 °C, the newly formed reverted austenite was sufficiently stable and was retained after air cooling. When the aging temperature increased to 700 °C, the thermal stability declined and the reverted austenite transformed to martenite.

- The steel showed a typical aging behavior. The maximum yield and tensile strengths obtained at 500 °C were 1063 and 1065 MPa, respectively, along with the poor elongation of 13.8% and Charpy impact energy of 24 J. When the aging temperature increased to 650 °C, the yield strength and tensile strength were decreased by 291 and 159 MPa, respectively, while the Charpy impact energy was increased by 108 J.

- After aging at 700 °C, due to the transformation from reverted austenite to fresh martenite, the yield and tensile strengths were slightly increased by 30 and 6 MPa, respectively but with some loss of the Charpy impact energy (by 27 J) and elongation (by 4.5%).

- The impact toughness was improved at the expense of strength as the aging temperature increased. The best combination of strength and toughness was obtained after aging at 650 °C. These enhancements were associated with matrix recovery, lowering of the Cu precipitation strengthening effect and formation of reverted austenite.

Author Contributions

Funding

Conflicts of Interest

References

- Thompson, S.W.; Krauss, G. Copper precipitation during continuous cooling and isothermal aging of A710-type steels. Metall. Mater. Trans. A 1996, 27A, 1573–1588. [Google Scholar] [CrossRef]

- Banerjee, K.; Chatterjee, U.K. Effect of microstructure on hydrogen embrittlement of weld-simulated HSLA-80 and HSLA-100 steels. Metall. Mater. Trans. A 2003, 34A, 1297–1309. [Google Scholar] [CrossRef]

- Dhua, S.K. Studies on influence of reheating temperature and cooling rate on structure-property behavior of lean chemistry HSLA-100 steel. Mater. Sci. Technol. 2011, 27, 1377–1384. [Google Scholar] [CrossRef]

- Vaynman, S.; Isheim, D.; Kolli, R.P.; Bhat, S.P.; Seidman, D.N.; Fine, M.E. High-strength low-carbon ferritic steel containing Cu-Fe-Ni-Al-Mn precipitates. Metall. Mater. Trans. A 2008, 39, 363–373. [Google Scholar] [CrossRef] [Green Version]

- Yin, G.Q.; Yang, C.F.; Lu, Y.N. HREM observation of age-precipitated particles in practical Cu-bearing ultra-low carbon steels. J. Mater. Sci. Technol. 2010, 26, 433–438. [Google Scholar] [CrossRef]

- Yoo, J.Y.; Choo, W.Y.; Park, T.W.; Kim, Y.W. Microstructures and age hardening characteristics of direct quenched Cu bearing HSLA steel. ISIJ Int. 1995, 35, 1034–1040. [Google Scholar] [CrossRef]

- Takahashi, J.; Kawakami, K.; Kobayashi, Y. Consideration of particle-strengthening mechanism of copper-precipitation-strengthened steels by atom probe tomography analysis. Mater. Sci. Eng. A 2012, 535, 144–152. [Google Scholar] [CrossRef]

- Jung, J.G.; Jung, M.; Lee, S.M.; Shin, E.; Shin, H.C.; Lee, Y.K. Cu precipitation kinetics during martensite tempering in a medium C steel. J. Alloys. Compd. 2013, 553, 299–307. [Google Scholar] [CrossRef]

- Heo, Y.U.; Kim, Y.K.; Kim, J.S.; Kim, J.K. Phase transformation of Cu precipitates from bcc to fcc in Fe-3Si-2Cu alloy. Acta Mater. 2013, 61, 519–528. [Google Scholar] [CrossRef]

- Lee, T.H.; Kim, Y.O.; Kim, S.J. Crystallographic model for bcc-to-9R martensitic transformation of Cu precipitates in ferritic steel. Philos. Mag. 2007, 87, 209–224. [Google Scholar] [CrossRef]

- Han, G.; Xie, Z.J.; Li, Z.Y.; Lei, B.; Shang, C.J.; Misra, R.D.K. Evolution of crystal structure of Cu precipitates in a low carbon steel. Mater. Des. 2017, 135, 92–101. [Google Scholar] [CrossRef]

- Wen, Y.R.; Li, Y.P.; Hirata, A.; Zhang, Y.; Fujita, T.; Furuhara, T.; Liu, C.T.; Chiba, A.; Chen, M.W. Synergistic alloying effect on microstructural evolution and mechanical properties of Cu precipitation-strengthened ferritic alloys. Acta Mater. 2013, 61, 7726–7740. [Google Scholar] [CrossRef]

- Kapoor, M.; Isheim, D.; Vaynman, S.; Fine, M.E.; Chung, Y.W. Effects of increased alloying element content on NiAl-type precipitate formation, loading rate sensitivity and ductility of Cu- and NiAl-precipitation-strengthened ferritic steels. Acta Mater. 2016, 104, 166–171. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.W.; Liu, C.T.; Wang, X.L.; Miller, M.K.; Ma, D.; Chen, G.; Williams, J.R.; Chin, B.A. Effects of proton irradiation on nanocluster precipitation in ferritic steel containing fcc alloying additions. Acta Mater. 2012, 60, 3034–3046. [Google Scholar] [CrossRef]

- Isheim, D.; Gagliano, M.S.; Fine, M.E.; Seidman, D.N. Interfacial segregation at Cu-rich precipitates in a high-strength low-carbon steel studied on a sub-nanometer scale. Acta Mater. 2006, 54, 841–849. [Google Scholar] [CrossRef]

- Jiao, Z.B.; Luan, J.H.; Zhang, Z.W.; Miller, M.K.; Ma, W.B.; Liu, C.T. Synergistic effects of Cu and Ni on nanoscale precipitation and mechanical properties of high-strength steels. Acta Mater. 2013, 61, 5996–6005. [Google Scholar] [CrossRef]

- Hwang, G.C.; Lee, S.; Yoo, J.Y.; Choo, W.Y. Effect of direct quenching on microstructure and mechanical properties of copper-bearing high-strength alloy steels. Mater. Sci. Eng. A 1998, 252, 256–268. [Google Scholar] [CrossRef]

- Ghosh, A.; Mishra, B.; Das, S.; Chatterjee, S. An ultra low carbon Cu bearing steel: Influence of thermomechanical processing and aging heat treatment on structure and properties. Mater. Sci. Eng. A 2004, 374, 43–56. [Google Scholar] [CrossRef]

- Ray, P.K.; Ganguly, R.I.; Panda, A.K. Optimization of mechanical properties of an HSLA-100 steel through control of heat treatment variables. Mater. Sci. Eng. A 2003, 346, 122–131. [Google Scholar] [CrossRef]

- Luo, H.W.; Shi, J.; Wang, C.; Cao, W.Q.; Sun, X.J.; Dong, H. Experimental and numerical analysis on formation of stable austenite during the intercritical annealing of 5Mn steel. Acta Mater. 2011, 59, 4002–4014. [Google Scholar] [CrossRef]

- Chen, J.; Lv, M.Y.; Liu, Z.Y.; Wang, G.D. Influence of heat treatments on the microstructural evolution and resultant mechanical properties in a low carbon medium Mn heavy steel plate. Metall. Mater. Trans. A 2016, 47A, 2300–2312. [Google Scholar] [CrossRef]

- Lei, M.; Guo, Y.Y. Formation of precipitated austenite in 9% Ni steel and its performance at cryogenic temperature. Acta Metall. Sin. 1989, 2, 244–248. [Google Scholar]

- ASTM E8M-00a, Standard Test Methods for Tension Testing of Metallic Materials [Metric]; ASTM International: West Conshohocken, PA, USA, 2001; pp. 1–22.

- Dhua, S.K.; Sen, S.K. Effect of direct quenching on the microstructure and mechanical properties of the lean-chemistry HSLA-100 steel plates. Mater. Sci. Eng. A 2011, 528, 6356–6365. [Google Scholar] [CrossRef]

- Dhua, S.K.; Ray, A.; Sarma, D.S. Effect of tempering temperatures on the mechanical properties and microstructures of HSLA-100 type copper-bearing steels. Mater. Sci. Eng. A 2001, 318, 197–210. [Google Scholar] [CrossRef]

- Mujahid, M.; Lis, A.K.; Garcia, C.J.; Deardo, A.J. HSLA-100 steels: Influence of aging heat treatment on microstructure and properties. J. Mater. Eng. Perform. 1998, 7, 247–257. [Google Scholar] [CrossRef]

- Caballero, F.G.; Bhadeshia, H.K.D.H.; Mawella, K.J.A.; Jones, D.G.; Brown, P. Design of novel high strength bainitic steels: Part 1. Mater. Sci. Tchnol. 2001, 17, 512–516. [Google Scholar] [CrossRef]

- Caballero, F.G.; Bhadeshia, H.K.D.H.; Mawella, K.J.A.; Jones, D.G.; Brown, P. Design of novel high strength bainitic steels: Part 2. Mater. Sci. Tchnol. 2001, 17, 517–522. [Google Scholar] [CrossRef] [Green Version]

- Gomez, G.; Perez, T.; Bhadeshia, H.K.D.H. Air cooled bainitic steels for strong, seamless pipes Part 1‒alloy design, kinetics and microstructure. Mater. Sci. Tchnol. 2009, 25, 1501–1507. [Google Scholar] [CrossRef]

- Panwar, S.; Goel, D.B.; Pandey, O.P.; Prasad, K.S. Aging of a copper bearing HSLA-100 steel. Bull. Mater. Sci. 2003, 26, 441–447. [Google Scholar] [CrossRef]

- Skoufari-Themistou, L.; Crowther, D.N.; Mintz, B. Strength and impact behaviour of age hardenable copper containing steels. Mater. Sci. Technol. 1999, 15, 1069–1079. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, M.; Xu, Y. Age Hardening Characteristics of an Ultra-Low Carbon Cu Bearing Steel. Materials 2020, 13, 4104. https://doi.org/10.3390/ma13184104

Sun M, Xu Y. Age Hardening Characteristics of an Ultra-Low Carbon Cu Bearing Steel. Materials. 2020; 13(18):4104. https://doi.org/10.3390/ma13184104

Chicago/Turabian StyleSun, Mingxue, and Yang Xu. 2020. "Age Hardening Characteristics of an Ultra-Low Carbon Cu Bearing Steel" Materials 13, no. 18: 4104. https://doi.org/10.3390/ma13184104

APA StyleSun, M., & Xu, Y. (2020). Age Hardening Characteristics of an Ultra-Low Carbon Cu Bearing Steel. Materials, 13(18), 4104. https://doi.org/10.3390/ma13184104