Mechanical Properties of Corner Joints Made of Honeycomb Panels with Double Arrow-Shaped Auxetic Cores

Abstract

1. Introduction

- Influence of material density as well as stiffness and rigidity of fasteners. It is exposed in the literature that values of linear modulus of elasticity (MOE and MPa) are greater for joints made of materials with bigger densities and homogenous, nonporous structure. There are studies on joint strength by which number of construction forms were tested i.e., structural-adhesive (double dowel or lamello), conventional metal fasteners (screws and confirmats), and more innovative products from companies like Blum, Hafele, and Titus plus [18,19,20,21,22,23,24,25,26,27,28,29,30,31,32];

- Influence of fastener/joint geometry on joint stiffness. The increase in fastener length and diameter results in joint strength improvement, although increasing length is more effective [6,36,43,44]. Material change as well as different walls inclination angle was taken into consideration in corner dovetail joint test. Among examined samples including 5 different inclination angle values (75°, 78°, 81°, 84°, and 87°), four types of materials (birch, oak, pine, and MDF) and two adhesives, polyvinyl acetate (PVAc) and Desmodur-VTKA (D-VTKA), the best option was oak with 84° glued with D-VTKA [45];

- Presence, type, and adhesives application technique. In the literature, there are studies concerning diversity of adhesives, glue layer thickness, and gluing application methods. In general, the use of adhesives significantly improves joint strength [12,18,22,46,47,48]. Furthermore, better stiffness is a result of using silicon glue rather than PVAc [21];

- Effect of narrow surfaces finishing, use of edge banding, as well as its type and thickness. There are studies in the literature on the rigidity of furniture joints made of laminated PB and MDF. In addition, sides of samples were covered with: melamine edge band 0.4 mm thick, PVAc (0.4, 1, and 2 mm thick) ,and birch veneer (0.4, 1, and 2 mm thick) [49]. It was proved that the strongest joint was made of MDF with melamine edge banding. Average joint strength was about 17% and 18% better in comparison to the second-best variant (PB and PVAc, 0.4 mm) in compression and tension tests, respectively. Fathollahzadeh et al. [50] subjected different types of furniture cases (made of laminated MDF and raw MDF in versions both with and without elements edging) to cyclic loading. It was found that the strength of construction elements with edging is 1.8 times higher;

- The effect of a fastener grain orientation changes in relation to the grain direction of the specimen on the pulled-out joint strength. The stress distribution in model consisting of a dowel embedded in a maple wood sample was checked numerically. The change in moisture content from 10% to 18% was simulated, and the direction of the dowel fibers was orientated at 0°, 30°, 60°, and 90° in relation to the fiber direction of the sample. It was shown that the highest virtual pull-out strength was observed for the variant with 90° [51];

- The influence of the back panel assembly method on the strength of the corner joints. The presence of the back panel significantly improves the strength of the connection. In one of the works, the assembly methods have been assessed, where a back panel was mounted by screws to 18 mm thick elements made of: raw PB, veneer-coated PB, plywood (PLY), and MDF. Back panels were installed directly and through wooden (birch) add-ons. In each case, the use of wooden add-ons increased the strength of the joint as a result of the screws being firmly embedded in the material [52];

- The influence of the fasteners mounting force on the joint strength. The numerical calculations have shown that the application of maximum force moment while screwing a confirmat-type fastener into PB does not cause it to crack along the thread. On the other hand, the board is damaged due to the pressure of the confirmat head [5]. In another work, different hinges mounting plates and drawer sliders assembly methods were tested: directly to the panels by Euro screws, wood screws and plastic muff, and wood screws and a mounting plate. Different torque values for screwing fasteners were taken into account. Based on the results, it was found out that the most advantageous way is to use screws with a muff and a force moment value of 1.342 Nm [42];

2. Materials and Methods

2.1. Materials

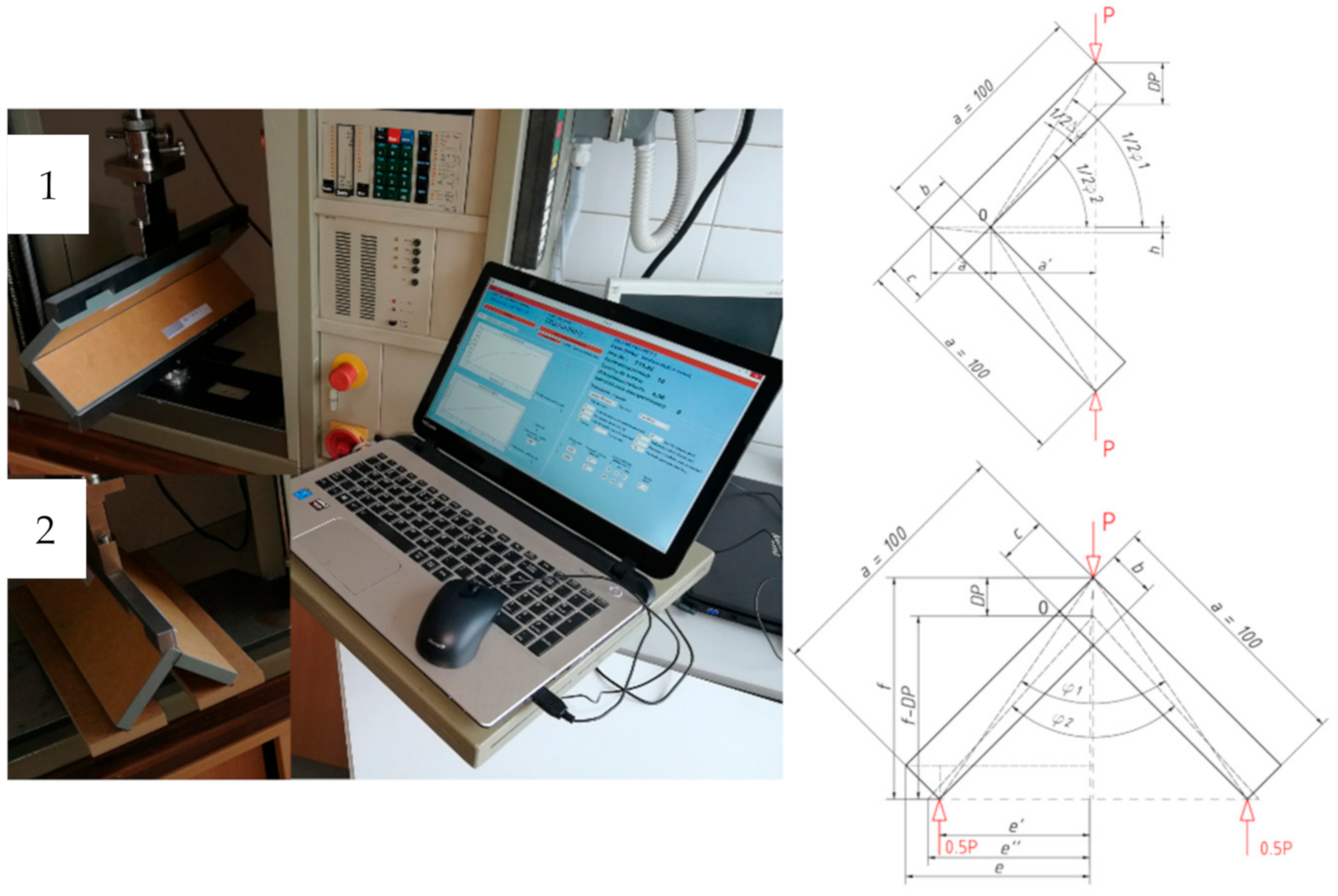

2.2. Corner Joints Stiffness Calculation Method

2.3. Corner Joints Rigidity Calculation Method

3. Samples Preparation

3.1. Core Cell Design

3.2. Cores and Honeycombs Preparation

3.3. Corner Joints Preparation

4. Results and Discussion

4.1. Materials and Panels Properties

4.2. Corner Joints Stiffness

- For compression test: the stiffness coefficient of AUX-2 is 15% bigger than HEX-1 and AUX-1 is 3.4% bigger than HEX-2;

- For tension test: AUX-2 is 7.5% stiffer than HEX-1 and AUX-1 is 3.2% stiffer than HEX-2.

- The compressed AUX-1 joints expose a stiffness coefficient of 30.4% bigger than AUX-2, although the tensioned AUX-1 joints show a stiffness coefficient of 12.3% bigger than AUX-2;

- The compressed joints HEX-2 have a 45.0% bigger stiffness coefficient K than HEX-1, and tensioned HEX-2 show a stiffness coefficient of 17.0% bigger than HEX 1.

- HEX-1 by 165%,

- HEX-2 is 138%,

- AUX-1 by 133%,

- AUX-2 is 148% bigger than the value calculated for tensioned joints.

- In compression test: AUX-2:HEX-1 and AUX-1:HEX-2 do not differ significantly;

- In tension test: AUX-2:HEX-1 and AUX-1:HEX-2 do not differ significantly.

4.3. Corner Joints Strength

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Smardzewski, J. Furniture Design; Springer: Cham, Switzerland, 2015. [Google Scholar]

- Eckelman, C.A.; Suddarth, S.K. Analysis and design of furniture frames. Wood Sci. Technol. 1969, 3, 239–255. [Google Scholar] [CrossRef]

- Eckelman, C.A.; Rabiej, R. A comprehensive method of analysis of case furniture. For. Prod. J. 1985, 35, 62–68. [Google Scholar]

- Eckelman, C.A.; Munz, S. Rational design of cases with front frames and semi-rigid joints. For. Prod. J. 1987, 37, 25–30. [Google Scholar]

- Smardzewski, J.; Ozarska, B. Rigidity of cabinet furniture with semi-rigid joints of the confirmat type. Electron. J. Polish Agric. Univ. Ser. Wood Technol. 2005, 8, 32. [Google Scholar]

- Tankut, A.N.; Tankut, N. Section modulus of corner joints in furniture frames as engineering design criteria for their efficient construction. Mater. Des. 2011, 32, 2391–2395. [Google Scholar] [CrossRef]

- Smardzewski, J.; Lewandowski, W.; Imirzi, H.Ö. Elasticity modulus of cabinet furniture joints. Mater. Des. 2014, 60, 260–266. [Google Scholar] [CrossRef]

- Smardzewski, J.; Prekrat, S. Stress Distribution in Disconnected Furniture Joints. Electron. J. Polish Agric. Univ. 2002, 5, 4. [Google Scholar]

- Cai, L.; Yu, S.; Guo, X. The prediction of case furniture deflection. J. Northeast For. Univ. 1992, 3, 68–74. [Google Scholar]

- Cai, L.; Fenghu, W. Influence of the stiffness of corner joint on case furniture deflection. Holz Roh Werkst. 1993, 51, 406–408. [Google Scholar] [CrossRef]

- Nicholls, T.; Crisan, R. Study of the stress-strain state in corner joints and box-type furniture using finite element analysis (FEA). Holz Roh Werkst. 2002, 60, 66–71. [Google Scholar] [CrossRef]

- Smardzewski, J. Technological heterogeneity of adhesive bonds in wood joints. Wood Sci. Technol. 2002, 36, 213–227. [Google Scholar] [CrossRef]

- Mostowski, R.; Sydor, M. Board Delamination With Edge Breakage As One of Failure Mechanisms in Semi-Rigid Corner Connections-Numerical Analysis. In Proceedings of the 47th International Conference of Departments of Design of Machine Elements and Mechanisms, Prague, Chech Republic, 13–15 September 2006. [Google Scholar]

- Smardzewski, J.; Prekrat, S. Effect of Glueline Shape on Strength of Mortise and Tenon Joint Utjecaj oblika lijepljene površine na čvrstoću spoja rupe i čepa. Drv. Ind. 2010, 61, 223–228. [Google Scholar]

- Smardzewski, J.; Kłos, R. Modeling of joint substitutive rigidity of board elements. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2011, 73, 7–15. [Google Scholar]

- Hajdarević, S.; Martinović, S. Effect of tenon length on flexibility of mortise and tenon joint. Procedia Eng. 2014, 69, 678–685. [Google Scholar] [CrossRef][Green Version]

- Smardzewski, J.; Majewski, A. Mechanical properties of auxetic honeycomb core with triangular cells. In Proceedings of the 25th International Scientific Conference: New Materials and Technologies in the Function of Wooden Products, Zagreb, Croatia, 17 October 2014; pp. 103–112. [Google Scholar]

- Altinok, M.; Taş, H.H.; Çimen, M. Effects of combined usage of traditional glue joint methods in box construction on strength of furniture. Mater. Des. 2009, 30, 3313–3317. [Google Scholar] [CrossRef]

- Altinok, M.; Tas, H.H.; Sancak, E. Load carrying capacity of spline joints as affected by board and adhesives type. Sci. Res. Essays 2009, 4, 479–483. [Google Scholar]

- Eckelman, C.A.; Liu, W.-Q. Effect of number of fasteners on the strength of corner joints for cases. For. Prod. J. 1998, 48, 93–95. [Google Scholar]

- Taş, H.H. Strength properties of L-profiled furniture joints constructed with laminated wooden panels. Sci. Res. Essays 2010, 5, 545–550. [Google Scholar]

- Taş, H.H.; Altinok, M.; Çimen, M. The strength properties changing according to type corner joints and adhesive of the wood-based furnitures under the effect of dynamic forces. Wood Res. 2014, 59, 359–372. [Google Scholar]

- Kureli, I.; Altinok, M. Determination of mechanical performances of the portable fasteners used on case furniture joints. Afr. J. Agric. Res. 2011, 6, 4893–4901. [Google Scholar] [CrossRef]

- Arabi, M.; Faezipour, M.; Haftkhani, A.R.; Maleki, S. The effect of particle size on the prediction accuracy of screw withdrawal resistance (SWR) models. J. Indian Acad. Wood Sci. 2012, 9, 53–56. [Google Scholar] [CrossRef]

- Vassiliou, V.; Barboutis, I. Bending strength of furniture corner joints constructed with insert fittings. Ann. Wars. Univ. Life Sci. SGGW. For. Wood Technol. 2009, 67, 268–274. [Google Scholar]

- Atar, M.; Ozcifci, A.; Altinok, M.; Celikel, U. Determination of diagonal compression and tension performances for case furniture corner joints constructed with wood biscuits. Mater. Des. 2009, 30, 665–670. [Google Scholar] [CrossRef]

- Çetin Yerlikaya, N.; Aktaş, A. Enhancement of load-carrying capacity of corner joints in case-type furniture. Mater. Des. 2012, 37, 393–401. [Google Scholar] [CrossRef]

- Kasal, A.; Şener, S.; Mehmet Belgin, Ç.; Efe, H. Bending Strength of Screwed Corner Joints with Different Materials. Gazi Univ. J. Sci. 2010, 19, 155–161. [Google Scholar]

- Tunay, M.; Tankut, N. Effect of various factors on the rigidity of furniture cases. Afr. J. Biotechnol. 2009, 8, 5265–5270. [Google Scholar] [CrossRef]

- Korený, A.; Šimek, M. Experimental testing of cam fittings. Ann. Wars. Univ. Life Sci. SGGW. For. Wood Technol. 2011, 73, 51–59. [Google Scholar]

- Vassiliou, V.; Barboutis, I. Screw withdrawal capacity used in the eccentric joints of cabinet furniture connectors in particleboard and MDF. J. Wood Sci. 2005, 51, 572–576. [Google Scholar] [CrossRef]

- Tankut, A.N.; Tankut, N. Investigations the effects of fastener, glue, and composite material types on the strength of corner joints in case-type furniture construction. Mater. Des. 2009, 30, 4175–4182. [Google Scholar] [CrossRef]

- Ho, C.L.; Eckelman, C.A. The Use of Performance Tests in Evaluating Joint and Fastener Strength in Case Furniture. For. Prod. J. 1994, 44, 47–53. [Google Scholar]

- Tankut, A.N.; Tankut, N. The effects of joint forms (Shape) and dimensions on the strengths of mortise and tenon joints. Turk. J. Agric. For. 2005, 29, 493–498. [Google Scholar] [CrossRef]

- Ozkaya, K.; Burdurlu, E.; Ilce, A.C.; Ciiitcioghi, H.H. Diagonal tensile strength of an oriented strand-board (OSB) frame with dovetail corner joint. BioResources 2010, 5, 2690–2701. [Google Scholar] [CrossRef]

- Kasal, A. Effect of the number of screws and screw size on moment capacity of furniture corner joints in case construction. For. Prod. J. 2008, 58, 36–44. [Google Scholar]

- Malkoçoǧlu, A.; Yerlikaya, N.Ç.; Çakiroǧlu, F.L. Effects of number and distance between dowels of ready-to-assemble furniture on bending moment resistance of corner joints. Wood Res. 2013, 58, 671–680. [Google Scholar]

- Eckelman, C.A. Bending strength and moment-rotation characteristics of two-pin moment resisting dowel joints. For. Prod. J. 1971, 21, 35–39. [Google Scholar]

- Zhang, J.L.; Eckelman, C.A. Rational Design of Multi-Dowel Corner Joints in Case Construction. For. Prod. J. 1993, 43, 52–58. [Google Scholar]

- Koreny, A.; Simek, M.; Eckelman, C.A.; Haviarova, E. Mechanical properties of knock-down joints in honeycomb panels. BioResources 2013, 8, 4873–4882. [Google Scholar] [CrossRef][Green Version]

- Simek, M.; Haviarova, E.; Eckelman, C. The effect of end distance and number of ready-toassemble furniture fasteners on bending moment resistance of corner joints. Wood Fiber Sci. 2010, 42, 92–98. [Google Scholar]

- Smardzewski, J.; Majewski, A. Strength and durability of furniture drawers and doors. Mater. Des. 2013, 51, 61–66. [Google Scholar] [CrossRef]

- Zhang, J.L.; Eckelman, C.A. The Bending Moment Resistance of Single-Dowel Corner Joints in Case Construction. For. Prod. J. 1993, 43, 19–24. [Google Scholar]

- Smardzewski, J.; imirzi, H.Ö.; Lange, J.; Podskarbi, M. Assessment method of bench joints made of wood-based composites. Compos. Struct. 2015, 123, 123–131. [Google Scholar] [CrossRef]

- Atar, M.; Keskin, H.; Peker, H.; Ustundag, A.; Togay, A.; Candan, Z. Impacts of different joint angles and adhesives on diagonal tension performances of box-type furniture. BioResources 2010, 5, 343–355. [Google Scholar]

- Tout, R. Review of adhesives for furniture. Int. J. Adhes. Adhes. 2000, 20, 269–272. [Google Scholar] [CrossRef]

- Norvydas, V.; Baltrušaitis, A.; Juodeikieno, I. Investigation of miter corner joint strength of case furniture from particleboard. Medziagotyra 2012, 18, 352–357. [Google Scholar] [CrossRef]

- Altun, S.; Burdurlu, E.; Kiliç, M. Effect of adhesive type on the bending moment capacity of miter frame corner joints. BioResources 2010, 5, 1473–1483. [Google Scholar] [CrossRef]

- Tankut, A.N.; Tankut, N. Evaluation the effects of edge banding type and thickness on the strength of corner joints in case-type furniture. Mater. Des. 2010, 31, 2956–2963. [Google Scholar] [CrossRef]

- Fathollahzadeh, A.; Enayati, A.A.; Erdil, Y.Z. Effect of laboratory-accelerated aging treatment on the ultimate strength of a 4-sided MDF kitchen cabinet. Turk. J. Agric. For. 2013, 37, 649–656. [Google Scholar] [CrossRef]

- Wang, Y.; Lee, S.H. Design and analysis on interference fit in the hardwood dowelglued joint by finite element method. Procedia Eng. 2014, 79, 166–172. [Google Scholar] [CrossRef][Green Version]

- Atar, M.; Özçifçi, A. The effects of screw and back panels on the strength of corner joints in case furniture. Mater. Des. 2008, 29, 519–525. [Google Scholar] [CrossRef]

- Eckelman, C.A. The withdrawal strength of screws from Medium Density Fiberboard. For. Prod. J. 1988, 38, 21–24. [Google Scholar]

- Erdil, Y.Z.; Zhang, J.; Eckelman, C.A. Holding strength of screws in plywood and oriented strandboard. For. Prod. J. 2002, 52, 55–62. [Google Scholar]

- Tankut, N. The influence of pilot hole on the moment resistance of screwed T-Type furniture joints. For. Wood Technol. 2011, 84, 75–84. [Google Scholar]

- Haftkhani, A.R.; Ebrahimi, G.; Tajvidi, M.; Layeghi, M.; Arabi, M. Lateral resistance of joints made with various screws in commercial wood plastic composites. Mater. Des. 2011, 32, 4062–4068. [Google Scholar] [CrossRef]

- Seidl, R.J. Paper Honeycomb Cores for Structural Sandwich Panels—Report No. 1918; United States Department of Agriculture: Washington, DC, USA, 1956. [Google Scholar]

- Barboutis, I.; Vassiliou, V. Strength properties of lightweight paper honeycomb panels for the furniture. 2005, p. 17. Available online: http://users.auth.gr/~jbarb/Publications/lightweight%20honeycomb%20furniture.pdf (accessed on 18 September 2020).

- Smardzewski, J.; Majewski, A.; Prekrat, S. Effect of cell-wall angle on the uniaxial crushing behaviour of paper hexagonal honeycombs. In the 24th International Scientific Conference: Wood is Good—User Oriented Material, Technology and Design, Proceedings; Faculty of Forestry, Zagreb University: Zagreb, Croatia, 2013; pp. 127–136. [Google Scholar]

- Petutschnigg, A.J.; Ebner, M. Lightweight paper materials for furniture - A design study to develop and evaluate materials and joints. Mater. Des. 2007, 28, 408–413. [Google Scholar] [CrossRef]

- Smardzewski, J.; Słonina, M.; Maslej, M. Stiffness and failure behaviour of wood based honeycomb sandwich corner joints in different climates. Compos. Struct. 2017, 168, 153–163. [Google Scholar] [CrossRef]

- Sam-Brew, S.; Semple, K.; Smith, G.D. Preliminary experiments on the manufacture of hollow core composite panels. For. Prod. J. 2011, 61, 381–389. [Google Scholar] [CrossRef]

- Xie, Y.; Yan, L.R. Experimental investigation into the static cushioning properties of rhombic honeycomb paperboard. Appl. Mech. Mater. 2011, 55–57, 1299–1304. [Google Scholar] [CrossRef]

- Smardzewski, J.; Prekrat, S. Auxetic structures in layered furniture panels. In Proceedings of the 29th International Conference Wood Science Technology, ICWST 2018, Implementation of Wood Science in Woodworking Sector, Zagreb, Croatia, 6–7 December 2018; pp. 163–171. [Google Scholar]

- Wojnowska, M.; Smardzewski, J. Sztywność i wytrzymałość warstwowych płyt komórkowych z auksetycznym, papierowym rdzeniem. In Proceedings of the Zagadnienia Aktual. Poruszane Przez Młodych Nauk. 13, Kraków, Poland, 14–21 April 2018; pp. 134–138. [Google Scholar]

- Peliński, K.; Wojnowska, M.; Maslej, M.; Słonina, M.; Smardzewski, J. Modeling of density of periodic structures cores of honeycomb panels. In Proceedings of the XXVIIIth International Conference Research for Furniture Industry, Poznań, Poland, 21–22 September 2017; pp. 127–137. [Google Scholar]

- Stavroulakis, G.E. Auxetic behaviour: Appearance and engineering applications. Phys. Status Solidi Basic Res. 2005, 242, 710–720. [Google Scholar] [CrossRef]

- Pasternak, E.; Dyskin, A.V. Materials and structures with macroscopic negative Poisson’s ratio. Int. J. Eng. Sci. 2012, 52, 103–114. [Google Scholar] [CrossRef]

- Critchley, R.; Corni, I.; Wharton, J.A.; Walsh, F.C.; Wood, R.J.K.; Stokes, K.R. A review of the manufacture, mechanical properties and potential applications of auxetic foams. Phys. Status Solidi Basic Res. 2013, 250, 1963–1982. [Google Scholar] [CrossRef]

- Wan, H.; Ohtaki, H.; Kotosaka, S.; Hu, G. A study of negative Poisson’s ratios in auxetic honeycombs based on a large deflection model. Eur. J. Mech. A/Solids 2004, 23, 95–106. [Google Scholar] [CrossRef]

- Donescu, S.; Chiroiu, V.; Munteanu, L. On the Young’s modulus of a auxetic composite structure. Mech. Res. Commun. 2009, 36, 294–301. [Google Scholar] [CrossRef]

- Mukhopadhyay, T.; Adhikari, S. Effective in-plane elastic properties of auxetic honeycombs with spatial irregularity. Mech. Mater. 2016, 95, 204–222. [Google Scholar] [CrossRef]

- Yang, L.; Harrysson, O.; West, H.; Cormier, D. Mechanical properties of 3D re-entrant honeycomb auxetic structures realized via additive manufacturing. Int. J. Solids Struct. 2015, 69–70, 475–490. [Google Scholar] [CrossRef]

- Sun, Y.; Pugno, N.M. In plane stiffness of multifunctional hierarchical honeycombs with negative Poisson’s ratio sub-structures. Compos. Struct. 2013, 106, 681–689. [Google Scholar] [CrossRef]

- Smardzewski, J. Elastic properties of cellular wood panels with hexagonal and auxetic cores. Holzforschung 2013, 67, 87–92. [Google Scholar] [CrossRef]

- Pelinski, K.; Smardzewski, J. Bending behavior of lightweight wood-based sandwich beams with auxetic cellular core. Polymers 2020, 12, 15. [Google Scholar] [CrossRef]

- Smardzewski, J.; Wojciechowski, K.W.; Poźniak, A. Auxetic Lattice Truss Cores Fabricated of LayWood. BioResources 2018, 13, 8823–8838. [Google Scholar] [CrossRef]

- Joscak, P.; Krasula, P.; Vimpel, P. Strength properties of corner joints and extending joints on honeycomb boards. Ann. Wars. Univ. Life Sci. SGGW. For. Wood Technol. 2014, 87, 97–104. [Google Scholar]

- Masters, I.G.; Evans, K.E. Models for the elastic deformation of honeycombs. Compos. Struct. 1996, 35, 403–422. [Google Scholar] [CrossRef]

- Grima, J.N.; Attard, D.; Ellul, B.; Gatt, R. An improved analytical model for the elastic constants of auxetic and conventional hexagonal honeycombs. Cell. Polym. 2011, 30, 287–310. [Google Scholar] [CrossRef]

- Shokri Rad, M.; Prawoto, Y.; Ahmad, Z. Analytical solution and finite element approach to the 3D re-entrant structures of auxetic materials. Mech. Mater. 2014, 74, 76–87. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, H. A review on auxetic structures and polymeric materials. Sci. Res. Essays 2010, 5, 1052–1063. [Google Scholar]

- Polish Committee for Standardization. PN EN 310: 1994. Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength; Polish Committee for Standardization: Warszawa, Poland, 1994. [Google Scholar]

- International Organization for Standardization. ISO 1924-2 Paper and Board: Determination of Tensile Properties. Part 2: Constant Rate of Elongation Method (20 mm/min); International Organization for Standardization: Geneva, Switzerland, 2008. [Google Scholar]

- Polish Committee for Standardization. PN EN 322: 1999. Wood-Based Panels—Determination of Moisture Content; Polish Committee for Standardization: Warszawa, Poland, 1999. [Google Scholar]

- International Organization for Standardization. ISO 536 Paper and Board—Determination of Grammage; International Organization for Standardization: Geneva, Switzerland, 2019. [Google Scholar]

- International Organization for Standardization. ISO 534 Paper and Board—Determination of Thickness, Density and Specific Volume; International Organization for Standardization: Geneva, Switzerland, 2011. [Google Scholar]

- Majewski, A.; Smardzewski, J.; Krystofiak, T. Mechanical properties of multi-layered panels with double-arrow shaped auxetic cores. In Proceedings of the The XXIXTH International Conference Research for Furniture Industry, Ankara, Turkey, 19–20 September 2019; pp. 1–18. [Google Scholar]

| Test Type | Sample Code | Number of Samples | Sample Dimensions mm3 |

|---|---|---|---|

| Beam 3-point bending | HEX-1 | 10 | 410 × 50 × 17 |

| HEX-2 | 10 | 410 × 50 × 17 | |

| AUX-1 | 10 | 410 × 50 × 17 | |

| AUX-2 | 10 | 410 × 50 × 17 | |

| Joint compression test | C-HEX-1 | 10 | 400 × 100 × 100 |

| C-HEX-2 | 5 | 400 × 100 × 100 | |

| C-AUX-1 | 10 | 400 × 100 × 100 | |

| C-AUX-2 | 10 | 400 × 100 × 100 | |

| Joint tension test | T-HEX-1 | 10 | 400 × 100 × 100 |

| T-HEX-2 | 5 | 400 × 100 × 100 | |

| T-AUX-1 | 10 | 400 × 100 × 100 | |

| T-AUX-2 | 10 | 400 × 100 × 100 |

| Paper | HDF | ||||

|---|---|---|---|---|---|

| Property | MPa | SD | Property | MPa | SD |

| MOEMD | 2236 | 389 | MOEUS | 4017 | 150 |

| MOECD | 692 | 156 | MOELS | 3945 | 341 |

| MORMD | 13 | 2 | MORUS | 42 | 2 |

| MORCD | 5 | 1 | MORLS | 39 | 4 |

| GMD/CD | 873 | – | GUS/LS | 1762 | - |

| GCD/MD | 291 | – | |||

| – | – | ||||

| 𝞾MD/CD | 0.28 | 0.07 | 𝞾US/LS | 0.28 | - |

| 𝞾CD/MD | 0.19 | 0.06 | |||

| Property | MOE | MOR | ρr |

|---|---|---|---|

| MPa | kg/m3 | ||

| AUX-1 | 1381 | 3.8 | 300.3 |

| SD | 83 | 0.2 | 4.1 |

| AUX-2 | 1852 | 8 | 296.9 |

| SD | 47 | 0.8 | 3.5 |

| HEX-1 | 2025 | 8.7 | 284.6 |

| SD | 85 | 0.4 | 5.1 |

| HEX-2 | 1394 | 3.9 | 276.1 |

| SD | 83 | 0.3 | 2.2 |

| Effect | SS | Degrees | MS | F | p |

|---|---|---|---|---|---|

| Free | 8,703,039 | 1 | 8,703,039 | 4,560,449 | 0,000,000 |

| TT | 1,326,762 | 1 | 1,326,762 | 695,232 | 0,000,000 |

| CT | 0,002,946 | 1 | 0,002,946 | 1544 | 0,218,916 |

| O | 0,005,477 | 1 | 0,005,477 | 2870 | 0,095,441 |

| TT*CT | 0,000,031 | 1 | 0,000,031 | 0016 | 0,899,017 |

| TT*O | 0,000,012 | 1 | 0,000,012 | 0006 | 0,937,948 |

| CT*O | 0,082,873 | 1 | 0,082,873 | 43,426 | 0,000,000 |

| TT*CT*O | 0,000,782 | 1 | 0,000,782 | 0410 | 0,524,591 |

| Error | 0,114,502 | 60 | 0,001,908 |

| TT | C | T | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CT | AUX | HEX | AUX | HEX | |||||||

| TT | CT | O | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | |

| 1 | C | AUX | 1 | x | 0.17299 | 0.00054 | 1.00000 | 0.00013 | 0.00013 | 0.00013 | 0.00013 |

| 2 | C | AUX | 2 | 0.17299 | x | 0.48487 | 0.52762 | 0.00013 | 0.00013 | 0.00013 | 0.00013 |

| 3 | C | HEX | 1 | 0.00054 | 0.48487 | x | 0.03181 | 0.00013 | 0.00013 | 0.00013 | 0.00013 |

| 4 | C | HEX | 2 | 1.00000 | 0.52762 | 0.03181 | x | 0.00013 | 0.00013 | 0.00013 | 0.00013 |

| 5 | T | AUX | 1 | 0.00013 | 0.00013 | 0.00013 | 0.00013 | x | 0.01850 | 0.00016 | 1.00000 |

| 6 | T | AUX | 2 | 0.00013 | 0.00013 | 0.00013 | 0.00013 | 0.01850 | x | 0.65786 | 0.17826 |

| 7 | T | HEX | 1 | 0.00013 | 0.00013 | 0.00013 | 0.00013 | 0.00016 | 0.65786 | x | 0.00794 |

| 8 | T | HEX | 2 | 0.00013 | 0.00013 | 0.00013 | 0.00013 | 1.00000 | 0.17826 | 0.00794 | x |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Majewski, A.; Krystofiak, T.; Smardzewski, J. Mechanical Properties of Corner Joints Made of Honeycomb Panels with Double Arrow-Shaped Auxetic Cores. Materials 2020, 13, 4212. https://doi.org/10.3390/ma13184212

Majewski A, Krystofiak T, Smardzewski J. Mechanical Properties of Corner Joints Made of Honeycomb Panels with Double Arrow-Shaped Auxetic Cores. Materials. 2020; 13(18):4212. https://doi.org/10.3390/ma13184212

Chicago/Turabian StyleMajewski, Adam, Tomasz Krystofiak, and Jerzy Smardzewski. 2020. "Mechanical Properties of Corner Joints Made of Honeycomb Panels with Double Arrow-Shaped Auxetic Cores" Materials 13, no. 18: 4212. https://doi.org/10.3390/ma13184212

APA StyleMajewski, A., Krystofiak, T., & Smardzewski, J. (2020). Mechanical Properties of Corner Joints Made of Honeycomb Panels with Double Arrow-Shaped Auxetic Cores. Materials, 13(18), 4212. https://doi.org/10.3390/ma13184212