Performance of Noise Reduction and Skid Resistance of Durable Granular Ultra-Thin Layer Asphalt Pavement

Abstract

:1. Introduction

2. Materials and Test Methods

2.1. Raw Materials

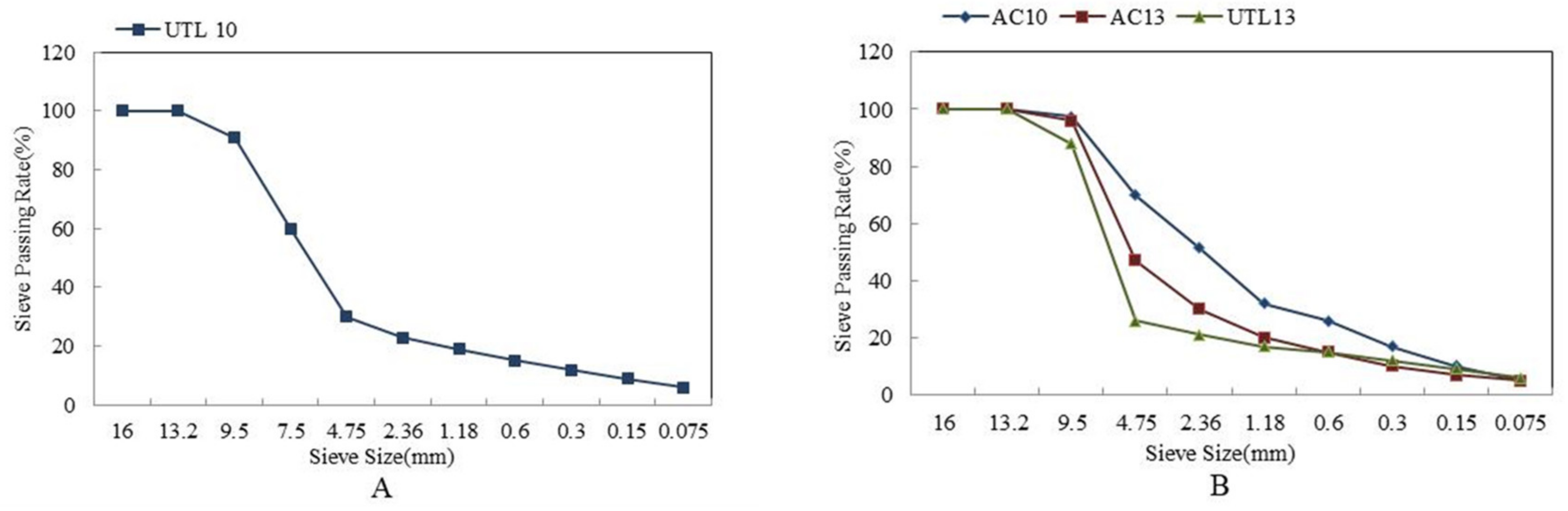

2.2. Aggregate Gradation

2.3. Test Methods

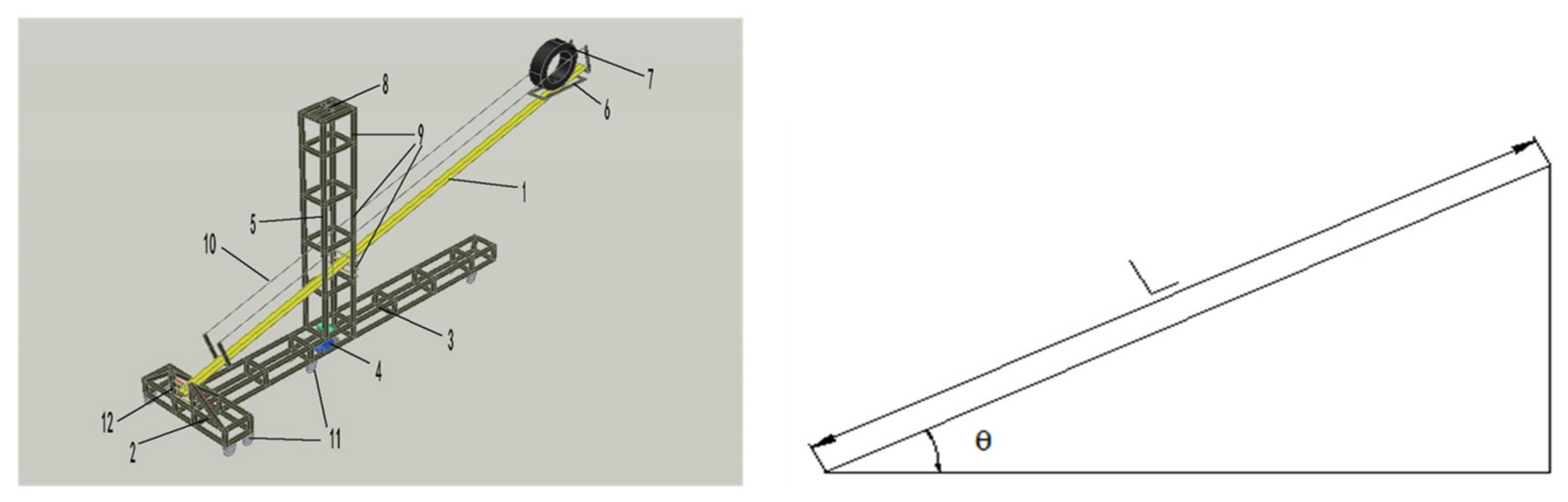

2.3.1. Durability Test

2.3.2. Tire/Road Noise Test Method

2.3.3. Skid Resistance Test Method

2.4. Significance Analysis of Each Factor

3. Experimental Results and Discussions

3.1. Durability

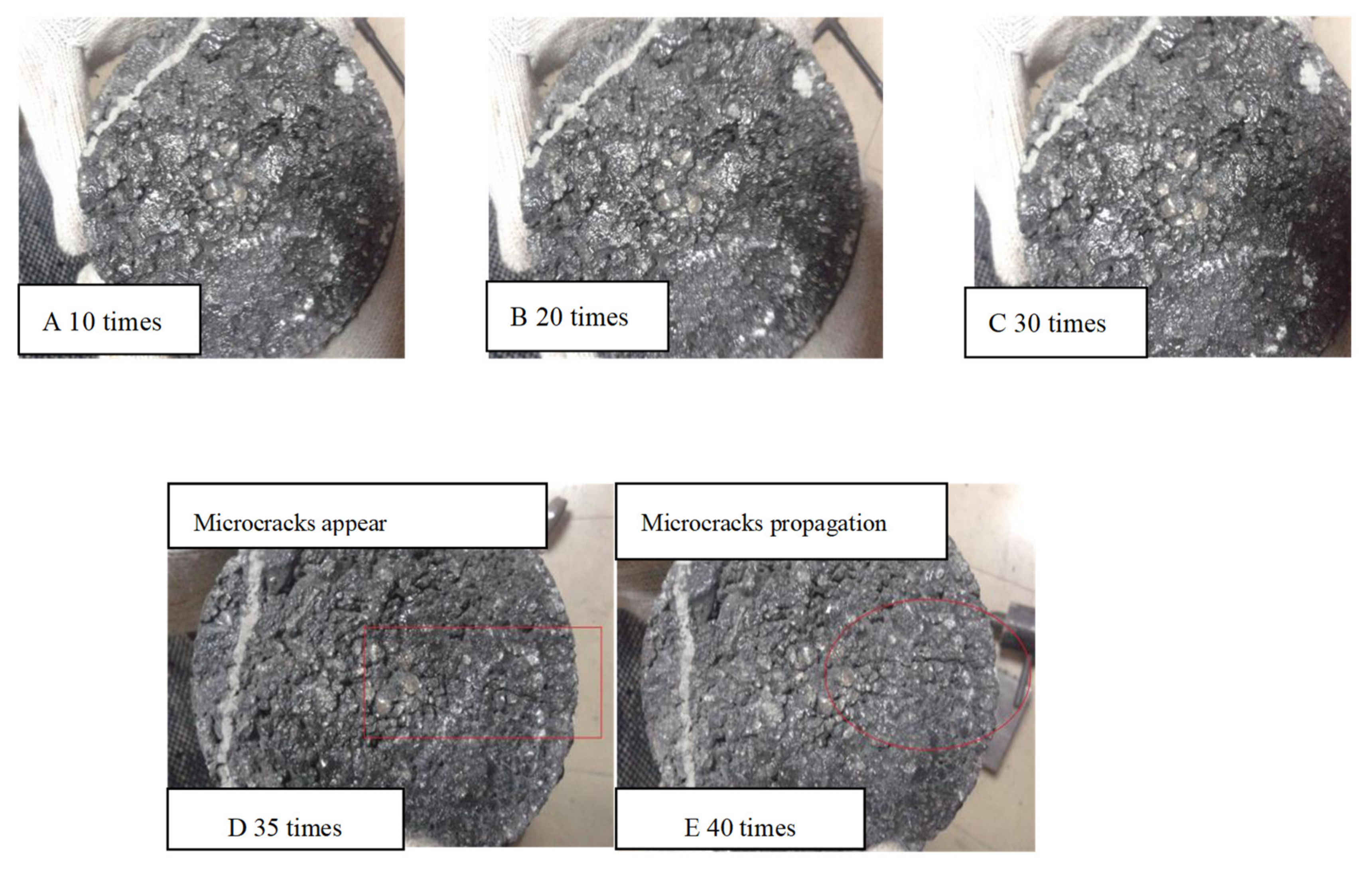

3.1.1. Determination of Impact Times

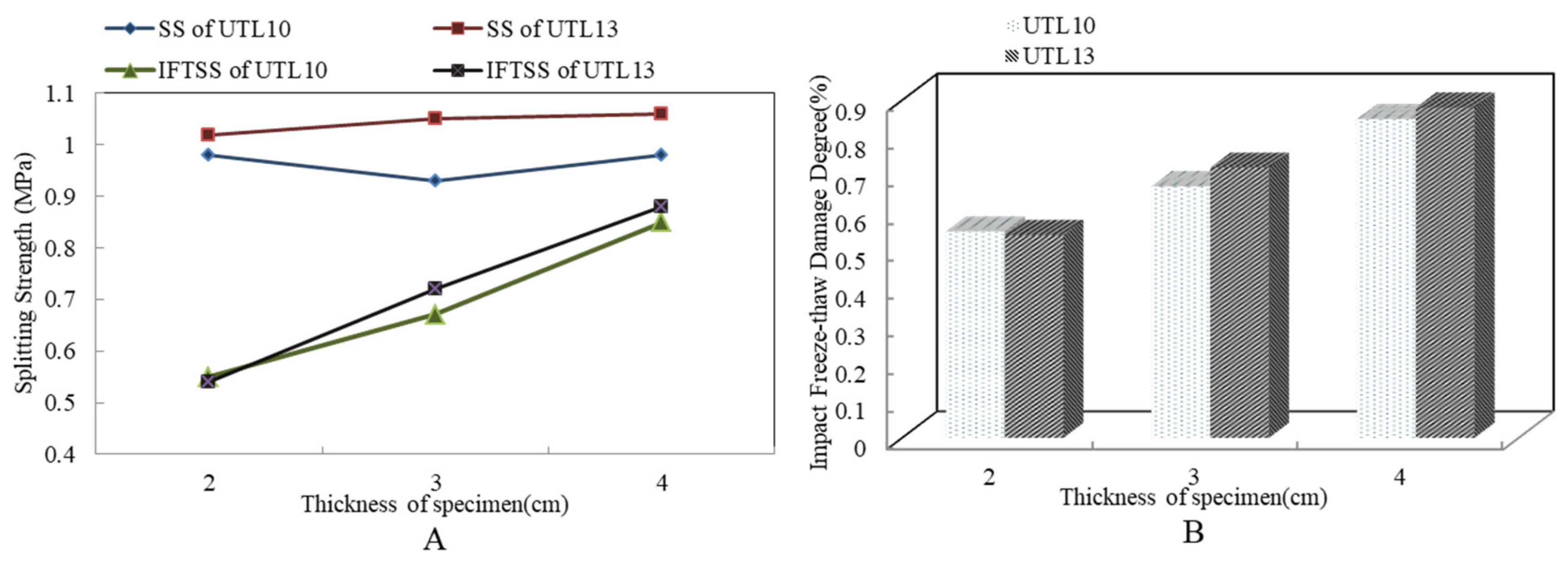

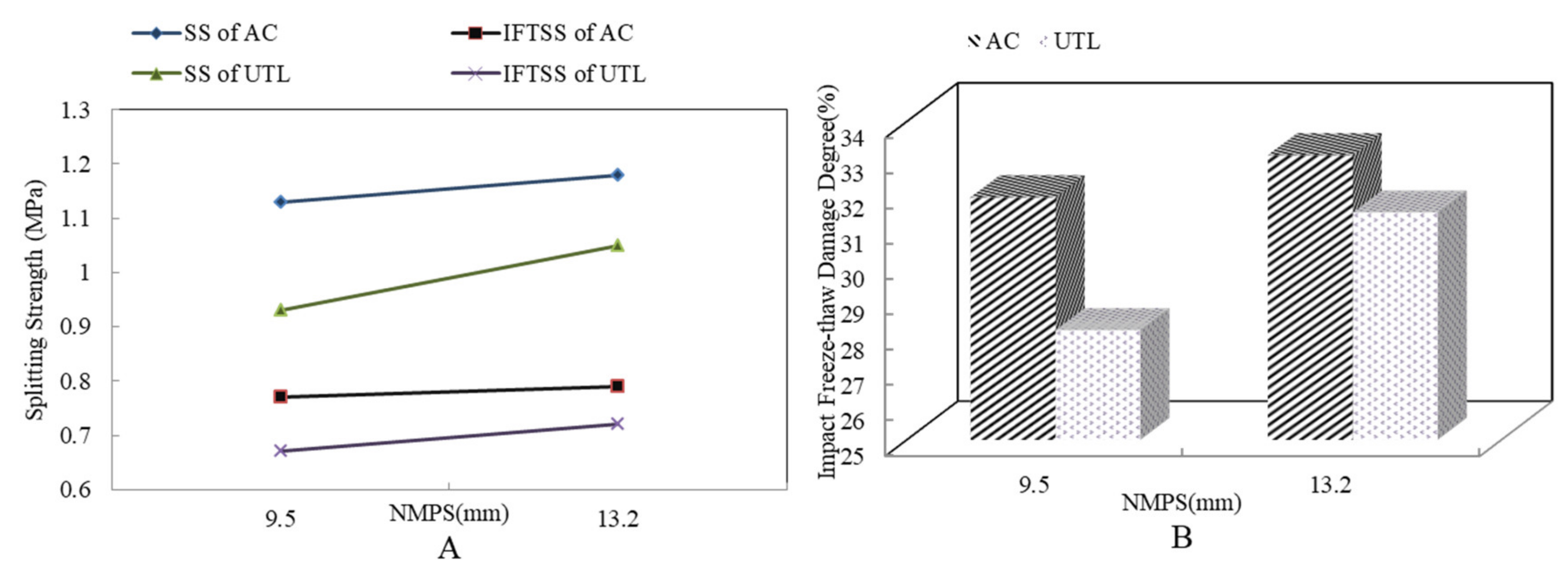

3.1.2. Effect of Pavement Thickness on Durability

3.1.3. Effect of Aggregate Gradation Type on Durability

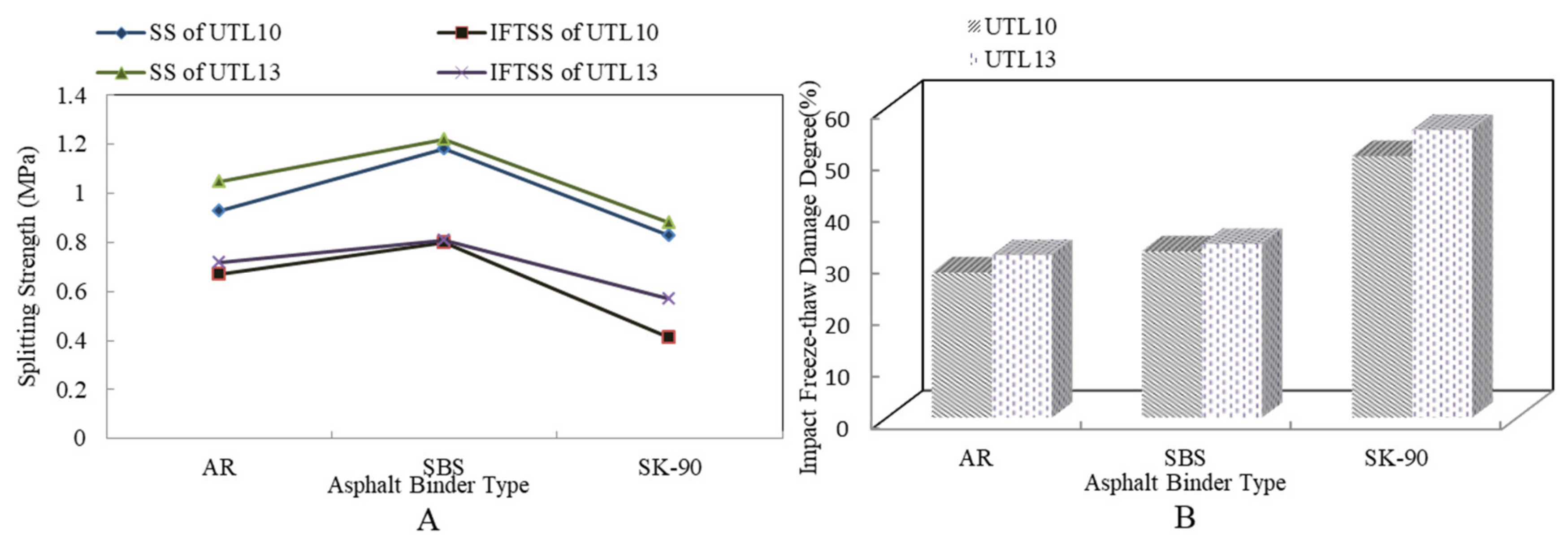

3.1.4. Effect of Asphalt Binder on Durability

3.1.5. Effect of KS Content on Durability

3.2. Noise Reduction of UTL

3.2.1. Effect of Aggregate Gradation on Tire/Road Noise

3.2.2. Effect of Asphalt Binder Type on Tire/Road Noise

3.2.3. Effect of KS Content on Tire/Road Noise

3.2.4. Effect of Pavement Thickness on Tire/Road Noise

3.3. Skid Resistance

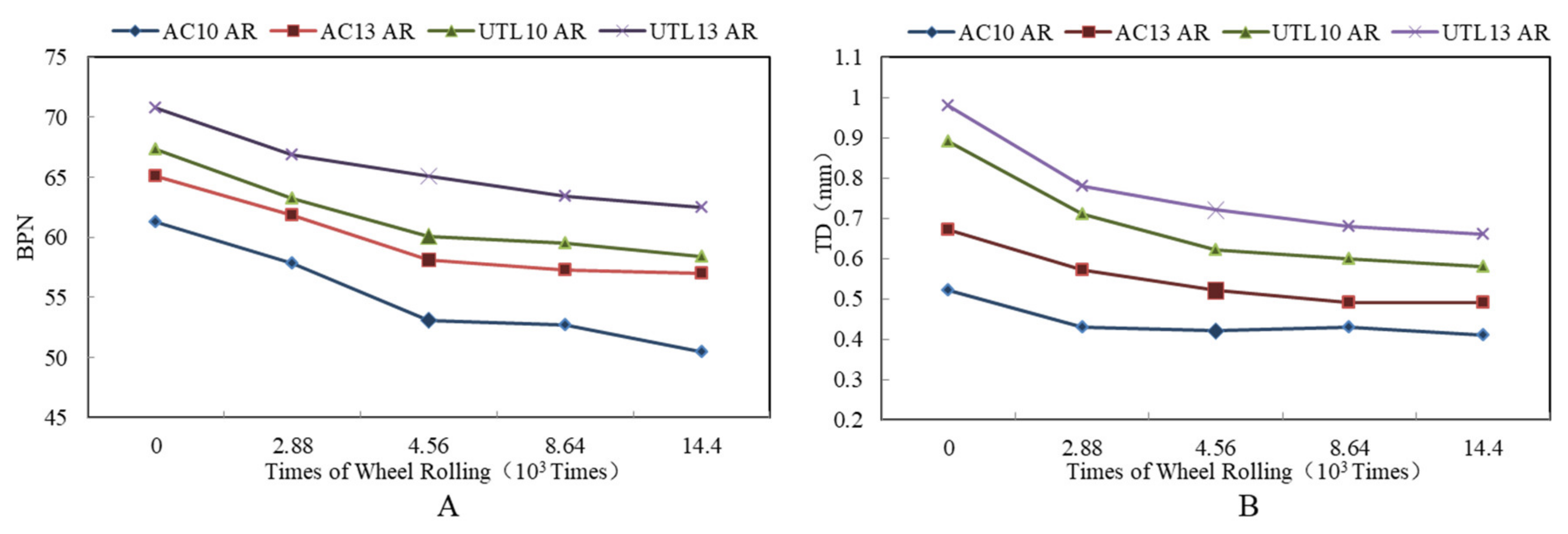

3.3.1. Effect of Aggregate Gradation on Skid Resistance

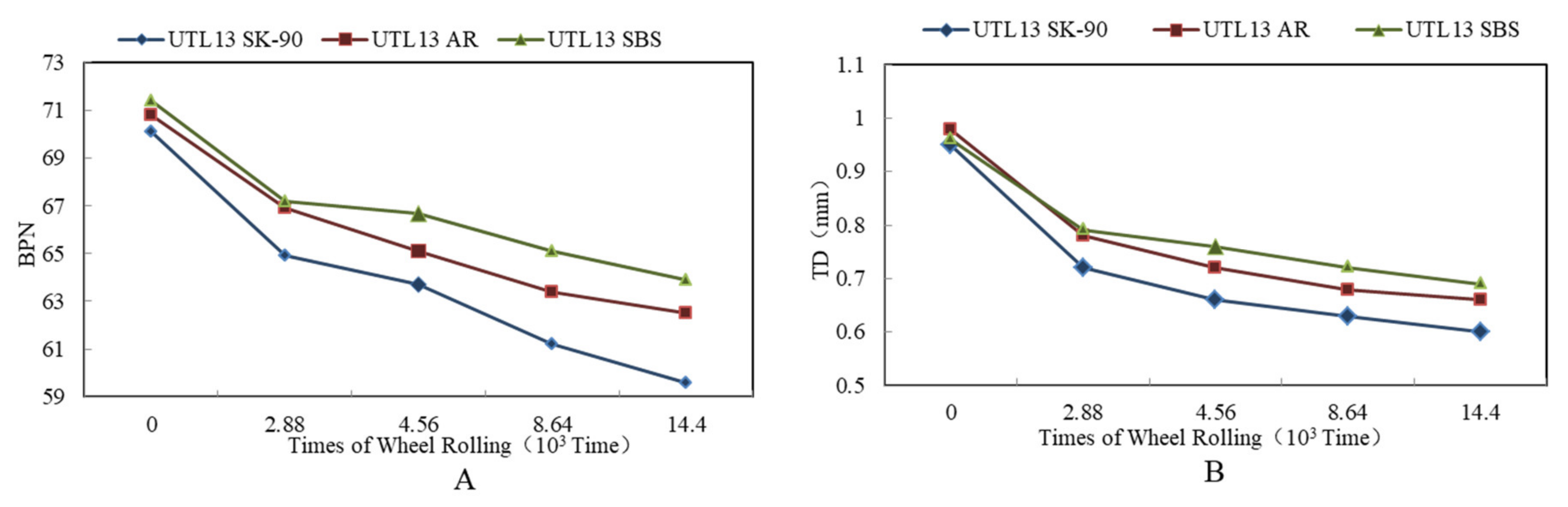

3.3.2. Effect of Asphalt Binder on Skid Resistance

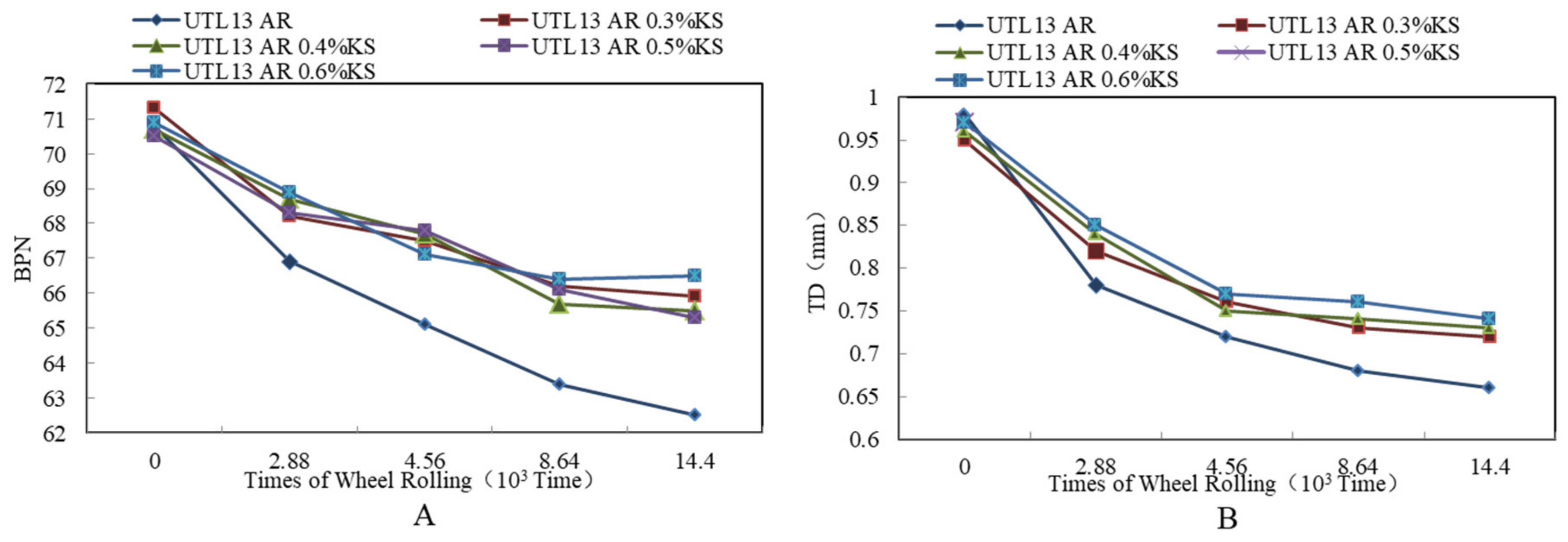

3.3.3. Effect of KS Content on Skid Resistance

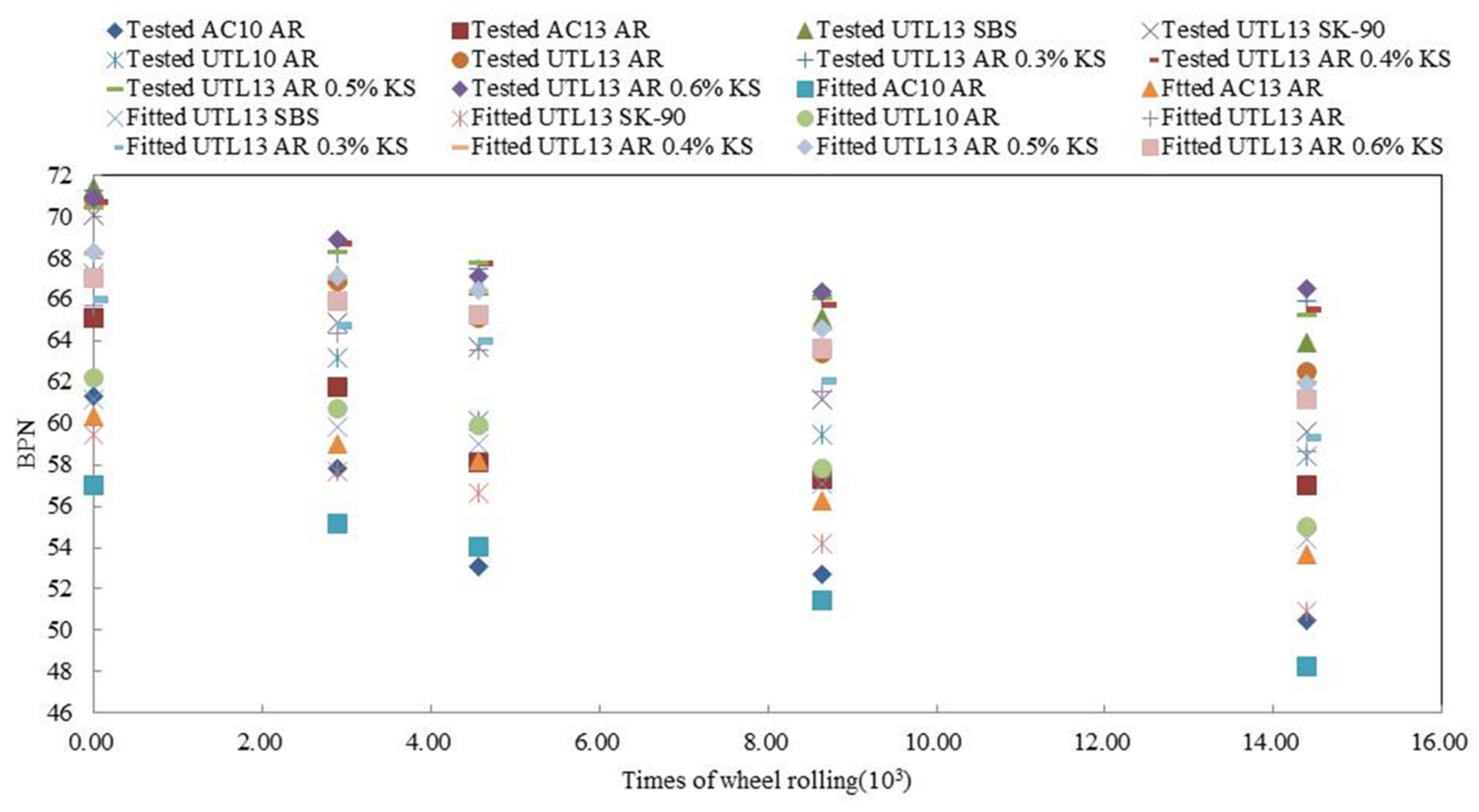

3.3.4. Long Term Model and Durability Benefit Evaluation of Skid Resistance

3.4. Significance Analysis of Each Factor

4. Conclusions

- (1)

- The self-falling impact tester and the corresponding impact freeze thaw split test method developed in this paper can better evaluate the durability characteristics of asphalt mixture. The evaluation index of IFTDD has a good correlation with durability. The importance of different factors affecting durability is: pavement thickness > asphalt type > KS content > gradation. The dense framework structure UTL has better durability than suspended dense structure AC.

- (2)

- The effect of KS additive on the comprehensive performance of UTL pavement is limited. Combining different performance indexes, when the KS content is 0.5%, the pavement performance and economic benefit of the dense framework structure rubber-modified asphalt mixture (UTL AR) are the best.

- (3)

- The importance of different factors affecting noise is: gradation > KS content > asphalt type, whereas the influence of pavement thickness is not significant. When NMAS is the same, the noise reduction of asphalt mixtures between different gradations has an obvious difference. Due to the rich surface texture and pores, UTL pavement had lower noise than that of AC. Additionally, pavement thickness has no obvious effect on noise. When specimen thickness increased from 2 cm to 4 cm, noise only reduced by 0.3 dB.

- (4)

- Due to the high damping coefficient and remarkable effect on absorbing tire/road vibration noise, the rubber-modified asphalt AR mixture has better noise reduction than that of the virgin asphalt and SBS modified asphalt mixture. However, the addition of KS additive can reduce the damping of asphalt mixture and increase the vibration noise of tire-pavement by improving the stiffness of asphalt mixture.

- (5)

- Under the reciprocating action of wheel loading, the skid resistance indexes of asphalt mixture showed rapid attenuation in the initial stage and stable change in the later stage. ‘S-type’ prediction model can effectively simulate the attenuation law of skid resistance. In addition, the skid resistance durability of UTL is evaluated by the long-term benefit index Eeff of pavement safety performance. As a result, the dense framework structure asphalt rubber mixture (UTL AR) has excellent skid resistance durability, which is an extremely important engineering value.

- (6)

- With comprehensive consideration of durability, noise reduction and skid resistance, rubber-modified asphalt UTL pavement with 13.2 mm NMAS (UTL13 AR), thickness of 3 cm and additive content of 0.5% is recommended to applied in field project.

Author Contributions

Funding

Conflicts of Interest

References

- Sandberg, U.; Ejsmont, J.A. Tire/Road Noise—Generation, Measurement, and Abatement. In Handbook of Noise and Vibration Control; Crocker, M.J., Ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2007; pp. 1054–1071. [Google Scholar]

- Tan, Y.; Yao, L. Performance Evaluation Indicator of Ultra-thin Wearing Course Asphalt Mixture. J. Harbin Inst. Technol. 2012, 44, 73–77. [Google Scholar]

- Cui, S.; Blackman, B.R.K. Durability of Asphalt Mixtures: Effect of Aggregate Type and Adhesion Promoters. Int. J. Adhes. 2014, 54, 100–111. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.H.; Shen, Y. Analysis Interlayer Shear Stress of Ultra-Thin Wearing Course Considering Temperature and Different Interlayer Contact Conditions. Appl. Mech. Mater. 2014, 505–506, 102–105. [Google Scholar] [CrossRef]

- Angius, E.; Ding, H. Durability Assessment of Asphalt Binder. Constr. Build. Mater. 2018, 165, 264–271. [Google Scholar] [CrossRef]

- Berkowitz, M.; Filipovich, M. Oxidative and Thermoreversible Aging Effects on Performance-Based Rheological Properties of Six Latin American Asphalt Binders. Energy Fuels 2019, 33, 2604–2613. [Google Scholar] [CrossRef]

- Sandberg, U. Road Traffic Noise—The Influence of the Road Surface and Its Characterization. Appl. Acoust. 1987, 21, 97–118. [Google Scholar] [CrossRef]

- Li, M.; van Keulen, W. Investigation on Material Properties and Surface Characteristics Related to Tyre–Road Noise for Thin Layer Surfacings. Constr. Build. Mater. 2014, 59, 62–71. [Google Scholar] [CrossRef]

- Bennert, T.; Hanson, D. Influence of Pavement Surface Type on Tire/Pavement Generated Noise. J. Test. Eval. 2005, 33, 94–100. [Google Scholar] [CrossRef] [Green Version]

- Jing, L.; Tian, B. Improving Noise Reduction of Porous Cement Concrete Pavement. Highway 2010, 81–85. [Google Scholar]

- Hong, S.J.; Park, S.W. Tire-Pavement Noise Prediction Using Asphalt Pavement Texture. KSCE J. Civ. Eng. 2018, 22, 3358–3362. [Google Scholar] [CrossRef]

- Donavan, P.R.; Lodico, D.M. Measuring Tire-Pavement Noise at the Source. Natl. Coop. Highw. Res. Program Rep. 2009, 630, 1–44. [Google Scholar]

- ISO 11819-2. Acoustics-Measurement of the Influence of Road Surfaces on the Traffic Noise-Part 2: The Close-Proximity Method; International Organization for Standardization: Geneva, Switzerland, 2017.

- AASHTO TP 76-12. Standard Method of Test for Measurement of Tire/Pavement Noise Using The on-Board Sound Intensity (OBSI) Method; American Association of state Highway and transportation officials: Washington, DC, USA, 2015.

- Ren, W.; Han, S. A New Laboratory Test Method for Tire-Pavement Noise. Measurement 2019, 145, 137–143. [Google Scholar] [CrossRef]

- Pitaksringkarn, J.; Tanwanichkul, L. A Correlation between Pavement Skid Resistance and Wet-Pavement Related Accidents in Thailand. In Proceedings of the 4th International Conference on Engineering, Applied Sciences and Technology, Phuket, Thailand, 4–7 July 2018. [Google Scholar]

- Ahammed, M.A.; Tighe, S.L. Pavement Surface Mixture, Texture, and Skid Resistance: A Factorial Analysis. In Proceedings of the Airfield and Highway Pavements, Bellevue, WA, USA, 15–18 October 2008. [Google Scholar]

- Liu, H.; Zhang, Z.; Guo, D. Research Progress on Characteristic Technique of Pavement Micro-Texture and Testing Technology of Pavement Skid Resistance at Home and Abroad. In Proceedings of the 2011 International Conference on Remote Sensing, Environment and Transportation Engineering, Nanjing, China, 24–26 June 2011. [Google Scholar]

- Guan, H.; Liu, J. Anti-Skid Thin Layer on Asphalt Pavement of Super Long Downgrades. Appl. Mech. Mater. 2011, 97–98, 611–615. [Google Scholar] [CrossRef]

- Liu, F.; Sun, J. Study on Anti-Skid Performance Degradation of Coating-Type Color Anti-Skid Pavement. Appl. Mech. Mater. 2014, 716–717, 314–318. [Google Scholar] [CrossRef]

- Cong, L.; Wang, T. Effect of Fine Aggregate Angularity on Skid-Resistance of Asphalt Pavement Using Accelerated Pavement Testing. Constr. Build. Mater. 2018, 168, 41–46. [Google Scholar]

- Li, W.; Han, S. The Skeleton Characteristics of Coarse Aggregates in Granular Ultra-thin Asphalt Mixture. Mater. Rep. 2019, 33, 617–624. [Google Scholar]

- JTG E20-2011. In Specifications and Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering; Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- Sha, Q. Aggregate Gradation Design Method of SAC and Other Coarse Aggregate Gap Gradation. Highway 2005, 143–150. [Google Scholar]

- Croll, J.G.A. Possible Role of Thermal Ratchetting in Alligator Cracking of Asphalt Pavements. Int. J. Pavement Eng. 2009, 10, 447–453. [Google Scholar] [CrossRef]

- Han, S.; Gao, W. An Evaluation Method of Durability of Thin-Layer Surfacing Asphalt Mixture ZL201510464130.5, 18 November 2015.

- Li, W.; Han, S. Research on Road Performances and Noise Reduction Characteristic of Rubber-Fiber Micro-Surfacing Mixture. J. Railw. Sci. Eng. 2017, 14, 1623–1631. [Google Scholar]

- Han, S.; Gao, W. An Accelerated Wear Test Device for Pavement ZL200920032379, 23 December 2009.

- JTG 5142-2019. In Technical Specifications for Maintenance of Highway Asphalt Pavement; Ministry of Transport of the People’s Republic of China: Beijing, China, 2019.

- AAT Report. Report to NCHRP Project 1-42; Top-down Fatique Cracking of Hot-mix Asphalt Layers Transportation Research Board: Washington, DC, USA, 2010.

- Xiong, R.; Chen, S. Application of Grey Entropy Method to Analyze Influencing Factors of Durability of Asphalt Mixture under Freeze-thaw and Corrosion. J. Highw. Transp. Res. Dev. 2013, 30, 28–32. [Google Scholar]

- He, T. Experimental Study on Adhesion between Asphalt and Aggregate and Water Stability of Asphalt Mixture under Freeze-thaw Cycle; Lanzhou University of Technology: Lanzhou, China, 2019. [Google Scholar]

- Becker, Y.; Mendez, M.P.; Rodriguez, Y. Polymer Modified Asphalt. Vis. Technol. 2001, 9, 39–50. [Google Scholar]

- Yildirim, Y. Polymer Modified Asphalt Binders. Constr. Build. Mater. 2007, 21, 66–72. [Google Scholar] [CrossRef]

- Chen, K.; Zeng, X. Acoustic Measurement; Science Press: Beijing, China, 2005; pp. 19–21. [Google Scholar]

- Sakhaeifar, M.; Banihashemrad, A. Tyre–pavement interaction noise levels related to pavement surface characteristics. Road Mater. Pavement Des. 2018, 19, 1044–1056. [Google Scholar] [CrossRef]

- Guo, Z.; Yi, J. Study on the Influential Factors of Noise Characteristics in Dense-Graded Asphalt Mixtures and Field Asphalt Pavements. Shock Vib. 2018, 2018, 1–13. [Google Scholar] [CrossRef]

- Masad, E.; Rezaei, A. Field Evaluation of Asphalt Mixture Skid Resistance and Its Relationship to Aggregate Characteristics; The Texas A&M University: College Station, TX, USA, 2009. [Google Scholar]

- Liu, L. Research on Anti-sliding Decay Law of Asphalt Pavement; Changsha University of Science & Technology: Changsha, China, 2019. [Google Scholar]

- Wu, M.; Wang, D. Study on Performance Prediction Model of Asphalt Pavement. Guangdong Highw. Commun. 2009, 1, 5–9. [Google Scholar]

- JTJ073.2-2001. In Technical Specifications for Maintenance of Highway Asphalt Pavement; Ministry of Transport of the People’s Republic of China: Beijing, China, 2001.

- JTG F40-2017. In Technical Specification for Construction of Highway Asphalt Pavements; Ministry of Transport of the People’s Republic of China: Beijing, China, 2017.

- Khurshid, M.B.; Irfan, M. Comparison of Methods for Evaluating Pavement Interventions. Transp. Res. Rec. J. Transp. Res. Board 2009, 2108, 25–36. [Google Scholar] [CrossRef]

| Technical Indexes | Aggregate Size/mm | |||

|---|---|---|---|---|

| 13.2–16 | 9.5–13.2 | 4.75–9.5 | 2.36–4.75 | |

| Apparent relative density | 2.967 | 2.964 | 2.938 | 2.843 |

| Bulk volume relative density | 2.927 | 2.879 | 2.877 | 2.791 |

| Technical Indexes | Penetration/(0.1 mm) | Softening Point/°C | Ductility/cm | Rotational Viscosity/(Pa·s) | ||

|---|---|---|---|---|---|---|

| At 10 °C | At 5 °C | At 135 °C | At 180 °C | |||

| Virgin Asphalt | 90 | 46 | >100 | - | - | - |

| Asphalt Rubber | 62 | 59.8 | - | 9.3 | 3.28 | 1.03 |

| SBS Modified Asphalt | 56 | 88.7 | - | 38 | 1.7 | 0.275 |

| Influence Factors | Parameters of Rut Board Specimen | |||

|---|---|---|---|---|

| Asphalt | Thickness/cm | Gradation | KS content/% | |

| Gradation Type | Asphalt Rubber | 3 | UTL10, UTL13, AC10, AC13 | 0 |

| Asphalt Type | SK-90, SBS, Asphalt Rubber | 3 | UTL13 | 0 |

| Content of Admixture | Asphalt Rubber | 3 | UTL13 | 0.3, 0.4, 0.5, 0.6 |

| Pavement Thickness | Asphalt Rubber | 2 | UTL10, UTL13, AC10, AC13 | 0 |

| 3 | ||||

| 4 | ||||

| Gradation | Sound Intensity Level/dB | Sound Pressure Level/dB |

|---|---|---|

| AC10 | 76.2 | 78.9 |

| AC13 | 80.4 | 83.3 |

| UTL10 | 74.9 | 77.6 |

| UTL13 | 77.3 | 80.1 |

| Asphalt Mixture | Asphalt Binder | Sound Intensity Level/dB | Sound Pressure Level/dB |

|---|---|---|---|

| UTL-13 3 cm | AR | 77.3 | 80.1 |

| SBS | 79.6 | 82.2 | |

| SK-90 | 77.9 | 81.7 |

| Asphalt Mixture | KS Content | Sound Intensity Level/dB | Sound Pressure Level/dB |

|---|---|---|---|

| UTL-13 AR 3 CM | 0% | 77.3 | 80.1 |

| 0.3% | 77.2 | 80.0 | |

| 0.4% | 78.2 | 81.0 | |

| 0.5% | 78.7 | 81.6 | |

| 0.6% | 80.2 | 83.1 |

| Asphalt Mixture | Thickness/cm | Sound Intensity Level/dB | Sound Pressure Level/dB |

|---|---|---|---|

| AC10 AR | 2 cm | 76.4 | 79.1 |

| 3 cm | 76.2 | 78.9 | |

| 4 cm | 76.7 | 79.5 | |

| AC13 AR | 2 cm | 80.1 | 83.0 |

| 3 cm | 80.4 | 83.3 | |

| 4 cm | 80.3 | 83.0 | |

| UTL10 AR | 2 cm | 74.4 | 77.3 |

| 3 cm | 74.9 | 77.6 | |

| 4 cm | 74.3 | 77.0 | |

| UTL13 AR | 2 cm | 77.4 | 80.2 |

| 3 cm | 77.3 | 80.1 | |

| 4 cm | 77.6 | 80.4 |

| Function Model | Asphalt Mixture | β | k | R2 | T/(103 Times) |

|---|---|---|---|---|---|

| AC10 AR | −0.135 | −0.063 | 0.819 | 40.98 | |

| AC13 AR | 0.173 | −0.044 | 0.807 | 65.34 | |

| UTL13 SBS | 0.248 | −0.044 | 0.810 | 78.49 | |

| UTL13 SK−90 | 0.088 | −0.057 | 0.789 | 61.49 | |

| UTL10 AR | 0.347 | −0.047 | 0.739 | 65.13 | |

| UTL13 AR | 0.694 | −0.047 | 0.796 | 72.54 | |

| UTL13 AR 0.3% KS | 0.726 | −0.045 | 0.761 | 80.09 | |

| UTL13 AR 0.4% KS | 0.973 | −0.045 | 0.789 | 76.99 | |

| UTL13 AR 0.5% KS | 0.984 | −0.046 | 0.807 | 81.99 | |

| UTL13 AR 0.6% KS | 0.841 | −0.041 | 0.819 | 87.42 |

| Function Model | Asphalt Mixture | β | k | R2 | T/(103 Times) |

|---|---|---|---|---|---|

| AC10 AR | −2.056 | −0.146 | 0.829 | 13.88 | |

| AC13 AR | −0.590 | −0.100 | 0.807 | 35.02 | |

| UTL13 SBS | −0.570 | −0.088 | 0.825 | 46.99 | |

| UTL13 SK−90 | −0.938 | −0.164 | 0.816 | 39.18 | |

| UTL10 AR | 0.736 | −0.129 | 0.843 | 37.40 | |

| UTL13 AR | 1.192 | −0.123 | 0.822 | 42.94 | |

| UTL13 AR 0.3% KS | 1.412 | −0.111 | 0.777 | 49.50 | |

| UTL13 AR 0.4% KS | 0.852 | −0.112 | 0.814 | 48.05 | |

| UTL13 AR 0.5% KS | 0.867 | −0.115 | 0.891 | 47.09 | |

| UTL13 AR 0.6% KS | 0.832 | −0.110 | 0.765 | 48.91 |

| Mixture Types | BPN | TD | ||||||

|---|---|---|---|---|---|---|---|---|

| TBPN/103 | Eavg | Eeff/% | Rank | TTD/103 | Eavg | Eeff/% | Rank | |

| AC-10 AR | 40.98 | 45.23 | 22.3 | 10 | 13.88 | 0.64 | 16.4 | 10 |

| AC-13 AR | 65.34 | 49.22 | 33.0 | 9 | 35.02 | 0.69 | 25.5 | 8 |

| UTL-13 SBS | 78.49 | 51.63 | 39.5 | 4 | 46.99 | 0.74 | 34.5 | 5 |

| UTL-13 SK-90 | 61.49 | 49.61 | 34.1 | 7 | 39.18 | 0.69 | 25.5 | 8 |

| UTL-10 AR | 65.13 | 49.39 | 33.5 | 8 | 37.40 | 0.70 | 27.3 | 7 |

| UTL-13 AR | 72.54 | 50.62 | 36.8 | 6 | 42.94 | 0.73 | 32.7 | 6 |

| UTL-13 AR 0.3% KS | 80.09 | 51.38 | 38.9 | 5 | 49.50 | 0.77 | 40.0 | 1 |

| UTL-13 AR 0.4% KS | 76.99 | 52.54 | 42.0 | 1 | 48.05 | 0.77 | 40.0 | 1 |

| UTL-13 AR 0.5% KS | 81.99 | 52.32 | 41.4 | 2 | 47.09 | 0.76 | 38.8 | 3 |

| UTL-13 AR 0.6% KS | 87.42 | 51.87 | 40.2 | 3 | 48.91 | 0.75 | 36.4 | 4 |

| Influencing Factors | Dependent Variables | |||||||

|---|---|---|---|---|---|---|---|---|

| Durability | Noise | BPN | TD | |||||

| F | P | F | P | F | P | F | P | |

| Pavement Thickness | 1851.942 | <0.001 | 2.793 | 0.114 | - | - | - | - |

| Asphalt type | 1744.118 | <0.001 | 34.935 | <0.001 | 35.317 | <0.001 | 2.387 | 0.147 |

| Gradation | 41.550 | <0.001 | 133.59 | <0.001 | 34.648 | <0.001 | 41.867 | <0.001 |

| KS content | 266.952 | <0.001 | 48.390 | <0.001 | 101.194 | <0.001 | 8.371 | 0.001 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Han, S.; Huang, Q. Performance of Noise Reduction and Skid Resistance of Durable Granular Ultra-Thin Layer Asphalt Pavement. Materials 2020, 13, 4260. https://doi.org/10.3390/ma13194260

Li W, Han S, Huang Q. Performance of Noise Reduction and Skid Resistance of Durable Granular Ultra-Thin Layer Asphalt Pavement. Materials. 2020; 13(19):4260. https://doi.org/10.3390/ma13194260

Chicago/Turabian StyleLi, Wei, Sen Han, and Qibo Huang. 2020. "Performance of Noise Reduction and Skid Resistance of Durable Granular Ultra-Thin Layer Asphalt Pavement" Materials 13, no. 19: 4260. https://doi.org/10.3390/ma13194260