Impacts of Stress Relief Treatments on Microstructure, Mechanical and Corrosion Properties of Metal Active-Gas Welding Joint of 2205 Duplex Stainless Steel

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Experimental Material

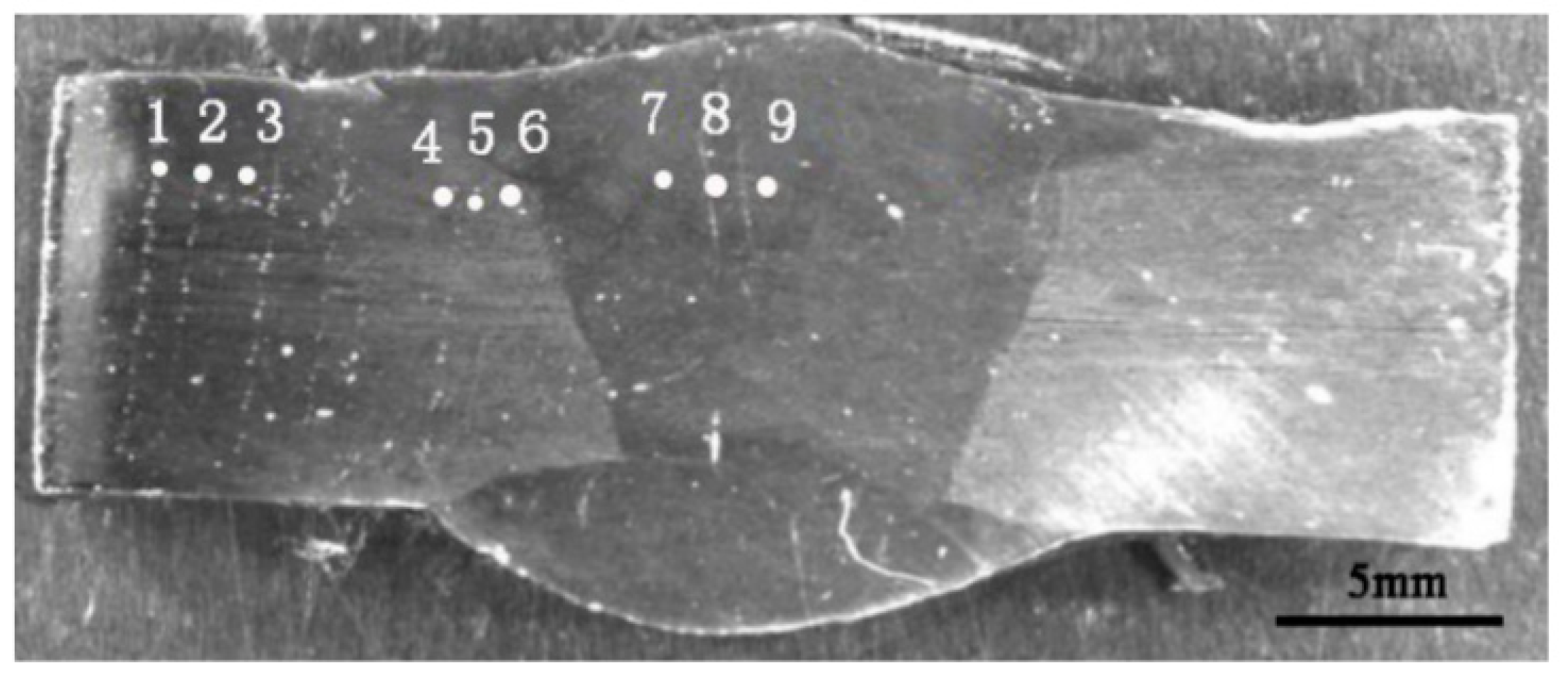

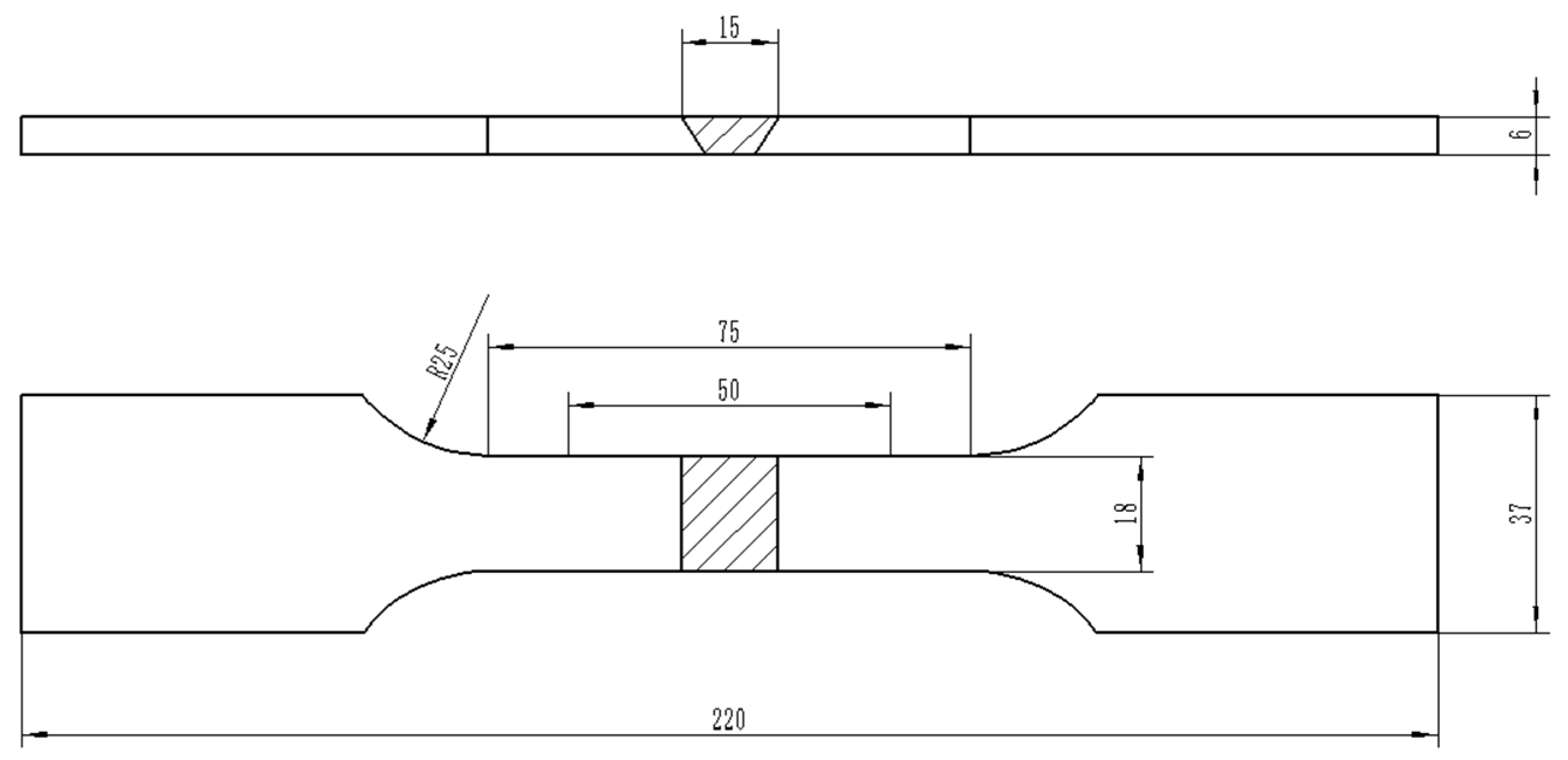

2.2. Experimental Process

3. Results

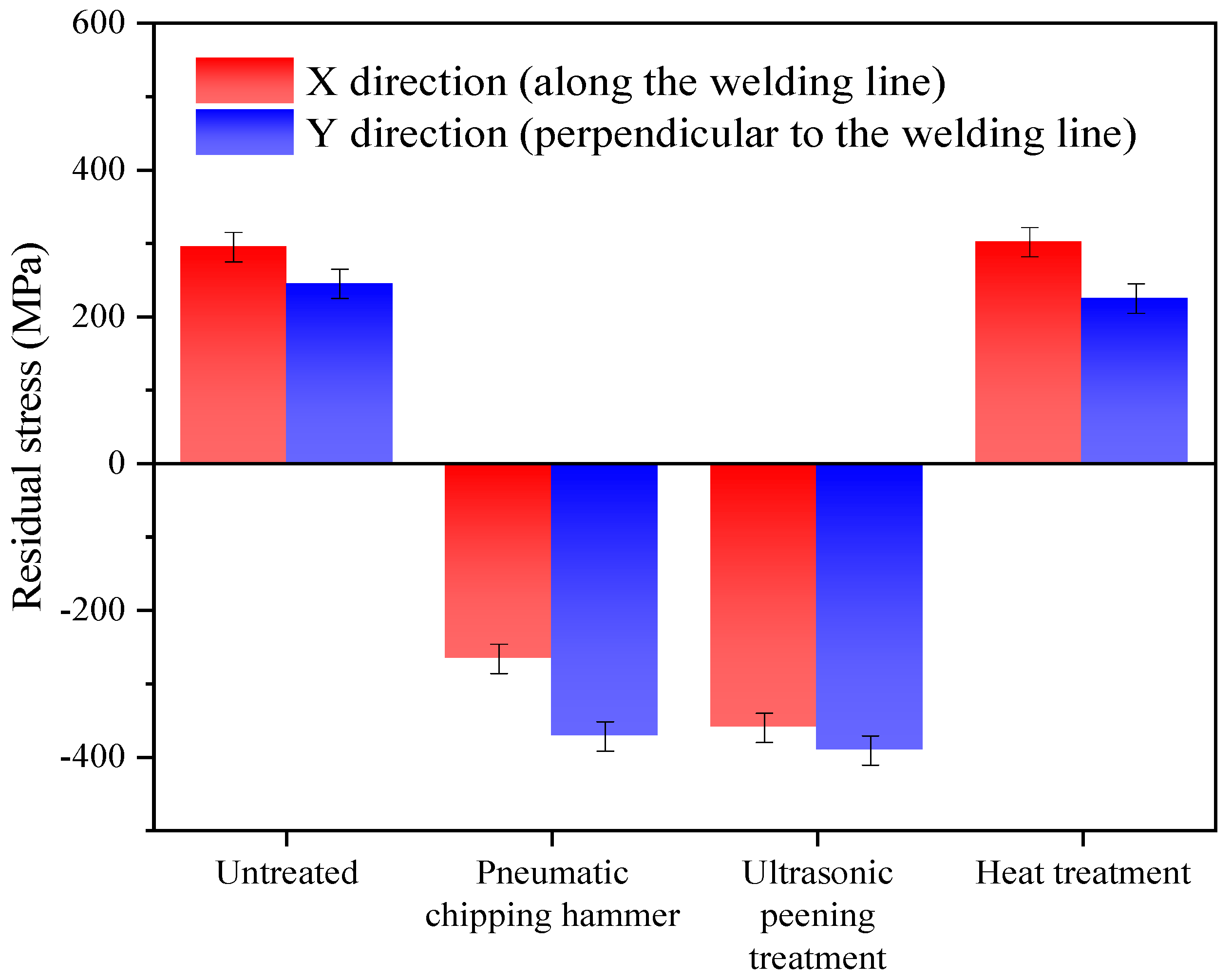

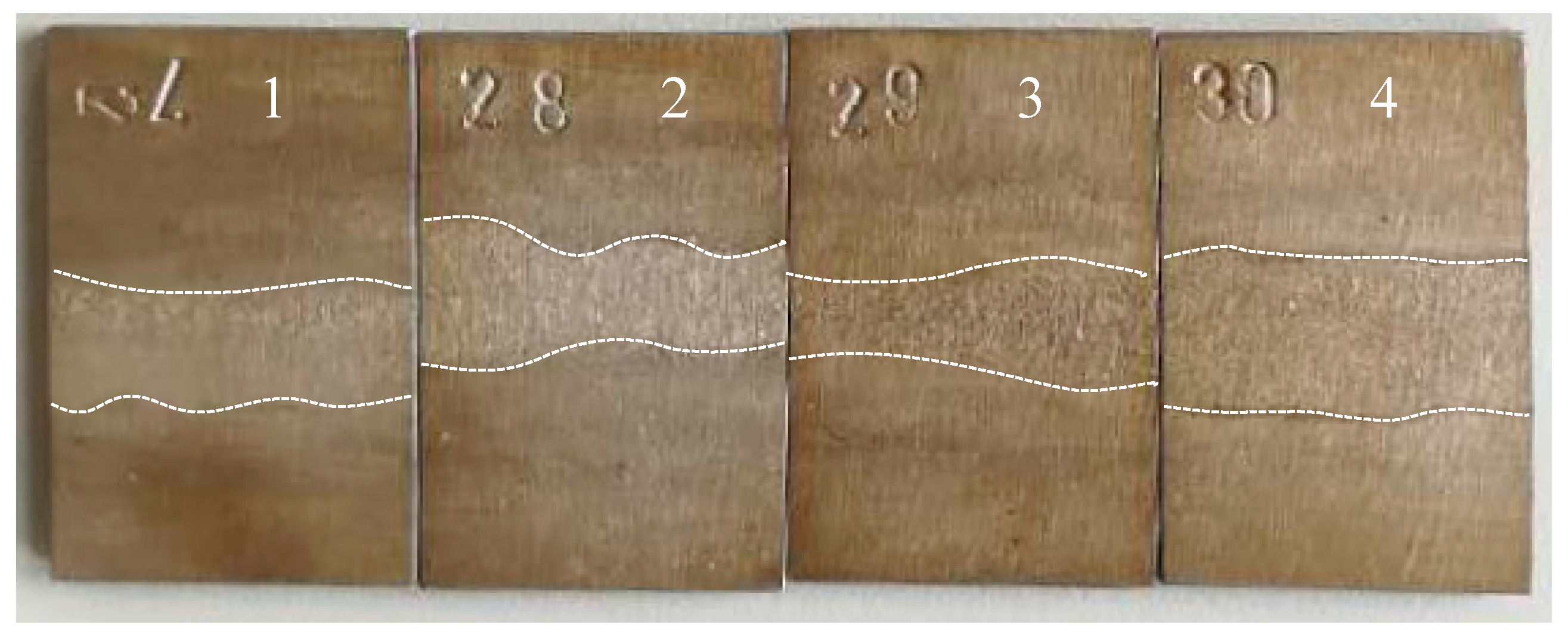

3.1. Residual Stress Analysis

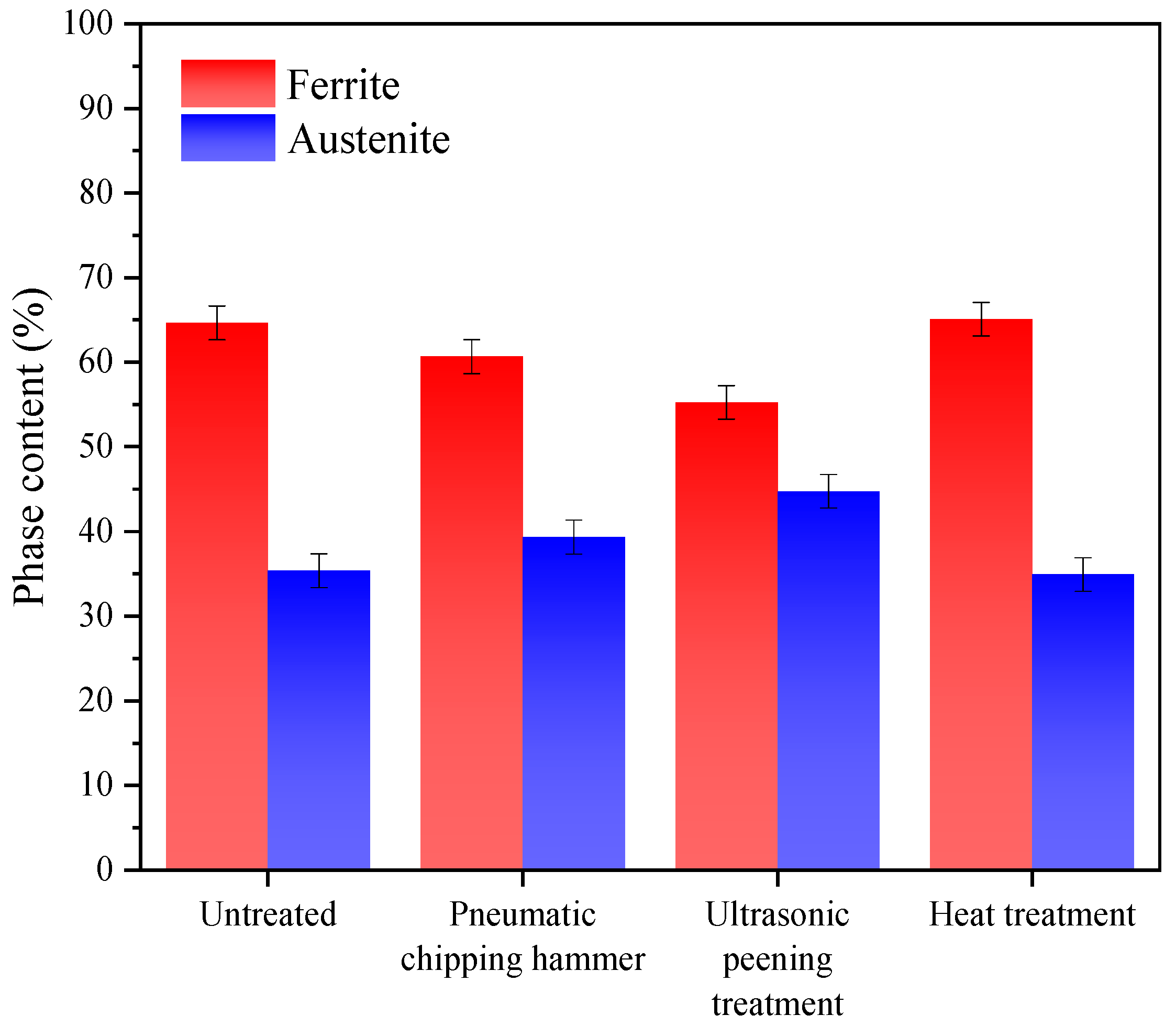

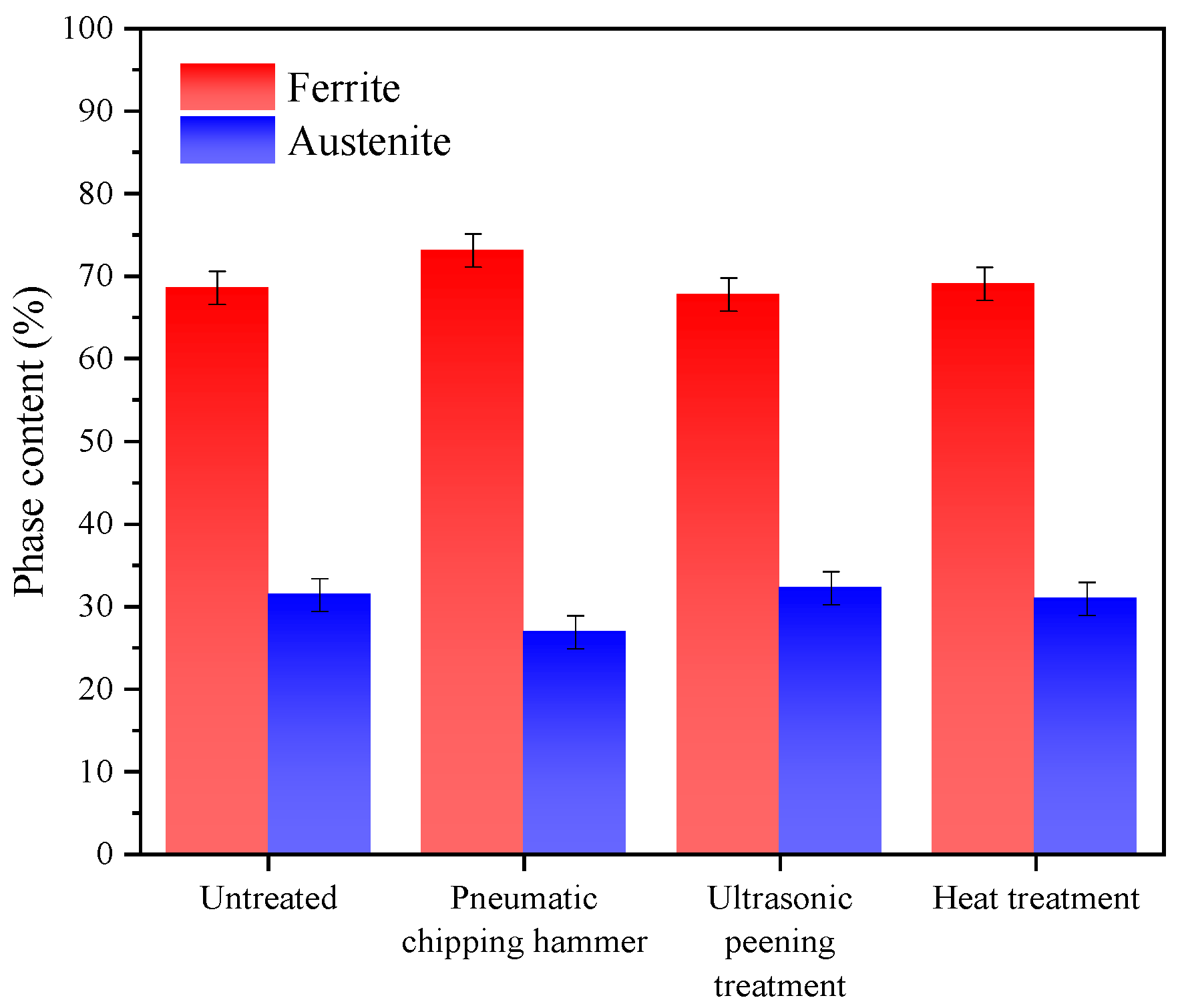

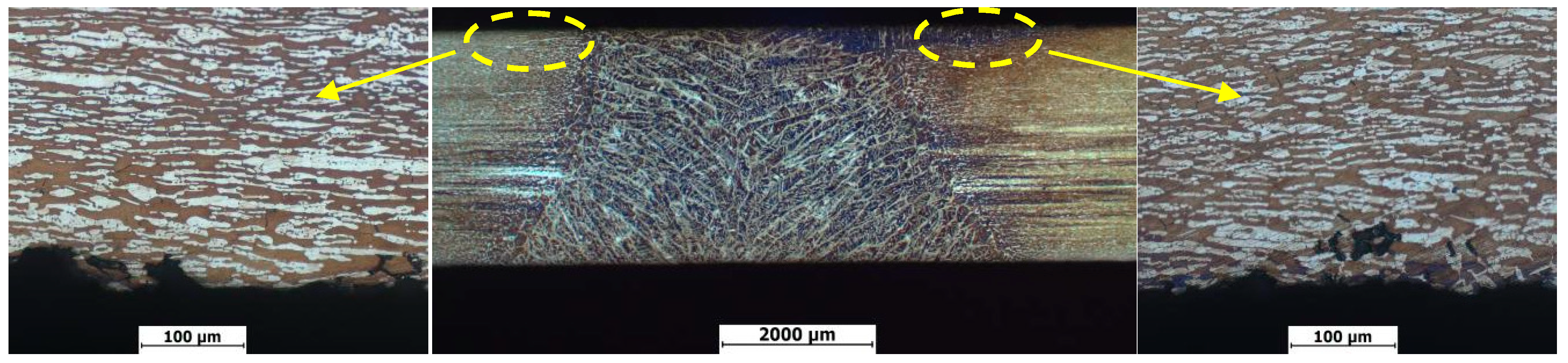

3.2. Metallographic Structure

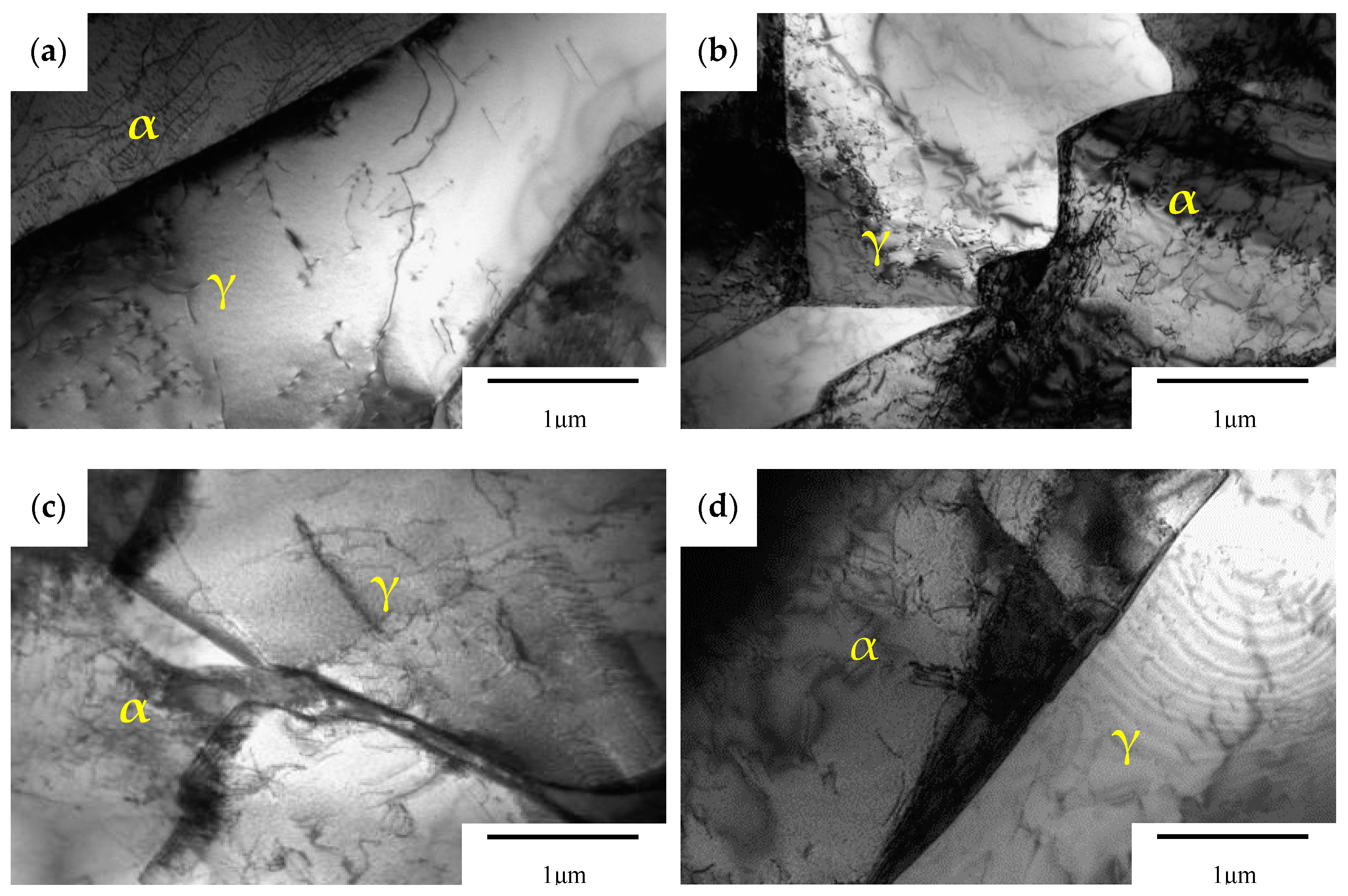

3.3. TEM Observation

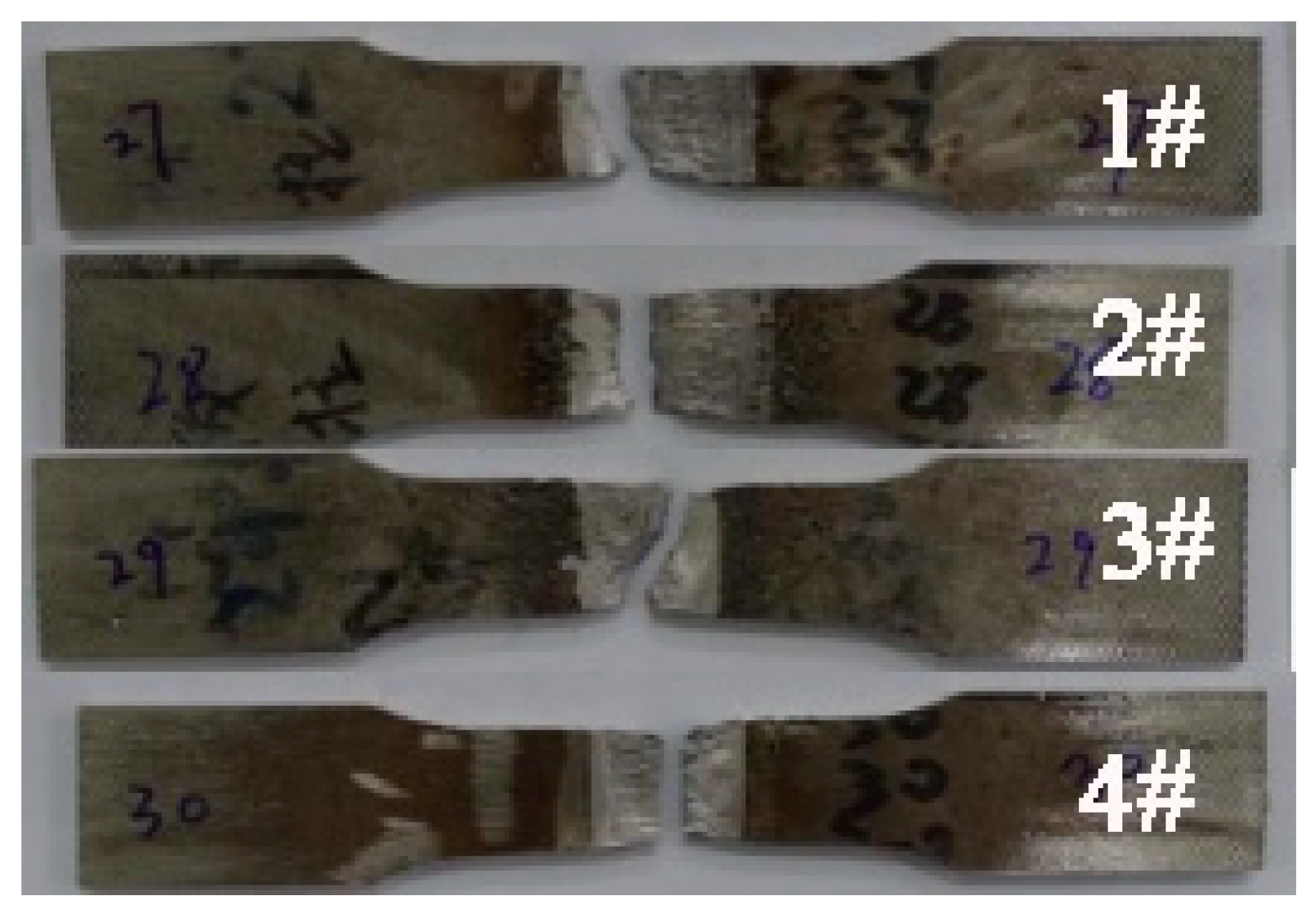

3.4. Mechanical Property

3.5. Corrosion Resistance

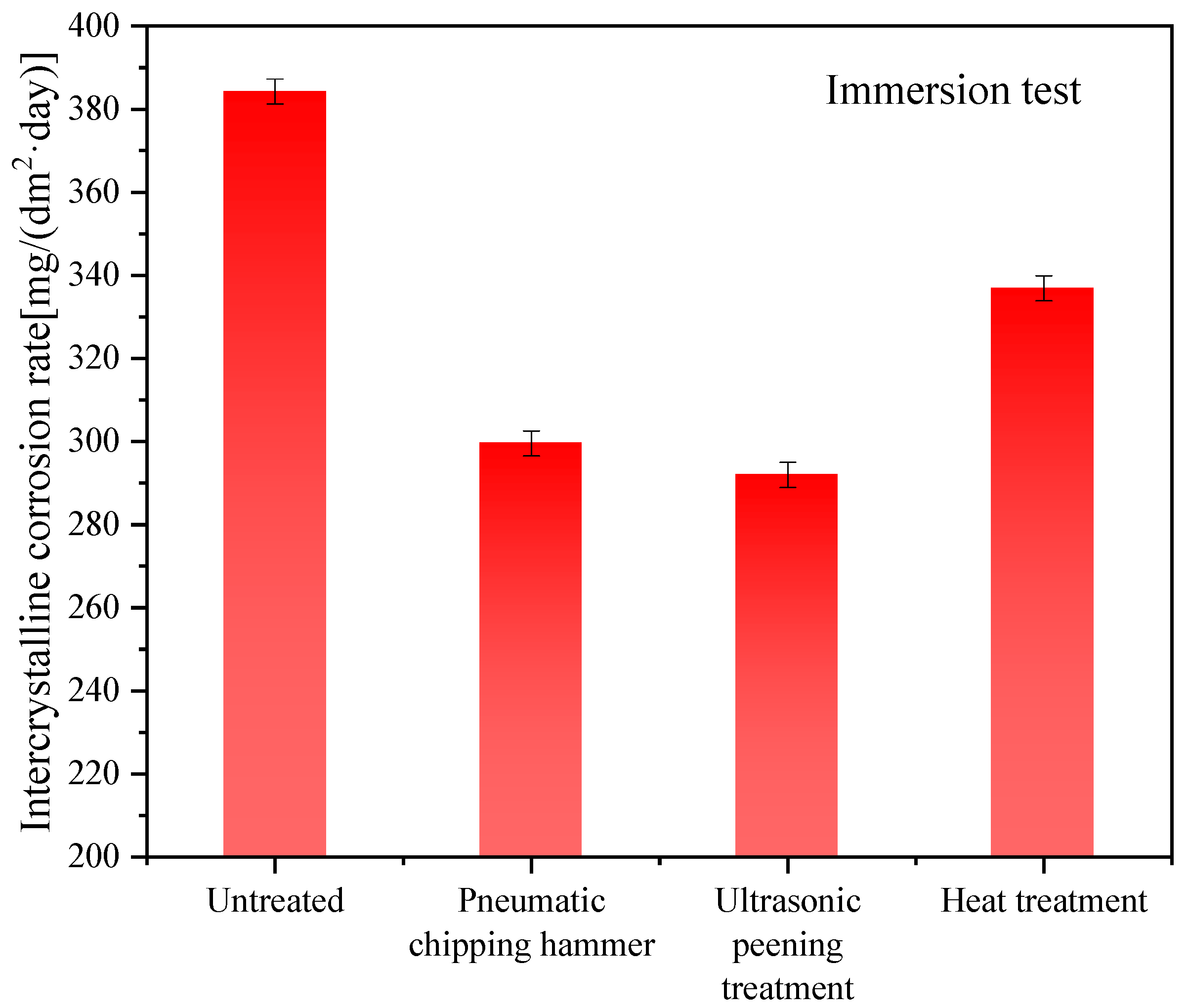

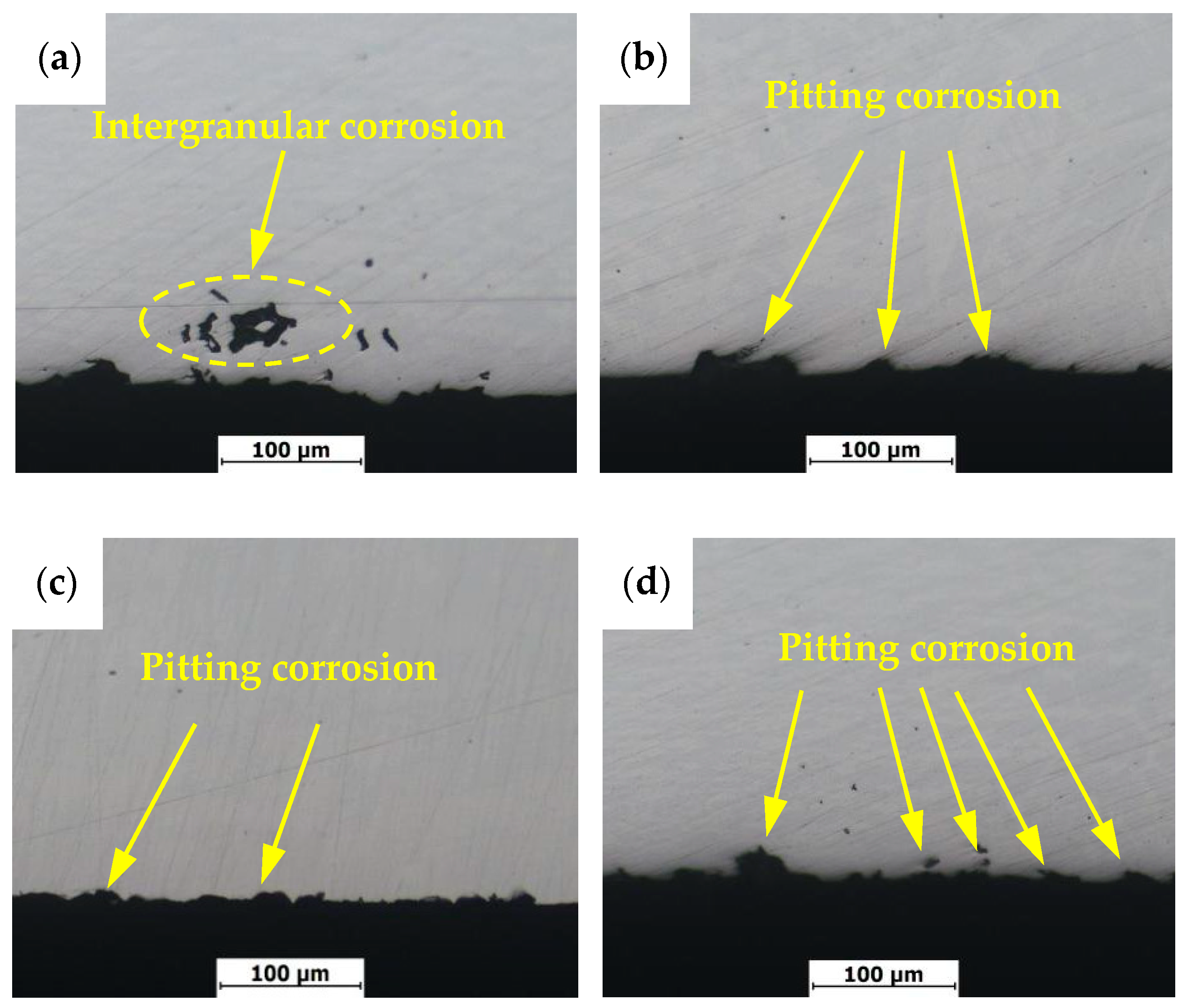

3.5.1. Resistance to Intergranular Corrosion

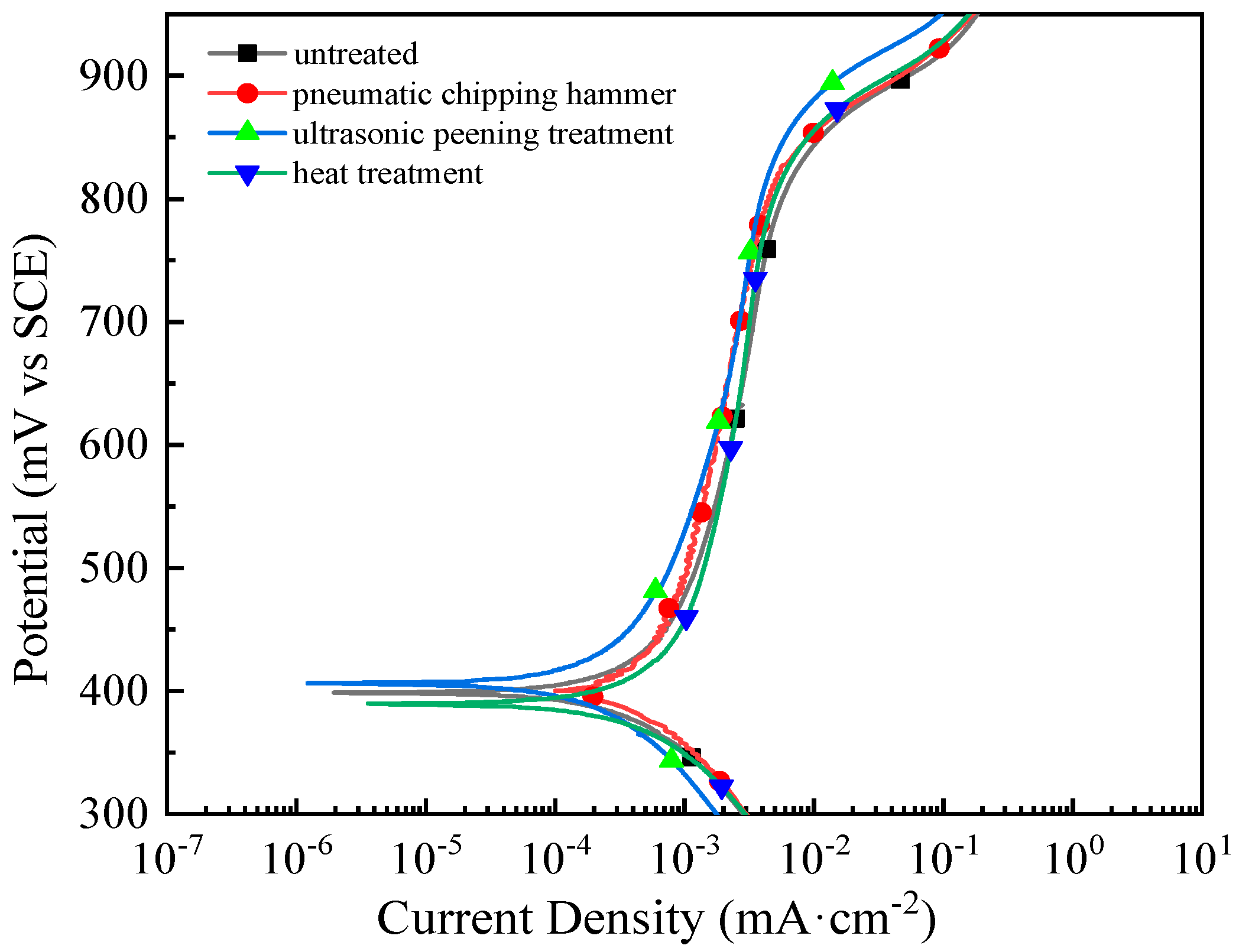

3.5.2. Electrochemical Corrosion Resistance

4. Conclusions

- After the pneumatic chipping hammer and ultrasonic peeing treatment, the stress states of the welded joints were effectively improved from residual tensile stress to residual compressive stress. The stress values along the weld direction and perpendicular to the weld direction of the specimens treated by the pneumatic chipping hammer were 560 MPa and 617 MPa respectively, and those of the specimens treated by ultrasonic peening were 654 MPa and 636 MPa respectively. The ultrasonic peening treatment proved to be the best option. On the contrary, low-temperature stress-relieving annealing had no obvious effect on stress distribution.

- Pneumatic chipping hammer and ultrasonic peening treatment can change the weld surface of two-phase grain growth direction, from vertical growth to growth parallel to the weld axis. Furthermore, dislocation density in the two-phase microstructure increases. The average strengths of specimens treated by pneumatic chipping hammer and ultrasonic peening were close to that before treatment, 825 MPa and 829 MPa respectively. Furthermore, the hardness of specimens treated by pneumatic chipping hammer and ultrasonic peening treatment increased slightly, to about 280 and 270 respectively. For stress relief annealing specimens, static recovery occurred, dislocation density decreased and no second phase precipitation occurred. The welded joint strength decreased to 797 MPa and hardness decreased to about HV 260.

- The pneumatic chipping hammer, ultrasonic peening treatment and stress relief annealing treatment can effectively improve corrosion resistance of welded joints, and the intergranular corrosion rates decrease from 384.22 mdd to 299.58 mdd, 291.95 mdd and 336.86 mdd, respectively.

Author Contributions

Funding

Conflicts of Interest

References

- Krizan, D.; Duprez, L.; De Cooman, B.C. Properties of laser welded SAF 2205 duplex stainless steel sheet. Steel Res. Int. 2004, 75, 829–835. [Google Scholar] [CrossRef]

- Emami, S.; Saeid, T.; Abdollah-zadeh, A. Effect of friction stir welding parameters on the microstructure and microtexture evolution of SAF 2205 stainless steel. J. Alloys Compd. 2019, 810, 151797. [Google Scholar] [CrossRef]

- Kordatos, J.D.; Fourlaris, G.; Papadimitriou, G. The effect of cooling rate on the mechanical and corrosion properties of SAF 2205 (UNS 31803) duplex stainless steel welds. Scr. Mater. 2001, 44, 401–408. [Google Scholar] [CrossRef]

- Okano, S.; Mochizuki, M. Engineering model of metal active gas welding process for efficient distortion analysis. ISIJ Int. 2017, 57, 511–516. [Google Scholar] [CrossRef] [Green Version]

- Russo, S.P.; Matteis, P.; Scavino, G. Dissimilar metal active gas welding of TWIP and DP steel sheets. Steel Res. Int. 2015, 86, 495–501. [Google Scholar] [CrossRef]

- Lopes, B.; Rodrigues, S.; Silva, E.; Reis, G.; Martins, W.; Damascena, J.; Leal, V. Influence of MIG/MAG welding process on mechanical and pitting corrosion behaviors on the super-duplex stainless steel SAF 2507 welded joints. Mater. Sci. Appl. 2018, 9, 228–245. [Google Scholar] [CrossRef] [Green Version]

- García-Rentería, M.A.; López-Morelos, V.H.; García-Hernández, R.; Dzib-Pérez, L.; García-Ochoa, E.M.; González-Sánchez, J. Improvement of localised corrosion resistance of AISI 2205 duplex stainless steel joints made by gas metal arc welding under electromagnetic interaction of low intensity. Appl. Surf. Sci. 2014, 321, 252–260. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Yang, B.; Han, J.; Wu, H.C.; Wang, X.T. Effect of precipitated phases on the pitting corrosion of Z3CN20.09M cast duplex stainless steel. Mater. Trans. 2013, 54, 839–843. [Google Scholar] [CrossRef] [Green Version]

- Świerczyńska, A.; Fydrych, D.; Landowski, M.; Rogalski, G.; Łabanowski, J. Hydrogen embrittlement of X2CrNiMoCuN25-6-3 super duplex stainless steel welded joints under cathodic protection. Constr. Build. Mater. 2019, 238, 117697. [Google Scholar] [CrossRef]

- Varbai, B.; Pickle, T.; Májlinger, K. Effect of heat input and role of nitrogen on the phase evolution of 2205 duplex stainless steel weldment. Int. J. Pres. Ves. Pip. 2019, 176, 103952. [Google Scholar] [CrossRef]

- Deng, D.; Murakawa, H.; Liang, W. Numerical and experimental investigations on welding residual stress in multi-pass butt-welded austenitic stainless steel pipe. Comp. Mater. Sci. 2008, 42, 234–244. [Google Scholar] [CrossRef]

- Deng, D.; Murakawa, H. Numerical simulation of temperature field and residual stress in multi-pass welds in stainless steel pipe and comparison with experimental measurements. Comp. Mater. Sci. 2006, 37, 269–277. [Google Scholar] [CrossRef]

- Shen, W.; Yan, R.; Liu, E.; Xu, L. Fatigue growth behavior for surface crack in welding joints under combined compressive and bending stresses. Int. J. Fatigue 2015, 77, 50–63. [Google Scholar] [CrossRef]

- Cho, J.; Lee, C.H. FE analysis of residual stress relaxation in a girth-welded duplex stainless steel pipe under cyclic loading. Int. J. Fatigue 2016, 82, 462–473. [Google Scholar] [CrossRef]

- Gideon, B.; Ward, L. Intergranular corrosion and residual stress determination of duplex stainless steel pipeline girth welds. Corros. Prev. 2008, 110, 1–11. [Google Scholar]

- Alam, M.K.; Edrisy, A.; Urbanic, J.; Pineault, J. Microhardness and stress analysis of laser-cladded AISI 420 martensitic stainless steel. J. Mater. Eng. Perform. 2017, 26, 1076–1084. [Google Scholar] [CrossRef]

- Badji, R.; Bouabdallah, M.; Bacroix, B.; Kahloun, C.; Belkessa, B.; Maza, H. Phase transformation and mechanical behavior in annealed 2205 duplex stainless steel welds. Mater. Charact. 2008, 59, 447–453. [Google Scholar] [CrossRef]

- Laamouri, A.; Sidhom, H.; Braham, C. Evaluation of residual stress relaxation and its effect on fatigue strength of AISI 316L stainless steel ground surfaces: Experimental and numerical approaches. Int. J. Fatigue 2013, 48, 109–121. [Google Scholar] [CrossRef] [Green Version]

- Jang, C.; Cho, P.Y.; Kim, M.; Oh, S.; Yang, J. Effects of microstructure and residual stress on fatigue crack growth of stainless steel narrow gap welds. Mater. Des. 2010, 31, 1862–1870. [Google Scholar] [CrossRef]

- Nao-Aki, N.; Hu, K.; Sano, Y.; Hosokawa, Y.; Wang, X. Accuracy of disk method to predict roll residual stress by measuring the sliced disk stress. ISIJ Int. 2017, 57, 1433–1441. [Google Scholar]

- Sekine, Y.; Soyama, H. Evaluation of equibiaxial compressive stress introduced into austenitic stainless steel using an eddy current method. J. Nondestruct. Eval. 2012, 31, 99–107. [Google Scholar] [CrossRef]

- Wang, Y.D.; Peng, R.L.; Wang, X.L.; McGreevy, R.L. Grain-orientation-dependent residual stress and the effect of annealing in cold-rolled stainless steel. Acta Mater. 2002, 50, 1717–1734. [Google Scholar] [CrossRef]

- Park, H.; Cooman, B.C.D. Creep-induced microstructure evolution of type 2205 duplex stainless steel during continuous annealing processing. Steel Res. Int. 2014, 85, 756–770. [Google Scholar] [CrossRef]

- Garzón, C.M.; Ramirez, A.J. Growth kinetics of secondary austenite in the welding microstructure of a UNS S32304 duplex stainless steel. Acta Mater. 2006, 54, 3321–3331. [Google Scholar] [CrossRef]

- Zhang, W.; Debroy, T.; Palmer, T.A.; Elmer, J.W. Modeling of ferrite formation in a duplex stainless steel weld considering non-uniform starting microstructure. Acta Mater. 2005, 53, 4441–4453. [Google Scholar] [CrossRef]

- Cabrera, J.M.; Mateo, A.; Llanes, L.; Prado, J.M.; Anglada, M. Hot deformation of duplex stainless steels. J. Mater. Process. Technol. 2003, 143, 321–325. [Google Scholar] [CrossRef]

- Zhou, T.; Xiong, Y.; Zha, X.Q.; Yue, Y.; Lu, Y.; He, T.T.; Ren, F.Z.; Rani, E.; Singh, H.; Komi, J.; et al. Hot-deformation-induced structural and mechanical properties of Ce-modified SAF 2507 super duplex stainless steel. J. Mater. Res. Technol. 2020, 9, 8379–8390. [Google Scholar] [CrossRef]

- Hertzman, S.; Brolund, B.; Ferreira, P.J. An experimental and theoretical study of heat-affected zone austenite reformation in three duplex stainless steels. Metall. Mater. Trans. A 1997, 28, 277–285. [Google Scholar] [CrossRef]

- Corolleur, A.; Fanica, A.; Passot, G. Ferrite content in the heat affected zone of duplex stainless steels. BHM Berg-und Hüttenmännische Mon. 2015, 160, 413–418. [Google Scholar] [CrossRef]

- Zhou, T.; Xiong, Y.; Yue, Y.; Lu, Y.; Chen, Y.N.; He, T.T.; Ren, F.Z.; Sing, H.; Komi, J.; Huttula, M.; et al. Controlled cold rolling effect on microstructure and mechanical properties of Ce-modified SAF 2507 super duplex stainless steel. Mater. Sci. Eng. A 2019, 766, 138352. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, Y.M.; Koh, J.Y.; Lee, T.H.; Woo, W.C.; Han, H.N. Evaluation of single crystal elastic constants and stacking fault energy in high-nitrogen duplex stainless steel by in-situ neutron diffraction. Scr. Mater. 2016, 119, 1–4. [Google Scholar] [CrossRef]

- Ahmed, M.Z.; Bhattacharjee, P.P. Microstructure, texture, and tensile properties of a severely warm-rolled and annealed duplex stainless steel. Steel Res. Int. 2016, 87, 472–483. [Google Scholar] [CrossRef]

- Lin, D.Y.; Liu, Y.F.; Chen, C.H.; Chen, Y.C.; Huang, W.P.; Yang, S.M.; Wang, H.S. The effect of annealing temperature on the corrosion behavior of silver alloyed 2205 duplex stainless steel. Int. J. Mater. Res. 2014, 105, 258–264. [Google Scholar] [CrossRef]

- Zhang, W.W.; Cong, S.; Luo, S.B.; Fang, J.H. Effects of energy density and shielding medium on performance of laser beam welding (LBW) joints on SAF2205 duplex stainless steel. JOM 2018, 70, 1554–1559. [Google Scholar] [CrossRef]

- Hwang, H.; Park, Y. Effects of heat treatment on the phase ratio and corrosion resistance of duplex stainless steel. Mater. Trans. 2009, 50, 1548–1552. [Google Scholar] [CrossRef] [Green Version]

| Material | C | Si | Mn | Cr | Ni | Mo | N | Fe |

|---|---|---|---|---|---|---|---|---|

| 2205 | 0.025 | 0.60 | 1.50 | 22.50 | 5.70 | 3.00 | 0.15 | Balance |

| ER2209 | 0.017 | 0.57 | 1.61 | 22.06 | 8.84 | 2.68 | 0.11 | Balance |

| Processing Method | Corrosion Potential (mV) | Corrosion Current Density (mA/cm2) | Pitting Potential (mV) |

|---|---|---|---|

| Untreated | 398 | 7.3 × 10−4 | 821 |

| Pneumatic chipping hammer | 400 | 6.3 × 10−4 | 856 |

| Ultrasonic peening treatment | 407 | 4.6 × 10−4 | 895 |

| Heat treatment | 389 | 7.1 × 10−4 | 852 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zha, X.-q.; Xiong, Y.; Zhou, T.; Ren, Y.-f.; Hei, P.-h.; Zhai, Z.-l.; Kömi, J.; Huttula, M.; Cao, W. Impacts of Stress Relief Treatments on Microstructure, Mechanical and Corrosion Properties of Metal Active-Gas Welding Joint of 2205 Duplex Stainless Steel. Materials 2020, 13, 4272. https://doi.org/10.3390/ma13194272

Zha X-q, Xiong Y, Zhou T, Ren Y-f, Hei P-h, Zhai Z-l, Kömi J, Huttula M, Cao W. Impacts of Stress Relief Treatments on Microstructure, Mechanical and Corrosion Properties of Metal Active-Gas Welding Joint of 2205 Duplex Stainless Steel. Materials. 2020; 13(19):4272. https://doi.org/10.3390/ma13194272

Chicago/Turabian StyleZha, Xiao-qin, Yi Xiong, Tian Zhou, Yong-feng Ren, Peng-hui Hei, Zhi-liang Zhai, Jukka Kömi, Marko Huttula, and Wei Cao. 2020. "Impacts of Stress Relief Treatments on Microstructure, Mechanical and Corrosion Properties of Metal Active-Gas Welding Joint of 2205 Duplex Stainless Steel" Materials 13, no. 19: 4272. https://doi.org/10.3390/ma13194272

APA StyleZha, X.-q., Xiong, Y., Zhou, T., Ren, Y.-f., Hei, P.-h., Zhai, Z.-l., Kömi, J., Huttula, M., & Cao, W. (2020). Impacts of Stress Relief Treatments on Microstructure, Mechanical and Corrosion Properties of Metal Active-Gas Welding Joint of 2205 Duplex Stainless Steel. Materials, 13(19), 4272. https://doi.org/10.3390/ma13194272