Recycled Nylon Fiber from Waste Fishing Nets as Reinforcement in Polymer Cement Mortar for the Repair of Corroded RC Beams

Abstract

:1. Introduction

2. Experimental Program

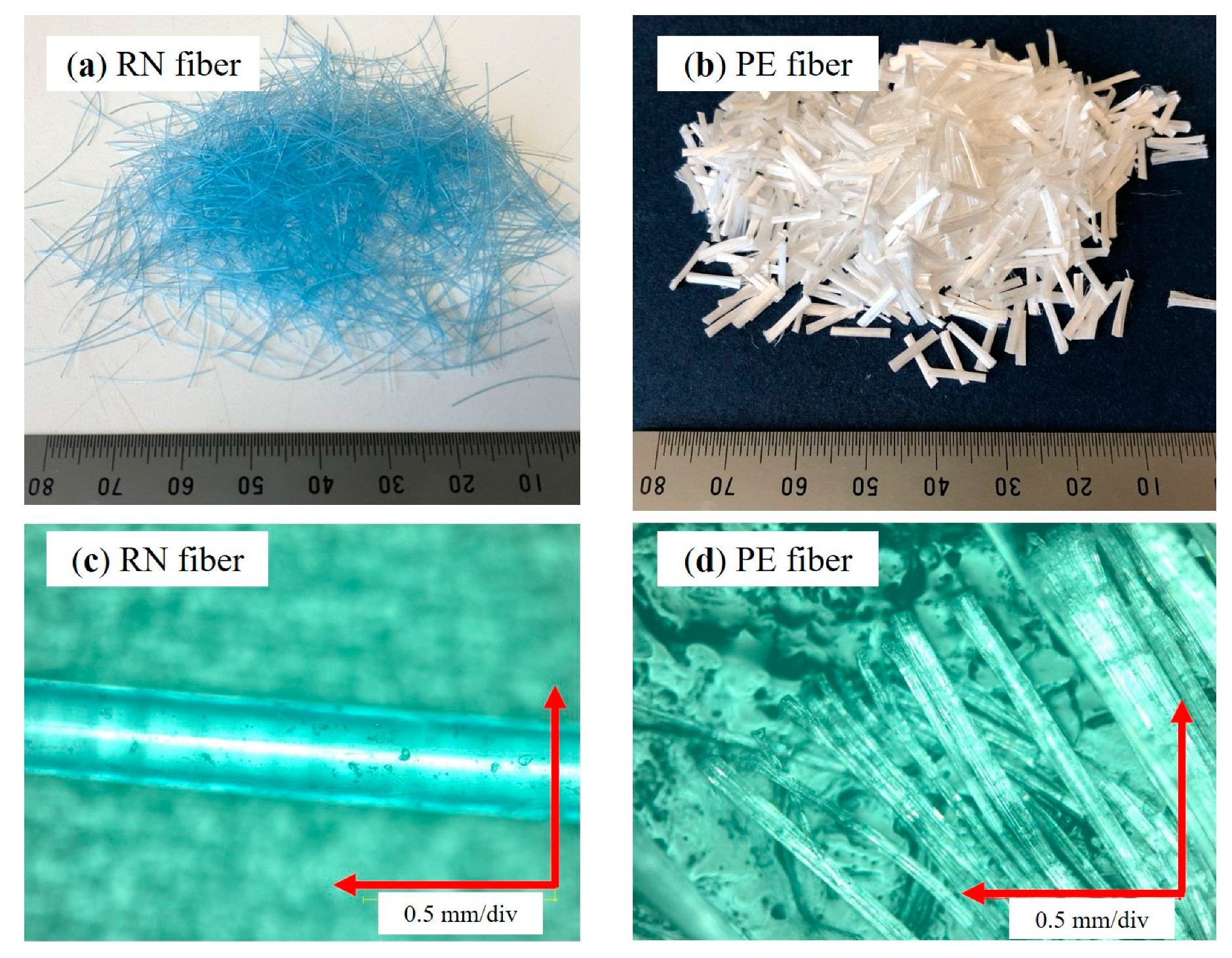

2.1. Testing Materials

2.2. Exposure and Repair Operations

2.3. Loading Tests

3. Results and Discussion

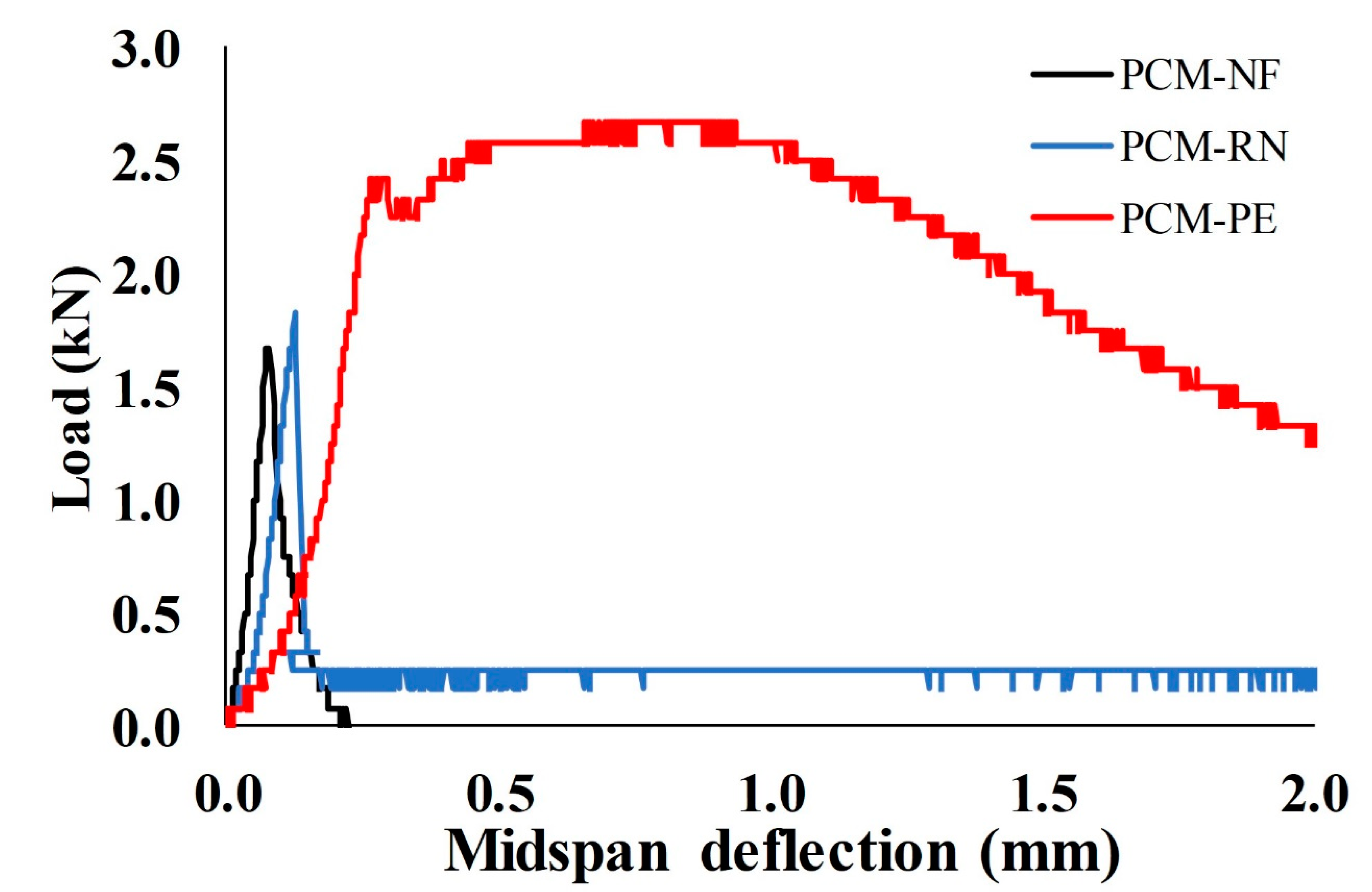

3.1. Mechanical Behavior of Polymer Cement Mortar (PCM) Specimens

3.1.1. Flowability

3.1.2. Compressive and Flexural Strengths

3.1.3. Failure Behavior

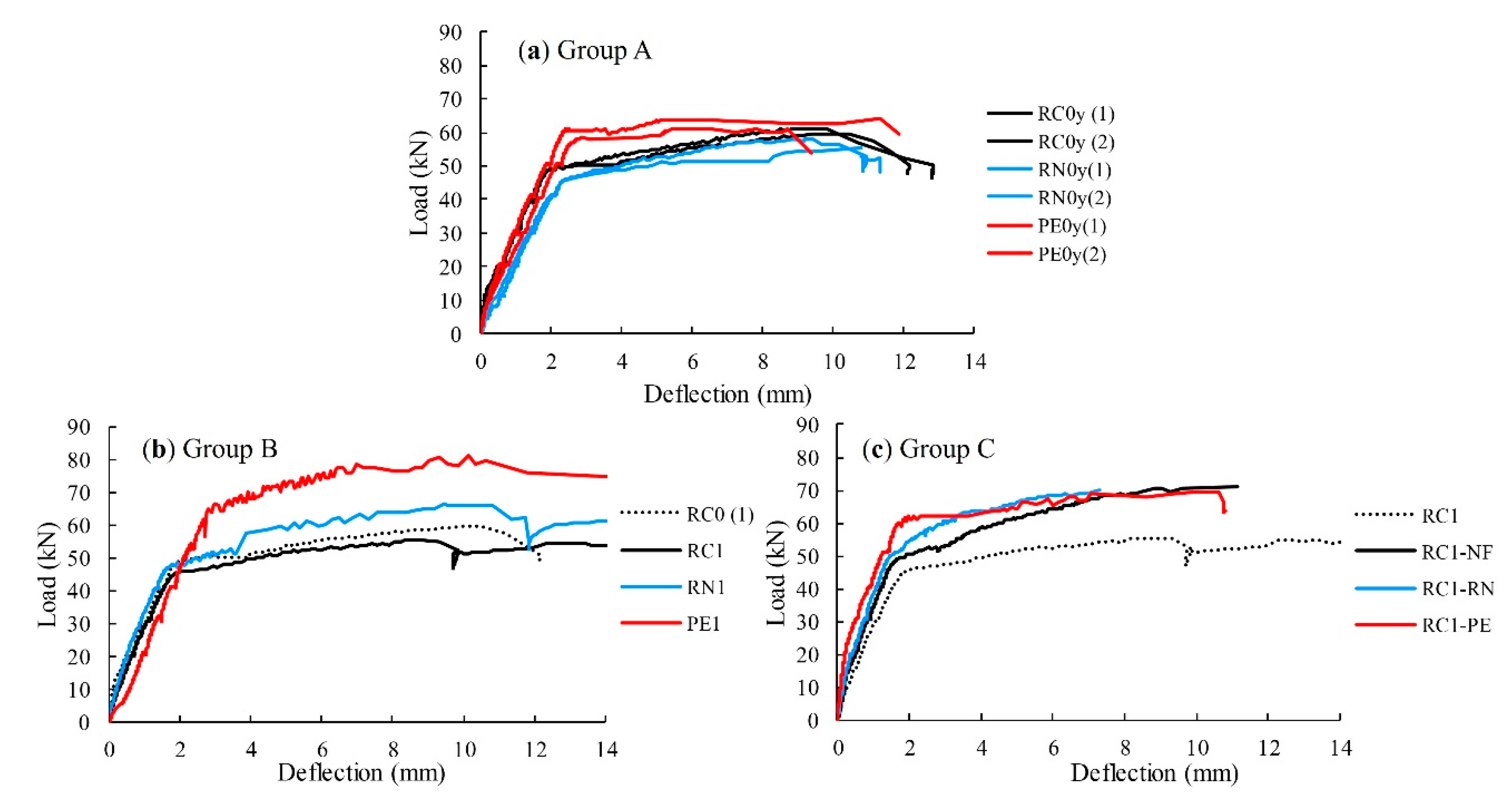

3.2. Mechanical Behavior of Reinforced Concrete (RC) Beams

3.2.1. Flexural Capacity

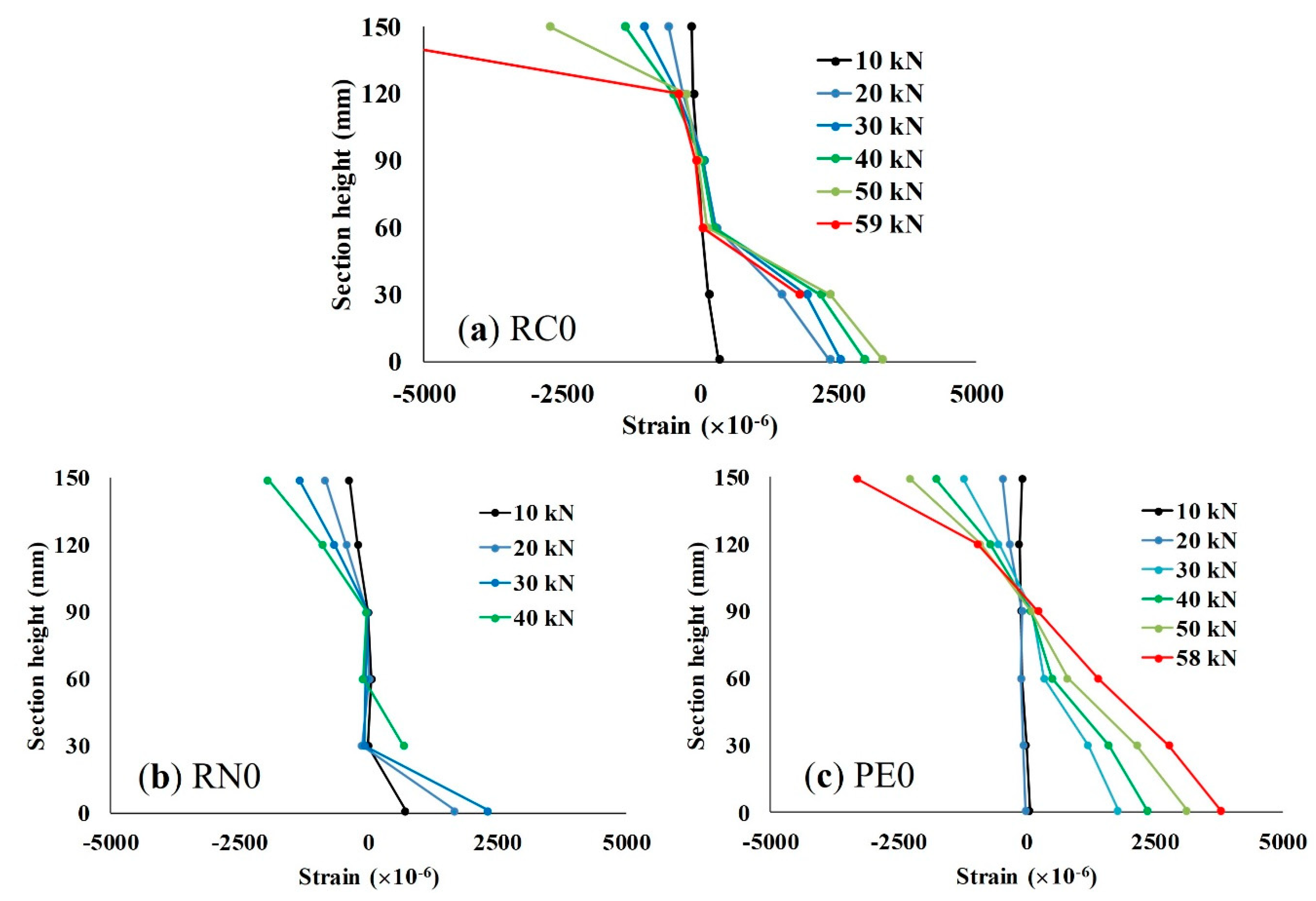

3.2.2. Strain Distribution

3.2.3. Crack Formation

3.2.4. Rebar Mass Loss

4. Conclusions

- The addition of RN seems to have no noticeable effect on the flowability of fresh PCM. However, the addition of PE fiber results in a reduction of flowability of PCM up to 23.7% due to the geometry and surface property of PE fiber.

- The addition of RN fiber results in a reduction of compressive strength and flexural capacity of PCM. In contrast, the addition of PE fiber increases the compressive and flexural strengths of PCM up to 24% and 39%, respectively.

- The addition of RN and PE fibers enables the PCM to sustain more flexural loads after the peak. PCM-RN retains a stable post-peak load of approximately 13.6% of the yield load, while the use of PCM-PE led to an increase in the load after the yield point. The addition of RN short fiber helps prevent abrupt failure of the beams; however, its flexural strength is inferior to those of PE.

- RN and PE fibers can be used as a reinforcement material for the repair of lightly corroded RC beams. Spraying reinforced PCM can compensate the flexural capacity that deteriorated due to the corrosion of tensile rebar; however, the effectiveness of the RN fibers is inferior to that of PE fibers.

- Adding fibers helps distribute stresses throughout the beam under the bending load. RN fiber helps transfer stresses through wide cracks and spreads the cracks toward the support of the beams. PE fiber prevents severe damage of the beams by distributing damage from a wide crack to many small cracks.

- The rate of crack openings is reduced in the RC beams repaired by PCM reinforced with fiber. The beams that were repaired with PCM-PE exhibit the lowest crack opening and the rate of crack openings, followed by PCM–RN.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Daily Mail Online. Available online: https://www.dailymail.co.uk/sciencetech/article-7201755/Ocean-cleanup-effort-drags-5-TON-ghost-net-Pacific-Ocean-Garbage-Patch.html (accessed on 28 August 2020).

- Richardson, K.; Hardesty, B.D.; Wilcox, C. Estimates of fishing gear loss rates at a global scale: A literature review and meta-analysis. Fish Fish. 2019, 20, 1218–1231. [Google Scholar] [CrossRef] [Green Version]

- Valderrama, L.B.; Matthews, J.L.; Hoeksema, B.W. Pollution and coral damage caused by derelict fishing gear on coral reefs around Koh Tao, Gulf of Thailand. Mar. Pollut. Bull. 2018, 135, 1107–1116. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.; Lee, J.; Lim, S. Navigational threats by derelict fishing gear to navy ships in the Korean seas. Mar. Pollut. Bull. 2017, 119, 100–105. [Google Scholar] [CrossRef] [PubMed]

- National Geographic. Available online: https://www.nationalgeographic.com/magazine/2018/06/plastic-planet-waste-pollution-trash-crisis/ (accessed on 28 August 2020).

- Charter, M.; Carruthers, R.; Femmer, S.J. Products from Waste Fishing Nets Accessories, Clothing, Footwear, Home Ware, Recreation. Circular Ocean. 2018. [Google Scholar]

- Wang, Y. Fiber and textile waste Utilization. Waste Biomass Valori. 2010, 1, 135–143. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Ozbakkaloglu, T. Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Constr. Build. Mater. 2015, 94, 73–82. [Google Scholar] [CrossRef]

- Alhozaimy, A.; Soroushian, P.; Mirza, F. Mechanical properties of polypropylene fiber reinforced concrete and the effects of pozzolanic materials. Cem. Concr. Compos. 1996, 18, 85–92. [Google Scholar] [CrossRef]

- Allan, M.; Kukacka, L. Strength and durability of polypropylene fibre reinforced grouts. Cem. Concr. Res. 1995, 25, 511–521. [Google Scholar] [CrossRef]

- Fallah, S.; Nematzadeh, M. Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Constr. Build. Mater. 2017, 132, 170–187. [Google Scholar] [CrossRef]

- Karahan, O.; Atiş, C. The durability properties of polypropylene fiber reinforced fly ash concrete. Mater. Des. 2011, 32, 1044–1049. [Google Scholar] [CrossRef]

- Ramezanianpour, A.; Esmaeili, M.; Ghahari, S.; Najafi, M. Laboratory study on the effect of polypropylene fiber on durability, and physical and mechanical characteristic of concrete for application in sleepers. Constr. Build. Mater. 2013, 44, 411–418. [Google Scholar] [CrossRef]

- Söylev, T.; Özturan, T. Durability, physical and mechanical properties of fiber-reinforced concretes at low-volume fraction. Constr. Build. Mater. 2014, 73, 67–75. [Google Scholar] [CrossRef]

- Toutanji, H.; McNeil, S.; Bayasi, Z. Chloride permeability and impact resistance of polypropylene-fiber-reinforced silica fume concrete. Cem. Concr. Res. 1998, 28, 961–968. [Google Scholar] [CrossRef]

- Zheng, Z.; Feldman, D. Synthetic Fibre-reinforced Concrete. Prog. Polym. Sci. 1995, 20, 185–210. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Q. Effect of polypropylene fiber on durability of concrete composite containing fly ash and silica fume. Compos. B. Eng. 2013, 45, 1587–1594. [Google Scholar] [CrossRef]

- Özkan, Ş.; Demir, F. The hybrid effects of PVA fiber and basalt fiber on mechanical performance of cost effective hybrid cementitious composites. Constr. Build. Mater. 2020, 263. [Google Scholar] [CrossRef]

- Lee, S. Effect of Nylon Fiber Addition on the Performance of Recycled Aggregate Concrete. Appl. Sci. 2019, 9, 767. [Google Scholar] [CrossRef] [Green Version]

- Ozger, O.; Girardi, F.; Giannuzzi, G.; Salomoni, V.; Majorana, C.; Fambri, L.; Baldassino, N.; Di Maggio, R. Effect of nylon fibres on mechanical and thermal properties of hardened concrete for energy storage systems. Mater. Des. 2013, 51, 989–997. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, X.; Chai, J. Damage performance and compressive behavior of early-age green concrete with recycled nylon fiber fabric under an axial load. Constr. Build. Mater. 2019, 209, 105–114. [Google Scholar] [CrossRef]

- Alimrani, N.S.; Balazs, G.L. Synthetic fibres or fibre cocktail in terms of shear capacity of concrete after elevated temperatures. Mech. Mater. 2020, 148, 103504. [Google Scholar] [CrossRef]

- Algin, Z.; Gerginci, S. Freeze-thaw resistance and water permeability properties of roller compacted concrete produced with macro synthetic fibre. Constr. Build. Mater. 2020, 234, 117382. [Google Scholar] [CrossRef]

- Bankir, M.B.; Korkut Sevim, U. Performance optimization of hybrid fiber concretes against acid and sulfate attack. J. Build. Eng. 2020, 32, 101433. [Google Scholar] [CrossRef]

- Wang, J.; Dai, Q.; Si, R.; Guo, S. Mechanical, durability, and microstructural properties of macro synthetic polypropylene (PP) fiber-reinforced rubber concrete. J. Clean. Prod. 2019, 234, 1351–1364. [Google Scholar] [CrossRef]

- Simões, T.; Costa, H.; Dias-da-Costa, D.; Júlio, E. Influence of type and dosage of micro-fibres on the physical properties of fibre reinforced mortar matrixes. Constr. Build. Mater. 2018, 187, 1277–1285. [Google Scholar] [CrossRef]

- Song, P.; Hwang, S.; Sheu, B. Strength properties of nylon- and polypropylene-fiber-reinforced concretes. Cem. Concr. Res. 2005, 35, 1546–1550. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A.; Lucchetti, M.C.; Petrucci, E. Recycled fibers in reinforced concrete: A systematic literature review. J. Clean. Prod. 2020, 248, 119207. [Google Scholar] [CrossRef]

- Fraternali, F.; Farina, I.; Polzone, C.; Pagliuca, E.; Feo, L. On the use of R-PET strips for the reinforcement of cement mortars. Compos. B Eng. 2013, 46, 207–210. [Google Scholar] [CrossRef]

- Foti, D. Preliminary analysis of concrete reinforced with waste bottles PET fibers. Constr. Build. Mater. 2011, 25, 1906–1915. [Google Scholar] [CrossRef]

- Pereira De Oliveira, L.; Castro-Gomes, J. Physical and mechanical behaviour of recycled PET fibre reinforced mortar. Constr. Build. Mater. 2011, 25, 1712–1717. [Google Scholar] [CrossRef]

- Silva, D.; Betioli, A.; Gleize, P.; Roman, H.; Gómez, L.; Ribeiro, J. Degradation of recycled PET fibers in Portland cement-based materials. Cem. Concr. Res. 2005, 35, 1741–1746. [Google Scholar] [CrossRef]

- Al-Hadithi, A.I.; Noaman, A.T.; Mosleh, W.K. Mechanical properties and impact behavior of PET fiber reinforced self-compacting concrete (SCC). Compos. Struct. 2019, 224, 111021. [Google Scholar] [CrossRef]

- Adnan, H.M.; Dawood, A.O. Strength behavior of reinforced concrete beam using re-cycle of PET wastes as synthetic fibers. Case Stud. Constr. 2020, 13, e00367. [Google Scholar]

- Pešić, N.; Živanović, S.; Garcia, R.; Papastergiou, P. Mechanical properties of concrete reinforced with recycled HDPE plastic fibres. Constr. Build. Mater. 2016, 115, 362–370. [Google Scholar] [CrossRef] [Green Version]

- Yin, S.; Tuladhar, R.; Riella, J.; Chung, D.; Collister, T.; Combe, M.; Sivakugan, N. Comparative evaluation of virgin and recycled polypropylene fibre reinforced concrete. Constr. Build. Mater. 2016, 114, 134–141. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Abdul Awal, A.S.M.; Mohd Yatim, J.B. The impact resistance and mechanical properties of concrete reinforced with waste polypropylene carpet fibres. Constr. Build. Mater. 2017, 143, 147–157. [Google Scholar] [CrossRef]

- Maria, I.; Bertelsen, G.; Ottosen, L. Engineering properties of fibres from waste fishing nets Materials, Systems and Structures in Civil Engineering Circular Ocean. In Proceedings of the International RILEM Conference on Materials, Systems and Structures in Civil Engineering: Conference Workshop on Cold Region Engineering, Copenhagen, Denmark, 22–24 August 2016. [Google Scholar]

- Gurutz, M.; Galder, K.; Eider, M.; Nekane, G.; Aitor, A.; Cristina, P.R. Thermomechanical recycling of polyamide 6 from fishing nets waste. J. Appl. 2020, 137, 48442. [Google Scholar]

- Spadea, S.; Farina, I.; Carrafiello, A.; Fraternali, F. Recycled nylon fibers as cement mortar reinforcement. Constr. Build. Mater. 2015, 80, 200–209. [Google Scholar] [CrossRef] [Green Version]

- Park, J.K.; Kim, D.J.; Kim, M.O. Mechanical behavior of waste fishing net fiber-reinforced cementitious composites subjected to direct tension. J. Build. Eng. 2021, 33, 101622. [Google Scholar] [CrossRef]

- Ottosen, L.M.; Svensson, S.J.; Bertelsen, I.M.G. Discarded nylon fishing nets as fibre reinforcement in cement mortar. WIT Trans. Ecol. 2019, 231, 245–256. [Google Scholar]

- Orasutthikul, S.; Unno, D.; Yokota, H. Effectiveness of recycled nylon fiber from waste fishing net with respect to fiber reinforced mortar. Constr. Build. Mater. 2017, 146, 594–602. [Google Scholar] [CrossRef] [Green Version]

- ASTM C1557-03, Standard Test Method for Tensile Strength and Young’s Modulus of Fibers; ASTM International: West Conshohocken, PA, USA, 2003.

- JSCE E 601, Test Method for Half-Cell Potential of Uncoated Rebars in Concrete Structures; Japan Society of Civil Engineers: Tokyo, Japan, 2002.

- JIS A 1106, Method of Test for Flexural Strength of Concrete; Japan Standards Association: Tokyo, Japan, 2019. (In Japanese)

- JIS R 5201, Physical Testing Methods for Cement; Japan Standards Association: Tokyo, Japan, 2015. (In Japanese)

- JIS A 1108, Method of Test for Compressive Strength of Concrete; Japan Standards Association: Tokyo, Japan, 2018. (In Japanese)

| Fiber | Diameter (mm) | Length (mm) | Density (g/cm3) | Tensile Strength (MPa) |

|---|---|---|---|---|

| Recycled nylon (RN) | 0.24 | 20 | 1.13 | 440 |

| Polyethylene (PE) | 0.01–0.1 | 9 | 1.05 | n/a |

| Specimen Name | Condition | Tidal Exposure | Sprayed Material | |

|---|---|---|---|---|

| Group A | RC0 | Normal RC | No | - |

| RN0 | Upgraded RC | No | PCM–RN | |

| PE0 | Upgraded RC | No | PCM–PE | |

| Group B | RC1 | Normal RC | 14 months | - |

| RN1 | Upgraded RC | 14 months | PCM–RN | |

| PE1 | Upgraded RC | 14 months | PCM–PE | |

| Group C | RC1–NF | Normal RC | 14 months | PCM–NF |

| RC1–RN | Normal RC | 14 months | PCM–RN | |

| RC1–PE | Normal RC | 14 months | PCM–PE | |

| Mix | Water (kg) | Fiber (g) |

|---|---|---|

| PCM–NF | 4.93 | - |

| PCM–RN | 4.93 | 0.164 |

| PCM–PE | 4.93 | 0.160 |

| Specimen Name | Flow Diameter (mm) | %ΔFlow Diameter |

|---|---|---|

| PCM–NF | 165 | - |

| PCM–RN | 164 | −0.7 |

| PCM–PE | 126 | −23.7 |

| Specimen Name | Compressive Strength Tests | Flexural Strength Tests | |||||

|---|---|---|---|---|---|---|---|

| f’c (MPa) | SD | %Δf’c | Pcr (kN) | fb (MPa) | SD | %Δfb | |

| PCM–NF | 32.7 | 3.65 | - | 1.69 | 4.77 | 0.14 | - |

| PCM–RN | 24.0 1 | 3.53 | −31.4 | 1.56 | 4.37 | 0.72 | −8.4 |

| PCM–PE | 43.5 | 1.41 | 24.3 | 2.36 | 6.64 | 0.82 | 39.2 |

| Specimen Name | Py (kN) | Pu (kN) | %ΔPy | %ΔPu | Failure Type | Mass Loss of Each Tensile Bar (%) | ||

|---|---|---|---|---|---|---|---|---|

| Group A | RC0 (1) | 49.1 | 59.6 | - | - | Flexural | - | |

| RC0 (2) | 48.1 | 60.9 | - | - | Flexural | - | ||

| RN0 (1) | 41.4 | 55.4 | −14.8 | −8.0 | Flexural–shear | - | ||

| RN0 (2) | 45.1 | 58.0 | −7.2 | −3.7 | Flexural–shear | - | ||

| PE0 (1) | 58.5 | 61.0 | 20.4 | 1.2 | Flexural | - | ||

| PE0 (2) | 60.7 | 64.2 | 24.9 | 6.6 | Flexural–shear | - | ||

| Group B | RC1 | 45.2 | 56.2 | −7.0 | −6.7 | Flexural | 0.9 | 1.8 |

| RN1 | 48.3 | 66.5 | −0.6 | 10.4 | Flexural–shear | 0.8 | 0.7 | |

| PE1 | 64.6 | 81.1 | 32.9 | 34.6 | Flexural | 0.6 | 0.7 | |

| Group C | RC1–NF | 49.1 | 70.8 | 1.0 | 17.5 | Flexural–shear | 0.6 | 0.5 |

| RC1–RN | 50.2 | 69.9 | 3.3 | 16.0 | Flexural | 0.6 | 0.5 | |

| RC1–PE | 62.0 | 69.7 | 27.6 | 15.7 | Flexural | 0.8 | 0.9 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Srimahachota, T.; Yokota, H.; Akira, Y. Recycled Nylon Fiber from Waste Fishing Nets as Reinforcement in Polymer Cement Mortar for the Repair of Corroded RC Beams. Materials 2020, 13, 4276. https://doi.org/10.3390/ma13194276

Srimahachota T, Yokota H, Akira Y. Recycled Nylon Fiber from Waste Fishing Nets as Reinforcement in Polymer Cement Mortar for the Repair of Corroded RC Beams. Materials. 2020; 13(19):4276. https://doi.org/10.3390/ma13194276

Chicago/Turabian StyleSrimahachota, Teeranai, Hiroshi Yokota, and Yoshikazu Akira. 2020. "Recycled Nylon Fiber from Waste Fishing Nets as Reinforcement in Polymer Cement Mortar for the Repair of Corroded RC Beams" Materials 13, no. 19: 4276. https://doi.org/10.3390/ma13194276

APA StyleSrimahachota, T., Yokota, H., & Akira, Y. (2020). Recycled Nylon Fiber from Waste Fishing Nets as Reinforcement in Polymer Cement Mortar for the Repair of Corroded RC Beams. Materials, 13(19), 4276. https://doi.org/10.3390/ma13194276