Numerical Simulation and Experimental Study on Residual Stress in the Curved Surface Forming of 12CrNi2 Alloy Steel by Laser Melting Deposition

Abstract

:1. Introduction

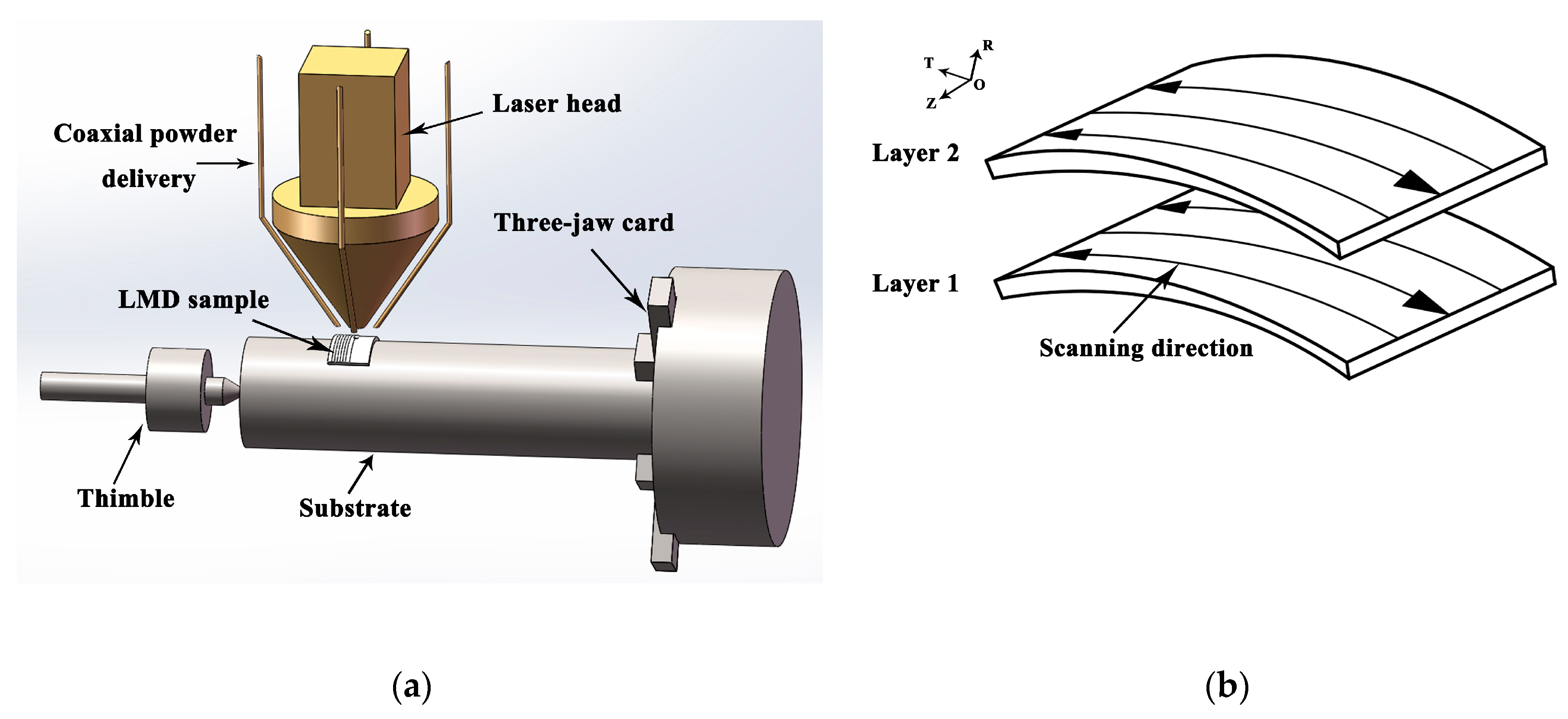

2. Finite Element Model

2.1. Geometric Model

2.2. Finite Element Calculation Settings

2.3. Load and Boundary Conditions

2.3.1. Heat Source Model and Latent Heat

2.3.2. Boundary Conditions

2.4. Stress Analysis

3. Experimental Materials and Methods

3.1. Materials and Deposition Processes

3.2. Testing of Material Parameters

3.2.1. Testing of the Thermophysical Parameters of Materials

3.2.2. Testing of Mechanical Properties at High Temperature

3.3. Observation on the Morphology of the Molten Pool of the Sample

4. Results and Discussion

4.1. Test Results of Material Parameters

4.1.1. Thermophysical Parameters

4.1.2. Mechanical Properties at High Temperatures

4.2. Experimental Results and Model Verification

4.2.1. Experimental Results

4.2.2. The Heat Source Check

4.3. Thermal Stress Evolution

4.4. Residual Stress Distribution

4.5. The Influence of Scanning Mode on Stress

4.6. Effect of Interlayer Cooling on Residual Stress

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Qian, P.; Shiyun, D.; Xueliang, K.; Shixing, Y.; Ping, M. Effect of process parameters on formability of laser melting deposited 12CrNi2 alloy steel. Young Sci. Forum 2018, 10710, 1071045. [Google Scholar]

- Zhou, Y.; Chen, S.; Chen, X.; Cui, T.; Liang, J.; Liu, C. The evolution of bainite and mechanical properties of direct laser deposition 12CrNi2 alloy steel at different laser power. Mater. Sci. Eng. A 2019, 742, 150–161. [Google Scholar] [CrossRef]

- Hongwei, K.; Zhihong, D.; Wei, Z.; Yujiang, X.; Xiao, P. Laser melting deposition of a porosity-free alloy steel by application of high oxygen-containing powders mixed with Cr particles. Vacuum 2019, 159, 319–323. [Google Scholar]

- Dong, Z.; Kang, H.; Xie, Y.; Chi, C.; Peng, X. Effect of powder oxygen content on microstructure and mechanical properties of a laser additively-manufactured 12CrNi2 alloy steel. Mater. Lett. 2019, 236, 214–217. [Google Scholar] [CrossRef]

- Wang, K.B.; Liu, Y.X.; Zhao, X.; Lin, J.J.; Lv, Y.H. Microstructure and mechanical property of 12CrNi2 high strength steel fabricated by laser additive manufacturing. IOP Conf. Ser. Mater. Sci. Eng. 2018, 423, 012077. [Google Scholar] [CrossRef]

- Weng, Y.Q.; Yang, C.F.; Shang, C.J. State-of-the-art and development trends of HSLA steels in China. J. Iron Steel Res. Int. 2011, 46, 1–10. [Google Scholar]

- Yumashev, A.; Ślusarczyk, B.; Kondrashev, S.; Mikhaylov, A. Global indicators of sustainable development: Evaluation of the influence of the human development index on consumption and quality of energy. Energies 2020, 13, 2768. [Google Scholar] [CrossRef]

- Chen, S.Y.; Wang, R.X.; Ma, J.; Liang, J.; Cui, T.; Liu, C.S. Effect of scanning speed on microstructure and properties of 12CrNi2Re alloy steel prepared by laser additive manufacturing. In Proceedings of the 2017 International Conference on Materials Science and Biological Engineering (ICMSBE 2017), Yinchuan, China, 9–10 August 2017. [Google Scholar]

- Ding, C.; Cui, X.; Jiao, J.; Zhu, P. Effects of substrate preheating temperatures on the microstructure, properties, and residual stress of 12CrNi2 prepared by laser cladding deposition technique. Materials 2018, 11, 2401. [Google Scholar] [CrossRef] [Green Version]

- Qian, P.; Shiyun, D.; Xueliang, K.; Ping, M.; Shixing, Y. Effect of preheating on the microstructure and properties of laser melting deposited 12CrNi2 alloy steel. Chin. J. Eng. 2018, 40, 1342–1350. [Google Scholar]

- Liu, F.; Lin, X.; Leng, H.; Cao, J.; Liu, Q.; Huang, C.; Huang, W. Microstructural changes in a laser solid forming Inconel 718 superalloy thin wall in the deposition direction. Opt. Laser Technol. 2013, 45, 330–335. [Google Scholar] [CrossRef]

- Niu, F.; Wu, D.; Ma, G.; Wang, J.; Zhuang, J.; Jin, Z. Rapid fabrication of eutectic ceramic structures by laser engineered net shaping. Procedia CIRP 2016, 42, 91–95. [Google Scholar] [CrossRef]

- Tamanna, N.; Crouch, R.; Kabir, I.R.; Naher, S. An analytical model to predict and minimize the residual stress of laser cladding process. Appl. Phys. A 2018, 124, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Gan, Z.; Yu, G.; He, X.; Li, S. Numerical simulation of thermal behavior and multicomponent mass transfer in direct laser deposition of Co-base alloy on steel. Int. J. Heat Mass Tranf. 2017, 104, 28–38. [Google Scholar] [CrossRef] [Green Version]

- Gao, W.; Zhao, S.; Wang, Y.; Zhang, Z.; Liu, F.; Lin, X. Numerical simulation of thermal field and Fe-based coating doped Ti. Int. J. Heat Mass Transf. 2016, 92, 83–90. [Google Scholar] [CrossRef]

- Qian, T.T.; Liu, D.; Tian, X.J.; Liu, C.M.; Wang, H.M. Microstructure of TA2/TA15 graded structural material by laser additive manufacturing process. T Nonferrous Metal. Soc. 2014, 24, 2729–2736. [Google Scholar] [CrossRef]

- Liang, H.; Wei, T.; Wenhe, L.; Chao, Z. Study of thermal-mechanical coupling behavior in laser cladding. Laser Optoelectron. Prog. 2014, 51, 091401. [Google Scholar] [CrossRef]

- Li, C.; Yu, Z.B.; Gao, J.X.; Han, X.; Dong, X. Numerical simulation and experiment of thermo-elastic-plastic-flow multi-field coupling in laser cladding process. China Surf. Eng. 2019, 32, 124–134. [Google Scholar]

- Dang, Y.X.; Qi, W.J.; Lu, L.L. Research status and development trend of numerical simulation of laser cladding technology. Hot Work. Technol. 2016, 45, 23–27. [Google Scholar]

- Farahmand, P.; Kovacevic, R. An experimental–numerical investigation of heat distribution and stress field in single-and multi-track laser cladding by a high-power direct diode laser. Opt. Laser Technol. 2014, 63, 154–168. [Google Scholar] [CrossRef]

- Nazemi, N.; Urbanic, J.; Alam, M. Hardness and residual stress modeling of powder injection laser cladding of P420 coating on AISI 1018 substrate. Int. J. Adv. Manuf. Technol. 2017, 93, 3485–3503. [Google Scholar] [CrossRef]

- Chew, Y.X.; Pang, J.H.L.; Bi, G.J.; Song, B. Thermo-mechanical model for simulating laser cladding induced residual stresses with single and multiple clad beads. J. Mater. Process. Technol. 2015, 224, 89–101. [Google Scholar] [CrossRef]

- Gong, C.; Wang, L.F.; Zhu, G.X.; Song, T.L. Numerical simulation of residual stress in 316L stainless steel cladding layer by laser additive manufacturing. Appl. Laser 2018, 38, 402–408. [Google Scholar]

- Alimardani, M.; Toyserkani, E.; Huissoon, J.P. A 3D dynamic numerical approach for temperature and thermal stress distributions in multilayer laser solid freeform fabrication process. Opt. Laser Eng. 2007, 45, 1115–1130. [Google Scholar] [CrossRef]

- Dai, D.P.; Jiang, X.H.; Cai, J.P.; Lu, F.G.; Chen, Y.; Li, Z.G.; Deng, D. Numerical simulation of temperature field and stress distribution in Inconel718 Ni base alloy induced by laser cladding. Chin. J. Lasers 2015, 42, 0903005. [Google Scholar]

- Xueliang, K.; Shiyun, D.; Hongbin, W.; Shixing, Y.; Xiaoting, L.; Binshi, X. Effect of laser power on gradient microstructure of low-alloy steel built by laser melting deposition. Mater. Lett. 2020, 262, 127073. [Google Scholar]

- Kiran, A.; Hodek, J.; Vavřík, J.; Urbánek, M.; Džugan, J. Numerical simulation development and computational optimization for directed energy deposition additive manufacturing process. Materials 2020, 13, 2666. [Google Scholar] [CrossRef]

- Gharbi, M.; Peyre, P.; Gorny, C.; Carin, M.; Morville, S.; Le Masson, P.; Carron, D.; Fabbro, R. Influence of various process conditions on surface finishes induced by the direct metal deposition laser technique on a Ti-6Al-4V alloy. J. Mater. Process. Technol. 2013, 213, 791–800. [Google Scholar] [CrossRef] [Green Version]

- Qu, H.P.; Wang, H.M. Microstructure and mechanical properties of laser melting deposited γ-TiAl intermetallic alloys. Mater. Sci. Eng. A 2007, 466, 187–194. [Google Scholar] [CrossRef]

- Cottam, R.; Thorogood, K.; Lui, Q.; Wong, Y.C.; Brandt, M. The effect of laser cladding deposition rate on residual stress formation in Ti-6Al-4V clad layers. Key Eng. Mater. 2012, 520, 309–313. [Google Scholar] [CrossRef]

- Miao, X.; Wu, M.; Han, J.; Li, H.; Ye, X. Effect of laser rescanning on the characteristics and residual stress of selective laser melted titanium Ti6Al4V alloy. Materials 2020, 13, 3940. [Google Scholar] [CrossRef]

- Li, J.; Wang, H.M. Microstructure and mechanical properties of rapid directionally solidified Ni-base superalloy Rene’41 by laser melting deposition manufacturing. Mater. Sci. Eng. A 2010, 527, 4823–4829. [Google Scholar] [CrossRef]

- Schnier, G.; Wood, J.; Galloway, A. Investigating the effects of process variables on the residual stresses of weld and laser cladding. Adv. Mater. Res. 2014, 996, 481–487. [Google Scholar] [CrossRef] [Green Version]

- Nazemi, N.; Urbanic, R.J. A numerical investigation for alternative toolpath deposition solutions for surface cladding of stainless steel P420 powder on AISI 1018 steel substrate. Int. J. Adv. Manuf. Technol. 2018, 96, 4123–4143. [Google Scholar] [CrossRef]

- Amine, T.; Newkirk, J.W.; Liou, F. Numerical simulation of the thermal history multiple laser deposited layers. Int. J. Adv. Manuf. Technol. 2014, 73, 1625–1631. [Google Scholar] [CrossRef]

- Yong, Y.; Fu, W.; Deng, Q.; Chen, D. A comparative study of vision detection and numerical simulation for laser cladding of nickel-based alloy. J. Manuf. Process. 2017, 28, 364–372. [Google Scholar] [CrossRef]

- Zhang, J.; Song, J.L.; Li, Y.T.; Chen, F. Numerical simulation of the temperature field in multi-layer powder-feeding laser cladding forming. Appl. Mech. Mater. 2012, 1867, 1418–1423. [Google Scholar] [CrossRef]

- Hua, L.; Tian, W.; Liao, W.; Zeng, C. Numerical simulation of temperature field and residual stress distribution for laser cladding remanufacturing. Adv. Mech. Eng. 2014, 6, 413–422. [Google Scholar] [CrossRef]

- Ding, L.; Li, M.X.; Huang, D.Y.; Jang, H.Y. Numerical simulation of temperature field and stress field to multiple laser cladding Co coatings. Appl. Mech. Mater. 2014, 2839, 382–387. [Google Scholar] [CrossRef]

- Kovacevic, R.; Zhang, Z.; Farahmand, P. Laser cladding of 420 stainless steel with molybdenum on mild steel A36 by a high power direct diode laser. Mater. Des. 2016, 109, 686–699. [Google Scholar]

- Shi, Q.M.; Gu, D.D.; Dai, D.H.; Du, L.; Ma, C.L.; Xia, M.J. Relation of thermal behavior and microstructure evolution during multi-track laser melting deposition of Ni-based material. Opt. Laser Technol. 2018, 108, 207–217. [Google Scholar]

- Zhanyong, Z.; Liang, L.; Le, T.; Peikang, B.; Jing, L.; Liyun, W. Simulation of Stress Field during the Selective Laser Melting Process of the Nickel-Based Superalloy, GH4169. Materials 2018, 11, 1525. [Google Scholar]

- Xuan, Z.; Yaohui, L.; Shiyun, D.; Shixing, Y.; Xiaoting, L.; Yuxin, L.; Peng, H.; Tiesong, L.; Binshi, X.; Hongsheng, H. The martensitic strengthening of 12CrNi2 low-alloy steel using a novel scanning strategy during direct laser deposition. Opt. Laser Technol. 2020, 132, 106487. [Google Scholar]

- GB/T22588-2008. Determination of Thermal Diffusivity or Thermal Conductivity by the Flash Method; Standardization Administration of China Standardization Administrat: Beijing, China, 2008.

- GB/T 228.2-2015. Metallic Materials-Tensile Testing-Part 2: Method of Test at Elevated Temperature; China Iron and Steel Association: Beijing, China, 2015. [Google Scholar]

| Element | C | Fe | Si | Cr | Ni | Mn | O |

|---|---|---|---|---|---|---|---|

| Content | 0.12 | Bal | 0.34 | 1 | 1.59 | 0.57 | 0.008 |

| Parameter Name | The Sample Size | Test Standards or Equipment |

|---|---|---|

| The thermal conductivity and specific heat capacity | φ12.5 mm × 2.5 mm | GB/T22588-2008 [44] |

| Density | φ15 mm × 35 mm | UAE/PH-TDWN010 automatic true density analyzer |

| The thermal expansion coefficient | φ3 mm × 50 mm | Thermal expansion analyzer (Baehr, Pirmasens Germany) |

| Name | Experimental Value | Simulation Value | Error |

|---|---|---|---|

| The width of melt pool/mm | 3.46 | 3.32 | 4% |

| The depth of melt pool/mm | 1.04 | 0.94 | 9.6% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, Z.; Hu, X.; Dong, S.; Yan, S.; Zhao, X. Numerical Simulation and Experimental Study on Residual Stress in the Curved Surface Forming of 12CrNi2 Alloy Steel by Laser Melting Deposition. Materials 2020, 13, 4316. https://doi.org/10.3390/ma13194316

Cui Z, Hu X, Dong S, Yan S, Zhao X. Numerical Simulation and Experimental Study on Residual Stress in the Curved Surface Forming of 12CrNi2 Alloy Steel by Laser Melting Deposition. Materials. 2020; 13(19):4316. https://doi.org/10.3390/ma13194316

Chicago/Turabian StyleCui, Zhaoxing, Xiaodong Hu, Shiyun Dong, Shixing Yan, and Xuan Zhao. 2020. "Numerical Simulation and Experimental Study on Residual Stress in the Curved Surface Forming of 12CrNi2 Alloy Steel by Laser Melting Deposition" Materials 13, no. 19: 4316. https://doi.org/10.3390/ma13194316