Study on Strengthening Mechanism of 9Cr-1.5Mo-1Co and 9Cr-3W-3Co Heat Resistant Steels

Abstract

1. Introduction

2. Materials and Methods

3. Results

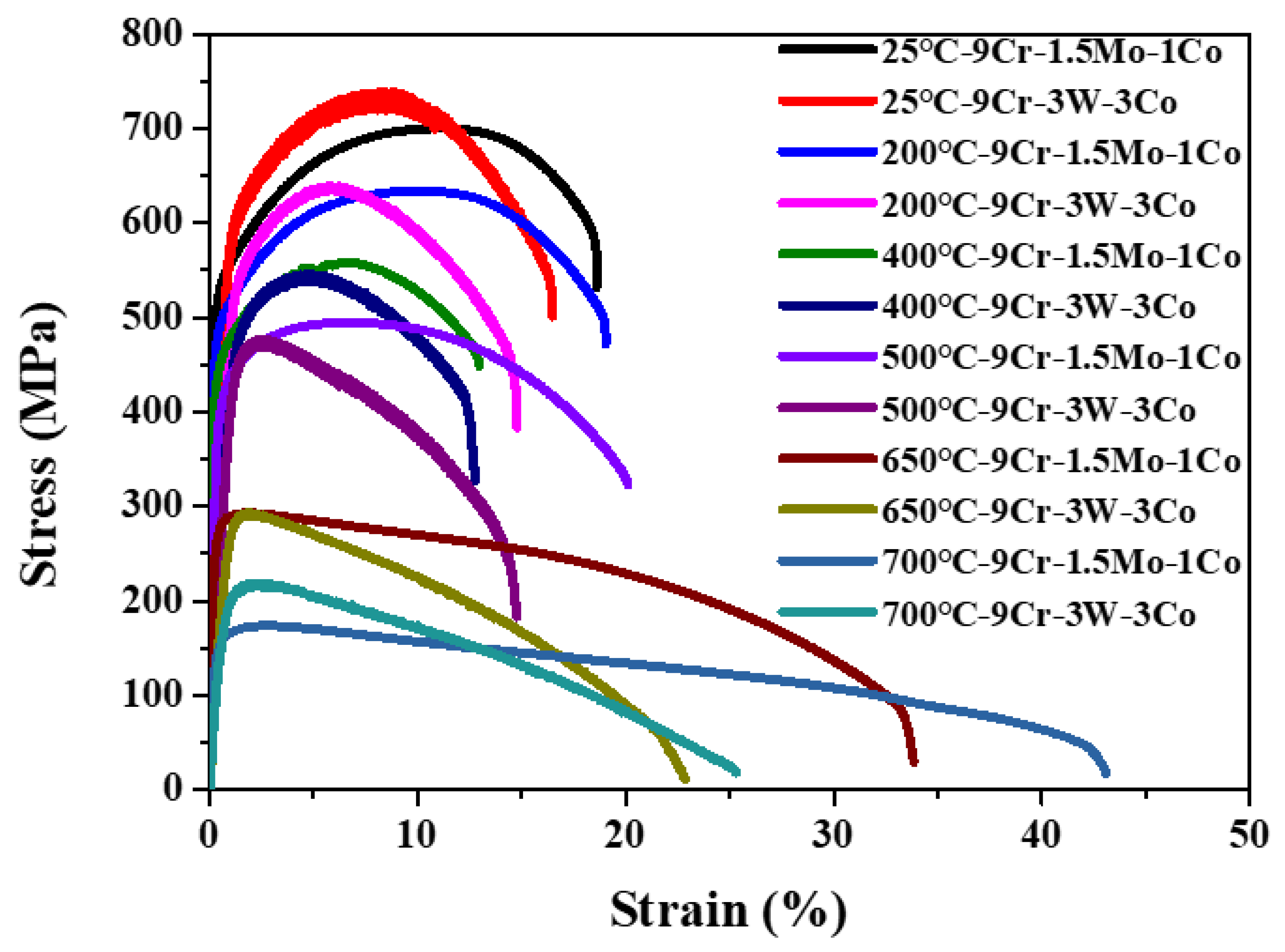

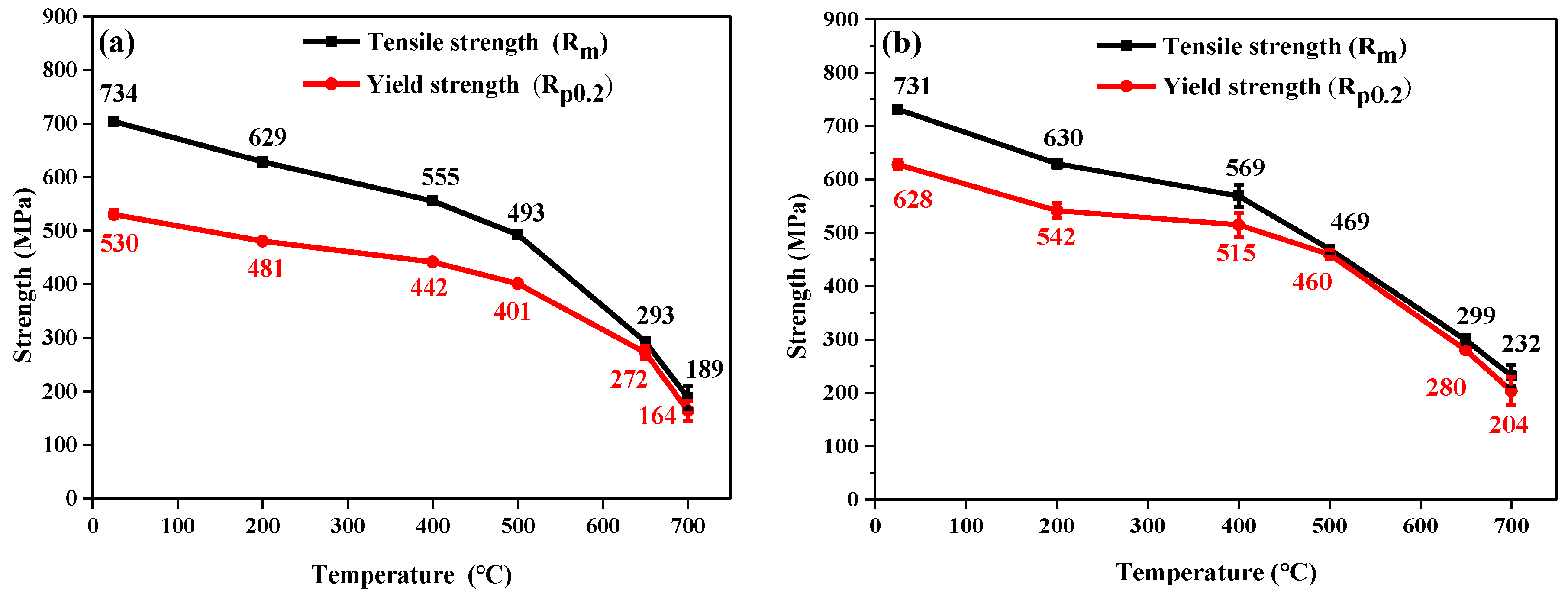

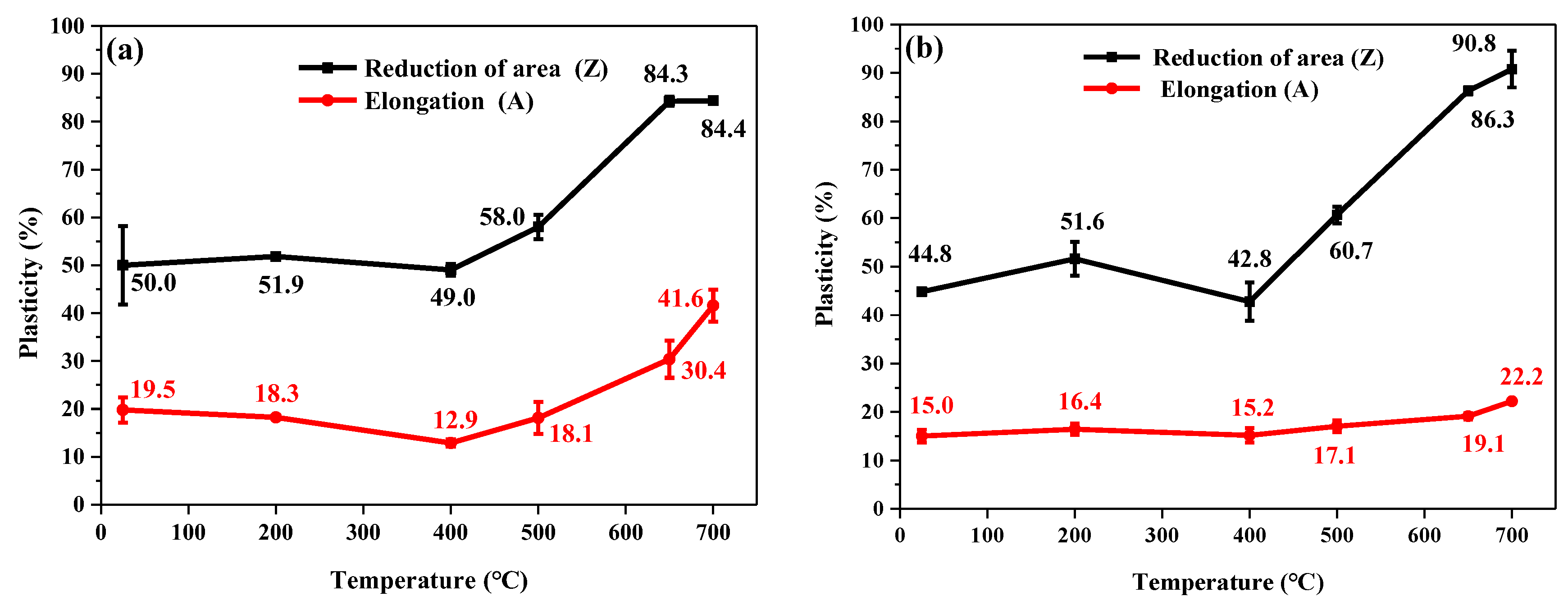

3.1. Evolution of High-Temperature Strength under As-Received

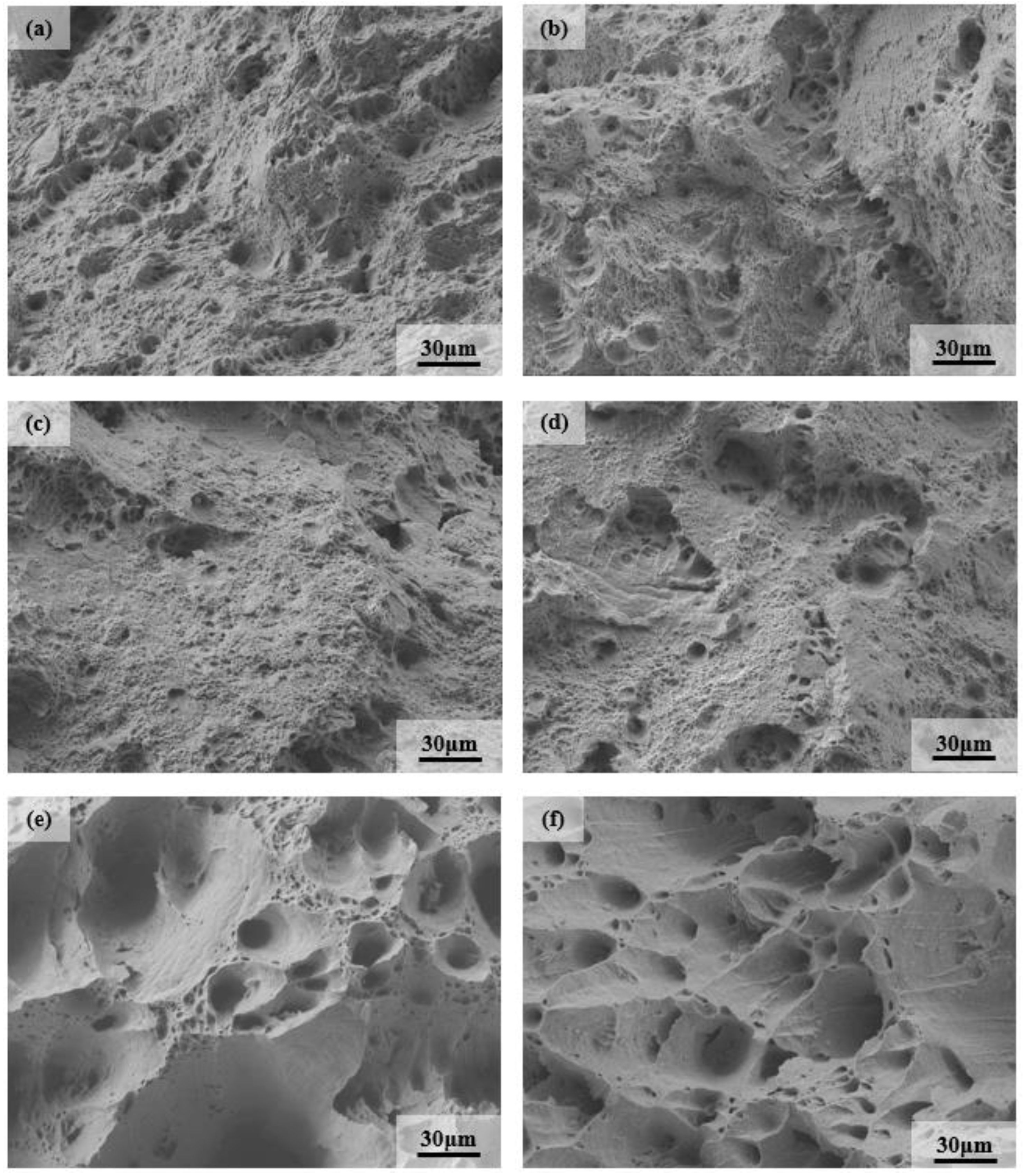

3.2. Analysis of Fracture Morphology after High Temperature Tensile

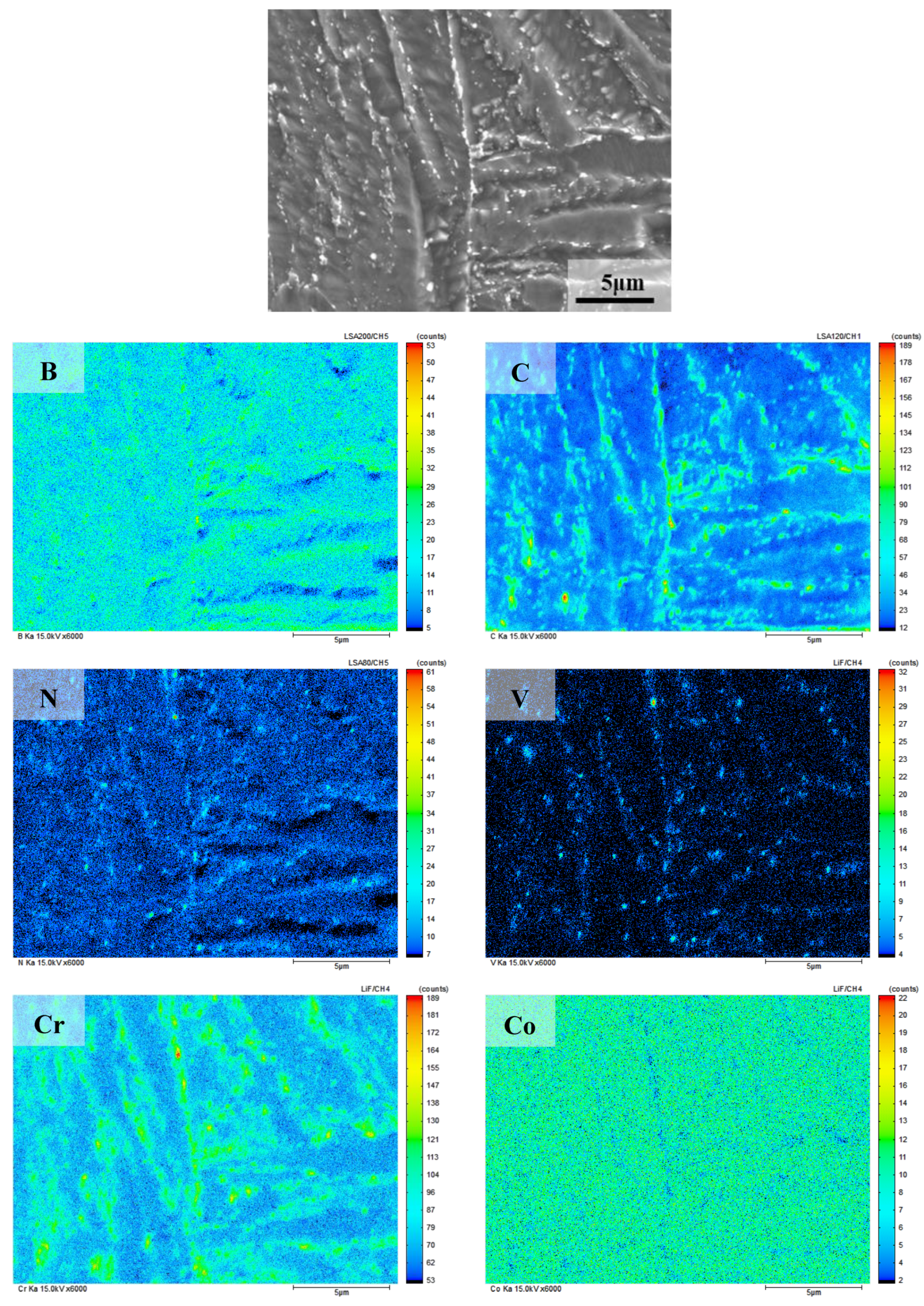

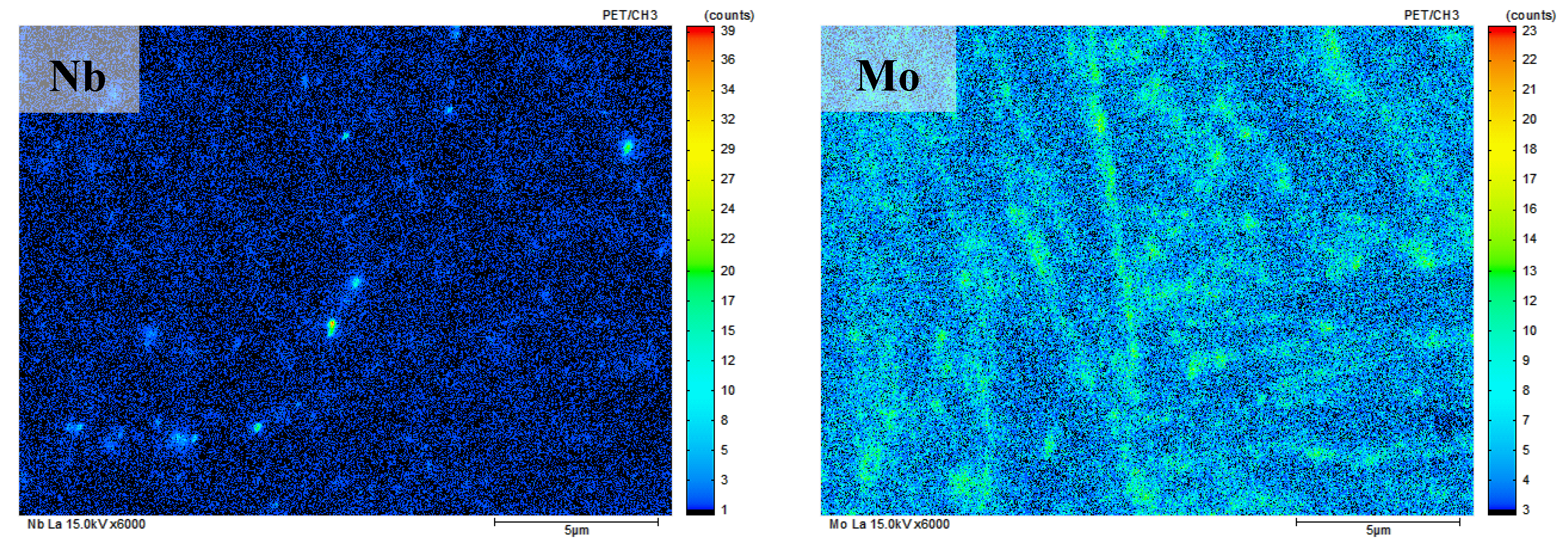

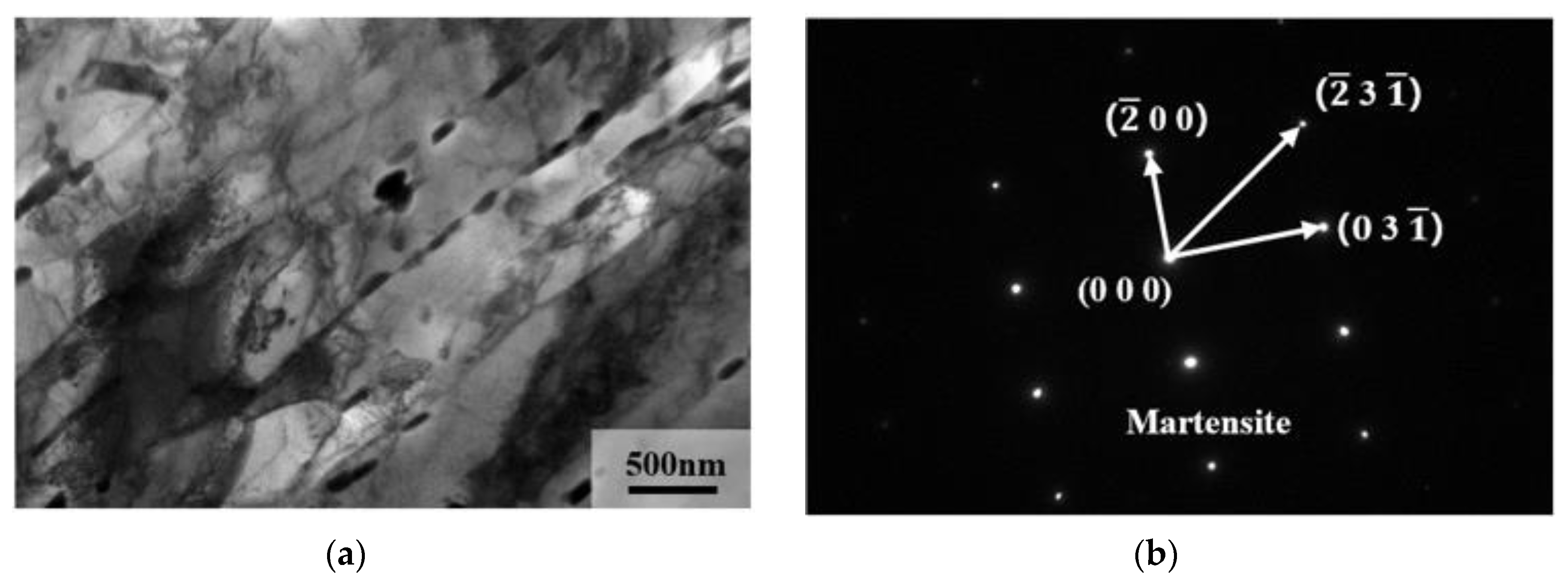

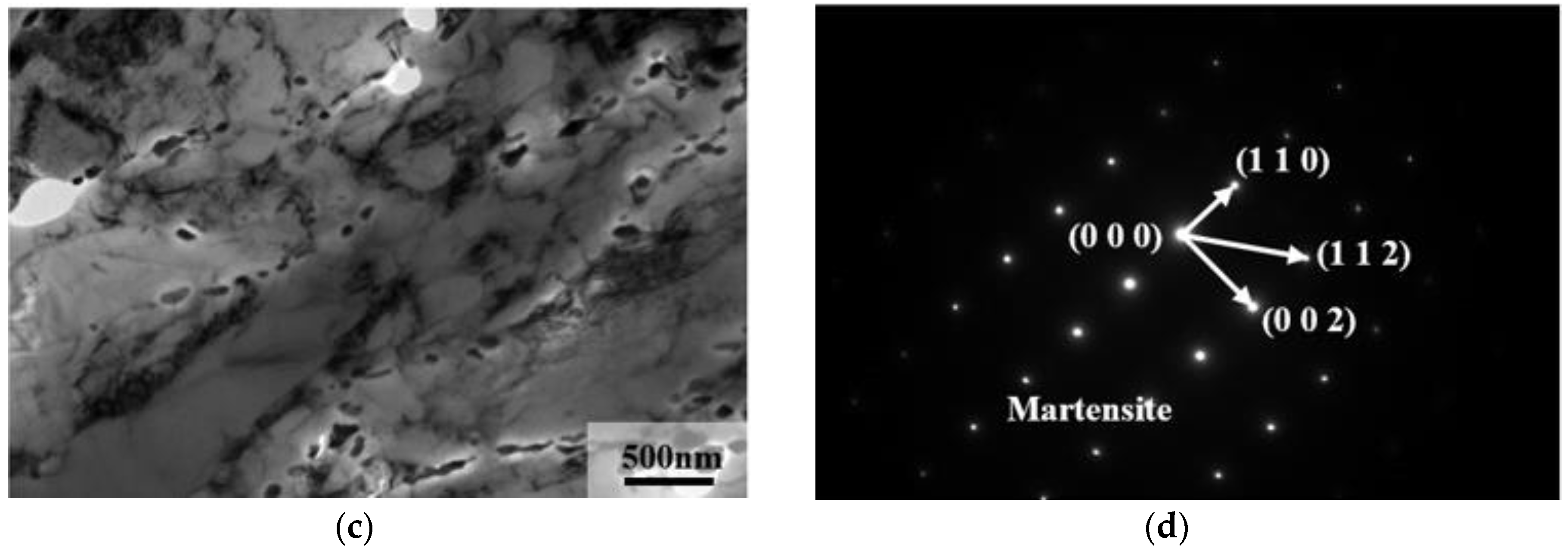

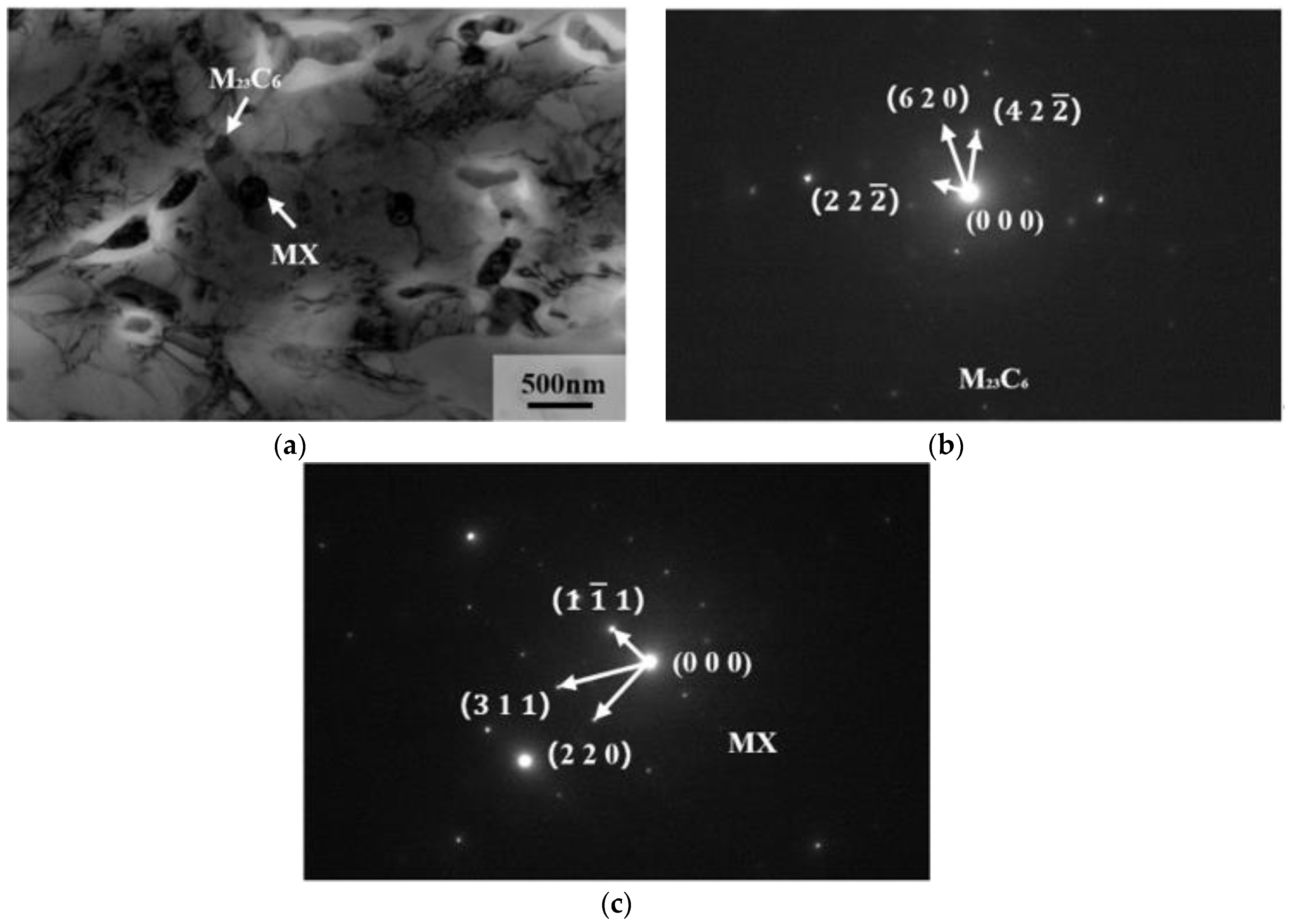

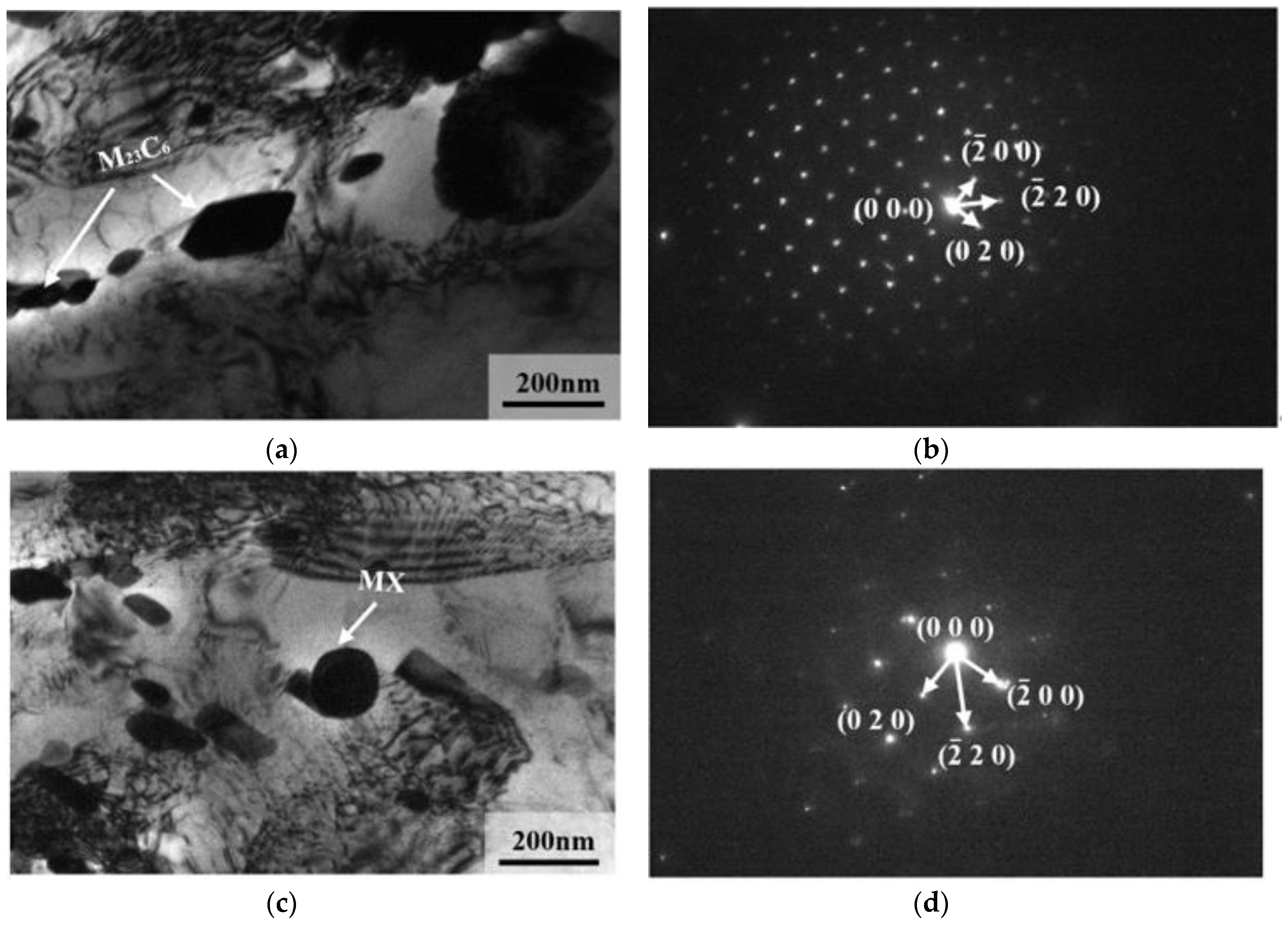

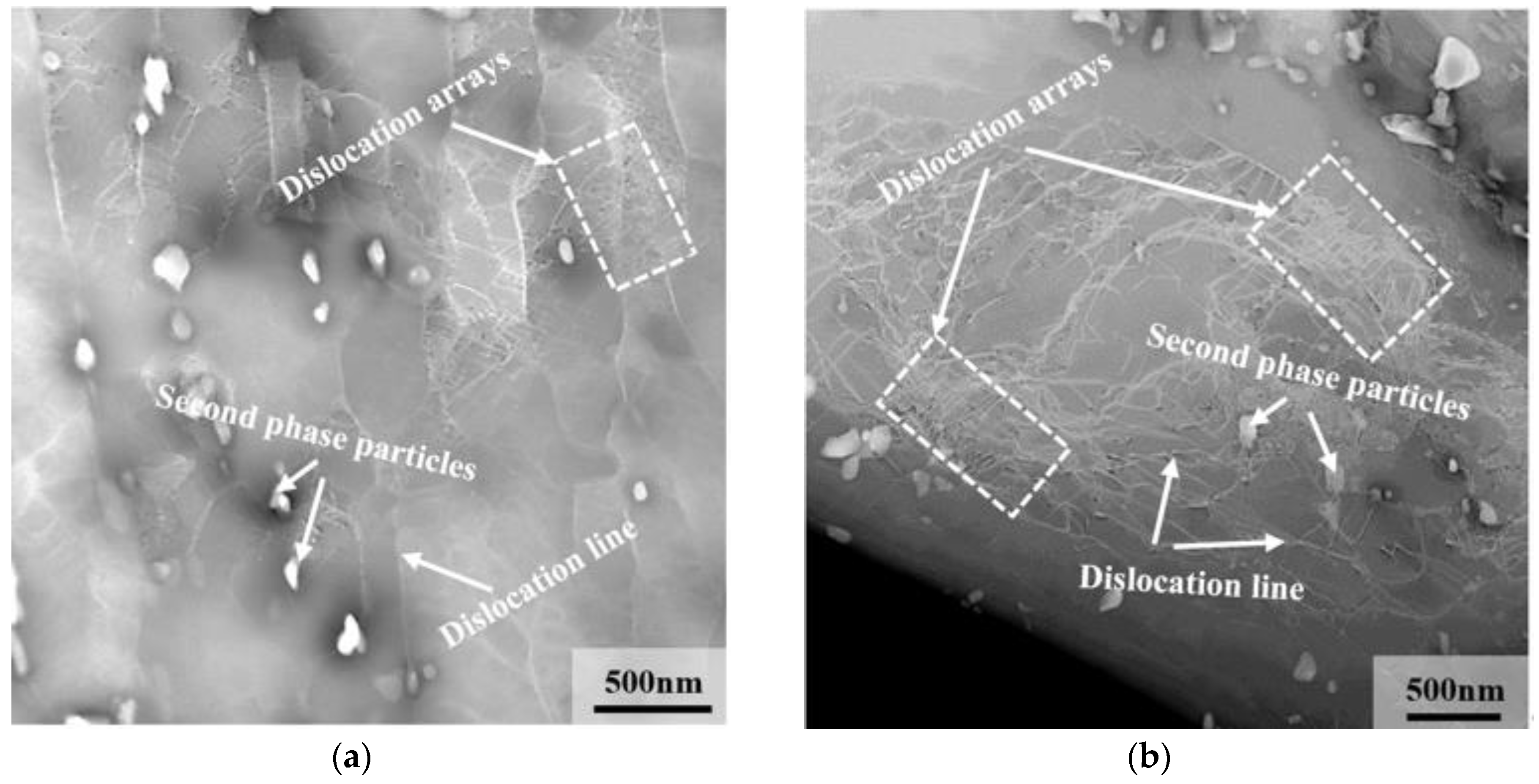

3.3. Microstructural Characterization of the As-Received Steel

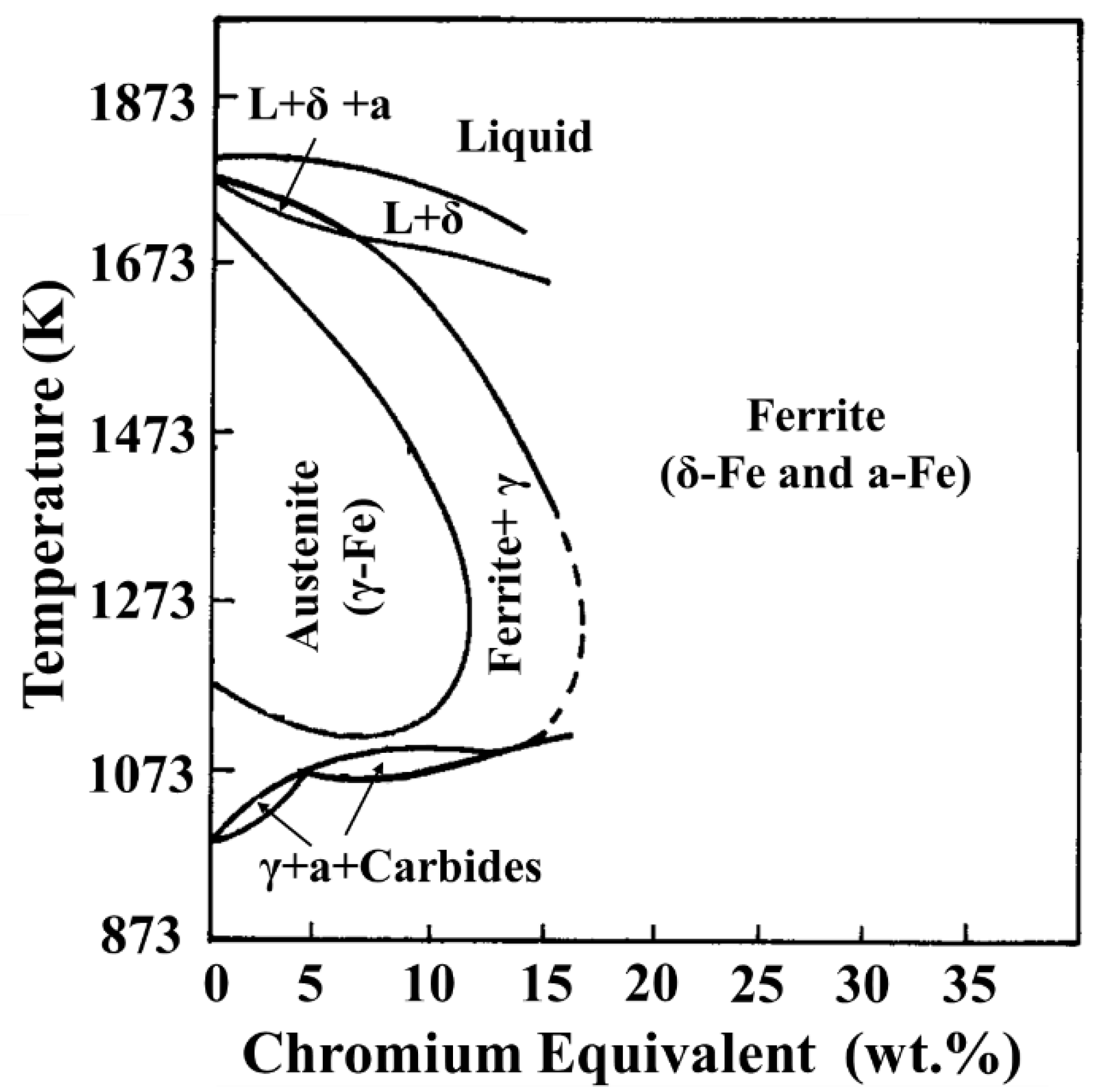

4. Discussion

40 × %C − 2 × %Mn − 4 × %Ni − 2 × %Co − 30 × %N − %Cu

5. Conclusions

- At the same temperature, the overall yield strength of 9Cr–3W–3Co heat-resistant steel is better than that of 9Cr–1.5Mo–1Co heat-resistant steel. At room temperature, the yield strength of 9Cr–3W–3Co heat-resistant steel is 628 MPa, while that of 9Cr–1.5Mo–1Co heat-resistant steel is 530 MPa. When the tensile temperature is increased to 700 °C, the yield strength of 9Cr–3W–3Co heat-resistant steel is 204 MPa, while that of 9Cr–1.5Mo–1Co heat-resistant steel is 164 MPa.

- The strength of 9Cr–3W–3Co heat-resistant steel and 9Cr–1.5Mo–1Co heat-resistant steel is affected by grain boundary, dislocation, precipitation, and solid solution atoms, but the width of the martensitic lath of 9Cr–1.5Mo–1Co heat-resistant steel is smaller than that of 9Cr–3W–3Co heat-resistant steel, and the dislocation density of 9Cr–3W–3Co heat-resistant steel is larger than that of 9Cr–1.5Mo–1Co heat-resistant steel.

- The excellent high-temperature mechanical properties of 9Cr–3W–3Co heat-resistant steel are mainly attributed to the solution strengthening caused by Co and W atoms and the high-density dislocations distributed in the matrix, while the precipitates are mainly pinned dislocations and hinder the movement of dislocations. However, the high temperature strength of 9Cr–1.5Mo–1Co heat-resistant steel is mainly due to the refinement and precipitation of the martensitic lath and the pinning of the grain boundary.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Abe, F.; Kern, T.U.; Viswanathan, R. Creep-Resistant Steels, Encyclopedia of Materials: Ence and Technology (Second Edition). Mat. Sci. 2001, 16, 1840–1845. [Google Scholar] [CrossRef]

- Viswanathan, R.; Henry, J.F.; Tanzosh, J.G.; Stanko, G.; Shingledecker, J.; Vitalis, B.; Purgert, R. US Program on Materials Technology for Ultra-Supercritical Coal Power Plants. J. Mater. Eng. Perform. 2013, 22, 2904–2915. [Google Scholar] [CrossRef]

- Abe, F. Research and Development of Heat-Resistant Materials for Advanced USC Power Plants with Steam Temperatures of 700 degrees C and above. Engineering 2015, 1, 211–224. [Google Scholar] [CrossRef]

- Abe, F. Progress in Creep-Resistant Steels for High Efficiency Coal-Fired Power Plants. J. Press Vessel Technol. 2016, 138, 040840. [Google Scholar] [CrossRef]

- Masuyama, F. History of power plants and progress in heat resistant steels. ISIJ Int. 2001, 41, 612–625. [Google Scholar] [CrossRef]

- Abe, F. Precipitate design for creep strengthening of 9% Cr tempered martensitic steel for ultra-supercritical power plants. Sci. Technol. Adv. Mater. 2008, 9, 1. [Google Scholar] [CrossRef]

- Viswanathan, R.; Bakker, W. Materials for ultrasupercritical coal power plants-boiler materials: Part 1. J. Mater. Eng. Perform. 2001, 10, 81–95. [Google Scholar] [CrossRef]

- Vivas, J.; Capdevila, C.; Altstadt, E.; Houska, M.; Sabirov, I.; San-Martín, D. Microstructural Degradation and Creep Fracture Behavior of Conventionally and Thermomechanically Treated 9% Chromium Heat Resistant Steel. Met. Mater. Int. 2019, 25, 343–352. [Google Scholar] [CrossRef]

- Aghajani, A.; Somsen, C.; Eggeler, G. On the effect of long-term creep on the microstructure of a 12% chromium tempered martensite ferritic steel. Acta Mater. 2009, 57, 5093–5106. [Google Scholar] [CrossRef]

- Fournier, B.; Dalle, F.; Sauzay, M.; Longour, J.; Salvi, M.; Caes, C.; Tournie, I.; Giroux, P.F.; Kim, S.H. Comparison of various 9–12%Cr steels under fatigue and creep-fatigue loadings at high temperature. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2011, 528, 6934–6945. [Google Scholar] [CrossRef]

- Jin, X.; Zhu, B.; Li, Y.; Zhao, Y.; Xue, F.; Zhang, G. Effect of the microstructure evolution on the high-temperature strength of P92 heat-resistant steel for different service times. Int. J. Press. Vessel. Pip. 2020, 186, 104131. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Z.; Wang, X.; Chen, Z.; Ma, L. Evolution of the microstructure in aged G115 steels with the different concentration of tungsten. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2018, 729, 161–169. [Google Scholar] [CrossRef]

- Xiao, B.; Xu, L.; Zhao, L.; Jing, H.; Han, Y.; Song, K. Transient creep behavior of a novel tempered martensite ferritic steel G115. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2019, 742, 628. [Google Scholar] [CrossRef]

- Saini, N.; Mulik, R.S.; Mahapatra, M.M. Study on the effect of ageing on laves phase evolution and their effect on mechanical properties of P92 steel. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2018, 716, 179–188. [Google Scholar] [CrossRef]

- Dudova, N.; Plotnikova, A.; Molodov, D.; Belyakov, A.; Kaibyshev, R. Structural changes of tempered martensitic 9%Cr-2%W-3%Co steel during creep at 650 degrees C. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2012, 534, 632–639. [Google Scholar] [CrossRef]

- Jia, C.H.; Liu, Y.C.; Liu, C.X.; Li, C.; Li, H.J. Precipitates evolution during tempering of 9CrMoCoB (CB2) ferritic heat-resistant steel. Mater. Charact. 2019, 152, 12–20. [Google Scholar] [CrossRef]

- Taneike, M.; Abe, F.; Sawada, K. Creep-strengthening of steel at high temperatures using nano-sized carbonitride dispersions. Nature 2003, 424, 294–296. [Google Scholar] [CrossRef] [PubMed]

- Sawada, K.; Kubo, K.; Abe, F. Creep behavior and stability of MX precipitates at high temperature in 9Cr-0.5Mo-1.8W-VNb steel. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2001, 319, 784–787. [Google Scholar] [CrossRef]

- Du, Y.; Li, X.; Zhang, X.; Chung, Y.W.; Isheim, D.; Vaynman, S. Design and Characterization of a Heat-Resistant Ferritic Steel Strengthened by MX Precipitates. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2020, 51, 638–647. [Google Scholar] [CrossRef]

- Yan, P.; Liu, Z.; Bao, H.; Weng, Y.; Liu, W. Effect of microstructural evolution on high-temperature strength of 9Cr-3W-3Co martensitic heat resistant steel under different aging conditions. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2013, 588, 22–28. [Google Scholar] [CrossRef]

- Yan, P.; Liu, Z.; Bao, H.; Weng, Y.; Liu, W. Effect of tempering temperature on the toughness of 9Cr-3W-3Co martensitic heat resistant steel. Materials Design. 2014, 54, 874–879. [Google Scholar] [CrossRef]

- Wang, S.S.; Peng, D.L.; Chang, L.; Hui, X.D. Enhanced mechanical properties induced by refined heat treatment for 9Cr-0.5Mo-1.8W martensitic heat resistant steel. Mater. Des 2013, 50, 174–180. [Google Scholar] [CrossRef]

- Nikitin, I.; Fedoseeva, A.; Kaibyshev, R. Strengthening mechanisms of creep-resistant 12%Cr-3%Co steel with low N and high B contents. J. Mater. Sci. 2020, 55, 7530–7545. [Google Scholar] [CrossRef]

- Kostka, A.; Tak, K.G.; Hellmig, R.; Estrin, Y.; Eggeler, G. On the contribution of carbides and micrograin boundaries to the creep strength of tempered martensite ferritic steels. Acta Mater. 2007, 55, 539–550. [Google Scholar] [CrossRef]

- Rojas, D.; Garcia, J.; Prat, O.; Carrasco, C.; Sauthoff, G.; Kaysser-Pyzalla, A.R. Design and characterization of microstructure evolution during creep of 12% Cr heat resistant steels. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2010, 527, 3864–3876. [Google Scholar] [CrossRef]

- Guguloth, K.; Roy, N. Study on the creep deformation behavior and characterization of 9Cr-1Mo-V-Nb steel at elevated temperatures. Mater. Charact. 2018, 146, 279–298. [Google Scholar] [CrossRef]

- Wang, S.; Chang, L.; Lin, D.; Chen, X.; Hui, X. High Temperature Strengthening in 12Cr-W-Mo Steels by Controlling the Formation of Delta Ferrite. Met. Mater. Trans. A 2014, 45, 4371–4385. [Google Scholar] [CrossRef]

- Kipelova, A.; Kaibyshev, R.; Belyakov, A.; Molodov, D. Microstructure evolution in a 3% Co modified P911 heat resistant steel under tempering and creep conditions. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2011, 528, 1280–1286. [Google Scholar] [CrossRef]

- George, G.; Shaikh, H.; Parvathavarthini, N.; George, R.P.; Khatak, H.S. On the microstructure-polarization behavior correlation of a 9Cr-1Mo steel weld joint. J. Mater. Eng. Perform. 2001, 10, 460–467. [Google Scholar] [CrossRef]

- Maruyama, K.; Sawada, K.; Koike, J.I. Strengthening mechanisms of creep resistant tempered martensitic steel. ISIJ Int. 2001, 41, 641–653. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Cr | Mo | Ni | V | Nb | Co | W |

|---|---|---|---|---|---|---|---|---|---|---|

| 9Cr-1.5Mo-1Co | 0.05~0.15 | 0.2~0.4 | 0.5~1 | 9~12 | 1.5 | 0~0.3 | 0~0.3 | 0~0.1 | 1.00 | 0 |

| 9Cr-3W-3Co | 0.05~0.15 | 0.2~0.4 | 0.5~1 | 9~12 | 0 | 0~0.3 | 0~0.3 | 0~0.1 | 3.00 | 2.80 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, L.; Chen, X.; Wu, T.; Zhai, Q. Study on Strengthening Mechanism of 9Cr-1.5Mo-1Co and 9Cr-3W-3Co Heat Resistant Steels. Materials 2020, 13, 4340. https://doi.org/10.3390/ma13194340

Zhao L, Chen X, Wu T, Zhai Q. Study on Strengthening Mechanism of 9Cr-1.5Mo-1Co and 9Cr-3W-3Co Heat Resistant Steels. Materials. 2020; 13(19):4340. https://doi.org/10.3390/ma13194340

Chicago/Turabian StyleZhao, Long, Xiangru Chen, Tieming Wu, and Qijie Zhai. 2020. "Study on Strengthening Mechanism of 9Cr-1.5Mo-1Co and 9Cr-3W-3Co Heat Resistant Steels" Materials 13, no. 19: 4340. https://doi.org/10.3390/ma13194340

APA StyleZhao, L., Chen, X., Wu, T., & Zhai, Q. (2020). Study on Strengthening Mechanism of 9Cr-1.5Mo-1Co and 9Cr-3W-3Co Heat Resistant Steels. Materials, 13(19), 4340. https://doi.org/10.3390/ma13194340