Mechanical Properties Analysis of the AA2519-AA1050-Ti6Al4V Explosive Welded Laminate

Abstract

1. Introduction

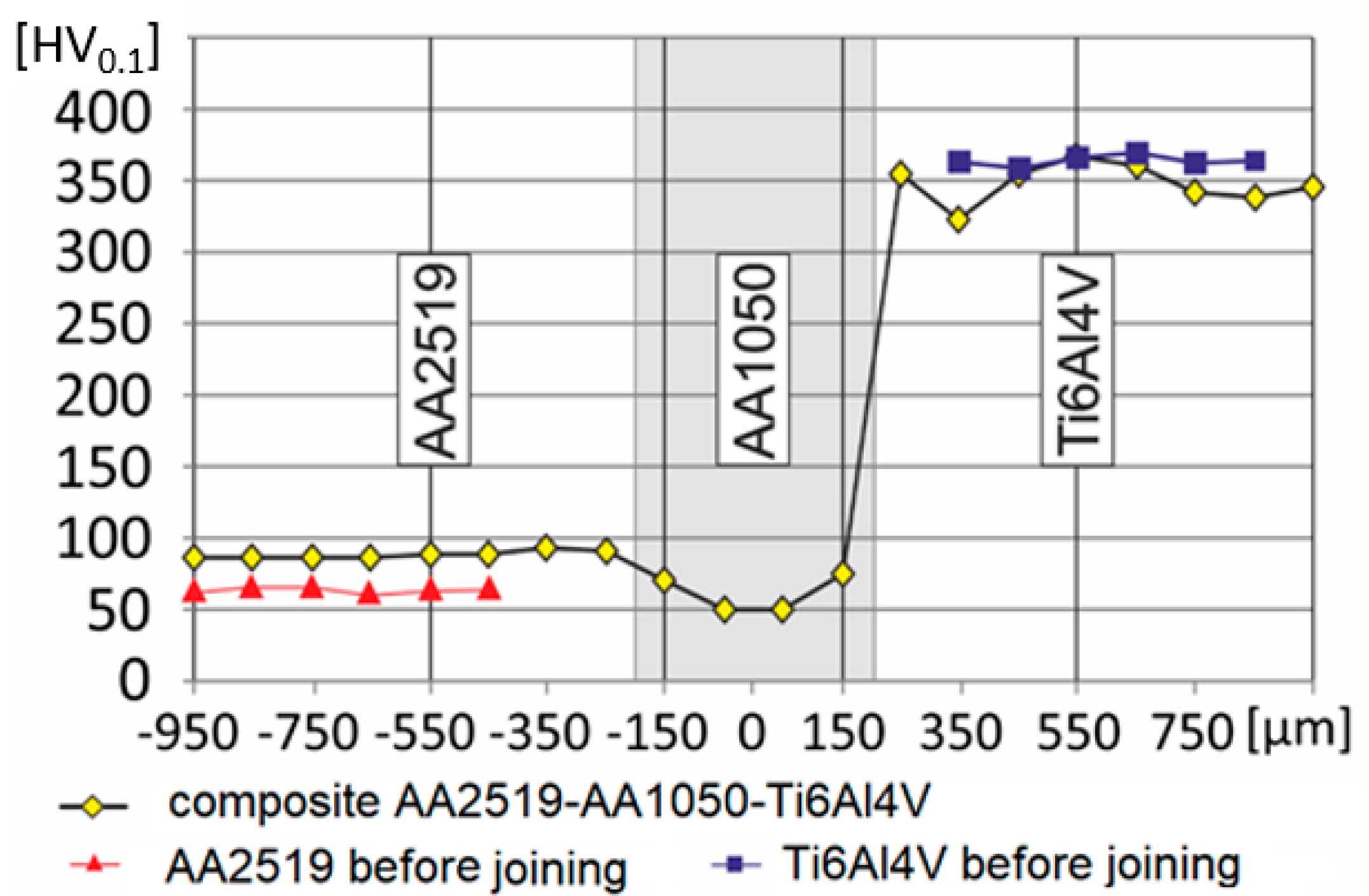

2. Materials

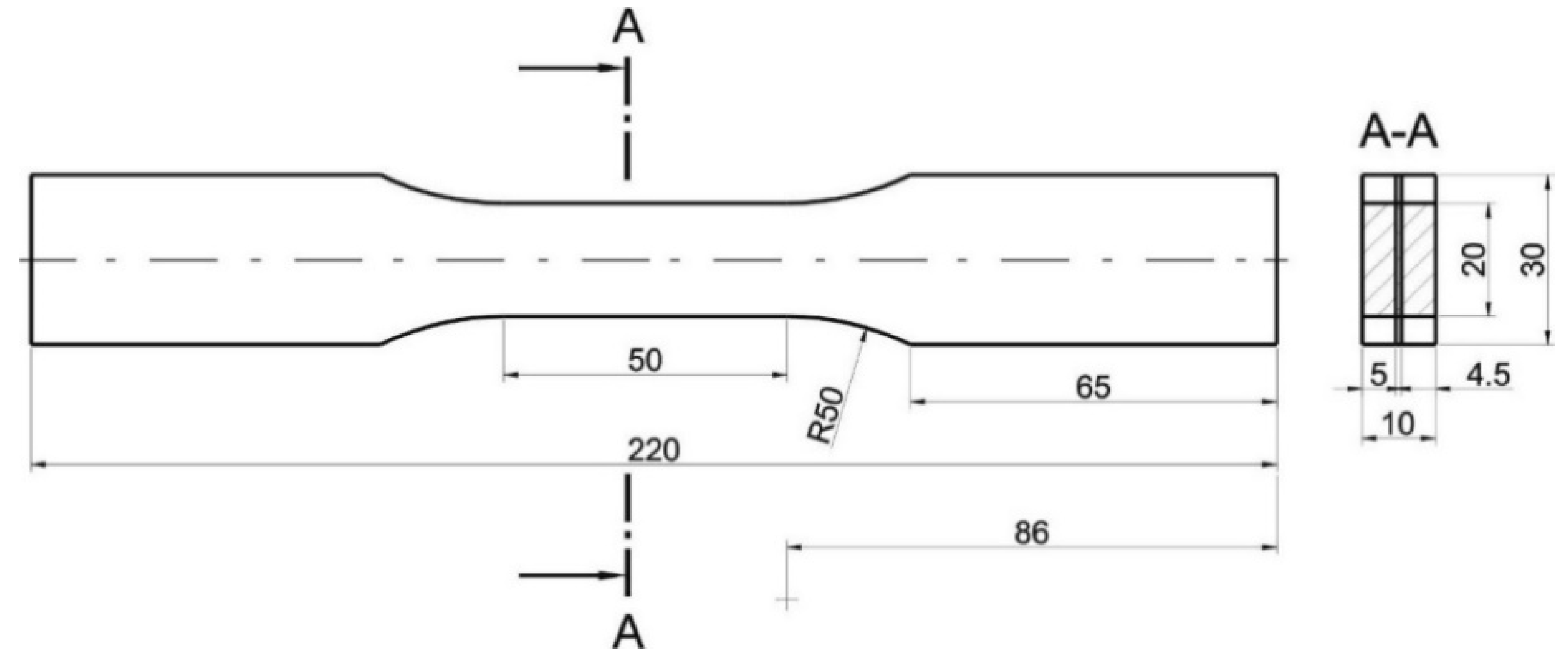

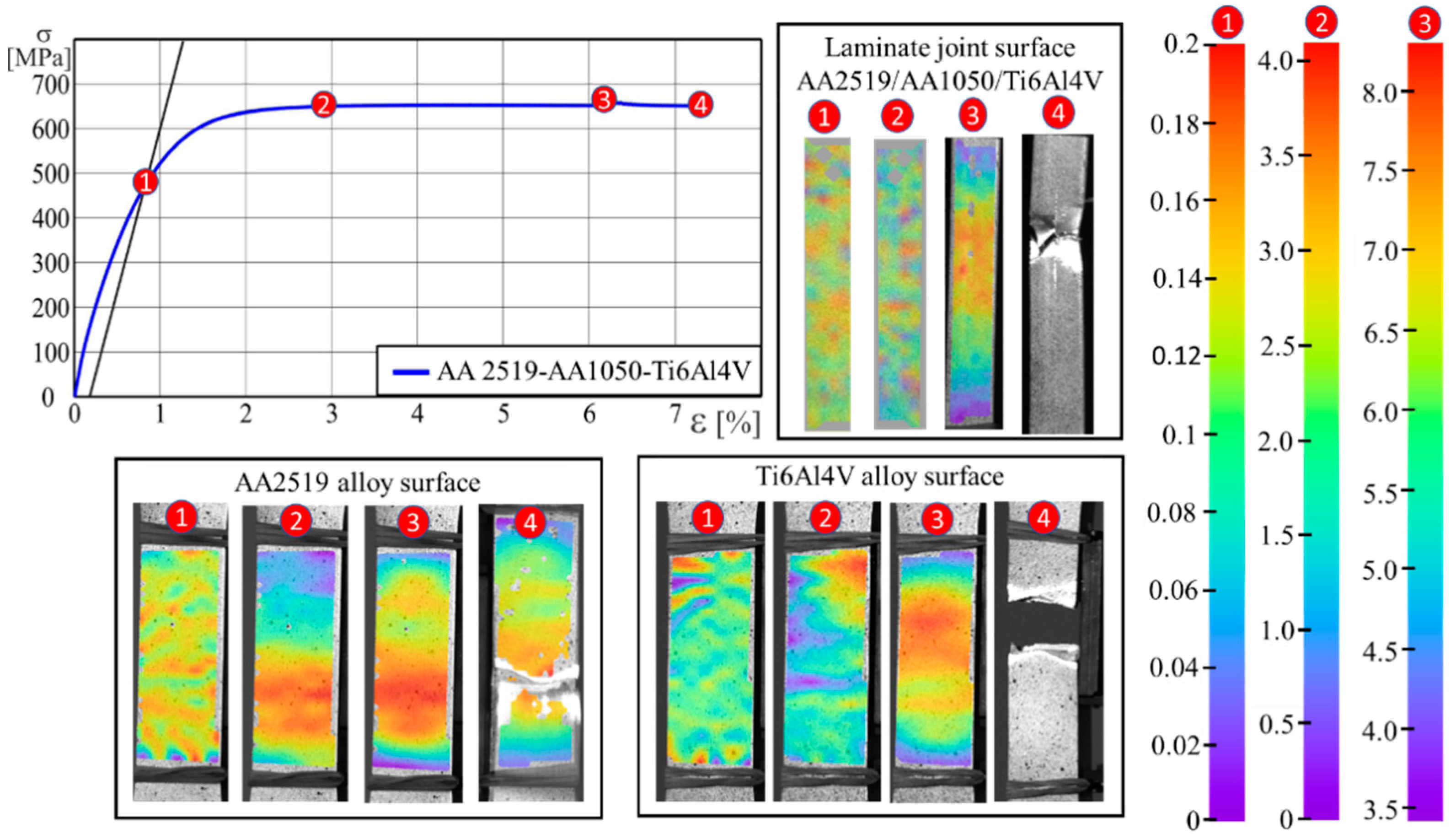

3. Testing Basic Strength Properties

4. Residual Stress Measurements

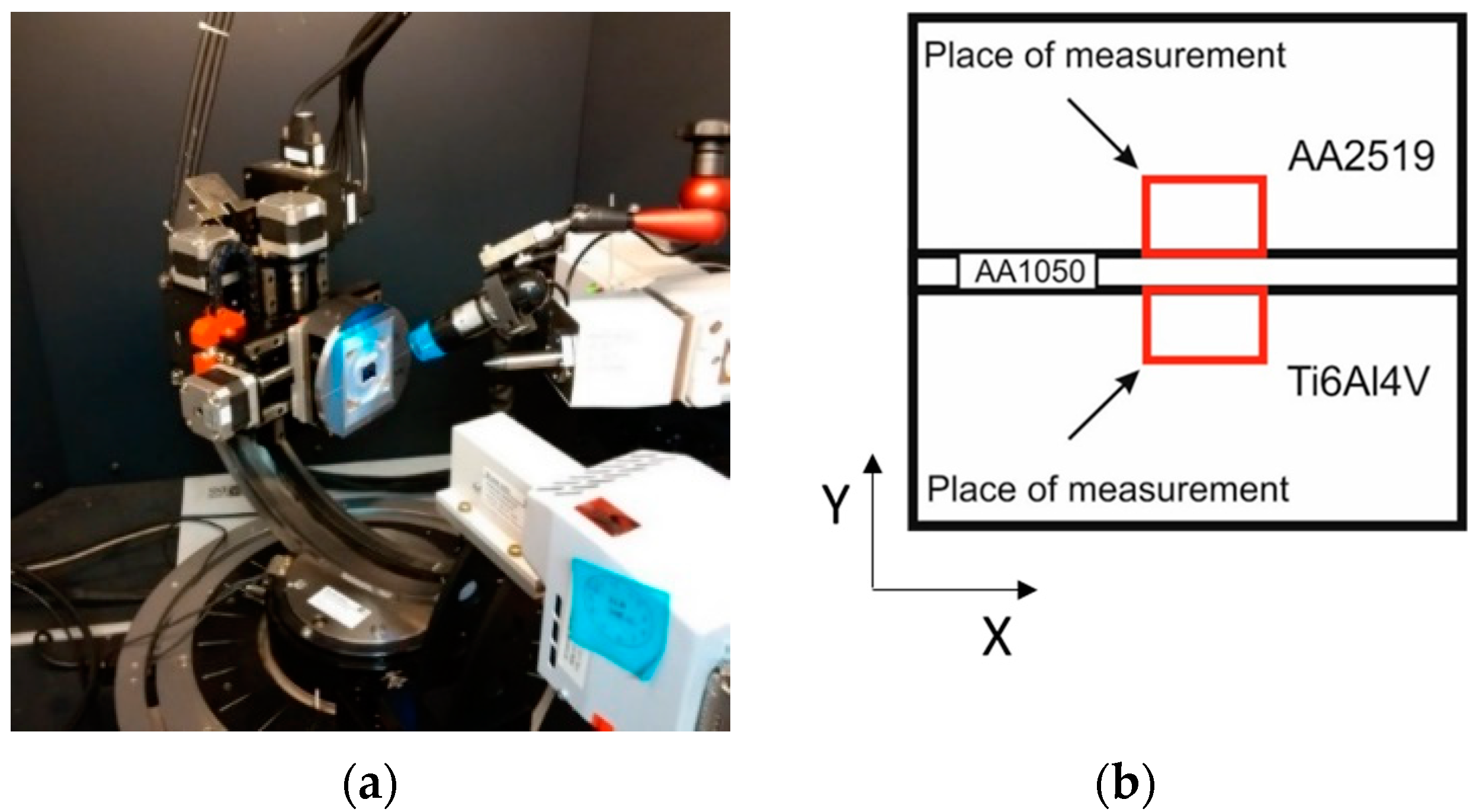

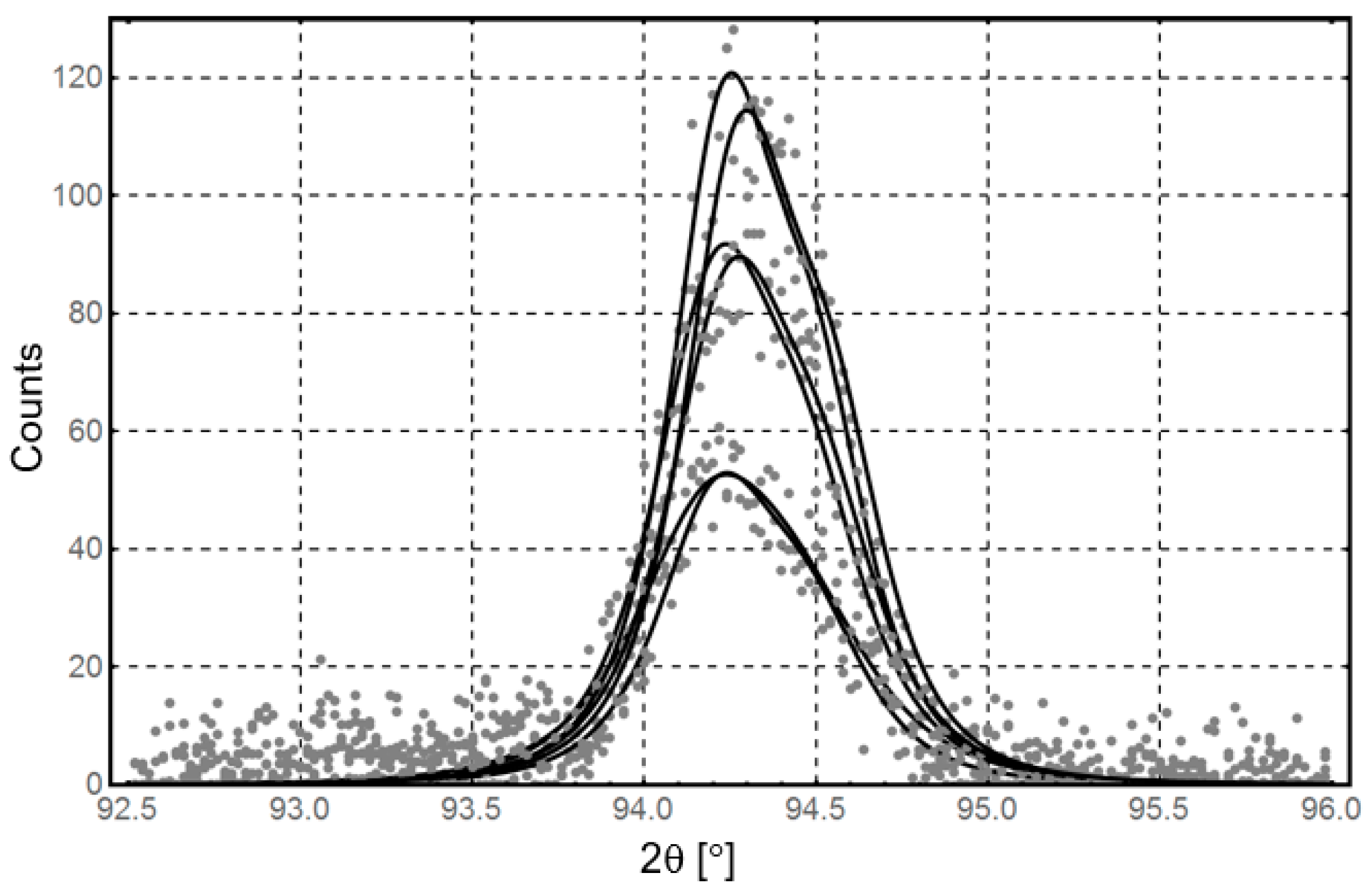

4.1. X-ray Stress Measurements

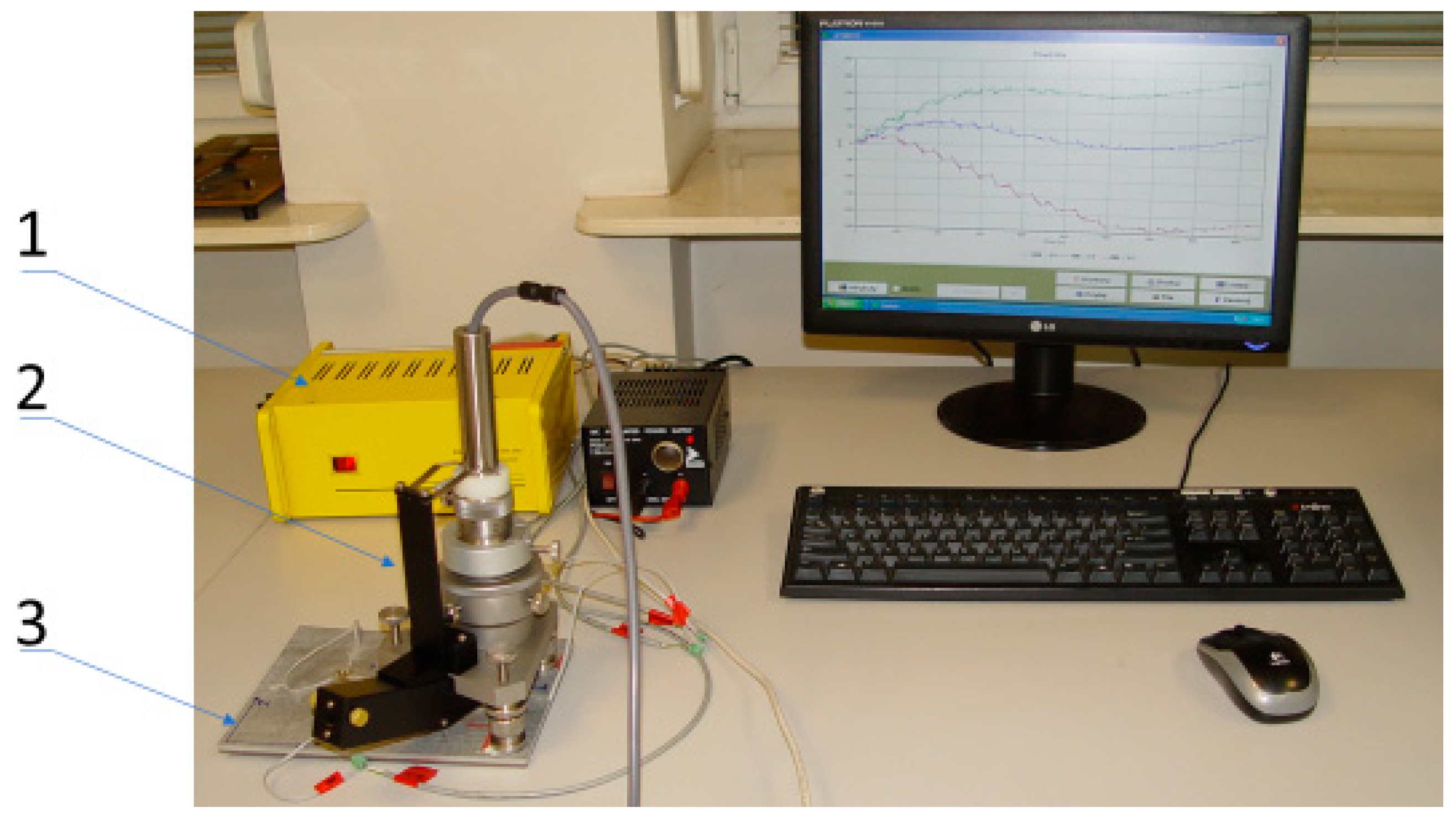

4.2. Residual Stresses Based on the Hole-Drilling Strain Gauge Method

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Crum, K.A.; McMichael, J.; Novak, M. Advances in aluminum relative to ship survivability. In Proceedings of the American Society of Naval Engineers Day 2012 Conference, Alexandria, VA, USA, 9–10 February 2012; American Society for Naval Engineers: Alexandria, VA, USA, 2012. [Google Scholar]

- Galka, A. Application of explosive metal cladding in manufacturing new advanced layered materials on the example of titanium Ti6Al4V—Aluminum AA2519 bond. Mater. Wysokoenerg./High-Energ. Mater. 2015, 7, 73–79. [Google Scholar]

- De Rosset, W.S.; Burkins, M.; Roopchand, B. Welding of Electron Beam Single Melt Ti-6Al-4V Plate; Army Reserch Laboratory: Adelphi, CA, USA, 2002. [Google Scholar]

- Dudek, Ł.; Hryniewicz, T.; Rokosz, K. Zastosowanie tytanu i wybranych stopów tytanu w lotnictwie. Autobusy 2016, 8, 62–66. [Google Scholar]

- Antolak-Dudka, A.; Płatek, P.; Durejko, T.; Baranowski, P.; Małachowski, J.; Sarzyński, M.; Czujko, T. Static and dynamic loading behavior of Ti6Al4V honeycomb structures manufactured by Laser Engineered Net Shaping (LENSTM) technology. Materials 2019, 12, 1225. [Google Scholar] [CrossRef]

- Courtesy of Boeing Commercial Airplane Group. New Materials for Next-Generation Commercial Transports Committee on New Materials for Advanced Civil Aircraft; Publication NMAB-476; National Academy Press: Washington, DC, USA, 1996. [Google Scholar]

- Crouch, I.G. Metallic armour e from cast aluminium alloys to high strength steels. Mater. Forum 1988, 12, 31–37. [Google Scholar]

- Dimiduk, D.M. Gamma titanium aluminide alloys—An assessment within the competition of aerospace structural materials. Mater. Sci. Eng. 1999, 263, 281–288. [Google Scholar] [CrossRef]

- National Research Council. Division on Engineering and Physical Sciences, Commission on Engineering and Technical Systems, Committee to Perform a Technology Assessment Focused on Logistics Support Requirements for Future Army Combat Systems, Reducing the Logistics Burden for the Army after Next: Doing More with Less; National Academies Press: Washington, DC, USA, 1999; p. 224. [Google Scholar]

- Szachogluchowicz, I.; Sniezek, L.; Mierzynski, J.; Koperski, W. Experimental study on ballistic AA 2519/Ti6Al4V laminate according to STANAG 4569 Level 1. In Proceedings of the 11th International Conference on Intelligent Technologies in Logistics and Mechatronics Systems, ITELMS 2016, Panevezys, Lithuania, 28–29 April 2016; pp. 155–163. [Google Scholar]

- Szachogluchowicz, I.; Sniezek, L.; Hutsaylyuk, V.; Koperski, W. Experimental Study on Ballistic Resistance Test of AA2519/AA1050/Ti6A14V Laminate According to STANAG 4569 Level 2. In Proceedings of the Challenges To National Defence In Contemporary Geopolitical Situation, CNDCGS’ 2018, Vilnius, Lithuania, 25–27 April 2018; pp. 15–24. [Google Scholar]

- Wachowski, M.; Fras, T.; Kosturek, R.; Sniezek, L.; Szachogluchowicz, I.; Grzelak, K. The Effect of Hypervelocity Impact Loading on Explosively Welded Ti/Al/Al Plate. MATEC Web Conf. 2019, 253. [Google Scholar] [CrossRef]

- Fras, T.; Szachogluchowicz, I.; Sniezek, L. Ti6Al4V-AA1050-AA2519 explosively-cladded plates under impact loading. Eur. Phys. J. Spec. Top. 2018, 227, 17–27. [Google Scholar] [CrossRef]

- Akbari-Mousavi, S.A.A.; Barrett, L.M.; Al-Hassani, S.T.S. Explosive welding of metal plates. J. Mater. Process. Technol. 2008, 202, 224–239. [Google Scholar] [CrossRef]

- Findik, F. Recent developments in explosive welding. Mater. Des. 2011, 32, 1081–1093. [Google Scholar]

- Wang, Y.; Beom, H.G.; Sun, M.; Lin, S. Numerical simulation of explosive welding using the material point method. Int. J. Impact Eng. 2011, 38, 51–60. [Google Scholar] [CrossRef]

- Grignon, F.; Benson, D.; Vecchio, K.S.; Meyer, M.A. Explosive welding of aluminum to aluminum: Analysis, computations and experiments. Int. J. Impact Eng. 2004, 30, 1333–1351. [Google Scholar] [CrossRef]

- Akbari Mousavi, S.A.A.; Al-Hassani, S.T.S. Finite element simulation of explosively-driven plate impact with application to explosive welding. Mater. Des. 2008, 29, 1–19. [Google Scholar] [CrossRef]

- Bataev, I.A.; Bataev, A.A.; Mali, V.I.; Pavliukova, D.V. Structural and mechanical properties of metallic–intermetallic laminate composites produced by explosive welding and annealing. Mater. Des. 2012, 35, 225–234. [Google Scholar] [CrossRef]

- Jiang, S.; Li, S.; Zhang, L. Microstructure evolution of Al3Ti liquid solid interface. Trans. Nonferr. Met. Soc. China 2013, 23, 3545–3552. [Google Scholar] [CrossRef]

- Lysak, V.I.; Kuzmin, S.V. Explosive Welding of Metal Layered Composite Materials; Paton Electric Welding Institute of NASU: Kyiv, Ukraine, 2003; p. 117. [Google Scholar]

- Kluczyński, J.; Sniezek, L.; Grzelak, K.; Torzewski, J. The influence of layer re-melting on tensile and fatigue strength of selective laser melted 316L steel. In Proceedings of the 12th International Conference on Intelligent Technologies in Logistics and Mechatronics Systems, ITELMS 2018, Panevezys, Lithuania, 26–27 April 2018; pp. 115–123. [Google Scholar]

- Sniezek, L.; Grzelak, K.; Torzewski, J.; Kluczyński, J. Study of the mechanical properties components made by SLM additive technology. In Proceedings of the 11th International Conference on Intelligent Technologies in Logistics and Mechatronics Systems, ITELMS 2016, Panevezys, Lithuania, 28–29 April 2016; pp. 145–153. [Google Scholar]

- Kluczyński, J.; Sniezek, L.; Grzelak, K.; Torzewski, J.; Szachogłuchowicz, I.; Wachowski, M.; Łuszczek, J. Crack growth behavior of additively manufactured 316L steel-influence of build orientation and heat treatment. Materials 2020, 13, 3259. [Google Scholar] [CrossRef]

- Kluczyński, J.; Śniezek, L.; Grzelak, K.; Oziebło, A.; Perkowski, K.; Torzewski, J.; Szachogłuchowicz, I.; Gocman, K.; Wachowski, M.; Kania, B. Comparison of different heat treatment processes of selective laser melted 316L steel based on analysis of mechanical properties. Materials 2020, 13, 3805. [Google Scholar] [CrossRef]

- Kluczyński, J.; Śnieżek, L.; Grzelak, K.; Janiszewski, J.; Płatek, P.; Torzewski, J.; Szachogłuchowicz, I.; Gocman, K. Influence of Selective Laser Melting Technological Parameters on the Mechanical Properties of Additively Manufactured Elements Using 316L Austenitic Steel. Materials 2020, 13, 1449. [Google Scholar] [CrossRef]

- Kluczyński, J.; Śnieżek, L.; Kravcov, A.; Grzelak, K.; Svoboda, P.; Szachogłuchowicz, I.; Franek, O.; Morozov, N.; Torzewski, J.; Kubeček, P. The Examination of Restrained Joints Created in the Process of Multi-Material FFF Additive Manufacturing Technology. Materials 2020, 13, 903. [Google Scholar] [CrossRef]

- Szachogluchowicz, I.; Sniezek, L.; Hutsaylyuk, V. Low Cycle Fatigue Properties Laminate AA2519-TI6Al4V. Procedia Eng. 2015, 114, 26–33. [Google Scholar] [CrossRef]

- Szachogluchowicz, I.; Sniezek, L.; Sulym, H.; Gloc, M. Testing and verification modeling of wave-shape formation under explosion welding to laminate AA 2519-Ti6Al4V. Procedia Struct. Integr. 2016, 2, 2375–2380. [Google Scholar] [CrossRef]

- Szachogluchowicz, I.; Sniezek, L.; Hutsaylyuk, V. Low cycle fatigue properties of AA2519–Ti6Al4V laminate bonded by explosion welding. Eng. Fail. Anal. 2016, 69, 77–87. [Google Scholar] [CrossRef]

- Kania, B.; Indyka, P.; Tarkowski, L.; Beltowska-Lehman, E. X-ray diffraction grazing-incidence methods applied for gradient-free residual stress profile measurements in electrodeposited Ni coatings. J. Appl. Cryst. 2015, 48, 71–78. [Google Scholar] [CrossRef]

- Xia, H.; Wang, S.; Ben, H. Microstructure and mechanical properties of Ti/Al explosive cladding. Mater. Des. 2014, 56, 1014–1019. [Google Scholar] [CrossRef]

- Sniezek, L.; Szachogluchowicz, I.; Sulym, H.; Turchyn, I.; Pasternak, I. Elastodynamic modeling of wave initiation processes during the explosion welding. In Proceedings of the 10th International Conference on Intelligent Technologies in Logistics and Mechatronics Systems, ITELMS 2015, Panevezys, Lithuania, 21–22 May 2015; pp. 245–250. [Google Scholar]

- Peng, L.M.; Wang, J.H.; Li, H.; Zhao, J.H.; He, L.H. Synthesis and microstructural characterization of Ti–Al3Ti metal–intermetallic laminate (MIL) composites. Scr. Mater. 2005, 52, 243–248. [Google Scholar] [CrossRef]

- Wachowski, M.; Sniezek, L.; Szachogłuchowicz, I.; Kosturek, R.; Płocinski, T. Microstructure and fatigue life of Cp-Ti/316L bimetallic joints obtained by means of explosive welding. Bull. Polish Acad. Sci. Tech. Sci. 2018. [Google Scholar] [CrossRef]

- Kurek, A.; Wachowski, M.; Nieslony, A.; Plocinski, T.; Kurzydlowski, K.J. Fatigue tests and metallographic of explosively cladded steel-titanium bimetal. Arch. Metall. Mater. 2014, 59, 1566–1570. [Google Scholar] [CrossRef]

- Sniezek, L.; Szachogluchowicz, I.; Wachowski, M.; Torzewski, J.; Mierzynski, J. High cycle fatigue properties of explosively welded laminate AA2519/AA1050/Ti6Al4V. Procedia Struct. Integr. 2017, 5, 422–429. [Google Scholar] [CrossRef]

- Rohatgi, A.; Harach, D.J.; Vecchio, K.S.; Harvey, K.P. Resistance-curve and fracture behavior of Ti–Al3Ti metallic–intermetallic laminate (MIL) composites. Acta Mater. 2003, 51, 2933–2957. [Google Scholar] [CrossRef]

- Boronski, D.; Kotyk, M.; Mackowiak, P.; Sniezek, L. Mechanical properties of explosively welded AA2519-AA1050-Ti6Al4V layered material at ambient and cryogenic conditions. Mater. Des. 2017, 133, 390–403. [Google Scholar] [CrossRef]

- Milosavljevi, M.; Stojanovi, N.; Perusko, D.; Timotijevi, B.; Topreka, D.; Kova, J.; Dra, G.; Jeynes, C. Ion irradiation induced Al–Ti interaction in nano-scaled Al/Ti multilayers. Appl. Surf. Sci. 2012, 258, 2043–2046. [Google Scholar] [CrossRef]

- Bazarnik, P.; Adamczyk-Cieślak, B.; Galka, A.; Plonka, B.; Sniezek, L.; Cantonie, M.; Lewandowska, M. Mechanical and microstructural characteristics of Ti6Al4V/AA2519 and Ti6Al4V/AA1050/AA2519 laminates manufactured by explosive welding. Mater. Des. 2016, 111, 146–157. [Google Scholar] [CrossRef]

- Malachowski, J.; Damaziak, K.; Platek, P.; Sarzynski, M.; Kupidura, P.; Wozniak, R.; Zahor, M. Numerical and experimental failure analysis of rifle extractor. In Engineering Failure Analysis; Elsevier Ltd.: Frisco, CO, USA, 2016. [Google Scholar] [CrossRef]

- Platek, P.; Damaziak, K.; Malachowski, J.; Kupidura, P.; Wozniak, R.; Zahor, M. Numerical study of modular 5.56 mm standard assault rifle referring to dynamic characteristics. Def. Sci. J. 2015, 65, 431–437. [Google Scholar] [CrossRef]

| Strength Properties | Chemical Composition [wt %] | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R0.2 [MPa] | Rm [MPa] | A [%] | Si | Fe | Cu | Mg | Zn | Ti | V | Zr | Sc | Al |

| 312 | 335 | 6.5 | 0.06 | 0.08 | 5.77 | 0.18 | 0.01 | 0.04 | 0.12 | 0.2 | 0.36 | rest |

| Strength Properties | Chemical Composition [wt %] | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| R0.2 [MPa] | Rm [MPa] | A [%] | O | V | Al | Fe | H | C | N | Ti |

| 950 | 1020 | 14 | <0.20 | 3.5 | 5.5 | <0.30 | <0.0015 | <0.08 | <0.05 | rest |

| Strength Properties | Chemical Composition [wt %] | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| R0.2 [MPa] | Rm [MPa] | A [%] | Fe | Si | Zn | Mg | Ti | Mn | Cu | Al |

| 78 | 168 | 2.9 | 0.4% | 0.25< | 0.07< | 0.18 | 0.05< | 0.05< | 0.05< | rest |

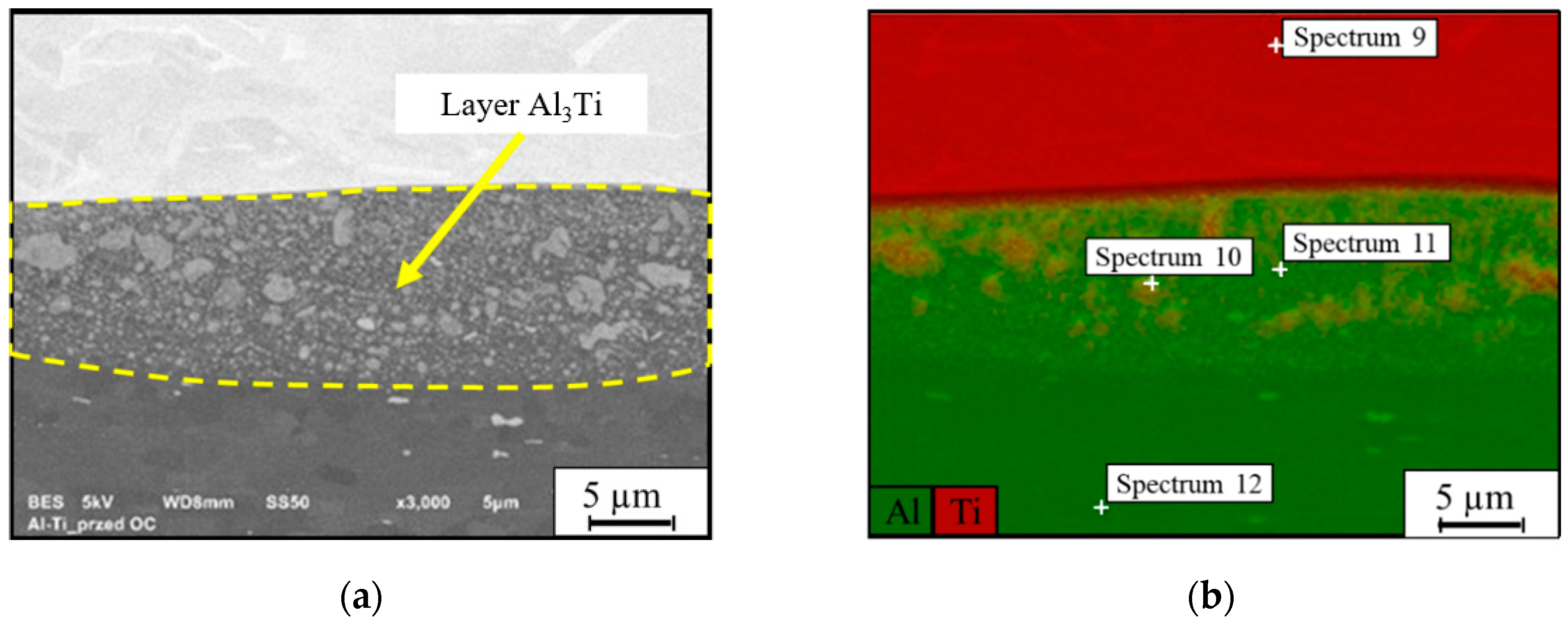

| Measurement Point Name | Chemical Composition [%] | |

|---|---|---|

| Ti | Al | |

| Spectrum 9 | 92.8 | 7.2 |

| Spectrum 10 | 69.6 | 30.4 |

| Spectrum 11 | 83.1 | 16.9 |

| Spectrum 12 | 0 | 100 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szachogluchowicz, I.; Sniezek, L.; Slezak, T.; Kluczyński, J.; Grzelak, K.; Torzewski, J.; Fras, T. Mechanical Properties Analysis of the AA2519-AA1050-Ti6Al4V Explosive Welded Laminate. Materials 2020, 13, 4348. https://doi.org/10.3390/ma13194348

Szachogluchowicz I, Sniezek L, Slezak T, Kluczyński J, Grzelak K, Torzewski J, Fras T. Mechanical Properties Analysis of the AA2519-AA1050-Ti6Al4V Explosive Welded Laminate. Materials. 2020; 13(19):4348. https://doi.org/10.3390/ma13194348

Chicago/Turabian StyleSzachogluchowicz, Ireneusz, Lucjan Sniezek, Tomasz Slezak, Janusz Kluczyński, Krzysztof Grzelak, Janusz Torzewski, and Teresa Fras. 2020. "Mechanical Properties Analysis of the AA2519-AA1050-Ti6Al4V Explosive Welded Laminate" Materials 13, no. 19: 4348. https://doi.org/10.3390/ma13194348

APA StyleSzachogluchowicz, I., Sniezek, L., Slezak, T., Kluczyński, J., Grzelak, K., Torzewski, J., & Fras, T. (2020). Mechanical Properties Analysis of the AA2519-AA1050-Ti6Al4V Explosive Welded Laminate. Materials, 13(19), 4348. https://doi.org/10.3390/ma13194348