Analysis of Welded Joint Properties on an AISI316L Stainless Steel Tube Manufactured by SLM Technology

Abstract

1. Introduction

2. Materials and Methods

2.1. Powder Characterisation

2.2. Settings and SLM Sample Fabrication

2.3. Density Measurement

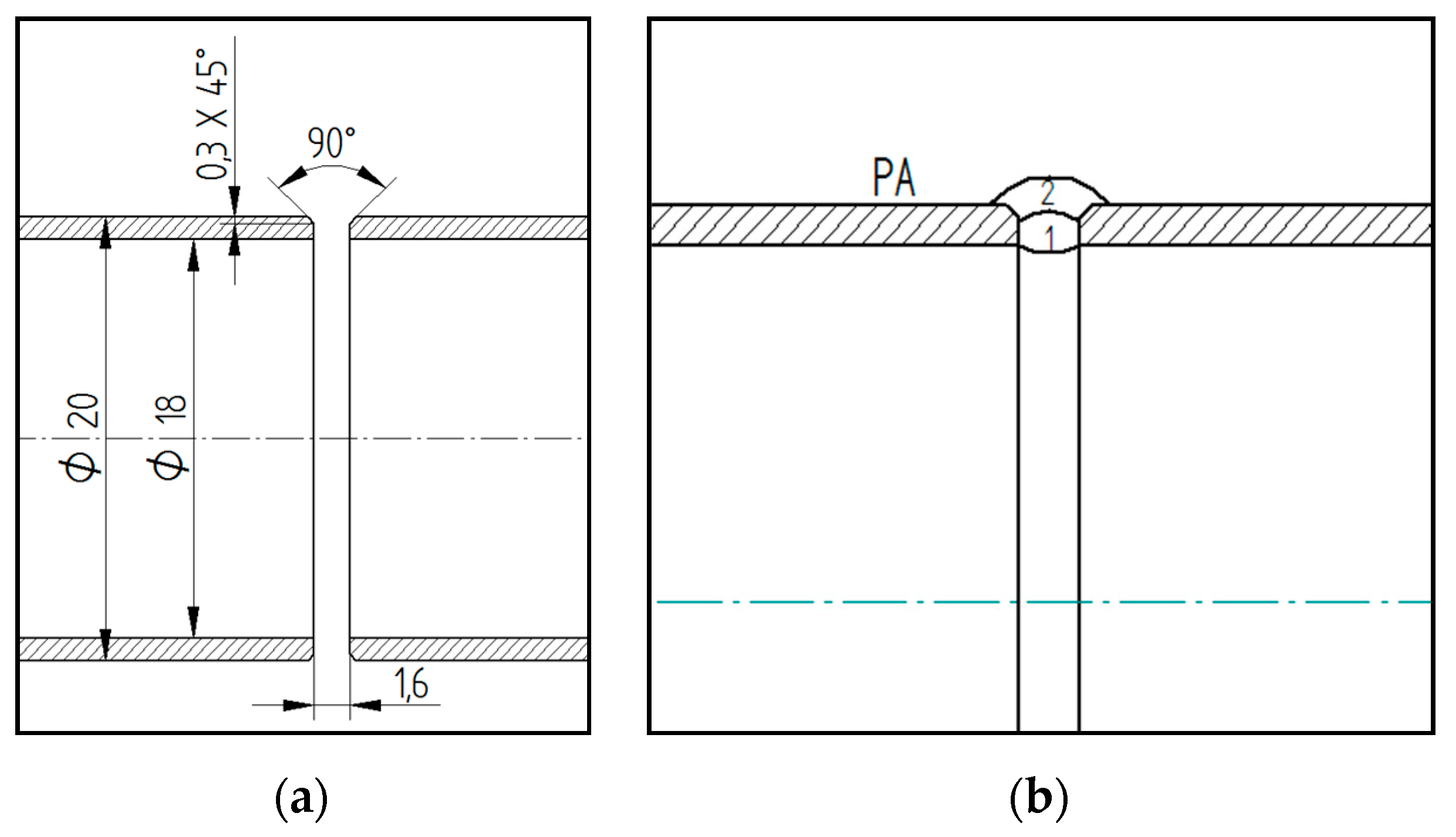

2.4. Welding of Pipes Samples

2.5. Mechanical Properties Measurement

3. Results

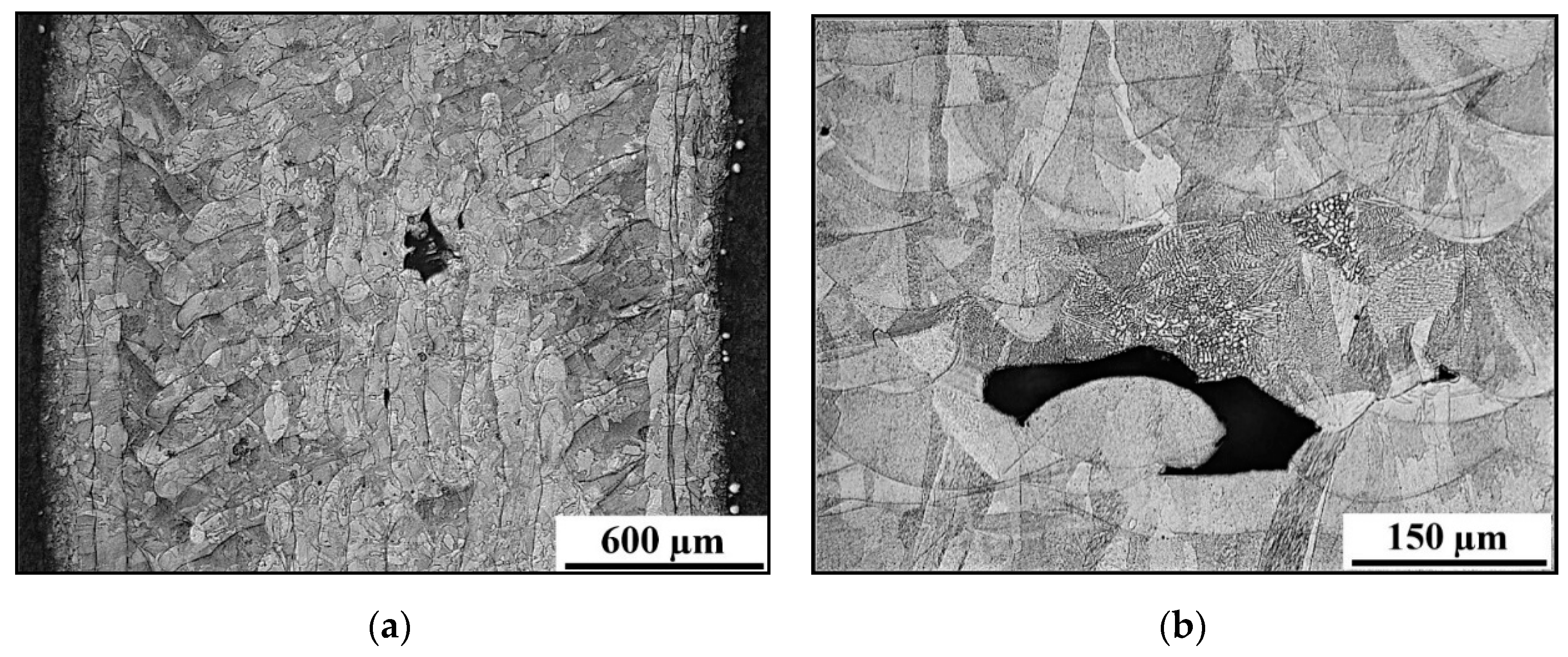

3.1. Evaluation of Base Material Porosity

3.2. Evaluation of Weld Defects

3.3. Evaluation of Mechanical Properties

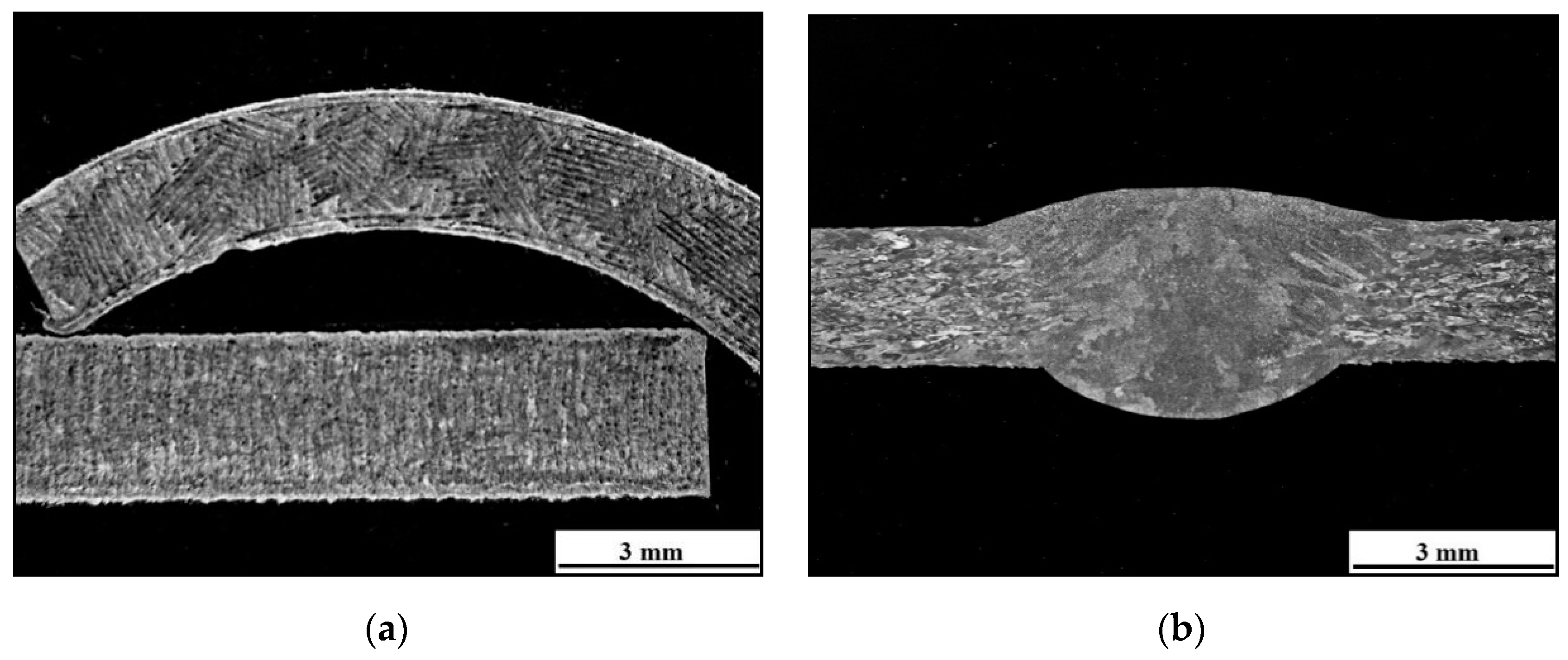

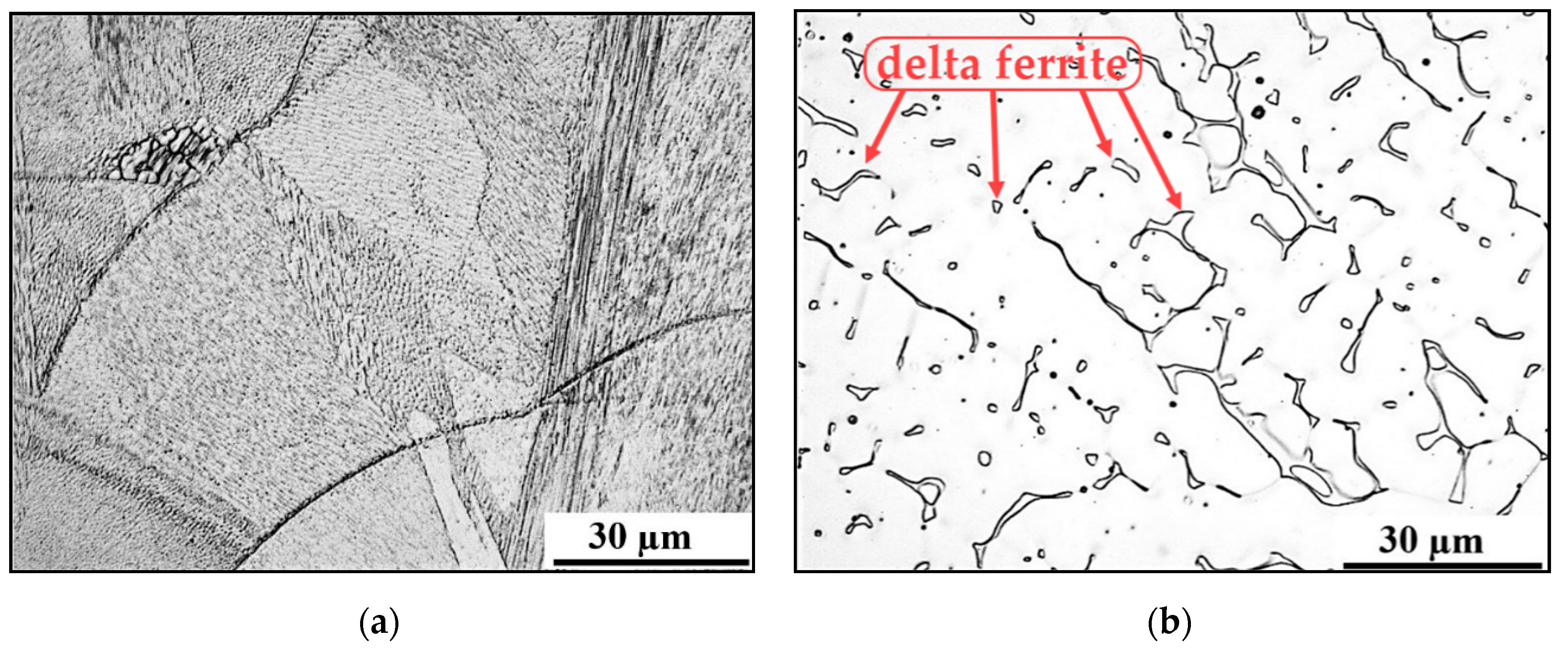

3.3.1. Metallographic Analysis

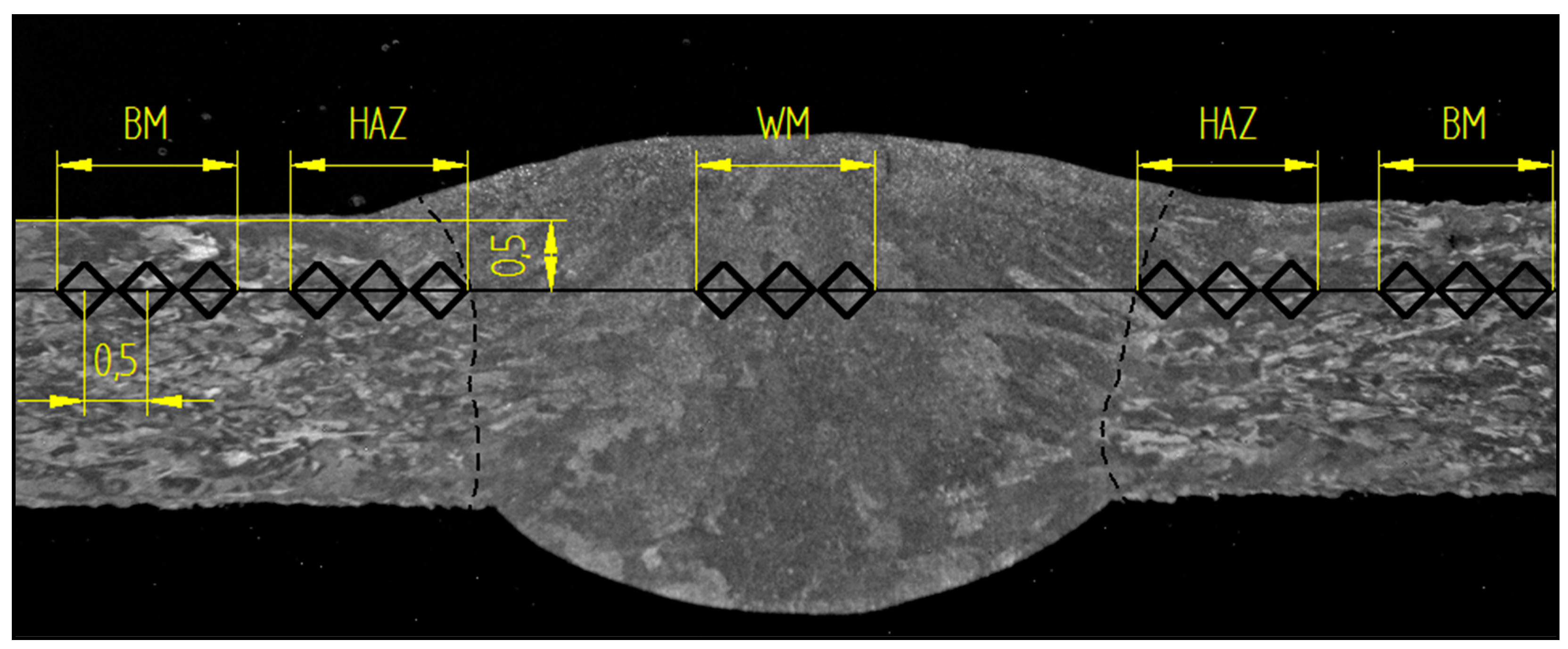

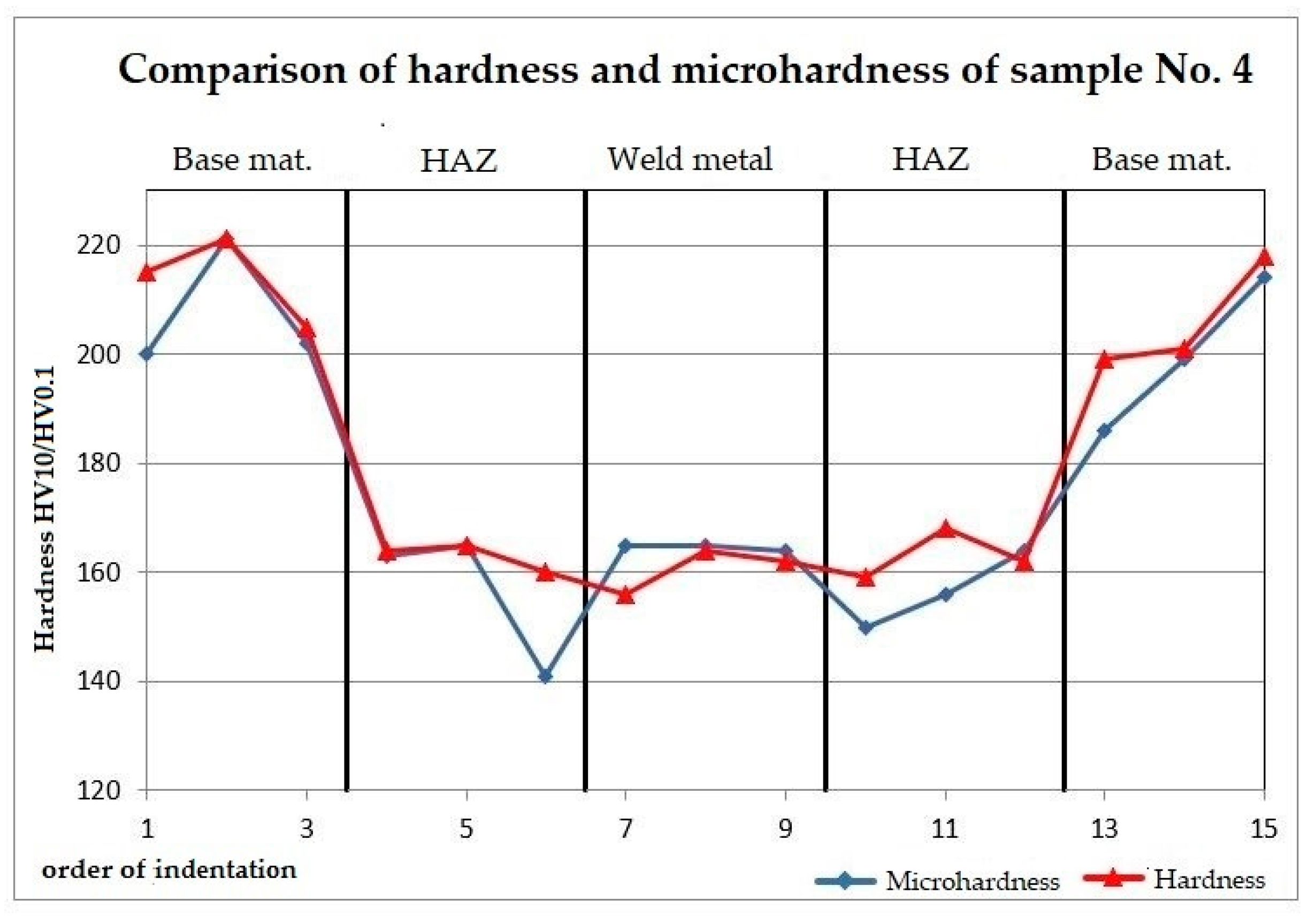

3.3.2. Hardness and Microhardness

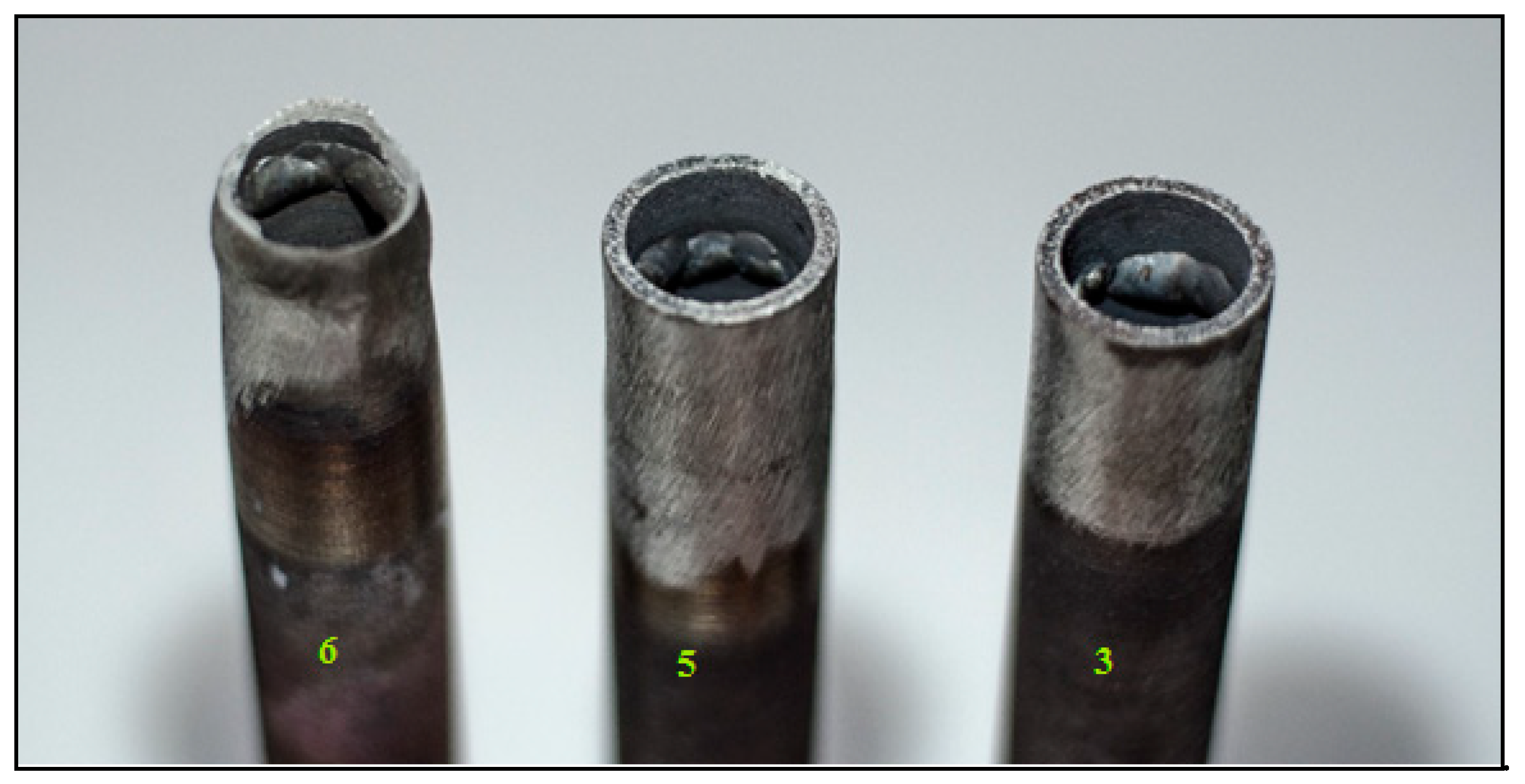

3.3.3. Tensile Properities

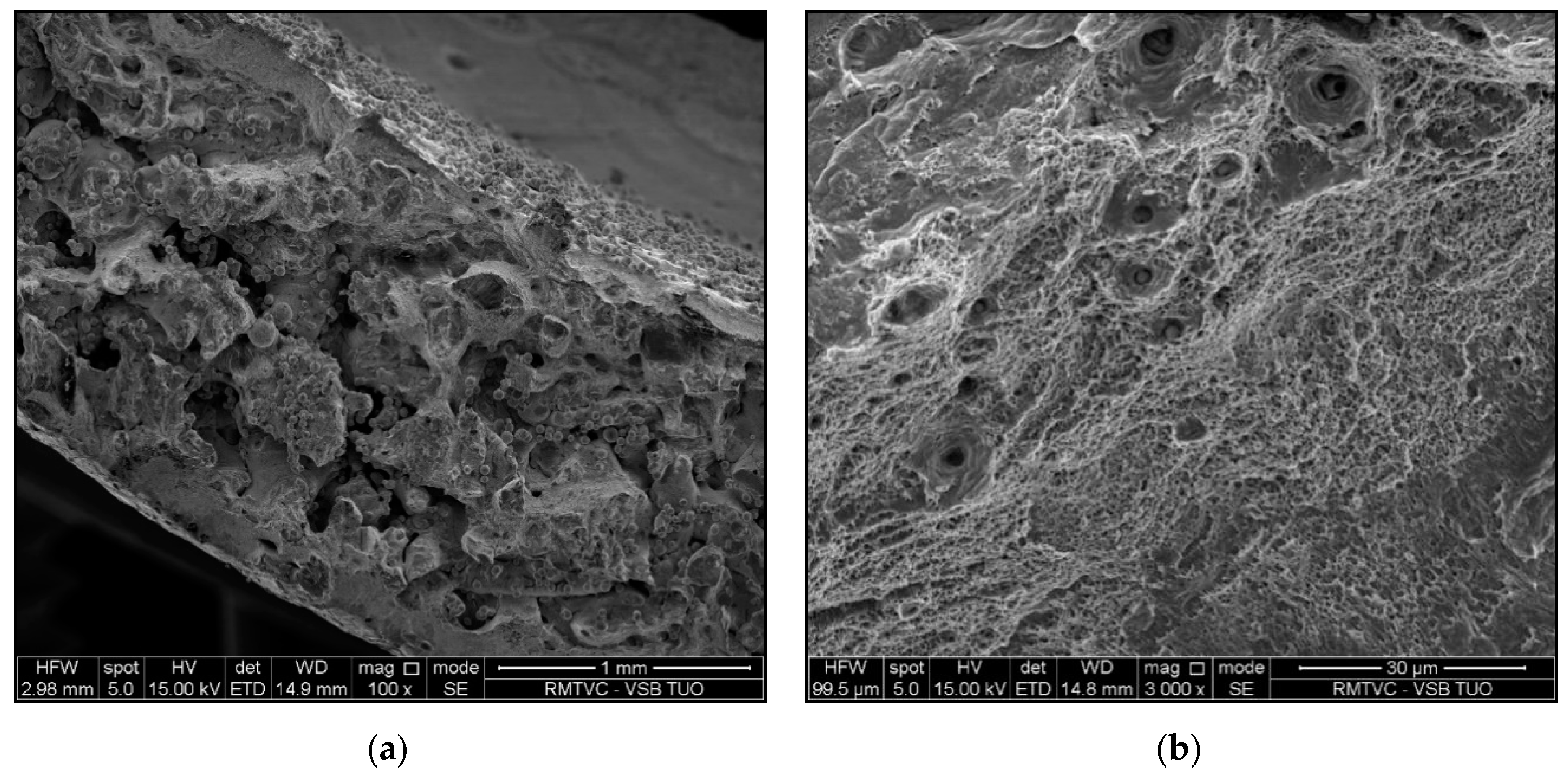

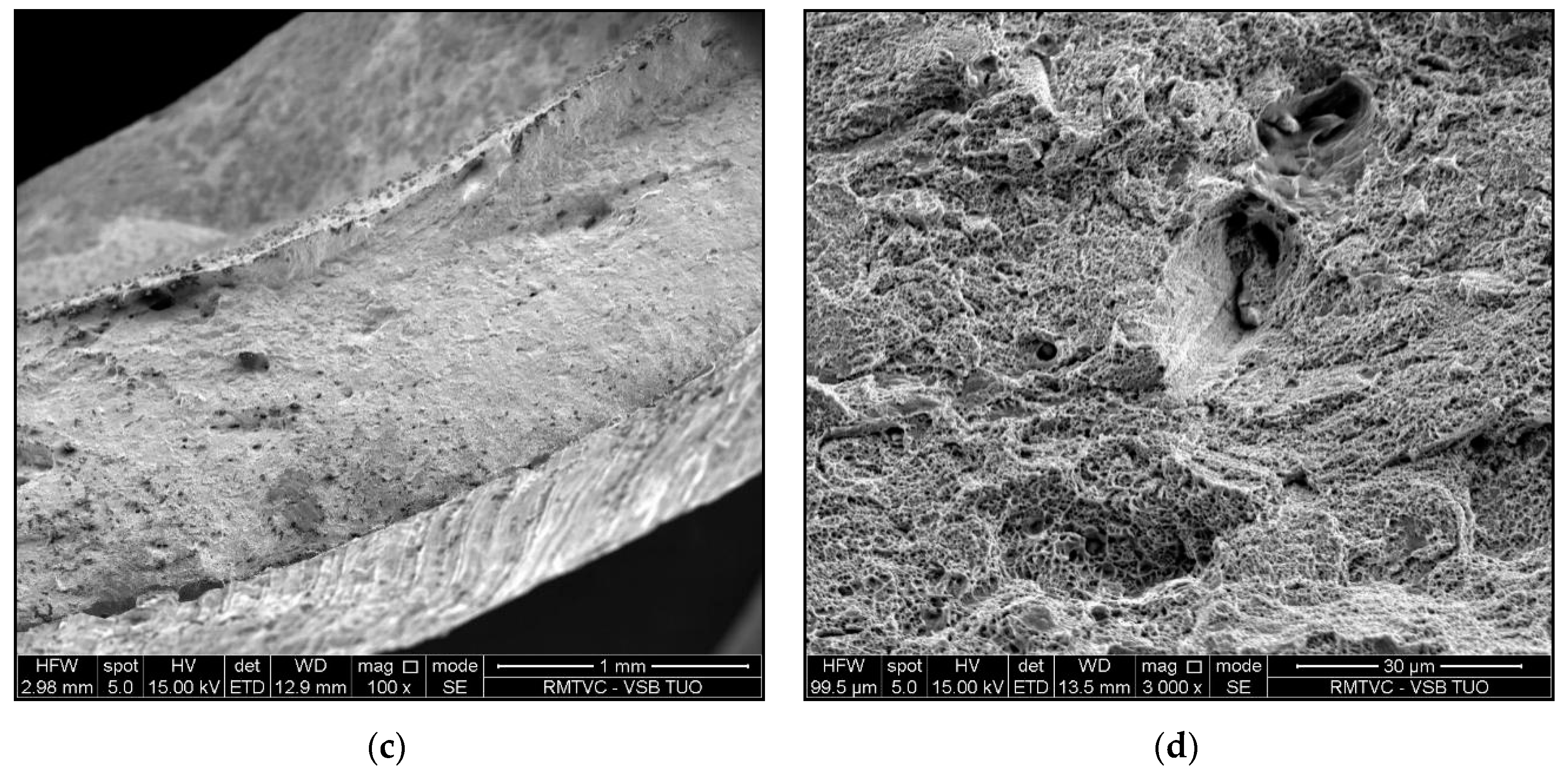

3.3.4. Fractography of Fracture Surfaces

4. Discussion

4.1. Porosity Formation

4.2. Mechanical Properties Analysis

5. Conclusions

- The relative density of components manufactured by the SLM method is 98.12%.

- The defects in the base material, which mainly include pores, have affected the mechanical properties of the welded joints so much that they initiated premature fracture before or just above the yield point.

- Material failure occurred in the area of the base material near the heat affected zone (HAZ).

- The microhardness is about 30% lower in the HAZ zone than in the base material.

- In terms of microstructure, a higher temperature (closer to the fuse boundary) has a positive effect. The original texture of 3D printing changes to an almost homogeneous austenitic structure. From this point of view, heat treatment of SLM products at temperatures above 1000 °C can be recommended after 3D printing.

- Two of the three samples broke outside the “weld zone”. This was probably because of the SLM process parameters.

- The weld material did not show any porosity and therefore the TIG method is suitable for welding the SLMed steel AISI316L.

Author Contributions

Funding

Conflicts of Interest

References

- Eckel, Z.C.; Zhou, C.; Martin, J.H.; Jacobsen, A.J.; Carter, W.B.; Schaedler, T.A. Additive manufacturing of polymer-derived ceramics. Science 2016, 351, 58–62. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Kamath, C.; El-dasher, B.; Gallegos, G.F.; King, W.E.; Sisto, A. Density of additively-manufactured, 316L SS parts using laser powder-bed fusion at powers up to 400 W. Int. J. Adv. Manuf. Technol. 2014, 74, 65–78. [Google Scholar] [CrossRef]

- Zhang, C.; Bao, Y.; Zhu, H.; Nie, X.; Zhang, W.; Zhang, S.; Zeng, X. A comparison between laser and TIG welding of selective laser melted AlSi10Mg. Opt. Laser Technol. 2019, 120, 105696, ISSN 0030-3992. [Google Scholar] [CrossRef]

- Kuryntsev, S.V. The influence of pre-heat treatment on laser welding of T-joints of workpieces made of selective laser melting steel and cold rolled stainless steel. Opt. Laser Technol. 2018, 107, 59–66, ISSN 0030-3992. [Google Scholar] [CrossRef]

- Matilainen, V.; Pekkarinen, J.; Salminen, A. Weldability of additive manufactured stainless steel. Phys. Procedia 2016, 83, 808–817, ISSN 1875-3892. [Google Scholar] [CrossRef]

- Yu, H.; Li, F.; Yang, J.; Shao, J.; Wang, Z.; Zeng, X. Investigation on laser welding of selective laser melted Ti-6Al-4V parts: Weldability, microstructure and mechanical properties. Mater. Sci. Eng. A 2018, 712, 20–27. [Google Scholar] [CrossRef]

- Voropaev, A.; Stramko, M.; Sorokin, A.; Logachev, I.; Kuznetsov, M.; Gook, S. Laser welding of Inconel 718 nickel-based alloy layer-by-layer products. Mater. Today Proc. 2020, 30, 473–477, ISSN 2214-7853. [Google Scholar] [CrossRef]

- Scherillo, F.; Astarita, A.; Prisco, U.; Contaldi, V.; di Petta, P.; Langella, A.; Squillace, A. Friction stir welding of AlSi10Mg plates produced by selective laser melting. Metallogr. Microstruct. Anal. 2018, 7, 457–463. [Google Scholar] [CrossRef]

- Liverani, E.; Toschi, S.; Ceschini, L.; Fortunato, A. Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J. Mater. Process. Technol. 2017, 249, 255–263, ISSN 0924-0136. [Google Scholar] [CrossRef]

- Hajnys, J.; Pagac, M.; Kotera, O.; Petru, J.; Scholz, S. Influence of basic process parameters on mechanical and internal properties of 316l steel in slm process for renishaw AM400. MM Sci. J. 2019, 2790–2794. [Google Scholar] [CrossRef]

- Pagáč, M.; Hajnyš, J.; Petrů, J.; Zlámal, T. Comparison of hardness of surface 316L stainless steel made by additive technology and cold rolling. In Materials Science Forum; Trans Tech Publications: Stafa-Zurich, Switzerland, 2018; Volume 919, pp. 84–91. [Google Scholar] [CrossRef]

- Pagáč, M.; Hajnyš, J.; Petrů, J.; Zlámal, T.; Šofer, M. The study of mechanical properties stainless steel 316L after production from metal powder with using additive technology and by method selective laser melting. In Proceedings of the METAL 2017-26th International Conference on Metallurgy and Materials, Conference Proceedings, Brno, Czech Republic, 24–26 May 2017; pp. 962–967. [Google Scholar]

- Suryawanshi, J.; Prashanth, K.G.; Ramamurty, U. Mechanical behavior of selective laser melted 316L stainless steel. Mater. Sci. Eng. A 2017, 696, 113–121, ISSN 09215093. [Google Scholar] [CrossRef]

- Tanprayoon, D.; Srisawadi, S.; Sato, Y.; Tsukamoto, M.; Suga, T. Microstructure and hardness response of novel 316L stainless steel composite with TiN addition fabricated by SLM. Opt. Laser Technol. 2020, 129, 106238, ISSN 0030-3992. [Google Scholar] [CrossRef]

- Guo, P.; Zou, B.; Huang, C.; Gao, H. Study on microstructure, mechanical properties and machinability of efficiently additive manufactured AISI 316L stainless steel by high-power direct laser deposition. J. Mater. Process. Technol. 2017, 240, 12–22. [Google Scholar] [CrossRef]

- Löber, L.; Flache, C.; Petters, R.; Kühn, U.; Eckert, J. Comparison of different post processing technologies for SLM generated 316l steel parts. Rapid Prototyp. J. 2013, 19, 173–179. [Google Scholar]

- Oyelola, O.; Crawforth, P.; M’saoubi, R.; Clare, A.T. Machining of additively manufactured parts: Implications for surface integrity. Procedia CIRP 2016, 45, 119–122, ISSN 22128271. [Google Scholar] [CrossRef]

- Pagáč, M.; Hajnyš, J.; Malotová, Š.; Zlámal, T.; Petrů, J. The influence of the laser power on the utility properties of the surface roughness parameter of the overhangs during the SLM process. In Proceedings of the METAL 2018—27th International Conference on Metallurgy and Materials, Conference Proceedings, Brno, Czech Republic, 23–25 May 2018; pp. 814–819. [Google Scholar]

- Kaynak, Y.; Ozhan, K. The effect of post-processing operations on surface characteristics of 316L stainless steel produced by selective laser melting. Addit. Manuf. 2019, 26, 84–93, ISSN 22148604. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Casalino, G.; Contuzzi, N.; Ludovico, A.D. Taguchi optimization of the surface finish obtained by laser ablation on selective laser molten steel parts. Procedia CIRP 2013, 12, 462–467, ISSN 22128271. [Google Scholar] [CrossRef]

- Čep, R.; Janásek, A.; Petrů, J.; Sadílek, M.; Mohyla, P.; Valíček, J.; Harnicarova, M.; Czan, A. Surface roughness after machining and influence of feed rate on process. Precis. Mach. VII 2014, 581, 341–347, ISSN 1013-9826. [Google Scholar] [CrossRef]

- Fieger, T.V.; Sattler, M.F.; Witt, G. Developing laser beam welding parameters for the assembly of steel SLM parts for the automotive industry. Rapid Prototyp. J. 2018, 24, 1288–1295, ISSN 1355-2546. [Google Scholar] [CrossRef]

- Yang, J.; Wang, Y.; Li, F.; Huang, W.; Jing, G.; Wang, Z.; Zeng, X. Weldability, microstructure and mechanical properties of laser-welded selective laser melted 304 stainless steel joints. J. Mater. Sci. Technol. 2019, 35, 1817–1824, ISSN 1005-0302. [Google Scholar] [CrossRef]

- Vontorová, J.; Váňová, P. Determination of carburized layer thickness by GDOES method. AIMS Mater. Sci. 2018, 5, 34–43. [Google Scholar] [CrossRef]

- Vontorová, J.; Dobiáš, V.; Mohyla, P. Utilization of GDOES for the study of friction layers formed on the surface of brake discs during the friction process. Chem. Pap. 2017, 71, 1507–1514, ISSN 0366-6352WOS:000405694900014. [Google Scholar] [CrossRef]

- Hajnys, J.; Pagáč, M.; Měsíček, J.; Petru, J.; Król, M. Influence of scanning strategy parameters on residual stress in the SLM process according to the bridge curvature method for AISI 316L stainless steel. Materials 2020, 13, 1659. [Google Scholar] [CrossRef]

- Jajarmi, E.; Sajjadi, S.A.; Mohebbi, J. Predicting the relative density and hardness of 3YPSZ/316L composites using adaptive neuro-fuzzy inference system and support vector regression models. Measurement 2019, 145, 472–479, ISSN 0263-2241. [Google Scholar] [CrossRef]

- GE Additive 316L [online]. Germany. 2016. Available online: https://www.ge.com/additive/sites/default/files/2019-07/GEAP_316L_DS_EN_A4_v1.pdf (accessed on 24 September 2020).

- Hlinka, J.; Kraus, M.; Hajnys, J.; Pagac, M.; Petrů, J.; Brytan, Z.; Tański, T. Complex corrosion properties of AISI 316L steel prepared by 3D printing technology for possible implant applications. Materials 2020, 13, 1527. [Google Scholar] [CrossRef]

- EN ISO 6892-1: 2019 Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. ISO. 2019. Available online: http://goktasmetal.com/wp-content/uploads/2016/01/TS%20EN%20ISO%206892-1.pdf (accessed on 24 September 2020).

- Bansod, A.; Patil, A.; Verma, J.; Shukla, S. Microstructure, mechanical and electrochemical evaluation of dissimilar low Ni SS and 304 SS using different filler materials. Mater. Res. 2019, 22. [Google Scholar] [CrossRef]

- Sun, Z.; Tan, X.; Tor, S.B.; Yeong, W.Y. Selective laser melting of stainless steel 316L with low porosity and high build rates. Mater. Des. 2016, 104, 197–204, ISSN 0264-1275. [Google Scholar] [CrossRef]

- Yasa, E.; Kruth, J.P. Microstructural investigation of selective laser melting 316L stainless steel parts exposed to laser re-melting. Procedia Eng. 2011, 19, 389–395. [Google Scholar] [CrossRef]

- Deev, A.A.; Kuznetcov, P.A.; Petrov, S.N. Anisotropy of mechanical properties and its correlation with the structure of the stainless steel 316L produced by the SLM method. Phys. Procedia 2016, 83, 789–796, ISSN 1875-3892. [Google Scholar] [CrossRef]

| C | Mn | Si | P | S | Cr | Ni | Mo | W | Cu | Ti | Nb | Al | B |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.016 | 1.17 | 0.22 | 0.023 | 0.0067 | 17.72 | 14.24 | 2.73 | 0.19 | 0.077 | 0.0003 | 0.013 | 0.01 | 0.002 |

| Laser Power [W] | Scanning Speed [mm/s] | Layer Thickness [µm] | Strategy |

|---|---|---|---|

| 200 | 650 | 50 | Chessboard |

| Sample | Indication Immediately after Spraying | Indication after 10 min |

|---|---|---|

| No. 1 | - | Crater crack in weld metal |

| No. 2 | - | - |

| No. 3 | Yes | Pores in the base material around the perimeter |

| No. 4 | - | - |

| No. 5 | Yes | Pores in the base material around the perimeter |

| No. 6 | - | - |

| No. 7 | - | - |

| No. 8 | - | Isolated defects in the base material |

| Sample No. | Max. Load | Tensile Strength | Place of Rupture |

|---|---|---|---|

| - | kN | MPa | - |

| 3 | 33.3 | 267 | Out of weld |

| 5 | 46.1 | 375 | Out of weld |

| 6 | 70.0 | 573 | HAZ (Heat Affected Zone) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohyla, P.; Hajnys, J.; Sternadelová, K.; Krejčí, L.; Pagáč, M.; Konečná, K.; Krpec, P. Analysis of Welded Joint Properties on an AISI316L Stainless Steel Tube Manufactured by SLM Technology. Materials 2020, 13, 4362. https://doi.org/10.3390/ma13194362

Mohyla P, Hajnys J, Sternadelová K, Krejčí L, Pagáč M, Konečná K, Krpec P. Analysis of Welded Joint Properties on an AISI316L Stainless Steel Tube Manufactured by SLM Technology. Materials. 2020; 13(19):4362. https://doi.org/10.3390/ma13194362

Chicago/Turabian StyleMohyla, Petr, Jiri Hajnys, Kristýna Sternadelová, Lucie Krejčí, Marek Pagáč, Kateřina Konečná, and Pavel Krpec. 2020. "Analysis of Welded Joint Properties on an AISI316L Stainless Steel Tube Manufactured by SLM Technology" Materials 13, no. 19: 4362. https://doi.org/10.3390/ma13194362

APA StyleMohyla, P., Hajnys, J., Sternadelová, K., Krejčí, L., Pagáč, M., Konečná, K., & Krpec, P. (2020). Analysis of Welded Joint Properties on an AISI316L Stainless Steel Tube Manufactured by SLM Technology. Materials, 13(19), 4362. https://doi.org/10.3390/ma13194362