New Feedstock System for Fused Filament Fabrication of Sintered Alumina Parts

Abstract

:1. Introduction

2. Materials and Methods

- Material (filler, binder, and surfactant) selection;

- Compounding and rheological characterization;

- Filament extrusion;

- Feedstock printing; and

- Thermal post-processing (debinding, sintering)

2.1. Material Selection

2.2. Compounding and Rheological Characterization

2.3. Filament Extrusion and Printing via FFF

2.4. Debinding and Sintering

3. Results and Discussion

3.1. Material Selection

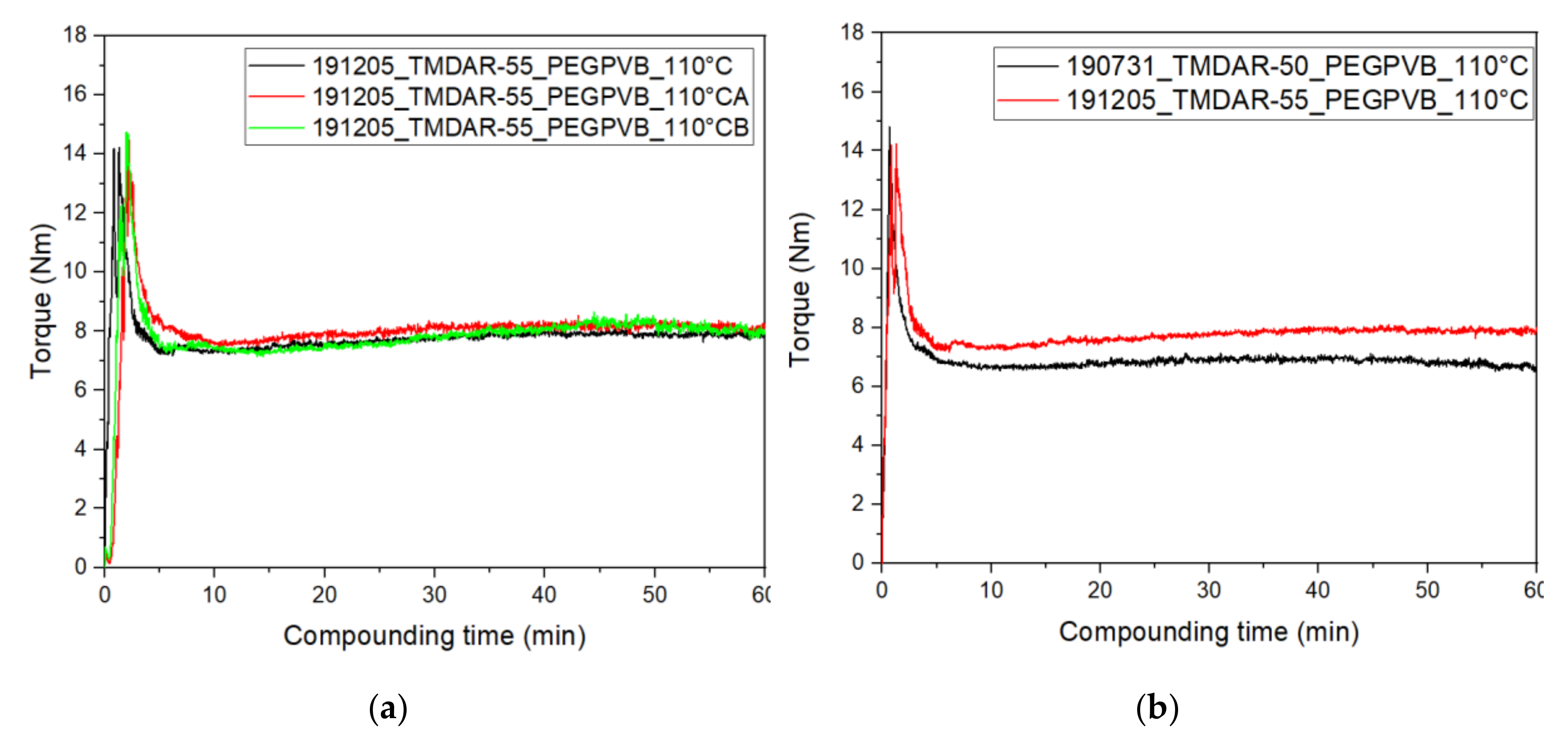

3.2. Compounding and Rheological Characterization

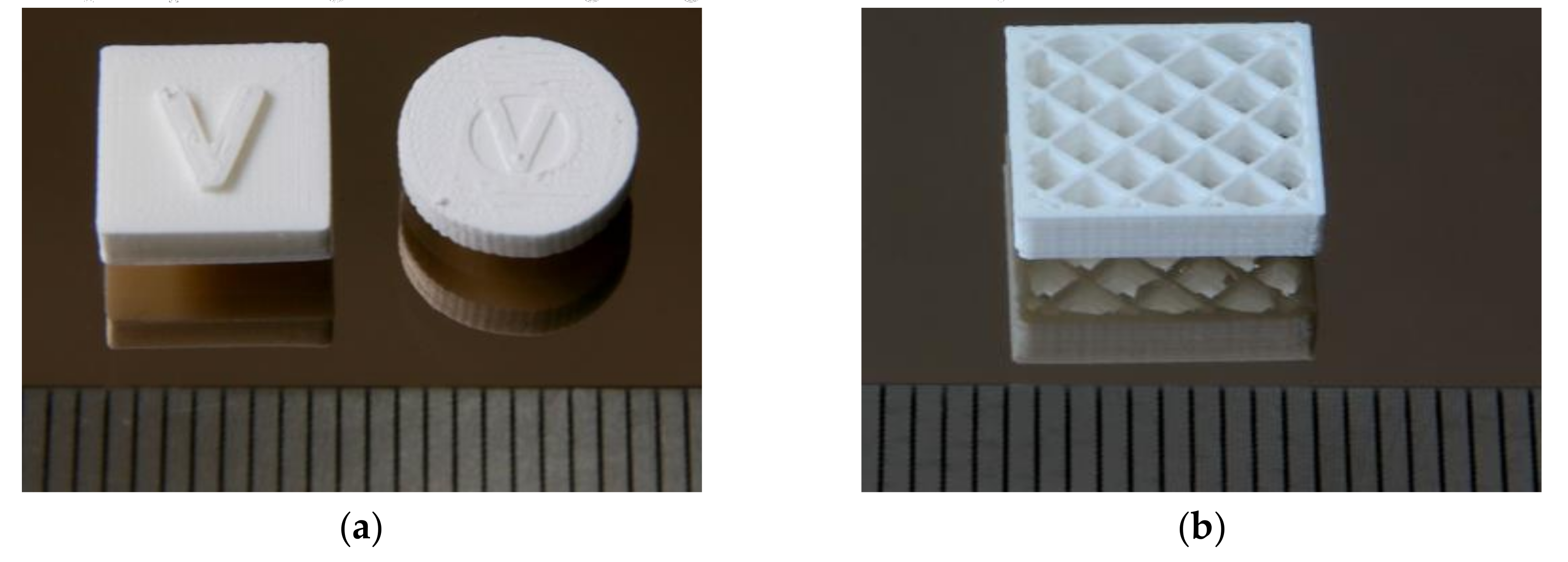

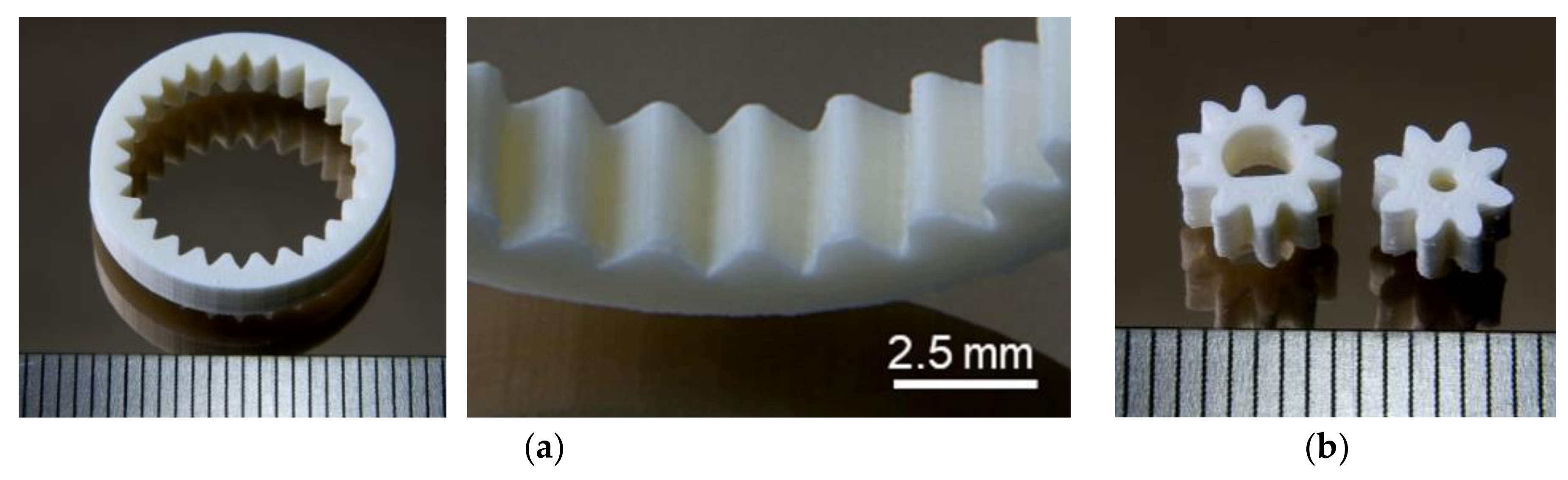

3.3. Filament Extrusion and Printing via FFF

3.4. Debinding and Sintering

3.5. Process Chain Evaluation

3.6. Comparison with Injection Molding

4. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lin, L.; Kollipara, P.S.; Zheng, Y. Digital manufacturing of advanced materials: Challenges and perspective. Mater. Today 2019, 28, 49–62. [Google Scholar] [CrossRef] [PubMed]

- Quanjin, M.; Rejab, M.R.M.; Idris, M.S.; Kumar, N.M.; Abdullah, M.H.; Reddy, G.R. Recent 3D and 4D intelligent printing technologies: A comparative review and future perspective. Proc. Comp. Sci. 2020, 167, 1210–1219. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part. B: Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Singh, R. Material issues in additive manufacturing: A review. J. Manuf. Process. 2017, 25, 185–200. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO/ASTM 52900:2018. Additive manufacturing—General principles—Terminology; International Organization for Standardization: Geneva, Switzerland; Beuth Publisher GmbH: Berlin, Germany, 2018. [Google Scholar]

- Tiller, B.; Reid, A.; Zhu, B.; Guerreiro, J.; Domingo-Roca, R.; Curt Jackson, J.; Windmill, J.F.C. Piezoelectric microphone via a digital light processing 3D printing process. Mater. Des. 2019, 165, 107593. [Google Scholar] [CrossRef]

- Gonzalez, G.; Chiappone, A.; Roppolo, I.; Fantino, E.; Bertana, V.; Perrucci, F.; Scaltrito, L.; Pirri, F.; Sangermano, M. Development of 3D printable formulations containing CNT with enhanced electrical properties. Polymer 2017, 109, 246–253. [Google Scholar] [CrossRef]

- Khatri, B.; Lappe, K.; Habedank, M.; Mueller, T.; Megnin, C.; Hanemann, T. Fused Deposition Modeling of ABS-Barium Titanate Composites: A Simple Route towards Tailored Dielectric Devices. Polymers 2018, 10, 666. [Google Scholar] [CrossRef] [Green Version]

- Hanemann, T.; Syperek, D.; Nötzel, D. 3D Printing of ABS Barium Ferrite Composites. Materials 2020, 13, 1481. [Google Scholar] [CrossRef] [Green Version]

- Angelopoulos, P.M.; Samouhos, M.; Taxiarchou, M. Functional fillers in composite filaments for fused filament fabrication; a review. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Mahmood, M.A.; Popescu, A.C.; Mihailescu, I.N. Metal Matrix Composites Synthesized by Laser-Melting Deposition: A Review. Materials 2020, 13, 2593. [Google Scholar] [CrossRef] [PubMed]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Dowling, L.; Kennedy, J.; O’Shaughnessy, S.; Trimble, D. A review of critical repeatability and reproducibility issues in powder bed fusion. Mater. Des. 2020, 186, 108346. [Google Scholar] [CrossRef]

- Lunetto, V.; Galati, M.; Settineri, L.; Iuliano, L. Unit process energy consumption analysis and models for Electron Beam Melting (EBM): Effects of process and part designs. Addit. Manuf. 2020, 33, 101115. [Google Scholar] [CrossRef]

- Zakeri, S.; Vippola, M.; Levänen, E. A comprehensive review of the photopolymerization of ceramic resins used in stereolithography. Addit. Manuf. 2020, 35, 101177. [Google Scholar] [CrossRef]

- Hostaša, J.; Schwentenwein, M.; Toci, G.; Esposito, L.; Brouczek, D.; Piancastelli, A.; Pirri, A.; Patrizi, B.; Vannini, M.; Biasini, V. Transparent laser ceramics by stereolithography. Scr. Mater. 2020, 187, 194–196. [Google Scholar] [CrossRef]

- Zhou, T.; Zhang, L.; Yao, Q.; Ma, Y.; Hou, C.; Sun, B.; Shao, C.; Gao, P.; Chen, H. SLA 3D printing of high quality spine shaped β-TCP bioceramics for the hard tissue repair applications. Ceram. Int. 2020, 46, 7609–7614. [Google Scholar] [CrossRef]

- Xing, B.; Cao, C.; Zhao, W.; Shen, M.; Wang, C.; Zhao, Z. Dense 8 mol% yttria-stabilized zirconia electrolyte by DLP stereolithography. J. Eur. Ceram. Soc. 2020, 40, 1418–1423. [Google Scholar] [CrossRef]

- Scheithauer, U.; Abel, J.; Schwarzer, E.; Weingarten, S.; Kunz, W.; Moritz, T.; Klemm, H. CerAMfacturing of Si3N4 Components. CeramApplications 2020, 8, 36–41. [Google Scholar]

- Noetzel, D.; Eickhoff, R.; Hanemann, T. Fused Filament Fabrication of Small Ceramic Components. Materials 2018, 11, 1463. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Noetzel, D.; Hanemann, T.; Eickhoff, R. Charakterisierung additiv gefertigter keramischer Bauteile via FFF-Verfahren. Keram. Z. 2019, 71, 56–61. [Google Scholar] [CrossRef]

- Gorjan, L.; Galusca, C.; Sami, M.; Sebastian, T.; Clemens, F. Effect of stearic acid on rheological properties and printability of ethylene vinyl acetate based feedstocks for fused filament fabrication of alumina. Addit. Manuf. 2020, 36, 101391. [Google Scholar] [CrossRef]

- Gorjan, L.; Tonello, R.; Sebastian, T.; Colombo, P.; Clemens, F. Fused deposition modeling of mullite structures from a preceramic polymer and γ-alumina. J. Eur. Ceram. Soc. 2019, 39, 2463–2471. [Google Scholar] [CrossRef]

- Cano, S.; Lube, T.; Huber, P.; Gallego, A.; Naranjo, J.A.; Berges, C.; Schuschnigg, S.; Herranz, G.; Kukla, C.; Holzer, C.; et al. Influence of the Infill Orientation on the Properties of Zirconia Parts Produced by Fused Filament Fabrication. Materials 2020, 13, 3158. [Google Scholar] [CrossRef]

- Cano, S.; Gonzalez-Gutierrez, J.; Sapkota, J.; Spoerk, M.; Arbeiter, F.; Schuschnigg, S.; Holzer, C.; Kukla, C. Additive manufacturing of zirconia parts by fused filament fabrication and solvent debinding: Selection of binder formulation. Addit. Manuf. 2019, 26, 117–128. [Google Scholar] [CrossRef]

- Scheithauer, U.; Weingarten, S.; Johne, R.; Schwarzer, E.; Abel, J.; Richter, H.J.; Moritz, T.; Michaelis, A. Ceramic-Based 4D Components: Additive Manufacturing (AM) of Ceramic-Based Functionally Graded Materials (FGM) by Thermoplastic 3D Printing (T3DP). Materials 2017, 10, 1368. [Google Scholar] [CrossRef] [Green Version]

- Vaidyanathan, R.; Walish, J.; Lombardi, J.L.; Kasichainula, S.; Calvert, P.; Cooper, K.C. The extrusion freeforming of functional ceramic prototypes. JOM 2000, 52, 34–37. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Kukla, C.; Sapkota, J.; Holzer, C. Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives. Materials 2018, 11, 840. [Google Scholar] [CrossRef] [Green Version]

- Hanemann, T.; Weber, O. Polymethylmethacrylate/polyethyleneglycol-based partially water soluble binder system for micro ceramic injection moulding. Microsyst. Technol. 2014, 20, 51–58. [Google Scholar] [CrossRef]

- Weber, O.; Hanemann, T. Green-conscious ceramic injection molding. In Advanced Processing and Manufacturing Technologies for Structural and Multifunctional Materials VI; Ihji, T., Singh, M., Halbig, M., Mathur, S., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2013; pp. 63–71. [Google Scholar] [CrossRef]

- Medesi, A.J.; Noetzel, D.; Hanemann, T. PVB/PEG-Based Feedstocks for Injection Molding of Alumina Microreactor Components. Materials 2019, 12, 1219. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Medesi, A.J.; Nötzel, D.; Wohlgemuth, J.; Franzreb, M.; Hanemann, T. Ceramic Injection Moulding using 3D-Printed Mould Inserts. Ceram. Mod. Tech. 2019, 1, 104–110. [Google Scholar] [CrossRef]

- Hanemann, T.; Honnef, K.; Hausselt, J. Process chain development for the rapid prototyping of microstructured polymer, ceramic and metal parts: Composite flow behaviour optimisation, replication via reaction moulding and thermal postprocessing. Int. J. Adv. Manuf. Technol. 2007, 33, 167–175. [Google Scholar] [CrossRef]

- Piotter, V.; Hanemann, T.; Heldele, R.; Mueller, T.; Plewa, K.; Ruh, A. Metal and Ceramic Parts fabricated by Microminiature powder injection molding. Int. J. Powder Met.. 2010, 46, 21–28. [Google Scholar]

- Antusch, S.; Hoffmann, J.; Klein, A.; Gunn, J.A.; Rieth, M. Processing of complex near-net-shaped tungsten parts by PIM. Nucl. Mater. Energy 2018, 16, 71–75. [Google Scholar] [CrossRef]

- Tülümen, M.; Hanemann, T.; Piotter, D.; Stenzel, D. Investigation of Feedstock Preparation for Injection Molding of Oxide-Oxide Ceramic Composites. J. Manuf. Mater. Process. 2019, 3, 9. [Google Scholar] [CrossRef] [Green Version]

- Agarwala, M.K.; Jamalabad, V.R.; Langrana, N.A.; Safari, A.; Whalen, P.J.; Danforth, S.C. Structural quality of parts processed by fused deposition. Rapid Prototyp. J. 1996, 2, 4–19. [Google Scholar] [CrossRef]

| Item | PEG/PVP | Reference Wax/PE |

|---|---|---|

| Solid | Al2O3 | Al2O3 |

| Solid load (vol.%) | 50 | 55 |

| Extrusion temperature (°C) | <170 | <170 |

| Printing speed (mm/s) | 10 | 10 |

| Platform temperature (°C) | 60 | 70 |

| Used nozzle diameter (mm) | 0.25 | 0.25 |

| Printing quality | Very good | Very good |

| Step/Temperature (°C) | Rate (°C/min) | Dwell Time @ Temperature (min) |

|---|---|---|

| 25–120 | 0.2 | 120 |

| 180 | 0.2 | 120 |

| 250 | 0.2 | 120 |

| 500 | 0.2 | 60 |

| 500–25 | n.a. | n.a. |

| Step/Temperature (°C) | Rate (°C/min) | Dwell Time @ Temperature (min) |

|---|---|---|

| 25–1400 | 3 | 360 |

| 1400–25 | 10 | 25 |

| Item | PEG/PVP 1 | Reference Wax/PE 1 [23,24] |

|---|---|---|

| Ceramic | Al2O3 | Al2O3 |

| Compounding | ✓ | ✓ |

| Filament extrusion | ✓ | ✓ |

| FFF printing | ✓ | ✓ |

| Max. printable solid load (Vol.%) | 50 | 55 |

| Debinding | ✓ | ✓ |

| Sintering | ✓ | ✓ |

| Max. ceramic part density (% Th.) | 97.1 ± 1.4 | 99.4 (50 vol.%), 99.6 (55 vol.%) [24] |

| Average shrinkage | 20.75% ± 0.8% | 20.4% ± 1.4% (50 vol.%); 18.0% ± 1.6% (55 vol.%) [24] |

| Item | FFF-Printed | Injection Molded |

|---|---|---|

| Replicated part | Cuboid | Disc |

| Number of considered parts | 10 | 10 |

| Theoretical alumina density (g/cm³) | 3.97 | 3.97 |

| Average sinter density (% Th.) | 97.1 ± 1.4 | 100 |

| Maximum part density (% Th.) | 98.5 | 100 |

| Shrinkage x-axis | 21.0% ± 0.5% | 20.0% ± 0.3% |

| Shrinkage y-axis | 20.8% ± 0.5% | 20.1% ± 0.2%. |

| Shrinkage z-axis | 20.5% ± 0.8% | 21.7% ± 1.1% |

| Average shrinkage | 20.75% ± 0.8% | 20.6% + 2.1%−0.9% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nötzel, D.; Hanemann, T. New Feedstock System for Fused Filament Fabrication of Sintered Alumina Parts. Materials 2020, 13, 4461. https://doi.org/10.3390/ma13194461

Nötzel D, Hanemann T. New Feedstock System for Fused Filament Fabrication of Sintered Alumina Parts. Materials. 2020; 13(19):4461. https://doi.org/10.3390/ma13194461

Chicago/Turabian StyleNötzel, Dorit, and Thomas Hanemann. 2020. "New Feedstock System for Fused Filament Fabrication of Sintered Alumina Parts" Materials 13, no. 19: 4461. https://doi.org/10.3390/ma13194461

APA StyleNötzel, D., & Hanemann, T. (2020). New Feedstock System for Fused Filament Fabrication of Sintered Alumina Parts. Materials, 13(19), 4461. https://doi.org/10.3390/ma13194461