Microtips’ manufacturing procedure consists of two steps. The first step is the application of a liquid monomer mixture as a drop at the end of a cleaved optical fiber [

6,

13,

14] or immersion of the optical fiber into a cuvette with this mixture. In the second step, light propagated in the optical fiber core cures the photopolymer so it becomes a hardened 3D polymer microstructure. The main elements of the technology are: monomer mixture photopolymerization ability, light source radiation parameters, and type of applied optical fiber. Proper selection of these parameters significantly influences the microtip shape. Therefore, the next section of the paper is dedicated to the detailed description of the impact of these parameters on the geometry of these types of micro-optic elements.

2.1. Monomer Mixtures and Optical Properties of Polymers

From the huge number of monomers that could be the basis for microtips’ production, the ones that are photopolymerizable were selected. Many tests were carried out, after which two types of multifunctional acrylate monomers met all requirements. In each of the tested mixtures, 3-functional pentaerythritol triacrylate (PETA; Sigma-Aldrich, St. Louis, MO, USA) or 2-functional tricyclo decanedimethanol diacrylate (TCDMA; Sigma-Aldrich, St. Louis, Missouri, United States) were used, and various additives depending on the light source were used in the experiment. Two types of photo-initiating systems (PISs) were used; the mixture was cured with UV (ultraviolet) or VIS (visible) radiation. The UV-curable mixture contained only two compounds, i.e., monomer and photo-initiator. The ranges of possible percentage compositions of mixtures are presented in

Table 1.

In this mixture, the PIS 2,2-Dimethoxy-2-phenylacetophenone (DMPAP) was used, which belonged to the α-Dialkoxy-acetophenones’ photo-initiator class [

14]. The VIS-curable mixture needs three compounds, i.e., monomer, sensitizer dye, and co-initiator. In this mixture, Eosin Y disodium salt and methyldiethanolamine (MDEA) were used as sensitizer and co-initiator, respectively. Eosin Y is photosensitive in the spectral range from 450 nm to 550 nm and allows use of the trigger photopolymerization process for the used VIS light source [

15]. Both above-mentioned chemical compounds were purchased from Sigma-Aldrich. Applications of different spectral ranges of the light sources and various compositions of the monomer mixtures allow obtaining polymers with different refractive indices (RI) [

1,

16]. In

Table 2 are presented measurements of RIs of the above-mentioned polymers. All prepared materials were measured on the Abbe refractometer, where uncertainty is defined at the level of 2σ where σ is the standard deviation of RI.

In all cases, the RI of the prepared mixtures increases after polymerization. Referring them to silica glass for which RIs are of around 1.4607 at 530 nm and around 1.4745 at 365 nm, both polymers have higher RIs. Moreover, the microtip can have an anisotropic structure with a higher RI in the center and with a lower RI in the outer section. However, as was shown by tomographic examinations [

8,

17], this difference reaches a value of around 0.0007 and the assumption that the RI distribution is homogeneous is acceptable.

2.2. Light Sources’ Parameters

In previous papers, the results obtained by using separately coherent light sources [

3,

13] or UV LED [

14] have been presented. In this paper, the influence on the microtip geometry of such source parameters as a full width at half maximum (FWHM) and a central wavelength are investigated. As the light source, the coherent laser at a wavelength of 532 nm and two broadband UV and VIS LEDs were used and compared.

Spectral characteristics of the light sources used in all experiments are presented in

Figure 1. VIS light sources have central wavelengths at 512 nm, 532 nm for a broadband LED (M530F2, ThorLabs, Newton, New Jersey), and an Nd YAG solid-state laser (Samba, Cobolt, Hubner Group company, Solna, Sweden), respectively. Their calculated FWHMs are of about 20 nm and less than 0.1 nm, respectively. The spectral characteristics of UV LED (M365FP1, ThorLabs, Newton, New Jersey) has a central wavelength of around 365 nm with a 5.0 nm FWHM.

In

Figure 2a,b, examples of intensity patterns in the near field of the fiber output for the standard gradient-index MMF with a 62.5 µm core were shown when the fiber was illuminated by the above-mentioned VIS light sources, whereas in

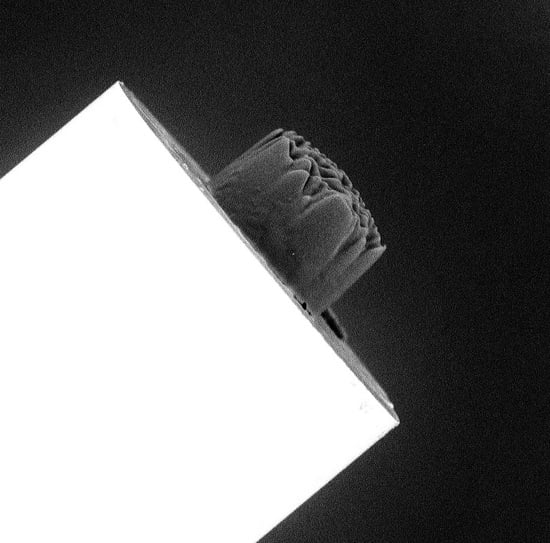

Figure 2c,d, a pair of microtips based on PETA monomer manufactured by using these sources is presented. The surface shape of the manufactured microtips reflects the modal characteristics of the used optical fiber illuminated by given sources. The broadband spectral characteristics of UV LED have a uniform Gaussian-like intensity distribution; the microtip has smooth edges and apex, while the intensity speckle pattern of the narrowband laser remodels these patterns in the 3D polymer structure. Both microtips have quasi-trapezoidal cross-sections, wider in the bottoms (base) and narrower at their tops.

Although the broadband source is key for obtaining a smooth microtip surface [

14], the other source parameter has an influence on the general microtip shape. In

Figure 3 are shown SEM images of the microtips manufactured by using UV (

Figure 3a) and VIS (

Figure 3b) LEDs based on a PETA monomer obtained on the same type of MMF as in the previous test. Depending on the used UV or VIS LEDs’ source, the microtip cross-section shape is quasi-rectangular or quasi-trapezoidal, respectively. Additionally, the microtip manufactured by UV light has a rounded apex while the other has a flat one. The above aspect will be deeper discussed in

Section 2.4 and summarized in

Section 3.

2.3. Selected Multi-Mode Optical Fibers

As was shown in the previous section, the optical fiber influences the microtip’s shape due to its modal characteristics. Therefore, different types of optical fibers were selected to optimize the procedure of microtip manufacturing. In this paper were used: gradient-index MMF with a 62.5 µm core diameter and three step-index MMFs with 50 µm, 105 µm, and 200 µm cores diameters. Based on the previous studies, these MMFs were selected in terms of their reflective properties [

13,

14]. In

Table 3, the main parameters of the used MMFs are presented. They were divided into categories related to the core and cladding diameters, numerical aperture (NA), and RI profile distribution. All selected optical fibers were purchased from ThorLabs, and their specific names were presented.

In

Figure 4 are presented the selected microtips obtained using the UV LED and both PETA and TCDMA monomer mixtures at the ends of the MMFs from

Table 3. Each of the micro-element was prepared at various optical power and exposure times to show the possibility of shaping this type of optical microstructure.

As demonstrated, all of them have smooth surfaces, but their shapes significantly differ. The microtip on a 50 µm step-index MMF from

Figure 4a has a quasi-rectangular cross-section with a flat apex. The microtip on a 62.5 µm gradient-index MMF (

Figure 4b) is quasi-rectangular with a rounded apex similar to the microtip in

Figure 3a. Increasing the core size of the step-index optical fiber to 105 µm resulted in the shape change to quasi-rounded with high curvature (

Figure 4c). Further increase of the core size of the same MMF refractive index profile formed a microtip with a quasi-rectangular cross-section and conical apex (

Figure 4d). The above results showed the possibility for microtip shaping by choosing suitable optical fibers.

2.4. Technical Parameters of the Manufacturing Process

Technical parameters in the manufacturing process are: position of the fiber, amount of optical energy absorbed by the mixture, and amount of mixture that can be assessed as the droplet size. As an application method of the monomer mixture was used a drop deposition at the end of a cleaved optical fiber by the method previously described [

4]. Immersing the optical fiber into a cuvette with the monomer mixture does not give positive results.

The shape of the liquid drop deposited at the MMF’s end depends on surface tension forces defined by optical fiber diameter, amount, and viscosity of the monomer mixture [

1]. In

Figure 5 are shown two pairs of optical microscope images of the optical fiber with deposited monomer drops (

Figure 5a,c) and formed microtips for the same optical power and different exposure times (

Figure 5b,d). The applied drops of the mixture (

Figure 5a,c) have the same height and the same shape because the surface tension forces form a rounded shape on the forehead of the fiber. The photopolymerization process creates a 3D polymer microstructure in the form of a microtip and the height of the microtip varies depending on the absorption by mixture energy, which is proportional to the exposure time, in this example. In the first case (

Figure 5b), the short exposure time produces a 20 µm high trapezoidal microtip and in the second case (

Figure 5d) the microtip is rectangular at 39 µm high and is equal to the size of the initial drop.

The exposure time, for a given optical power of the source, should be enough to polymerize over the entire area of the applied drop. It results from the fact that the chain process of photopolymerization occurs when the mixture is illuminated with a VIS source, defined in

Section 2.1. After radiation stops, the polymerization process is stopped as well. As noted in [

18], the cured part of the mixture becomes an extension of the optical fiber core and acts as a waveguide, illuminating and curing subsequent layers of the liquid polymer. Time of exposure does not affect the shape of the edge or the top of the microtip, but it determines its height. Keeping the same optical power, the resulting microtips have the same height as the height of the liquid drop if the exposure time is long enough for polymerization along the entire length of the drop. If the exposure time is too short, not all of the liquid mixture is polymerized, and the microtip has a lower height than the initial drop. For a different testing time of exposure (1 s, 10 s, 20 s, 30 s, 60 s, 120 s), it was found that 60 s is enough to cure the entire height of the drop. Reduced exposure time means less energy delivered to the system, so the manufactured microtip is lower than microtip for longer times.

Microtips produced on the gradient-index MMF had a slightly rounded apex with a large radius of curvature. The curvature is in proportional relation to the curvature of the liquid drop before photopolymerization and the microtip’s apex radius is always smaller than the drop’s radius (see

Figure 6). This discrepancy results from the fact that the polymerization process runs only in a certain area of the drop and the apex shapes are determined by the mode distribution of the light beam on the optical fiber output. This shrinking process of the material occurs when it changes its state from liquid to solid. The experimental results showed that for optical powers within the range of 5 µW–40 µW and exposure times from 1 s to 60 s, the average difference between the curvature radius of the microtip’s apex and drop is of about 26 µm for the VIS light sources and of 36 µm for UV LED. It was previously noted [

19] that elements produced on an SMF’s end face had a greater curvature radius than the fiber core diameter, and the microtip curvature radius increased with the exposure time. While for the used MMF, the microtip’s apex curvature radius can be greater or smaller than 62.5 µm and it depends on optical power. Besides, no relationship was found between exposure time and the microtips’ curvature radius. In

Figure 6, the microscope images of the liquid drop and microtip with the approximation circles are presented.

The difference between the drop’s curvature and microtip’s apex in the above figures is around 32.5 µm. By careful control of the mixture amount, the microtip height is similar every time. In

Table 4, the average microtips’ heights with their uncertainties for an MMF gradient-index with a 62.5 µm core diameter and both monomers’ mixture (PETA, TCDMA) are presented. Moreover, research results have shown that the highest microtip fabricated on an MMF with the core diameter of: 50 µm, 62.5 µm, 105 µm, and 200 µm have lengths of about: 31 µm, 39 µm, 29 µm, and 63 µm, respectively. The position of the optical fiber was always the same, i.e., MMF’s end was directed vertically downward. However, it is worth noting that no differences were found in the microtip’s creation in various fiber settings in space. What is most important here is that the adhesion force between the fiber and the polymer drops while the gravity force is of secondary importance.

During the experiment, it was found that absorbed optical energy is a more important parameter. This energy is defined by optical power and exposure time. Depending on this parameter, microtips have different base sizes [

13,

14]. Moreover, it has been noticed that with the optical power increase, the microtip base diameter increases as well. The rate of this change depends on the monomer mixture composition and the source spectral characteristics. In

Figure 7 the results for microtips, based on mixtures with PETA (black dots) and TCDMA (red dots) monomers, manufactured by VIS laser are presented.

SEM images of microtips allow measuring the size of their bases. Analysis of the data related to the PETA-based microtips (black) indicates that, theoretically, the microtip base covers the entire core of the MMF at the optical power of about 30 μW (black curve approximation) while the experimental value is of around 40 μW. For the mixture with the TCDMA monomer, the approximated optical power value of 150 μW is enough to form a microtip with a base diameter similar to the core diameter of the used MMF (red curve), while the experiment’s obtained value (red dots) was of 300 μW.