Abrasive Wear Behavior of Cryogenically Treated Boron Steel (30MnCrB4) Used for Rotavator Blades

Abstract

:1. Introduction

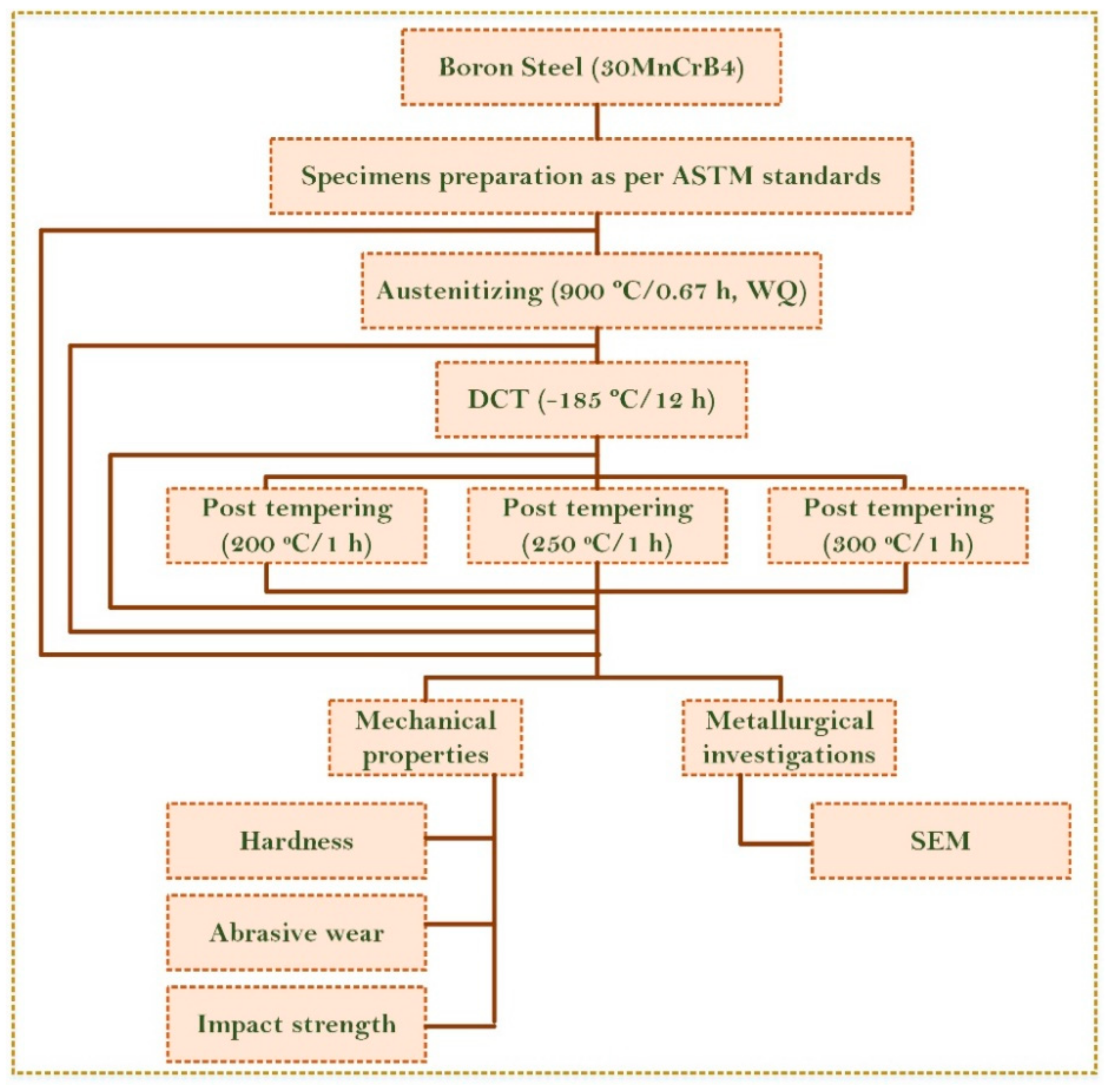

2. Materials and Methods

2.1. Untreated Material

2.2. Methods

2.2.1. Austenitization

2.2.2. Deep Cryogenic Treatment

2.2.3. Post Tempering

2.3. Metallurgical Investigation

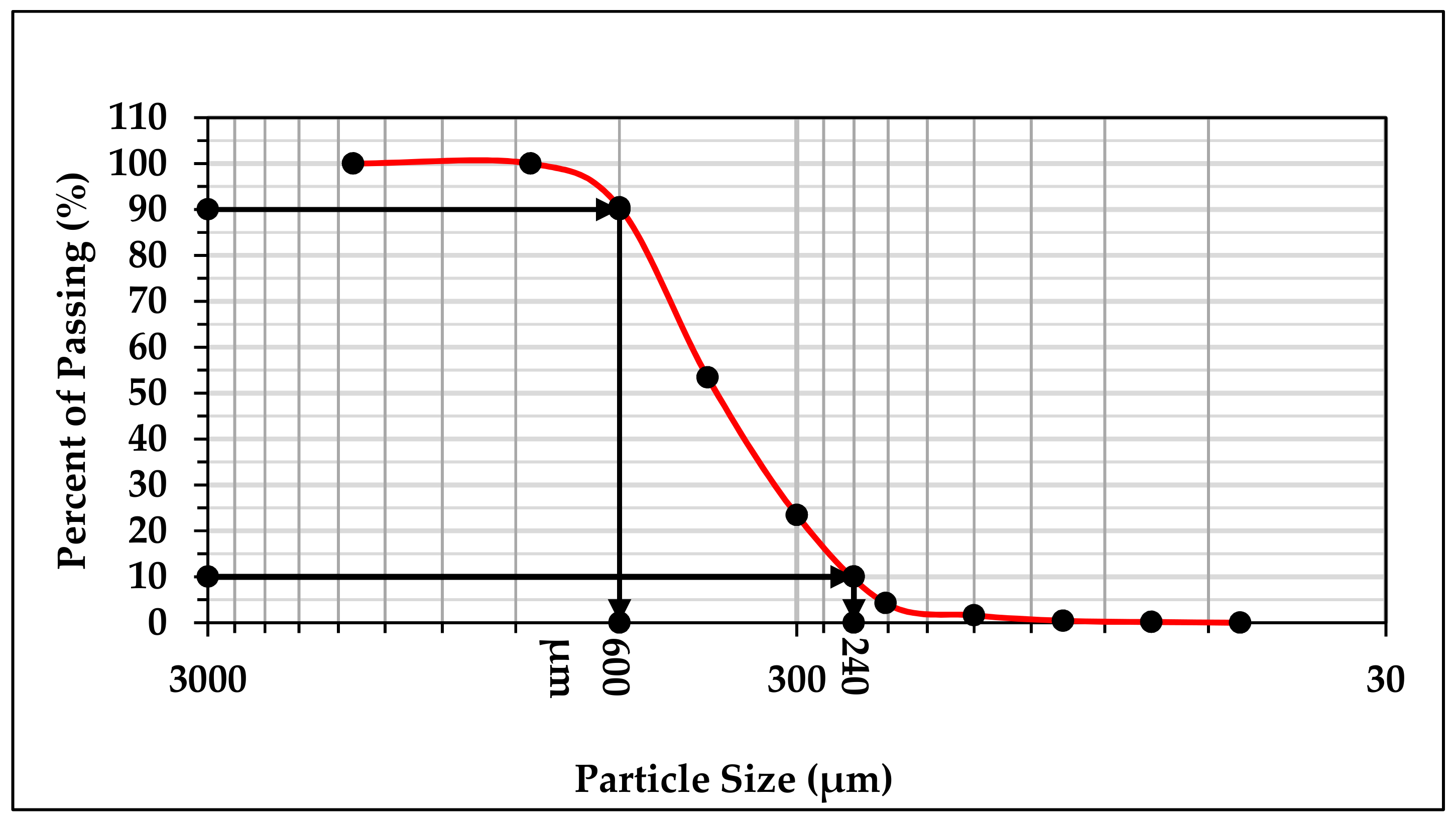

2.4. Mechanical Properties

3. Results and Discussions

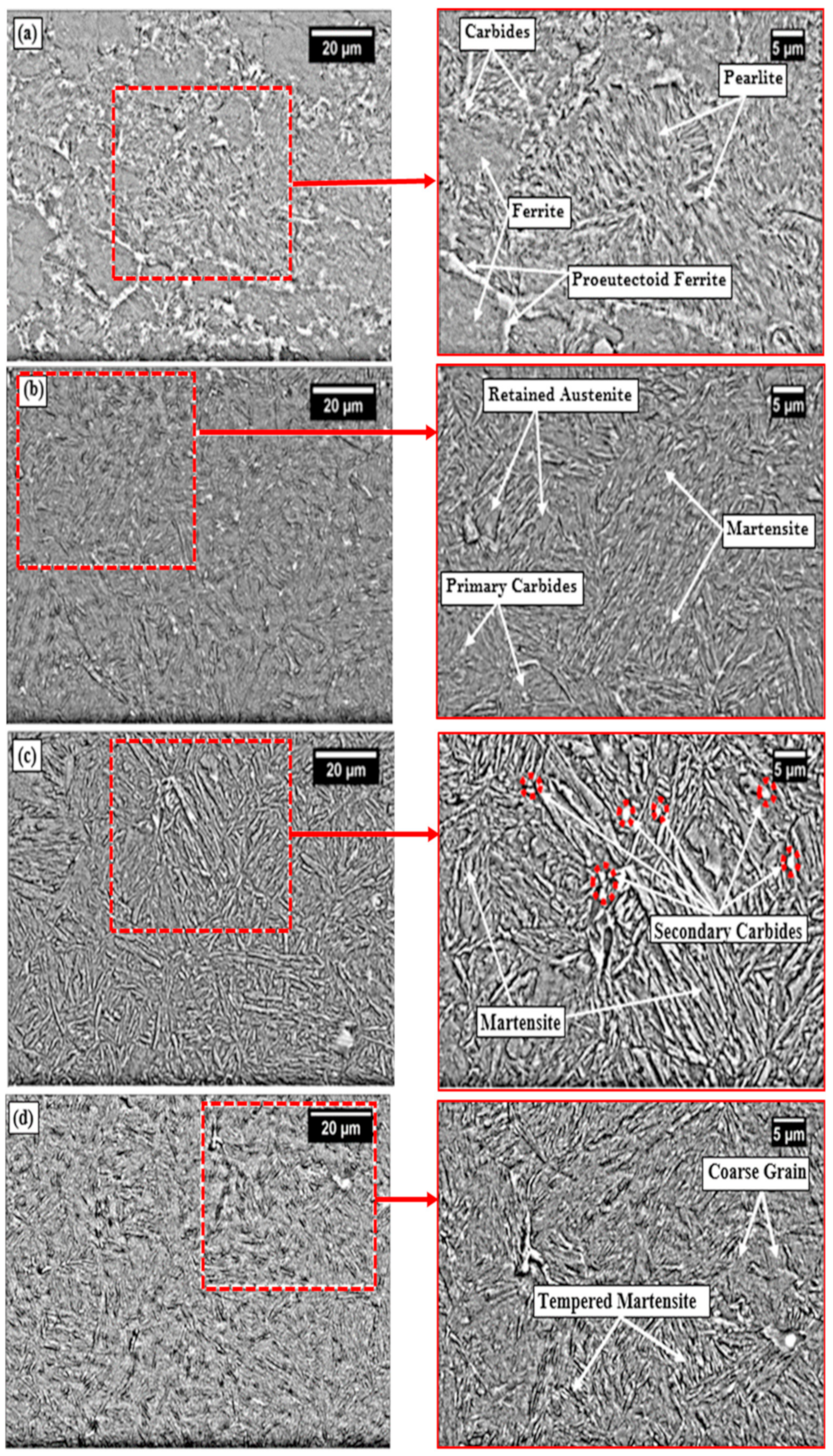

3.1. Microstructure

3.2. Hardness

3.3. Impact Strength

3.4. Abrasive Wear

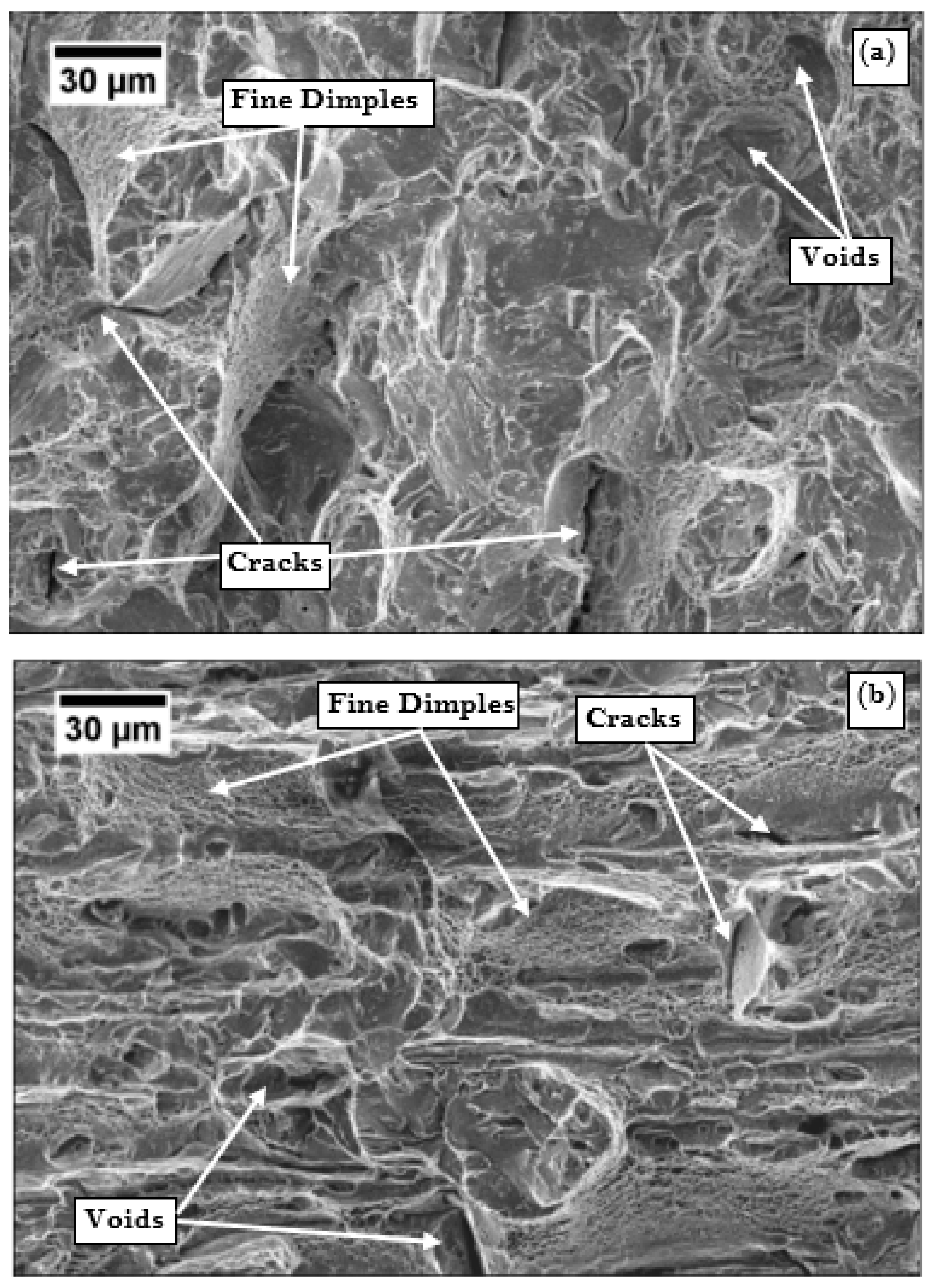

Worn Surface Morphology

3.5. Economic Analysis

| The cost of one blade (including cost of hardening) | =Rs. 215 |

| Size of rotavator | =07 Feet |

| Total number of blades | =48 |

| Weight of one blade | =1.04 Kg |

| Number of blades to be cryogenically treated in one lot | =5 × 48 = 240 |

| Additional cost for proposed cryogenic treatment on one lot | =Rs. 7800 |

| Additional cost/blade | =7800/240 = Rs. 32.50 |

| Percentage improvement in wear resistance of blade after cryogenic treatment in comparison with CHT (hardened) | =25.7% |

| Percentage increase in cost per blade due to cryogenic treatment | =15.12% |

4. Conclusions

- (1)

- During deep cryogenic treatment, retained austenite left after conventional heat treatment was transformed into martensite. Cryogenic treatment also resulted in formation of secondary carbides and helped in bringing more uniformity in distribution of secondary carbides. Tempering post cryogenic treatment led to grain coarsening and martensite decomposition;

- (2)

- Hardness of cryotreated (CDCT-T0) specimen was improved by 260.73% compared to UT material, due to the formation of martensite along with the precipitation of secondary carbides. Tempering post cryogenic treatment caused reduction in hardness due to grain coarsening and martensite decomposition;

- (3)

- Impact strength of the cryotreated (CDCT-T0) specimen was augmented by 50% in comparison with CHT specimen, due to increasing the nucleation of carbides, which facilitated the precipitation of a higher number of fine carbides during cryogenic treatment, resulting in a higher impact strength of material. Post tempering enhanced the impact strength, which further increased with higher tempering temperature;

- (4)

- Abrasive wear volume loss in cryotreated (CDCT-T0) specimens were reduced by 60% compared to UT samples, owing to improvement in hardness, RA conversion into martensite, and the formation of secondary carbides. Tempering post cryogenic treatment resulted in decline in abrasive wear resistance;

- (5)

- The additional cost of 15.12% was incurred due to cryogenic treatment, whereas the expected augmentation in wear resistance of rotavator blade material was 25.70%. The economic analysis clearly justified the additional cost of cryogenic treatment.

Author Contributions

Funding

Conflicts of Interest

References

- Saxena, A.C. Dushyant Singh Techno Economically Viable Production Package of Rotavator Blade for Entrepreneurs. Agric. Eng. Today 2010, 34, 23–25. [Google Scholar]

- Ferguson, S.A.; Fielke, J.M.; Riley, T.W. Wear of cultivator shares in abrasive South Australian soils. J. Agric. Eng. Res. 1998, 69, 99–105. [Google Scholar] [CrossRef]

- Salokhe, V.M.; Gee-Clough, D. Coating of cage wheel lugs to reduce soil adhesion. J. Agric. Eng. Res. 1988, 41, 201–210. [Google Scholar] [CrossRef]

- Salokhe, V.M.; Gee-Clough, D.; Tamtomo, P. Wear testing of enamel coated rings. Soil Tillage Res. 1991, 21, 121–131. [Google Scholar] [CrossRef]

- Kumar, S.; Mondal, D.P.; Jha, A.K. Effect of microstructure and chemical composition of hardfacing alloy on abrasive wear behavior. J. Mater. Eng. Perform. 2000, 9, 649–655. [Google Scholar] [CrossRef]

- Singh, P.; Bansal, A.; Kumar Goyal, D. Erosion wear evaluation of HVOF sprayed WC-12Co coating on some pipeline materials using Taguchi approach. Kovove Mater. 2019, 57, 113–120. [Google Scholar] [CrossRef] [Green Version]

- Bansal, A.; Singh, J.; Singh, H. Slurry Erosion Behavior of HVOF-Sprayed WC-10Co-4Cr Coated SS 316 Steel with and Without PTFE Modification. J. Therm. Spray Technol. 2019, 28, 1448–1465. [Google Scholar] [CrossRef]

- Karoonboonyanan, S.; Salokhe, V.M.; Niranatlumpong, P. Wear resistance of thermally sprayed rotary tiller blades. Wear 2007, 263, 604–608. [Google Scholar] [CrossRef]

- Bayhan, Y. Reduction of wear via hardfacing of chisel ploughshare. Tribol. Int. 2006, 39, 570–574. [Google Scholar] [CrossRef]

- Chahar, V.K.; Tiwari, G.S. Wear characteristics of reversible cultivator shovels treated with different surface hardening processes. J. Inst. Eng. Agric. Eng. Div. 2009, 90, 42–45. [Google Scholar]

- Raval, A.H.; Kaushal, O.P. Wear and tear of hard surfaced cultivator shovel. Agric. Mech. Asia Afr. Lat. Am. 1990, 21, 46–48. [Google Scholar]

- Moore, M.A.; McLees, V.A.; King, F.S. Hard-facing soil-engaging equipment. Agric. Eng. 1979, 34, 15–19. [Google Scholar]

- Buchely, M.F.; Gutierrez, J.C.; León, L.M.; Toro, A. The effect of microstructure on abrasive wear of hardfacing alloys. Wear 2005, 259, 52–61. [Google Scholar] [CrossRef]

- Kumar, S.; Mondal, D.P.; Khaira, H.K.; Jha, A.K. Improvement in high stress abrasive wear property of steel by hardfacing. J. Mater. Eng. Perform. 1999, 8, 711–715. [Google Scholar] [CrossRef]

- Moore, M.A. The abrasive wear resistance of surface coatings. J. Agric. Eng. Res. 1975, 20, 167–179. [Google Scholar] [CrossRef]

- Atïk, E. Mechanical properties and wear strengths in aluminiumalumina composites. Mater. Struct. Constr. 1998, 31, 418–422. [Google Scholar] [CrossRef]

- Meric, C.; Sahin, S.; Backir, B.; Koksal, N.S. Investigation of the boronizing effect on the abrasive wear behavior in cast irons. Mater. Des. 2006, 27, 751–757. [Google Scholar] [CrossRef]

- Allaoui, O.; Bouaouadja, N.; Saindernan, G. Characterization of boronized layers on a XC38 steel. Surf. Coatings Technol. 2006, 201, 3475–3482. [Google Scholar] [CrossRef]

- Béjar, M.A.; Moreno, E. Abrasive wear resistance of boronized carbon and low-alloy steels. J. Mater. Process. Technol. 2006, 173, 352–358. [Google Scholar] [CrossRef]

- Bourithis, L.; Papadimitriou, G. Boriding a plain carbon steel with the plasma transferred arc process using boron and chromium diboride powders: Microstructure and wear properties. Mater. Lett. 2003, 57, 1835–1839. [Google Scholar] [CrossRef]

- Sharma, M.C.; Mubeen, A. Effect of shot size on peening intensity for local peening. J. Mech. Work. Technol. 1983, 8, 155–160. [Google Scholar] [CrossRef]

- Singh, D.; Saxena, A.C. Characterization of Materials Used for Rotavator Blades. Agric. Eng. Today 2011, 35, 10–14. [Google Scholar]

- Yazici, A. Wear behavior of carbonitride-treated ploughshares produced from 30MnB5 steel for soil tillage applications. Met. Sci. Heat Treat. 2011, 53, 248–253. [Google Scholar] [CrossRef]

- Singh, D.; Saha, K.P.; Mondal, D.P. Development of mathematical model for prediction of abrasive wear behaviour in agricultural grade medium carbon steel. Indian J. Eng. Mater. Sci. 2011, 18, 125–136. [Google Scholar]

- Bhakat, A.K.; Mishra, A.K.; Mishra, N.S.; Jha, S. Metallurgical life cycle assessment through prediction of wear for agricultural grade steel. Wear 2004, 257, 338–346. [Google Scholar] [CrossRef]

- Gupta, A.K.; Jesudas, D.M.; Das, P.K.; Basu, K. Performance evaluation of different types of steel for duck foot sweep application. Biosyst. Eng. 2004, 88, 63–74. [Google Scholar] [CrossRef]

- Jha, A.K.; Prasad, B.K.; Modi, O.P.; Das, S.; Yegneswaran, A.H. Correlating microstructural features and mechanical properties with abrasion resistance of a high strength low alloy steel. Wear 2003, 254, 120–128. [Google Scholar] [CrossRef]

- Singla, A.K.; Singh, J.; Sharma, V.S. Processing of materials at cryogenic temperature and its implications in manufacturing: A review. Mater. Manuf. Process. 2018, 33, 1603–1640. [Google Scholar] [CrossRef]

- Kumar, T.V.; Thirumurugan, R.; Viswanath, B. Influence of Cryogenic Treatment on the Metallurgy of Ferrous Alloys - A Review. Mater. Manuf. Process. 2017, 32, 1789–1805. [Google Scholar] [CrossRef]

- Akincioğlu, S.; Gökkaya, H.; Uygur, İ. A review of cryogenic treatment on cutting tools. Int. J. Adv. Manuf. Technol. 2015, 78, 1609–1627. [Google Scholar] [CrossRef]

- Gill, S.S.; Singh, H.; Singh, R.; Singh, J. Cryoprocessing of cutting tool materials—A review. Int. J. Adv. Manuf. Technol. 2010, 48, 175–192. [Google Scholar] [CrossRef]

- Kalsi, N.S.; Sehgal, R.; Sharma, V.S. Cryogenic Treatment of Tool Materials: A Review. Mater. Manuf. Process. 2010, 25, 1077–1100. [Google Scholar] [CrossRef]

- Baldissera, P.; Delprete, C. Deep Cryogenic Treatment: A Bibliographic Review. Open Mech. Eng. J. 2008, 2, 1–11. [Google Scholar] [CrossRef]

- Yong, J.; Ding, C.; Qiong, J. Effect of cryogenic thermocycling treatment on the structure and properties of magnesium alloy AZ91. Met. Sci. Heat Treat. 2012, 53, 589–591. [Google Scholar] [CrossRef]

- Bhale, P.; Shastri, H.; Mondal, A.K.; Masanta, M.; Kumar, S.; Li, X.; Yao, Y.; Shaffer, D.; Reinstadtler, C.; Roth, J.T.; et al. Effect of Deep Cryogenic Treatment on Microstructure and Properties of AE42 Mg Alloy. J. Mater. Eng. Perform. 2016, 25, 3590–3598. [Google Scholar] [CrossRef]

- Mohan, K.; Suresh, J.A.; Ramu, P.; Jayaganthan, R. Microstructure and Mechanical Behavior of Al 7075-T6 Subjected to Shallow Cryogenic Treatment. J. Mater. Eng. Perform. 2016, 25, 2185–2194. [Google Scholar] [CrossRef]

- Steier, V.F.; Ashiuchi, E.S.; Reißig, L.; Araújo, J.A. Effect of a Deep Cryogenic Treatment on Wear and Microstructure of a 6101 Aluminum Alloy. Adv. Mater. Sci. Eng. 2016. [Google Scholar] [CrossRef] [Green Version]

- Singla, A.K.; Singh, J.; Kumar, P.; Kumar, A.; Sharma, V.S. Effect of cryogenic treatment on the wear resistance and microstructure of Ti-6AL-4V. Indian J. Eng. Mater. Sci. 2018, 25, 243–249. [Google Scholar]

- Singla, A.K.; Singh, J.; Sharma, V.S. Impact of Cryogenic Treatment on Mechanical Behavior and Microstructure of Ti-6Al-4V ELI Biomaterial. J. Mater. Eng. Perform. 2019, 28, 5931–5945. [Google Scholar] [CrossRef]

- Krolczyk, G.M.; Maruda, R.W.; Krolczyk, J.B.; Wojciechowski, S.; Mia, M.; Nieslony, P.; Budzik, G. Ecological trends in machining as a key factor in sustainable production—A review. J. Clean. Prod. 2019, 218, 601–615. [Google Scholar] [CrossRef]

- Mia, M.; Gupta, M.K.; Lozano, J.A.; Carou, D.; Pimenov, D.Y.; Królczyk, G.; Khan, A.M.; Dhar, N.R. Multi-objective optimization and life cycle assessment of eco-friendly cryogenic N2 assisted turning of Ti-6Al-4V. J. Clean. Prod. 2019, 210, 121–133. [Google Scholar] [CrossRef]

- Kopac, J.; Pusavec, F.; Krolczyk, G. Cryogenic machining, surface integrity and machining performance. Arch. Mater. Sci. Eng. 2015, 71, 83–93. [Google Scholar]

- Eller, T.K.; Greve, L.; Andres, M.T.; Medricky, M.; Hatscher, A.; Meinders, V.T.; Van Den Boogaard, A.H. Plasticity and fracture modeling of quench-hardenable boron steel with tailored properties. J. Mater. Process. Technol. 2014, 214, 1211–1227. [Google Scholar] [CrossRef]

- Namklang, P.; Uthaisangsuk, V. Description of microstructures and mechanical properties of boron alloy steel in hot stamping process. J. Manuf. Process. 2016, 21, 87–100. [Google Scholar] [CrossRef]

- Naderi, M. Hot Stamping of Ultra High Strength Steels; Springer International Publishing: Cham, Switzerland, 2007. [Google Scholar]

- Singh, T.P.; Singh, J.; Singh, K. An investigation on abrasive wear behaviour of rotary blade (AISI 30MnCrB4 ) under different quenching parameters. In Proceedings of the CPIE, Jalandhar, India, 19–21 December 2016. [Google Scholar]

- ASTM. E 23-12c Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. Standards 2013, i, 1–25. [Google Scholar]

- ASTM. International G65-16: Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel. ASTM Stand. 2013, 4, 1–12. [Google Scholar]

- Avery, H.S. The measurement of wear resistance. Wear 1961, 4, 427–449. [Google Scholar] [CrossRef]

- Singh, T.P.; Singh, J.; Singh, K. Enhancing the abrasive wear resistance of rotary blade material (AISI 30MnCrB4) by cryogenic treatment. J. Sci. Ind. Res. 2018, 77, 92–97. [Google Scholar]

- Nahvi, S.M. Abrasive Wear Behaviour of Steels and Advanced HVOF-Sprayed WC-M Coatings. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2011. [Google Scholar]

- Moore, M.A.; Swanson, P.A. The effect of particle shape on abrasive wear: A comparison of theory and experiment. In Proceedings International Conference on Wear of Materials; Ludema, K.C., Ed.; ASME: New York, NY, USA, 1983; pp. 1–11. [Google Scholar]

- Kašparová, M.; Zahálka, F.; Houdková, S.; Ctibor, P. Abrasive wear of WC-NiMoCrFeCo thermally sprayed coatings in dependence on different types of abrasive sands. Kovove Mater. 2010, 48, 73–85. [Google Scholar]

- Singh, D.; Mondal, D.P.; Modi, O.P.; Sethi, V.K. Low stress abrasive wear response of boron steel under three body abrasion: Effect of heat treatment and peening intensities. Indian J. Eng. Mater. Sci. 2010, 17, 208–212. [Google Scholar]

- Güler, H.; Ertan, R.; Özcan, R. Influence of heat treatment parameters on the micrestructure and mechanical properties of boron-alloyed steels. Mater. Test. 2012, 54, 619–624. [Google Scholar] [CrossRef]

- Liu, H.; Wang, J.; Yang, H.; Shen, B. Effects of cryogenic treatment on microstructure and abrasion resistance of CrMnB high-chromium cast iron subjected to sub-critical treatment. Mater. Sci. Eng. A 2008, 478, 324–328. [Google Scholar] [CrossRef]

- Gola, A.M.; Ghadamgahi, M.; Ooi, S.W. Microstructure evolution of carbide-free bainitic steels under abrasive wear conditions. Wear 2017, 376–377, 975–982. [Google Scholar] [CrossRef]

- Li, H.; Tong, W.; Cui, J.; Zhang, H.; Chen, L.; Zuo, L. The influence of deep cryogenic treatment on the properties of high-vanadium alloy steel. Mater. Sci. Eng. A 2016, 662, 356–362. [Google Scholar] [CrossRef]

- Song, Z.; Zhao, S.; Jiang, T.; Sun, J.; Wang, Y.; Zhang, X.; Liu, H.; Liu, Y. Effect of nanobainite content on the dry sliding wear behavior of an Al-Alloyed high carbon steel with nanobainitic microstructure. Materials 2019, 12, 1618. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Xiao, M.; Ye, G.; Zhao, K.; Yang, M. Effects of deep cryogenic treatment on microstructural evolution and alloy phases precipitation of a new low carbon martensitic stainless bearing steel during aging. Mater. Sci. Eng. A 2018, 732, 167–177. [Google Scholar] [CrossRef]

- Chintha, A.R. Metallurgical aspects of steels designed to resist abrasion, and impact-abrasion wear. Mater. Sci. Technol. 2019, 35, 1133–1148. [Google Scholar] [CrossRef] [Green Version]

- Jaswin, M.A.; Lal, D.M. Impact Behavior of Cryogenically Treated En 52 and 21-4N Valve Steels. Int. J. Mech. Ind. Sci. Eng. 2014, 8, 159–164. [Google Scholar]

- Vuorinen, E.; Ojala, N.; Heino, V.; Rau, C.; Gahm, C. Erosive and abrasive wear performance of carbide free bainitic steels—Comparison of field and laboratory experiments. Tribol. Int. 2016, 98, 108–115. [Google Scholar] [CrossRef]

- Chand, N.; Neogi, S. Mechanism of material removal during three-body abrasion of FRP composite. Tribol. Lett. 1998, 4, 81–85. [Google Scholar] [CrossRef]

- Nadig, D.S.; Jacob, S.; Karunanithi, R.; Manjunatha, R.; Subramanian, D.; Prasad, M.V.N.; Sen, G.; Jha, A.K. Studies of cryotreatment on the performance of integral diaphragm pressure transducers for space application. Cryogenics 2010, 50, 561–565. [Google Scholar] [CrossRef]

- Vuorinen, E.; Heino, V.; Ojala, N.; Haiko, O.; Hedayati, A. Erosive-abrasive wear behavior of carbide-free bainitic and boron steels compared in simulated field conditions. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 3–13. [Google Scholar] [CrossRef]

- Hernandez, S.; Leiro, A.; Rodríguez, M.; Vuorinen, E.; Sundin, K.; Prakash, B. High temperature three-body abrasive wear of 0.25C 1.42Si steel with carbide free bainitic (CFB) and martensitic microstructures. Wear 2016, 360–361, 21–28. [Google Scholar] [CrossRef]

| Elements | As Received | As Per Standards |

|---|---|---|

| C | 0.29 | 0.24–0.30 |

| Mn | 1.23 | 1.10–1.40 |

| Si | 0.221 | 0.40 |

| P | 0.032 | 0.030 |

| Cr | 0.306 | 0.30–0.60 |

| B | 0.002 | 0.0008–0.0050 |

| Fe | balance | balance |

| Factors | Levels | ||

|---|---|---|---|

| 1 | 2 | 3 | |

| A: Medium | Water | Oil | Oil-Water |

| B: Temperature (°C) | 800 | 850 | 900 |

| C: Time (min) | 20 | 30 | 40 |

| Sr. No. | Parameters | Level |

|---|---|---|

| 1 | Soaking temperature (°C) | −185 |

| 2 | Cooling rate (°C/min) | 0.5 |

| 3 | Soaking period (h) | 12 |

| 4 | Heating rate (°C/min) | 0.5 |

| Sr. No. | Type of Treatment | Specimen Coding |

|---|---|---|

| 1 | Untreated Material | UT |

| 2 | CHT (900 °C/0.67 h, WQ) | CHT |

| 3 | CHT (900 °C/0.67 h, WQ) + DCT (−185 °C/12 h) | CDCT-T0 |

| 4 | CHT (900 °C/0.67 h, WQ) + DCT (−185 °C/12 h) + Tempering (200 °C/1 h, FC) | CDCT-T1 |

| 5 | CHT (900 °C/0.67 h, WQ) + DCT (−185 °C/12 h) + Tempering (250 °C/1 h, FC) | CDCT-T2 |

| 6 | CHT (900 °C/0.67 h, WQ) + DCT (−185 °C/12 h) + Tempering (300 °C/1 h, FC) | CDCT-T3 |

| Parameters | Unit | Value |

|---|---|---|

| Load | N | 130 |

| Speed | m/s | 3.17 |

| Rotational speed of wheel | rpm | 200 |

| Abrasive flow rate | g/min | 300 |

| Abrasive size | µm | 212–425 |

| Sliding distance | m | 1900 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, T.P.; Singla, A.K.; Singh, J.; Singh, K.; Gupta, M.K.; Ji, H.; Song, Q.; Liu, Z.; Pruncu, C.I. Abrasive Wear Behavior of Cryogenically Treated Boron Steel (30MnCrB4) Used for Rotavator Blades. Materials 2020, 13, 436. https://doi.org/10.3390/ma13020436

Singh TP, Singla AK, Singh J, Singh K, Gupta MK, Ji H, Song Q, Liu Z, Pruncu CI. Abrasive Wear Behavior of Cryogenically Treated Boron Steel (30MnCrB4) Used for Rotavator Blades. Materials. 2020; 13(2):436. https://doi.org/10.3390/ma13020436

Chicago/Turabian StyleSingh, Tejinder Pal, Anil Kumar Singla, Jagtar Singh, Kulwant Singh, Munish Kumar Gupta, Hansong Ji, Qinghua Song, Zhanqiang Liu, and Catalin I. Pruncu. 2020. "Abrasive Wear Behavior of Cryogenically Treated Boron Steel (30MnCrB4) Used for Rotavator Blades" Materials 13, no. 2: 436. https://doi.org/10.3390/ma13020436

APA StyleSingh, T. P., Singla, A. K., Singh, J., Singh, K., Gupta, M. K., Ji, H., Song, Q., Liu, Z., & Pruncu, C. I. (2020). Abrasive Wear Behavior of Cryogenically Treated Boron Steel (30MnCrB4) Used for Rotavator Blades. Materials, 13(2), 436. https://doi.org/10.3390/ma13020436