Durability of Structural Lightweight Concrete with Sintered Fly Ash Aggregate

Abstract

1. Introduction

1.1. Specificity of Lightweight Aggregate Concrete’s Durability

1.2. Water Tightness of Lightweight Aggregate Concretes

1.3. Chloride Penetration of Lightweight Aggregate Concretes

1.4. Carbonation of Lightweight Aggregate Concretes

1.5. Freeze-Thaw Resistance of Lightweight Aggregate Concretes

2. Materials and Methods

2.1. Constituent Materials

2.2. Concrete Compositions and the Preparation Procedure

2.3. Molding Specimens

2.4. Procedures for Testing Hardened Concrete

3. Results

3.1. Water Absorption

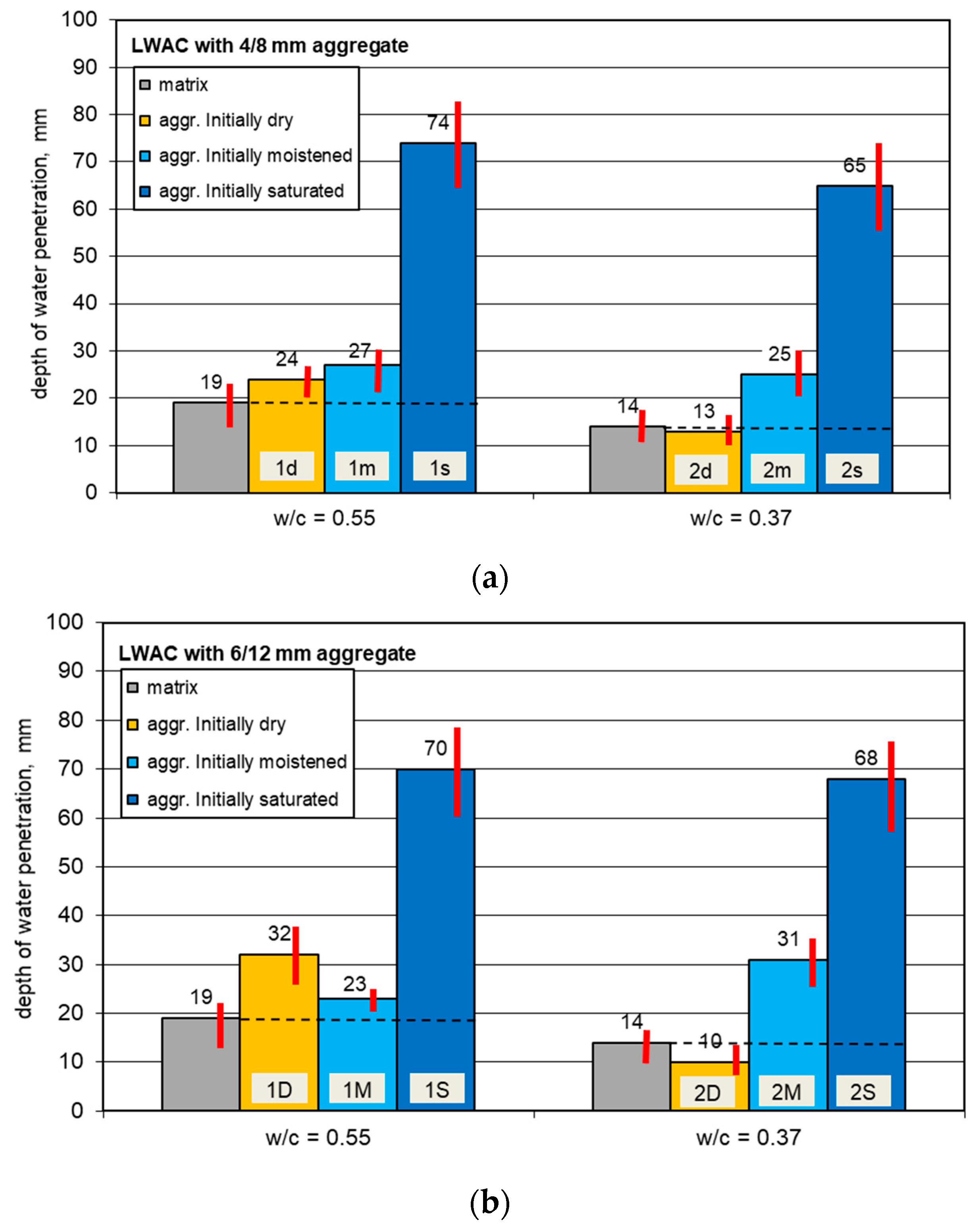

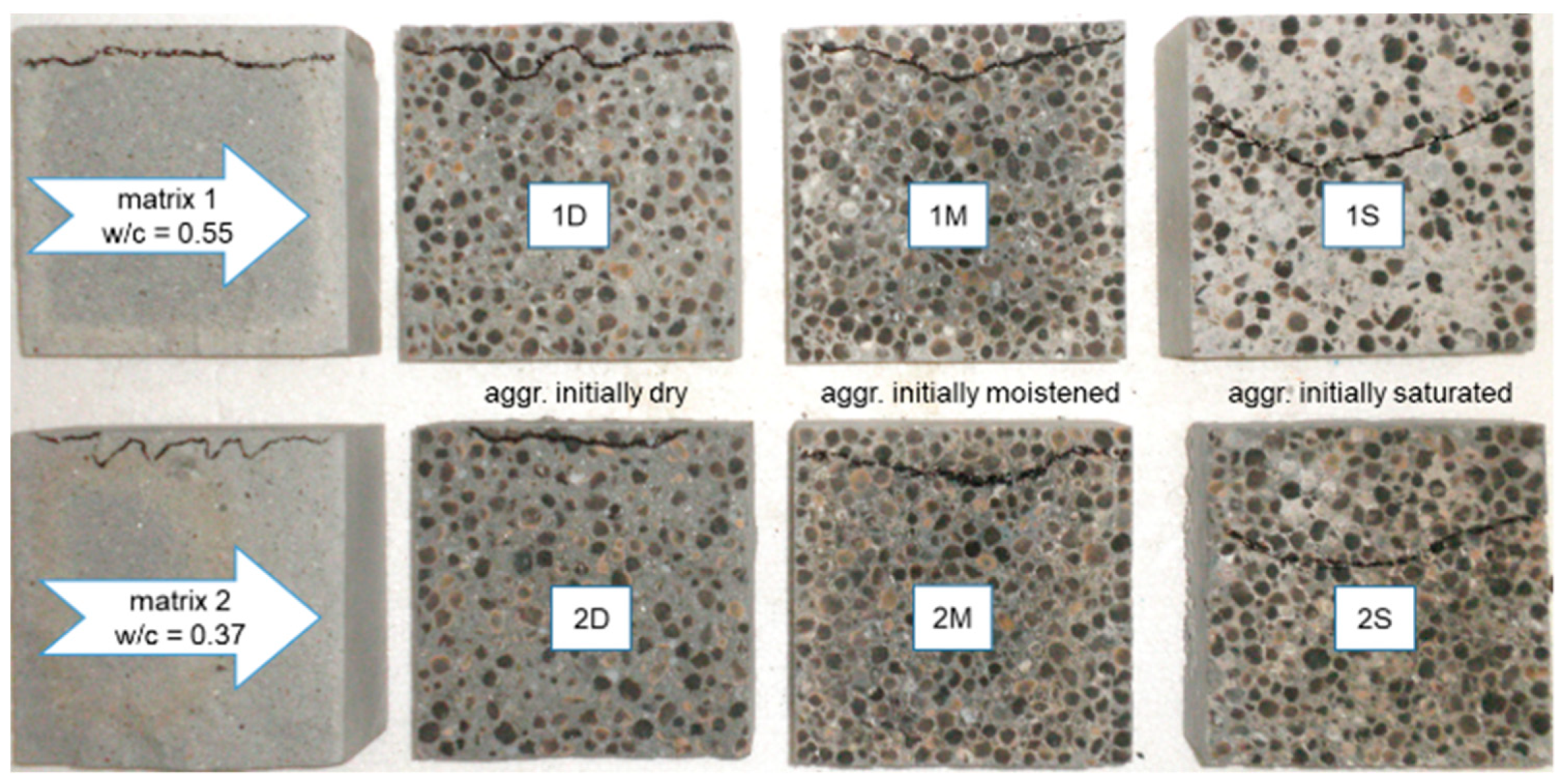

3.2. Water Permeability

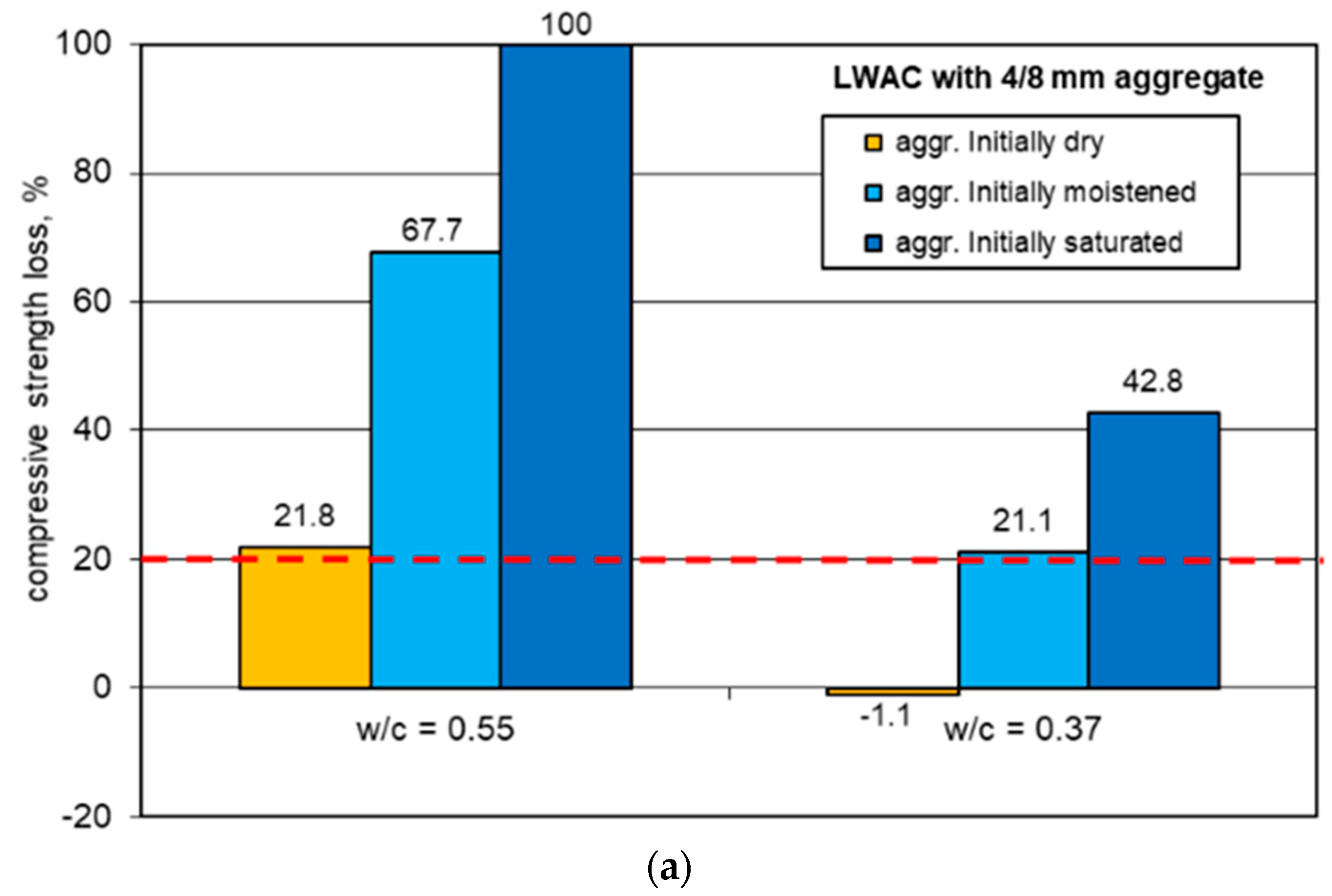

3.3. Freeze-Thaw Resistance

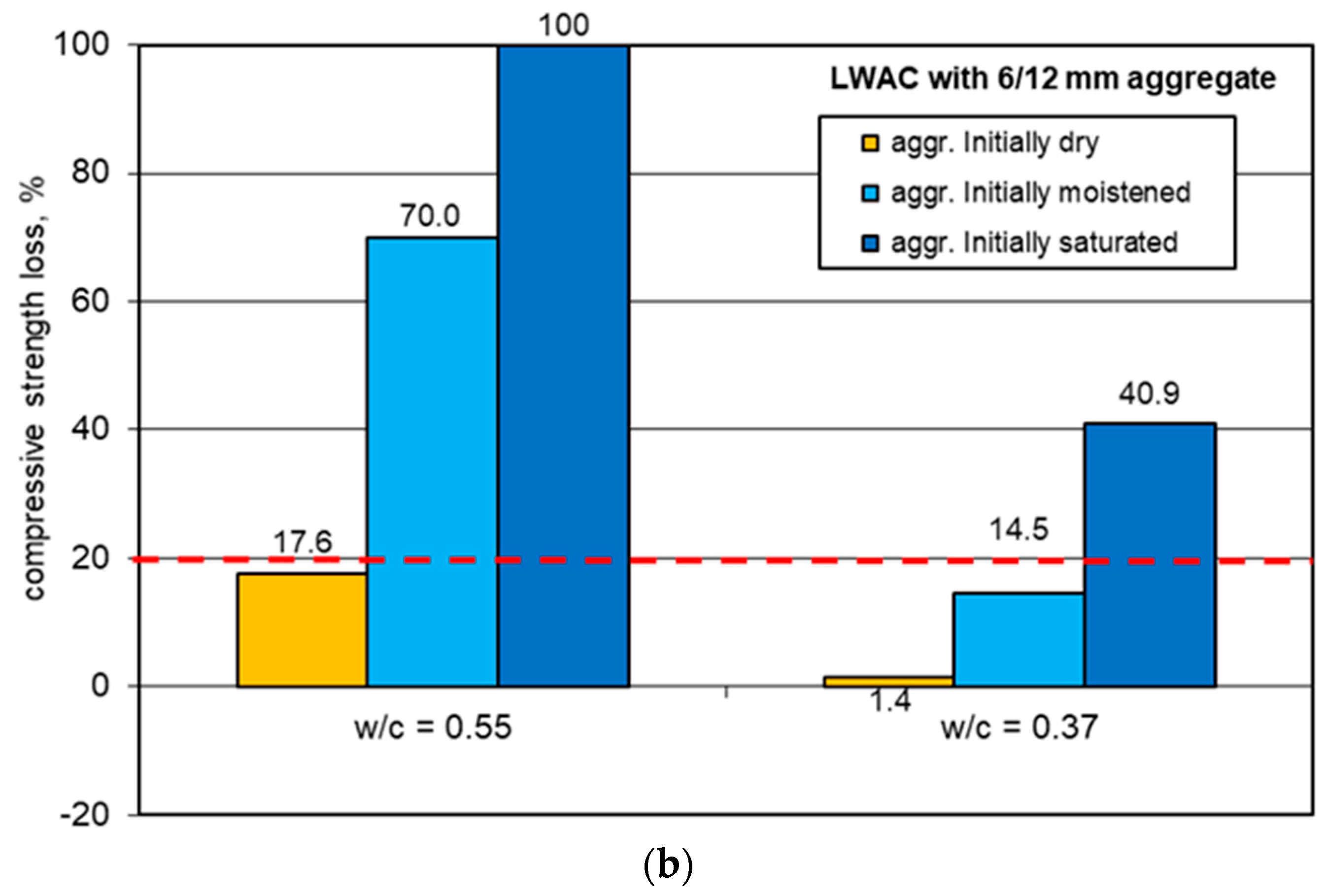

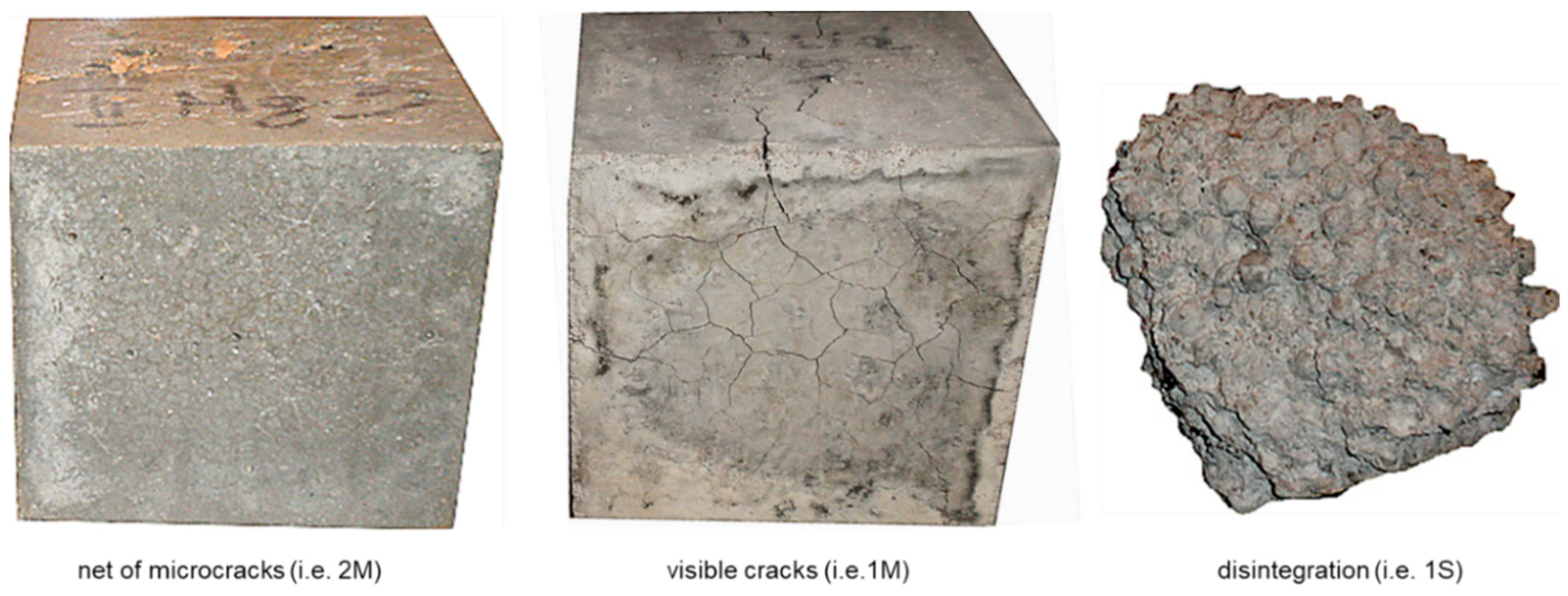

4. Discussion

4.1. Water Absorption

4.2. Water Permeability

4.3. Freeze-Thaw Resistance

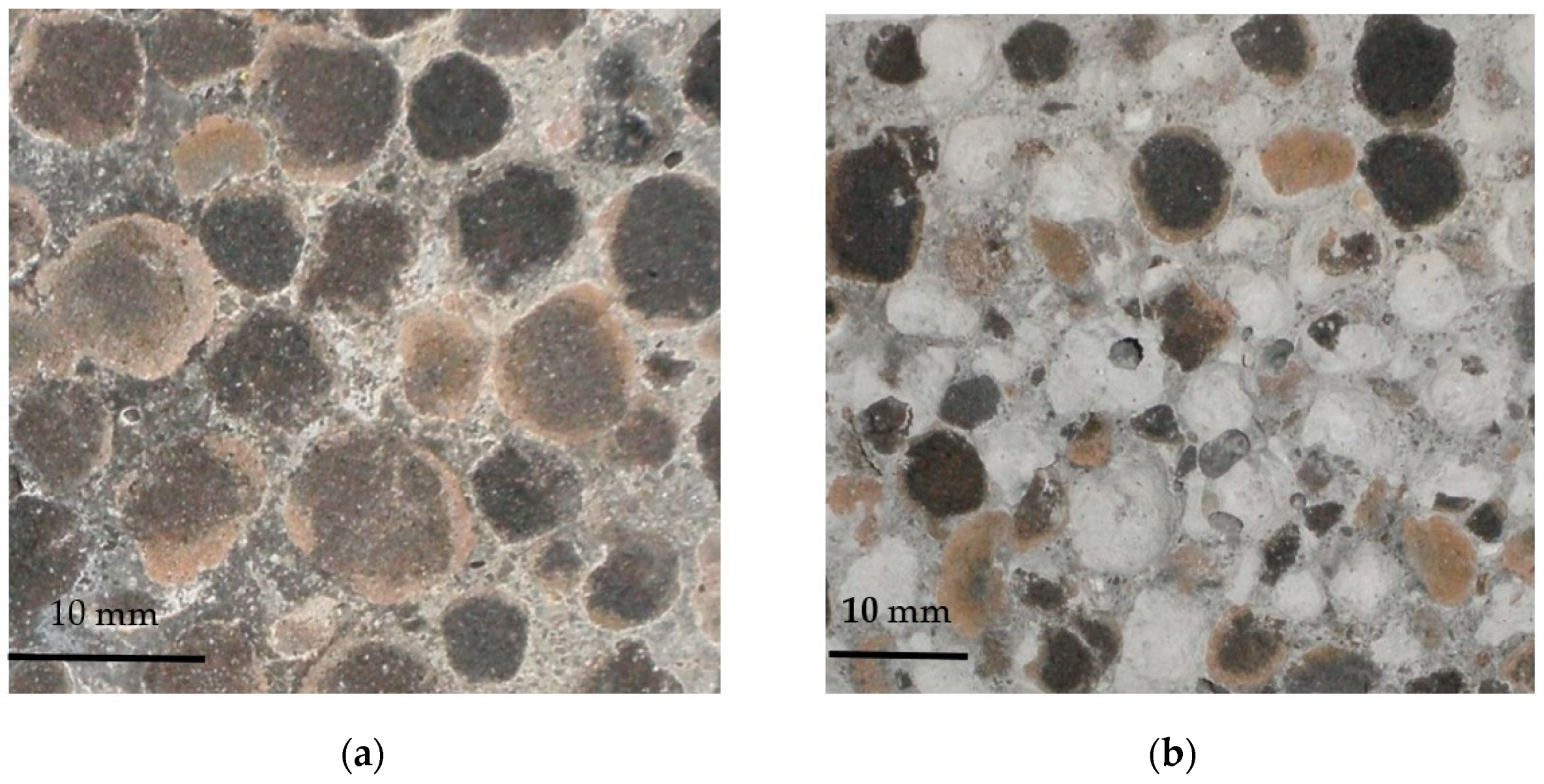

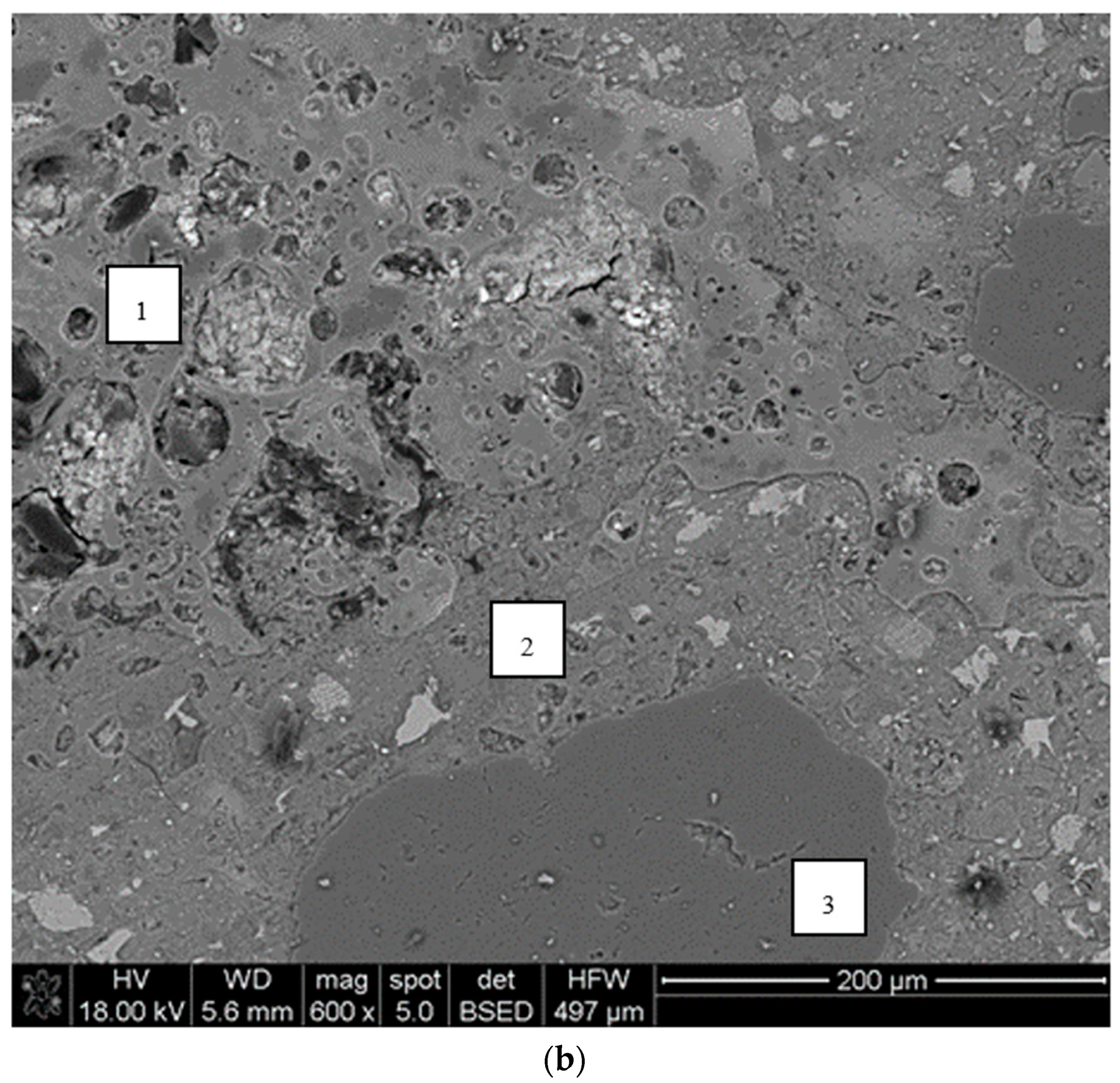

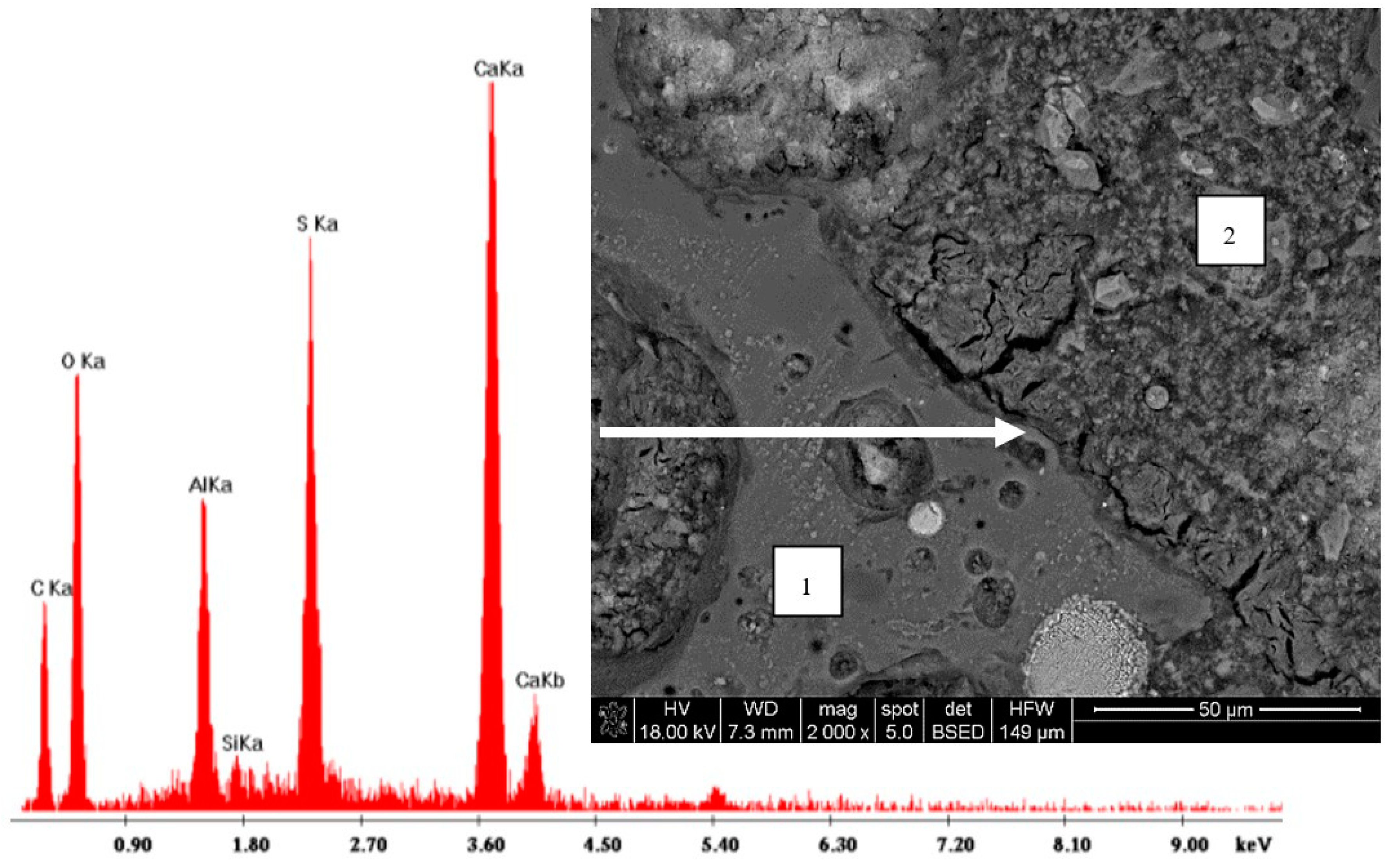

4.4. Microstructure Analysis

5. Conclusions

- The lightweight aggregate water absorption and its initial moisture content influence the concrete durability to a large extent. Nevertheless, even the application of LWA with water absorption as high as ca 25% makes it possible to produce durable concrete. However, in the case of such an aggregate, the procedure of LWA initial pre-saturation should not be allowed in practice;

- Regardless of the nominal water–cement ratio or cement content, concretes made of the initially saturated sintered fly aggregate revealed very high levels of water absorption (up to 22%), an unacceptable depth of water penetration under pressure (up to 74 mm), and a lack of freeze-thaw resistance;

- Limiting the initial sintered fly ash moisture content to 17–18% enhanced the concrete water tightness considerably, but it was not able to ensure a good freeze-thaw resistance. To make such concrete resistant to freezing–thawing cycles, it is also necessary to limit w/c and apply an LWA fraction not containing too many crushed particles;

- The application of the initially dry sintered fly ash aggregate and cement matrix with a relatively low nominal water–cement ratio (w/c = 0.37) led to a comparatively low LWAC water absorption and permeability, as well as a complete freeze-thaw resistance, even without air entraining. The matrix’s volume share, cement content, and even concrete strength were found to be of secondary importance;

- The microstructure of the interfacial transition zone may be a reliable indicator of the durability of LWAC. A tight and homogenous ITZ was observed in durable lightweight aggregate concretes, especially those made of an initially dry aggregate. In the case of the application of a pre-saturated aggregate, the interfacial transition zone was characterized by a high content of ettringite and accompanying microcracks resulted in a poor concrete durability;

- There are no direct relationships among factors commonly considered to affect concrete’s durability, i.e., the water absorption, compressive strength, or cement content and permeability, and freeze-thaw resistance of the tested LWAC with a sintered fly ash aggregate. Generally, the much greater water absorption of LWAC should not be identified with its lower durability in comparison to NWAC.

Funding

Acknowledgments

Conflicts of Interest

References

- Bentz, D.P.; Weiss, W.J. Internal Curing: A 2010 State-of-the-Art Review; NIST IR 7765; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2011; p. 7765. [CrossRef]

- Chandra, S.; Berntsson, L. Lightweight Aggregate Concrete: Science, Technology and Applications, 1st ed.; William Andrew: Norwich, NY, USA, 2002. [Google Scholar]

- Clarke, J. Structural Lightweight Aggregate Concrete; Chapman &Hall: Glasgow, Scotland, 1993. [Google Scholar]

- Zhang, M.-H.; Gjørv, O.E. Microstructure of the Interfacial Zone between Lightweight Aggregate and Cement Paste. Cem. Concr. Res. 1990, 20, 610–618. [Google Scholar] [CrossRef]

- Wasserman, R.; Bentur, A. Interfacial Interactions in Lightweight Aggregate Concretes and Their Influence on the Concrete Strength. Cem. Concr. Compos. 1996, 18, 67–76. [Google Scholar] [CrossRef]

- Neville, A. Aggregate Bond and Modulus of Elasticity of Concrete. Mater. J. 1997, 94, 71–74. [Google Scholar] [CrossRef]

- Domagała, L. The Influence of Porous Aggregate on Microstructure of the Interfacial Transition Zone in Lightweight Concrete. Cem. Wapno Beton 2011, 2, 101–114. [Google Scholar]

- Elsharief, A.; Cohen, M.D.; Olek, J. Influence of Lightweight Aggregate on the Microstructure and Durability of Mortar. Cem. Concr. Res. 2005, 35, 1368–1376. [Google Scholar] [CrossRef]

- Domagała, L. The Effect of Lightweight Aggregate Water Absorption on the Reduction of Water-Cement Ratio in Fresh Concrete. Procedia Eng. 2015, 108, 206–213. [Google Scholar] [CrossRef]

- Nadesan, M.S.; Dinakar, P. Structural Concrete Using Sintered Flyash Lightweight Aggregate: A Review. Constr. Build. Mater. 2017, 154, 928–944. [Google Scholar] [CrossRef]

- Zhang, M.H.; Gjvorv, O.E. Mechanical Properties of High-Strength Lightweight Concrete. Mater. J. 1991, 88, 240–247. [Google Scholar] [CrossRef]

- Domagała, L. Modification of Properties of Structural Lightweight Concrete with Steel Fibres. J. Civ. Eng. Manag. 2011, 17, 36–44. [Google Scholar] [CrossRef]

- Domagała, L. A Study on the Influence of Concrete Type and Strength on the Relationship between Initial and Stabilized Secant Moduli of Elasticity. Solid State Phenom. 2017, 258, 566–569. [Google Scholar] [CrossRef]

- Lotfy, A.; Hossain, K.M.A.; Lachemi, M. Durability Properties of Lightweight Self-Consolidating Concrete Developed with Three Types of Aggregates. Constr. Build. Mater. 2016, 106, 43–54. [Google Scholar] [CrossRef]

- Yao, W.; Pang, J.; Liu, Y. Performance Degradation and Microscopic Analysis of Lightweight Aggregate Concrete after Exposure to High Temperature. Materials 2020, 13, 1566. [Google Scholar] [CrossRef]

- Domagała, L.; Hager, I. Wpływ wysokiej temperatury na wytrzymałość na ściskanie konstrukcyjnych betonów lekkich. Cem. Wapno Beton 2012, 17, 138–143. [Google Scholar]

- Kockal, N.U.; Ozturan, T. Durability of Lightweight Concretes with Lightweight Fly Ash Aggregates. Constr. Build. Mater. 2011, 25, 1430–1438. [Google Scholar] [CrossRef]

- Klieger, P.; Hanson, J.A. Freezing and Thawing Tests of Lightweight Aggregate Concrete. J. Proc. 1961, 57, 779–796. [Google Scholar] [CrossRef]

- Liu, X.; Chia, K.S.; Zhang, M.-H. Water Absorption, Permeability, and Resistance to Chloride-Ion Penetration of Lightweight Aggregate Concrete. Constr. Build. Mater. 2011, 25, 335–343. [Google Scholar] [CrossRef]

- Hossain, K.M.A.; Ahmed, S.; Lachemi, M. Lightweight Concrete Incorporating Pumice Based Blended Cement and Aggregate: Mechanical and Durability Characteristics. Constr. Build. Mater. 2011, 25, 1186–1195. [Google Scholar] [CrossRef]

- Zhang, M.-H.; Gjorv, O.E. Permeability of High-Strength Lightweight Concrete. Mater. J. 1991, 88, 463–469. [Google Scholar] [CrossRef]

- Tang, P.; Brouwers, H.J.H. The Durability and Environmental Properties of Self-Compacting Concrete Incorporating Cold Bonded Lightweight Aggregates Produced from Combined Industrial Solid Wastes. Constr. Build. Mater. 2018, 167, 271–285. [Google Scholar] [CrossRef]

- Nadesan, M.S.; Dinakar, P. Influence of Type of Binder on High-Performance Sintered Fly Ash Lightweight Aggregate Concrete. Constr. Build. Mater. 2018, 176, 665–675. [Google Scholar] [CrossRef]

- Haque, M.N.; Al-Khaiat, H.; Kayali, O. Strength and Durability of Lightweight Concrete. Cem. Concr. Compos. 2004, 26, 307–314. [Google Scholar] [CrossRef]

- Bogas, J.A.; Real, S. A Review on the Carbonation and Chloride Penetration Resistance of Structural Lightweight Aggregate Concrete. Materials 2019, 12, 3456. [Google Scholar] [CrossRef]

- Lo, T.Y.; Tang, W.C.; Nadeem, A. Comparison of Carbonation of Lightweight Concrete with Normal Weight Concrete at Similar Strength Levels. Constr. Build. Mater. 2008, 22, 1648–1655. [Google Scholar] [CrossRef]

- LWAC Material Properties-State-of-the-Art; BE96-3942/R14; EuroLightCon: Trondheim, Norway, 2000. [CrossRef]

- Fujiki, K.; Kokubu, K.; Hosaka, T. Freezing and Thawing Resistance of Lightweight Aggregate Concrete; American Concrete Institute: Tokushima, Japan, 1998; pp. 791–814. [Google Scholar]

- Pospíchal, O.; Kucharczyková, B.; Misák, P.; Vymazal, T. Freeze-Thaw Resistance of Concrete with Porous Aggregate. Procedia Eng. 2010, 2, 521–529. [Google Scholar] [CrossRef]

- Holm, T.A.; Bremner, T.W.; Newman, J.B. Concrete Bridge Decks: Lightweight Aggregate Concrete Subject to Severe Weathering. Concr. Int. 1984, 6, 49–54. [Google Scholar]

- Thienel, K.-C.; Schmidt-Döhl, F.; Feldrappe, V. In-Situ Tests on Existing LWAC Structures. In Proceedings of the Second International Conference on Structural Lightweight Aggregate, Kristiansand, Norway, 18–22 June 2000; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2000; pp. 912–921. [Google Scholar]

- Mao, J.; Ayuta, K. Freeze-Thaw Resistance of Lightweight Concrete and Aggregate at Different Freezing Rates. J. Mater. Civ. Eng. 2008, 20, 78–84. [Google Scholar] [CrossRef]

- EN 13055:2016: Lightweight Aggregates; European Committee for Standardization: Brussels, Belgium, 2016.

- EN 1097-3:1998: Tests for Mechanical and Physical Properties of Aggregates-Part 3: Determination of Loose Bulk Density and Voids; European Committee for Standardization: Brussels, Belgium, 1998.

- EN 1097-6:2013: Tests for Mechanical and Physical Properties of Aggregates-Part 6: Determination of Particle Density and Water Absorption; European Committee for Standardization: Brussels, Belgium, 2013.

- EN 12350-3:2019: Testing Fresh Concrete-Part 3: Vebe Test; European Committee for Standardization: Brussels, Belgium, 2019.

- EN 12390-2:2019: Testing Hardened Concrete-Part 2: Making and Curing Specimens for Strength Tests; European Committee for Standardization: Brussels, Belgium, 2019.

- EN 12390-7:2009: Testing Hardened Concrete-Part 7: Density of Hardened Concrete; European Committee for Standardization: Brussels, Belgium, 2009.

- EN 12390-3:2019: Testing Hardened Concrete-Part 3: Compressive Strength of Test Specimens; European Committee for Standardization: Brussels, Belgium, 2019.

- EN 12390-8:2019: Testing Hardened Concrete-Part 8: Depth of Penetration of Water under Pressure; European Committee for Standardization: Brussels, Belgium, 2019.

- PN-88/B-06250 Beton Zwykły; Polski Komitet Normalizacyjny: Warsaw, Poland, 2008.

- PN-B-06265:2018-10/Ap1:2019-05 Concrete—Specification, Performance, Production and Conformity—National Annex to PN-EN 206+A1:2016-12; Polski Komitet Normalizacyjny: Warsaw, Poland, 2018.

- EN 206:2013+A1:2016/FprA2 Concrete–Specification, Performance, Production and Conformity; European Committee for Standardization: Brussels, Belgium, 2013.

- DIN 1045-2:2008: Concrete, Reinforced and Prestressed Concrete Structures-Part 2: Concrete–Specification, Performance, Production and Conformity–Application Rules for DIN EN 206-1; Deutsches Institut fur Normung: Berlin, Germany, 2008.

- EHE 08:2010: Instrucción de Hormigón Estructural; Ministerio de Fomento, Comisión Permanente del Hormigón: Madrid, Spain, 2010.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

| Fraction | Specific Density, kg/m3 | Particle Density, kg/m3 | Bulk Density, kg/m3 | Water Absorption after 24 h, % | Max. Water Absorption, % | Crushing Resistance, MPa |

|---|---|---|---|---|---|---|

| 4/8 mm | 2490 | 1320 | 730 | 19.3 | 25.3 | 8.0 |

| 6/12 mm | 2490 | 1340 | 720 | 18.8 | 24.3 | 7.2 |

| Component | CaO, % | SiO2, % | Al2O3, % | Fe2O3, % | SO3, % | MgO, % | Na2Oeqv., % | Loss of Ignition, % |

|---|---|---|---|---|---|---|---|---|

| CEM I 42,5R | 63.6 | 22.1 | 5.6 | 3.1 | 2.6 | 1.2 | 0.8 | 0.9 |

| Lytag | 2.2 | 58.0 | 22.0 | 3.1 | 0.3 | 1.4 | 0.9 | <4 |

| Mix Designation | Nominal w/c | LWA Fraction, mm | LWA Initial Moisture Content, % | LWA Volume Share, % |

|---|---|---|---|---|

| 1d | 0.55 | 4/8 | 0.0 | 42 |

| 1m | 0.55 | 4/8 | 17.0 | 59 |

| 1s | 0.55 | 4/8 | 25.3 | 68 |

| 1D | 0.55 | 6/12 | 0.0 | 46 |

| 1M | 0.55 | 6/12 | 17.7 | 61 |

| 1S | 0.55 | 6/12 | 24.3 | 67 |

| 2d | 0.37 | 4/8 | 0.0 | 41 |

| 2m | 0.37 | 4/8 | 17.0 | 58 |

| 2s | 0.37 | 4/8 | 25.3 | 70 |

| 2D | 0.37 | 6/12 | 0.0 | 43 |

| 2M | 0.37 | 6/12 | 17.7 | 60 |

| 2S | 0.37 | 6/12 | 24.3 | 68 |

| Mix Designation | LWA 1, kg/m3 | Natural Sand, kg/m3 | Cement, kg/m3 | Water, kg/m3 | Superplasticizer, kg/m3 |

|---|---|---|---|---|---|

| 1d | 572 | 619 | 516 | 284 | 0.0 |

| 1m | 950 | 406 | 338 | 186 | 0.0 |

| 1s | 1171 | 288 | 239 | 132 | 0.0 |

| 1D | 603 | 610 | 508 | 279 | 0.0 |

| 1M | 945 | 404 | 336 | 185 | 0.0 |

| 1S | 1110 | 306 | 225 | 140 | 0.0 |

| 2d | 559 | 700 | 584 | 216 | 14.6 |

| 2m | 935 | 463 | 386 | 143 | 9.6 |

| 2s | 1191 | 322 | 268 | 99 | 7.0 |

| 2D | 569 | 666 | 555 | 205 | 13.9 |

| 2M | 925 | 462 | 386 | 142 | 9.6 |

| 2S | 1129 | 346 | 288 | 107 | 7.2 |

| Test | Specimens | Specimens Number | Concrete Age | Procedure |

|---|---|---|---|---|

| Density | Cube 150 mm | 3 | 28 days | EN 12390-7 [38] |

| Compressive Strength | Cube 150 mm | 6 | 28 days | EN 12390-3 [39] |

| Water Permeability | Cube 150 mm | 6 | 28 + 7 days | EN 12390-8 [40] |

| Water Absorption | Cube 150 mm | 3 | 28 days | PN-88/B-06250 [41] |

| Freeze-Thaw Resistance | Cube 100 mm | 12 | 28 + 7 days | PN-B-06265 [42] |

| Mix Designation | Dm 1, kg/m3 | Dm 2, kg/m3 | fcm 1, MPa | Sf 1, MPa | fcm 2, MPa | Sf 2 MPa | WAm, % | SWA, % |

|---|---|---|---|---|---|---|---|---|

| 1d | 2160 | 1800 | 56.1 | 2.4 | 62.3 | 3.8 | 10.0 | 0.05 |

| 1m | 2000 | 1630 | 45.6 | 2.5 | 48.5 | 2.2 | 12.9 | 0.05 |

| 1s | 1810 | 1470 | 25.1 | 1.8 | 25.0 | 1.7 | 21.9 | 0.05 |

| 1D | 1990 | 1820 | 53.2 | 2.9 | 59.6 | 3.0 | 9.4 | 0.00 |

| 1M | 1990 | 1620 | 42.1 | 2.3 | 45.0 | 2.0 | 13.0 | 0.09 |

| 1S | 1930 | 1500 | 30.3 | 1.9 | 30.1 | 2.2 | 18.7 | 0.05 |

| 2d | 2040 | 1920 | 71.0 | 3.3 | 83.5 | 3.8 | 6.1 | 0.08 |

| 2m | 2110 | 1720 | 59.5 | 2.5 | 64.0 | 3.6 | 11.7 | 0.09 |

| 2s | 2050 | 1600 | 40.8 | 2.8 | 40.4 | 3.0 | 18.1 | 0.05 |

| 2D | 2030 | 1920 | 69.8 | 3.2 | 79.4 | 2.9 | 5.6 | 0.05 |

| 2M | 2100 | 1720 | 53.4 | 2.5 | 58.5 | 2.9 | 11.2 | 0.09 |

| 2S | 1980 | 1560 | 32.3 | 2.2 | 32.0 | 2.0 | 16.7 | 0.12 |

| matrix 1 | 2040 | 1750 | 43.2 | 2.1 | 45.5 | 2.3 | 14.4 | 0.05 |

| matrix 2 | 2160 | 1970 | 60.1 | 3.3 | 63.3 | 3.3 | 10.3 | 0.09 |

| Mix Design | fcm1, MPa | Sf1, MPa | fcm2, MPa | Sf1, MPa | (fcm1 − fcm2)/fcm1, % | Weight Loss, % | Specimens’ Condition after 150 (200 *) Freezing–Thawing Cycles |

|---|---|---|---|---|---|---|---|

| 1d | 65.1 | 2.2 | 50.9 | 5.8 | 21.8 | 3.4 | net of microcracks or no cracks |

| 1m | 56.7 | 1.8 | 18.3 | 2.0 | 67.7 | 7.5 | visible cracks |

| 1s | 31.5 | 2.2 | 0.0 | - | 100 | 100 | disintegration after 10–30 cycles |

| 1D | 58.5 | 4.0 | 48.2 | 4.5 | 17.6 | 2.5 | net of microcracks or no cracks |

| 1M | 49.4 | 1.6 | 14.8 | 3.4 | 70.0 | 5.3 | visible cracks |

| 1S | 34.3 | 2.4 | 0.0 | - | 100 | 100 | disintegration after 10–30 cycles |

| 2d | 72.3 | 8.6 | 73.1 | 4.2 | −1.1 | −0.5 | no cracks |

| 2d * | 74.4 | 2.7 | 73.9 | 3.5 | 0.7 | 0.2 | no cracks |

| 2m | 65.5 | 3.5 | 51.7 | 7.0 | 21.1 | 4.7 | net of microcracks or no cracks |

| 2s | 49.5 | 1.3 | 28.3 | 6.6 | 42.8 | 7.4 | net of microcracks or visible cracks |

| 2D | 71.3 | 3.3 | 70.3 | 7.5 | 1.4 | −0.5 | no cracks |

| 2M | 52.5 | 3.9 | 44.9 | 6.1 | 14.5 | 1.4 | net of microcracks or no cracks |

| 2S | 36.2 | 1.3 | 21.4 | 4.7 | 40.9 | 2.6 | net of microcracks or visible cracks |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Domagała, L. Durability of Structural Lightweight Concrete with Sintered Fly Ash Aggregate. Materials 2020, 13, 4565. https://doi.org/10.3390/ma13204565

Domagała L. Durability of Structural Lightweight Concrete with Sintered Fly Ash Aggregate. Materials. 2020; 13(20):4565. https://doi.org/10.3390/ma13204565

Chicago/Turabian StyleDomagała, Lucyna. 2020. "Durability of Structural Lightweight Concrete with Sintered Fly Ash Aggregate" Materials 13, no. 20: 4565. https://doi.org/10.3390/ma13204565

APA StyleDomagała, L. (2020). Durability of Structural Lightweight Concrete with Sintered Fly Ash Aggregate. Materials, 13(20), 4565. https://doi.org/10.3390/ma13204565