Complex Permittivity and Electromagnetic Interference Shielding Effectiveness of OPEFB Fiber-Polylactic Acid Filled with Reduced Graphene Oxide

Abstract

:1. Introduction

2. Material and Methods

2.1. Materials

2.2. Synthesis of rGO

2.3. Fabrication of rGO/OPEFB/PLA Composites

2.4. Characterization

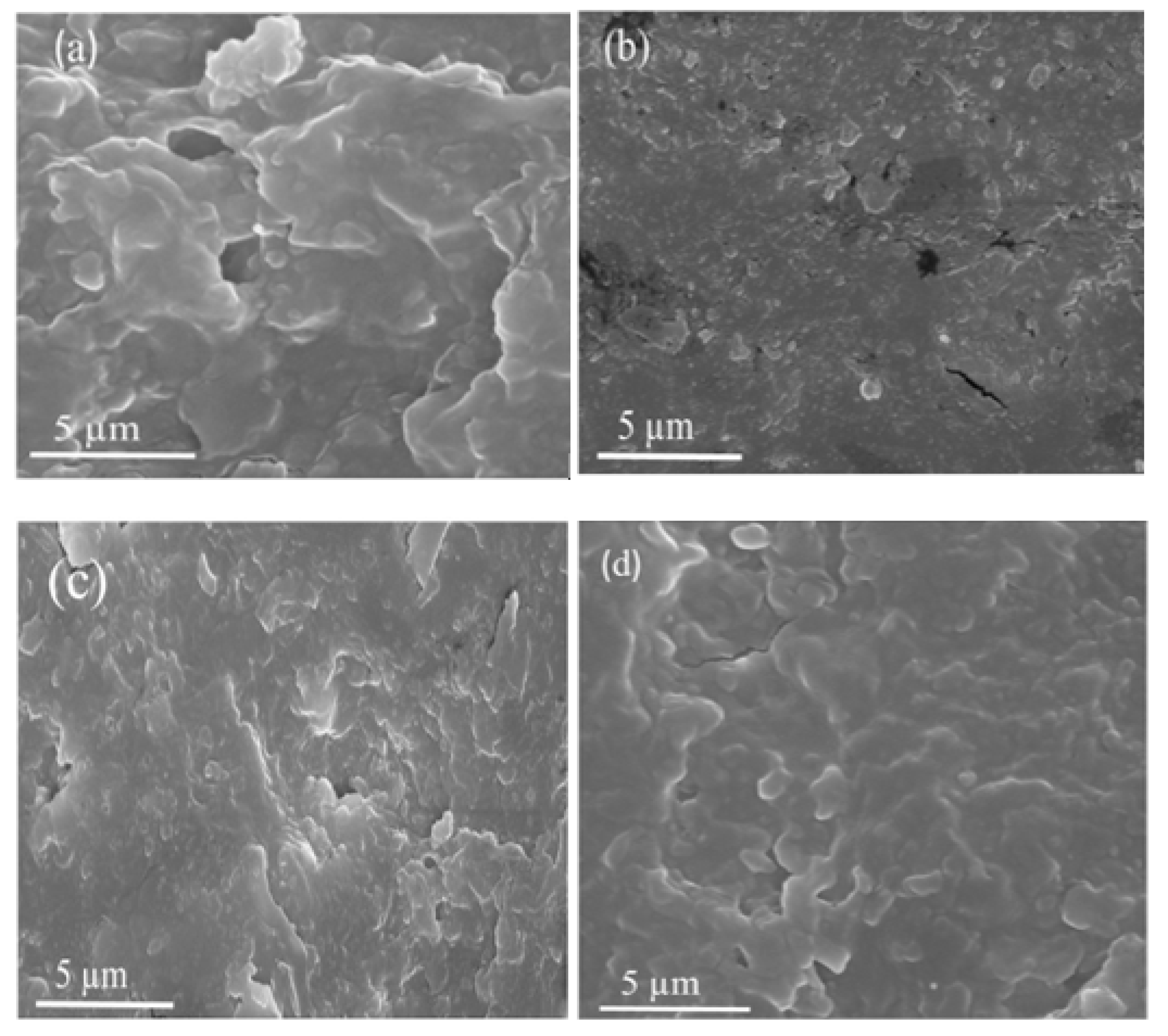

2.4.1. Structure and Composition

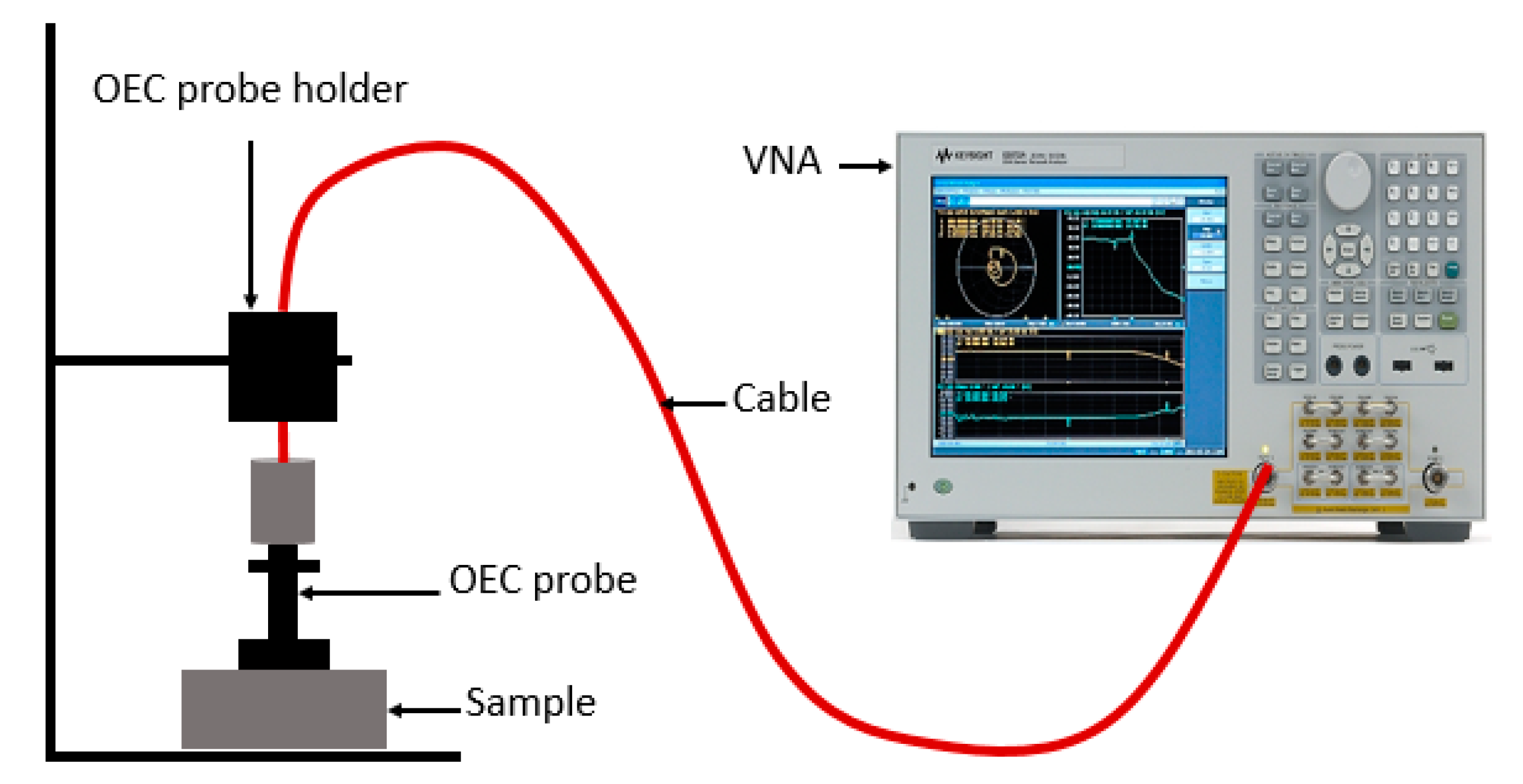

2.4.2. Dielectric Properties

2.4.3. Shielding Effectiveness

3. Results and Discussion

3.1. Field Emission Scanning Electron Microscopy

3.2. X-ray Diffraction

3.3. Fourier Transform Infrared

3.4. Dielectric Properties

3.5. Shielding Effectiveness

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, L.L.; Tay, B.K.; See, K.Y.; Sun, Z.; Tan, L.K.; Lua, D. Electromagnetic interference shielding effectiveness of carbon-based materials prepared by screen printing. Carbon 2009, 47, 1905–1910. [Google Scholar] [CrossRef]

- Engels, S.; Schneider, N.L.; Lefeldt, N.; Hein, C.M.; Zapka, M.; Michalik, A.; Elbers, D.; Kittel, A.; Hore, P.J.; Mouritsen, H. Anthropogenic electromagnetic noise disrupts magnetic compass orientation in a migratory bird. Nature 2014, 509, 353–356. [Google Scholar] [CrossRef] [PubMed]

- Hamzany, Y.; Feinmesser, R.; Shpitzer, T.; Mizrachi, A.; Hilly, O.; Hod, R.; Bahar, G.; Otradnov, I.; Gavish, M.; Nagler, M.G. Is Human Saliva an Indicator of the Adverse Health Effects of Using Mobile Phones? Mary Ann Liebert: New York, NY, USA, 2013. [Google Scholar]

- Choudary, V.; Dhawan, S.K.; Saini, P. Polymer based nanocomposites for electromagnetic interference (EMI) shielding. In EMI Shielding Theory and Development of New Materials; Research Signpost: Kerala, India, 2012; pp. 67–100. [Google Scholar]

- Thomassin, J.M.; Jerome, C.; Pardoen, T.; Bailly, C.; Huynen, I.; Detrembleur, C. Polymer/carbon-based composites as electromagnetic interference (EMI) shielding materials. Mater. Sci. Eng. R Rep. 2013, 74, 211–232. [Google Scholar] [CrossRef]

- Verma, M.; Chauhan, S.S.; Dhawan, S.K.; Choudhary, V. Graphene nanoplatelets/carbon nanotubes/polyurethane composites as efficient shield against electromagnetic polluting radiations. Compos. Part B Eng. 2017, 120, 118–127. [Google Scholar] [CrossRef]

- Bagotia, N.; Choudhary, V.; Sharma, D.K. Synergistic effect of graphene/multiwalled carbon nanotube hybrid fillers on mechanical, electrical and EMI shielding properties of polycarbonate/ethylene methyl acrylate nanocomposites. Compos. Part B Eng. 2019, 159, 378–388. [Google Scholar] [CrossRef]

- Ravindren, R.; Mondal, S.; Nath, K.; Das, N.C. Prediction of electrical conductivity, double percolation limit and electromagnetic interference shielding effectiveness of copper nanowire filled flexible polymer blend nanocomposites. Compos. Part B Eng. 2019, 164, 559–569. [Google Scholar] [CrossRef]

- Bagotia, N.; Choudhary, V.; Sharma, D.K. A review on the mechanical, electrical and EMI shielding properties of carbon nanotubes and graphene reinforced polycarbonate nanocomposites. Polym. Adv. Technol. 2018, 29, 1547–1567. [Google Scholar] [CrossRef]

- Huang, J.; Zhu, Y.; Xu, L.; Chen, J.; Jiang, W.; Nie, X. Massive enhancement in the thermal conductivity of polymer composites by trapping graphene at the interface of a polymer blend. Compos. Sci. Technol. 2016, 129, 160–165. [Google Scholar] [CrossRef]

- Cao, M.S.; Song, W.L.; Hou, Z.L.; Wen, B.; Yuan, J. The effects of temperature and frequency on the dielectric properties, electromagnetic interference shielding and microwave-absorption of short carbon fiber/silica composites. Carbon 2010, 48, 788–796. [Google Scholar] [CrossRef]

- Im, J.S.; Kim, J.G.; Lee, Y.S. Fluorination effects of carbon black additives for electrical properties and EMI shielding efficiency by improved dispersion and adhesion. Carbon 2009, 47, 2640–2647. [Google Scholar] [CrossRef]

- Kuang, T.; Chang, L.; Chen, F.; Sheng, Y.; Fu, D.; Peng, X. Facile preparation of lightweight high-strength biodegradable polymer/multi-walled carbon nanotubes nanocomposite foams for electromagnetic interference shielding. Carbon 2016, 105, 305–313. [Google Scholar] [CrossRef]

- Goyal, R.K.; Kadam, A. Polyphenylene sulphide/graphite composites for EMI shielding applications. Adv. Mater. Lett. 2010, 1, 143–147. [Google Scholar] [CrossRef]

- Kumar, K.P.; Sekaran, A.S.J. Some natural fibers used in polymer composites and their extraction processes: A review. J. Reinf. Plast. Compos. 2014, 33, 1879–1892. [Google Scholar] [CrossRef]

- Challabi, A.J.H.; Chieng, B.W.; Ibrahim, N.A.; Ariffin, H.; Zainuddin, N. Effect of Superheated Steam Treatment on the Mechanical Properties and Dimensional Stability of PALF/PLA Biocomposite. Polymers 2019, 11, 482. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huda, M.S.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Effect of fiber surface-treatments on the properties of laminated biocomposites from poly (lactic acid) (PLA) and kenaf fibers. Compos. Sci. Technol. 2008, 68, 424–432. [Google Scholar] [CrossRef]

- Abdalhadi, D.M.; Abbas, Z.; Ahmad, A.F.; Matori, K.A.; Esa, F. Controlling the Properties of OPEFB/PLA Polymer Composite by Using Fe2O3 for Microwave Applications. Fibers Polym. 2018, 19, 1513–1521. [Google Scholar] [CrossRef]

- Ferreira, W.H.; Dahmouche, K.; Andrade, C.T. Tuning the mechanical and electrical conductivity properties of graphene-based thermoplastic starch/poly (lactic acid) hybrids. Polym. Compos. 2019, 40, E1131–E1142. [Google Scholar] [CrossRef]

- Huang, H.D.; Ren, P.G.; Xu, J.Z.; Xu, L.; Zhong, G.J.; Hsiao, B.S.; Li, Z.M. Improved barrier properties of poly (lactic acid) with randomly dispersed graphene oxide nanosheets. J. Membr. Sci. 2014, 464, 110–118. [Google Scholar] [CrossRef]

- Zhang, H.B.; Yan, Q.; Zheng, W.G.; He, Z.; Yu, Z.Z. Tough graphene—Polymer microcellular foams for electromagnetic interference shielding. ACS Appl. Mater. Interfaces 2011, 3, 918–924. [Google Scholar] [CrossRef]

- Ahmad, A.F.; Ab Aziz, S.; Abbas, Z.; Obaiys, S.J.; Khamis, A.M.; Hussain, I.R.; Zaid, M.H.M. Preparation of a chemically reduced graphene oxide reinforced epoxy resin polymer as a composite for electromagnetic interference shielding and microwave-absorbing applications. Polymers 2018, 10, 1180. [Google Scholar] [CrossRef] [Green Version]

- Kashi, S.; Gupta, R.K.; Baum, T.; Kao, N.; Bhattacharya, S.N. Morphology, electromagnetic properties and electromagnetic interference shielding performance of poly lactide/graphene nanoplatelet nanocomposites. Mater. Des. 2016, 95, 119–126. [Google Scholar] [CrossRef]

- Mensah, E.E.; Abbas, Z.; Azis, R.A.S.; Ibrahim, N.A.; Khamis, A.M. Complex Permittivity and Microwave Absorption Properties of OPEFB Fiber–Polycaprolactone Composites Filled with Recycled Hematite (α-Fe2O3) Nanoparticles. Polymers 2019, 11, 918. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ravindren, R.; Mondal, S.; Nath, K.; Das, N.C. Synergistic effect of double percolated co-supportive MWCNT-CB conductive network for high-performance EMI shielding application. Polym. Adv. Technol. 2019, 30, 1506–1517. [Google Scholar] [CrossRef]

- Aujara, K.M.; Chieng, B.W.; Ibrahim, N.A.; Zainuddin, N.; Thevy Ratnam, C. Gamma-Irradiation Induced Functionalization of Graphene Oxide with Organosilanes. Int. J. Mol. Sci. 2019, 20, 1910. [Google Scholar] [CrossRef] [Green Version]

- Liu, P.; Yao, Z.; Zhou, J. Preparation of reduced graphene oxide/Ni0. 4Zn0. 4Co0. 2Fe2O4 nanocomposites and their excellent microwave absorption properties. Ceram. Int. 2015, 41, 13409–13416. [Google Scholar] [CrossRef]

- Kristiani, A.; Effendi, N.; Aristiawan, Y.; Aulia, F.; Sudiyani, Y. Effect of combining chemical and irradiation pretreatment process to characteristic of oil palm’s empty fruit bunches as raw material for second-generation bioethanol. Energy Procedia 2015, 68, 195–204. [Google Scholar] [CrossRef] [Green Version]

- Harun, N.A.F.; Baharuddin, A.S.; Zainudin, M.H.M.; Bahrin, E.K.; Naim, M.N.; Zakaria, R. Cellulase production from treated oil palm empty fruit bunch degradation by locally isolated Thermobifida fusca. BioResources 2012, 8, 676–687. [Google Scholar]

- Wan, Y.J.; Gong, L.X.; Tang, L.C.; Wu, L.B.; Jiang, J.X. Mechanical properties of epoxy composites filled with silane-functionalized graphene oxide. Compos. Part A App. Sci. Manuf. 2014, 64, 79–89. [Google Scholar] [CrossRef]

- Sun, C.; Li, C.; Tan, H.; Zhang, Y. Synergistic effects of wood fiber and polylactic acid during co-pyrolysis using TG-FTIR-MS and Py-GC/MS. Energy Convers. Manag. 2019, 202, 112212. [Google Scholar] [CrossRef]

- Manoratne, C.H.; Rosa, S.R.D.; Kottegoda, I.R.M. XRD-HTA, UV visible, FTIR and SEM interpretation of reduced graphene oxide synthesized from high purity vein graphite. Mater. Sci. Res. India 2017, 14, 19–30. [Google Scholar] [CrossRef]

- Kamatchi, R.; Venkatachalapathy, S.; Srinivas, B.A. Synthesis, stability, transport properties, and surface wettability of reduced graphene oxide/water nanofluids. Int. J. Therm. Sci. 2015, 97, 17–25. [Google Scholar] [CrossRef]

- Abdalhadi, D.M.; Abbas, Z.; Ahmad, A.F.; Ibrahim, N.A. Determining the complex permittivity of oil palm empty fruit bunch fibre material by open-ended coaxial probe technique for microwave applications. BioResources 2017, 12, 3976–3991. [Google Scholar] [CrossRef] [Green Version]

- Phang, S.W.; Tadokoro, M.; Watanabe, J.; Kuramoto, N. Microwave absorption behaviors of polyaniline nanocomposites containing TiO2 nanoparticles. Curr. Appl. Phys. 2008, 8, 391–394. [Google Scholar] [CrossRef]

- Chai, J.; Zhang, D.; Cheng, J.; Jia, Y.; Ba, X.; Gao, Y.; Zhu, L.; Wang, H.; Cao, M. Facile synthesis of highly conductive MoS 2/graphene nanohybrids with hetero-structures as excellent microwave absorbers. RSC Adv. 2018, 8, 36616–36624. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Sheng, G.; Jiang, X.; Tanaka, T. Effects of inorganic fillers on withstanding short-time breakdown and long-time electrical aging of epoxy composites. IEEJ Trans. Electr. Electron. Eng. 2017, 12, S10–S15. [Google Scholar] [CrossRef]

- Kashi, S.; Gupta, R.K.; Bhattacharya, S.N.; Varley, R.J. Experimental and simulation study of effect of thickness on performance of (butylene adipate-co-terephthalate) and poly lactide nanocomposites incorporated with graphene as stand-alone electromagnetic interference shielding and metal-backed microwave absorbers. Compos. Sci. Technol. 2020, 195, 108186. [Google Scholar]

- Kashi, S.; Gupta, R.K.; Baum, T.; Kao, N.; Bhattacharya, S.N. Dielectric properties and electromagnetic interference shielding effectiveness of graphene-based biodegradable nanocomposites. Mater. Des. 2016, 109, 68–78. [Google Scholar] [CrossRef]

- Maleknejad, Z.; Gheisari, K.; Raouf, A.H. Structure, microstructure, magnetic, electromagnetic, and dielectric properties of nanostructured Mn–Zn ferrite synthesized by microwave-induced urea–nitrate process. J. Supercond. Nov. Magn. 2016, 29, 2523–2534. [Google Scholar] [CrossRef]

- Zhou, W.; Yu, D. Thermal and dielectric properties of the aluminum particle/epoxy resin composites. J. Appl. Polym. Sci. 2010, 118, 3156–3166. [Google Scholar] [CrossRef]

- Ameli, A.; Jung, P.U.; Park, C.B. Electrical properties and electromagnetic interference shielding effectiveness of polypropylene/carbon fiber composite foams. Carbon 2013, 60, 379–391. [Google Scholar] [CrossRef]

| Frequency (GHz) | 2% | 4% | 6% | 8% |

|---|---|---|---|---|

| 8 | 12.7 | 17.9 | 22.5 | 25.4 |

| 10 | 15.6 | 19.6 | 22.9 | 26.1 |

| 12 | 16.1 | 21.3 | 26.4 | 31.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibrahim Lakin, I.; Abbas, Z.; Azis, R.S.; Abubakar Alhaji, I. Complex Permittivity and Electromagnetic Interference Shielding Effectiveness of OPEFB Fiber-Polylactic Acid Filled with Reduced Graphene Oxide. Materials 2020, 13, 4602. https://doi.org/10.3390/ma13204602

Ibrahim Lakin I, Abbas Z, Azis RS, Abubakar Alhaji I. Complex Permittivity and Electromagnetic Interference Shielding Effectiveness of OPEFB Fiber-Polylactic Acid Filled with Reduced Graphene Oxide. Materials. 2020; 13(20):4602. https://doi.org/10.3390/ma13204602

Chicago/Turabian StyleIbrahim Lakin, Ismail, Zulkifly Abbas, Rabaah Syahidah Azis, and Ibrahim Abubakar Alhaji. 2020. "Complex Permittivity and Electromagnetic Interference Shielding Effectiveness of OPEFB Fiber-Polylactic Acid Filled with Reduced Graphene Oxide" Materials 13, no. 20: 4602. https://doi.org/10.3390/ma13204602

APA StyleIbrahim Lakin, I., Abbas, Z., Azis, R. S., & Abubakar Alhaji, I. (2020). Complex Permittivity and Electromagnetic Interference Shielding Effectiveness of OPEFB Fiber-Polylactic Acid Filled with Reduced Graphene Oxide. Materials, 13(20), 4602. https://doi.org/10.3390/ma13204602