Preparation and Characterization of a Type of Green Vacuum Insulation Panel Prepared with Straw Core Material

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Materials

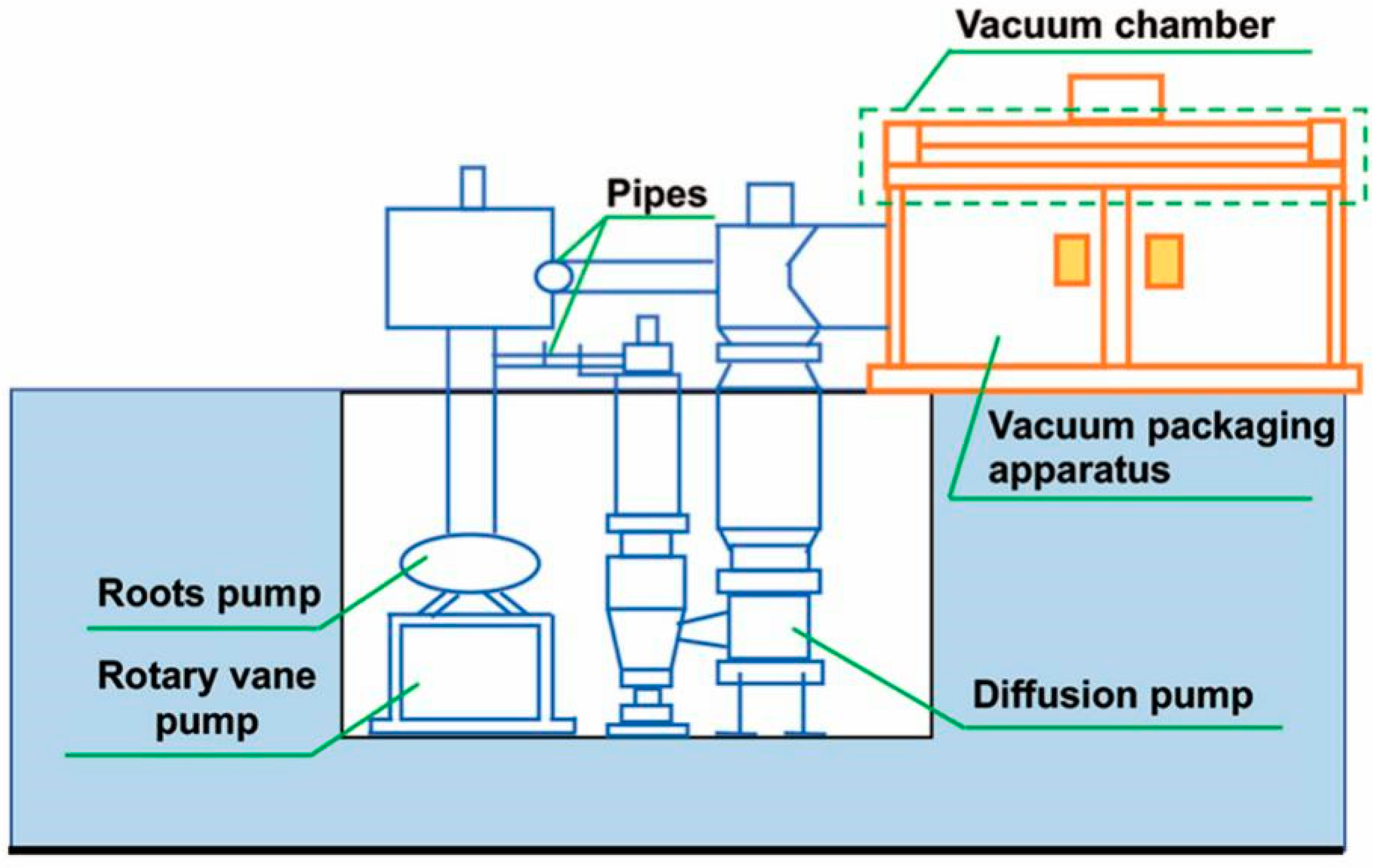

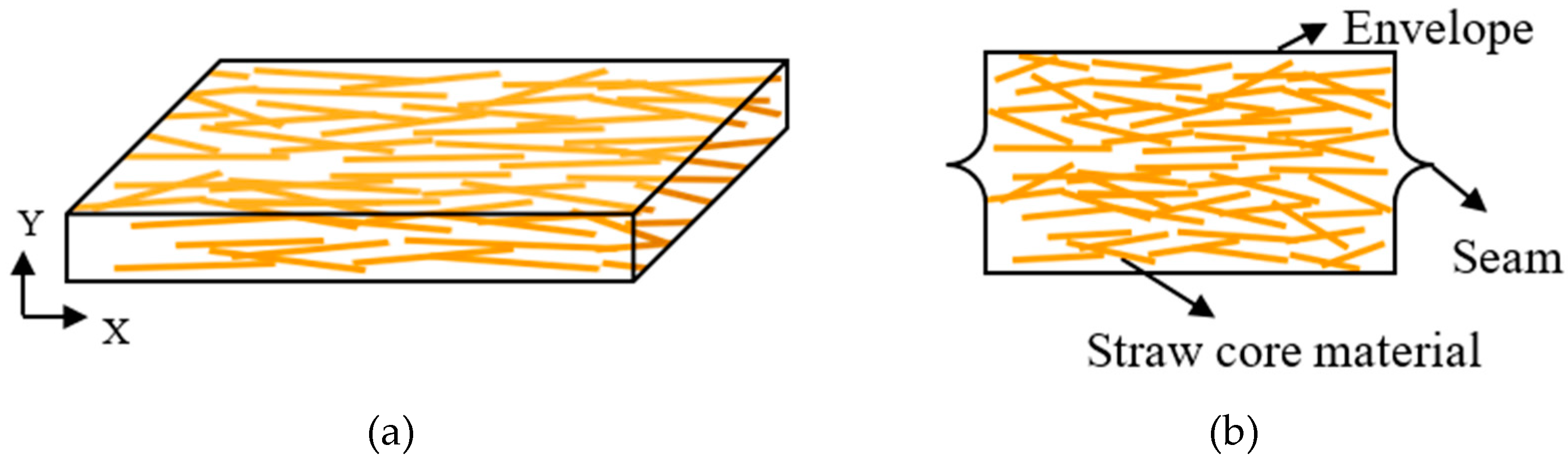

2.2. VIP Fabrication

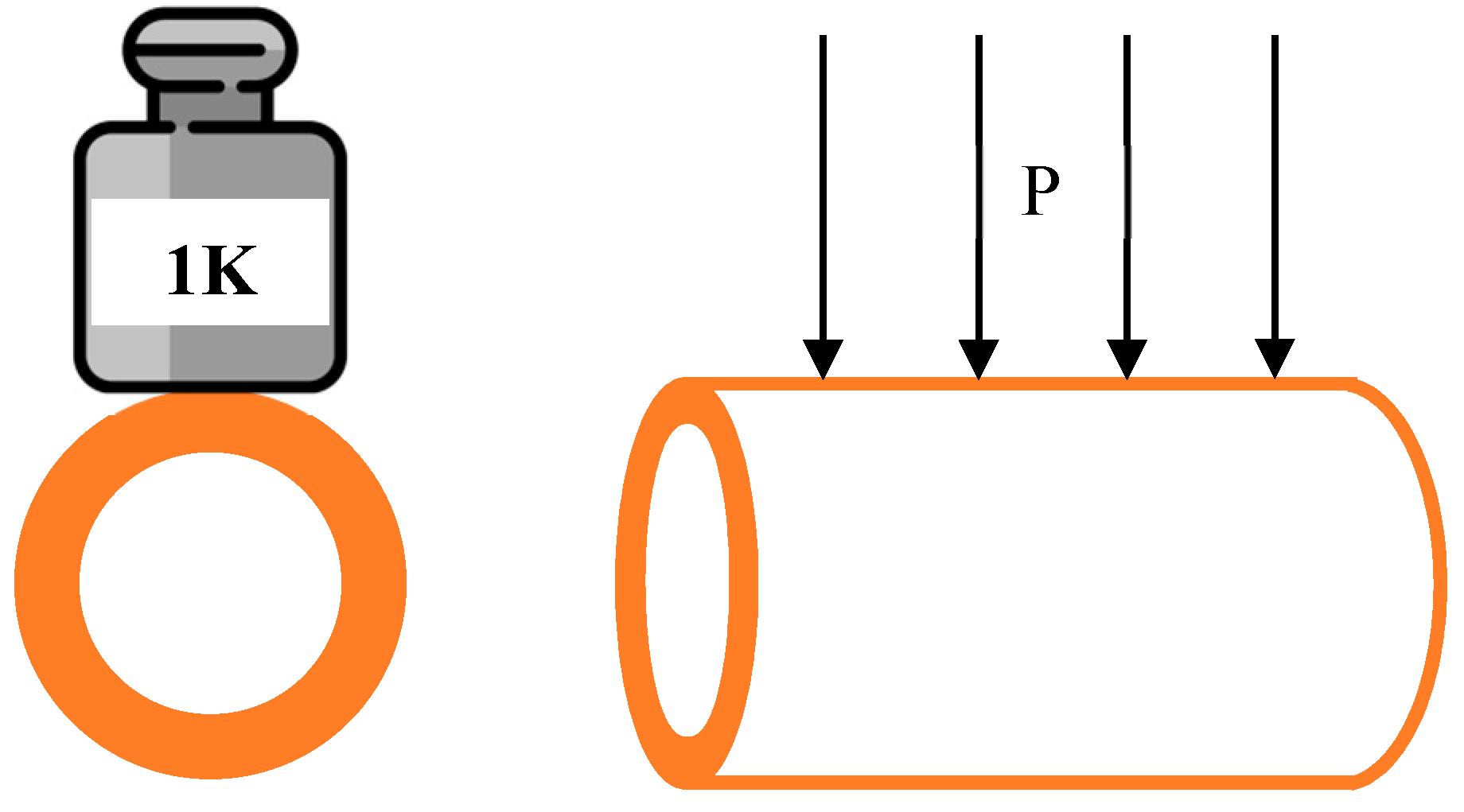

2.2.1. Core Material

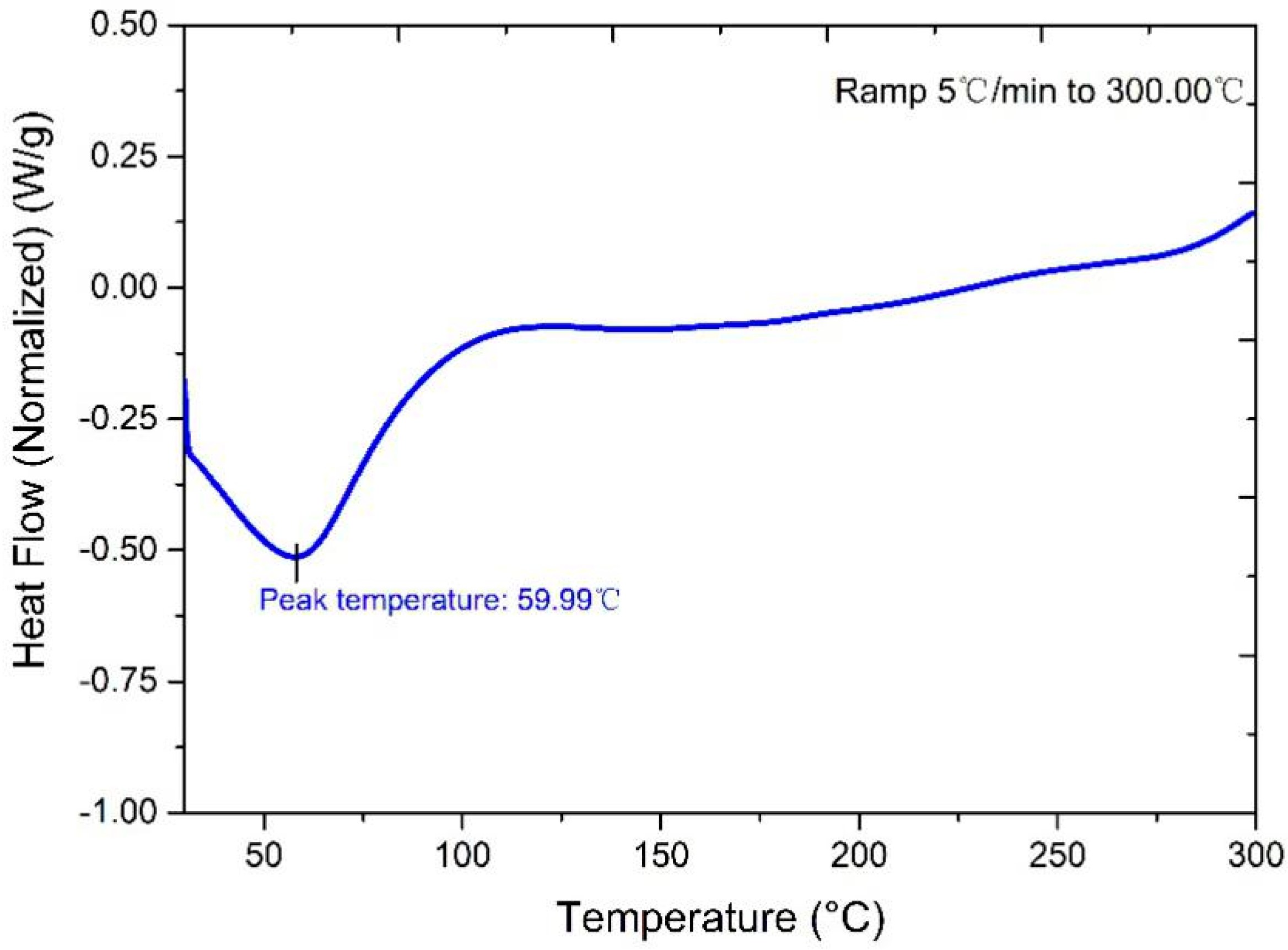

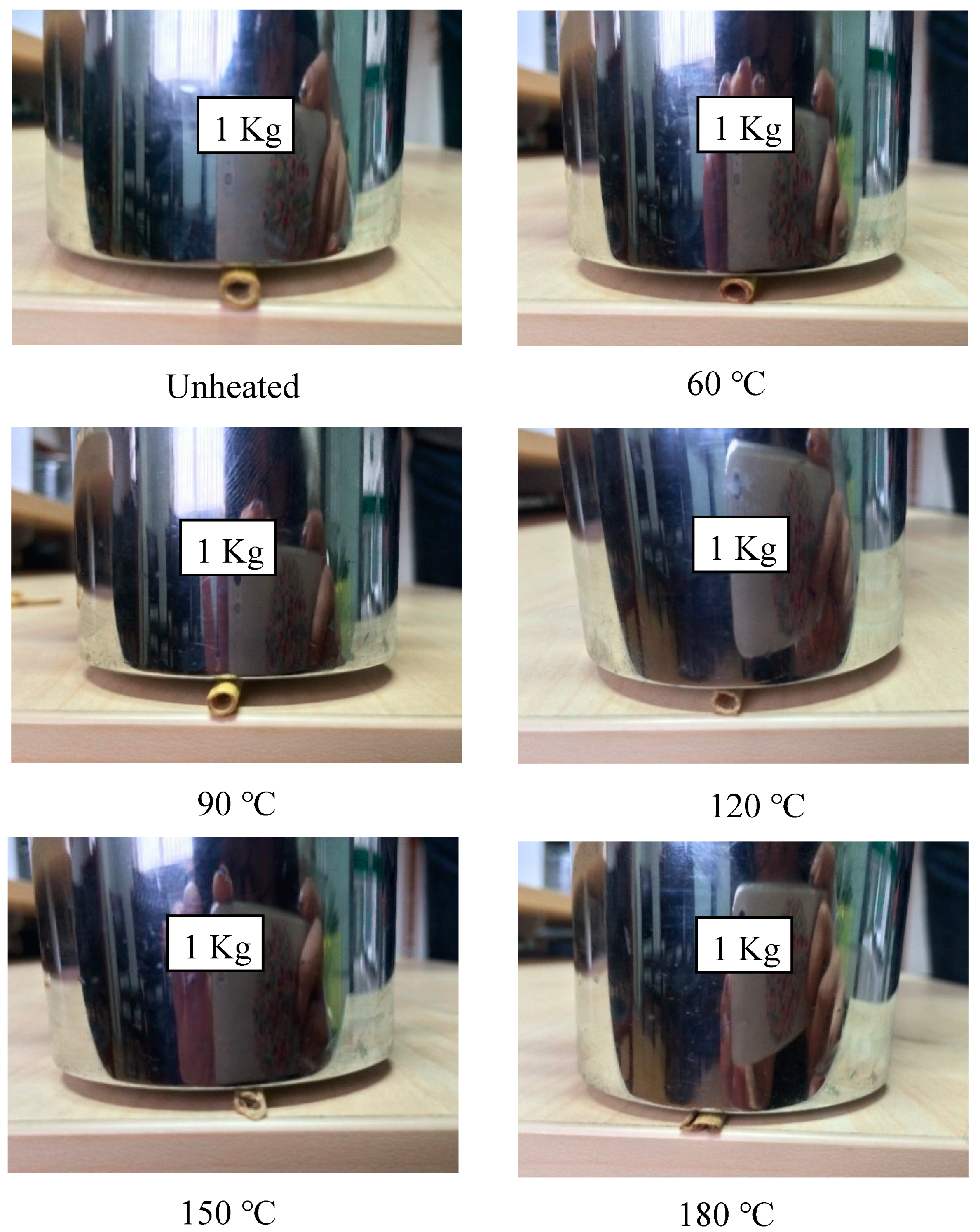

2.2.2. Getter

2.2.3. VIP

2.3. Characterization

3. Results and Discussion

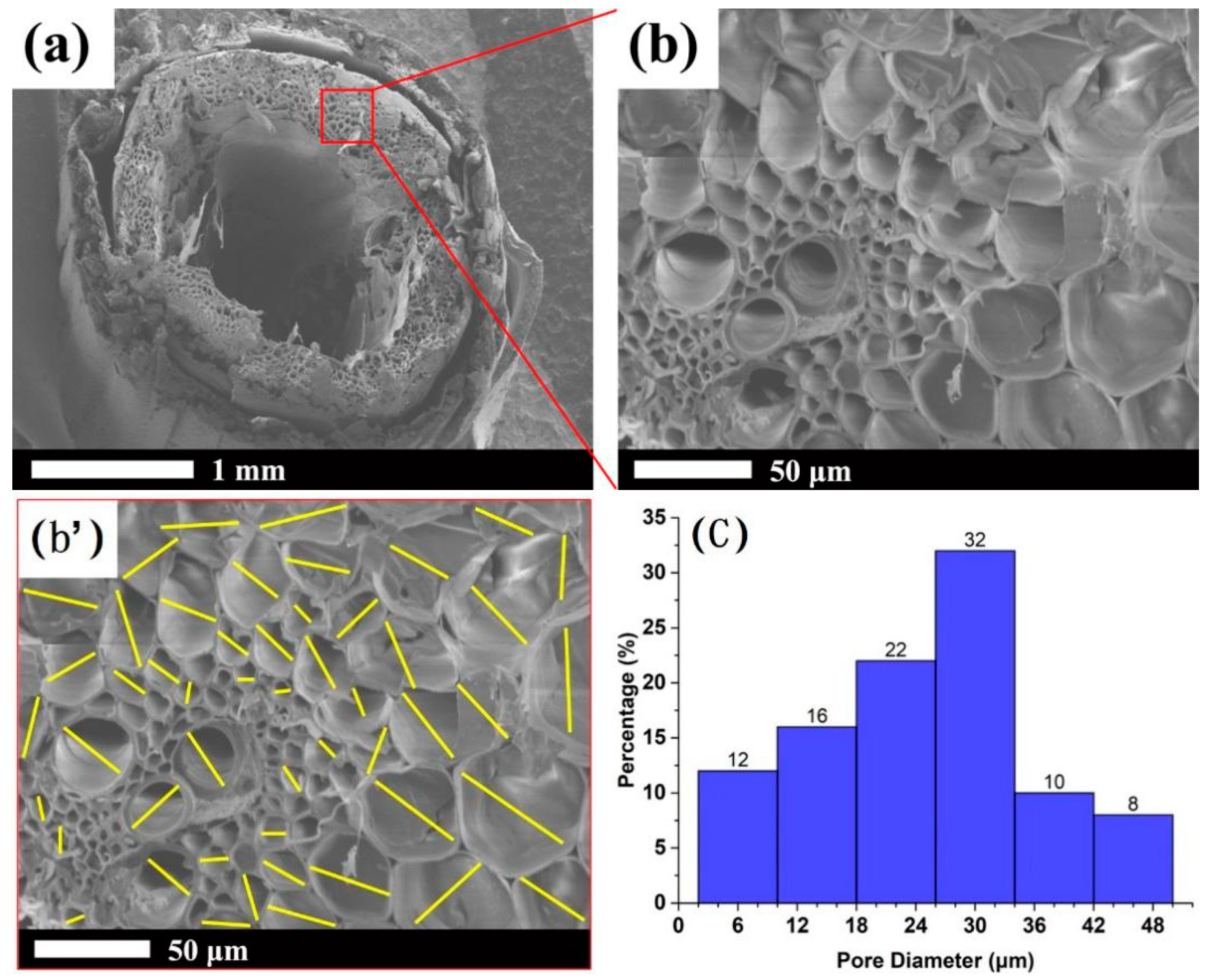

3.1. Material Characterization

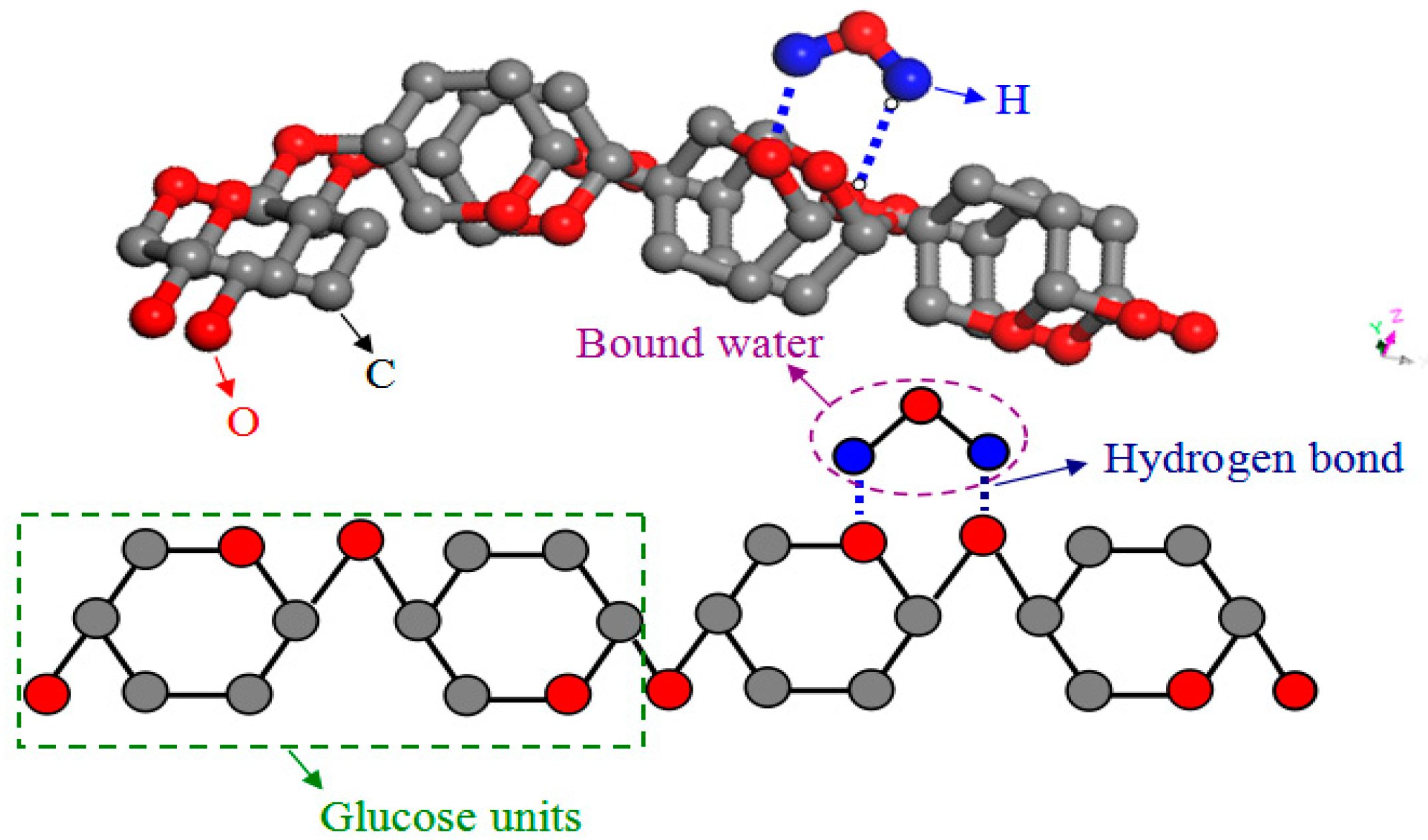

3.2. Thermal Insulation Mechanism

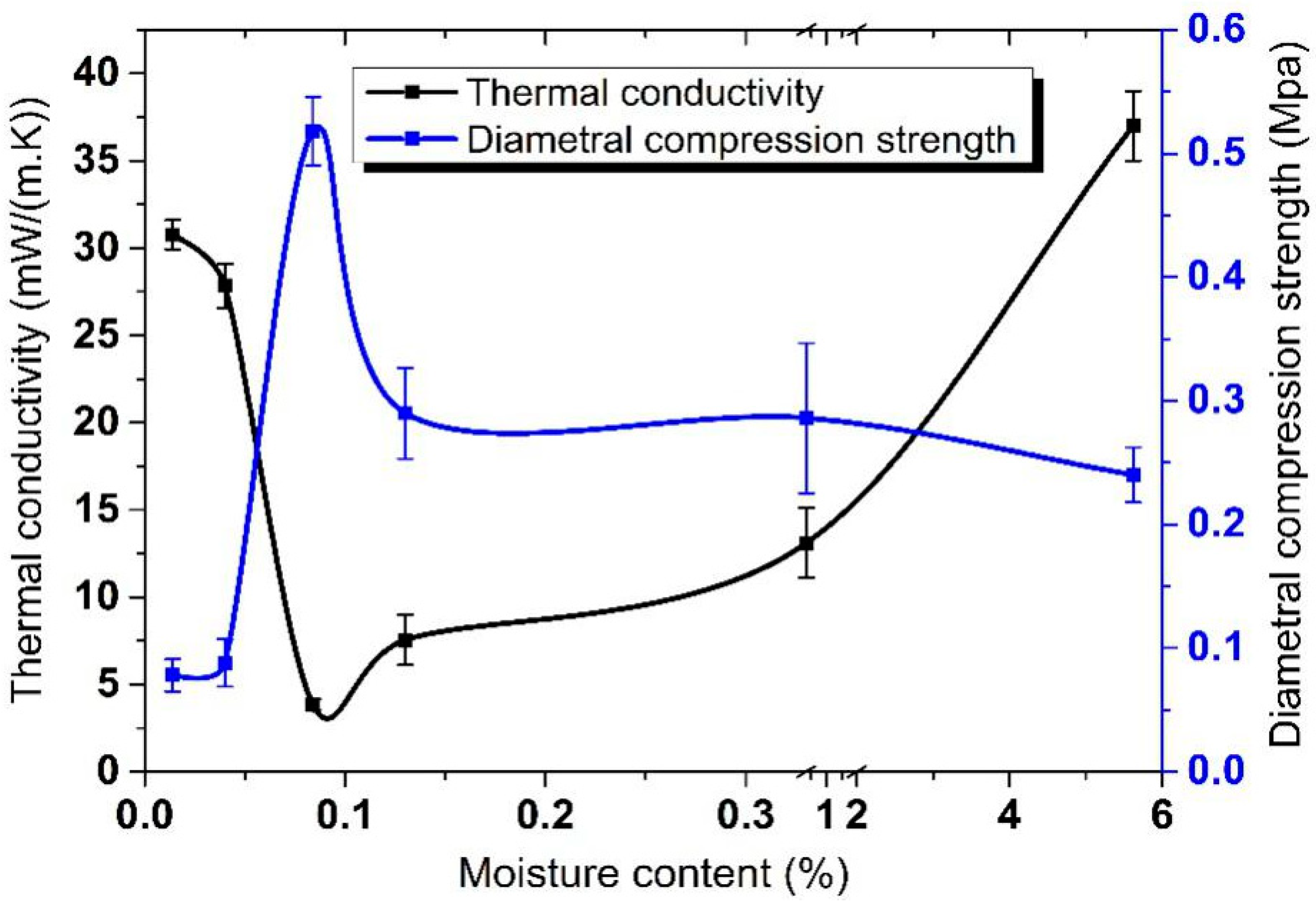

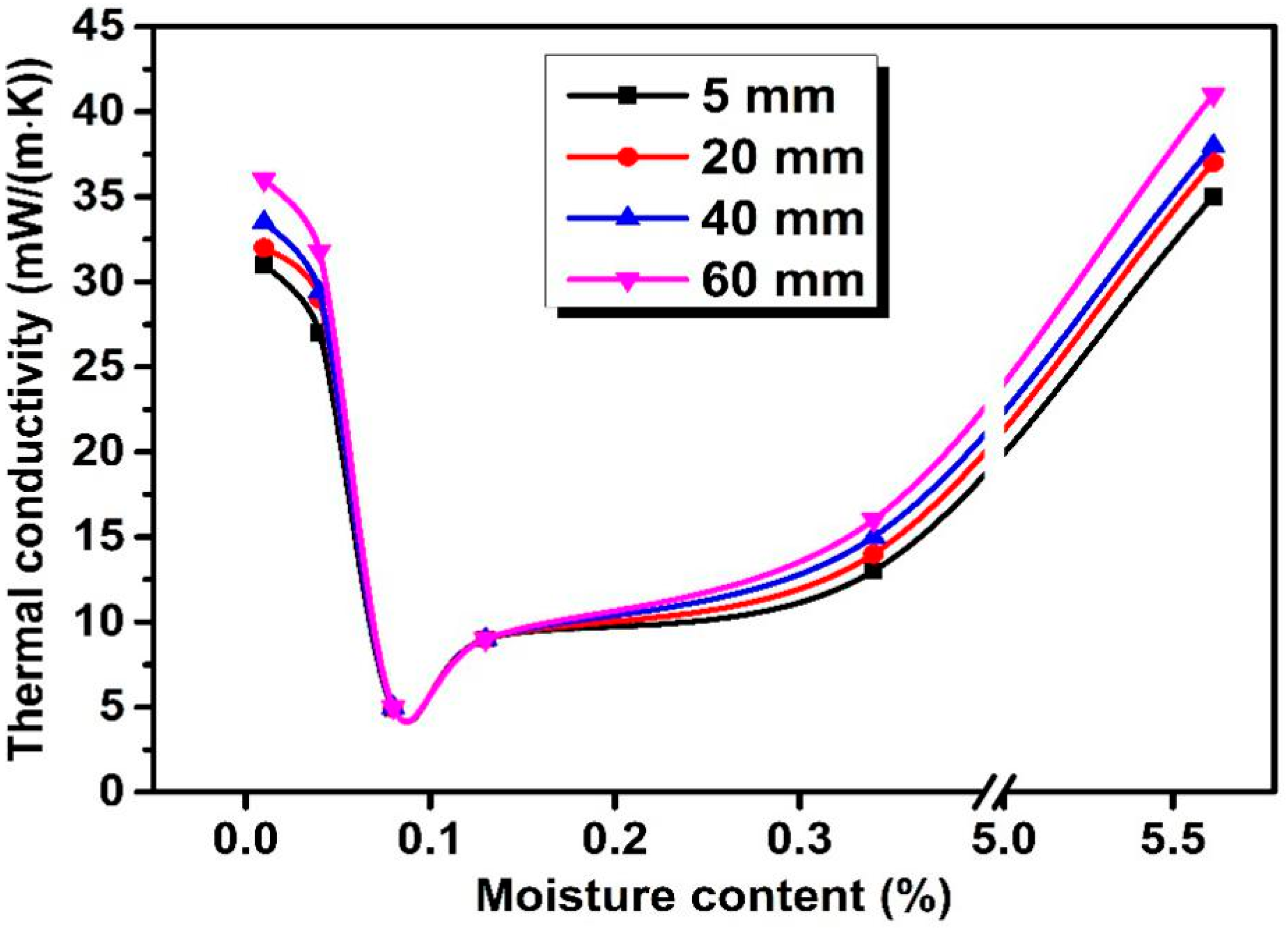

3.3. Thermal Conductivity, Diametral Compression Strength and Moisture Content Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zach, J.; Novak, V.; Peterkowva, J.; Bubenik, J. Development of Vacuum Insulation Panels with Utilization of Organic By-Products. Energies 2020, 13, 1165. [Google Scholar] [CrossRef] [Green Version]

- Simmler, H.; Brunner, S. Vacuum insulation panels for building application: Basic properties, aging mechanisms and service life. Energy Build. 2005, 37, 1122–1131. [Google Scholar] [CrossRef]

- Fricke, J.; Heinemann, U.; Ebert, H.P. Vacuum insulation panels—From research to market. Vacuum 2008, 82, 680–690. [Google Scholar] [CrossRef] [Green Version]

- Yang, C.G.; Li, Y.J.; Gao, X.; Xu, L. A review of vacuum degradation research and the experimental outgassing research of the core material–PU foam on vacuum. Phys. Procedia 2012, 32, 239–244. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.; Lee, J.H.; Song, T.H. Vacuum insulation properties of phenolic foam. Int. J. Heat Mass Transf. 2012, 55, 5343–5349. [Google Scholar] [CrossRef]

- Tseng, P.C.; Chu, H.S. An experimental study of the heat transfer in PS foam insulation. Heat Mass Transf. 2009, 45, 399–406. [Google Scholar] [CrossRef]

- Wu, J.W.; Sung, W.F.; Chu, H.S. Thermal conductivity of polyurethane foams. Int. J. Heat Mass Transf. 1999, 42, 2211–2217. [Google Scholar] [CrossRef]

- Zhao, S.Y.; Zhang, B.M.; He, X.D. Temperature and pressure dependent effective thermal conductivity of fibrous insulation. Int. J. Therm. Sci. 2009, 48, 440–448. [Google Scholar] [CrossRef]

- Kwon, J.S.; Jang, C.H.; Jung, H.; Song, T.H. Vacuum maintenance in vacuum insulation panels exemplified with a staggered beam VIP. Energy Build. 2010, 42, 590–597. [Google Scholar] [CrossRef]

- Kistler, S.S. The relation between heat conductivity and structure in silica aerogel. J. Phys. Chem. 1935, 39, 79–86. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, H.; Wang, W. Performance of Straw/Linear Low Density Polyethylene Composite Prepared with Film-Roll Hot Pressing. Polymers 2020, 12, 860. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mutani, G.; Azzolino, C.; Marci, M.; Mancuso, S. Straw Buildings: A Good Compromise between Environmental Sustainability and Energy-Economic Savings. Appl. Sci. 2020, 10, 2858. [Google Scholar] [CrossRef] [Green Version]

- Cui, B.-L. Straw Carbonization and Separation Technique and Separating Device Used Thereby. CHN. Patent No. 200810180011, 18 October 2008. [Google Scholar]

- Li, C.D.; Chen, Z.F.; Boafo, F.E.; Xu, T.Z.; Wang, L. Effect of pressure holding time of extraction process on thermal conductivity of glass fiber VIPs. J. Mater. Process. Technol. 2014, 214, 539–543. [Google Scholar] [CrossRef]

- Brunner, S.; Wakili, K.G. (Eds.) In Proceedings of the 11th International Vacuum Insulation Symposium, Duebendorf, Switzerland, 19–20 September 2013. Available online: http://www.empa.ch/ivis2013 (accessed on 13 July 2020).

- Nemat-Alla, M. Reproducing hoop stress–strain behavior for tubular material using lateral compression test. Int. J. Mech. Sci. 2003, 45, 605–621. [Google Scholar] [CrossRef]

- Wei, K.; Lv, C.; Chen, M.; Zhou, X.; Dai, Z.; Shen, D. Development and performance evaluation of a new thermal insulation material from rice straw using high frequency hot-pressing. Energy Build. 2015, 87, 116–122. [Google Scholar] [CrossRef]

- Jelle, B.P. Traditional, state-of-the-art and future thermal building insulation materials and solutions–Properties, requirements and possibilities. Energy Build. 2011, 43, 2549–2563. [Google Scholar] [CrossRef] [Green Version]

- Lee, D.; Stevens, P.C.; Zeng, S.Q.; Hunt, A.J. Thermal characterization of carbon-opacified silica aerogels. J. Non-Cryst. Solids 1995, 186, 285–290. [Google Scholar] [CrossRef]

- Collishaw, P.G.; Evans, J.R.G. An assessment of expressions for the apparent thermal conductivity of cellular materials. J. Mater. Sci. 1994, 29, 486–498. [Google Scholar] [CrossRef]

- Lee, O.J.; Lee, K.H.; Yim, T.J.; Kim, S.Y.; Yoo, K.P. Determination of mesopore size of aerogels from thermal conductivity measurements. J. Non-Cryst. Solids 2002, 298, 287–292. [Google Scholar] [CrossRef]

- Kwon, J.S.; Jung, H.; Yeo, I.S.; Song, T.H. Outgassing characteristics of a polycarbonate core material for vacuum insulation panels. Vacuum 2011, 85, 839–846. [Google Scholar] [CrossRef]

- Li, C.D.; Duan, Z.C.; Chen, Q.; Chen, Z.F.; Boafo, F.E.; Wu, W.P. The effect of drying condition of glass fiber core material on the thermal conductivity of vacuum insulation panel. Mater. Des. 2013, 50, 1030–1037. [Google Scholar] [CrossRef]

- Wang, L.; Skreiberg, Ø.; Becidan, M. Investigation of additives for preventing ash fouling and sintering during barley straw combustion. Appl. Therm. Eng. 2014, 70, 1262–1269. [Google Scholar] [CrossRef]

- Eitelberger, J.; Hofstetter, K. A comprehensive model for transient moisture transport in wood below the fiber saturation point: Physical background, implementation and experimental validation. Int. J. Therm. Sci. 2011, 50, 1861–1866. [Google Scholar] [CrossRef]

- Engelund, E.T.; Thygesen, L.G.; Hoffmeyer, P. Water sorption in wood and modified wood at high values of relative humidity. Part 2: Appendix. Theoretical assessment of the amount of capillary water in wood microvoids. Holzforschung 2010, 64, 325–330. [Google Scholar] [CrossRef]

- Kwon, J.S.; Jang, C.H.; Jung, H.; Song, T.H. Effective thermal conductivity of various filling materials for vacuum insulation panels. Int. J. Heat Mass Transf. 2009, 52, 5525–5532. [Google Scholar] [CrossRef]

- Habets, S.; de Wild, P.J.; Huijgen, W.J.J.; van Eck, E.R.H. The influence of thermochemical treatments on the lignocellulosic structure of wheat straw as studied by natural abundance 13C NMR. Bioresour. Technol. 2013, 146, 585–590. [Google Scholar] [CrossRef]

- Di, X.; Gao, Y.; Bao, C.; Ma, S. Thermal insulation property and service life of vacuum insulation panels with glass fiber chopped strand as core materials. Energy Build. 2014, 73, 176–183. [Google Scholar] [CrossRef]

- Alam, M.; Singh, H.; Brunner, S.; Naziris, C. Experimental characterisation and evaluation of the thermo-physical properties of expanded perlite—Fumed silica composite for effective vacuum insulation panel (VIP) core. Energy Build. 2014, 69, 442–450. [Google Scholar] [CrossRef] [Green Version]

- Faessel, M.; Delisée, C.; Bos, F.; Castéra, P. 3D Modelling of random cellulosic fibrous networks based on X-ray tomography and image analysis. Compos. Sci. Technol. 2005, 65, 1931–1940. [Google Scholar] [CrossRef]

| Core Material | Fiber Diameter (mm) | Pore Diameter (μm) | Porosity (%) | Bulk Density (kg/m3) | Thermal Conductivity mW/(m·K) |

|---|---|---|---|---|---|

| Straw | 0.1–1.3 (mean 0.7) | 2–50 | >95% | 100 | 3.5 |

| PU [4] | -- | 150–200 | >95% | 55–65 | ≤10 |

| PF [5] | -- | 200–400 | 98% | 25 | 5 |

| PS [6] | -- | 85–374 | >93% | 41–70 | 6.5 |

| Drying Temperature (°C) | Moisture Content (%) | Diametral Compression Strength (MPa) | Thermal Conductivity mW/(m·K) |

|---|---|---|---|

| Ambient temp | 5.62 | 0.24 | 37.0 |

| 5.64 | 0.21 | 39.2 | |

| 5.62 | 0.25 | 36.7 | |

| 5.61 | 0.27 | 33.9 | |

| 5.63 | 0.23 | 38.2 | |

| 60 | 0.34 | 0.29 | 13.4 |

| 0.34 | 0.31 | 12.2 | |

| 0.35 | 0.25 | 14.3 | |

| 0.36 | 0.21 | 15.4 | |

| 0.32 | 0.37 | 10.2 | |

| 90 | 0.13 | 0.29 | 7.6 |

| 0.15 | 0.23 | 9.8 | |

| 0.13 | 0.29 | 7.7 | |

| 0.12 | 0.32 | 6.4 | |

| 0.12 | 0.32 | 6.2 | |

| 120 | 0.08 | 0.53 | 3.8 |

| 0.08 | 0.53 | 3.6 | |

| 0.09 | 0.48 | 4.0 | |

| 0.09 | 0.50 | 4.3 | |

| 0.08 | 0.55 | 3.5 | |

| 150 | 0.04 | 0.08 | 28.0 |

| 0.04 | 0.09 | 27.2 | |

| 0.03 | 0.07 | 29.5 | |

| 0.04 | 0.08 | 28.3 | |

| 0.05 | 0.12 | 26.1 | |

| 180 | 0.01 | 0.06 | 32.1 |

| 0.02 | 0.09 | 30.3 | |

| 0.02 | 0.09 | 30.0 | |

| 0.01 | 0.07 | 31.0 | |

| 0.01 | 0.08 | 30.4 |

| Drying Temperature (°C) | Time (Day) | Inner Pressure (Pa) | Thermal Conductivity (mW/(m·K)) | ||

|---|---|---|---|---|---|

| A | B | A | B | ||

| Ambient temp | 3 | 5.6 | 5.1 | 37.0 | 36.7 |

| 7 | 9.3 | 6.2 | 40.0 | 38.4 | |

| 30 | 16.8 | 10.5 | 45.7 | 41.2 | |

| 60 | 3 | 5.3 | 4.5 | 13.1 | 12.9 |

| 7 | 8.9 | 6.7 | 16.3 | 14.3 | |

| 30 | 16.2 | 9.8 | 24.6 | 18.1 | |

| 90 | 3 | 5.1 | 4.2 | 7.6 | 7.4 |

| 7 | 8.1 | 6.3 | 9.8 | 8.2 | |

| 30 | 15.9 | 9.3 | 17.3 | 12.0 | |

| 120 | 3 | 4.6 | 3.9 | 3.9 | 3.8 |

| 7 | 7.8 | 6.1 | 5.2 | 4.1 | |

| 30 | 15.3 | 8.7 | 12.9 | 7.7 | |

| 150 | 3 | 4.5 | 3.9 | 28.0 | 27.6 |

| 7 | 7.7 | 6.0 | 31.5 | 28.2 | |

| 30 | 15.2 | 8.6 | 40.2 | 32.5 | |

| 180 | 3 | 4.4 | 3.8 | 31.0 | 30.3 |

| 7 | 7.7 | 6.0 | 33.7 | 31.9 | |

| 30 | 15.2 | 8.7 | 44.3 | 36.2 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Yang, Y.; Chen, Z.; Hong, Y.; Chen, Z.; Wu, J. Preparation and Characterization of a Type of Green Vacuum Insulation Panel Prepared with Straw Core Material. Materials 2020, 13, 4604. https://doi.org/10.3390/ma13204604

Wang L, Yang Y, Chen Z, Hong Y, Chen Z, Wu J. Preparation and Characterization of a Type of Green Vacuum Insulation Panel Prepared with Straw Core Material. Materials. 2020; 13(20):4604. https://doi.org/10.3390/ma13204604

Chicago/Turabian StyleWang, Lu, Yong Yang, Zhaofeng Chen, Yiyou Hong, Zhou Chen, and Jiankun Wu. 2020. "Preparation and Characterization of a Type of Green Vacuum Insulation Panel Prepared with Straw Core Material" Materials 13, no. 20: 4604. https://doi.org/10.3390/ma13204604

APA StyleWang, L., Yang, Y., Chen, Z., Hong, Y., Chen, Z., & Wu, J. (2020). Preparation and Characterization of a Type of Green Vacuum Insulation Panel Prepared with Straw Core Material. Materials, 13(20), 4604. https://doi.org/10.3390/ma13204604