Dielectric Tunability Properties in (110)-Oriented Epitaxial 0.5Ba(Ti0.8Zr0.2)O3-0.5(Ba0.7Ca0.3)TiO3 Thin Films Prepared by PLD Method

Abstract

:1. Introduction

2. Experimental

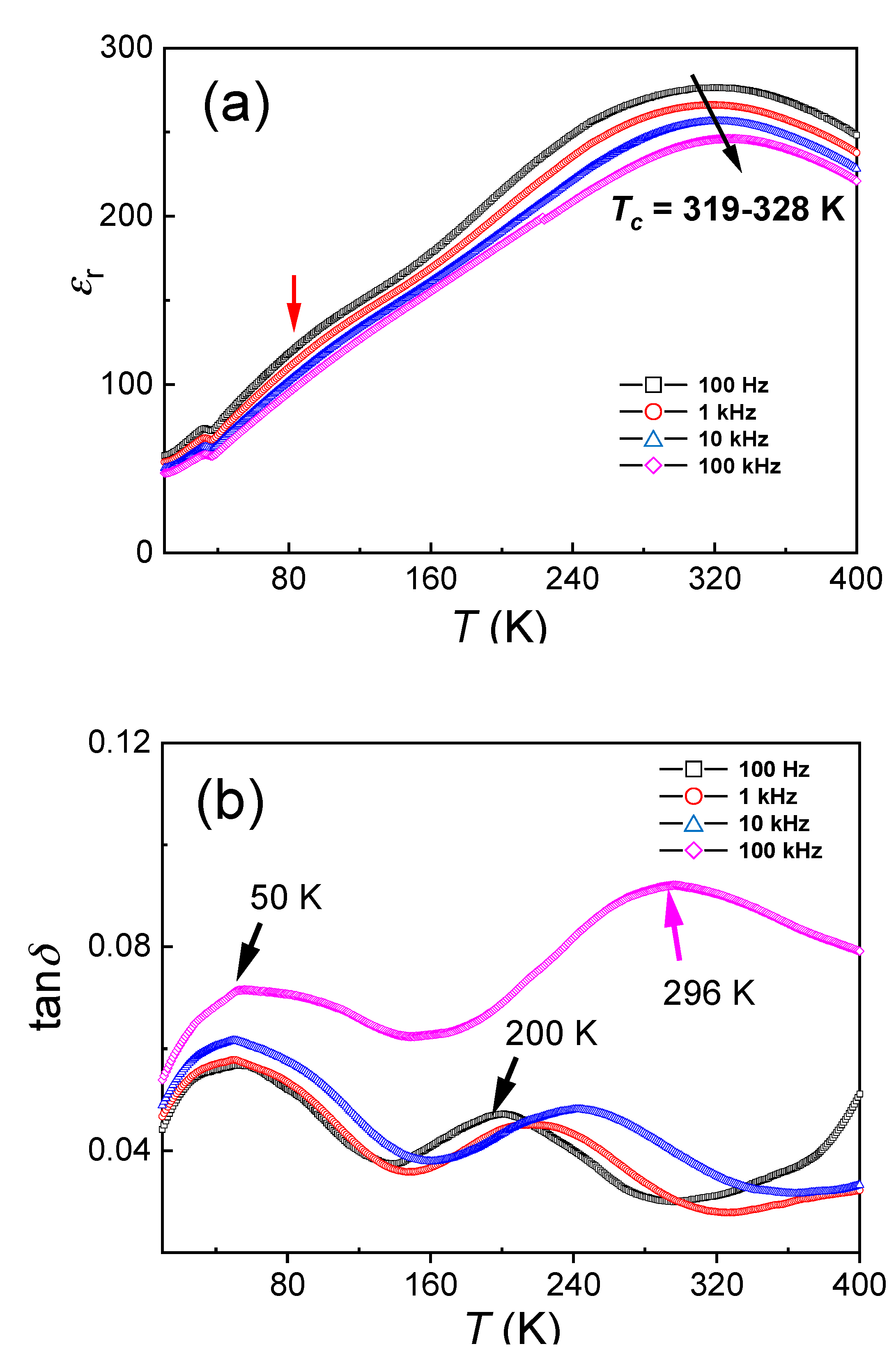

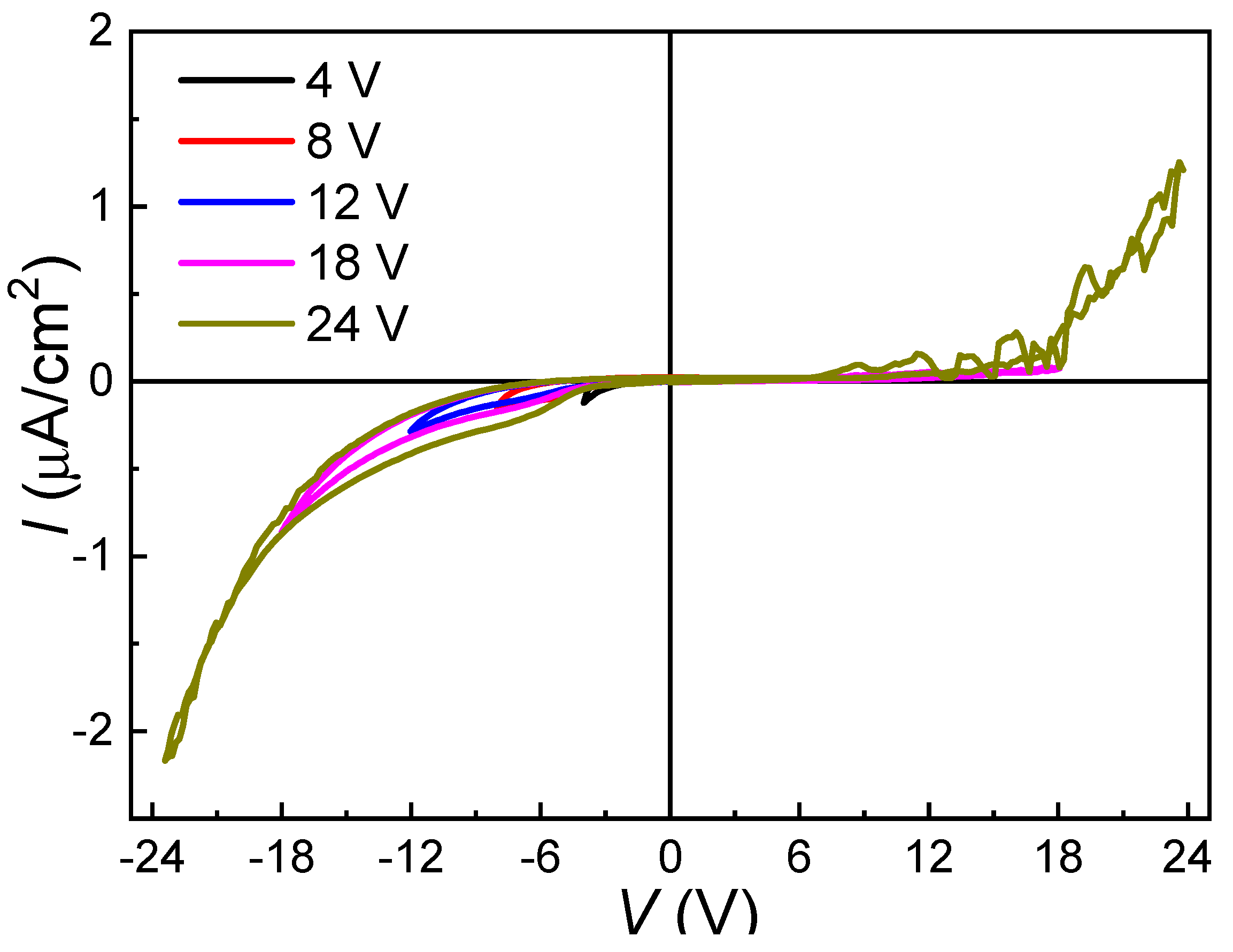

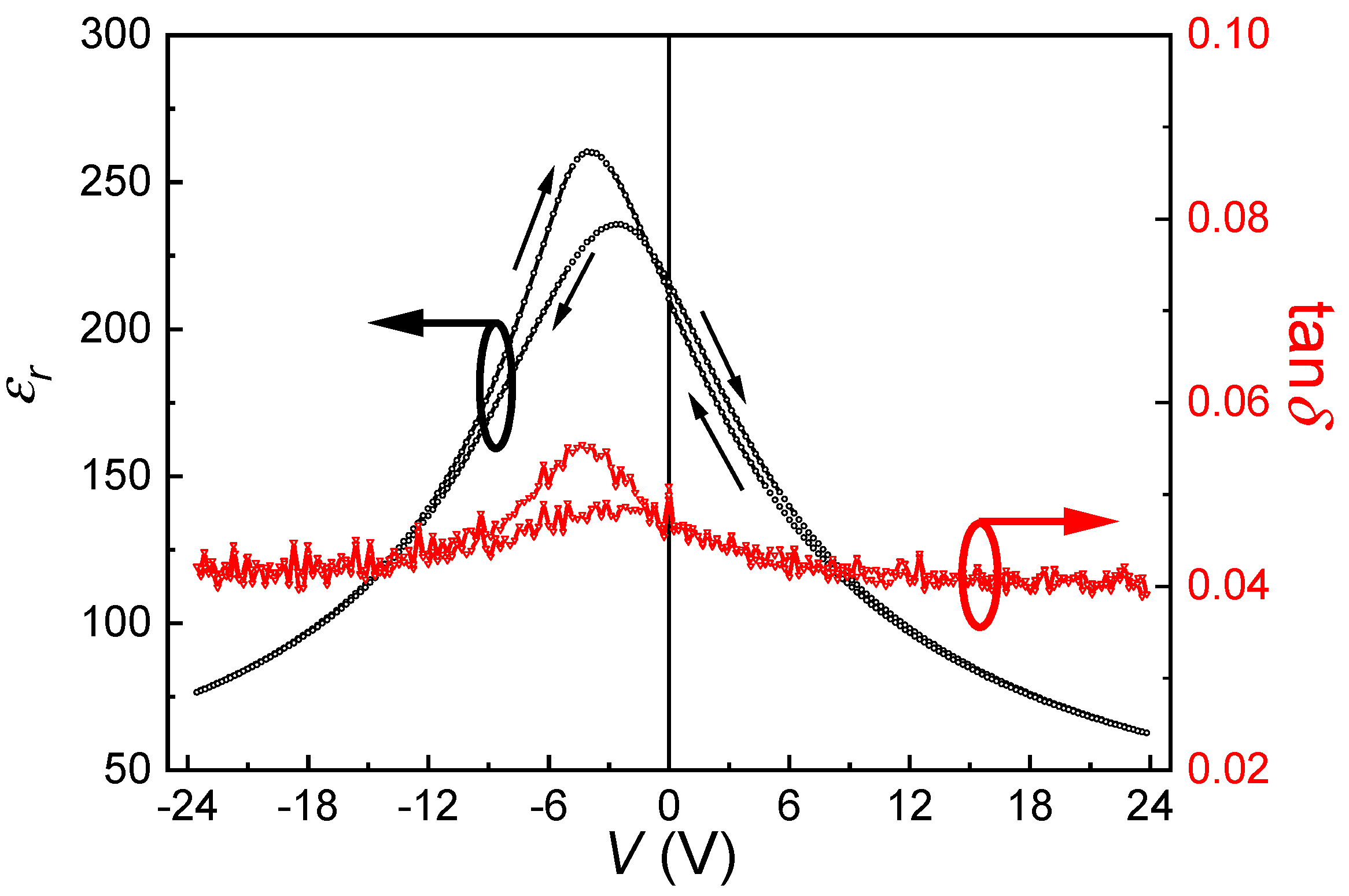

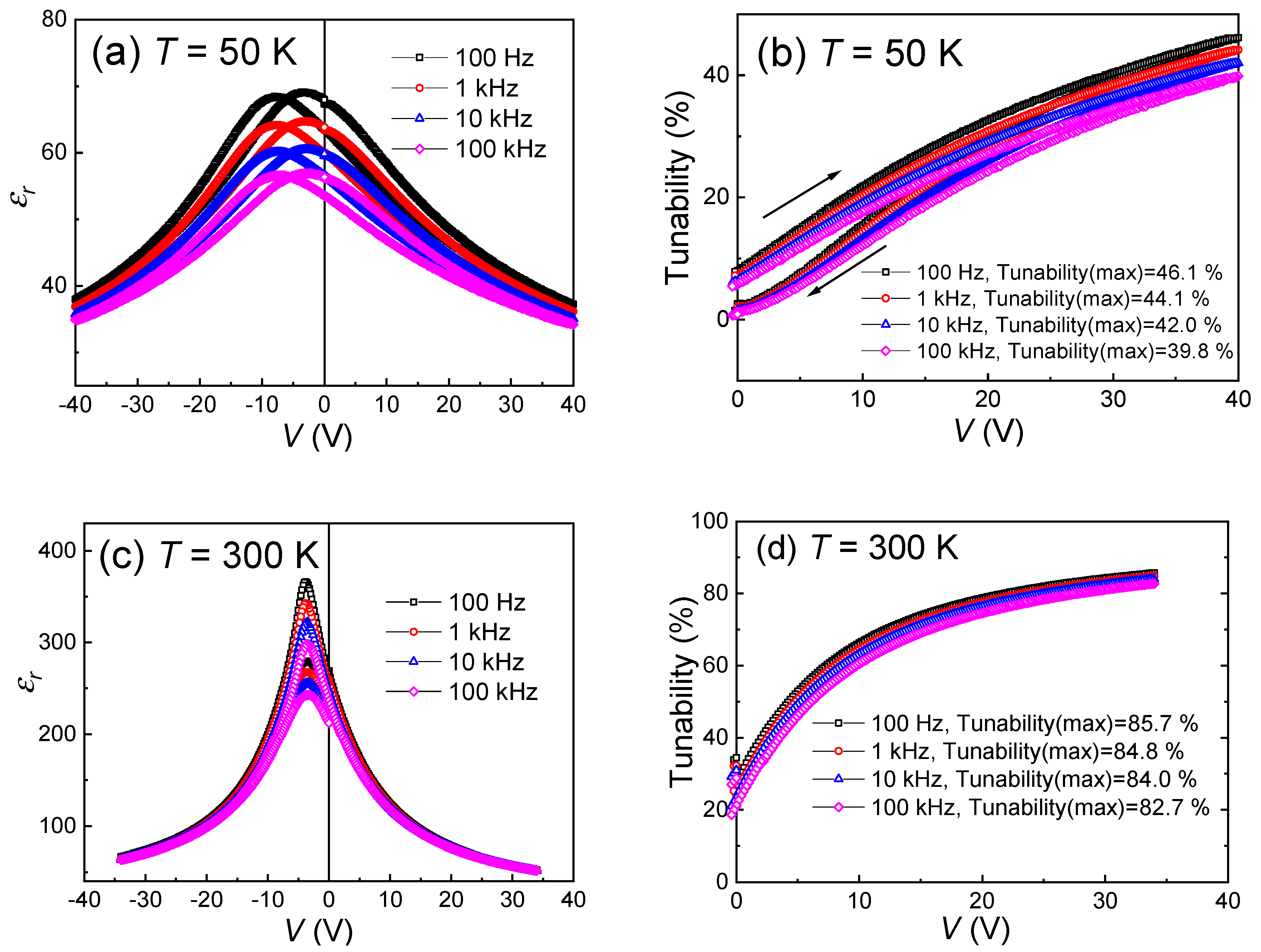

3. Results and Discussions

4. Summary

Author Contributions

Funding

Conflicts of Interest

References

- Yang, Z.; Goto, H.; Matsumoto, M.; Maeda, R. Active micromixer for microfluidic systems using lead-zirconate-titanate (PZT)-generated ultrasonic vibration. Electrophoresis 2000, 21, 116–119. [Google Scholar] [CrossRef]

- Gross, S.J.; Tadigadapa, S.; Jackson, T.N.; Trolier-McKinstry, S.; Zhang, Q.Q. Lead-zirconate-titanate-based piezoelectric micromachined switch. Appl. Phys. Lett. 2003, 82, 174–176. [Google Scholar] [CrossRef]

- Zhou, D.; Kamlah, M.; Munz, D. Effects of uniaxial prestress on the ferroelectric hysteretic response of soft PZT. J. Eur. Ceram. Soc. 2005, 25, 25–432. [Google Scholar] [CrossRef]

- Liu, W.F.; Ren, X.B. Large piezoelectric effect in Pb-Free ceramics. Phys. Rev. Lett. 2009, 103, 257602–257605. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, B.Z.; Blendell, J.E.; Bowman, K.J. Temperature-Dependent poling behavior of lead-free BZT–BCT piezoelectrics. J. Am. Ceram. Soc. 2011, 94, 3192–3194. [Google Scholar] [CrossRef]

- Wang, Z.M.; Cai, Z.L.; Zhao, K.; Guo, X.L.; Chen, J.; Sun, W.; Cheng, Z.X.; Kimura, H.; Li, B.W.; Yuan, G.L.; et al. In-situ observation of nanomechanical behavior arising from critical-temperature-induced phase transformationin Ba (Zr0.2Ti0.8)O3-0.5(Ba0.7Ca0.3)TiO3 thin film. Appl. Phys. Lett. 2013, 103, 071902–071905. [Google Scholar] [CrossRef] [Green Version]

- Zimmermann, F.; Voigts, M.; Menesklou, W.; Ivers-Tiffée, E. Ba0.6Sr0.4TiO3 and BaZr0.3Ti0.7O3 thick films as tunable. J. Eur. Ceram. Soc. 2004, 24, 1729–1733. [Google Scholar] [CrossRef]

- Tang, X.G.; Chew, K.-H.; Chan, H.L.W. Diffuse phase transition and dielectric tunability of Ba(ZryTi1-y)O3 relaxor ferroelectric ceramics. Acta Mater. 2004, 52, 5177–5183. [Google Scholar] [CrossRef]

- Maiti, T.; Guo, R.; Bhalla, A.S. Enhanced electric field tunable dielectric properties of BaZrxTi1-xO3 relaxor ferroelectrics. Appl. Phys. Lett. 2007, 90, 182901–182903. [Google Scholar] [CrossRef]

- Peng, C.; Li, J.F.; Gong, W. Preparation and properties of (Bi1/2Na1/2)TiO3–Ba(Ti,Zr)O3 lead-free piezoelectric ceramics. Mater. Lett. 2005, 59, 1576–1580. [Google Scholar] [CrossRef]

- Mishra, P.; Sonia; Kumar, P. Effect of sintering temperature on dielectric, piezoelectric and ferroelectric properties of BZT–BCT 50/50 ceramics. J. Alloys Comp. 2012, 545, 210–215. [Google Scholar] [CrossRef]

- Xiao, F.; Ma, W.B.; Sun, Q.C.; Huan, Z.L.; Li, J.P.; Tang, C.C. The electrostrictive effect and dielectric properties of lead-free 0.5Ba(ZrxTi1-x)O3–0.5(Ba0.75Ca0.25)TiO3 ceramics. J. Mater. Sci. Mater. Electron. 2013, 24, 2653–2658. [Google Scholar] [CrossRef]

- Zhai, J.W.; Yao, X.; Zhang, L.Y.; Shen, B. Dielectric nonlinear characteristics of Ba(Zr0.35Ti0.65)O3 thin films grown by a sol-gel process. Appl. Phys. Lett. 2004, 84, 136–3138. [Google Scholar] [CrossRef]

- Zimmermann, F.; Voigts, M.; Weil, C.; Jakoby, R.; Wang, P.; Menesklou, W.; Ivers-Tiffée, E. Investigation of barium strontium titanate thick films for tunable phase shifters. J. Eur. Ceram. Soc. 2001, 21, 2019–2023. [Google Scholar] [CrossRef]

- Xu, J.; Menesklou, W.; Ivers-Tiffée, E. Processing and properties of BST thin films for tunable microwave devices. J. Eur. Ceram. Soc. 2004, 24, 1735–1739. [Google Scholar] [CrossRef]

- Luo, B.C.; Wang, D.Y.; Duan, M.M.; Li, S. Orientation-dependent piezoelectric properties in lead-free epitaxial 0.5BaZr0.2Ti0.8O3-0.5Ba0.7Ca0.3TiO3 thin films. Appl. Phys. Lett. 2013, 103, 122903. [Google Scholar] [CrossRef]

- Kolekar, Y.D.; Bhaumik, A.; Shaikh, P.A.; Ramana, C.V.; Ghosh, K. Polarization switching characteristics of 0.5BaTi0.8Zr0.2O3-0.5Ba0.7Ca0.3TiO3 lead free ferroelectric thin films by pulsed laser deposition. J. Appl. Phys. 2014, 115, 154102. [Google Scholar] [CrossRef]

- Puli, V.S.; Pradhan, D.K.; Adireddy, S.; Martinez, R.; Silwal, P.; Scott, J.F.; Ramana, C.V.; Chrisey, D.B.; Katiyar, R.S. Nanoscale polarization switching and leakage currents in (Ba0.955Ca0.045)(Zr0.17Ti0.83)O3 epitaxial thin films. J. Phys. D Appl. Phys. 2015, 48, 355502. [Google Scholar] [CrossRef]

- Puli, V.S.; Pradhan, D.K.; Coondoo, I.; Panwar, N.; Adireddy, S.; Luo, S.; Katiyar, R.S.; Chrisey, D.B. Observation of large enhancement in energy-storage properties of lead-free polycrystalline 0.5BaZr0.2Ti0.8O3-0.5Ba0.7Ca0.3TiO3 ferroelectric thin films. J. Phys. D Appl. Phys. 2019, 52, 255304. [Google Scholar] [CrossRef]

- Lin, Q.; Wang, D.; Li, S. Strong effect of oxygen partial pressure on electrical properties of 0.5Ba(Zr0.2Ti0.8)O3-0.5(Ba0.7Ca0.3)TiO3 thin films. J. Am. Ceram. Soc. 2015, 1–5. [Google Scholar] [CrossRef]

- Sharma, A.P.; Pradhan, D.K.; Xiao, B.; Pradhan, S.K.; Bahoura, M. Lead-free epitaxial ferroelectric heterostructures for energy storage applications. AIP Adv. 2018, 8, 125112. [Google Scholar] [CrossRef] [Green Version]

- Yao, S.; Ren, W.; Ji, H.; Wu, X.; Shi, P.; Xue, D.; Ren, X.; Ye, Z.G. High pyroelectricity in lead-free 0.5Ba(Zr0.2Ti0.8)O3-0.5(Ba0.7Ca0.3)TiO3 ceramics. J. Phys. D Appl. Phys. 2012, 45, 195301. [Google Scholar] [CrossRef]

- Bai, Y.; Han, X.; Qiao, L. Optimized electrocaloric refrigeration capacity in lead-free (1-x)BaZr0.2Ti0.8O3-xBa0.7Ca0.3TiO3 ceramics. Appl. Phys. Lett. 2013, 102, 252904. [Google Scholar]

- Coondoo, I.; Panwar, N.; Amorin, H.; Alguero, M.; Kholkin, A.L. Synthesis and characterization of lead-free 0.5Ba(Zr0.2Ti0.8)O3-0.5(Ba0.7Ca0.3)TiO3 ceramic. J. Appl. Phys. 2013, 113, 214107. [Google Scholar] [CrossRef] [Green Version]

- Silva, J.P.; Queiros, E.C.; Tavares, P.B.; Sekhar, K.C.; Kamakshi, K.; Moreira, J.A.; Almeida, A.; Pereira, M.; Gomes, M.J.M. Ferroelectric phase transitions studies in 0.5Ba(Zr0.2Ti0.8)O3-0.5(Ba0.7Ca0.3)TiO3 ceramics. J. Electroceram. 2015, 35, 135–140. [Google Scholar] [CrossRef]

- Damjanovic, D.; Biancoli, A.; Batooli, L.; Vahabzadeh, A.; Trodahl, J. Elastic, dielectric, and piezoelectric anomalies and Raman spectroscopy of 0.5Ba(Ti0.8Zr0.2)O3-0.5(Ba0.7Ca0.3)TiO3. Appl. Phys. Lett. 2012, 100, 192907. [Google Scholar] [CrossRef] [Green Version]

- Keeble, D.S.; Benabdallah, F.; Thomas, P.A.; Maglione, M.; Kreisel, J. Revised structural phase diagram of (Ba0.7Ca0.3TiO3)-(BaZr0.2Ti0.8O3). Appl. Phys. Lett. 2013, 102, 092903. [Google Scholar] [CrossRef]

- Setter, N.; Cross, L.E. The contribution of structural disorder to diffuse phase transitions in ferroelectrics. J. Mater. Sci. 1980, 15, 2478–2482. [Google Scholar] [CrossRef]

- Burns, G.; Dacol, F.H. Glassy polarization behavior in ferroelectric compounds Pb(Mg1/3Nb2/3)O3 and Pb(Zn1/3Nb2/3)O3. Sol. State Commun. 1983, 48, 853–856. [Google Scholar] [CrossRef]

- Cross, L.E. Relaxor Ferroelectrics. Ferroelectrics 1987, 76, 241–267. [Google Scholar] [CrossRef]

- Thomas, R.; Varadan, V.K.; Komarneni, S.; Dube, D.C. Diffuse phase transitions, electrical conduction, and low temperature dielectric properties of sol-gel derived ferroelectric barium titanate thin films. J. Appl. Phys. 2001, 90, 1480–1488. [Google Scholar] [CrossRef]

- Cheng, Z.-Y.; Katiyar, R.S.; Yao, X.; Bhalla, A.S. Temperature dependence of the dielectric constant of relaxor ferroelectrics. Phys. Rev. B 1998, 57, 8166–8177. [Google Scholar] [CrossRef]

- Glazounov, A.E.; Tagantsev, A.K. Direct evidence for Vogel-Fulcher freezing in relaxor ferroelectrics. Appl. Phys. Lett. 1998, 73, 856–858. [Google Scholar] [CrossRef]

- Mitsui, T.; Westphal, W.B. Dielectric and X-ray studies of CaxBa1-xTiO3 and CaxSr1-xTiO3. Phys. Rev. 1961, 124, 1354–1359. [Google Scholar] [CrossRef]

- Maiti, T.; Guo, R.; Bhalla, A.S. Structure-property phase diagram of BaZrxTi1-xO3 system. J. Am. Ceram. Soc. 2008, 91, 1769–1780. [Google Scholar] [CrossRef]

- Warren, W.L.; Tuttle, B.A.; Dimos, D.; Pike, G.E.; Al-Shareef, H.N.; Ramesh, R.; Evans, J.T., Jr. Imprint in ferroelectric capacitors. Jpn. J. Appl. Phys. 1996, 35, 1521–1524. [Google Scholar] [CrossRef]

- Abe, K.; Yanase, N.; Yasumoto, T.; Kawakubo, T. Voltage shift phenomena in heteroepitaxial BaTiO3 thin film capacitor. J. Appl. Phys. 2002, 91, 323. [Google Scholar] [CrossRef]

- Grossmann, M.; Lohse, O.; Bolten, D.; Boettger, U.; Schneller, T.; Waser, R. The interface screening model as origin of imprint in PbZrxTi1-xO3 thin films. I. Dopant, illumination, and bias dependence. J. Appl. Phys. 2002, 92, 2680–2687. [Google Scholar] [CrossRef]

- Gruverman, A.; Rodriguez, B.J.; Nemanich, R.J.; Kingon, A.I. Nanoscale observation of photoinduced domain pinning and investigation of imprint behavior in ferroelectric thin films. J. Appl. Phys. 2002, 92, 2734–2739. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Chan, H.K.; Lam, C.H.; Shin, F.G. Mechanisms of imprint effect on ferroelectric thin films. J. Appl. Phys. 2005, 98, 024111. [Google Scholar] [CrossRef] [Green Version]

- Ye, Z.; Tang, M.H.; Zhou, Y.C.; Zheng, X.J.; Cheng, C.P.; Hu, Z.S.; Hu, H.P. Modeling of imprint in hysteresis loop of ferroelectric thin films with top and bottom interface layers. Appl. Phys. Lett. 2007, 90, 042902. [Google Scholar] [CrossRef]

- Tagantsev, A.K.; Sherman, V.O.; Astafiev, K.F.; Venkatesh, J.; Setter, N. Ferroelectric materials for microwave tunable applications. J. Electroceram. 2003, 11, 5–66. [Google Scholar] [CrossRef]

- Kong, L.B.; Li, S.; Zhang, T.S.; Zhai, J.W.; Boey, F.Y.C.; Ma, J. Electrically tunable dielectric materials and strategies to improve their performances. Prog. Mater. Sci. 2010, 55, 840–893. [Google Scholar] [CrossRef]

- Ahmed, A.; Goldthorpe, I.A.; Khandani, A.K. Electrically tunable materials for microwave applications. Appl. Phys. Rev. 2015, 2, 011302. [Google Scholar] [CrossRef]

- Yuan, Z.; Lin, Y.; Weaver, J.; Chen, X.; Chen, C.L.; Subramanyam, G.; Jiang, J.C.; Meletis, E.I. Large dielectric tunability and microwave properties of Mn-doped (Ba,Sr)TiO3 thin films. Appl. Phys. Lett. 2005, 87, 152901. [Google Scholar] [CrossRef]

- Puli, V.S.; Pradhan, D.K.; Perez, W.; Katiyar, R.S. Structure, dielectric tunability, thermal stability and diffuse phase transition behavior of lead free BZT-BCT ceramic capacitors. J. Phys. Chem. Sol. 2013, 74, 466–475. [Google Scholar] [CrossRef]

- Chan, W.-H.; Chen, H.; Colla, E.V. Temporal effect of low-temperature ferroelectric behaviors in Pa0.97La0.02(Zr0.6Sn0.3Ti0.1)O3 ceramics. Appl. Phys. Lett. 2003, 82, 2314. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, B.; Xu, Y.; Zhang, F.; Wang, T.; Yao, Y. Dielectric Tunability Properties in (110)-Oriented Epitaxial 0.5Ba(Ti0.8Zr0.2)O3-0.5(Ba0.7Ca0.3)TiO3 Thin Films Prepared by PLD Method. Materials 2020, 13, 4771. https://doi.org/10.3390/ma13214771

Luo B, Xu Y, Zhang F, Wang T, Yao Y. Dielectric Tunability Properties in (110)-Oriented Epitaxial 0.5Ba(Ti0.8Zr0.2)O3-0.5(Ba0.7Ca0.3)TiO3 Thin Films Prepared by PLD Method. Materials. 2020; 13(21):4771. https://doi.org/10.3390/ma13214771

Chicago/Turabian StyleLuo, Bing, Yiwen Xu, Fuzeng Zhang, Tingting Wang, and Yingbang Yao. 2020. "Dielectric Tunability Properties in (110)-Oriented Epitaxial 0.5Ba(Ti0.8Zr0.2)O3-0.5(Ba0.7Ca0.3)TiO3 Thin Films Prepared by PLD Method" Materials 13, no. 21: 4771. https://doi.org/10.3390/ma13214771

APA StyleLuo, B., Xu, Y., Zhang, F., Wang, T., & Yao, Y. (2020). Dielectric Tunability Properties in (110)-Oriented Epitaxial 0.5Ba(Ti0.8Zr0.2)O3-0.5(Ba0.7Ca0.3)TiO3 Thin Films Prepared by PLD Method. Materials, 13(21), 4771. https://doi.org/10.3390/ma13214771