Mechanical Performance of Unstitched and Silk Fiber-Stitched Woven Kenaf Fiber-Reinforced Epoxy Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

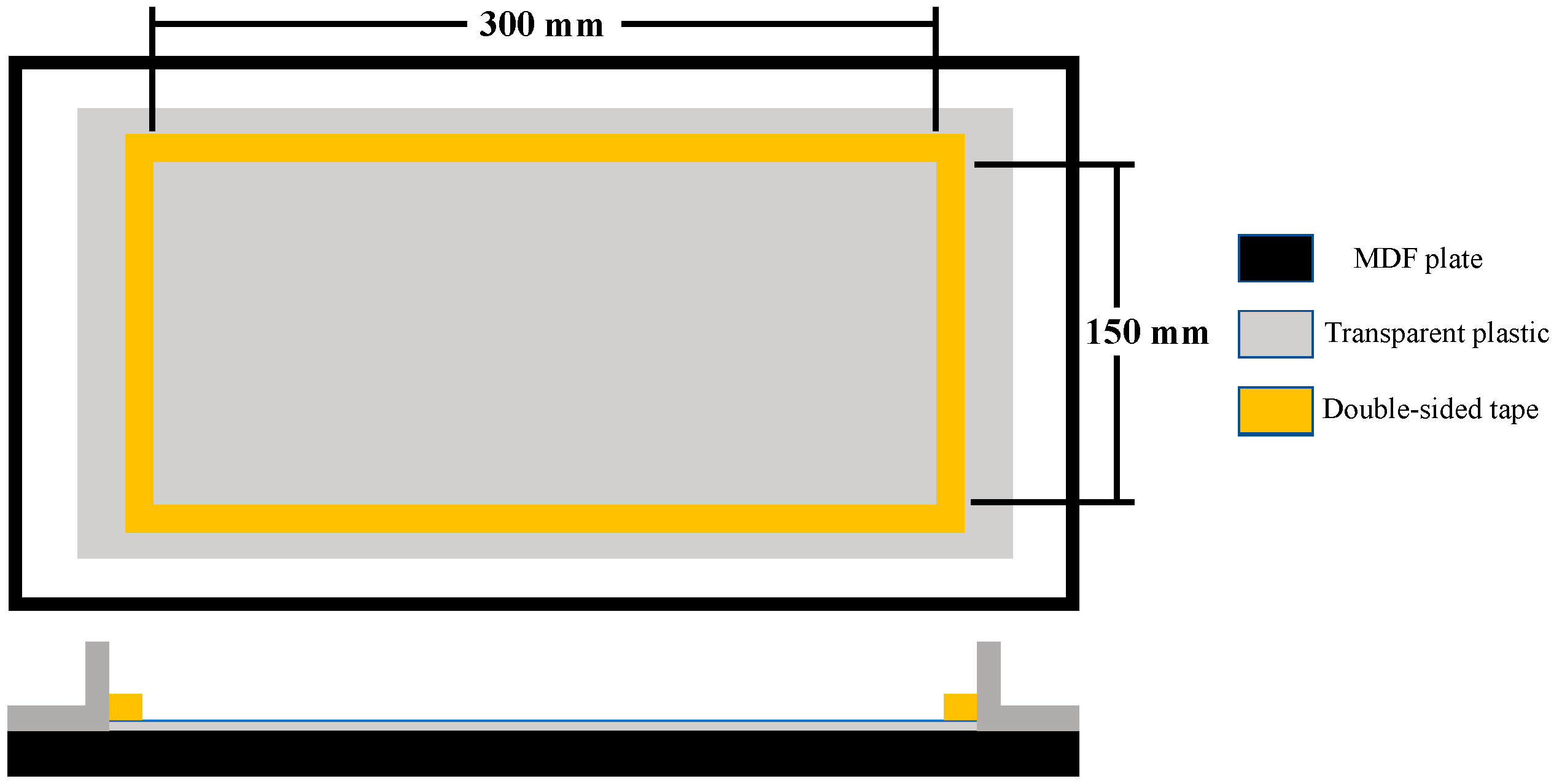

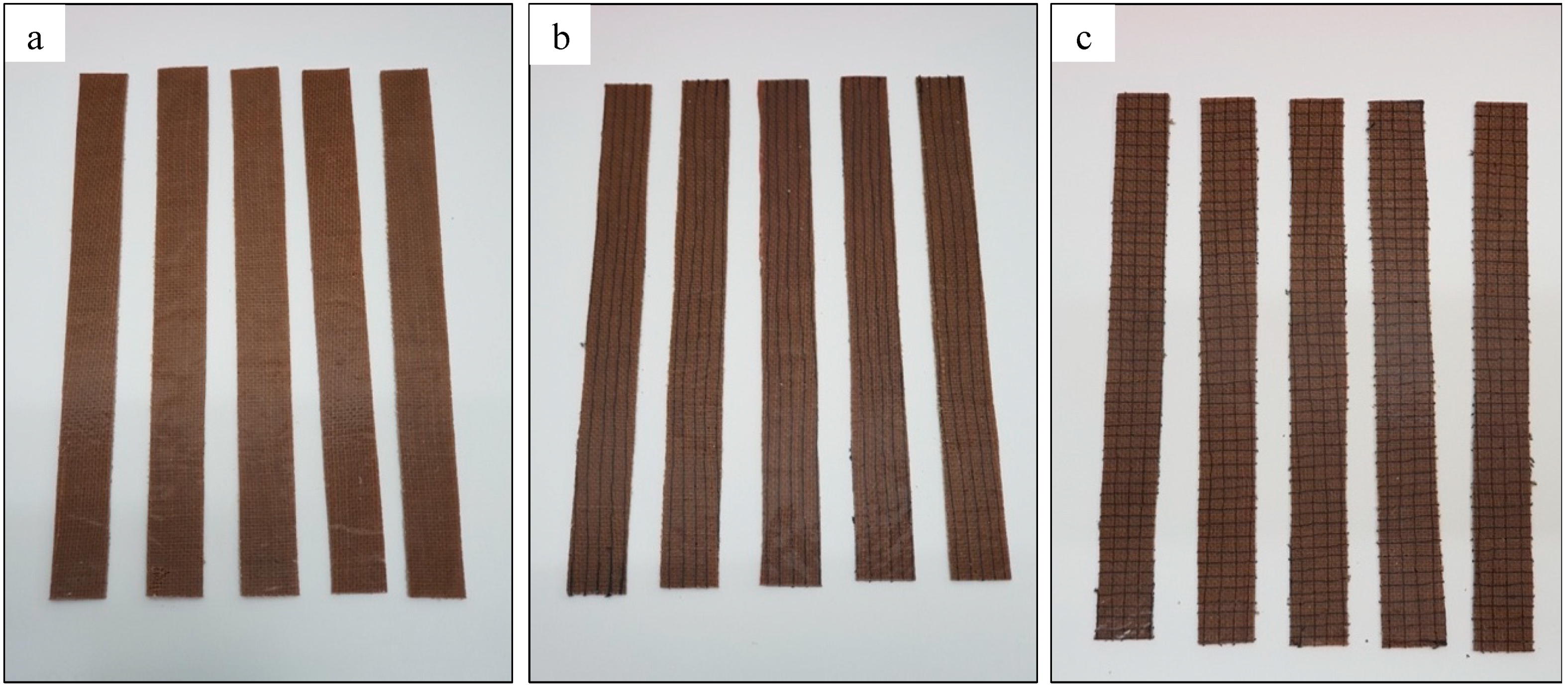

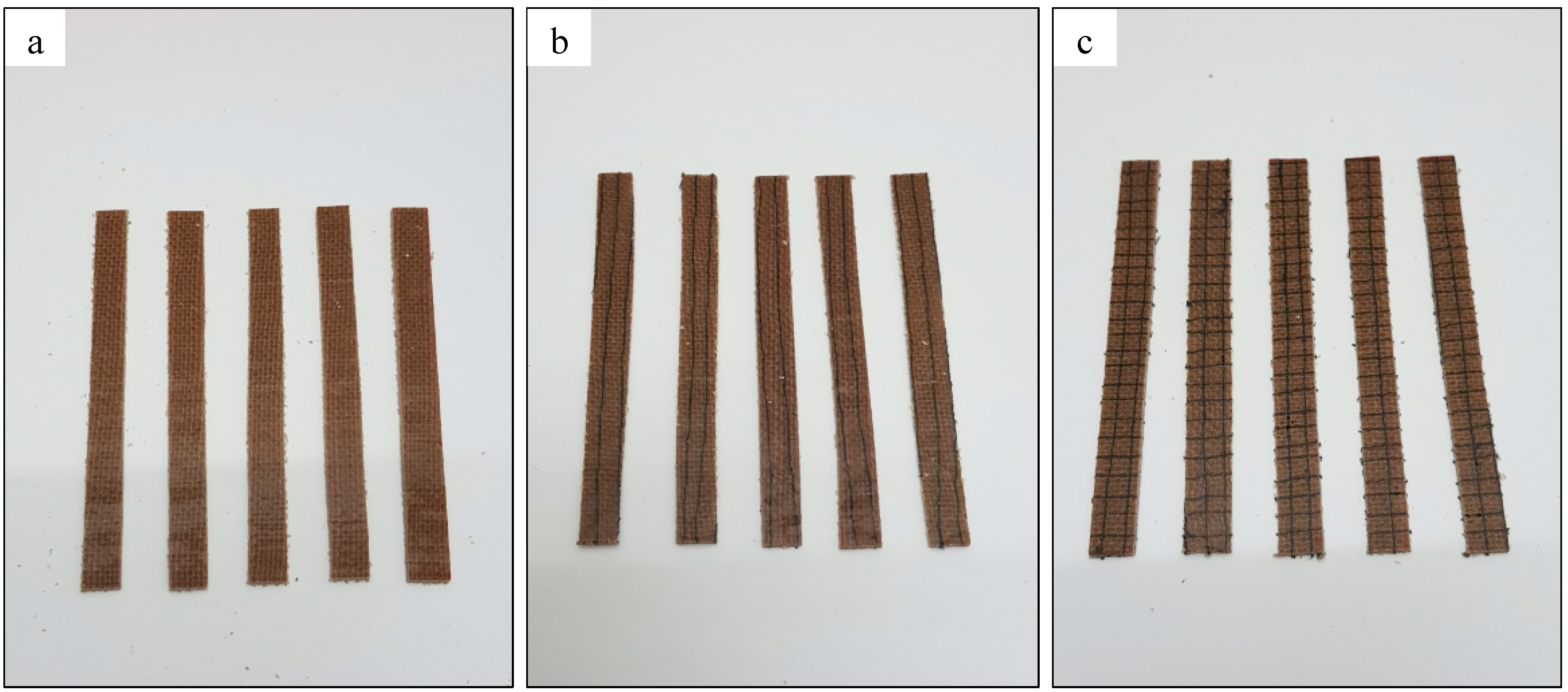

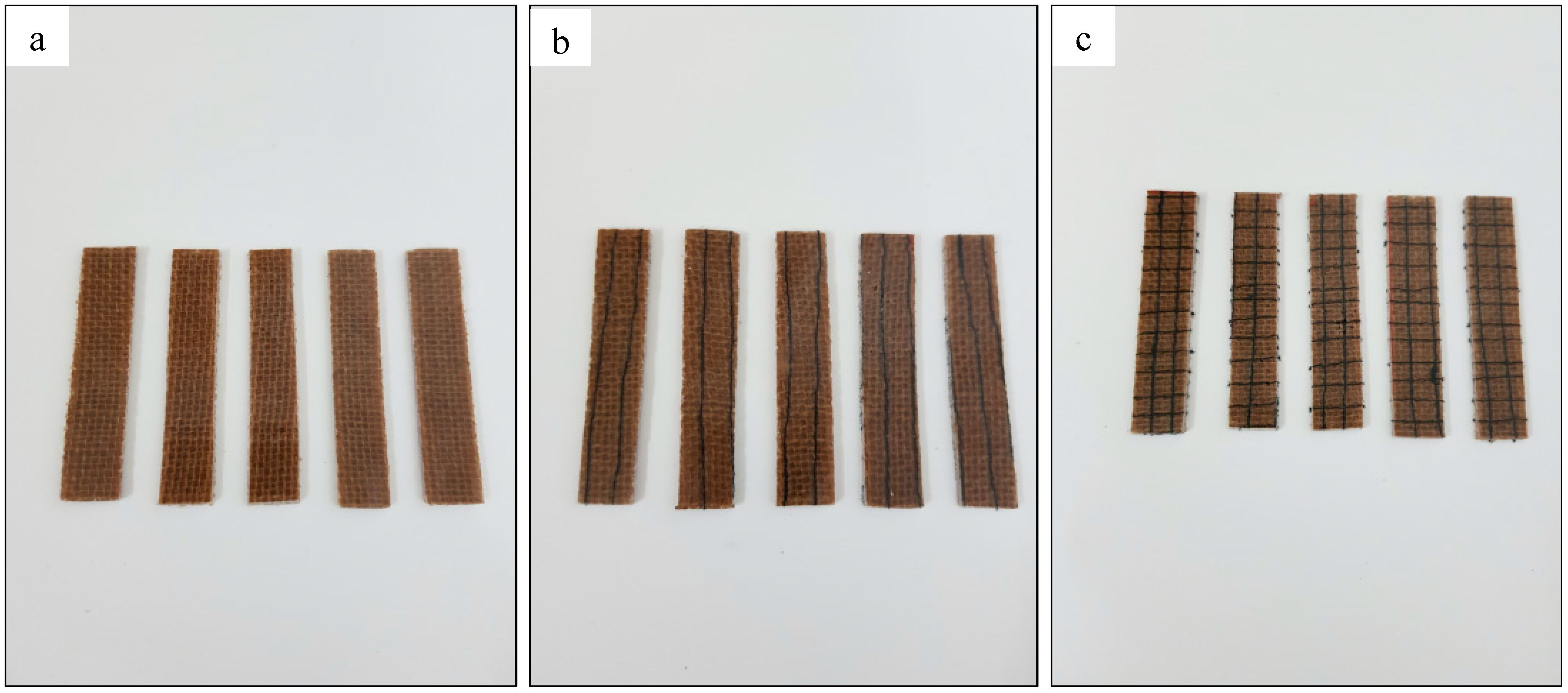

2.2. Preparation of Composite Laminates

2.3. Characterization

2.3.1. Tensile Testing

2.3.2. Flexural Testing

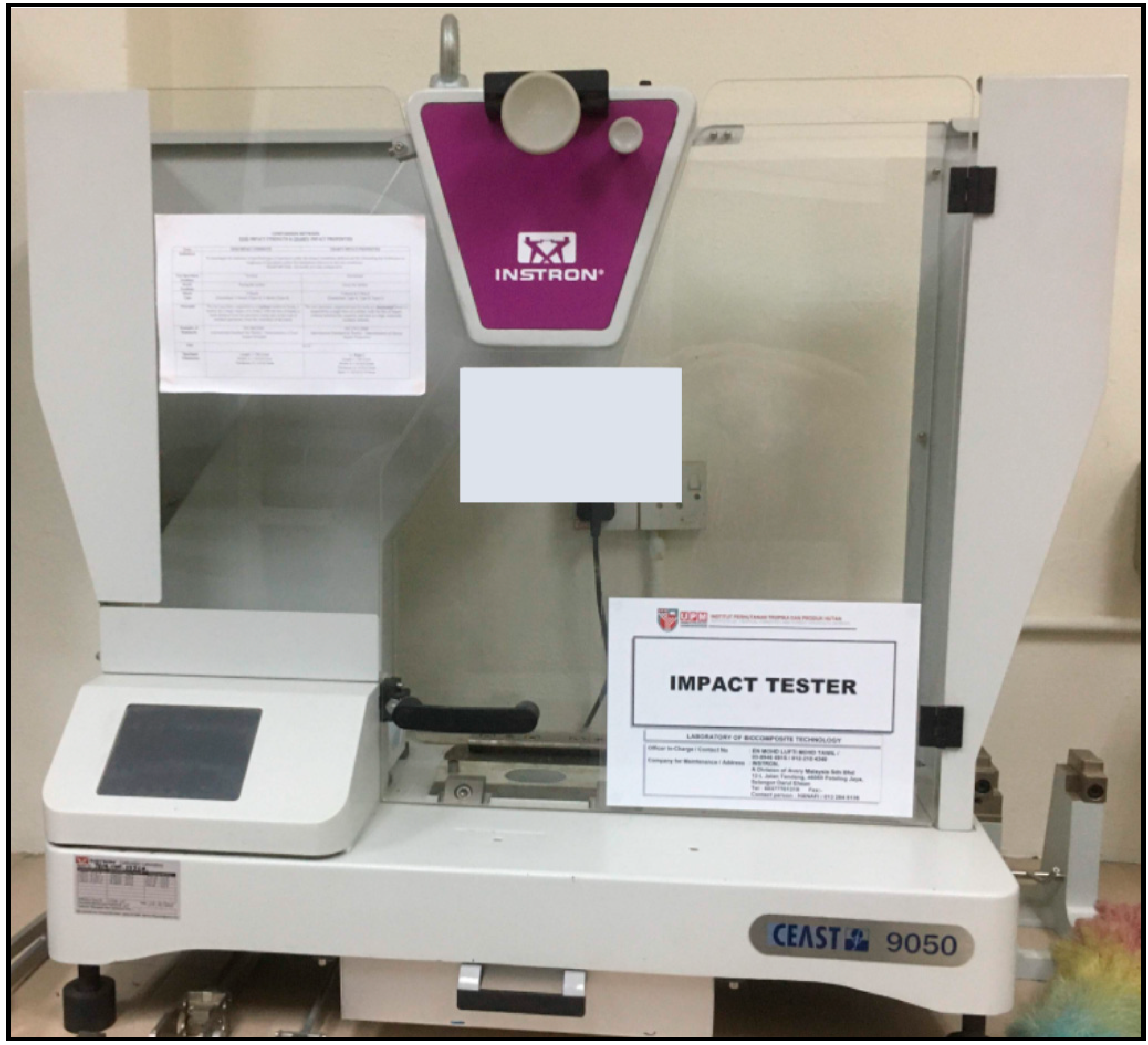

2.3.3. Impact Testing

2.4. Composite Failure Mechanism

3. Results and Discussion

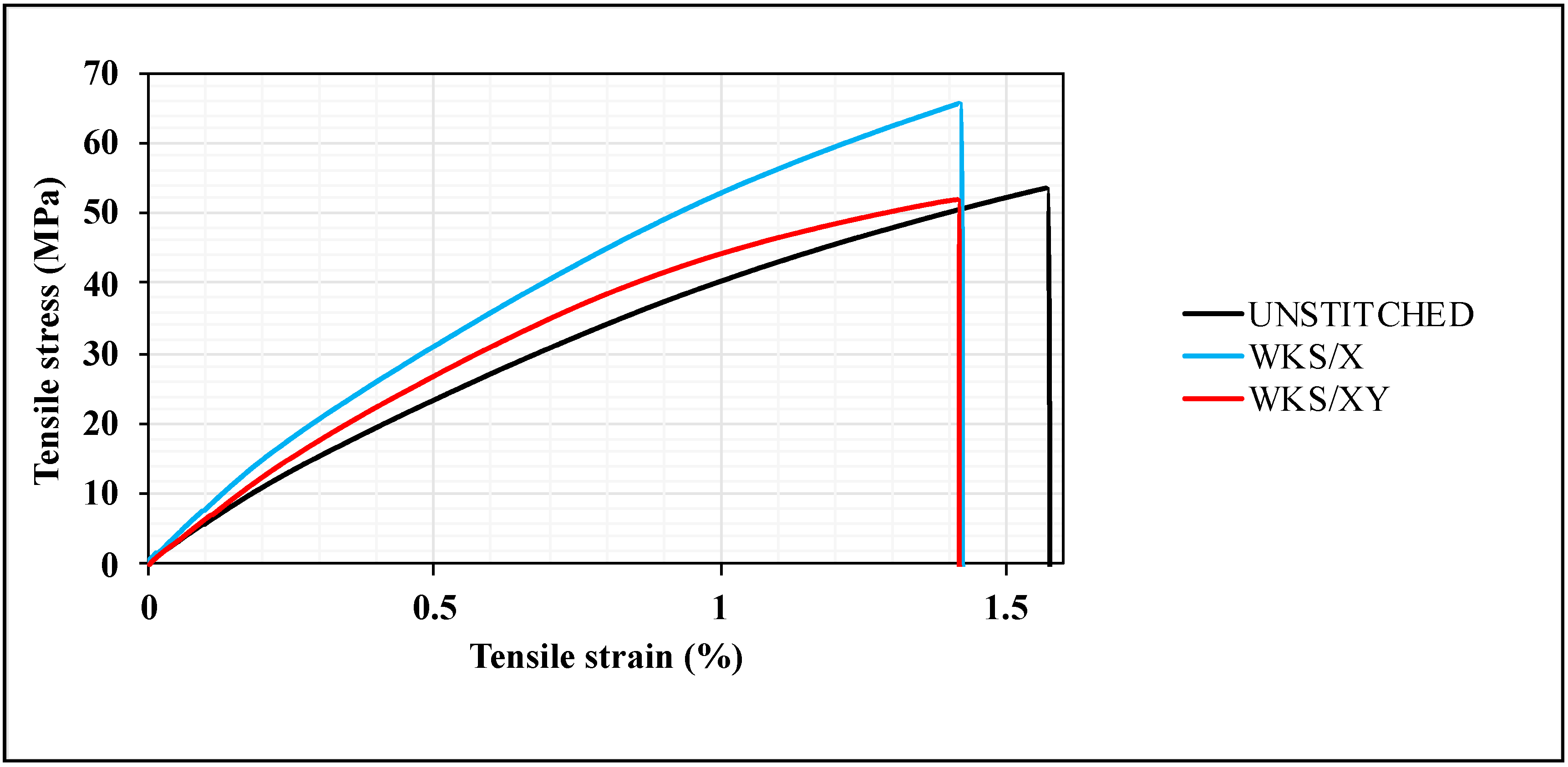

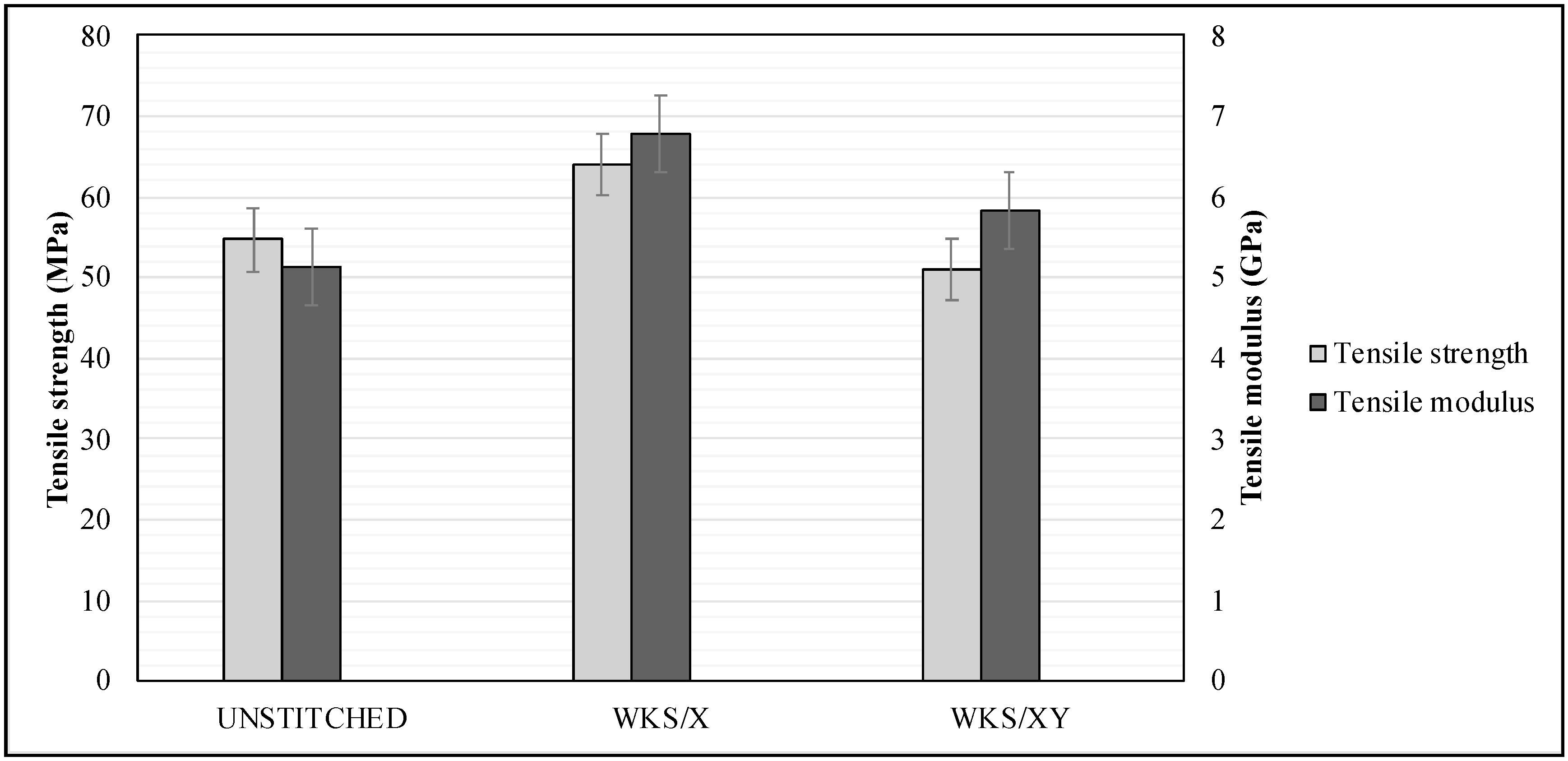

3.1. Tensile Test Results

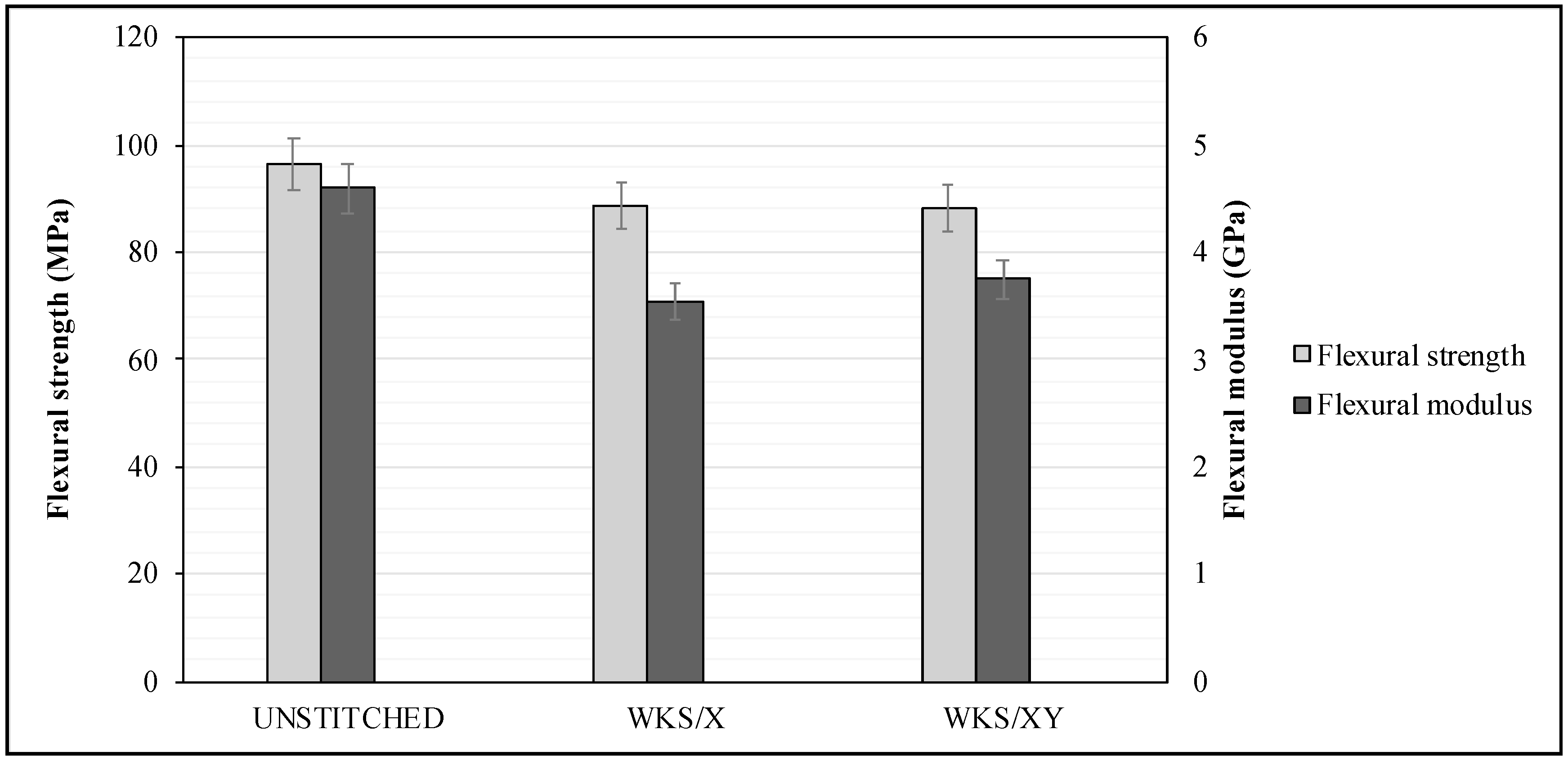

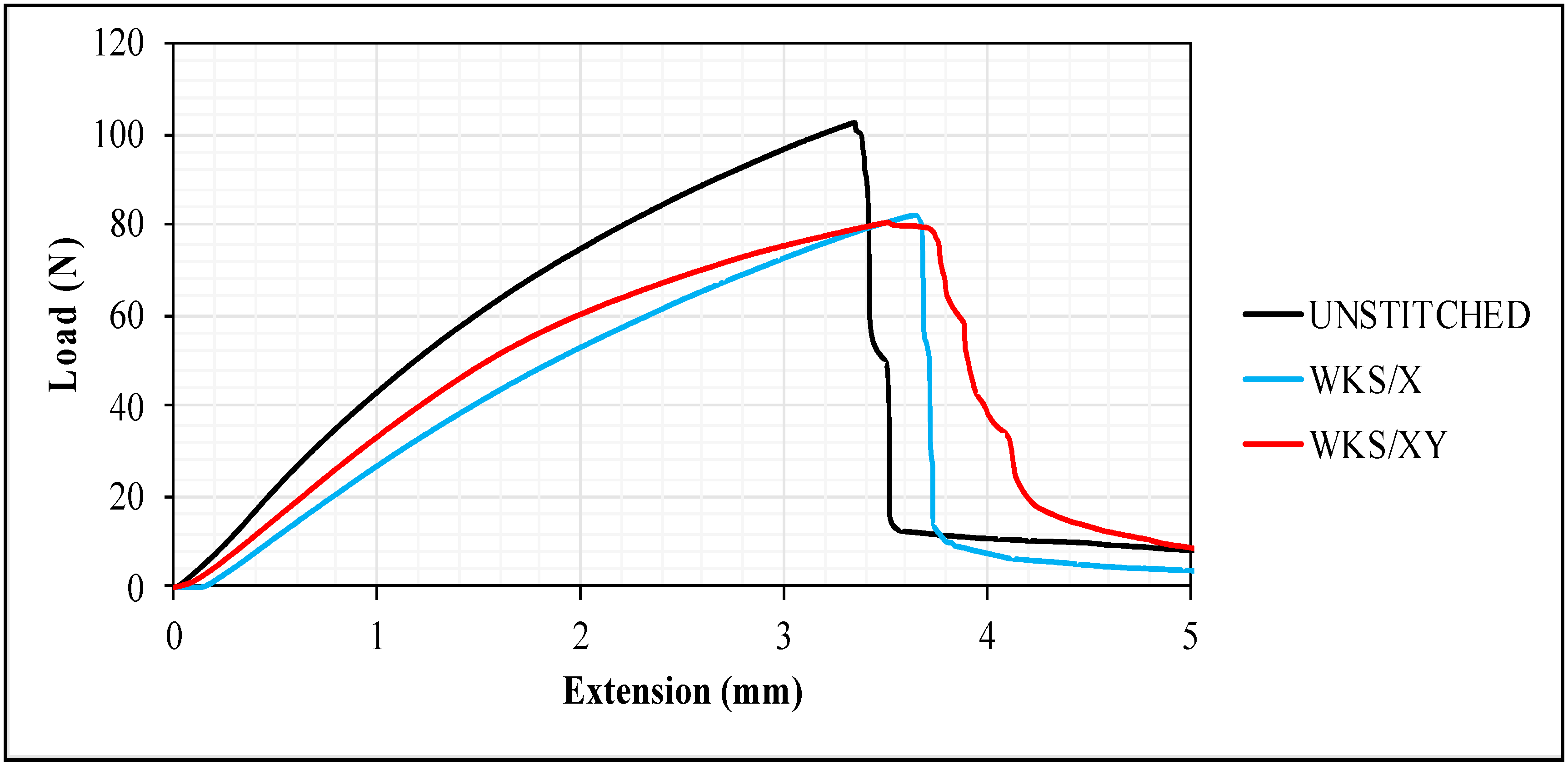

3.2. Flexural Test Results

3.3. Impact Test Results

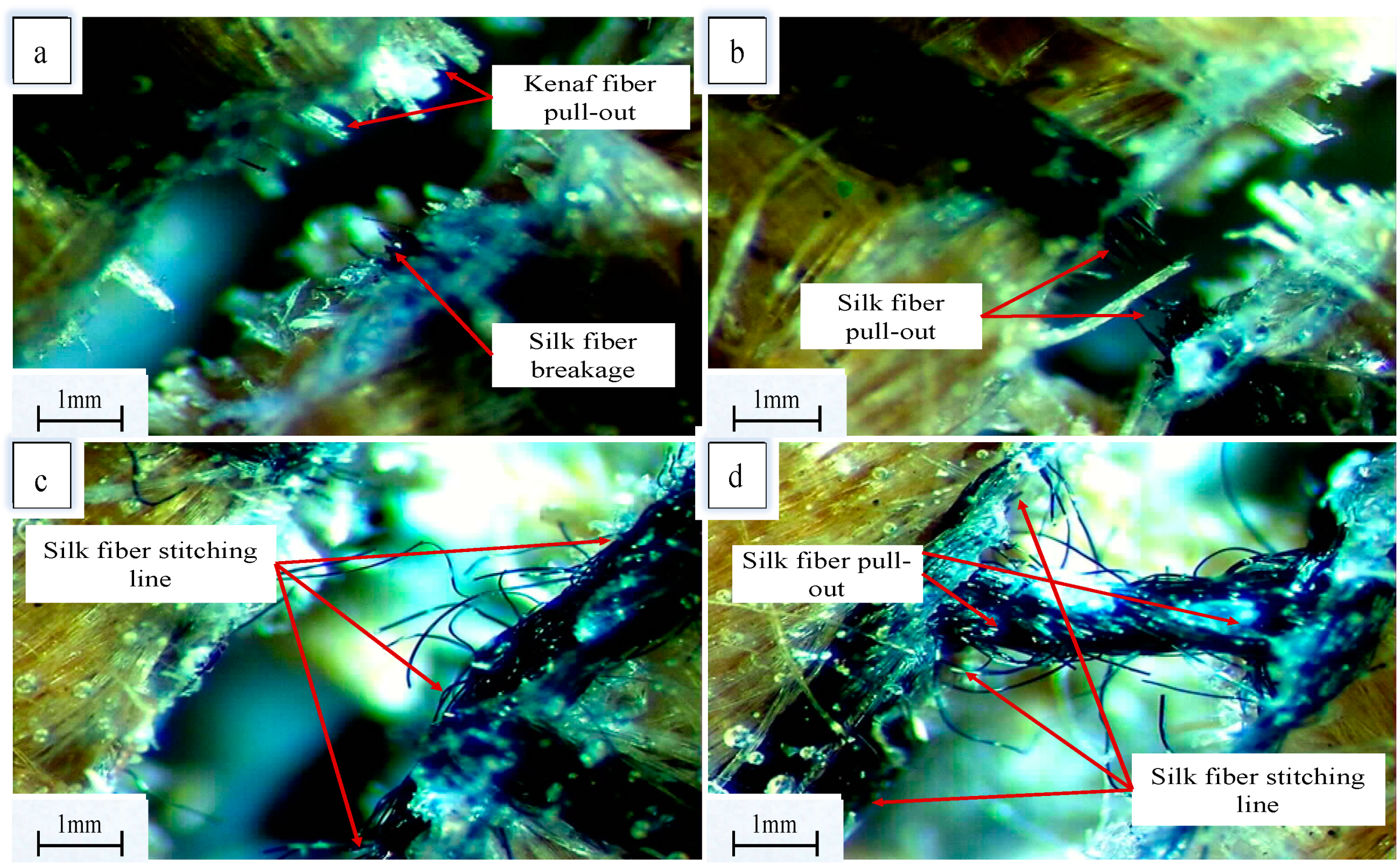

3.4. Composite Failure Mechanism

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shah, D.U. Natural fibre composites: Comprehensive Ashby-type materials selection charts. Mater. Des. 2014, 62, 21–31. [Google Scholar] [CrossRef]

- Dicker, M.P.M.; Duckworth, P.F.; Baker, A.B.; Francois, G.; Hazzar, M.K.; Weaver, P.M. Green composites: A review of material attributes and complementary applications. Compos. Part A Appl. Sci. Manuf. 2014, 56, 280–289. [Google Scholar] [CrossRef]

- Sharba, M.J. Fatigue strength prediction of hybrid composites via IR-thermography and energy loss methods. J. Ind. Text. 2020. [Google Scholar] [CrossRef]

- Sharba, M.J.; Leman, Z.; Sultan, M.T.H.; Ishak, M.R.; Hanim, M.A.A. Monotonic and fatigue properties of kenaf/glass hybrid composites under fully reversed cyclic loading. In IOP Conference Series: Materials Science and Engineering, Proceedings of the IOP Conference Series Materials Science and Engineering, Pahang, Malaysia, 18–19 August 2015; IOP Publishing: Bristol, UK, 2015; p. 12055. [Google Scholar]

- Sharba, M.J.; Leman, Z.; Sultan, M.T.H. Fatigue life prediction of textile/woven hybrid composites. In Durability and Life Prediction in Biocomposites, Fibre-Reinforced Composites and Hybrid; Elsevier: Amsterdam, The Netherlands, 2019; pp. 63–82. [Google Scholar]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.L. Application of Composite Materials on Sports Equipments. In Applied Mechanics and Materials; Trans Tech Publ: Baech, Switzerland, 2012; pp. 903–906. [Google Scholar]

- Gupta, G.; Kumar, A.; Tyagi, R.; Kumar, S. Application and future of composite materials: A review. Int J. Innov. Res. Sci. Eng. Technol. 2016, 5, 6907–6911. [Google Scholar]

- Keya, K.N.; Kona, N.A.; Koly, F.A.; Maraz, K.M.; Islam, M.N.; Khan, R.A. Natural fiber reinforced polymer composites: History, types, advantages and applications. Mater. Eng. Res. 2019, 1, 69–85. [Google Scholar] [CrossRef] [Green Version]

- Asim, M.; Paridah, M.T.; Jawaid, M.; Nasir, M.; Saba, N. Physical and flammability properties of kenaf and pineapple leaf fibre hybrid composites. In IOP Conference Series: Materials Science and Engineering, Proceedings of the IOP Conference Series: Materials Science and Engineering, Selangor, Malaysia, 21–23 November 2017; IOP Publishing: Bristol, UK, 2018; p. 12018. [Google Scholar]

- Adekunle, K.F. Surface treatments of natural fibres—A review: Part 1. Open J. Polym. Chem. 2015, 5, 41. [Google Scholar] [CrossRef] [Green Version]

- Khan, T.; Hameed Sultan, M.T.; Ariffin, A.H. The challenges of natural fiber in manufacturing, material selection, and technology application: A review. J. Reinf. Plast. Compos. 2018, 37, 770–779. [Google Scholar] [CrossRef]

- Corbin, A.C.; Boussu, F.; Ferreira, M.; Soulat, D. Influence of 3D warp interlock fabrics parameters made with flax rovings on their final mechanical behaviour. J. Ind. Text. 2020, 49, 1123–1144. [Google Scholar] [CrossRef]

- Ravandi, M.; Teo, W.S.; Tran, L.Q.N.; Yong, M.S.; Tay, T.E. Low velocity impact performance of stitched flax/epoxy composite laminates. Compos. Part B Eng. 2017, 117, 89–100. [Google Scholar] [CrossRef]

- Hu, X.; Ying, Z.; Cheng, X.; Wu, Z. Effect of Z-binder tension and internal micro-structure on damage behavior of 3D orthogonal woven composite. J. Ind. Text. 2019, 49, 551–571. [Google Scholar] [CrossRef]

- Castaneda, N.; Wisner, B.; Cuadra, J.; Amini, S.; Kontsos, A. Investigation of the Z-binder role in progressive damage of 3D woven composites. Compos. Part A Appl. Sci. Manuf. 2017, 98, 76–89. [Google Scholar] [CrossRef]

- Tong, L.; Mouritz, A.P.; Bannister, M.K. 3D Fibre Reinforced Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Caprino, G.; Lopresto, V.; Santoro, D. Ballistic impact behaviour of stitched graphite/epoxy laminates. Compos. Sci. Technol. 2007, 67, 325–335. [Google Scholar] [CrossRef]

- Hosur, M.V.; Vaidya, U.K.; Ulven, C.; Jeelani, S. Performance of stitched/unstitched woven carbon/epoxy composites under high velocity impact loading. Compos. Struct. 2004, 64, 455–466. [Google Scholar] [CrossRef]

- Lopresto, V.; Melito, V.; Leone, C.; Caprino, G. Effect of stitches on the impact behaviour of graphite/epoxy composites. Compos. Sci. Technol. 2006, 66, 206–214. [Google Scholar] [CrossRef]

- Zhao, N.; Rödel, H.; Herzberg, C.; Gao, S.L.; Krzywinski, S. Stitched glass/PP composite. Part I: Tensile and impact properties. Compos. Part A Appl. Sci. Manuf. 2009, 40, 635–643. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Kam, K.K.C.; Perrotey, P.; Joshi, S.C. Effect of fixation stitches on out-of-plane response of textile non-crimp fabric composites. J. Ind. Text. 2019, 48, 1151–1166. [Google Scholar] [CrossRef]

- Rong, M.Z.; Zhang, M.Q.; Liu, Y.; Zhang, Z.W.; Yang, G.C.; Zeng, H.M. Effect of stitching on in-plane and interlaminar properties of sisal/epoxy laminates. J. Compos. Mater. 2002, 36, 1505–1526. [Google Scholar] [CrossRef]

- Yaakob, M.Y.; Husin, M.A.; Abdullah, A.; Mohamed, K.A.; Khim, A.S.; Fang, M.L.C.; Sihombing, H. Effect of Stitching Patterns on Tensile Strength of Kenaf Woven Fabric Composites. Int. J. Integr. Eng. 2019, 11, 70–79. [Google Scholar] [CrossRef] [Green Version]

- Ravandi, M.; Teo, W.S.; Tran, L.Q.N.; Yong, M.S.; Tay, T.E. The effects of through-the-thickness stitching on the Mode I interlaminar fracture toughness of flax/epoxy composite laminates. Mater. Des. 2016, 109, 659–669. [Google Scholar] [CrossRef]

- Ude, A.U.; Ariffin, A.K.; Azhari, C.H. Impact damage characteristics in reinforced woven natural silk/epoxy composite face-sheet and sandwich foam, coremat and honeycomb materials. Int. J. Impact Eng. 2013, 58, 31–38. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M-14. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2014; Available online: www.astm.org (accessed on 10 October 2020).

- ASTM D790-10. Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; ASTM International: West Conshohocken, PA, USA, 2010; Available online: www.astm.org (accessed on 10 October 2020).

- ASTM D256-10. Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics; ASTM International: West Conshohocken, PA, USA, 2010; Available online: www.astm.org (accessed on 10 October 2020).

- Akil, H.; Omar, M.F.; Mazuki, A.A.M.; Safiee, S.Z.A.M.; Ishak, Z.M.; Bakar, A.A. Kenaf fiber reinforced composites: A review. Mater. Des. 2011, 32, 4107–4121. [Google Scholar] [CrossRef]

- Rouison, D.; Sain, M.; Couturier, M. Resin transfer molding of natural fiber reinforced composites: Cure simulation. Compos. Sci. Technol. 2004, 64, 629–644. [Google Scholar] [CrossRef]

- Larsson, F. Damage tolerance of a stitched carbon/epoxy laminate. Compos. Part A Appl. Sci. Manuf. 1997, 28, 923–934. [Google Scholar] [CrossRef]

- Takatoya, T.; Susuki, I. In-plane and out-of-plane characteristics of three-dimensional textile composites. J. Compos. Mater. 2005, 39, 543–556. [Google Scholar] [CrossRef]

- Reeder, J.R. Stitching vs. a toughened matrix: Compression strength effects. J. Compos. Mater. 1995, 29, 2464–2487. [Google Scholar] [CrossRef]

- Mouritz, A.P. Fracture and tensile fatigue properties of stitched fibreglass composites. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2004, 218, 87–93. [Google Scholar] [CrossRef]

- Jucienė, M.; Vobolis, J. Dependence of Stitch Length along the Seam on External Friction Force Theoretical Anglysis. Mater. Sci. 2009, 15, 273–276. [Google Scholar]

- Wu, E.; Wang, J. Behavior of stitched laminates under in-plane tensile and transverse impact loading. J. Compos. Mater. 1995, 29, 2254–2279. [Google Scholar] [CrossRef]

- Chung, W.C.; Jang, B.Z.; Chang, T.C.; Hwang, L.R.; Wilcox, R.C. Fracture behavior in stitched multidirectional composites. Mater. Sci. Eng. A 1989, 112, 157–173. [Google Scholar] [CrossRef]

- Xuan, J.; Li, D.; Jiang, L. Fabrication, properties and failure of 3D stitched carbon/epoxy composites with no stitching fibers damage. Compos. Struct. 2019, 220, 602–607. [Google Scholar] [CrossRef]

- Guénon, V.A.; Chou, T.W.; Gillespie, J.W. Toughness properties of a three-dimensional carbon-epoxy composite. J. Mater. Sci. 1989, 24, 4168–4175. [Google Scholar] [CrossRef]

- Jang, B.Z.S.W. Mechanical properties of multidirectional fiber composites. J. Reinf. Plast. Compos. 1989, 8, 538–564. [Google Scholar] [CrossRef]

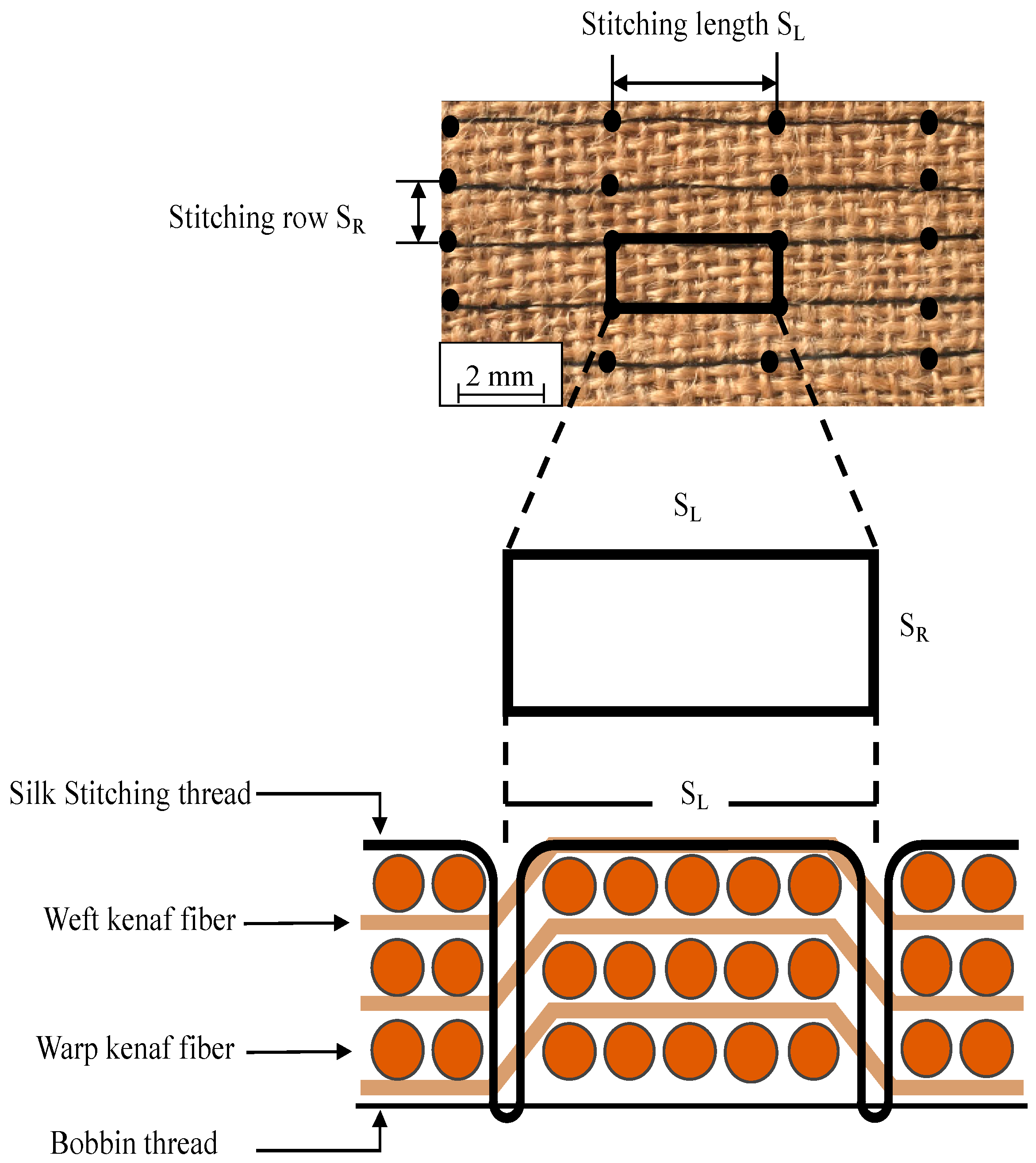

| Specimen | Lay Up | Stitching Material | Stitching Direction | Stitch Length SL mm | Stitch Row Spacing SR mm | Stitch Areal Fraction (%) | Stitch Density mm‒2 | |

|---|---|---|---|---|---|---|---|---|

| UNSTITCHED | [0]3 | - | - | - | - | - | - | 36 ± 2 |

| WKS/X | [0]3 | Silk | X 0° | 5 | 5 | 0.48 | 0.04 | 37.3 ± 2 |

| WKS/XY | [0]3 | Silk | X, Y 0°, 90° | 5 | 5 | 0.96 | 0.08 | 38 ± 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kirmasha, Y.K.; Sharba, M.J.; Leman, Z.; Sultan, M.T.H. Mechanical Performance of Unstitched and Silk Fiber-Stitched Woven Kenaf Fiber-Reinforced Epoxy Composites. Materials 2020, 13, 4801. https://doi.org/10.3390/ma13214801

Kirmasha YK, Sharba MJ, Leman Z, Sultan MTH. Mechanical Performance of Unstitched and Silk Fiber-Stitched Woven Kenaf Fiber-Reinforced Epoxy Composites. Materials. 2020; 13(21):4801. https://doi.org/10.3390/ma13214801

Chicago/Turabian StyleKirmasha, Yasir Khaleel, Mohaiman J. Sharba, Zulkiflle Leman, and Mohamed Thariq Hameed Sultan. 2020. "Mechanical Performance of Unstitched and Silk Fiber-Stitched Woven Kenaf Fiber-Reinforced Epoxy Composites" Materials 13, no. 21: 4801. https://doi.org/10.3390/ma13214801

APA StyleKirmasha, Y. K., Sharba, M. J., Leman, Z., & Sultan, M. T. H. (2020). Mechanical Performance of Unstitched and Silk Fiber-Stitched Woven Kenaf Fiber-Reinforced Epoxy Composites. Materials, 13(21), 4801. https://doi.org/10.3390/ma13214801