Buildability and Mechanical Properties of 3D Printed Concrete

Abstract

1. Introduction

2. Experimental Program

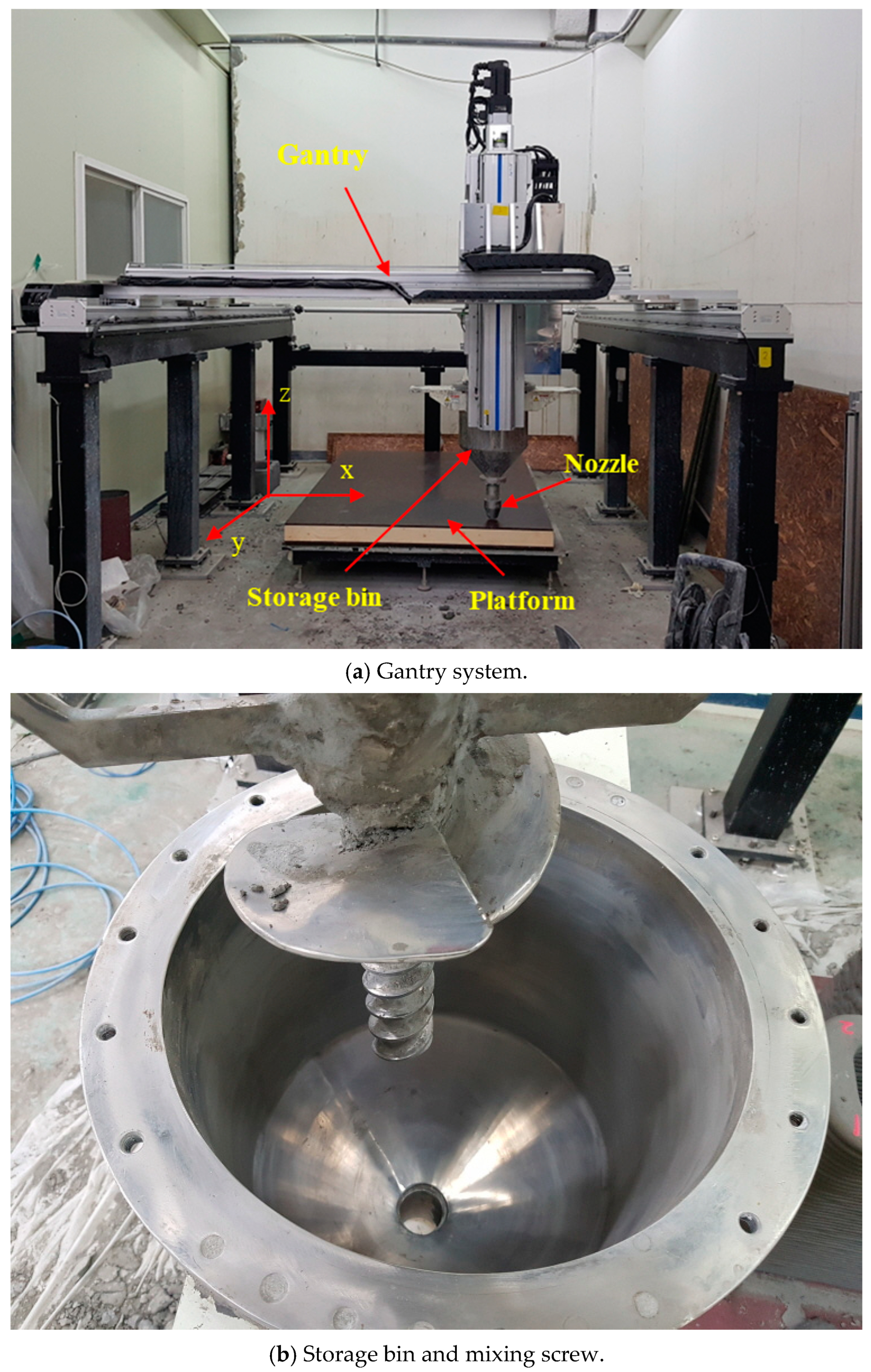

2.1. Printing Method

2.2. Printed Structures and Printing Process

2.3. Mixture

2.4. Material Properties in the Fresh State

3. Buildability in the Fresh State

3.1. Interlayer Interval Time

3.2. Lateral Supports

4. Mechanical Properties

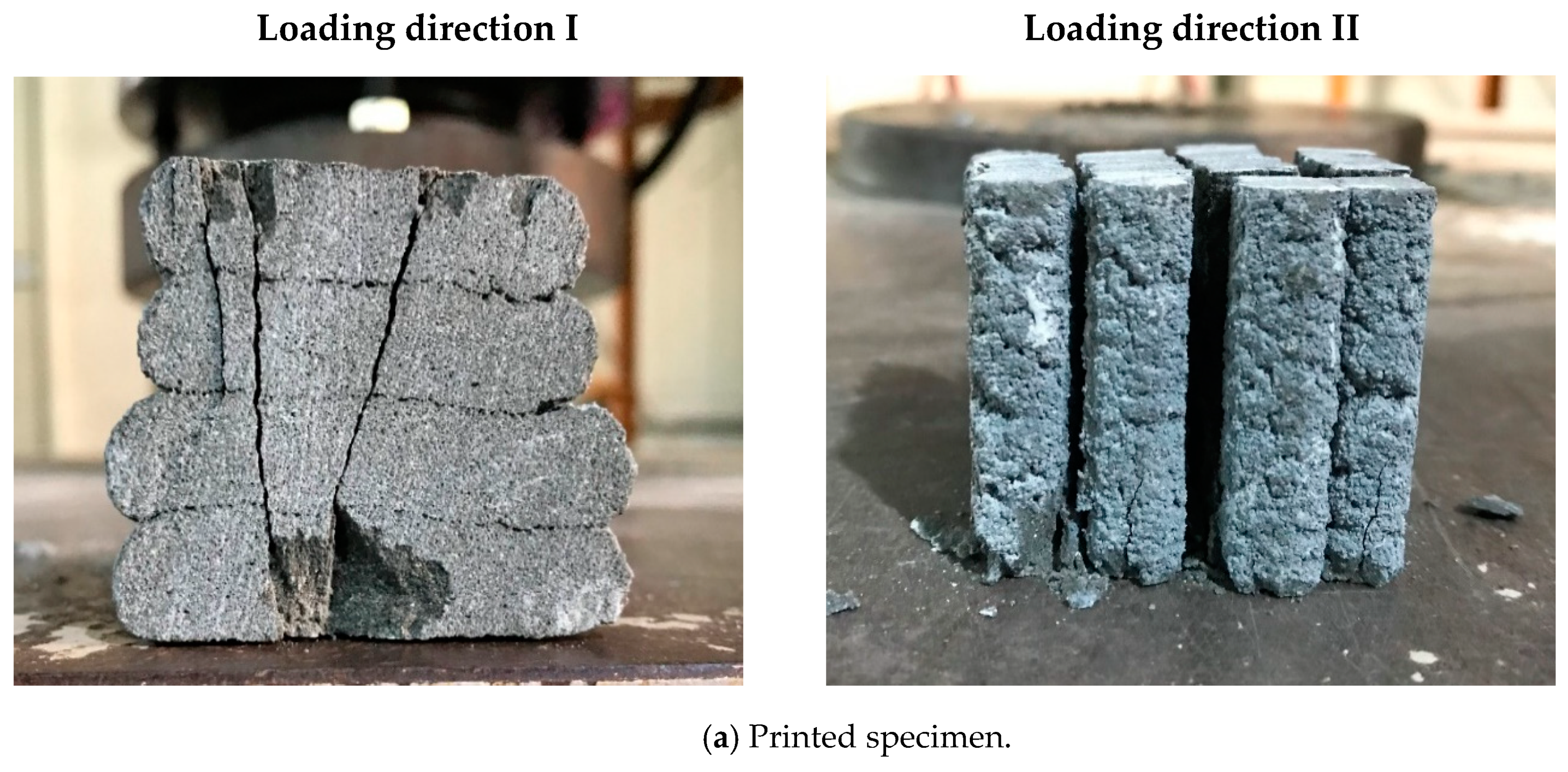

4.1. Specimen Preparation and Testing Methods

4.2. Compressive Strength

4.3. Splitting Tensile Strength

4.4. Flexural Tensile Strength

5. Conclusions

- The interlayer interval time significantly influenced the buildability of 3D printed concrete. The test results showed that an extended interlayer interval time of up to 300 s contributed to the green strength of the 3D printed concrete and thus increased the buildability of the 3D printed concrete.

- The 3D printed concrete structures with lateral supports could increase the resistance to collapse due to buckling failure. In particular, a wide connecting width between the lateral support and the structure wall improved the capacity of layer decomposition in the 3D printed concrete.

- The compressive strengths of the 3D printed cubic specimens were 32.3~42.6% lower than those of the monolithic specimens. In addition, the weak bonding performance between the reinforcement and concrete filaments caused the low compressive strength of the printed specimens in direction II.

- The splitting tensile strength of the 3D printed concrete specimens was 11.1~39.7% lower than that of the monolithic specimens, depending on the loading directions. The splitting tensile failure was accompanied by debonding between the printed layers, which implied that the bonding performance between the concrete filaments and reinforcements should be confirmed when interlayer reinforcements are included.

- The flexural tensile strengths of the 3D printed specimens without reinforcements at the interlayers were approximately half that of the monolithic cast specimens. The flexural tensile strength of the printed specimens was improved by the metal lath reinforcements. The failure pattern also revealed that the bonding between the interlayers and reinforcements might influence the flexural strength.

Author Contributions

Funding

Conflicts of Interest

Data Availability

References

- Hull, C.W. Apparatus for Production of Three-Dimensional Objects by Stereolithography. U.S. Patent 4,575,330, 11 March 1986. [Google Scholar]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.; Gibb, A.G.F.; Thorpe, T. Mix design and fresh properties for high-performance printing concrete. Mater. Struct. 2012, 45, 1221–1232. [Google Scholar] [CrossRef]

- Perkins, I.; Skitmore, M.; Skitmore, M. Three-dimensional printing in the construction industry: A review. Int. J. Constr. Manag. 2015, 15, 1–9. [Google Scholar] [CrossRef]

- Lim, S.; Le, T.; Webster, J.; Buswell, R.A.; Austin, S.; Gibb, A.; Thorpe, A. Fabricating construction components using layer manufacturing technology. In Proceedings of the International Conference on Global Innovation in Construction, Loughborough, UK, 13–16 September 2009; pp. 512–520. [Google Scholar]

- Lim, S.; Buswell, R.; Le, T.T.; Austin, S.A.; Gibb, A.G.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Autom. Constr. 2012, 21, 262–268. [Google Scholar] [CrossRef]

- Gosselin, C.; Duballet, R.; Roux, P.; Gaudillière, N.; Dirrenberger, J.; Morel, P. Large-scale 3D printing of ultra-high performance concrete—A new processing route for architects and builders. Mater. Des. 2016, 100, 102–109. [Google Scholar] [CrossRef]

- Labonnote, N.; Rønnquist, A.; Manum, B.; Rüther, P. Additive construction: State-of-the-art, challenges and opportunities. Autom. Constr. 2016, 72, 347–366. [Google Scholar] [CrossRef]

- Wu, P.; Wang, J.; Wang, X. A critical review of the use of 3-D printing in the construction industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef]

- Kidwell, J. Best Practices and Applications of 3D Printing in the Construction Industry; Construction Management: San Luis Obispo, CA, USA, 2017. [Google Scholar]

- Agustí-Juan, I.; Müller, F.; Hack, N.; Wangler, T.; Habert, G. Potential benefits of digital fabrication for complex structures: Environmental assessment of a robotically fabricated concrete wall. J. Clean. Prod. 2017, 154, 330–340. [Google Scholar] [CrossRef]

- Suhendro, B. Toward green concrete for better sustainable environment. Procedia Eng. 2014, 95, 305–320. [Google Scholar] [CrossRef]

- Agustí-Juan, I.; Habert, G. Environmental design guidelines for digital fabrication. J. Clean. Prod. 2017, 142, 2780–2791. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L. Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Constr. Build. Mater. 2018, 162, 613–627. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Liu, G.; Yang, Y.; Wu, M.; Pang, B. Fresh properties of a novel 3D printing concrete ink. Constr. Build. Mater. 2018, 174, 263–271. [Google Scholar] [CrossRef]

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Arch. Civ. Mech. Eng. 2018, 18, 311–319. [Google Scholar] [CrossRef]

- Nerella, V.N.; Hempel, S.; Mechtcherine, V. Effects of layer-interface properties on mechanical performance of concrete elements produced by extrusion-based 3D-printing. Constr. Build. Mater. 2019, 205, 586–601. [Google Scholar] [CrossRef]

- Hambach, M.; Volkmer, D. Properties of 3D-printed fiber-reinforced Portland cement paste. Cem. Concr. Compos. 2017, 79, 62–70. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Mohamed, N.A.N.; Tay, Y.W.D.; Tan, M.J. Measurement of tensile bond strength of 3D printed geopolymer mortar. Measurement 2018, 113, 108–116. [Google Scholar] [CrossRef]

- Xu, J.; Ding, L.; Cai, L.; Zhang, L.; Luo, H.; Qin, W. Volume-forming 3D concrete printing using a variable-size square nozzle. Autom. Constr. 2019, 104, 95–106. [Google Scholar] [CrossRef]

- Kruger, J.; Cho, S.; Zeranka, S.; Viljoen, C.; Van Zijl, G. 3D concrete printer parameter optimisation for high rate digital construction avoiding plastic collapse. Compos. Part B Eng. 2020, 183, 107660. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.; Law, R.; Gibb, A.G.; Thorpe, T. Hardened properties of high-performance printing concrete. Cem. Concr. Res. 2012, 42, 558–566. [Google Scholar] [CrossRef]

- Sanjayan, J.G.; Nematollahi, B.; Xia, M.; Marchment, T. Effect of surface moisture on inter-layer strength of 3D printed concrete. Constr. Build. Mater. 2018, 172, 468–475. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Tan, M.J. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction material. Mater. Lett. 2017, 209, 146–149. [Google Scholar] [CrossRef]

- Perrot, A.; Jacquet, Y.; Rangeard, D.; Courteille, E.; Sonebi, M. Nailing of layers: A promising way to reinforce concrete 3D printing structures. Materials 2020, 13, 1518. [Google Scholar] [CrossRef] [PubMed]

- Marchment, T.; Sanjayan, J. Mesh reinforcing method for 3D Concrete Printing. Autom. Constr. 2020, 109, 102992. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive manufacturing technologies: 3D printing, rapid prototyping, and direct digital manufacturing, second edition. Johns. Matthey Tech. Rev. 2015, 59, 193–198. [Google Scholar]

- Wolfs, R.; Bos, F.; Salet, T. Hardened properties of 3D printed concrete: The influence of process parameters on interlayer adhesion. Cem. Concr. Res. 2019, 119, 132–140. [Google Scholar] [CrossRef]

- Zareiyan, B.; Khoshnevis, B. Interlayer adhesion and strength of structures in Contour Crafting—Effects of aggregate size, extrusion rate, and layer thickness. Autom. Constr. 2017, 81, 112–121. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Hwang, D.; Yao, K.T.; Yeh, Z. Mega-scale fabrication by Contour Crafting. Int. J. Ind. Syst. Eng. 2006, 1, 301. [Google Scholar] [CrossRef]

- Nikita Chen-iun-tai. Apis-Cor. Available online: www.apis-cor.com (accessed on 15 March 2020).

- Lim, S.; Buswell, R.; Le, T.; Wackrow, R.; Austin, S.; Gibb, A.; Thorpe, T. Development of a viable concrete printing process. In Proceedings of the 28th International Symposium on Automation and Robotics in Construction (ISARC 2011), Seoul, Korea, 29 June–2 July 2011. [Google Scholar]

- Enrico Dini. D-Shape. Available online: https://www.d-shape.com (accessed on 13 April 2020).

- ASTM. Standard Specification for Flow Table for Use in Tests of Hydraulic Cement; ASTM C 230/C230M; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Voigt, T.; Malonn, T.; Shah, S.P. Green and early age compressive strength of extruded cement mortar monitored with compression tests and ultrasonic techniques. Cem. Concr. Res. 2006, 36, 858–867. [Google Scholar] [CrossRef]

- Panda, B.; Lim, J.H.; Tan, M.J. Mechanical properties and deformation behaviour of early age concrete in the context of digital construction. Compos. Part B Eng. 2019, 165, 563–571. [Google Scholar] [CrossRef]

- Suiker, A.S.; Wolfs, R.; Lucas, S.; Salet, T. Elastic buckling and plastic collapse during 3D concrete printing. Cem. Concr. Res. 2020, 135, 106016. [Google Scholar] [CrossRef]

- Roussel, N. Rheological requirements for printable concretes. Cem. Concr. Res. 2018, 112, 76–85. [Google Scholar] [CrossRef]

- Panda, B.; Mohamed, N.A.N.; Paul, S.C.; Singh, G.B.; Tan, M.J.; Šavija, B. The effect of material fresh properties and process parameters on Buildability and interlayer adhesion of 3D printed concrete. Materials 2019, 12, 2149. [Google Scholar] [CrossRef] [PubMed]

- Tay, Y.W.D.; Ting, G.H.A.; Qian, Y.; Panda, B.; He, L.; Qian, S. Time gap effect on bond strength of 3D-printed concrete. Virtual Phys. Prototyp. 2018, 14, 104–113. [Google Scholar] [CrossRef]

- Wolfs, R.; Bos, F.; Salet, T. Early age mechanical behaviour of 3D printed concrete: Numerical modelling and experimental testing. Cem. Concr. Res. 2018, 106, 103–116. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens); ASTM C 109/C109M-07; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- ASTM. Standard Test Method for Flexural Strength of Hydraulic Cement Mortars; ASTM C348-18; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM. Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; ASTM C 496/C 496M-04; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

| Group | Structure Identification | Dimensions | Nozzle Speed (mm/s) | Interlayer Interval Time (s) | RPMs of Mixing Screw (r/m) | Number of Deposition Layers | Ultimate State |

|---|---|---|---|---|---|---|---|

| Group 1 | S1 |  | 100 | 36 | 120 | 19 | Buckling |

| S2 | 80 | 45 | 120 | 49 | Buckling | ||

| S3 | 80 | 45 | 140 | 29 (1) | Tearing of concrete | ||

| Group 2 | S4 |  | 80 | 55 | 120 | 22 | Buckling |

| S5 |  | 80 | 57 | 120 | 28 (1) | Tearing of concrete | |

| S6 |  | 80 | 30 | 100 | 33 | Buckling | |

| Group 3 | S7 |  | 50 | 300 | 120 | 52 (1) | Printing stopped |

| S8 | 50 | 300 | 120 | 52 (1) | Printing stopped | ||

| S9 |  | 50 | 300 | 120 | 52 (1) | Printing stopped | |

| S10 (2) |  | 50 | 300 | 120 | 52 (1) | Printing stopped |

| W/B (%) | Unit Weight (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|

| Water | OPC | SF | FA | Sand | HWRA | Viscosity Agent | |

| 0.29 | 240 | 576 | 79 | 172 | 1154 | 8.27 | 1.65 |

| Strength | Loading Direction | Monolithic Specimen | Printed Specimen | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Without Metal Laths | With Metal Laths | |||||||||

| Number of Specimens | Mean (MPa) | SD (MPa) | Number of Specimens | Mean (MPa) | SD (MPa) | Number of Specimens | Mean (MPa) | SD (MPa) | ||

| Compressive strength () | Loading direction I | 5 | 72.8 | 9.0 | 5 | 23.5 | 9.8 | 5 | 24.6 | 0.7 |

| Loading direction II (III) | 5 | 5 | 31.0 | 8.3 | 5 | 24.0 | 3.5 | |||

| Splitting tensile strength () | Loading direction I | 5 | 11.3 | 2.7 | 5 | 4.5 | 0.3 | 5 | 4.4 | 0.8 |

| Loading direction II | 5 | 5 | 3.2 | 1.0 | 5 | 3.3 | 0.3 | |||

| Loading direction III | 5 | 5 | 1.8 | 1.2 | 5 | 1.2 | 0.4 | |||

| Flexural tensile strength () | Loading direction I | 5 | 11.9 | 1.1 | 5 | 6.5 | 0.8 | 5 | 18.5 | 4.0 |

| Loading direction II | 5 | 5 | 6.1 | 0.4 | 5 | 11.0 | 1.7 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Joh, C.; Lee, J.; Bui, T.Q.; Park, J.; Yang, I.-H. Buildability and Mechanical Properties of 3D Printed Concrete. Materials 2020, 13, 4919. https://doi.org/10.3390/ma13214919

Joh C, Lee J, Bui TQ, Park J, Yang I-H. Buildability and Mechanical Properties of 3D Printed Concrete. Materials. 2020; 13(21):4919. https://doi.org/10.3390/ma13214919

Chicago/Turabian StyleJoh, Changbin, Jungwoo Lee, The Quang Bui, Jihun Park, and In-Hwan Yang. 2020. "Buildability and Mechanical Properties of 3D Printed Concrete" Materials 13, no. 21: 4919. https://doi.org/10.3390/ma13214919

APA StyleJoh, C., Lee, J., Bui, T. Q., Park, J., & Yang, I.-H. (2020). Buildability and Mechanical Properties of 3D Printed Concrete. Materials, 13(21), 4919. https://doi.org/10.3390/ma13214919