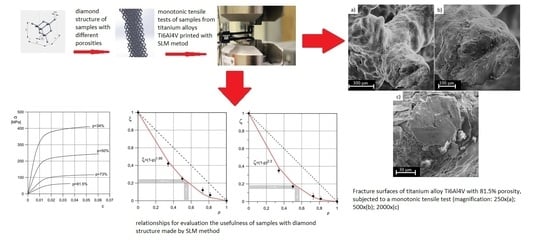

Strength Properties of a Porous Titanium Alloy Ti6Al4V with Diamond Structure Obtained by Laser Power Bed Fusion (LPBF)

Abstract

:1. Introduction

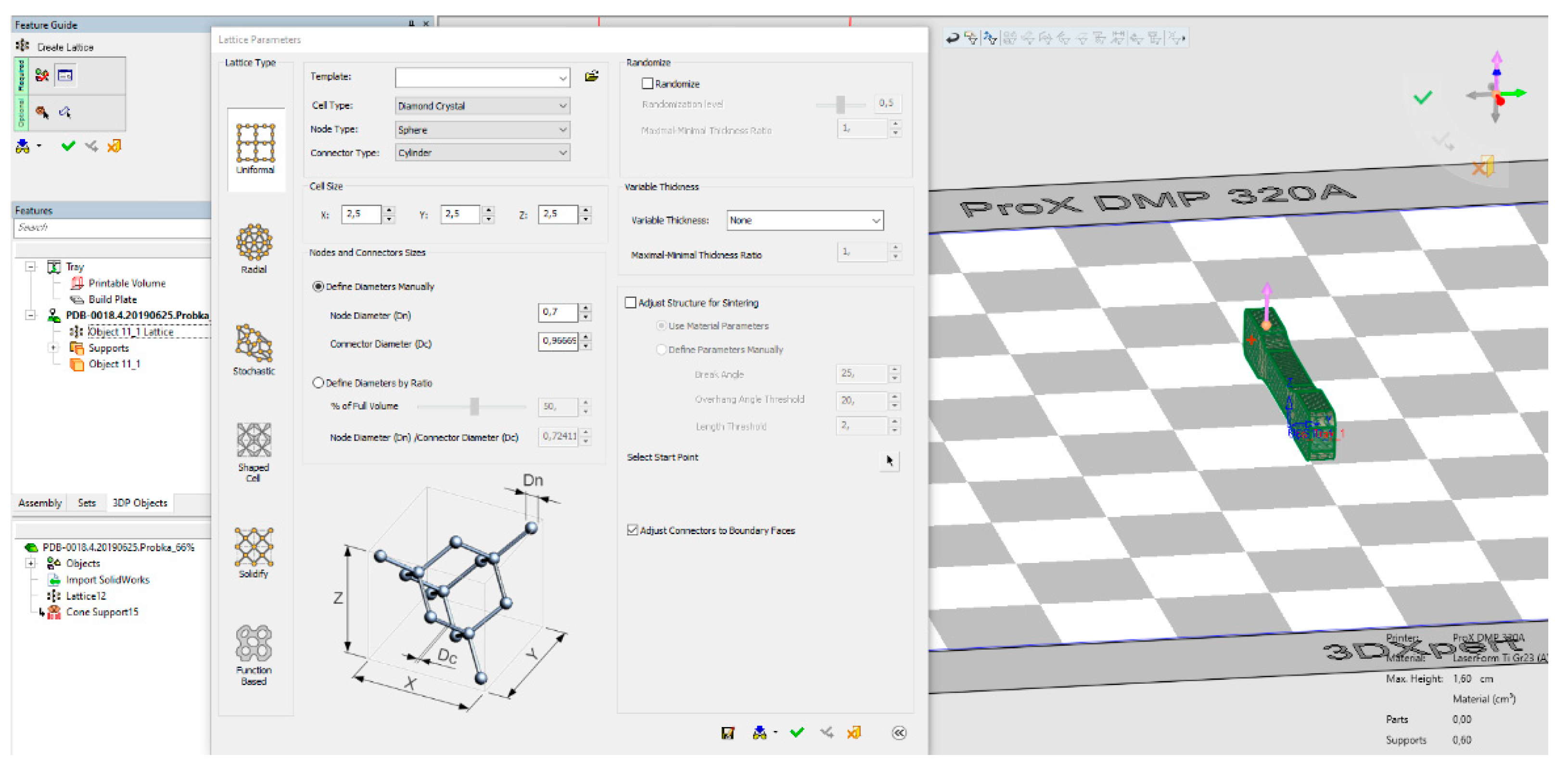

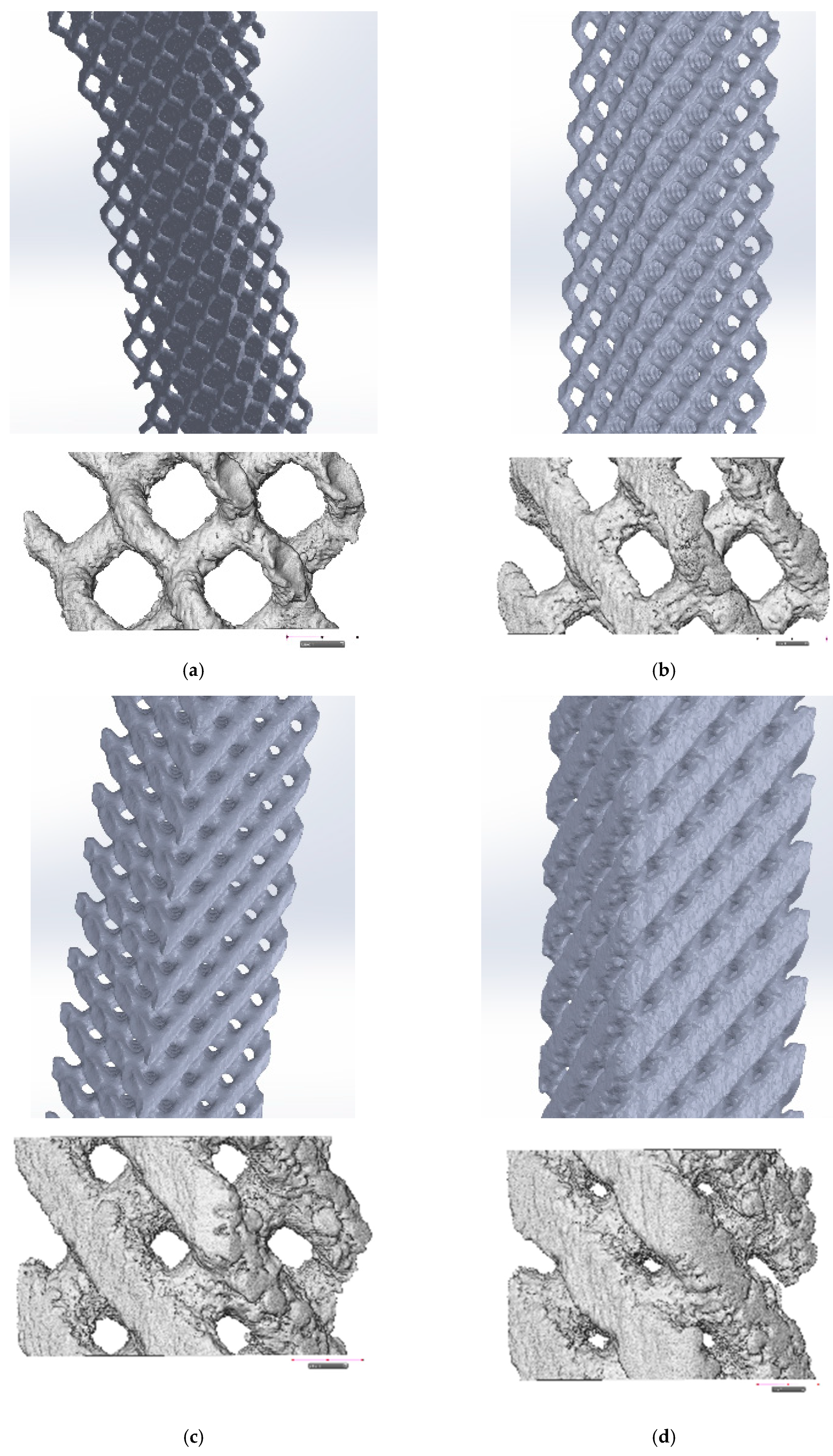

2. Materials and Methods

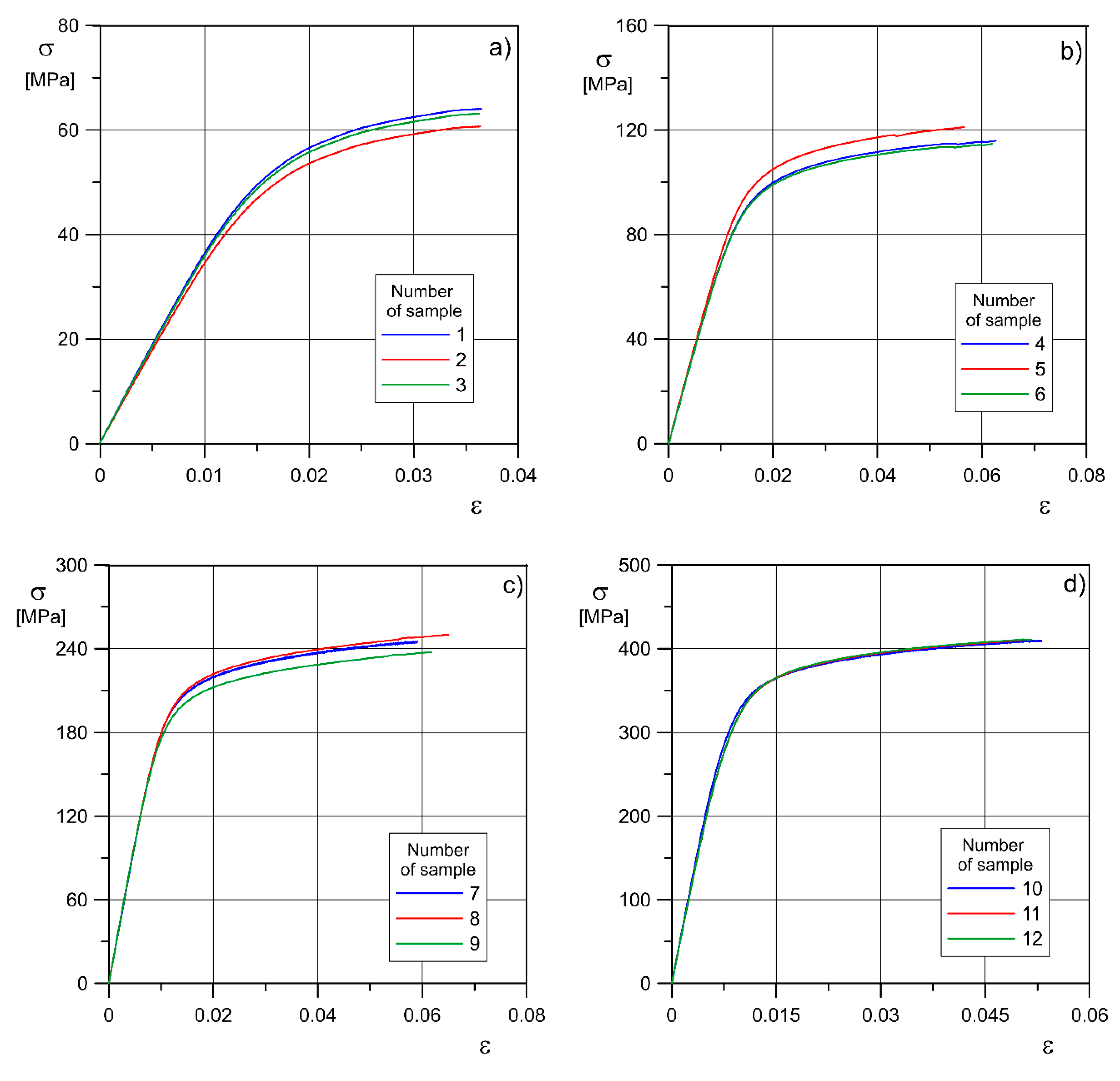

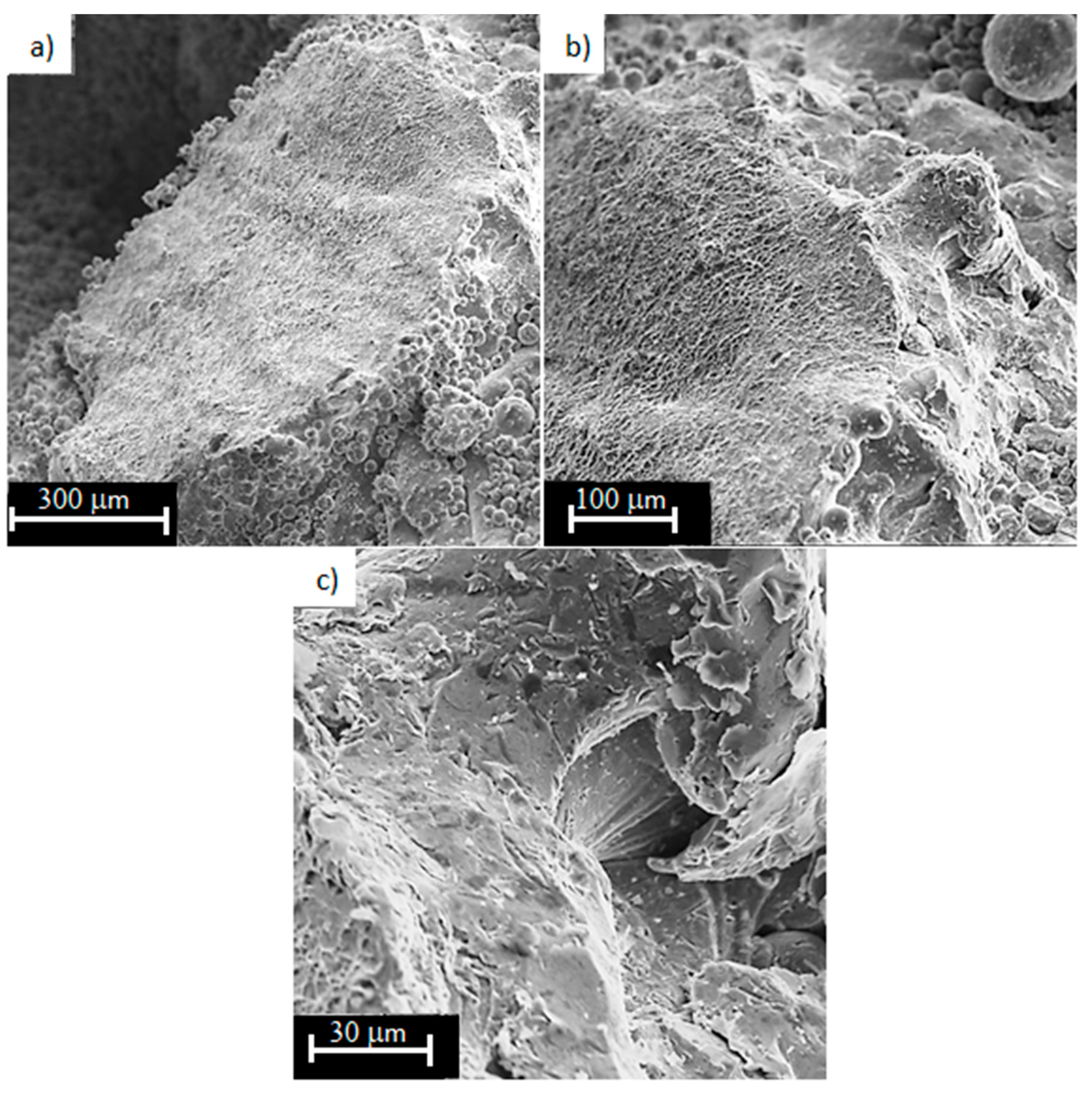

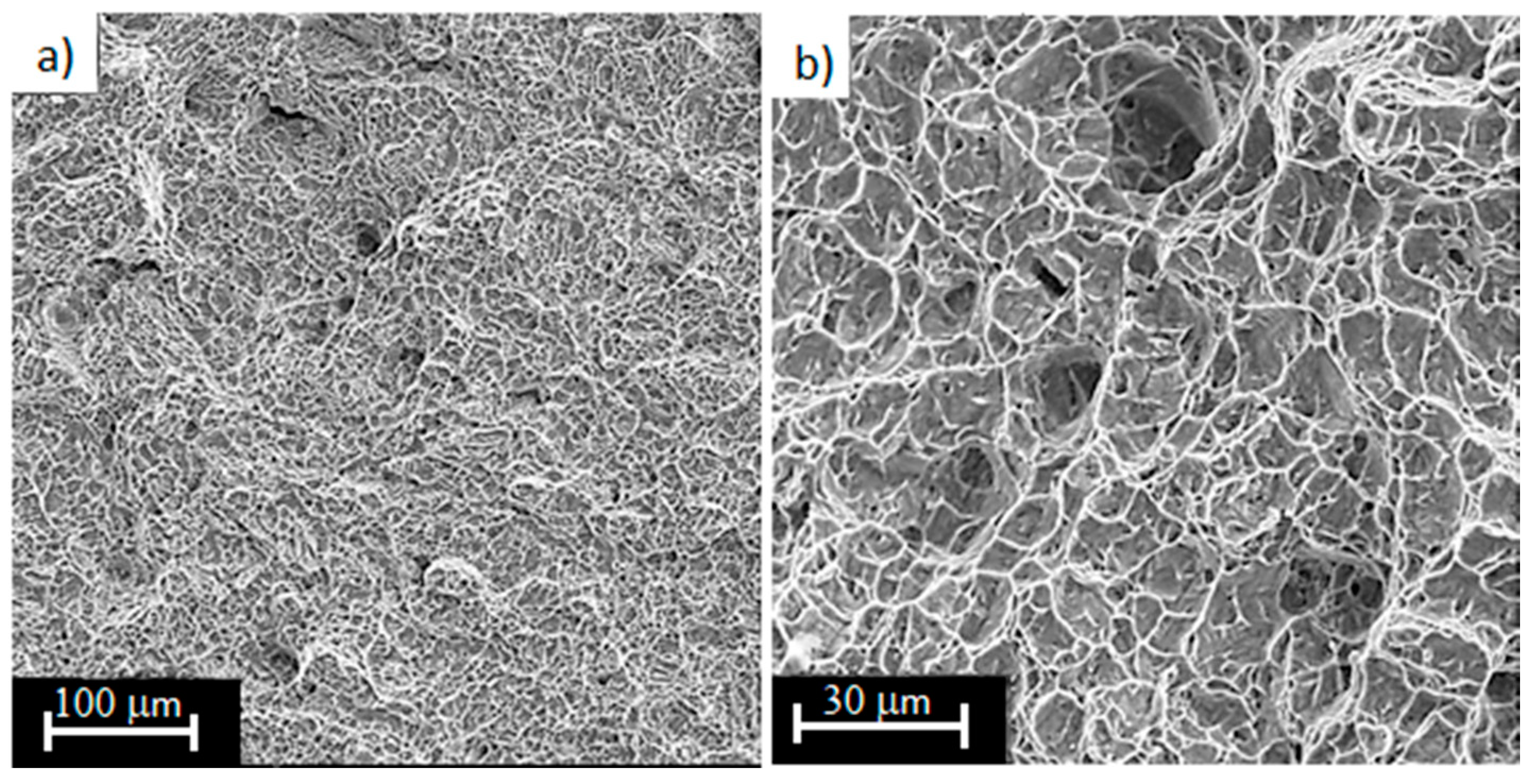

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sallica-Leva, E.; Jardini, A.L.; Fogagnolo, J.B. Microstructure and mechanical behawior of porous Ti–6Al–4V parts obtained by selective laser melting. J. Mech. Behav. Biomed. Mater. 2013, 26, 98–108. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Xu, S.; Zhou, S.; Xu, W.; Leary, M.; Choong, P.; Qian, M.; Brandt, M.; Xie, Y.M. Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: A review. Biomaterials 2016, 83, 127–141. [Google Scholar] [CrossRef] [PubMed]

- Shahali, H.; Jaggessar, A.; Yarlagadda, P.K.D.V. Recent advances in manufacturing and surface modification of titanium orthopaedic applications. Proc. Eng. 2017, 174, 1067–1076. [Google Scholar] [CrossRef] [Green Version]

- Singh, S.; Ramakrishna, S. Biomedical applications of additive manufacturing: Present and future. Curr. Opin. Biomed. Eng. 2017, 2, 105–115. [Google Scholar] [CrossRef]

- Diaz-Sanchez, R.M.; de-Paz-Carrion, A.; Serrera-Figallo, M.A.; Torres-Lagares, D.; Barranco, A.; León-Ramos, J.R.; Gutierrez-Perez, J.L. In vitro and in vivo study of titanium grade IV and titanium grade V implants with different surface treatments. Metals 2020, 10, 449. [Google Scholar] [CrossRef] [Green Version]

- Li, F.; Li, J.; Huang, T.; Kou, H.; Zhou, L. Compression fatigue behavior and failure mechanism of porous titanium for biomedical applications. J. Mech. Behav. Biomed. Mater. 2017, 65, 814–823. [Google Scholar] [CrossRef]

- ISO. ISO/ASTM 52911-1:2019. Additive Manufacturing—Design—Part 1: Laser-Based Powder Bed Fusion of Metals; ISO: Berlin, Germany.

- Attar, H.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Manufacture by selective laser melting and mechanical behavior of commercially pure titanium. Mater. Sci. Eng. A 2014, 593, 170–177. [Google Scholar] [CrossRef]

- Fousová, M.; Vojtěch, D.; Kubásek, J.; Jablonská, E.; Fojt, J. Promising characteristics of gradient porosity Ti-6Al-4V alloy prepared by SLM process. J. Mech. Behav. Biomed. Mater. 2017, 69, 368–376. [Google Scholar] [CrossRef]

- Harun, W.S.W.; Kamariah, M.S.I.N.; Muhamad, N.; Ghani, S.A.C.; Ahmad, F.; Mohamed, Z. A review of powder additive manufacturing processes for metallic biomaterials. Powder Tech. 2018, 327, 128–1151. [Google Scholar] [CrossRef]

- Ahmadi, S.M.; Hedayati, R.; Ashok Kumar Jain, R.K.; Li, Y.; Leeflang, S.; Zadpoor, A.A. Effects of laser processing parameters on the mechanical properties, topology, and microstructure of additively manufactured porous metallic biomaterials: A vector-based approach. Mater. Des. 2017, 134, 234–243. [Google Scholar] [CrossRef]

- Gong, H.; Rafi, K.; Gu, H.; Ram, G.D.J.; Starr, T.; Stucker, B. Influence of defects on mechanical properties of Ti–6Al–4 V components produced by selective laser melting and electron beam melting. Mater. Des. 2015, 86, 545–554. [Google Scholar] [CrossRef]

- Benedetti, M.; Cazzolli, M.; Fontanari, V.; Leoni, M. Fatigue limit of Ti6Al4V alloy produced by Selective Laser Sintering. Proc. Struc. Int. 2016, 2, 3158–3167. [Google Scholar] [CrossRef] [Green Version]

- Falkowska, A.; Seweryn, A. Fatigue of sintered porous materials based on 316L stainless steel under uniaxial loading. Mater. Sci. 2015, 51, 53–58. [Google Scholar] [CrossRef] [Green Version]

- Falkowska, A.; Seweryn, A.; Tomczyk, A. Fatigue life and strength of 316L sintered steel of varying porosity. Inter. J. Fatigue 2018, 111, 161–176. [Google Scholar] [CrossRef]

- Falkowska, A.; Seweryn, A.; Szusta, J. Predicting the fatigue strength and life of 316L steel sinters of varying porosity for implants in a uniaxial loading state. Eng. Fract. Mech. 2018, 200, 146–165. [Google Scholar] [CrossRef]

- Falkowska, A.; Seweryn, A. Fatigue life of 316L steel sinters of varying porosity under conditions of uniaxial periodically variable loading at a fixed stress amplitude. Inter. J. Fatigue 2018, 117, 496–510. [Google Scholar] [CrossRef]

- Bai, L.; Zhang, J.; Chen, X.; Yi, C.; Chen, R.; Zhang, Z. Configuration Optimization Design of Ti6Al4V Lattice Structure Formed by SLM. Materials 2018, 11, 1856. [Google Scholar] [CrossRef] [Green Version]

- Cao, X.; Duan, S.; Liang, J.; Wen, W.; Fang, D. Mechanical properties of an improved 3D-printed rhombic dodecahedron stainless steel lattice structure of variable cross section. Inter. J. Mech. Sci. 2018, 145, 53–63. [Google Scholar] [CrossRef]

- Yan, X.; Li, Q.; Yin, S.; Chen, Z.; Jenkins, R.; Chen, C.; Wang, J.; Ma, W.; Bolot, R.; Lupoi, R.; et al. Mechanical and in vitro study of an isotropic Ti6Al4V lattice structure fabricated using selective laser melting. J. Alloy. Compd. 2019, 782, 209–223. [Google Scholar] [CrossRef]

- Chen, S.Y.; Huang, J.C.; Pan, C.T.; Lin, C.H.; Yang, T.L.; Huang, Y.S.; Ou, C.H.; Chen, L.Y.; Lin, D.Y.; Lin, H.K.; et al. Microstructure and mechanical properties of open-cell porous Ti-6Al-4V fabricated by selective laser melting. J. Alloy. Compd. 2017, 713, 248–254. [Google Scholar] [CrossRef]

- Attar, H.; Löber, L.; Funk, A.; Calin, M.; Zhang, L.C.; Prashanth, K.G.; Scudino, S.; Zhang, Y.S.; Eckert, J. Mechanical behavior of porous commercially pure Ti and Ti–TiB composite materials manufactured by selective laser melting. Mater. Sci. Eng. A 2015, 625, 350–356. [Google Scholar] [CrossRef]

- Hedayati, R.; Ahmadia, S.M.; Lietaertc, K.; Pourana, B.; Lia, Y.; Weinansa, H.; Ranse, C.D.; Zadpoora, A.A. Isolated and modulated effects of topology and material type on the mechanical properties of additively manufactured porous biomaterials. J. Mech. Behav. Biomed. Mater. 2018, 79, 254–263. [Google Scholar] [CrossRef] [PubMed]

- Ran, Q.; Yang, W.; Hu, Y.; Shen, X.; Yu, Y.; Xiang, Y.; Cai, K. Osteogenesis of 3D printed porous Ti6Al4V implants with different pore sizes. J. Mech. Behav. Biomed. Mater. 2018, 84, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Pei, X.; Zhou, C.; Fan, Y.; Jiang, Q.; Ronca, A.; D’Amora, U.; Chen, Y.; Li, H.; Sun, Y.; et al. The biomimetic design and 3D printing of customized mechanical properties porous Ti6Al4V scaffold for load-bearing bone reconstruction. Mater. Des. 2018, 152, 30–39. [Google Scholar] [CrossRef]

- Wally, Z.J.; Haque, A.M.; Feteira, A.; Claeyssens, F.; Goodall, R.; Reilly, G.C. Selective laser melting processed Ti6Al4V lattices with graded porosities for dental applications. J. Mech. Behav. Biomed. Mater. 2019, 90, 20–29. [Google Scholar] [CrossRef] [Green Version]

- Van Hooreweder, B.; Apers, Y.; Lietaert, K.; Kruth, J.-P. Improving the fatigue performance of porous metallic biomaterials produced by Selective Laser Melting. Acta Biomater. 2017, 47, 193–202. [Google Scholar] [CrossRef]

- Dallago, M.; Fontanari, V.; Torresani, E.; Leoni, M.; Pederzolli, C.; Potrich, C.; Benedetti, M. Fatigue and biological properties of Ti-6Al-4V ELI cellular structures with variously arranged cubic cells made by selective laser melting. J. Mech. Behav. Biomed. Mater. 2018, 78, 381–394. [Google Scholar] [CrossRef]

- Hollander, D.A.; Von Walter, M.; Wirtz, T.; Sellei, R.; Schmidt-Rohfing, B.; Paar, O.; Erli, H. Structural, mechanical and in vitro characterization of individually structured Ti_6Al-4V produced by direct laser forming. Biomaterials 2006, 27, 955–963. [Google Scholar] [CrossRef]

- Krakhmalev, P.; Fredriksson, G.; Yadroistava, I.; Kazantseva, N.; du Plessis, A.; Yadroitsev, I. Deformation behavior and microstructure of Ti6Al4V manufactured by SLM. Phys. Procedia 2016, 83, 778–788. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Günther, J.; Leuders, S.; Koppa, P.; Tröster, T.; Henkel, S.; Biermann, H.; Niendorf, T. On the effect of internal channels and surface roughness on the high-cycle fatigue performance of Ti-6Al-4V processed by SLM. Mater. Des. 2018, 143, 1–11. [Google Scholar] [CrossRef]

- Sun, D.; Gua, D.; Lin, K.; Ma, J.; Chena, W.; Huang, J.; Sun, X.; Chu, M. Selective laser melting of titanium parts: Influence of laser process parameters on macro- and microstructures and tensile property. Powder Technol. 2019, 342, 371–379. [Google Scholar] [CrossRef]

- Mierzejewska, Ż.A.; Hudák, R.; Sidun, J. Mechanical properties and microstructure of DMLS Ti6Al4V alloy dedicated to biomedical applications. Materials 2019, 12, 176. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Losertová, M.; Kubeš, V. Microstructure and mechanical properties of selective laser melted Ti6Al4V alloy. IOP Conf. Ser. Mater. Sci. Eng. 2017, 266, 1–7. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, Y.; Qiao, L.; Jiang, D. Study on structures and properties of hexagonal porous Ti6Al4V alloy via selective laser melting. J. Funct. Mater. 2018, 49, 6080–6087. [Google Scholar]

- Peng, W.; Liu, Y.; Jiang, X.; Dong, X.; Jun, J.; Baur, D.A.; Xu, J.; Pan, H.; Xu, X. Bionic mechanical design and 3D printing of novel porous Ti6Al4V implants for biomedical applications. Biomed. Biotechnol. 2019, 20, 647–659. [Google Scholar] [CrossRef]

- Chlebus, E.; Kuźnicka, B.; Kurzynowski, T.; Dybała, B. Microstructure and mechanical behavior of Ti―6Al―7Nb alloy produced by selective laser melting. Mater. Charact. 2011, 62, 488–495. [Google Scholar] [CrossRef]

- Wang, Z.; Xiao, Z.; Tse, Y.; Huang, C.; Zhang, W. Optimization of processing parameters and establishment of a relationship between microstructure and mechanical properties of SLM titanium alloy. Opt. Laser Technol. 2019, 112, 159–167. [Google Scholar] [CrossRef]

- Wysocki, B.; Maj, P.; Krawczyńska, A.; Rożniatowski, K.; Zdunek, J.; Kurzydłowski, K.J.; Święszkowski, W. Microstructure and mechanical properties investigation of CP titanium processed by selective laser melting (SLM). J. Mater. Process. Tech. 2017, 241, 13–23. [Google Scholar] [CrossRef]

- Mierzejewska, Ż.A. Effect of laser Energy density, internal porosity and heat treatment on mechanical behawior of biomedical Ti6Al4V alloy obtained with DMLS technology. Materials 2019, 12, 2331. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.; Chen, C.; Shuai, S.; Zhao, R.; Liu, L.; Wang, X.; Hu, T.; Xuan, W.; Li, C.; Yu, J.; et al. Study of pore defect and mechanical properties in selective laser melted Ti6Al4V alloy based on X-ray computed tomography. Mater. Sci. Eng. A 2020, 797, 139981. [Google Scholar] [CrossRef]

- dell’Isola, F.; Seppecher, P.; Alibert, J.J.; Lekszycki, T.; Grygoruk, R.; Pawlikowski, M.; Steigmann, D.; Giorgio, I.; Andreaus, U.; Turco, E.; et al. Pantographic metamaterials: An example of mathematically driven design and of its technological challenges. Contin. Mech. Thermodyn. 2019, 31, 851–884. [Google Scholar] [CrossRef] [Green Version]

- dell’Isola, F.; Lekszycki, T.; Pawlikowski, M.; Grygoruk, R.; Greco, L. Designing a light fabric metamaterial being highly macroscopically tough under directional extension: First experimental evidence. Z. Angew. Math. Phys. 2015, 66, 3473–3498. [Google Scholar] [CrossRef]

- 3DSYSTEMS. DIRECT METAL PRINTERS. Available online: http://3dsystemspolska.pl/files/download/3dsystemspolska_dmp_specyfikacja_201602_web.pdf (accessed on 11 November 2019).

- Benedetti, M.; Fontanari, V.; Bandini, M.; Zanini, F.; Carmignato, S. Low- and high-cycle fatigue resistance of Ti-6Al-4V ELI additively manufactured via selective laser melting: Mean stress and defect sensitivity. Inter. J. Fatigue 2018, 107, 96–109. [Google Scholar] [CrossRef]

- ASTM E8/E8M-16ae1, Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2016.

- Doroszko, M.; Seweryn, A. Modeling of the tension and compression behavior of sintered 316L using micro computed tomography. Acta Mech. Autom. 2015, 9, 70–74. [Google Scholar] [CrossRef] [Green Version]

- Doroszko, M.; Seweryn, A. Pore-scale numerical modeling of large deformation behaviour of sintered porous metals under compression using computed microtomography. Mech. Mater. 2020, 141, 103259. [Google Scholar] [CrossRef]

- Yamada, H. Strenght of Biological Materials; Krieger, R.E., Ed.; Williams & Wilkins: New York, NY, USA, 1973. [Google Scholar]

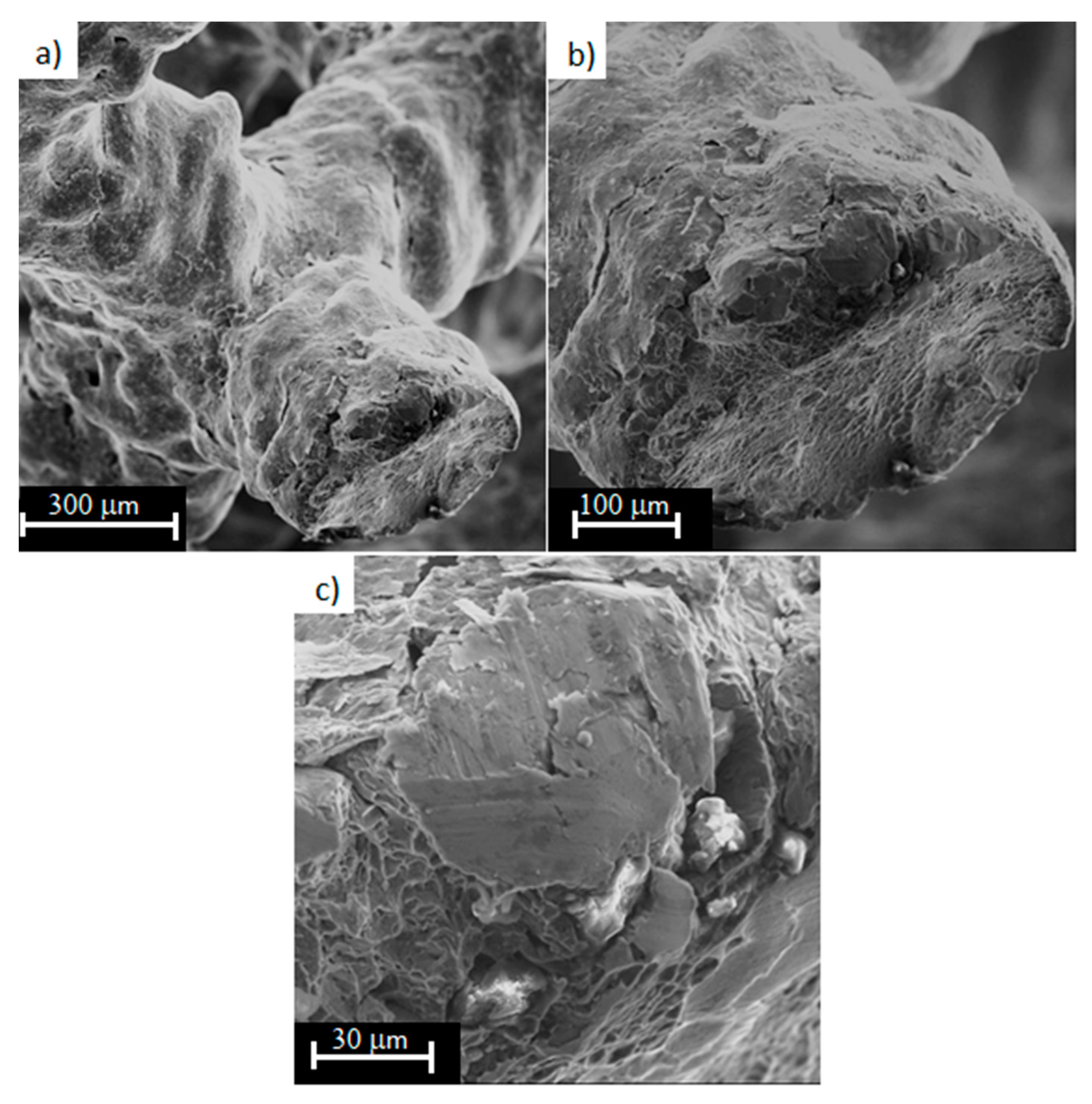

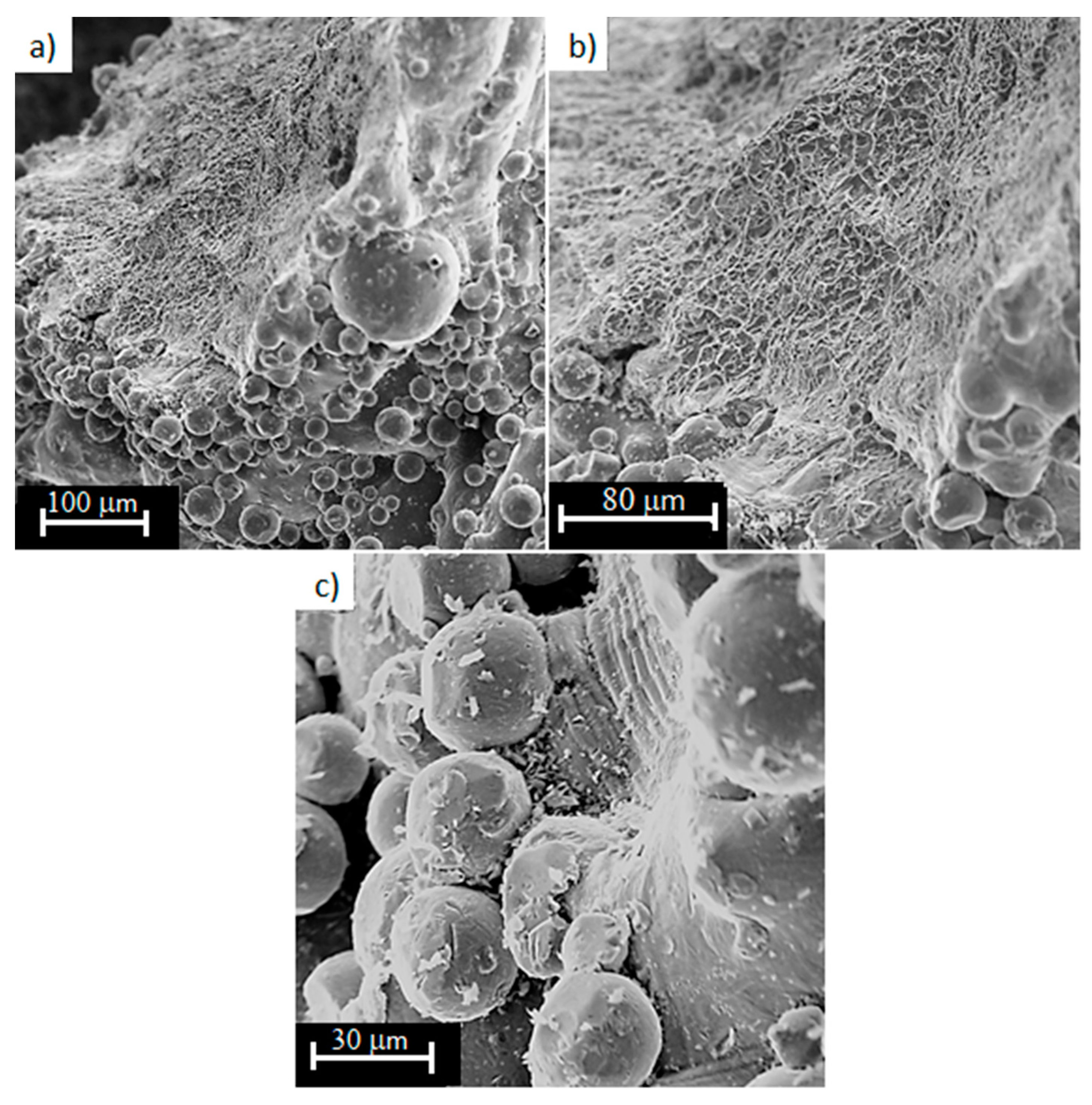

- Gu, D.; Shen, Y. Balling phenomena in direct laser sintering of stainless steel powder: Metallurgical mechanisms and control methods. Mater. Des. 2009, 30, 2903–2910. [Google Scholar] [CrossRef]

- Gu, D. New metallic materials development by laser additive manufacturing. In Laser Surface Engineering. Processes and Applications; Woodhead Publishing: Sarston, UK; Cambridge, UK, 2015; pp. 163–180. [Google Scholar]

- Liverani, E.; Toschi, S.; Ceschini, L.; Fortunato, A. Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J. Mater. Process. Tech. 2017, 249, 255–263. [Google Scholar] [CrossRef]

- Koutiri, I.; Pessard, E.; Peyre, P.; Amlou, O.; De Terris, T. Influence of SLM process parameters on the surface finish, porosity rate and fatigue behavior of as-built Inconel 625 parts. J. Mater. Process. Tech. 2018, 255, 536–546. [Google Scholar] [CrossRef]

- Sarker, A.; Tran, N.; Rifai, A.; Elambasseril, J.; Brandt, M.; Williams, R.; Leary, M.; Fox, K. Angle defines attachment: Switching the biological response to titanium interfaces by modifying the inclination angle during selective laser melting. Mater. Des. 2018, 154, 326–339. [Google Scholar] [CrossRef]

- Doroszko, M.; Seweryn, A. Numerical modeling of the tensile deformation process of sintered 316L based on microtomography of porous mesostructures. Mater. Des. 2015, 88, 493–504. [Google Scholar] [CrossRef]

- Doroszko, M.; Seweryn, A. A new numerical modelling method for deformation behaviour of metallic porous materials using X-ray computed microtomography. Mater. Sci. Eng. A 2017, 689, 142–156. [Google Scholar] [CrossRef]

| LaserFormTMTi Gr 23 (ASTM E8M) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Al | C | Fe | H | N | O | V | Y | Others Together |

| 5.50–6.50% | ≤0.08% | ≤0.25% | ≤0.12% | ≤0.03% | ≤0.13% | 3.50–4.50% | ≤0.005% | ≤0.40% |

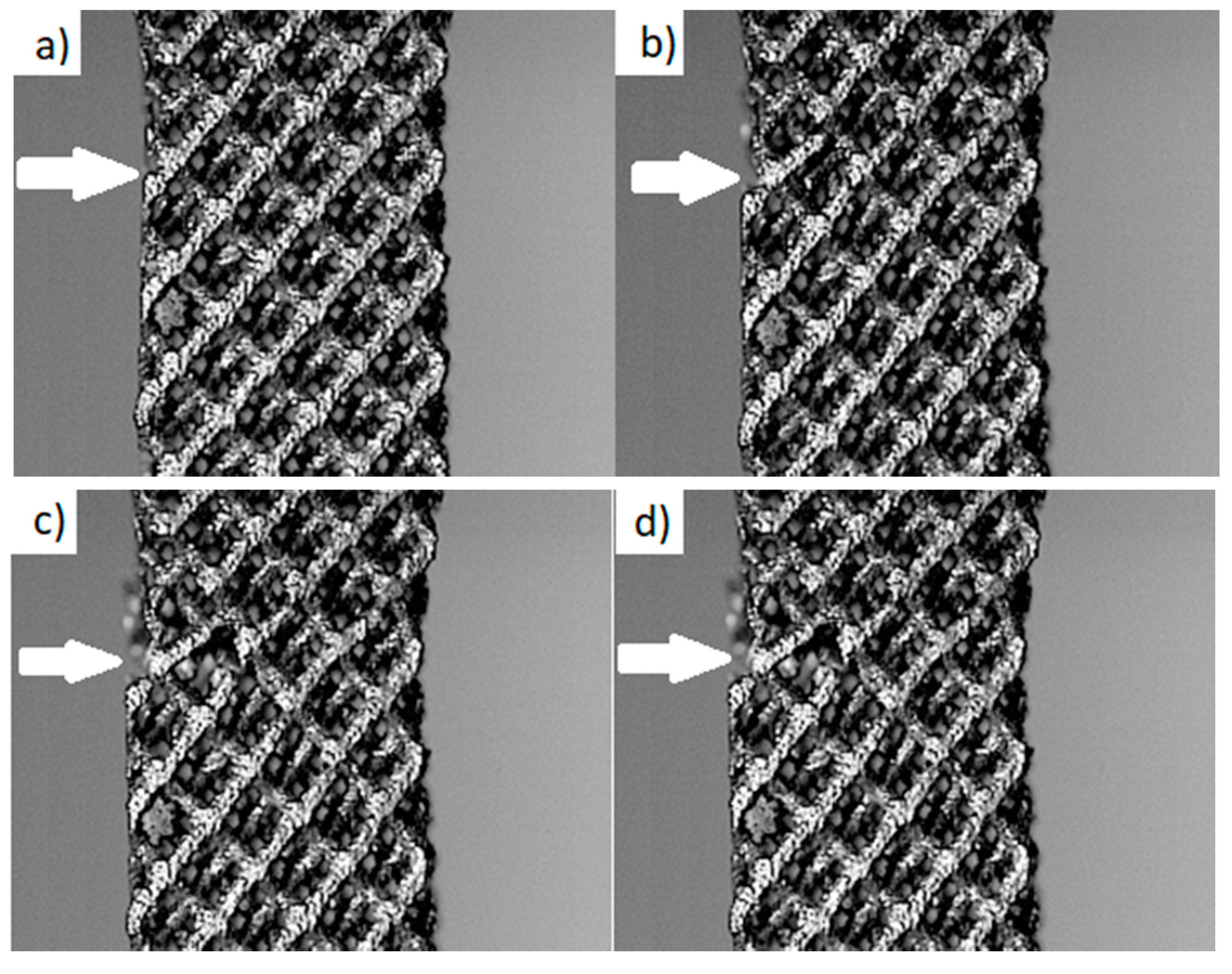

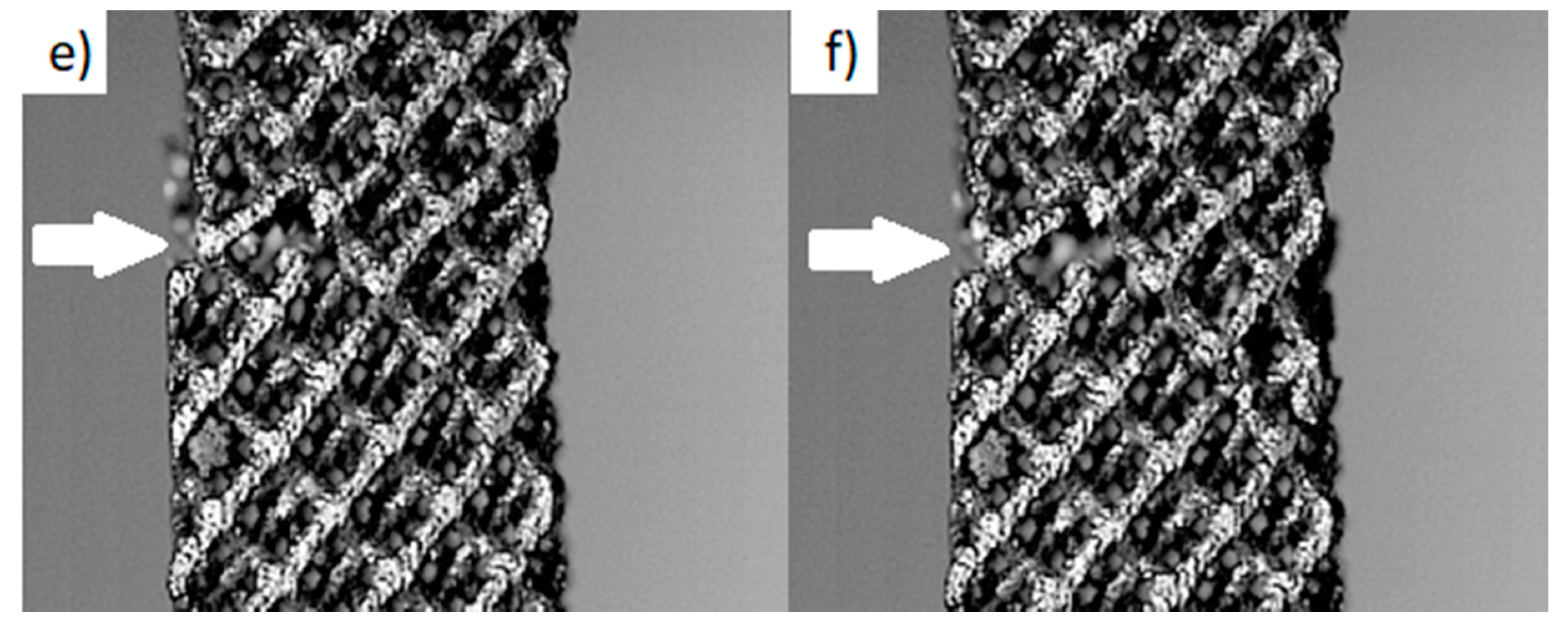

| Type of Sample | Density (%) | Porosity (%) | Beam Thickness (mm) | Weight (g) |

|---|---|---|---|---|

| Type 1 | 19 | 81 | 0.49 | 4.13 |

| Type 2 | 27 | 73 | 0.60 | 6.11 |

| Type 3 | 50 | 50 | 0.70 | 10.77 |

| Type 4 | 66 | 34 | 1.20 | 14.48 |

| Type 5 | 100 | near 0 | – | 19.85 |

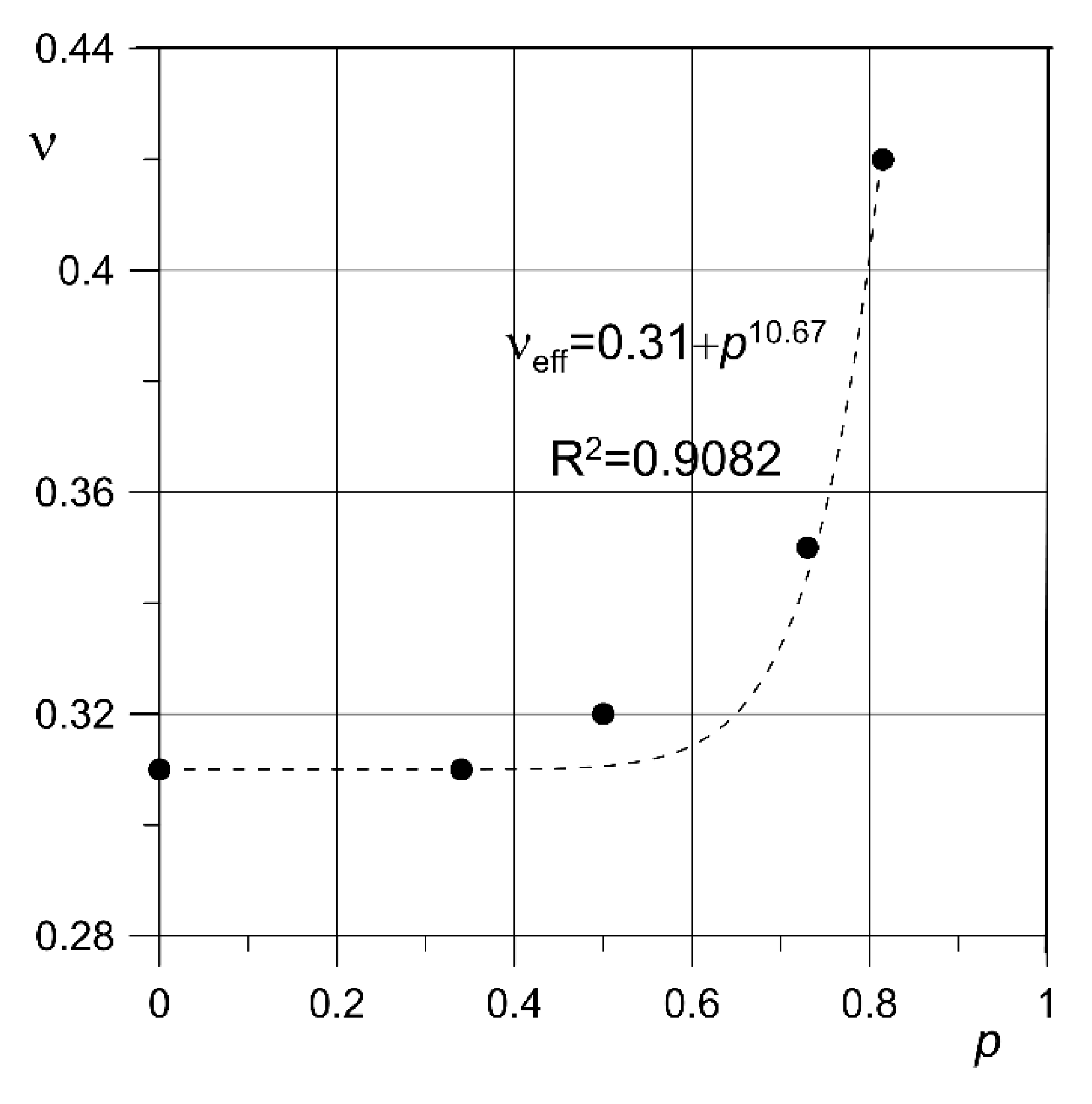

| Sample No. | p (%) | E (GPa) | ν | σu (MPa) | σ0.2 (MPa) | A | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 81 | 3.8 | 3.7 | 0.42 | 64.0 | 62.6 | 47.6 | 50.3 | 0.037 | 0.036 |

| 2 | 3.6 | 60.7 | 51.0 | 0.036 | ||||||

| 3 | 3.7 | 63.1 | 52.2 | 0.036 | ||||||

| 4 | 73 | 7.3 | 7.4 | 0.35 | 115.9 | 117.2 | 88.4 | 90.8 | 0.063 | 0.061 |

| 5 | 7.3 | 121.1 | 96.7 | 0.057 | ||||||

| 6 | 7.5 | 114.7 | 87.4 | 0.062 | ||||||

| 7 | 50 | 19.9 | 20.4 | 0.32 | 245.1 | 244.2 | 196.3 | 193.5 | 0.065 | 0.064 |

| 8 | 20.6 | 249.9 | 196.9 | 0.062 | ||||||

| 9 | 20.6 | 237.5 | 187.3 | 0.065 | ||||||

| 10 | 34 | 41.3 | 41.8 | 0.31 | 409.0 | 410.0 | 334.5 | 331.7 | 0.053 | 0.052 |

| 11 | 42.8 | 410.1 | 331.5 | 0.051 | ||||||

| 12 | 41.3 | 410.9 | 329.1 | 0.052 | ||||||

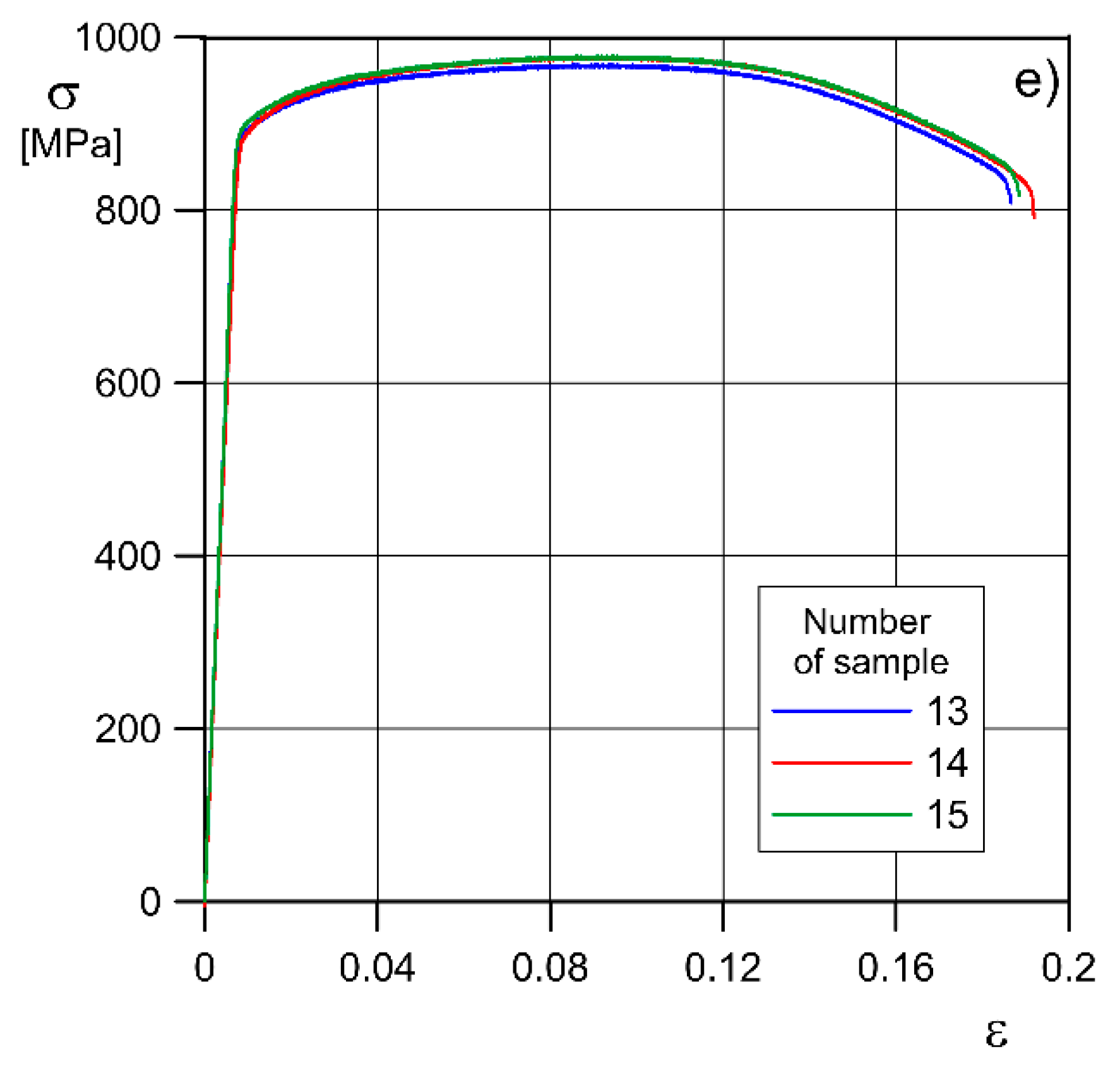

| 13 | - | 120.1 | - | 0.31 | 969.0 | - | 899.5 | - | 0.187 | - |

| 14 | near 0 | 116.5 | 118.7 | 977.6 | 975.1 | 895.9 | 898.8 | 0.192 | 0.189 | |

| 15 | - | 119.5 | - | 978.7 | - | 900.9 | - | 0.188 | - | |

| Solid material | 105–120 | 0.31–0.37 | 940 ±50 MPa * 1080 ± 100 MPa ** | 850 ± 100MPa * 1000 ±100MPa ** | 0.15 ± 0.05 * 0.11 ± 0.03 ** | |||||

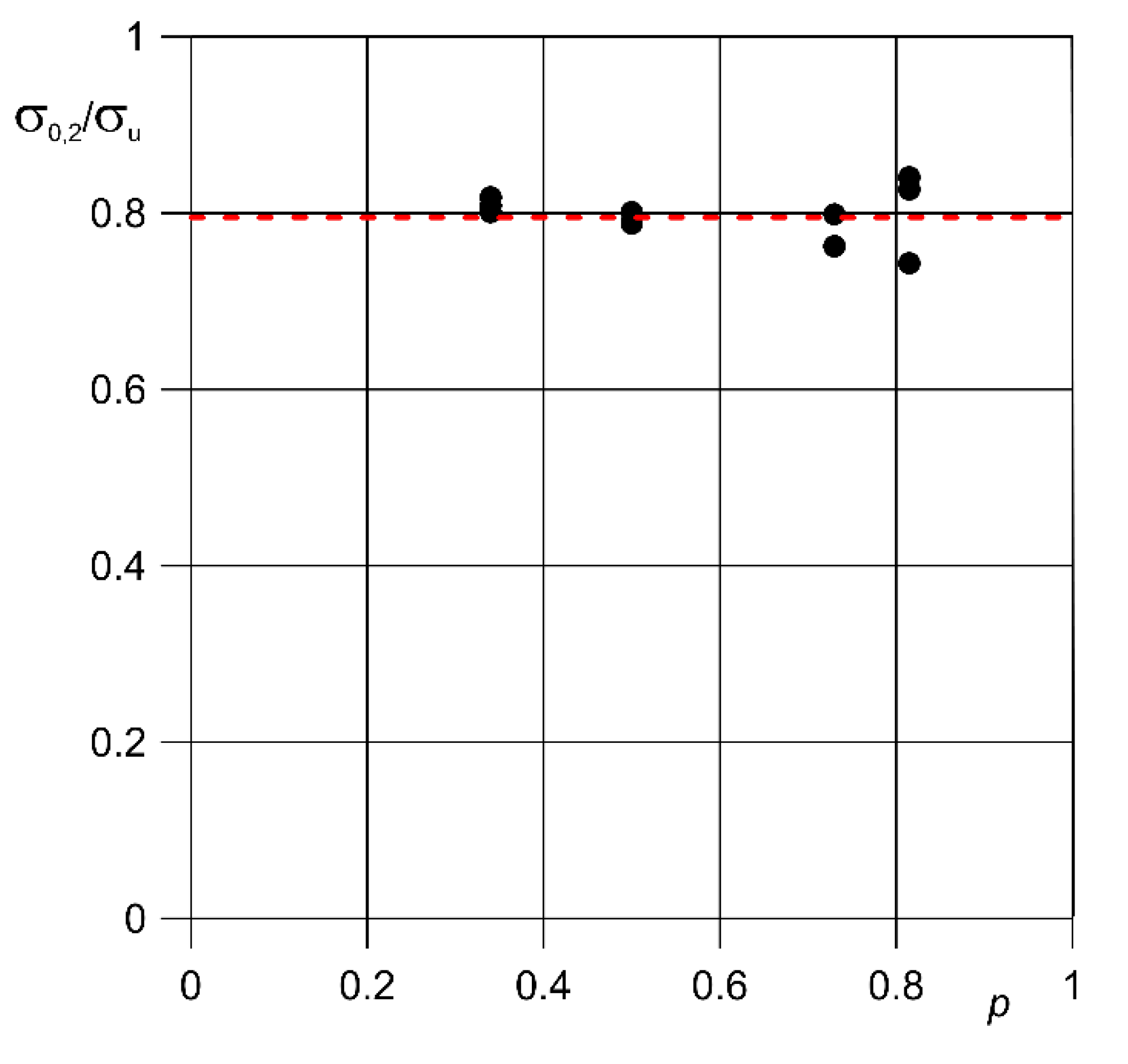

| p | σ0.2eff (MPa) | σueff (MPa) | σ0.2eff/σueff |

|---|---|---|---|

| 0.34 | 331.7 | 409.9 | 0.81 |

| 0.5 | 193.5 | 244.2 | 0.79 |

| 0.73 | 90.8 | 117.3 | 0.77 |

| 0.81 | 50.3 | 62.6 | 0.80 |

| Porosity (%) | K (MPa) | n | R2 |

|---|---|---|---|

| 81 | 110.66 | 0.17 | 0.9961 |

| 73 | 163.98 | 0.12 | 0.9914 |

| 50 | 317.69 | 0.09 | 0.9980 |

| 34 | 519.64 | 0.08 | 0.9952 |

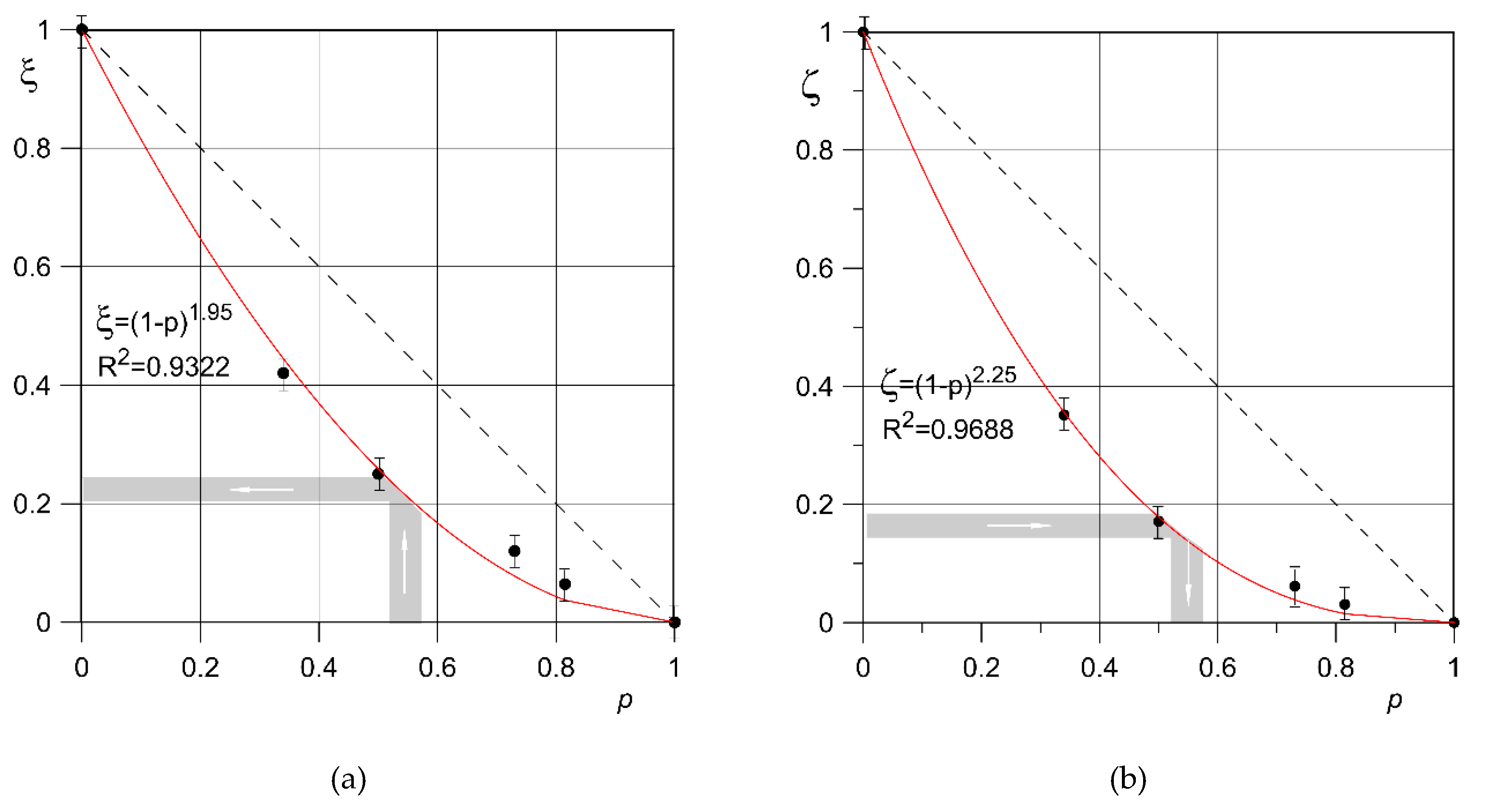

| p | σu (MPa) | σu/σu0 | E (GPa) | E/E0 |

|---|---|---|---|---|

| near 0 | 975.09 | 1 | 118.7 | 1 |

| 0.34 | 409.98 | 0.44 | 41.8 | 0.38 |

| 0.5 | 244.15 | 0.26 | 20.4 | 0.20 |

| 0.73 | 117.31 | 0.08 | 7.4 | 0.05 |

| 0.81 | 62.63 | 0.04 | 3.7 | 0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Falkowska, A.; Seweryn, A.; Skrodzki, M. Strength Properties of a Porous Titanium Alloy Ti6Al4V with Diamond Structure Obtained by Laser Power Bed Fusion (LPBF). Materials 2020, 13, 5138. https://doi.org/10.3390/ma13225138

Falkowska A, Seweryn A, Skrodzki M. Strength Properties of a Porous Titanium Alloy Ti6Al4V with Diamond Structure Obtained by Laser Power Bed Fusion (LPBF). Materials. 2020; 13(22):5138. https://doi.org/10.3390/ma13225138

Chicago/Turabian StyleFalkowska, Anna, Andrzej Seweryn, and Marcin Skrodzki. 2020. "Strength Properties of a Porous Titanium Alloy Ti6Al4V with Diamond Structure Obtained by Laser Power Bed Fusion (LPBF)" Materials 13, no. 22: 5138. https://doi.org/10.3390/ma13225138

APA StyleFalkowska, A., Seweryn, A., & Skrodzki, M. (2020). Strength Properties of a Porous Titanium Alloy Ti6Al4V with Diamond Structure Obtained by Laser Power Bed Fusion (LPBF). Materials, 13(22), 5138. https://doi.org/10.3390/ma13225138