Effects of Build Direction on the Mechanical Properties of a Martensitic Stainless Steel Fabricated by Selective Laser Melting

Abstract

:1. Introduction

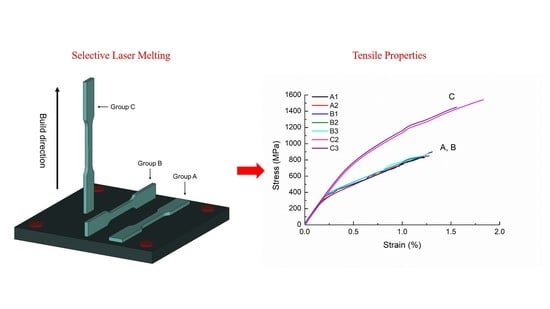

2. Experimental Procedures

2.1. Specimen Fabrication

2.2. Measurement of Density, Hardness, and Residual Stress

2.3. Uniaxial Tensile Test

2.4. Fractography and Microstructural Analysis

3. Results and Discussion

3.1. Density and Hardness

3.2. Residual Stress

3.3. Tensile Properties

3.4. Fractography and Microstructural Analysis

3.5. Effect of Build Direction

4. Conclusions

- (1)

- The dependence of microstructure and mechanical properties on build direction is confirmed for the martensitic mold steel, AISI 420 stainless steel, fabricated by SLM in a vertical direction and two horizontal directions.

- (2)

- Build direction effect causes anisotropic mechanical properties as the vertically built SLM specimens possess superior mechanical properties (yield stress, ultimate tensile stress, elongation, and hardness) to those of horizontally built ones. This is mainly attributed to the anisotropic microstructure in which the orientation of elongated cells and acicular structures in the vertical and horizontal builds is respectively parallel and perpendicular to the tensile loading direction. The residual compressive stress existing in the gauge section also contributes to the superior tensile properties of the vertical builds, as compared to the horizontal builds which exhibit residual tensile stress in the gauge section.

- (3)

- The SLM AISI 420 builds in as-built state exhibit elongated cells and acicular structures which are composed of martensite and retained austenite phases. The elongated cellular structures are generally oriented with the build direction due to a directional grain growth mechanism. However, build direction has a limited effect on the phase content as the SLM builds contain a comparable amount of martensite, namely 78.82%, 71.69%, and 76.71% for Groups A–C, respectively.

- (4)

- Fractography analysis reveals residual tensile stress and irregular inclusions both play an important role in determining the fracture origin site of the given SLM builds when subjected to uniaxial tensile loading.

Author Contributions

Funding

Conflicts of Interest

References

- Gouge, M.; Michaleris, P. Thermo-Mechanical Modeling of Additive Manufacturing, 1st ed.; Butterworth-Heinemann: Oxford, UK, 2018. [Google Scholar]

- Xia, M.; Gu, D.; Yu, G.; Dai, D.; Chen, H.; Shi, Q. Influence of hatch spacing on heat and mass transfer, thermodynamics and laser processability during additive manufacturing of Inconel 718 alloy. Int. J. Mach. Tools Manuf. 2016, 109, 147–157. [Google Scholar] [CrossRef]

- Shipley, H.; McDonnell, D.; Culleton, M.; Coull, R.; Lupoi, R.; O’Donnell, G.; Trimble, D. Optimisation of process parameters to address fundamental challenges during selective laser melting of Ti-6Al-4V: A review. Int. J. Mach. Tools Manuf. 2018, 128, 1–20. [Google Scholar] [CrossRef]

- Kok, Y.; Tan, X.P.; Wang, P.; Nai, M.L.S.; Loh, N.H.; Liu, E.; Tor, S.B. Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: A critical review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Chen, J.; Xue, L.; Wang, S.-H. Experimental studies on process-induced morphological characteristics of macro- and microstructures in laser consolidated alloys. J. Mater. Sci. 2011, 46, 5859–5875. [Google Scholar] [CrossRef] [Green Version]

- Deng, D.; Peng, L.R.; Brodin, H.; Moverare, J. Microstructure and mechanical properties of Inconel 718 produced by selective laser melting: Sample orientation dependence and effects of post heat treatments. Mater. Sci. Eng. A 2018, 713, 294–306. [Google Scholar] [CrossRef]

- Du, D.; Dong, A.; Shu, D.; Zhu, G.; Sun, B.; Li, X.; Lavernia, E. Influence of build orientation on microstructure, mechanical and corrosion behavior of Inconel 718 processed by selective laser melting. Mater. Sci. Eng. A 2019, 760, 469–480. [Google Scholar] [CrossRef]

- Bean, G.E.; McLouth, T.D.; Witkin, D.B.; Sitzman, S.D.; Adams, P.M.; Zaldivar, R.J. Build orientation effects on texture and mechanical properties of selective laser melting Inconel 718. J. Mater. Eng. Perform. 2019, 28, 1942–1949. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, J.; Zhao, Z.; Tan, H.; Lin, X.; Huang, W. Microstructure and anisotropic tensile behavior of laser additive manufactured TC21 titanium alloy. Mater. Sci. Eng. A 2016, 673, 204–212. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. Effect of the build orientation on the mechanical properties and fracture modes of SLM Ti–6Al–4V. Mater. Sci. Eng. A 2014, 616, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Zhou, L.; Yuan, T.; Li, R.; Tang, J.; Wang, M.; Mei, F. Anisotropic mechanical behavior of biomedical Ti-13Nb-13Zr alloy manufactured by selective laser melting. J. Alloy. Compd. 2018, 762, 289–300. [Google Scholar] [CrossRef]

- Wauthle, R.; Vrancken, B.; Beynaerts, B.; Jorissen, K.; Schrooten, J.; Kruth, J.-P.; Van Humbeeck, J. Effects of build orientation and heat treatment on the microstructure and mechanical properties of selective laser melted Ti6Al4V lattice structures. Addit. Manuf. 2015, 5, 77–84. [Google Scholar] [CrossRef]

- Hartunian, P.; Eshraghi, M. Effect of build orientation on the microstructure and mechanical properties of selective laser-melted Ti-6Al-4V alloy. J. Manuf. Mater. Process. 2018, 2, 69. [Google Scholar] [CrossRef] [Green Version]

- Sun, W.; Ma, Y.; Huang, W.; Zhang, W.; Qian, X. Effects of build direction on tensile and fatigue performance of selective laser melting Ti6Al4V titanium alloy. Int. J. Fatigue 2020, 130, 105260. [Google Scholar] [CrossRef]

- Dong, Z.; Liu, Y.; Li, W.; Liang, J. Orientation dependency for microstructure, geometric accuracy and mechanical properties of selective laser melting AlSi10Mg lattices. J. Alloy. Compd. 2019, 791, 490–500. [Google Scholar] [CrossRef]

- De Menezes, J.T.O.; Castrodeza, E.M.; Casati, R. Effect of build orientation on fracture and tensile behavior of A357 Al alloy processed by selective laser melting. Mater. Sci. Eng. A 2019, 766, 138392. [Google Scholar] [CrossRef]

- Zhang, Z.; Chu, B.; Wang, L.; Lu, Z. Comprehensive effects of placement orientation and scanning angle on mechanical properties and behavior of 316L stainless steel based on the selective laser melting process. J. Alloy. Compd. 2019, 791, 166–175. [Google Scholar] [CrossRef]

- Shrestha, R.; Simsiriwong, J.; Shamsaei, N. Fatigue behavior of additive manufactured 316L stainless steel parts: Effects of layer orientation and surface roughness. Addit. Manuf. 2019, 28, 23–38. [Google Scholar] [CrossRef]

- Liverani, E.; Toschi, S.; Ceschini, L.; Fortunato, A. Effect of selective laser melting SLM, process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J. Mater. Process. Technol. 2017, 249, 255–263. [Google Scholar] [CrossRef]

- Mooney, B.; Kourousis, K.I.; Raghavendra, R. Plastic anisotropy of additively manufactured maraging steel: Influence of the build orientation and heat treatments. Addit. Manuf. 2019, 25, 19–31. [Google Scholar] [CrossRef] [Green Version]

- Tan, C.; Zhou, K.; Kuang, M.; Ma, W.; Kuang, T. Microstructural characterization and properties of selective laser melted maraging steel with different build directions. Sci. Technol. Adv. Mater. 2018, 19, 746–758. [Google Scholar] [CrossRef] [Green Version]

- Isfahany, A.N.; Saghafian, H.; Borhani, G. The effect of heat treatment on mechanical properties and corrosion behavior of AISI420 martensitic stainless steel. J. Alloy. Compd. 2011, 509, 3931–3936. [Google Scholar] [CrossRef]

- Zhao, X.; Wei, Q.; Song, B.; Liu, Y.; Luo, X.; Wen, S.; Shi, Y. Fabrication and characterization of AISI 420 stainless steel using selective laser melting. Mater. Manuf. Process. 2015, 30, 1283–1289. [Google Scholar] [CrossRef]

- Saeidi, K.; Zapata, D.L.; Lofaj, F.; Kvetkova, L.; Olsen, J.; Shen, Z.; Akhtar, F. Ultra-high strength martensitic 420 stainless steel with high ductility. Addit. Manuf. 2019, 29, 100803. [Google Scholar] [CrossRef]

- MatWeb. 420 Stainless Steel. Available online: http://www.matweb.com/search/datasheettext.aspx?matguid=641544e4c9f1425390d05ae37d55440a (accessed on 16 October 2018).

- Tanaka, K. The cos α method for X-ray residual stress measurement using two-dimensional detector. Mech. Eng. Rev. 2019, 6, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Jamshidinia, M.; Sadek, A.; Wang, W.; Kelly, S. Additive manufacturing of steel alloys using laser powder-bed fusion. Adv. Mater. Process. 2015, 173, 20–24. [Google Scholar]

- Li, A.; Ji, V.; Lebrun, J.L.; Ingelbert, G. Surface roughness effects on stress determination by the X-ray diffraction method. Exp. Tech. 1995, 19, 9–11. [Google Scholar] [CrossRef]

- Mercelis, P.; Kruth, J.P. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Krakhmalev, P.; Yadroitsava, I.; Fredriksson, G.; Yadroitsev, I. In situ heat treatment in selective laser melted martensitic AISI 420 stainless steels. Mater. Des. 2015, 87, 380–385. [Google Scholar] [CrossRef]

- Bhadeshia, H.; Honeycombe, R. Steels: Microstructure and Properties, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Van Dijk, N.H.; Butt, A.M.; Zhau, L.; Sietsma, J.; Offerman, S.E.; Wright, J.P.; van der Zwaag, S. Thermal stability of retained austenite in TRIP steels studied by synchrotron X-ray diffraction during cooling. Acta Mater. 2005, 53, 5439–5447. [Google Scholar] [CrossRef]

- Takata, N.; Nishida, R.; Suzuki, A.; Kobashi, M.; Kato, M. Crystallographic features of microstructure in maraging steel fabricated by selective laser melting. Metals 2018, 8, 440. [Google Scholar] [CrossRef] [Green Version]

- Lewandowski, J.J.; Seifi, M. Metal additive manufacturing: A review of mechanical properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef] [Green Version]

| Laser Power | 420 W (First Three Layers); 400 W |

| Laser scanning speed | 0.7 m/s |

| Laser spot size | 0.2 mm |

| Layer thickness | 50 μm |

| Baseplate preheated temperature | 180 °C |

| Build direction | 3 types (Figure 2) |

| Scanning strategy | Island pattern with alternating path |

| Hatch distance | 0.2 mm |

| Specimen ID | Relative Density, ρr | Hardness (HRC) |

|---|---|---|

| A1 | 0.93 | 55.6 ± 2.4 |

| A2 | 0.98 | 56.1 ± 2.6 |

| A3 | 0.98 | 56.2 ± 0.6 |

| Group A (average) | 0.96 | 56.0 |

| B1 | 0.93 | 49.2 ± 4.2 |

| B2 | 0.94 | 57.3 ± 3.6 |

| B3 | 0.93 | 52.7 ± 4.6 |

| Group B (average) | 0.93 | 53.1 |

| C1 | 0.93 | 60.3 ± 4.6 |

| C2 | 0.90 | 58.1 ± 6.0 |

| C3 | 0.92 | 63.2 ± 4.1 |

| Group C (average) | 0.92 | 60.5 |

| Specimen ID | Yield Stress | Ultimate Tensile Stress | Elongation |

|---|---|---|---|

| (MPa) | (MPa) | (%) | |

| A1 | 481.1 | 830.5 | 1.23 |

| A2 | 487.0 | 852.4 | 1.28 |

| B1 | 489.9 | 899.3 | 1.35 |

| B2 | 518.4 | 829.8 | 1.17 |

| B3 | 511.2 | 890.1 | 1.27 |

| C2 | 982.2 | 1541 | 1.83 |

| C3 | 1005 | 1450 | 1.56 |

| Specimen Group | Retained Austenite | Martensite |

|---|---|---|

| (%) | (%) | |

| A | 21.2 | 78.8 |

| B | 28.3 | 71.7 |

| C | 23.3 | 76.7 |

| Specimen Group | Anisotropy Ratio in Yield Stress | Anisotropy Ratio in Ultimate Tensile Stress | Anisotropy Ratio in Elongation | Anisotropy Ratio in Hardness |

|---|---|---|---|---|

| A | 0.48 | 0.56 | 0.74 | 0.92 |

| B | 0.50 | 0.58 | 0.74 | 0.88 |

| C | 1 | 1 | 1 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, L.-C.; Yang, X.-H.; Ho, J.-R.; Tung, P.-C.; Lin, C.-K. Effects of Build Direction on the Mechanical Properties of a Martensitic Stainless Steel Fabricated by Selective Laser Melting. Materials 2020, 13, 5142. https://doi.org/10.3390/ma13225142

Shen L-C, Yang X-H, Ho J-R, Tung P-C, Lin C-K. Effects of Build Direction on the Mechanical Properties of a Martensitic Stainless Steel Fabricated by Selective Laser Melting. Materials. 2020; 13(22):5142. https://doi.org/10.3390/ma13225142

Chicago/Turabian StyleShen, Ling-Chieh, Xi-Huai Yang, Jeng-Rong Ho, Pi-Cheng Tung, and Chih-Kuang Lin. 2020. "Effects of Build Direction on the Mechanical Properties of a Martensitic Stainless Steel Fabricated by Selective Laser Melting" Materials 13, no. 22: 5142. https://doi.org/10.3390/ma13225142

APA StyleShen, L. -C., Yang, X. -H., Ho, J. -R., Tung, P. -C., & Lin, C. -K. (2020). Effects of Build Direction on the Mechanical Properties of a Martensitic Stainless Steel Fabricated by Selective Laser Melting. Materials, 13(22), 5142. https://doi.org/10.3390/ma13225142