Analysis of the Abrasive-Type Influence on the Effectiveness of Rotary Cleaning of Machine Parts with Complex Geometric Features

Abstract

1. Introduction

2. Materials and Methods

2.1. Description of the Test Stand Used for Rotational Cleaning

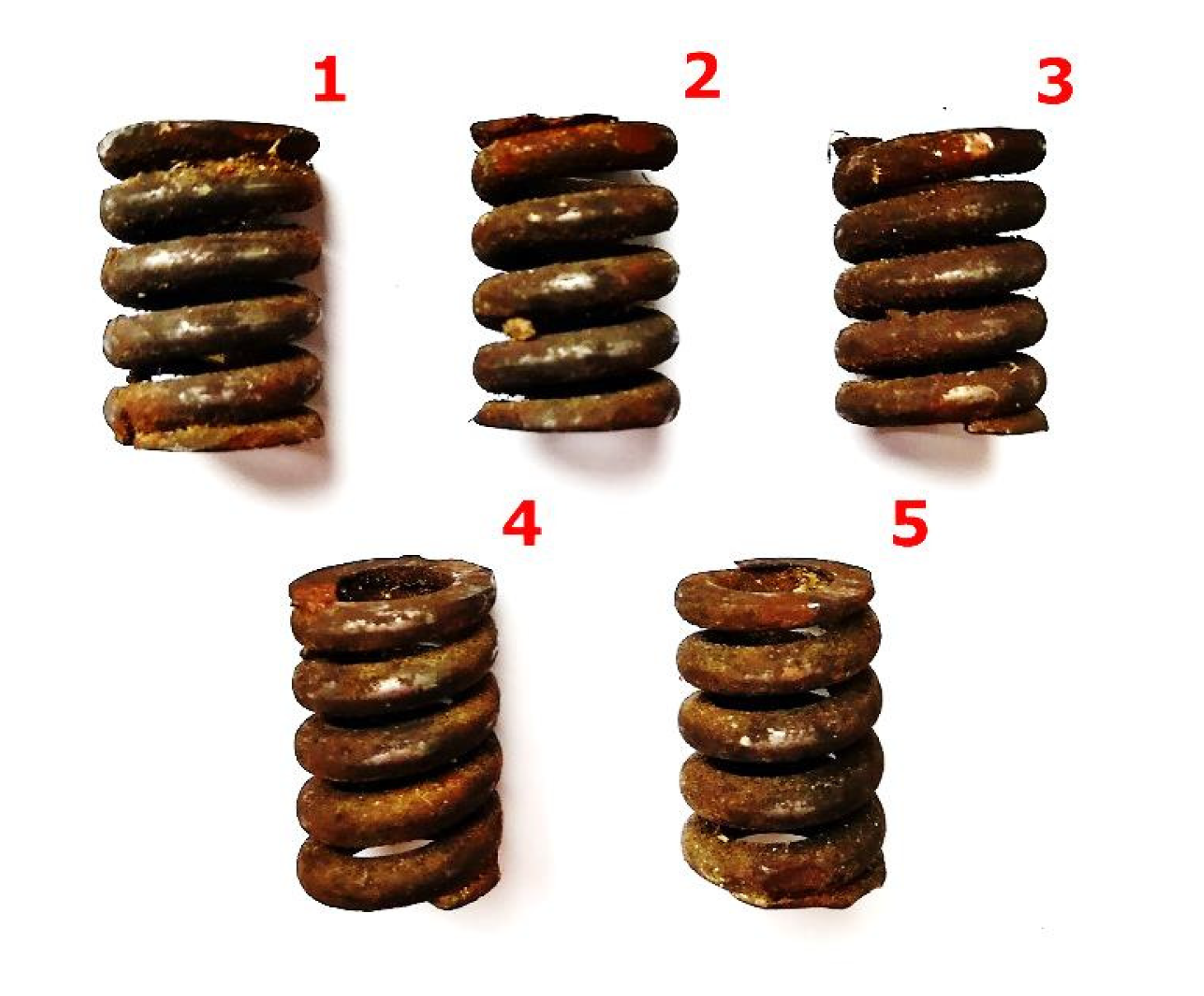

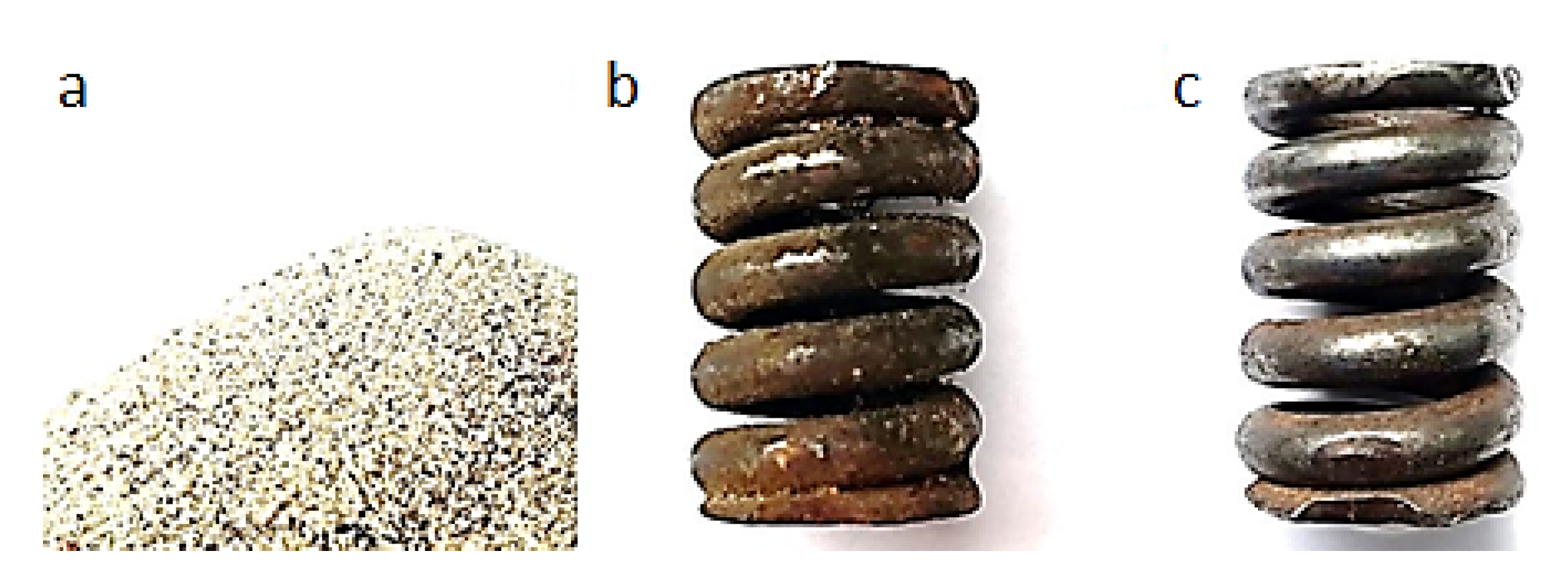

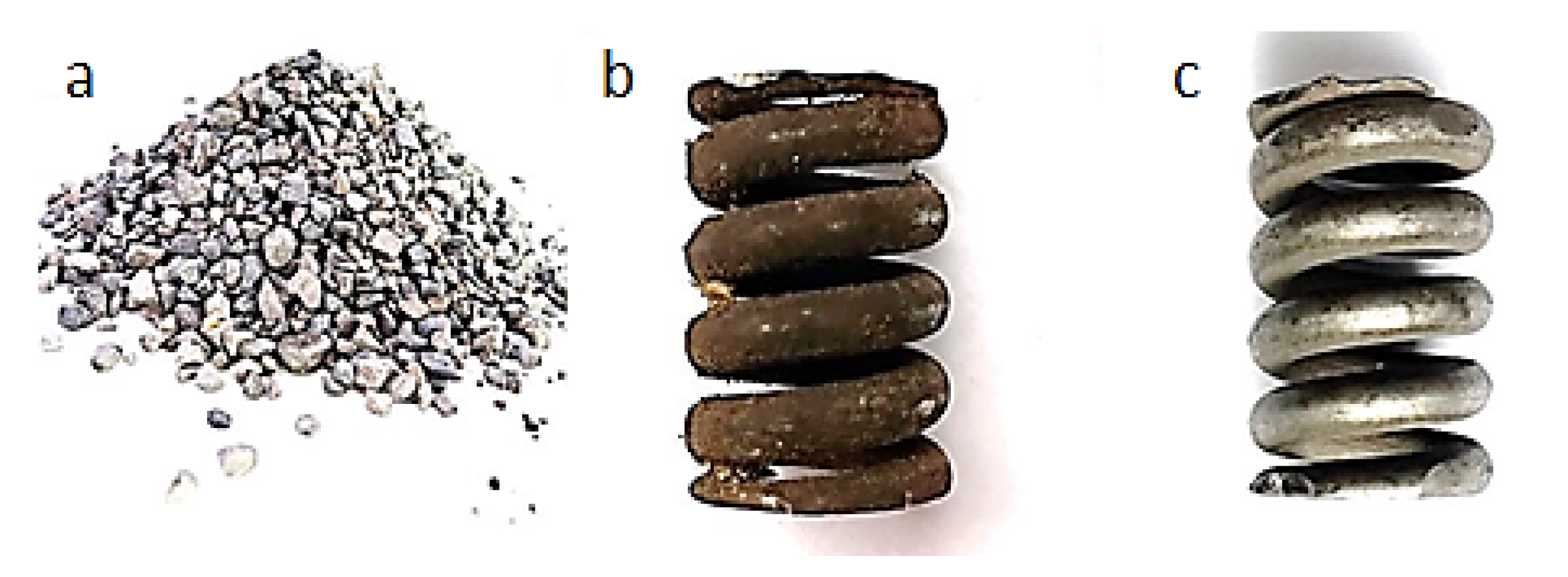

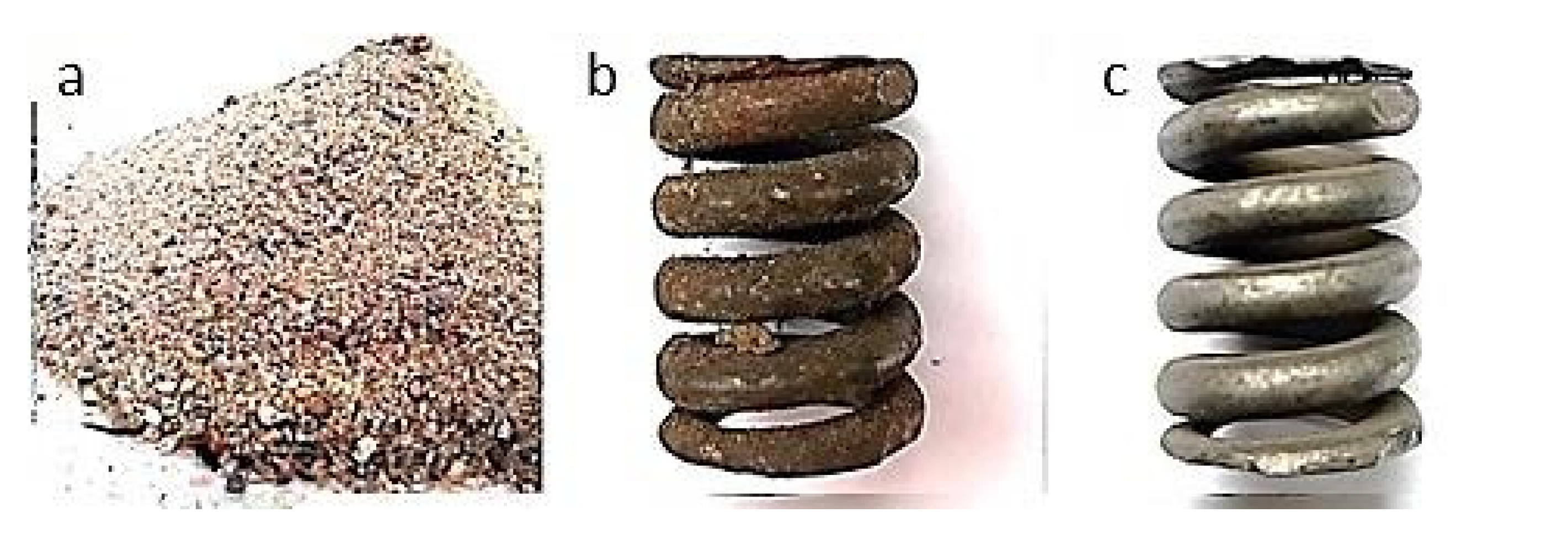

2.2. Description of the Research Samples

2.3. Description of the Research Procedure

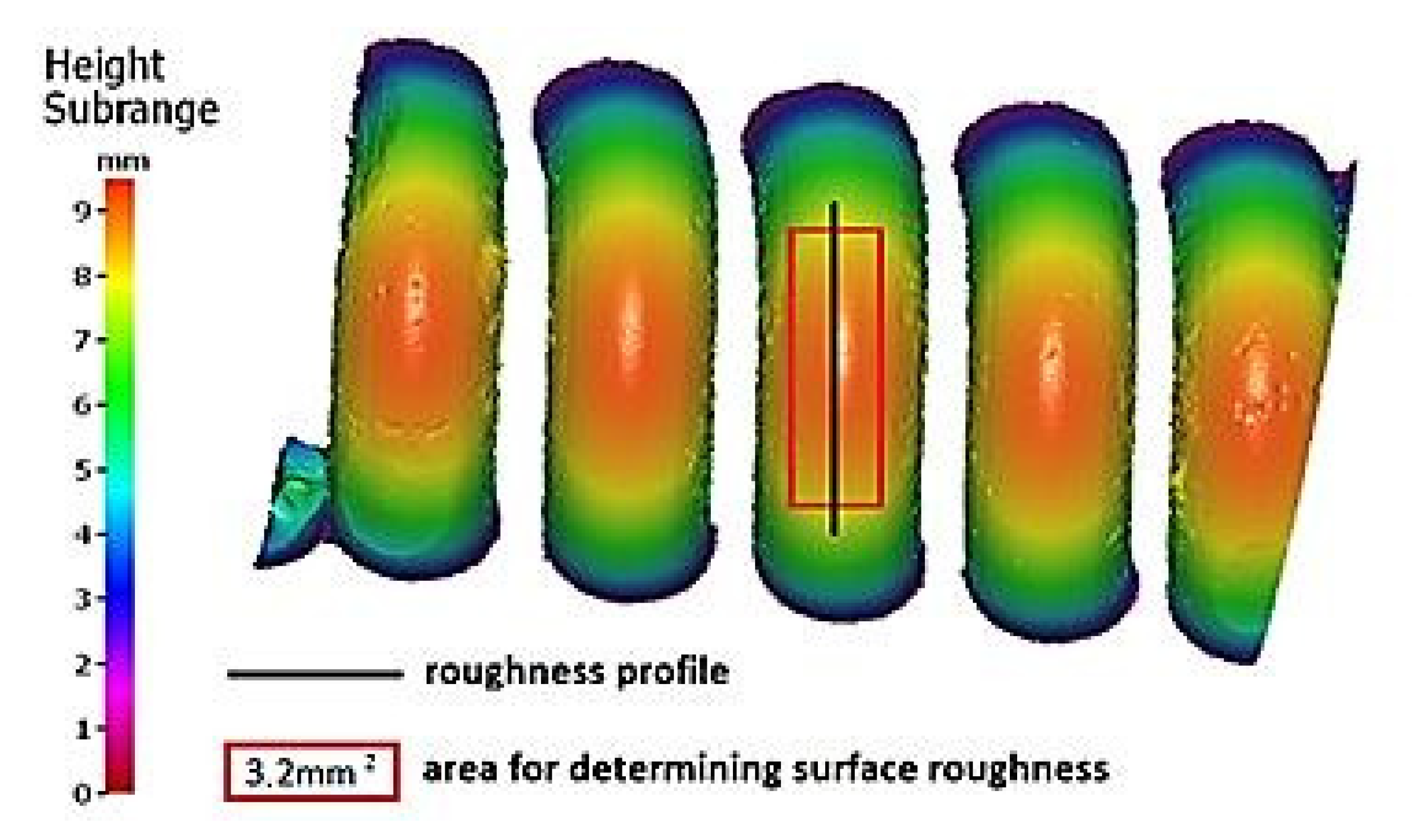

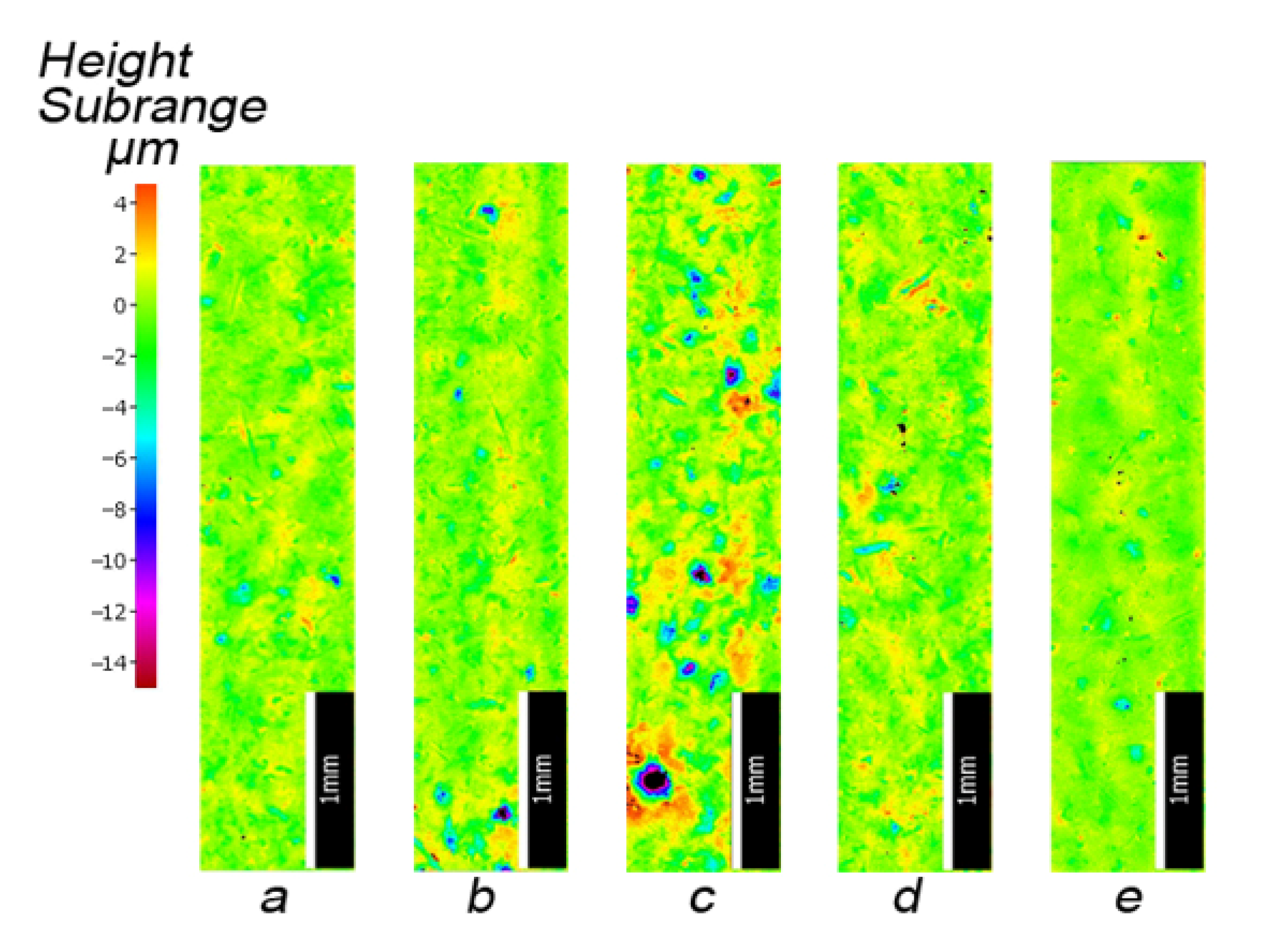

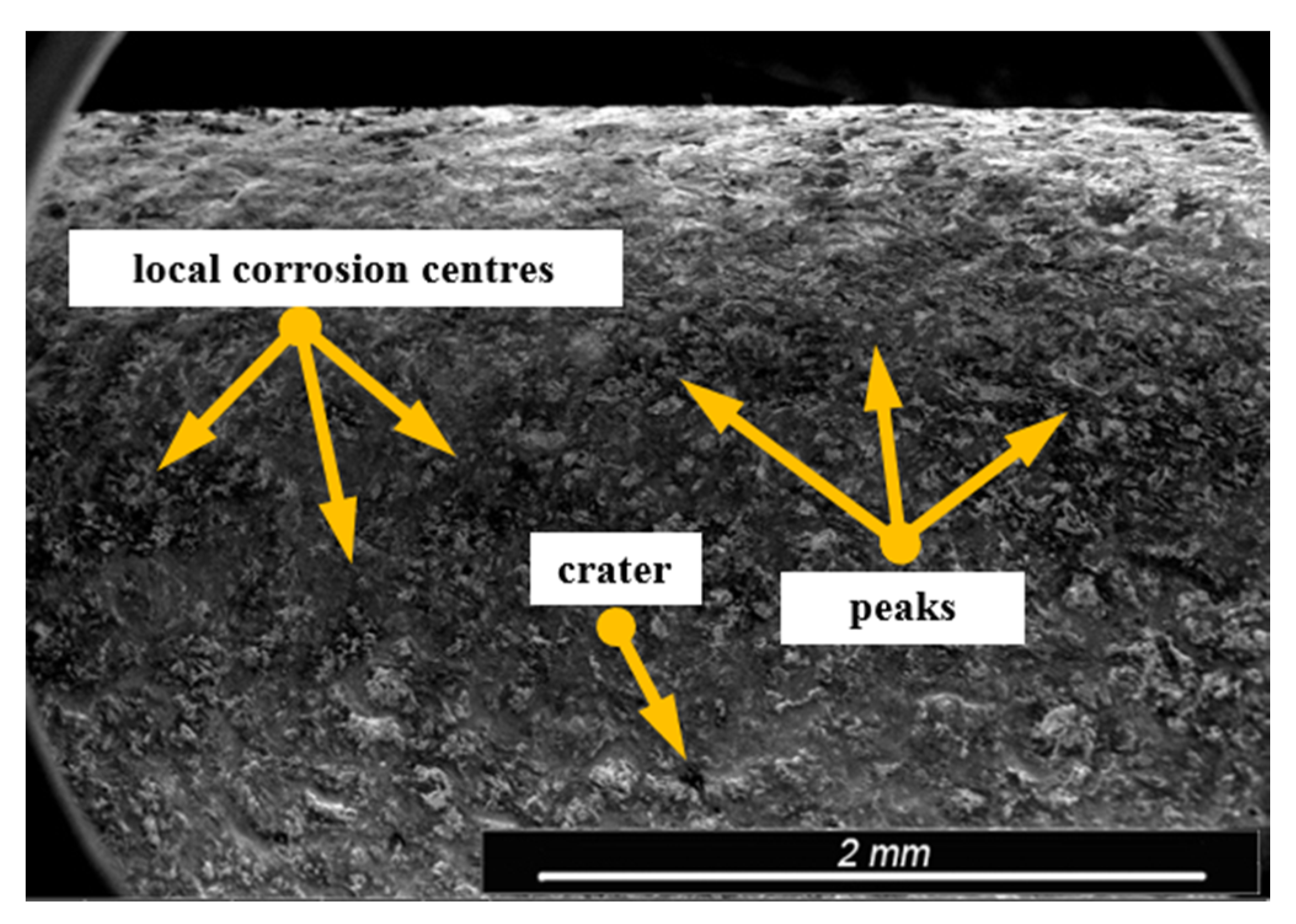

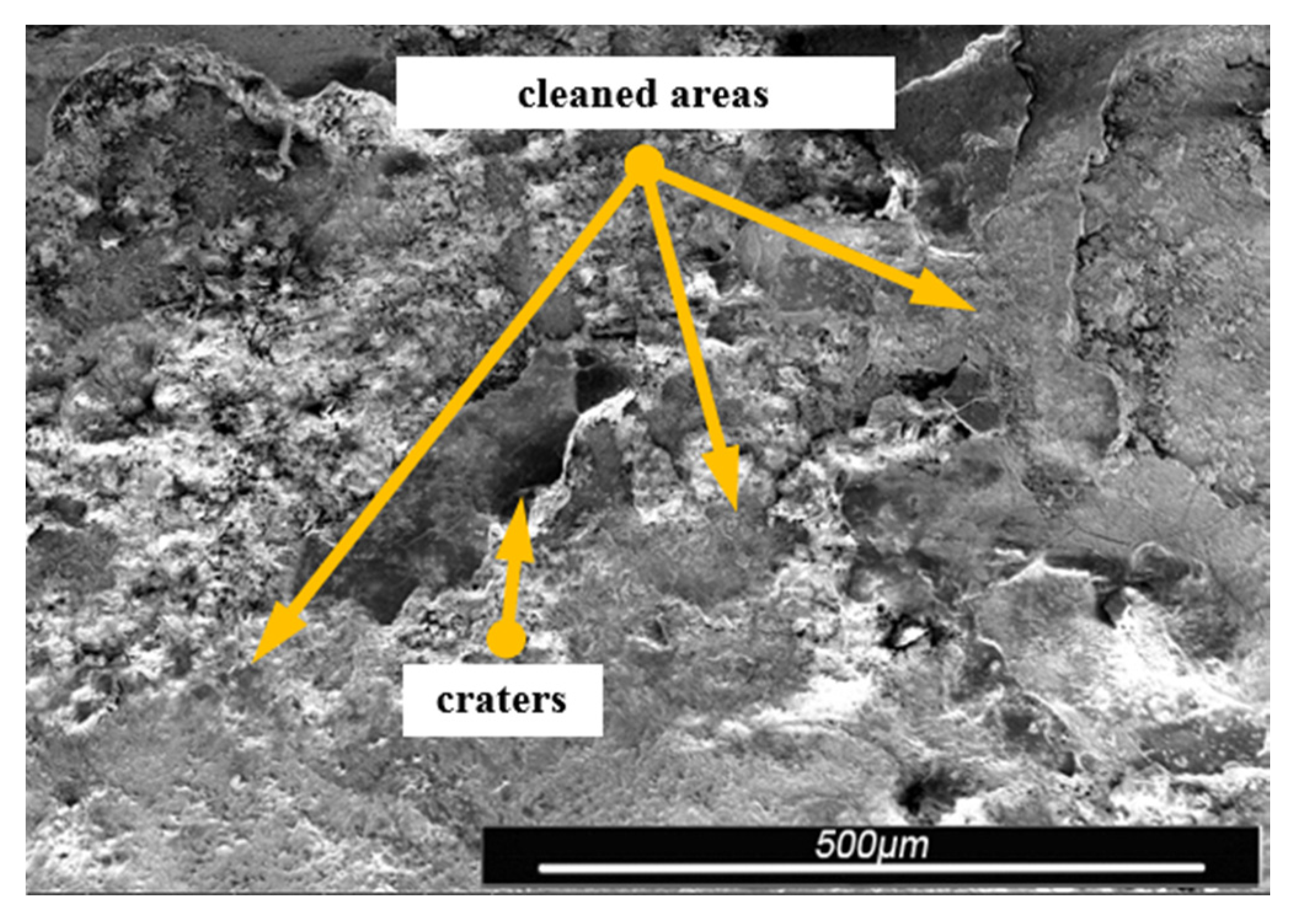

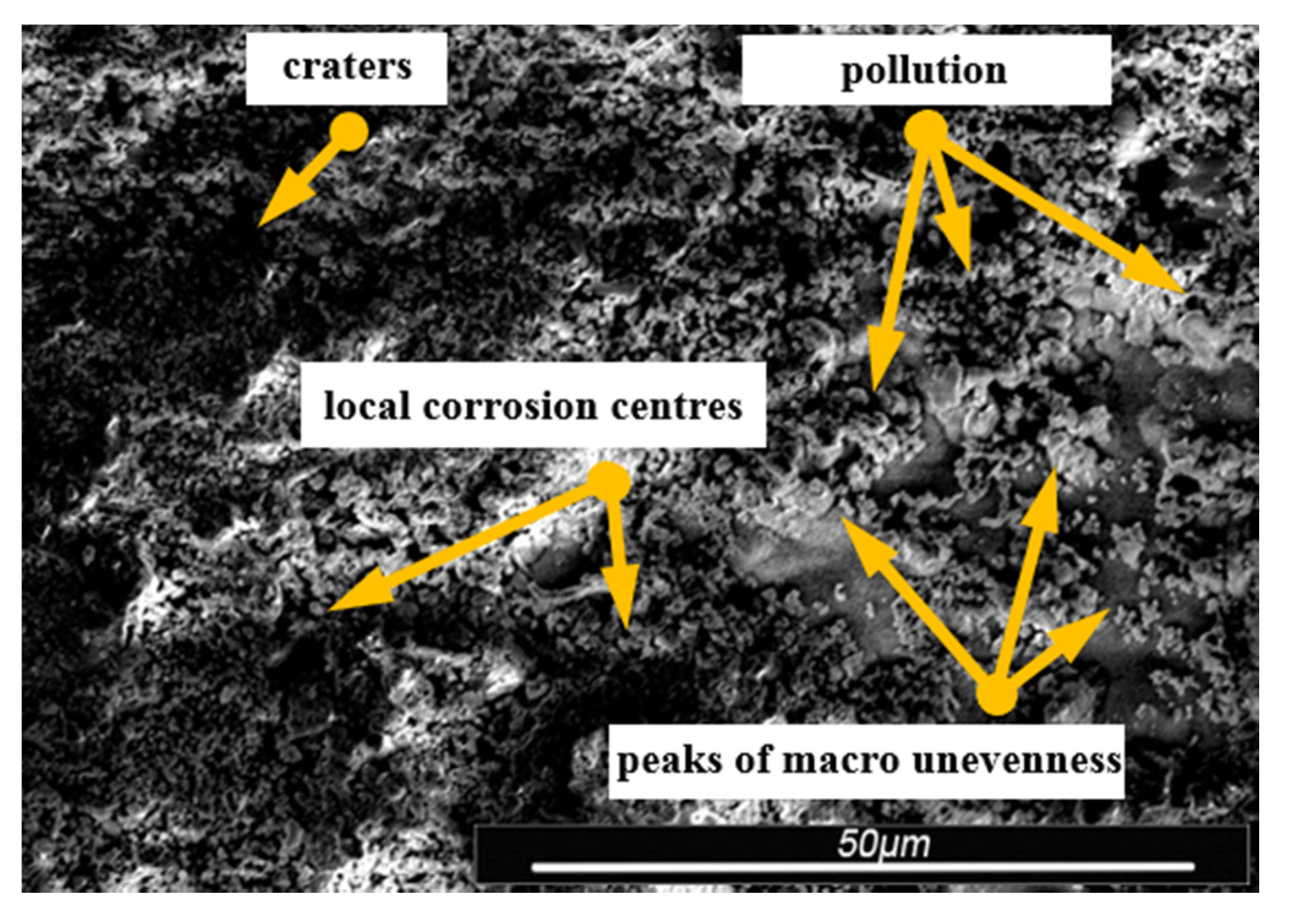

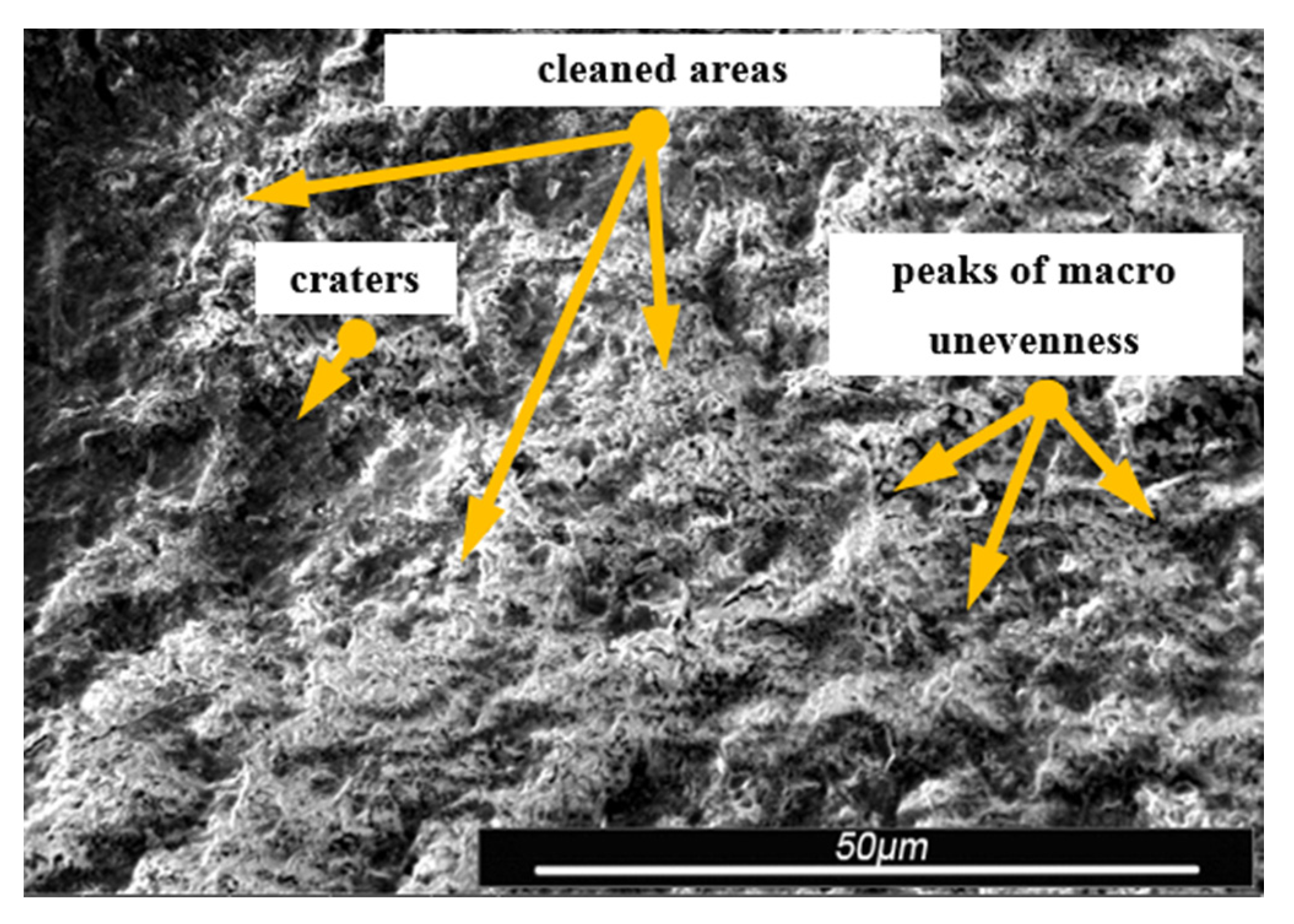

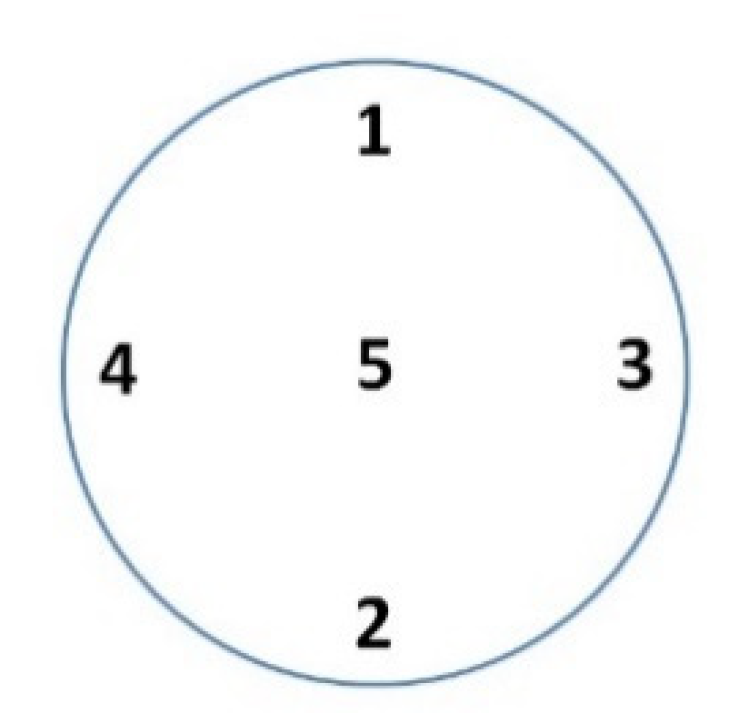

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Khonsari, M.M.; Booser, E.R. Applied Tribology: Bearing Design and Lubrication; Princeton University Press: Princeton, NJ, USA, 2017. [Google Scholar]

- Fernandez, I.; Lundgren, K.; Zandi, K. Evaluation of corrosion level of naturally corroded bars using different cleaning methods, computed tomography, and 3D optical scanning. Mater. Struct. 2018, 51, 51–78. [Google Scholar] [CrossRef]

- Molina Montasell, N.; Ferrer, B. Brake Rotor Corrosion and Friction Cleaning Effect on Vehicle Judder Performance; Technical Paper 2019-01-2115; SAE International: Troy, MI, USA, 15 September 2019. [Google Scholar]

- Paszeczko, M.; Dziedzic, K.; Mendyk, E.; Jozwik, J. Chemical and phase composition of the friction surfaces Fe-Mn-C-B-Si-Ni-Cr hardfacing coatings. J. Tribol. 2018, 1, 140. [Google Scholar]

- Jozwik, J. Evaluation of tribological properties and condition of Ti6Al4V titanium alloy surface. Teh. Vjesn. 2018, 25, 170–175. [Google Scholar]

- Pashechko, M.; Montusiewicz, J.; Dziedzic, K.; Jozwik, J. Multicriterion Assessment of Wear Resistance of Fe–Mn–C–B Eutectic Coatings Alloyed with Si, Ni, and Cr. Powder Met. Met. Ceram. 2017, 56, 316–322. [Google Scholar]

- Ralf, K.; Pilninger, J. Prediction and Classification of tools. Durban 2002, 1, 2226–2236. [Google Scholar]

- Kalinowska-Ozgowicz, E.; Korga, S. Wear resistance of structural steels as a result of boronising operations. Tribologia 2018, 49, 37–44. [Google Scholar] [CrossRef]

- Xie, X.; Huang, Q.; Long, J.; Ren, Q.; Hu, W.; Liu, S. A new monitoring method for metal rust removal states in pulsed laser derusting via acoustic emission techniques. J. Mater. Process. Technol. 2020, 275, 1–12. [Google Scholar] [CrossRef]

- Sidun, P.; Łukaszewicz, A. Verification of ram-press pipe bending process using elastoplastic FEM model. Acta Mech. Autom. 2017, 11, 47–52. [Google Scholar]

- Yang, L.; Zhang, P.; Shi, J.; Liang, L.; Tian, W.B.; Zhang, Y.M.; Sun, Z.M. Dual Electrolytic Plasma Processing for Steel Surface Cleaning and Passivation. J. Mater. Eng. Perform. 2017, 26, 5009–5015. [Google Scholar] [CrossRef]

- Parfenova, E.V.; Yerokhinb, A.; Nevyantsevaa, R.R.; Gorbatkova, M.V.; Liang, C.J.; Matthews, A. Towards smart electrolytic plasma technologies: An overview of methodological approaches to process modelling. Surf. Coat. Technol. 2015, 269, 2–22. [Google Scholar] [CrossRef]

- Bartha, L.; Koltay, E.; Mórik, G. Abrasive blast cleaning method for the renewal of worn-out acceleration tubes. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 1996, 111, 157–160. [Google Scholar] [CrossRef]

- Vachtsevanos, G.; Natarajan, K.A.; Rajamani, R.; Sandborn, P. Corrosion Processes, 1st ed.; Springer: New York, NY, USA, 2020. [Google Scholar]

- Duo, J. Corrosion Resistance of Stainless Steel Structures in High Temperature Polluted Water Environment. Ekoloji Derg. 2019, 107, 3079–3088. [Google Scholar]

- Li, X. Study on Corrosion Status and Control Strategies in Manufacturing and Public Utilities Field in China. In The Cost of Corrosion in China; Hou, B., Ed.; Springer: Singapore, 2019; pp. 765–941. [Google Scholar]

- Golovin, V.A.; Krasheninnikov, A.I.; Garkavenko, E.A.; Oleinik, S.V.; Shchelkov, V.A. Features of development of corrosion and inhibition of steel upon abrasive-dilatant cleaning. Prot. Met. Phys. Chem. Surf. 2015, 51, 1160–1164. [Google Scholar] [CrossRef]

- Aulin, V.; Lyashuk, O.; Hrynkiv, A.; Lysenko, S.; Zamota, T.; Vovk, Y.; Pankov, A.; Tykhyi, A.; Horkunenko, A. Determination of the Rational Composition of the Additive to Oil with the Use of the Katerynivka Friction Geo Modifier. Tribol. Ind. 2019, 41, 548–562. [Google Scholar] [CrossRef]

- Jozwik, J.; Dziedzic, K.; Usydus, I.; Krolczyk, G. HS 6-5-2 steel surface layer development in carbonitriding with zero flow method web of science. Teh. Vjesn. 2016, 23, 1405–1409. [Google Scholar]

- Winkler, E.M. The importance of air pollution in the corrosion of stone and metals. Eng. Geol. 1970, 4, 327–334. [Google Scholar] [CrossRef]

- Momber, A.W.; Greverath, W.D. Surface Preparation Standards for Steel Substrates—A Critical Review. J. Prot. Coat. Linings 2004, 21, 48–52. [Google Scholar]

- Dziedzic, K.; Paszeczko, M.; Barszcz, M.; Józwik, J. Structure and construction assessment of the surface layer of hardfaced coating after friction. Adv. Sci. Technol. Res. J. 2017, 3, 253–260. [Google Scholar] [CrossRef]

- Paszeczko, M.; Józwik, J.; Dziedzic, K.; Karolus, M.; Usydus, I. Surface hardening of HS6-5-2 quick-cuttingsteel in the course of chemical thermal treatment. Mater. Sci. 2017, 52, 834–840. [Google Scholar]

- Gösta, W. An Introduction to Corrosion and Protection of Metals; Springer: Heidelberg, Germany, 1985. [Google Scholar]

- ASTM G1-03(2017)e1. Standard Practice for Preparing, Cleaning, and Evaluation Corrosion Test Specimens; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Pytka, J.; Tarkowski, T.; Budzynski, P.; Jozwik, J. Method for Testing and Evaluating Grassy Runway Surface. J. Aircr. 2017, 54, 229–234. [Google Scholar] [CrossRef]

- Viswanathan, S. Progress in rust converters. Prog. Org. Coat. 2019, 127, 88–99. [Google Scholar]

- Yasser, M.; Wang, J. Impact Abrasive Machining. In Machining with Abrasives; Springer: Boston, MA, USA, 2010; pp. 385–419. [Google Scholar]

- Kim, I.; Jeong, Y.S. Fatigue strength improvement of welded joints by blast cleaning for subsequent painting. Int. J. Steel Struct. 2013, 13, 11–20. [Google Scholar] [CrossRef]

- Petiti, C.; Toniolo, L.; Gulotta, D.; Mariani, B.; Goidanich, S. Effects of cleaning procedures on the long-term corrosion behavior of bronze artifacts of the cultural heritage in outdoor environment. Environ. Sci. Pollut. Res. 2020, 27, 13081–13094. [Google Scholar] [CrossRef] [PubMed]

- Levy, A.V. Erosion and erosion-corosion of metals. Corossion 1995, 51, 872–883. [Google Scholar] [CrossRef]

- Jozwik, J.; Ostrowski, D.; Milczarczyk, R.; Krolczyk, G. Analysis of relation between the 3D printer laser beam power and the surface morphology properties in Ti-6Al-4V titanium alloy parts. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 215. [Google Scholar] [CrossRef]

- Momber, A. Blast Cleaning Technology; Springer: Heidelberg, Germany, 2008; pp. 339–347. [Google Scholar]

- Kruk, A.; Wusatowska-Sarnek, A.M.; Zietara, M.; Jemielniak, K.; Siemiatkowski, Z.; Czyrska-Filemonowicz, A. Characterization on white etching layer formed during ceramic milling of Inconel 718. Met. Mater. Int. 2018, 24, 1036–1045. [Google Scholar] [CrossRef]

- Dziedzic, K.; Zubrzycka-Wrobel, J.; Jozwik, J.; Barszcz, M.; Siwak, P.; Chalas, R. Research on tribological properties of dental composite materials. Adv. Sci. Technol. Res. J. 2016, 10, 144–149. [Google Scholar] [CrossRef]

- Golovanchikov, A.B.; Vorotneva, S.B. Promising Devices for Mechanical and Hydroabrasive Cleaning of Heat-Exchange Surfaces. Chem. Pet. Eng. 2015, 51, 20–25. [Google Scholar] [CrossRef]

- Haldar, B.; Ghara, T.; Ansari, R.; Das, S.; Saha, P. Abrasive jet system and its various applications in abrasive jet machining, erosion testing, shot-peening, and fast cleaning. Mater. Today Proc. 2018, 5, 13061–13068. [Google Scholar] [CrossRef]

- Józwik, J.; Dziedzic, K.; Barszcz, M.; Paszeczko, M. Analysis and Comparative Assessment of Basic Tribological Properties of Selected Polymer Composites. Materials 2020, 13, 75. [Google Scholar] [CrossRef]

- Łukaszewicz, A. Nonlinear numerical model of heat generation in the rotary friction welding. J. Frict. Wear 2018, 39, 476–482. [Google Scholar] [CrossRef]

- PN-ISO 8501-1. Preparation of Steel Substrates before Application of Paints and Related Products—Visual Assessment of Surface Cleanliness—Part 1: Rust Grades and Preparation Grades of Uncoated Steel Substrates and of Steel Substrates after Overall Removal of Previous Coatings; Polish Committee for Standardization: Warszawa, Poland, 2008. [Google Scholar]

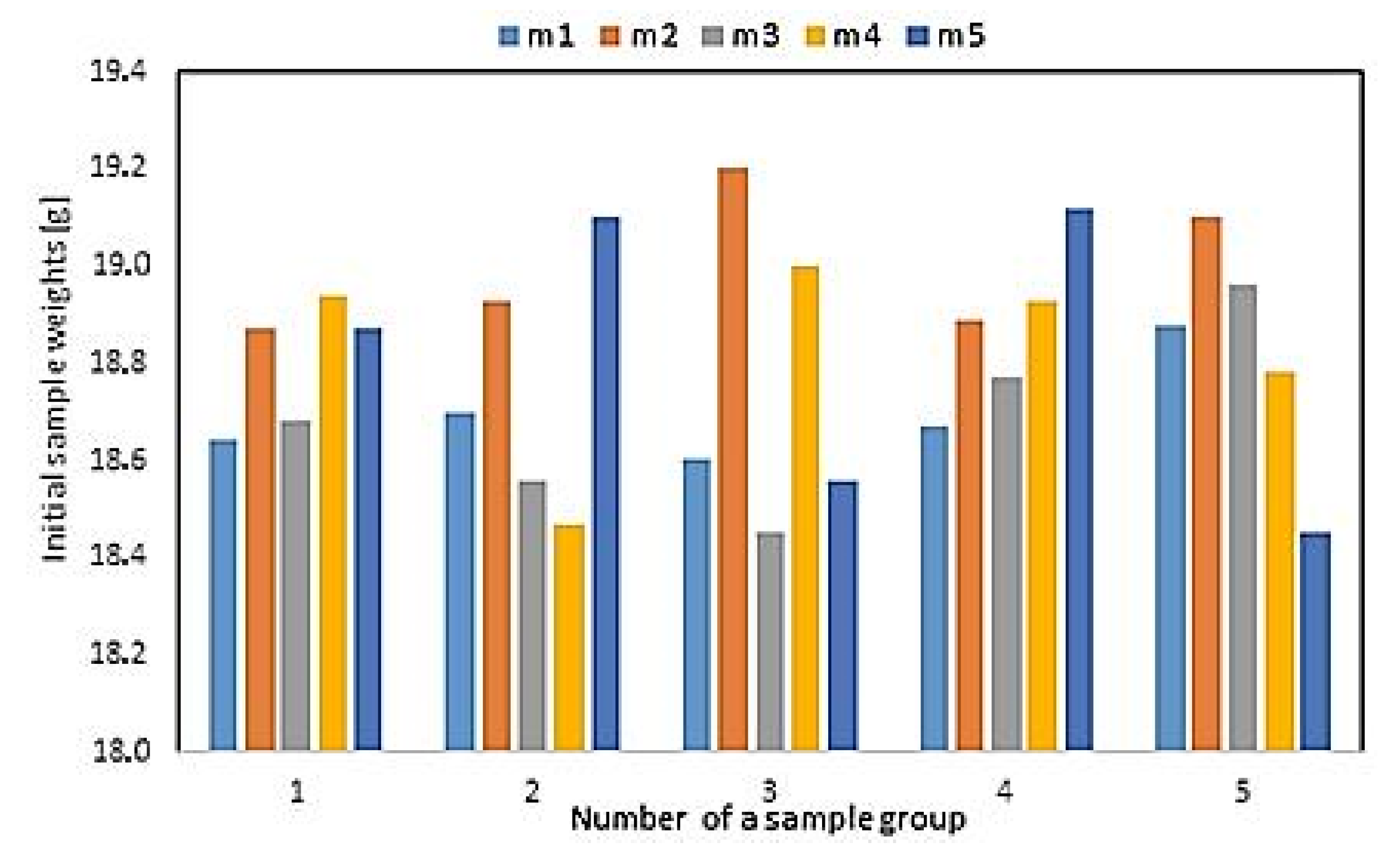

| Samples Group Number | Weight of the 1st Sample (g) | Weight of the 2nd Sample (g) | Weight of the 3rd Sample (g) | Weight of the 4th Sample (g) | Weight of the 5th Sample (g) |

|---|---|---|---|---|---|

| Group 1 | 18.64 | 18.70 | 18.60 | 18.67 | 18.88 |

| Group 2 | 18.87 | 18.93 | 19.20 | 18.89 | 19.10 |

| Group 3 | 18.68 | 18.56 | 18.45 | 18.77 | 18.96 |

| Group 4 | 18.94 | 18.47 | 19.00 | 18.93 | 18.78 |

| Group 5 | 18.87 | 19.10 | 18.56 | 19.12 | 18.45 |

| Samples Group Number | Abrasive Type | Average Weight of Samples in the Group; before Cleaning (g) | Average Weight of Samples in the Group; after Cleaning (g) | Average Sample Weight Loss in the Group (g) | Standard Deviation |

|---|---|---|---|---|---|

| Group 1 | grinding stone | 18.80 | 18.57 | 0.23 | 0.10 |

| Group 2 | basalt | 18.75 | 18.56 | 0.19 | 0.14 |

| Group 3 | fine gravel | 18.76 | 18.55 | 0.21 | 0.19 |

| Group 4 | glass | 18.87 | 18.68 | 0.19 | 0.21 |

| Group 5 | sand | 18.87 | 18.68 | 0.19 | 0.30 |

| Description | Name | Unit | Value | |||||

|---|---|---|---|---|---|---|---|---|

| Group 1 | Group 2 | Group 3 | Group 4 | Group 5 | Standard Deviation | |||

| Average height of selected area | Sa | μm | 0.69 | 0.81 | 1.44 | 0.87 | 0.59 | 0.33 |

| Root mean square height of selected area | Sq | μm | 0.96 | 1.24 | 2.32 | 1.21 | 0.83 | 0.58 |

| Maximum peak height of selected area | Sp | μm | 19.38 | 8.32 | 12.74 | 20.54 | 14.45 | 4.99 |

| Maximum valley depth of selected area | Sv | μm | 10.83 | 21.46 | 28.68 | 8.66 | 10.08 | 8.74 |

| Maximum height of selected area | Sz | μm | 30.22 | 29.79 | 41.42 | 29.21 | 24.53 | 6.23 |

| Ten-point height of selected area | S10z | μm | 24.17 | 27.54 | 37.28 | 25.47 | 20.31 | 6.34 |

| Skewness of selected area | Ssk | - | −0.92 | −3.35 | −3.41 | 0.05 | −0.81 | 1.58 |

| Kurtosis of selected area | Sku | - | 13.03 | 35.57 | 26.52 | 10.74 | 9.58 | 11.44 |

| Root mean square gradient of selected area | Sdq | - | 0.17 | 0.19 | 0.21 | 0.21 | 0.17 | 0.02 |

| Developed interfacial area ratio of selected area | Sdr | % | 1.38 | 1.90 | 2.14 | 2.16 | 1.54 | 0.35 |

| E Flatness using least squares reference plane of selected area | FLTt | μm | 30.22 | 29.79 | 41.42 | 29.21 | 24.53 | 6.23 |

| Lambda C: cutoff wavelength of selected area | Lc | μm | 800 | 800 | 800 | 800 | 800 | 0 |

| Place of Measurement | Sample Number | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | ||||

| A | B | A | B | A | B | |

| 1 | 401.5 | 482.7 | 440.2 | 564.8 | 579.7 | 544.5 |

| 376.6 | 464.1 | 532.6 | 529.4 | 505.9 | 486.2 | |

| 391.1 | 499.1 | 409.3 | 568.2 | 529.7 | 432.8 | |

| 368.8 | 498.4 | 422.5 | 580.4 | 508.6 | 454.7 | |

| 2 | 475.7 | 495.5 | 571.1 | 510.5 | 548.6 | 602.1 |

| 472.1 | 488.9 | 514.8 | 508.6 | 523.3 | 554.6 | |

| 495.8 | 493.7 | 469.4 | 434.0 | 440.0 | 480.3 | |

| 429.9 | 526.4 | 493.0 | 492.7 | 459.0 | 612.9 | |

| 3 | 361.6 | 525.5 | 414.2 | 560.1 | 547.4 | 458.8 |

| 378.3 | 482.5 | 435.9 | 472.8 | 575.5 | 508.9 | |

| 392.2 | 502.8 | 465.0 | 413.8 | 525.0 | 471.1 | |

| 427.8 | 518.3 | 483.7 | 522.2 | 451.8 | 560.8 | |

| 4 | 338.8 | 480.0 | 467.3 | 524.1 | 507.8 | 515.0 |

| 459.5 | 529.7 | 445.4 | 550.1 | 563.9 | 565.1 | |

| 371.6 | 461.8 | 541.2 | 519.7 | 588.9 | 522.7 | |

| 353.3 | 440.0 | 478.8 | 581.0 | 594.3 | 486.9 | |

| 5 | 346.0 | 442.1 | 503.6 | 550.1 | 564.8 | 600.7 |

| 371.1 | 459.0 | 510.7 | 543.3 | 540.1 | 547.4 | |

| 358.5 | 480.0 | 489.9 | 560.8 | 466.2 | 502.5 | |

| 319.9 | 442.8 | 557.7 | 548.0 | 489.2 | 519.4 | |

| Average (HV) | 394.51 | 485.67 | 482.32 | 526.73 | 525.49 | 521.37 |

| Standard deviation (HV) | 49.70 | 27.82 | 46.79 | 45.41 | 46.70 | 51.49 |

| Rank | Abrasive Fraction (mm) | Abrasive Name |

|---|---|---|

| 1 (the best) | 0.1–0.4 | fine gravel |

| 2 | 0.1–10.0 | grinding stone |

| 3 | 0.1–15.0 | glass |

| 4 | 0.2–0.5 | sand |

| 5 (the worst) | 0.2–0.8 | basalt |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korga, S.; Żyła, K.; Józwik, J. Analysis of the Abrasive-Type Influence on the Effectiveness of Rotary Cleaning of Machine Parts with Complex Geometric Features. Materials 2020, 13, 5144. https://doi.org/10.3390/ma13225144

Korga S, Żyła K, Józwik J. Analysis of the Abrasive-Type Influence on the Effectiveness of Rotary Cleaning of Machine Parts with Complex Geometric Features. Materials. 2020; 13(22):5144. https://doi.org/10.3390/ma13225144

Chicago/Turabian StyleKorga, Sylwester, Kamil Żyła, and Jerzy Józwik. 2020. "Analysis of the Abrasive-Type Influence on the Effectiveness of Rotary Cleaning of Machine Parts with Complex Geometric Features" Materials 13, no. 22: 5144. https://doi.org/10.3390/ma13225144

APA StyleKorga, S., Żyła, K., & Józwik, J. (2020). Analysis of the Abrasive-Type Influence on the Effectiveness of Rotary Cleaning of Machine Parts with Complex Geometric Features. Materials, 13(22), 5144. https://doi.org/10.3390/ma13225144