Comparison of Sandstone Damage Measurements Based on Non-Destructive Testing

Abstract

:1. Introduction

2. Materials and Methods

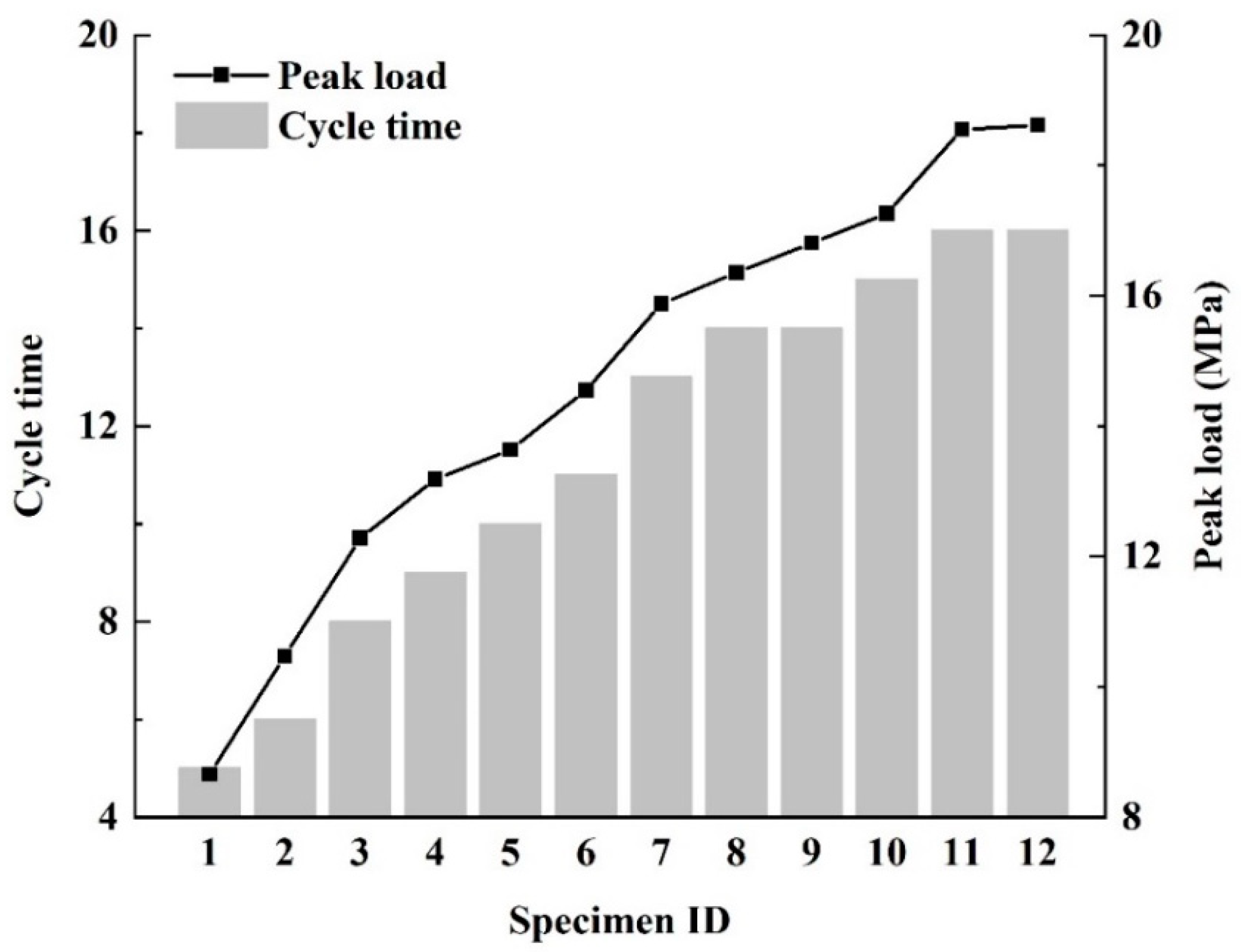

2.1. Sandstone Specimens and Pretreatment

2.2. Non-Destructive Testing

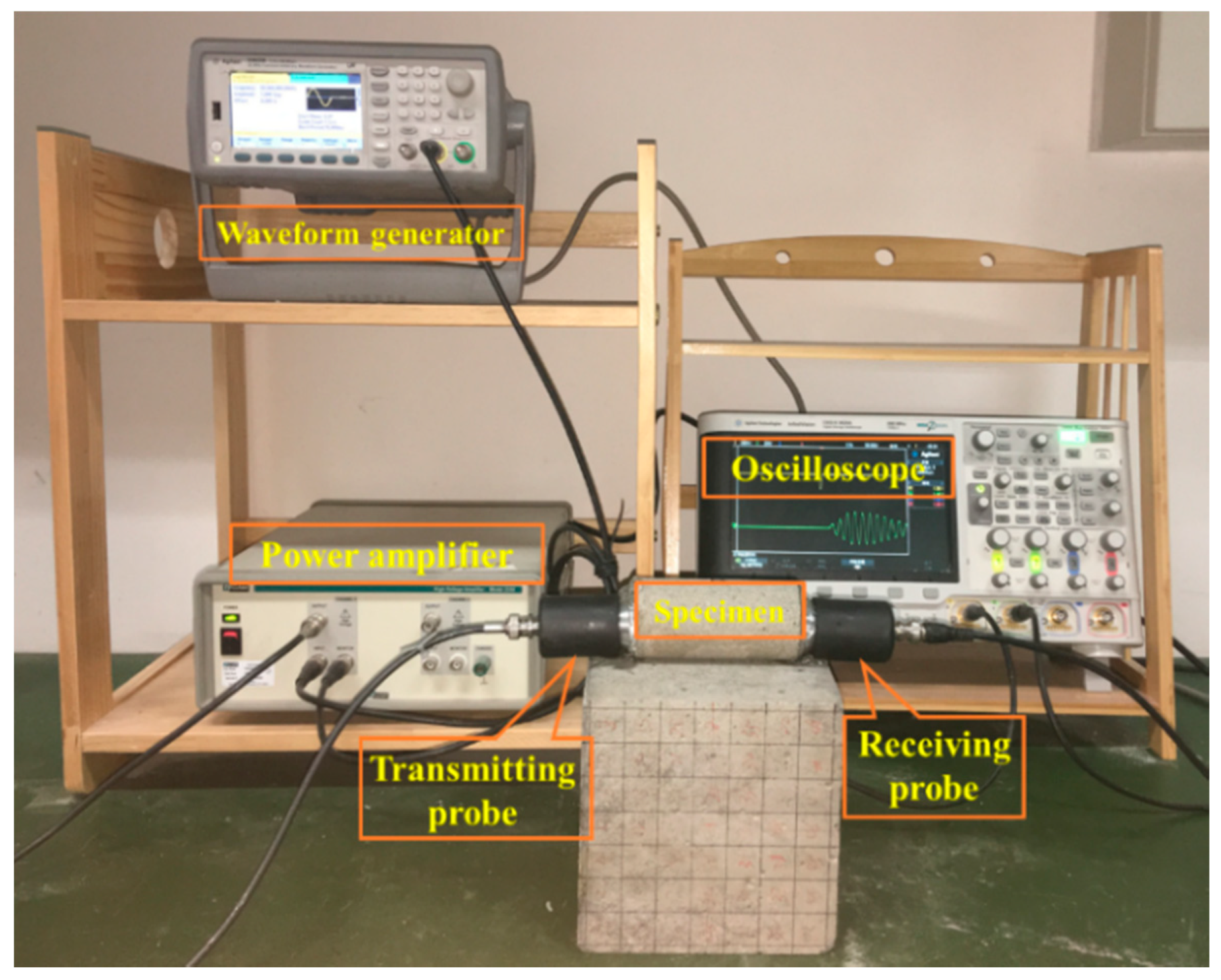

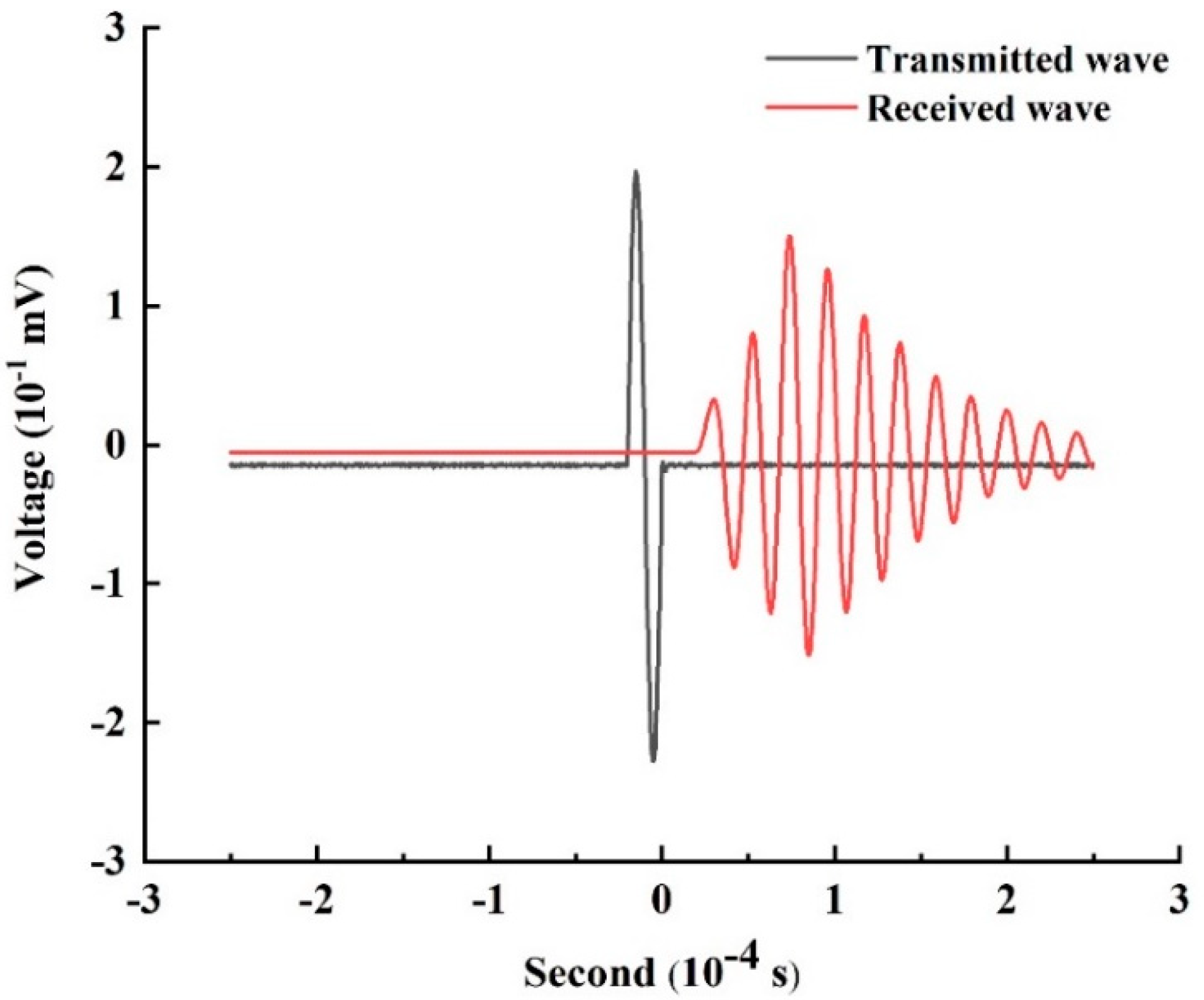

2.2.1. Ultrasonic Test

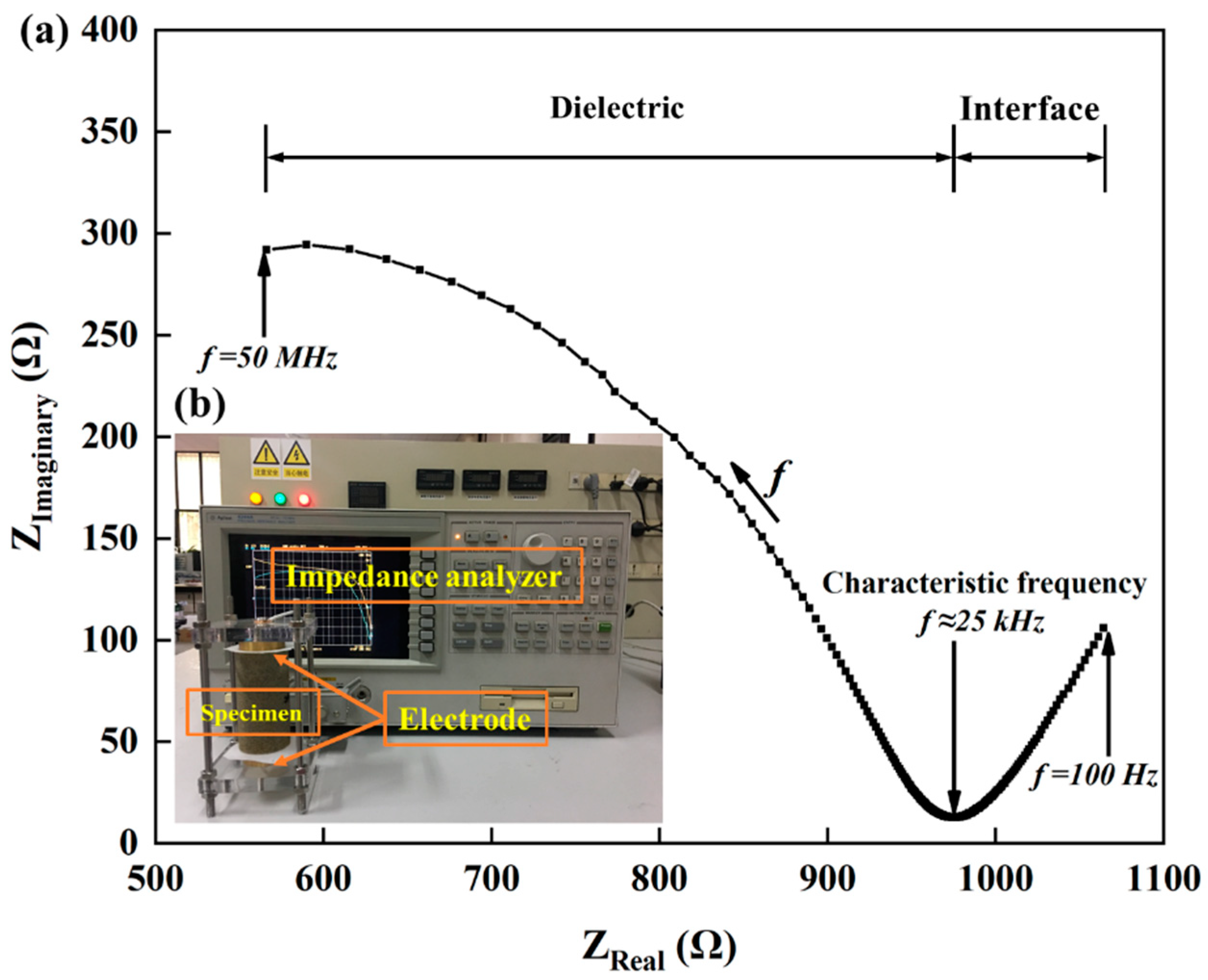

2.2.2. EIS Testing

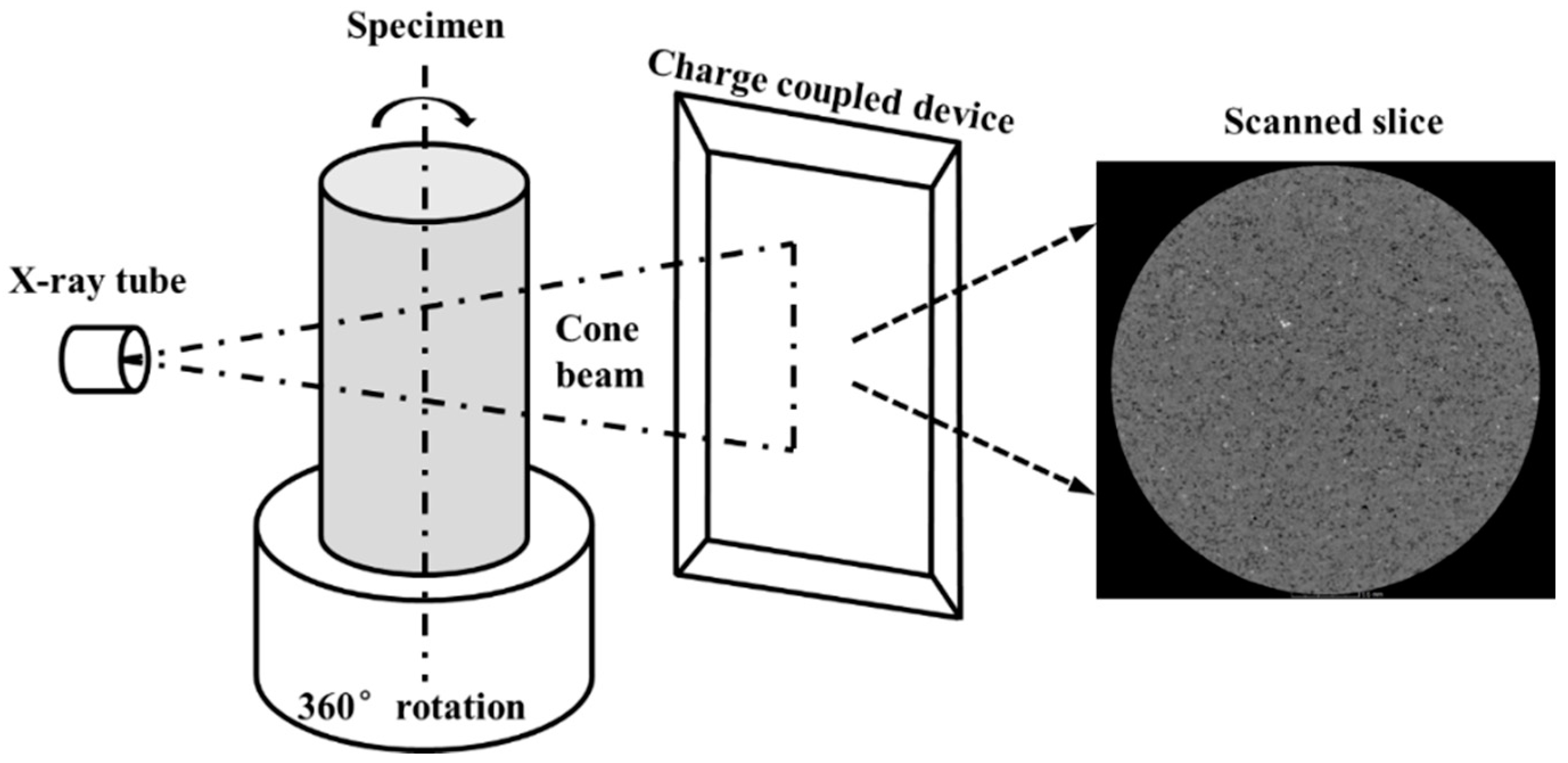

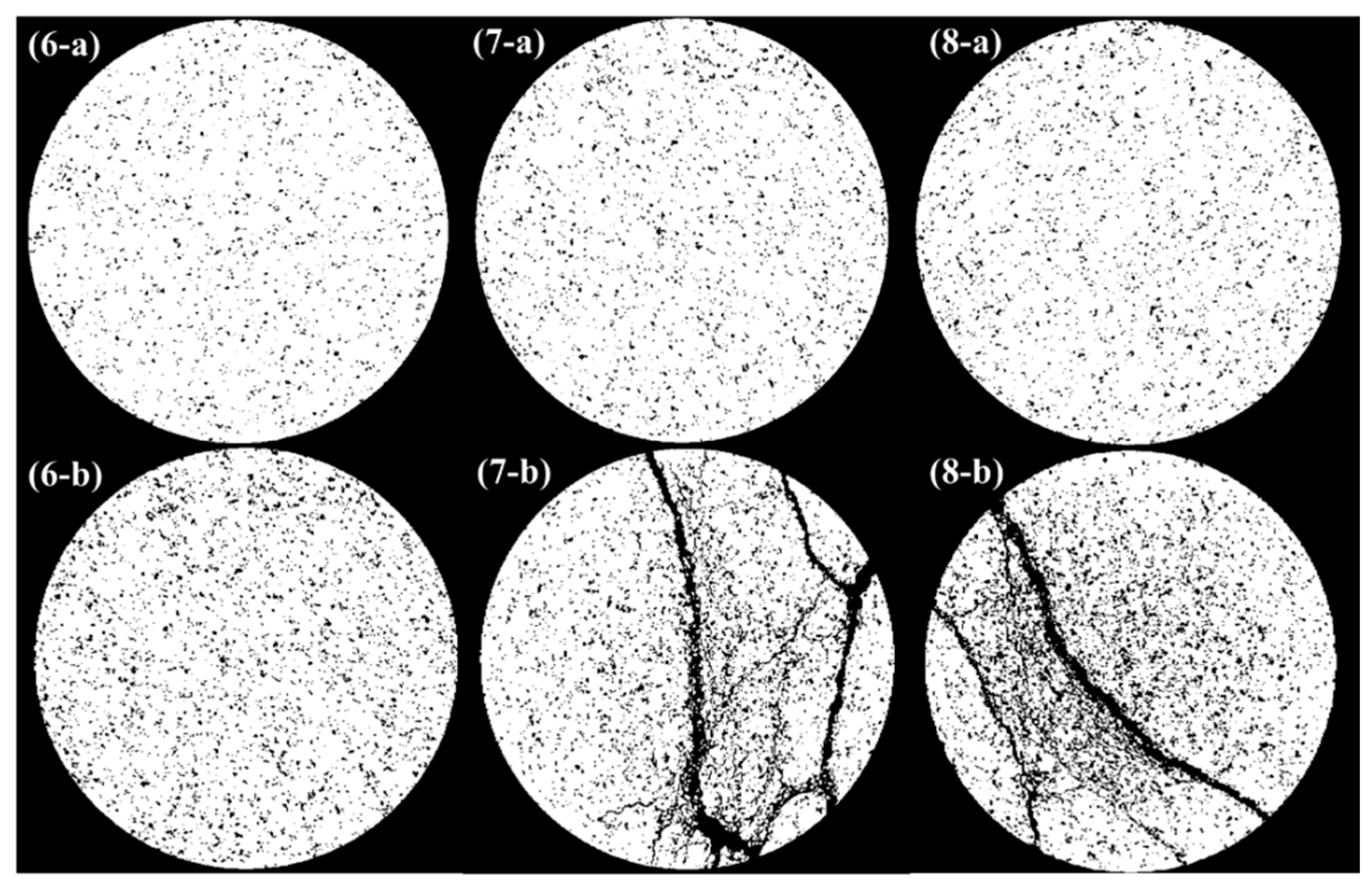

2.2.3. CT Scan Test

3. Results

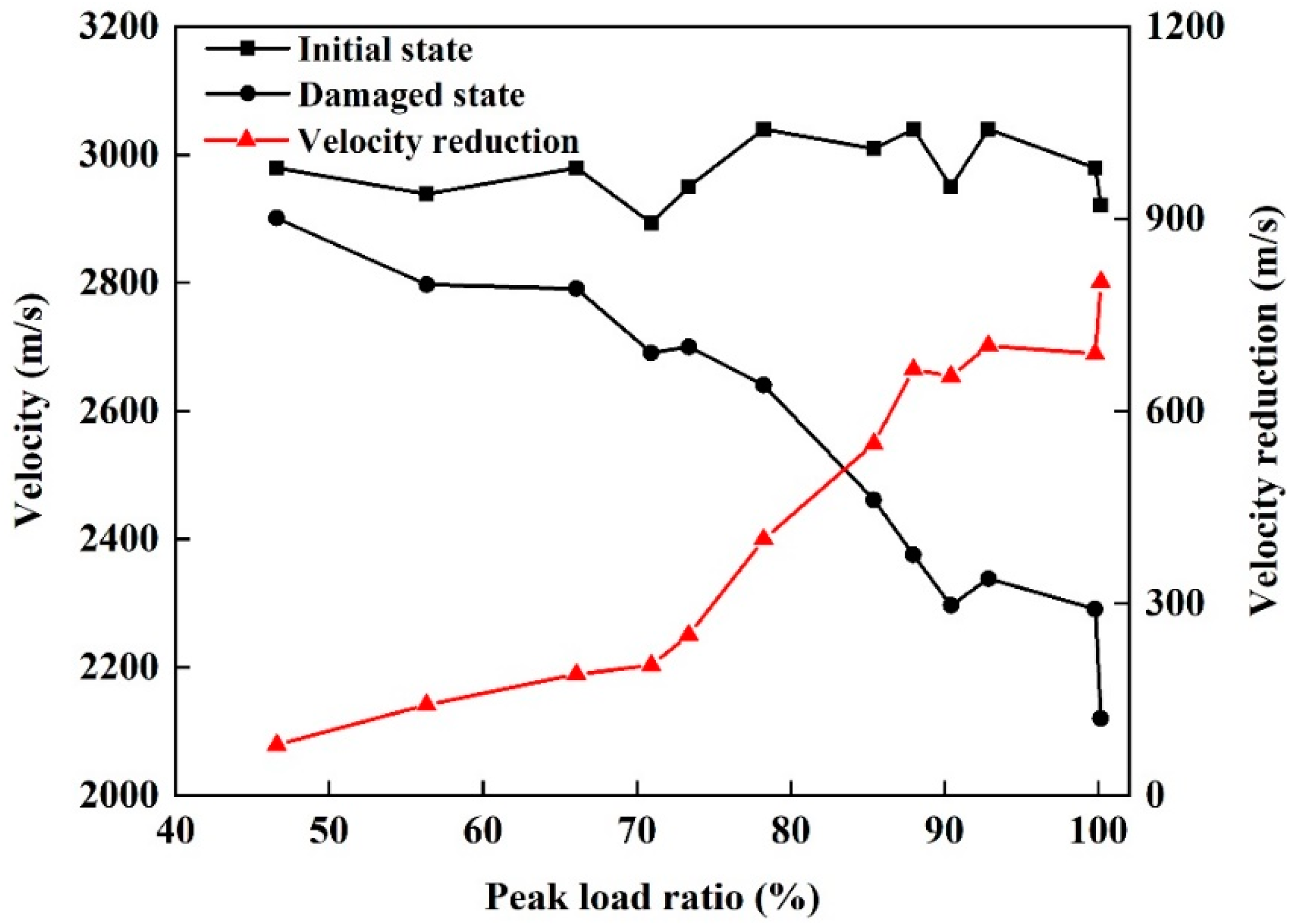

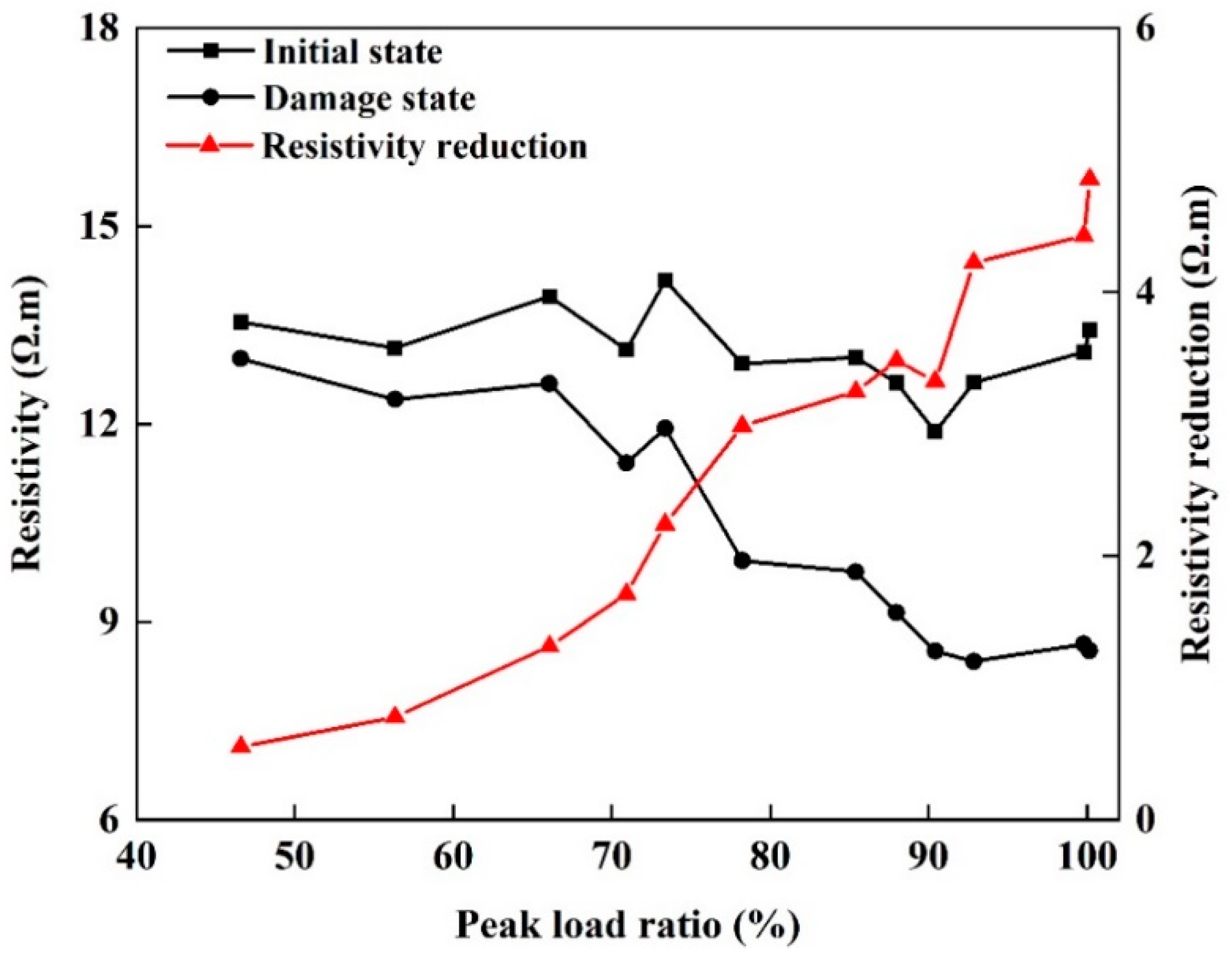

3.1. NDT Test Results

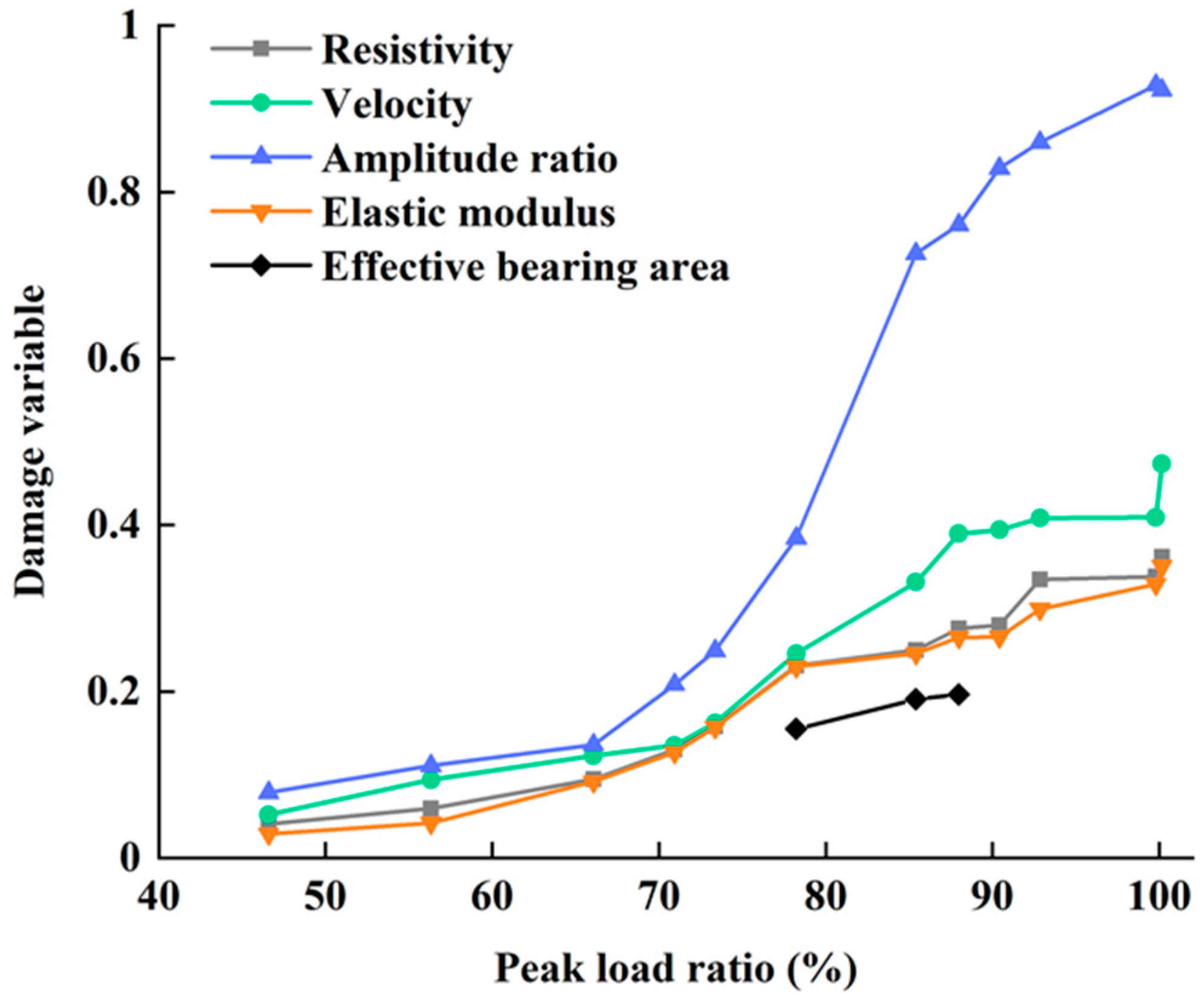

3.2. Damage Variables for Sandstone

4. Discussion

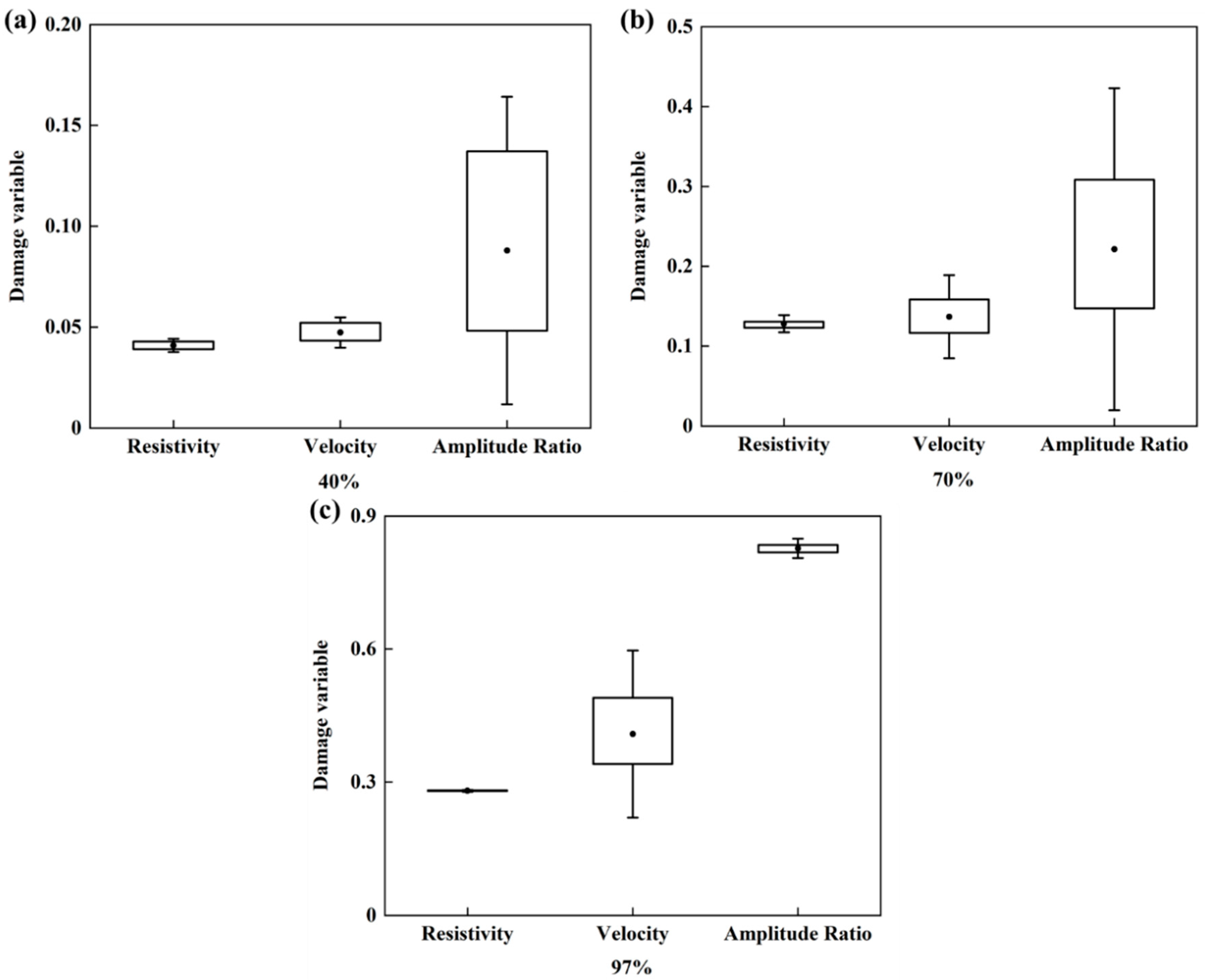

4.1. Stability of Damage Measurements

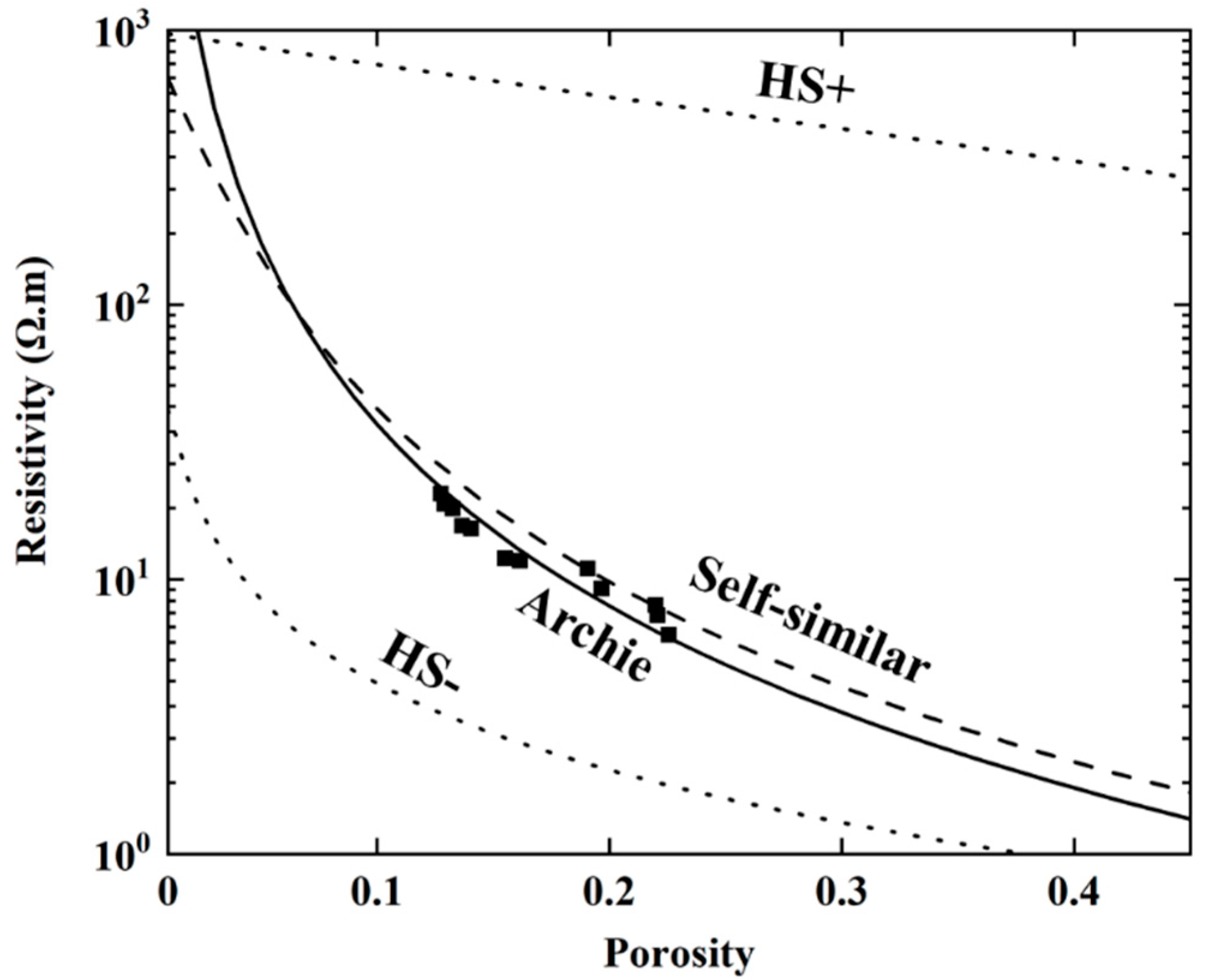

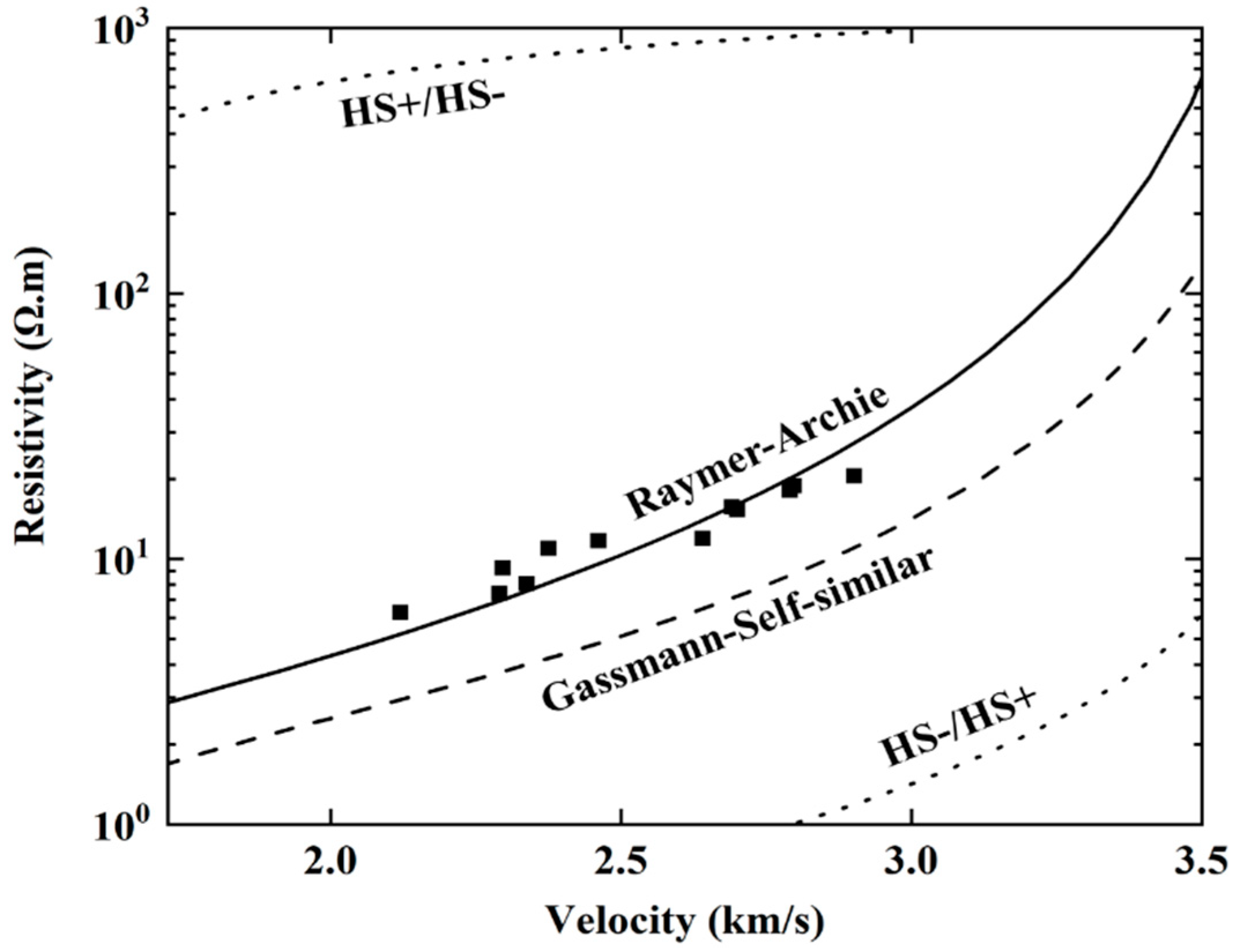

4.2. Mechanisms Behind Damage Measurements

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bernardi, D.; DeJong, J.T.; Montoya, B.M.; Martinez, B.C. Bio-bricks: Biologically cemented sandstone bricks. Constr. Build. Mater. 2014, 55, 462–469. [Google Scholar] [CrossRef]

- Dvorkin, J.; Brevik, I. Diagnosing high-porosity sandstones: Strength and permeability from porosity and velocity. Geophysics 1999, 64, 795–799. [Google Scholar] [CrossRef]

- Wang, Y.H.; Liu, Y.F.; Ma, H.T. Changing regularity of rock damage variable and resistivity under loading condition. Saf. Sci. 2012, 50, 718–722. [Google Scholar] [CrossRef]

- Shah, A.A.; Ribakov, Y. Non-destructive evaluation of concrete in damaged and undamaged states. Mater. Des. 2009, 30, 3504–3511. [Google Scholar] [CrossRef]

- Selleck, S.F.; Landis, E.N.; Peterson, M.L.; Shah, S.P.; Achenbach, J.D. Ultrasonic investigation of concrete with distributed damage. Aci. Mater. J. 1998, 95, 27–36. [Google Scholar]

- Alemu, B.L.; Aker, E.; Soldal, M.; Johnsen, Ø.; Aagaard, P. Effect of sub-core scale heterogeneities on acoustic and electrical properties of a reservoir rock: A CO2 flooding experiment of brine saturated sandstone in a computed tomography scanner. Geophys. Prospect. 2013, 61, 235–250. [Google Scholar] [CrossRef]

- Heap, M.J.; Vinciguerra, S.; Meredith, P.G. The evolution of elastic moduli with increasing crack damage during cyclic stressing of a basalt from Mt. Etna volcano. Tectonophysics 2009, 471, 153–160. [Google Scholar] [CrossRef]

- Antonaci, P.; Bruno, C.L.E.; Gliozzi, A.S.; Scalerandi, M. Monitoring evolution of compressive damage in concrete with linear and nonlinear ultrasonic methods. Cem. Concr. Res. 2010, 40, 1106–1113. [Google Scholar] [CrossRef]

- Yim, H.J.; Kwak, H.G.; Kim, J.H. Wave attenuation measurement technique for nondestructive evaluation of concrete. Nondestruct. Test. Eva. 2012, 27, 81–94. [Google Scholar] [CrossRef]

- Müller, T.M.; Gurevich, B.; Lebedev, M. Seismic wave attenuation and dispersion resulting from wave-induced flow in porous rocks—A review. Geophysics 2010, 75, 147–164. [Google Scholar] [CrossRef]

- Ranade, R.; Zhang, J.; Lynch, J.P.; Li, V.C. Influence of micro-cracking on the composite resistivity of Engineered Cementitious Composites. Cem. Concr. Res. 2014, 58, 1–12. [Google Scholar] [CrossRef]

- Kahraman, S.; Alber, M. Predicting the physico-mechanical properties of rocks from electrical impedance spectroscopy measurements. Int. J. Rock Mech. Min. 2006, 43, 543–553. [Google Scholar] [CrossRef]

- Zisser, N.; Nover, G. Anisotropy of permeability and complex resistivity of tight sandstones subjected to hydrostatic pressure. J. Appl. Geophys. 2009, 68, 356–370. [Google Scholar] [CrossRef]

- Yin, D.H.; Xu, Q.J. Defining the damage variable of sandstone from electrical impedance spectroscopy measurements. In Proceedings of the 14th International Congress on Rock Mechanics and Rock Engineering, Foz do Iguacu, Brazil, 13–18 September 2019; pp. 1053–1060. [Google Scholar]

- Wang, Y.; Li, X.; Zhang, B.; Wu, Y. Meso-damage cracking characteristics analysis for rock and soil aggregate with CT test. Sci. China Technol. Sci. 2014, 57, 1361–1371. [Google Scholar] [CrossRef]

- Yin, S.; Zhao, D.; Zhai, G. Investigation into the characteristics of rock damage caused by ultrasonic vibration. Int. J. Rock Mech. Min. 2016, 84, 159–164. [Google Scholar] [CrossRef]

- Landis, E.N.; Zhang, T.; Nagy, E.N.; Nagy, G.; Franklin, W.R. Cracking, damage and fracture in four dimensions. Mater. Struct 2007, 40, 357–364. [Google Scholar] [CrossRef]

- Shah, A.A.; Hirose, S. Nonlinear ultrasonic investigation of concrete damaged under uniaxial compression step loading. J. Mater. Civil. Eng. 2010, 22, 476–484. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, N.; Feng, X.; Kan, J.; Pan, D.; Qian, D. Experimental investigation of sandstone under cyclic loading: Damage assessment using ultrasonic wave velocities and changes in elastic modulus. Shock Vib. 2018, 2018, 1–13. [Google Scholar] [CrossRef]

- Alves, M.l.; Yu, J.; Jones, N. On the elastic modulus degradation in continuum damage mechanics. Comput. Struct. 2000, 76, 703–712. [Google Scholar] [CrossRef]

- Lemaitre, J.; Dufailly, J. Damage measurements. Eng. Fract. Mech. 1987, 28, 643–661. [Google Scholar] [CrossRef]

- Kahraman, S.; Alber, M. Electrical impedance spectroscopy measurements to estimate the uniaxial compressive strength of a fault breccia. Bull. Mater. Sci. 2014, 37, 1543–1550. [Google Scholar] [CrossRef]

- Gomaa, M.M.; Alikaj, P. Effect of electrode contact impedance on A.C. electrical properties of a wet hematite sample. Mar. Geophys. Res. 2010, 30, 265–276. [Google Scholar] [CrossRef]

- Lizarazo-Marriaga, J.; Higuera, C.; Claisse, P. Measuring the effect of the ITZ on the transport related properties of mortar using electrochemical impedance. Constr. Build. Mater. 2014, 52, 9–16. [Google Scholar] [CrossRef]

- Ma, T.; Yang, C.; Chen, P.; Wang, X.; Guo, Y. On the damage constitutive model for hydrated shale using CT scanning technology. J. Nat. Gas. Sci. Eng. 2016, 28, 204–214. [Google Scholar] [CrossRef]

- Ma, T.; Chen, P. Study of meso-damage characteristics of shale hydration based on CT scanning technology. Petrol. Explor. Dev. 2014, 41, 249–256. [Google Scholar] [CrossRef]

- Kassab, M.A.; Weller, A. Anisotropy of permeability, P-wave velocity and electrical resistivity of Upper Cretaceous carbonate samples from Tushka Area, Western Desert, Egypt. Egypt. J. Petrol. 2019, 28, 189–196. [Google Scholar] [CrossRef]

- Wang, H.; Sun, S.Z.; Yang, H.; Gao, H.; Xiao, Y.; Hu, H. The influence of pore structure on P- & S-wave velocities in complex carbonate reservoirs with secondary storage space. Pet. Sci. 2011, 8, 394–405. [Google Scholar]

- Kassab, M.A.; Weller, A. Study on P-wave and S-wave velocity in dry and wet sandstones of Tushka region, Egypt. Egypt. J. Petrol. 2015, 24, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Carcione, J.M.; Ursin, B.; Nordskag, J.I. Cross-property relations between electrical conductivity and the seismic velocity of rocks. Geophysics 2007, 72, E193–E204. [Google Scholar] [CrossRef]

- Krief, M.; Garat, J.; Stellingwerff, J.; Ventre, J. A petrophysical interpretation using the velocities of P and S waves (Full-Waveform Sonic). Log. Anal. 1990, 31, 355–369. [Google Scholar]

- Raymer, L.L.; Hunt, E.R.; Gardner, J.S. An Improved Sonic Transit Time-To-Porosity Transform. In Proceedings of the SPWLA 21st Annual Logging Symposium, Lafayette, Louisiana, 8–11 July 1980; p. 13. [Google Scholar]

- Werthmüller, D.; Ziolkowski, A.; Wright, D. Background resistivity model from seismic velocities. Geophysics 2013, 78, E213–E223. [Google Scholar] [CrossRef] [Green Version]

- Grana, D. Probabilistic approach to rock physics modeling. Geophysics 2014, 79, D123–D143. [Google Scholar] [CrossRef]

- Sen, P.N.; Scala, C.; Cohen, M.H. A self-similar model for sedimentary rocks with application to the dielectric constant of fused glass beads. Geophysics 1981, 46, 781–795. [Google Scholar] [CrossRef]

- Archie, G.E. The electrical resistivity log as an aid in determining some reservoir characteristics. Trans. AIME 1942, 146, 54–62. [Google Scholar] [CrossRef]

- Hashin, Z.; Shtrikman, S. A variational approach to the theory of the elastic behaviour of multiphase materials. J. Mech. Phys. Solids 1963, 11, 127–140. [Google Scholar] [CrossRef]

| ρs | ρf | Ks | Kf | Gs | vs | vf |

|---|---|---|---|---|---|---|

| 1000 | 0.29 | 25 | 2.25 | 8 | 3.7 | 1.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, D.; Xu, Q. Comparison of Sandstone Damage Measurements Based on Non-Destructive Testing. Materials 2020, 13, 5154. https://doi.org/10.3390/ma13225154

Yin D, Xu Q. Comparison of Sandstone Damage Measurements Based on Non-Destructive Testing. Materials. 2020; 13(22):5154. https://doi.org/10.3390/ma13225154

Chicago/Turabian StyleYin, Duohao, and Qianjun Xu. 2020. "Comparison of Sandstone Damage Measurements Based on Non-Destructive Testing" Materials 13, no. 22: 5154. https://doi.org/10.3390/ma13225154

APA StyleYin, D., & Xu, Q. (2020). Comparison of Sandstone Damage Measurements Based on Non-Destructive Testing. Materials, 13(22), 5154. https://doi.org/10.3390/ma13225154