Dynamic Tensile Properties and Energy Dissipation of High-Strength Concrete after Exposure to Elevated Temperatures

Abstract

:1. Introduction

2. Experimental Scheme and Theoretical Basis

2.1. Materials and Preparation of Specimens

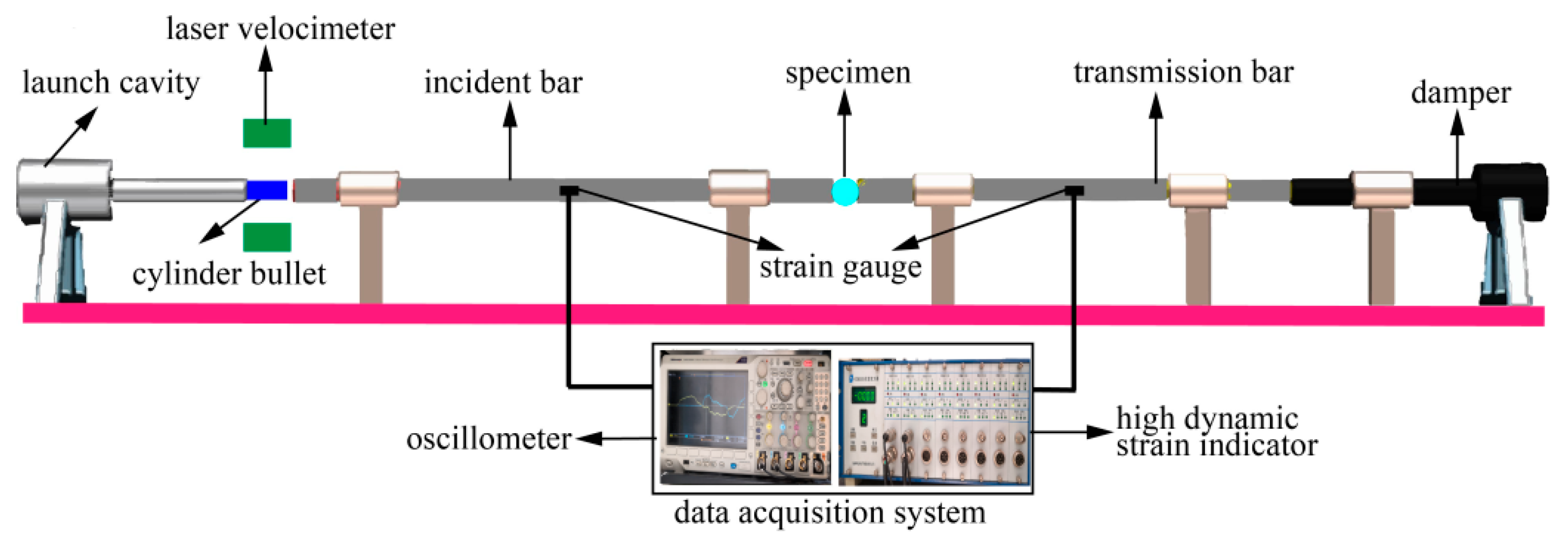

2.2. SHPB Test Equipment and Basic Principle

3. Test Results and Analysis

3.1. Static Test

3.2. Dynamic Splitting Tensile Test

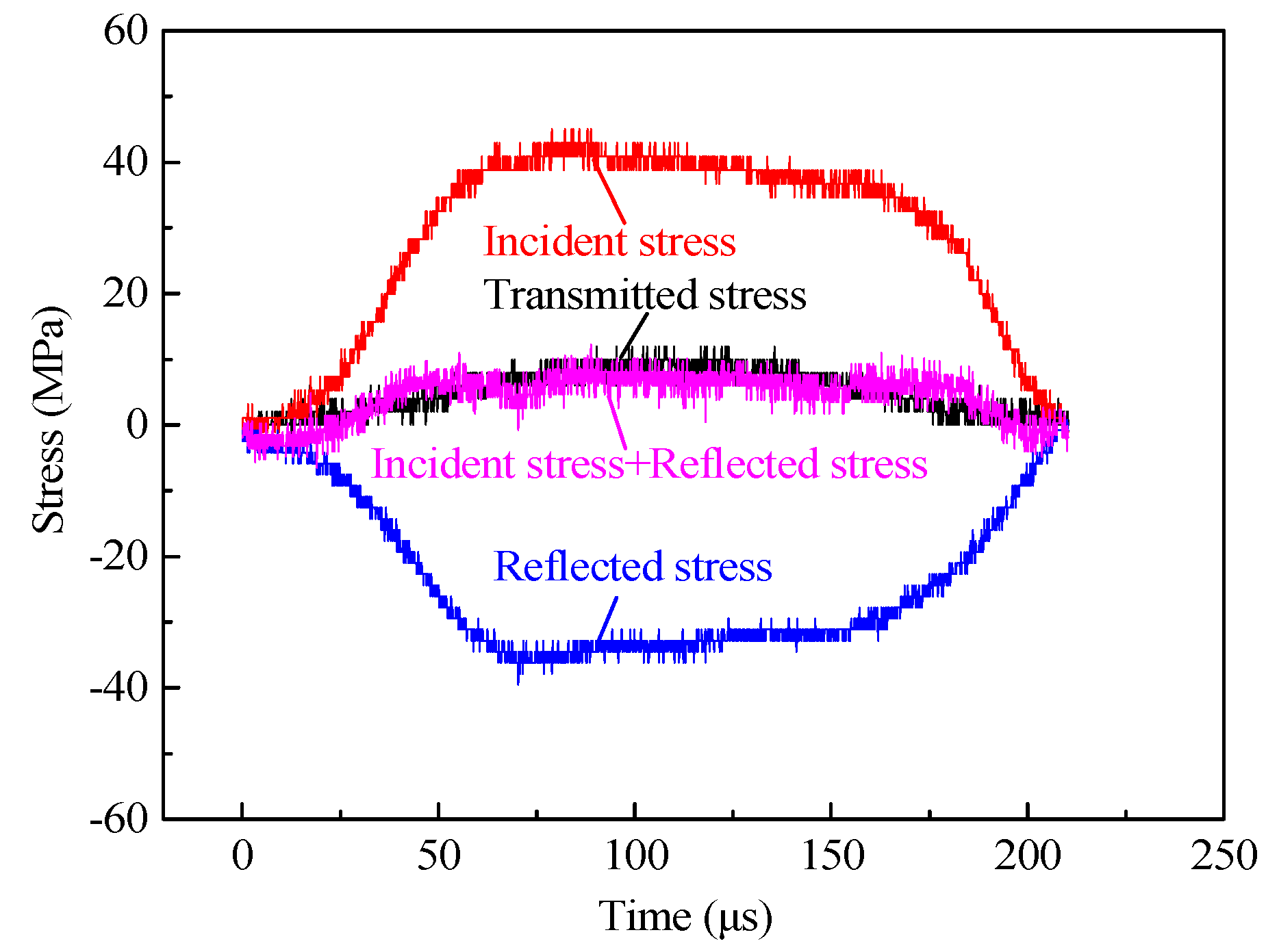

3.2.1. Analysis on Typical Waveform Curve of SHPB

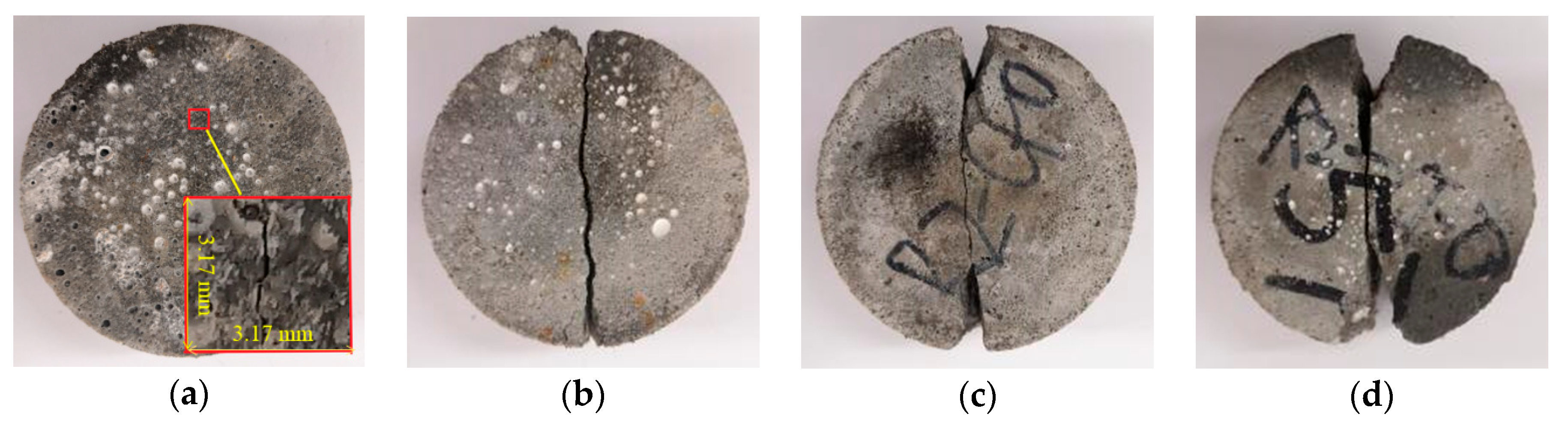

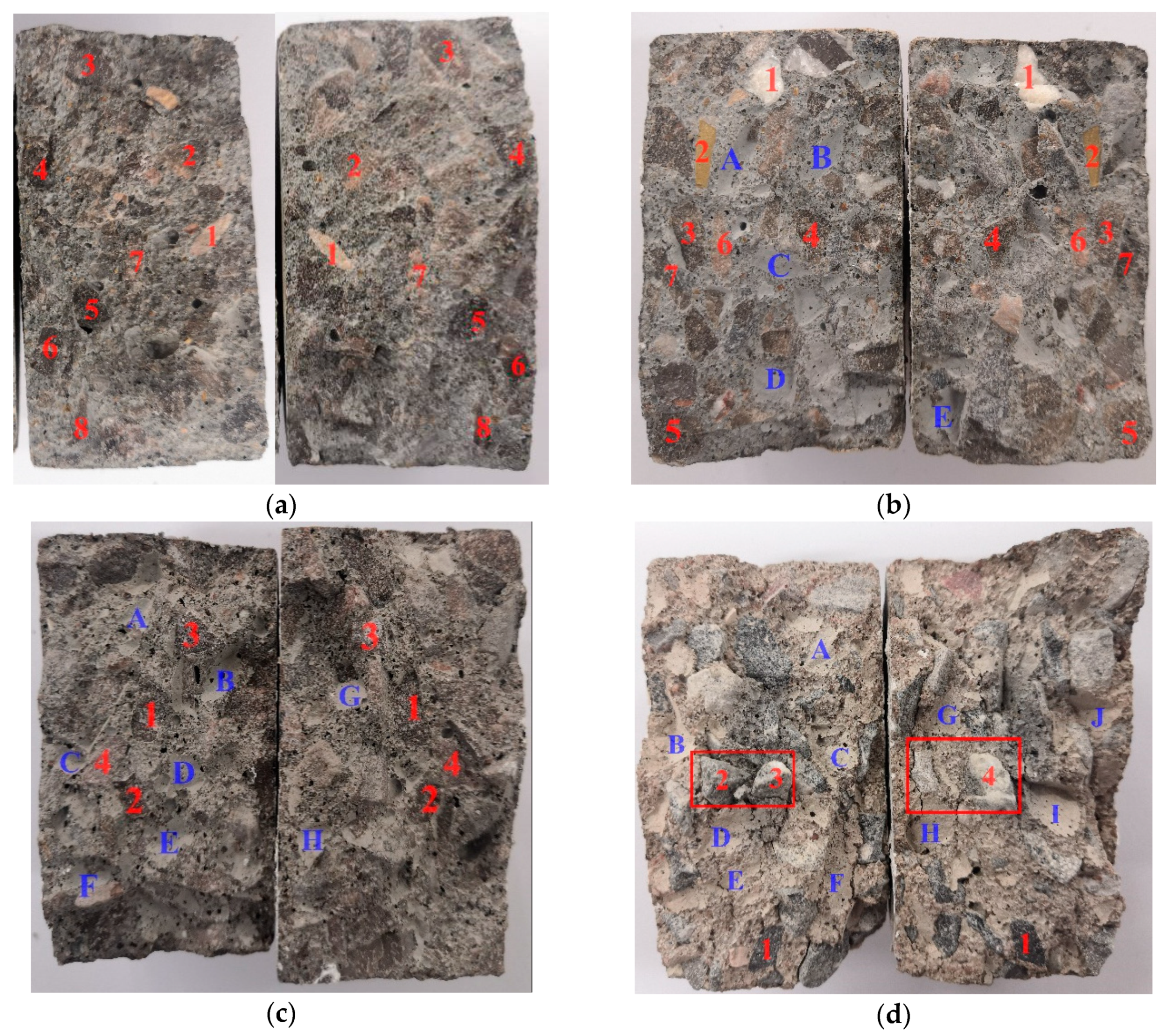

3.2.2. Damage and Fracture of the Specimens

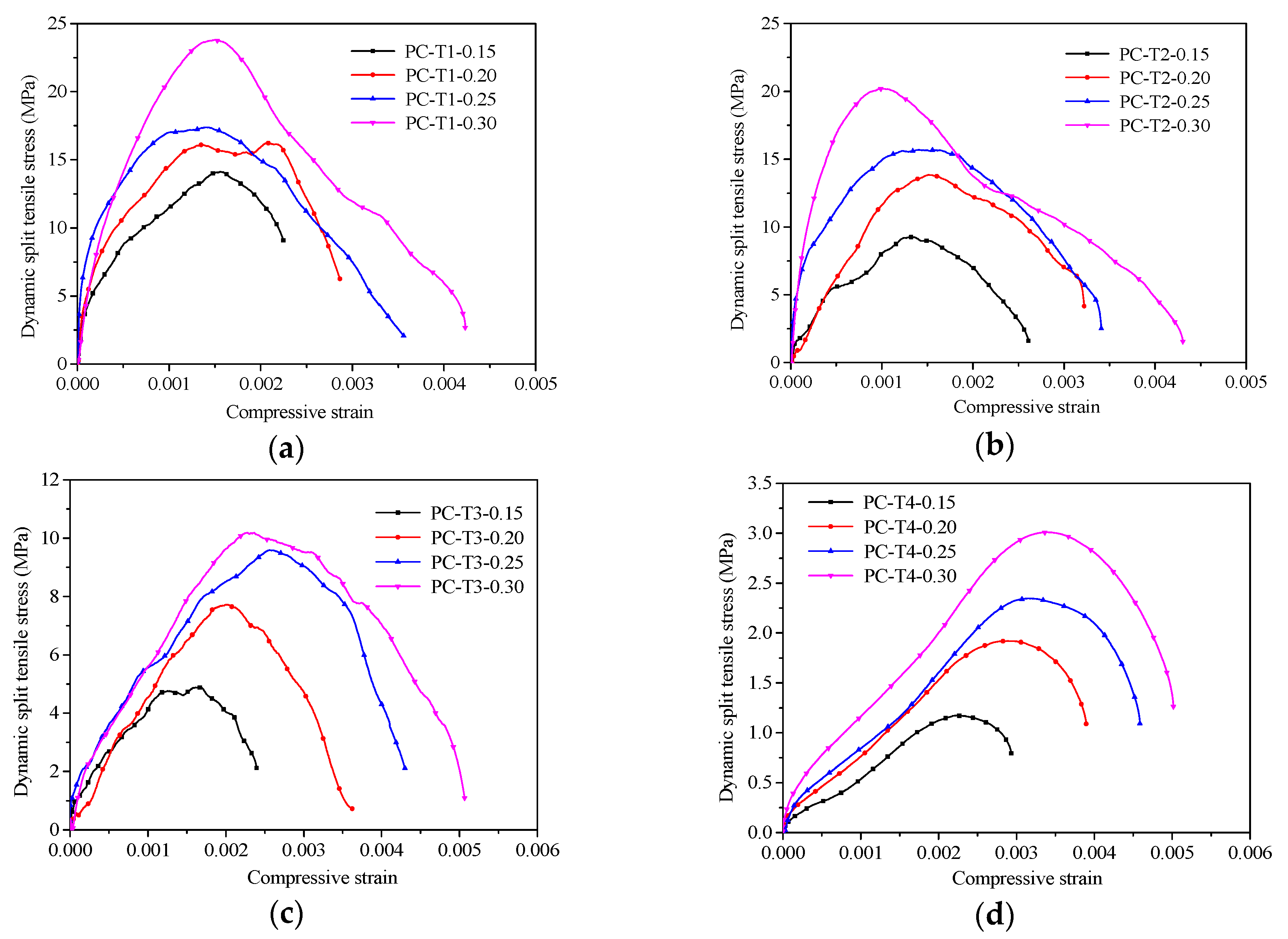

3.2.3. The Dynamic Stress–Strain Relationship of the Concrete after High Temperature

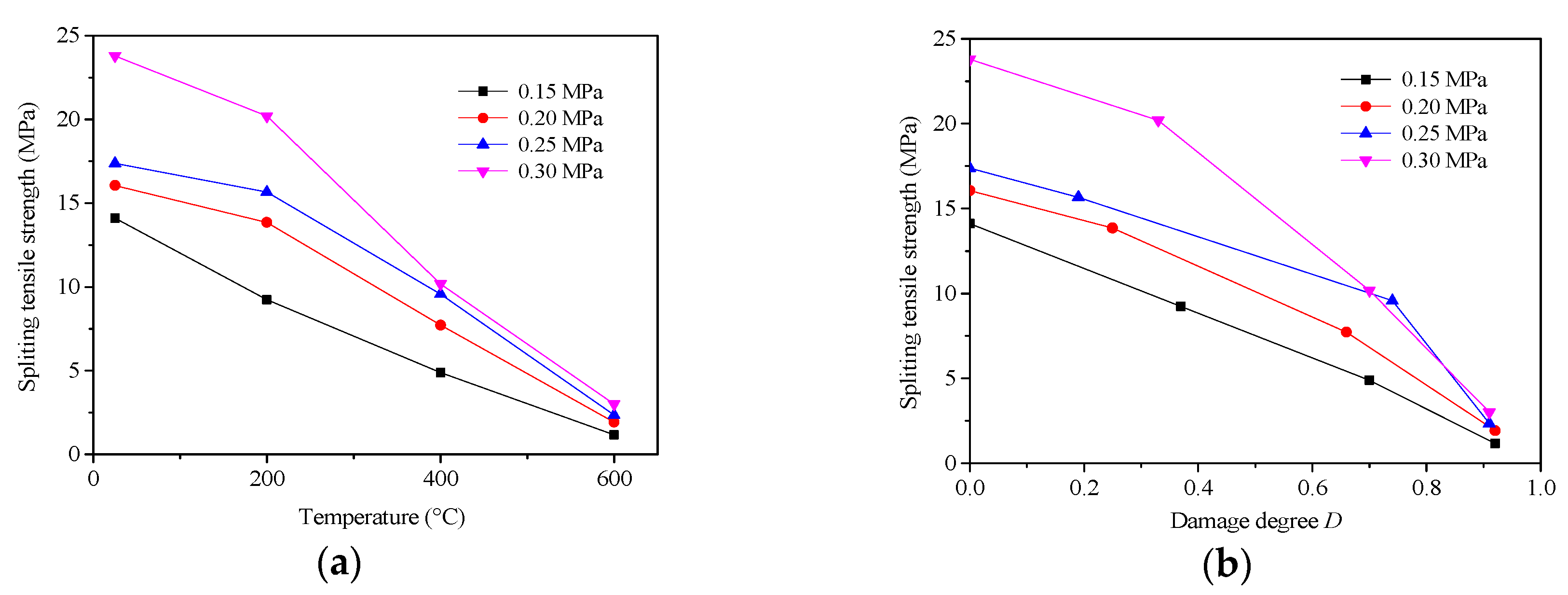

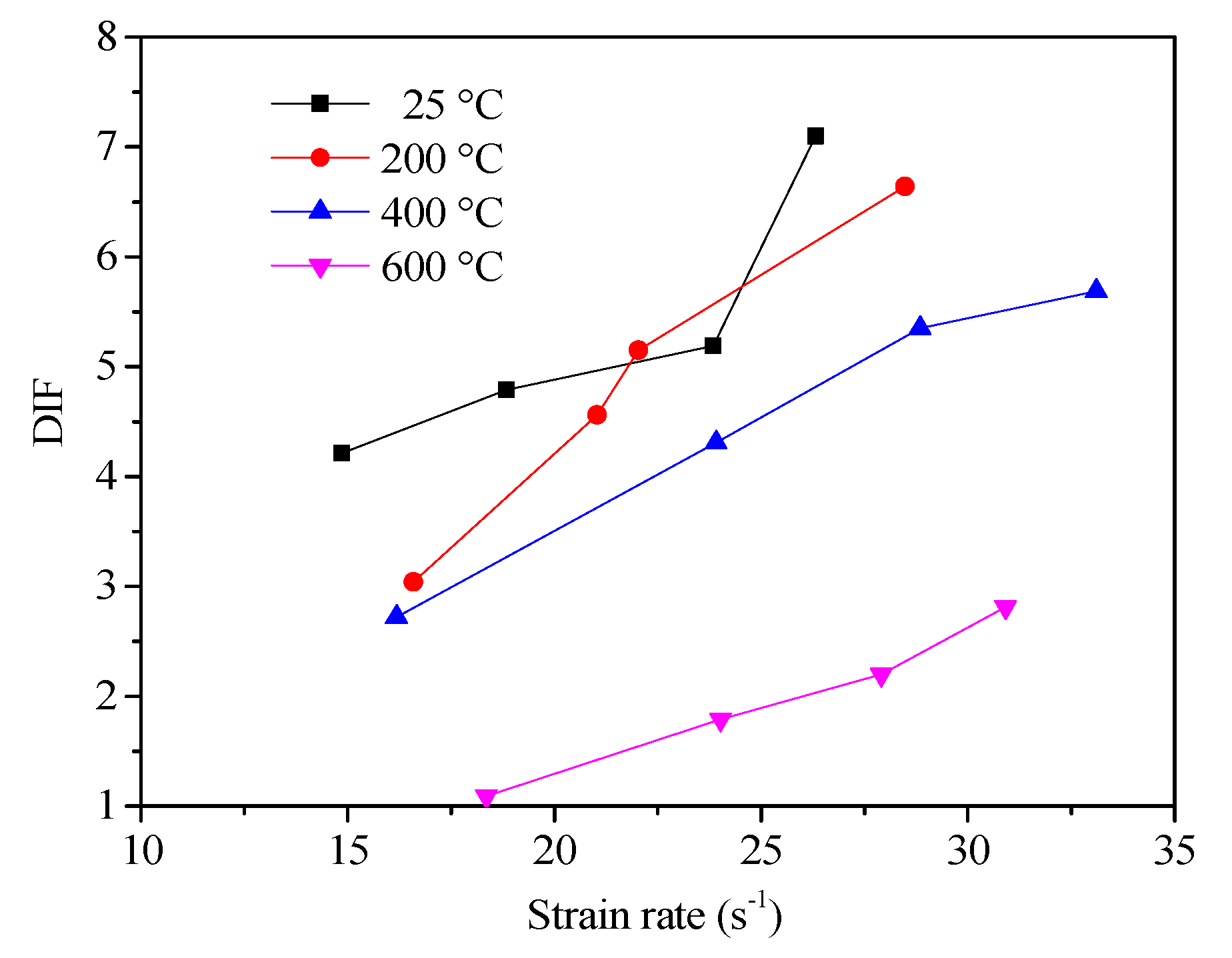

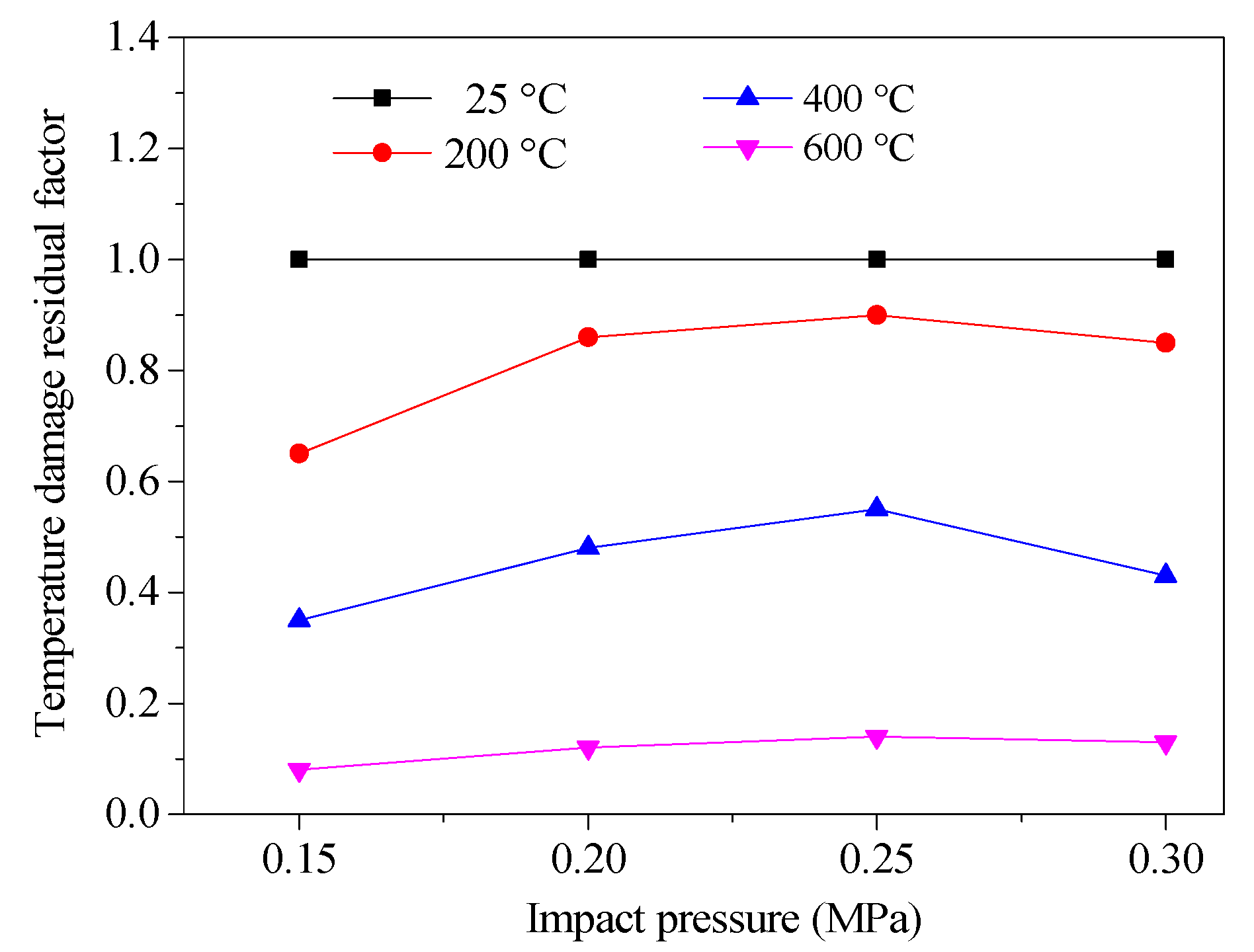

3.2.4. The Dynamic Tension Strength of Concrete after High Temperatures

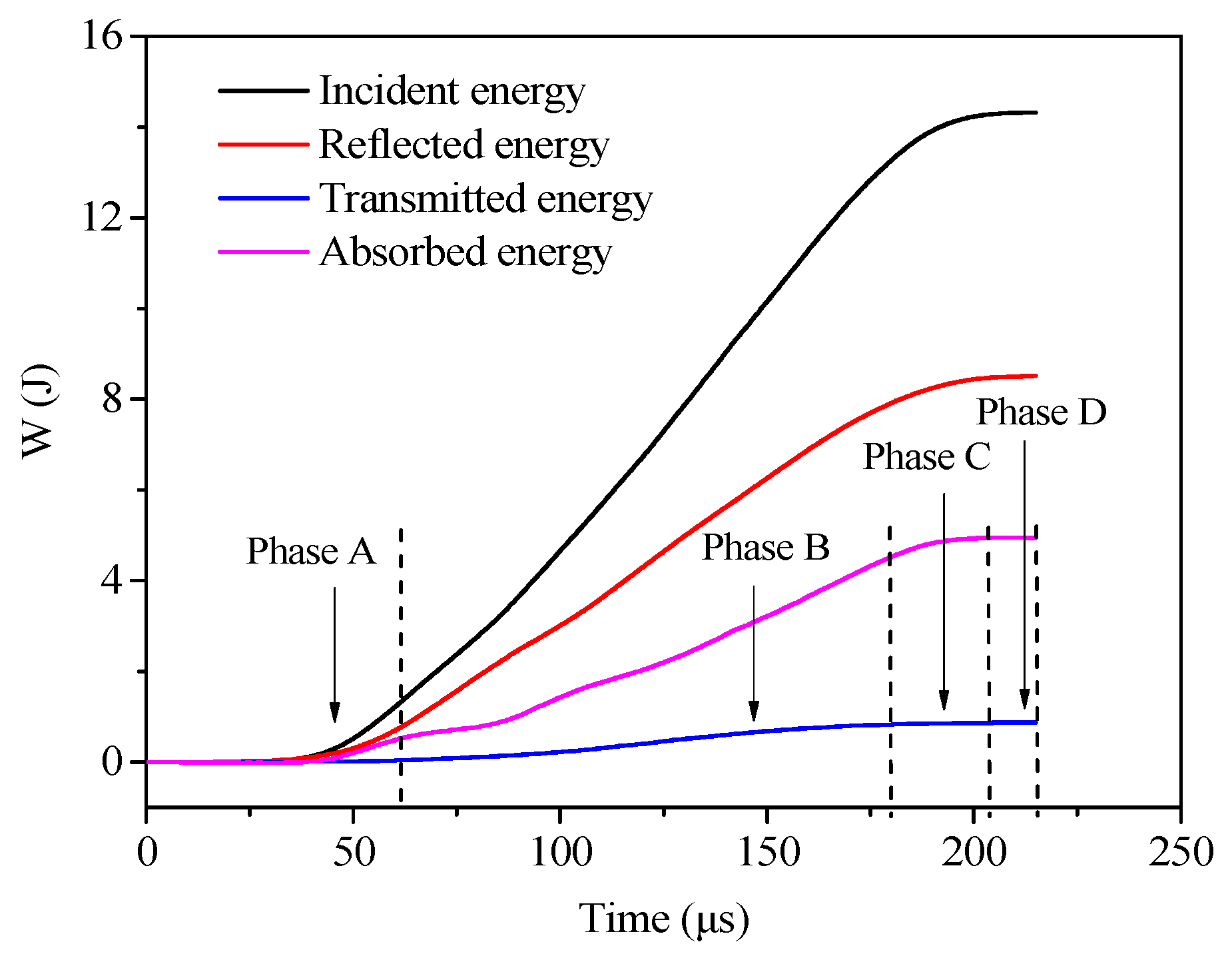

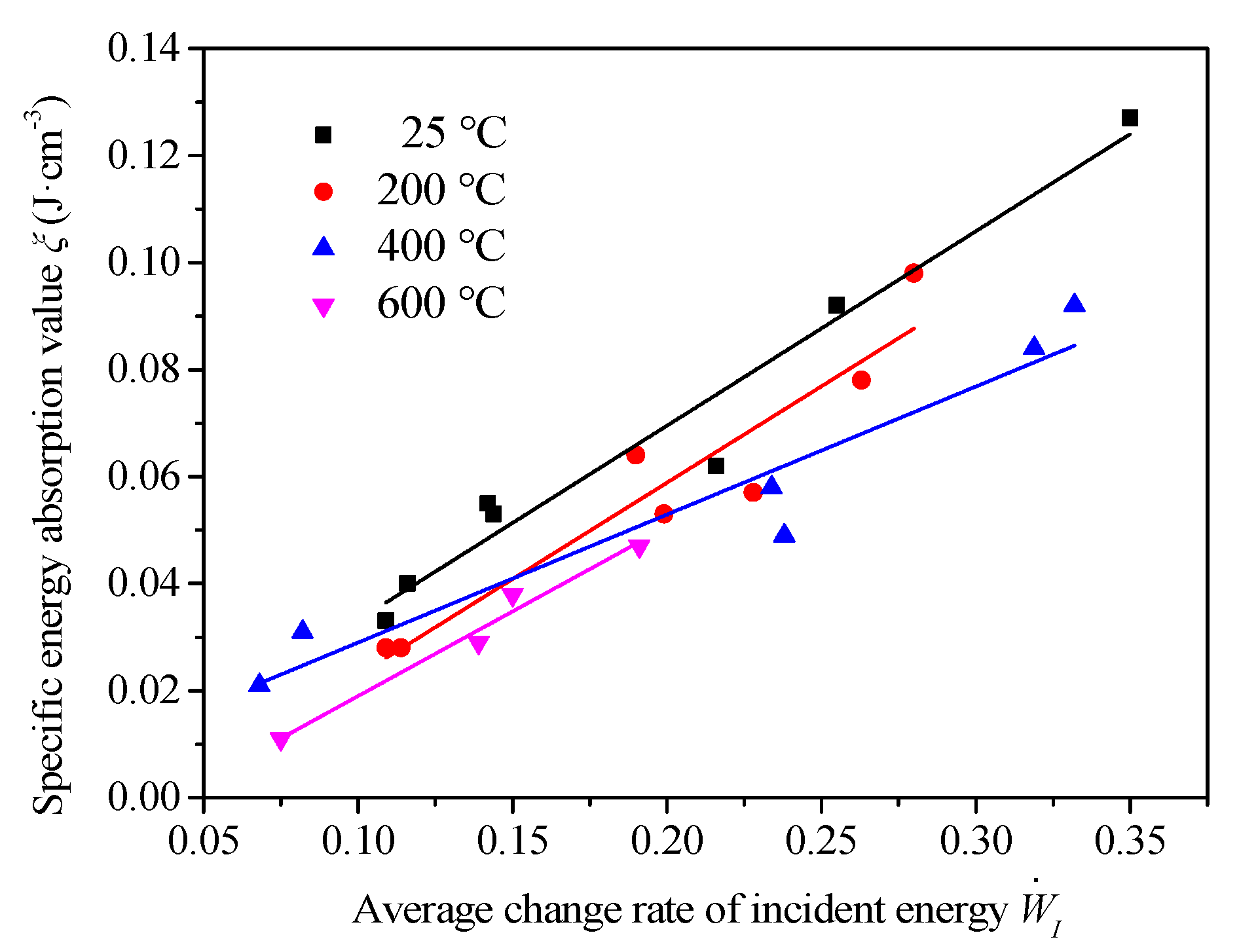

3.2.5. Energy Dissipation of Concrete after High Temperature

- Compaction stage (Phase A): At this time, the stress wave was on the rising edge. Under the action of the impact load, the pores in the concrete specimen were compacted and were in the compression deformation stage. The absorbed energy in the process was small, and the energy consumption curve grew slowly.

- Elastic phase (Phase B): In this phase, the incident energy, reflected energy, and absorbed energy curves all grew rapidly. Damage evolution and accumulation occurred inside the specimen, and the specimen absorbed a large amount of energy for crack initiation and internal crack growth [51].

- Yield stage (Phase C): In this stage, the cracks initiating inside the specimen further expanded and penetrated, and the rate of energy absorption gradually decreased, but the absorption energy continued to increase.

- Softening stage (Phase D): At this time, the incident loading basically ended, the absorption energy did not increase, and finally, each energy tended to a stable value and the energy curve remained level, indicating that the specimen had been completely destroyed.

4. Conclusions

- With the increase in temperature, the quasi-static and dynamic tensile strength of high strength concrete gradually decreased, and the damage degree of the specimen gradually increased.

- The dynamic tensile strength and specific energy absorption of high-strength concrete increased with the increase in the strain rate, but decreased with the increase in temperature, indicating that high-strength concrete had both a strain rate effect and temperature softening effect.

- In the dynamic splitting tensile test, when the high-strength concrete at room temperature was subjected to an impact load, the direction of the crack propagation in the mortar matrix did not change, but directly penetrated the coarse aggregate, causing the coarse aggregate particles to break, which was a brittle failure. With the increase in temperature, the debonding surface of the coarse aggregate and mortar matrix increased, and the number of broken coarse aggregates decreased, indicating that the crack propagation law gradually changed from directly passing through the coarse aggregate to extending along the bonding surface between the coarse aggregate and the mortar matrix.

- Based on the above test results, temperature had a great influence on the dynamic tensile properties of high-strength concrete. Based on the failure patterns of the specimens at high temperature, when high-strength concrete structures will be under environments of high temperatures and dynamic loads, the bond between the mortar and aggregate should be strengthened in the material proportioning design. Materials with high-temperature resistance and good tensile strength can be added to change the failure mode of the structure. The experimental results have reference significance for guiding the fire response and seismic design of high-strength concrete.

Author Contributions

Funding

Conflicts of Interest

References

- Li, X.J.; Zhang, Y.Y.; Shi, C.; Chen, X.D. Experimental and numerical study on tensile strength and failure pattern of high performance steel fiber reinforced concrete under dynamic splitting tension. Constr. Build. Mater. 2020, 259, 119796. [Google Scholar] [CrossRef]

- Guo, Y.B.; Gao, G.F.; Jing, L.; Shim, V.P.W. Quasi-static and dynamic splitting of high-strength concretes–tensile stress–strain response and effects of strain rate. Int. J. Impact Eng. 2019, 125, 188–211. [Google Scholar] [CrossRef]

- Kopczynski, P.E.C.; Faci, S.E. High-strength concrete comes of age. Struct. Mag. 2014, 15–16. [Google Scholar]

- Ren, J.; Dang, F.N.; Wang, H.; Xue, Y.; Fang, J.Y. Enhancement Mechanism of the Dynamic Strength of Concrete Based on the Energy Principle. Materials 2020, 13, 3658. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saaf, M. Effect of fire on FRP reinforced concrete members. Compos. Struct. 2002, 58, 11–20. [Google Scholar] [CrossRef]

- Chen, L.; Fang, Q.; Jiang, X.; Ruan, Z.; Hong, J. Combined effects of high temperature and high strain rate on normal weight concrete. Int. J. Impact Eng. 2015, 86, 40–56. [Google Scholar] [CrossRef]

- Abdallah, S.; Fan, M.; Rees, D.W.A. Effect of elevated temperature on pull-out behaviour of 4DH/5DH hooked end steel fibre. Compos. Struct. 2017, 165, 180–191. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Qian, C.; Sun, W. Mechanical properties of high-strength concrete after fire. Cem. Concr. Res. 2004, 34, 1001–1005. [Google Scholar] [CrossRef]

- Cheng, F.P.; Kodur, V.K.R.; Wang, T.C. Stress-strain curves for high-strength concrete at elevated temperatures. J. Mater. Civ. Eng. 2004, 16, 84–94. [Google Scholar] [CrossRef] [Green Version]

- Ghandehari, M.; Behnood, A.; Khanzadi, M. Residual mechanical properties of high-strength concretes after exposure to elevated temperatures. J. Mater. Civ. Eng. 2010, 22, 59–64. [Google Scholar] [CrossRef]

- Pothnis, J.R.; Ravikumar, G.; Arya, H.; Yerramalli, C.S.; Naik, N.K. Stress wave attenuation in aluminum alloy and mild steel specimens under SHPB tensile testing. J. Mater. Eng. Perform. 2018, 27, 677–686. [Google Scholar] [CrossRef]

- Ai, S.; Tang, L.; Mao, Y.; Liu, Y.; Fang, D. Numerical analysis on failure behaviour of polyurethane polymer concrete at high strain rates in compression. Comput. Mater. Sci. 2013, 69, 389–395. [Google Scholar] [CrossRef]

- Yang, S.; Braham, A.F. Influence of binder grade, gradation, temperature and loading rate on R-curve of asphalt concrete. Constr. Build. Mater. 2017, 154, 780–790. [Google Scholar] [CrossRef]

- Zhang, Q.B.; Zhao, J. A review of dynamic experimental techniques and mechanical behaviour of rock materials. Rock Mech. Rock Eng. 2014, 47, 1411–1478. [Google Scholar] [CrossRef] [Green Version]

- Xiao, J.; Li, Z.; Xie, Q.; Shen, L. Effect of strain rate on compressive behaviour of high-strength concrete after exposure to elevated temperatures. Fire Saf. J. 2016, 83, 25–37. [Google Scholar] [CrossRef]

- Li, L.; Zhang, R.B.; Jin, L.; Du, X.L.; Wu, J.; Duan, W.H. Experimental study on dynamic compressive behavior of steel fiber reinforced concrete at elevated temperatures. Constr. Build. Mater. 2019, 210, 673–684. [Google Scholar] [CrossRef]

- Zhai, Y.; Li, Y.B.; Li, Y.; Jiang, W.Q.; Liu, X.Y. Research on the Impact Loading and Energy Dissipation of Concrete after Elevated Temperature under Different Heating Gradients and Cooling Methods. Materials 2018, 11, 1651. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Lu, Z.H.; Zhang, Q.Y. Study on stochastic damage constitutive law for concrete material subjected to uniaxial compressive stress. J. Tongji Univ. 2003, 31, 505–509. [Google Scholar]

- Faiyadh, F.I.; AI-Ausi, M.A. Effect of elevated temperature on splitting tensile strength of fibre concrete. Int. J. Cem. Compos. Lightweight Concr. 1989, 11, 175–178. [Google Scholar] [CrossRef]

- Israngkura, N.; Ayudhya, B. Comparison of compressive and splitting tensile strength of autoclaved aerated concrete (AAC) containing water hyacinth and polypropylene fibre subjected to elevated temperatures. Mater. Struct. 2015, 49, 1455–1468. [Google Scholar] [CrossRef]

- Khaliq, W.; Kodur, V. Thermal and mechanical properties of fiber reinforced high performance self-consolidating concrete at elevated temperatures. Cem. Concr. Res. 2011, 41, 1112–1122. [Google Scholar] [CrossRef]

- Khaliq, W.; Kodur, V. Effect of high temperature on tensile strength of different types of high-strength concrete. ACI Mater. J. 2011, 108, 394–402. [Google Scholar]

- Ma, Q.; Guo, R.; Zhao, Z.; Lin, Z.; He, K. Mechanical properties of concrete at high temperature—A review. Constr. Build. Mater. 2015, 93, 371–383. [Google Scholar] [CrossRef]

- Xargay, H.; Folino, P.; Sambataro, L.; Etse, G. Temperature effects on failure behavior of self-compacting high strength plain and fiber reinforced concrete. Constr. Build. Mater. 2018, 165, 723–734. [Google Scholar] [CrossRef]

- Jin, X.; Du, X.H.; Yan, R.Z. Experimental research on the splitting tensile strength of high-performance concrete after elevated temperature. J. Taiyuan Univ. Technol. 2013, 44, 637–640. [Google Scholar]

- Zhou, X.; Hao, H. Mesoscale modelling of concrete tensile failure mechanism at high strain rates. Comput. Struct. 2008, 86, 2013–2026. [Google Scholar] [CrossRef]

- Qin, C.; Wu, M.X.; Zhang, C.H. Impact splitting tensile experiments of concrete and numerical modeling by meso-scale discrete elements. J. Hydraul. Eng. 2013, 32, 196–205. [Google Scholar]

- Shi, G.Y.; Wang, Z.L.; Shi, H. Experimental and numerical analysis of dynamic splitting behavior of C75 concrete. J. Harbin. Inst. Technol. 2019, 51, 109–116. [Google Scholar]

- Jin, L.; Hao, H.M.; Zhang, R.B. Meso-scale simulations on dynamic splitting tensile behaviors of concrete at elevated temperatures. Explor. Shock. 2020, 40, 1–12. [Google Scholar]

- Liang, X.W.; Wu, C.Q.; Yang, Y.K.; Wu, C.; Li, Z.X. Coupled effect of temperature and impact loading on tensile strength of ultra-high performance fibre reinforced concrete. Compos. Struct. 2019, 229, 1–9. [Google Scholar] [CrossRef]

- Adamu, M.; Mohammed, B.S.; Shahir, M. Mechanical properties and performance of high volume fly ash roller compacted concrete containing crumb rubber and nano silica. Constr. Build. Mater. 2018, 171, 521–538. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Adamu, M. Mechanical performance of roller compacted concrete pavement containing crumb rubber and nano silica. Constr. Build. Mater. 2018, 159, 234–251. [Google Scholar] [CrossRef]

- Liu, J.F. Experimental Study on the Dynamic Compressive Mechanical Properties of High-Strength Concrete. Master’s Thesis, Hebei University of Technology, Tianjin, China, 2012. [Google Scholar]

- Li, L.J.; Xie, W.F.; Liu, F.; Guo, Y.C.; Deng, J. Fire performance of high-strength concrete reinforced with recycled rubber particles. Mag. Concr. Res. 2011, 63, 187–195. [Google Scholar] [CrossRef]

- ASTM-International. Standard Specification for Chemical Admixtures for Concrete; ASTM C494; ASTM-International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- International Society for Rock Mechanics, Suggested methods for determining tensile strength of rock materials. Int. J. Rock Mech. Min. Sci. 1978, 15, 99–103. [CrossRef]

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Standard for Test Method of Mechanical Properties on Ordinary Concrete/GB/T 50082-2002; China Architecture & Building Press: Beijing, China, 2003.

- ASTM. Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory; ASTMC192/C192M-2012; ASTM-International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Wright, P.J.F. Comments on an indirect tensile test on concrete cylinders. Mag. Concr. Res. 1955, 7, 87–96. [Google Scholar] [CrossRef]

- Wang, Q.; Xing, L. Determination of fracture roughness KIC by using the flattened Brazilian disk specimen for rocks. Eng. Fract. Mech. 1999, 64, 193–201. [Google Scholar] [CrossRef]

- Gomez, J.T.; Shukla, A.; Sharma, A. Static and dynamic behavior of concrete and granite in tension with damage. Theor. Appl. Fract. Mech. 2001, 36, 37–49. [Google Scholar] [CrossRef]

- Erzar, B.; Forquin, P. An experimental method to determine the tensile strength of concrete at high rates of strain. Exp. Mech. 2010, 50, 941–955. [Google Scholar] [CrossRef]

- Lu, Y.; Li, Q. About the dynamic uniaxial tensile strength of concrete-like materials. Int. J. Impact Eng. 2011, 36, 171–180. [Google Scholar] [CrossRef]

- Sideris, K.K. Mechanical characteristics of self-consolidating concrete exposed to elevated temeperatures. J. Mater. Civ. Eng. 2007, 19, 648–654. [Google Scholar] [CrossRef]

- Anagnostopoulos, N.; Sideris, K.K.; Georgiadis, A. Mechanical characteristics of selfcompacting concretes with different filler materials exposed to elevated temperatures. Mater. Struct. 2009, 42, 1393–1405. [Google Scholar] [CrossRef]

- Chen, X.; Wu, S.; Zhou, J. Quantification of dynamic tensile behavior of cement-based materials. Constr. Build. Mater. 2014, 51, 15–23. [Google Scholar] [CrossRef]

- Ping, Q.; Ma, Q.Y.; Yuan, P. Energy dissipation analysis of stone specimens in SHPB tensile test. J. Min. Saf. Eng. 2013, 30, 401–407. [Google Scholar]

- Li, X.B. Rock Dynamics Fundamentals and Applications; Science Press: Beijing, China, 2014. [Google Scholar]

- Zhao, Z.; Jing, L.; Pei, Q.; Ma, H.W.; Wang, Z.H. An experimental study of the dynamic split tension properties of reinforced concrete. Strength Mater. 2016, 48, 63–68. [Google Scholar] [CrossRef]

- Caverzan, A.; Cadoni, E.; Prisco, M.D. Dynamic tensile behaviour of high performance fibre reinforced cementitious composites after high temperature exposure. Mech. Mater. 2013, 59, 87–109. [Google Scholar] [CrossRef]

- Sufian, A.; Russell, A.R. Microstructural pore changes and energy dissipation in Gosford sandstone during pre-failure loading using X-ray CT. Int. J. Rock Mech. Min. Sci. 2013, 57, 119–131. [Google Scholar] [CrossRef]

| Cement | Water | Fine Aggregate | Coarse Aggregate | Coal Ash | Silica Fume | Water Reducing Agent | Rubber |

|---|---|---|---|---|---|---|---|

| 385.9 | 154.36 | 699 | 1140 | 45.4 | 22.7 | 7.8 | 9.08 |

| Component | Density (kg/m3) | BET (m2/g) | Chemical Composition (wt.%) (XRF) | |||||

|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | MgO | |||

| Cement | 1910 | 1.477 | 31.31 | 1.94 | 0.9 | 0.23 | 43.49 | 0.29 |

| Silica fume | 310 | 23.7 | 0.8 | 97 | 0.6 | 0.1 | 1.0 | - |

| Temperature (°C) | Gas Pressure (MPa) | Wave Velocity (m/s) | Strain Rate (s−1) | Damage Degree D | Dynamic Tensile Strength (MPa) | DIF | |

|---|---|---|---|---|---|---|---|

| c1 | c2 | ||||||

| 25 | 0.15 | 5240 | 5240 | 14.86 | 0 | 14.11 | 4.21 |

| 0.20 | 5102 | 5102 | 18.84 | 0 | 16.06 | 4.79 | |

| 0.25 | 5454 | 5454 | 23.84 | 0 | 17.38 | 5.19 | |

| 0.30 | 5305 | 5305 | 26.32 | 0 | 23.79 | 7.10 | |

| 200 | 0.15 | 5438 | 4306 | 16.59 | 0.37 | 9.24 | 3.04 |

| 0.20 | 5329 | 4602 | 21.03 | 0.25 | 13.85 | 4.56 | |

| 0.25 | 5185 | 4667 | 22.03 | 0.19 | 15.67 | 5.15 | |

| 0.30 | 5213 | 4265 | 28.48 | 0.33 | 20.20 | 6.64 | |

| 400 | 0.15 | 5153 | 2810 | 16.18 | 0.70 | 4.88 | 2.72 |

| 0.20 | 5000 | 2903 | 23.92 | 0.66 | 7.72 | 4.31 | |

| 0.25 | 5379 | 2759 | 28.85 | 0.74 | 9.58 | 5.35 | |

| 0.30 | 5153 | 2811 | 33.11 | 0.70 | 10.18 | 5.69 | |

| 600 | 0.15 | 5231 | 1519 | 18.36 | 0.92 | 1.17 | 1.09 |

| 0.20 | 5013 | 1380 | 24.02 | 0.92 | 1.92 | 1.79 | |

| 0.25 | 5167 | 1583 | 27.91 | 0.91 | 2.35 | 2.20 | |

| 0.30 | 5106 | 1507 | 30.91 | 0.91 | 3.01 | 2.81 | |

| Specimen Number | Temperature (°C) | WI (J) | WR (J) | WT (J) | WS (J) | ξ (J/cm3) | |

|---|---|---|---|---|---|---|---|

| PC-T1-1 | 25 | 13.78 | 6.72 | 2.24 | 4.82 | 0.109 | 0.033 |

| PC-T1-2 | 14.40 | 6.11 | 2.71 | 5.58 | 0.116 | 0.040 | |

| PC-T1-3 | 23.34 | 12.62 | 2.91 | 7.81 | 0.142 | 0.055 | |

| PC-T1-4 | 22.03 | 11.12 | 3.30 | 7.61 | 0.144 | 0.053 | |

| PC-T1-5 | 28.74 | 16.82 | 2.94 | 8.98 | 0.216 | 0.062 | |

| PC-T1-6 | 42.89 | 25.47 | 3.94 | 13.48 | 0.255 | 0.092 | |

| PC-T1-7 | 50.73 | 25.85 | 5.27 | 19.61 | 0.350 | 0.127 | |

| PC-T2-1 | 200 | 14.31 | 8.50 | 0.87 | 4.94 | 0.114 | 0.028 |

| PC-T2-2 | 13.50 | 7.68 | 1.73 | 4.09 | 0.109 | 0.028 | |

| PC-T2-3 | 26.64 | 15.34 | 2.12 | 9.18 | 0.199 | 0.053 | |

| PC-T2-4 | 29.51 | 18.97 | 2.46 | 8.08 | 0.228 | 0.057 | |

| PC-T2-5 | 25.73 | 13.93 | 2.65 | 9.15 | 0.190 | 0.064 | |

| PC-T2-6 | 38.88 | 21.46 | 3.25 | 14.17 | 0.280 | 0.098 | |

| PC-T2-7 | 37.80 | 23.92 | 2.72 | 11.16 | 0.263 | 0.078 | |

| PC-T3-1 | 400 | 8.91 | 5.67 | 0.25 | 3.00 | 0.068 | 0.021 |

| PC-T3-2 | 10.07 | 4.44 | 0.14 | 4.58 | 0.082 | 0.031 | |

| PC-T3-3 | 31.41 | 21.28 | 0.99 | 9.14 | 0.238 | 0.049 | |

| PC-T3-4 | 29.98 | 20.54 | 1.04 | 8.39 | 0.234 | 0.058 | |

| PC-T3-5 | 41.94 | 28.45 | 1.00 | 12.49 | 0.319 | 0.084 | |

| PC-T3-6 | 41.94 | 27.84 | 0.91 | 13.19 | 0.332 | 0.092 | |

| PC-T4-1 | 600 | 11.09 | 9.42 | 0.01 | 1.66 | 0.075 | 0.011 |

| PC-T4-2 | 20.91 | 16.68 | 0.04 | 4.19 | 0.139 | 0.029 | |

| PC-T4-3 | 22.88 | 17.24 | 0.04 | 5.61 | 0.150 | 0.038 | |

| PC-T4-4 | 31.67 | 24.90 | 0.05 | 6.71 | 0.191 | 0.047 |

| Temperature (°C) | Equation | Correlation Coefficient (R2) |

|---|---|---|

| 25 | 0.9511 | |

| 200 | 0.8843 | |

| 400 | 0.9116 | |

| 600 | 0.9657 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, N.; Wang, H.-b.; Zong, Q.; Wang, M.-x.; Cheng, B. Dynamic Tensile Properties and Energy Dissipation of High-Strength Concrete after Exposure to Elevated Temperatures. Materials 2020, 13, 5313. https://doi.org/10.3390/ma13235313

Lv N, Wang H-b, Zong Q, Wang M-x, Cheng B. Dynamic Tensile Properties and Energy Dissipation of High-Strength Concrete after Exposure to Elevated Temperatures. Materials. 2020; 13(23):5313. https://doi.org/10.3390/ma13235313

Chicago/Turabian StyleLv, Nao, Hai-bo Wang, Qi Zong, Meng-xiang Wang, and Bing Cheng. 2020. "Dynamic Tensile Properties and Energy Dissipation of High-Strength Concrete after Exposure to Elevated Temperatures" Materials 13, no. 23: 5313. https://doi.org/10.3390/ma13235313

APA StyleLv, N., Wang, H.-b., Zong, Q., Wang, M.-x., & Cheng, B. (2020). Dynamic Tensile Properties and Energy Dissipation of High-Strength Concrete after Exposure to Elevated Temperatures. Materials, 13(23), 5313. https://doi.org/10.3390/ma13235313