Magnetic and Magneto-Caloric Properties of the Amorphous Fe92−xZr8Bx Ribbons

Abstract

:1. Introduction

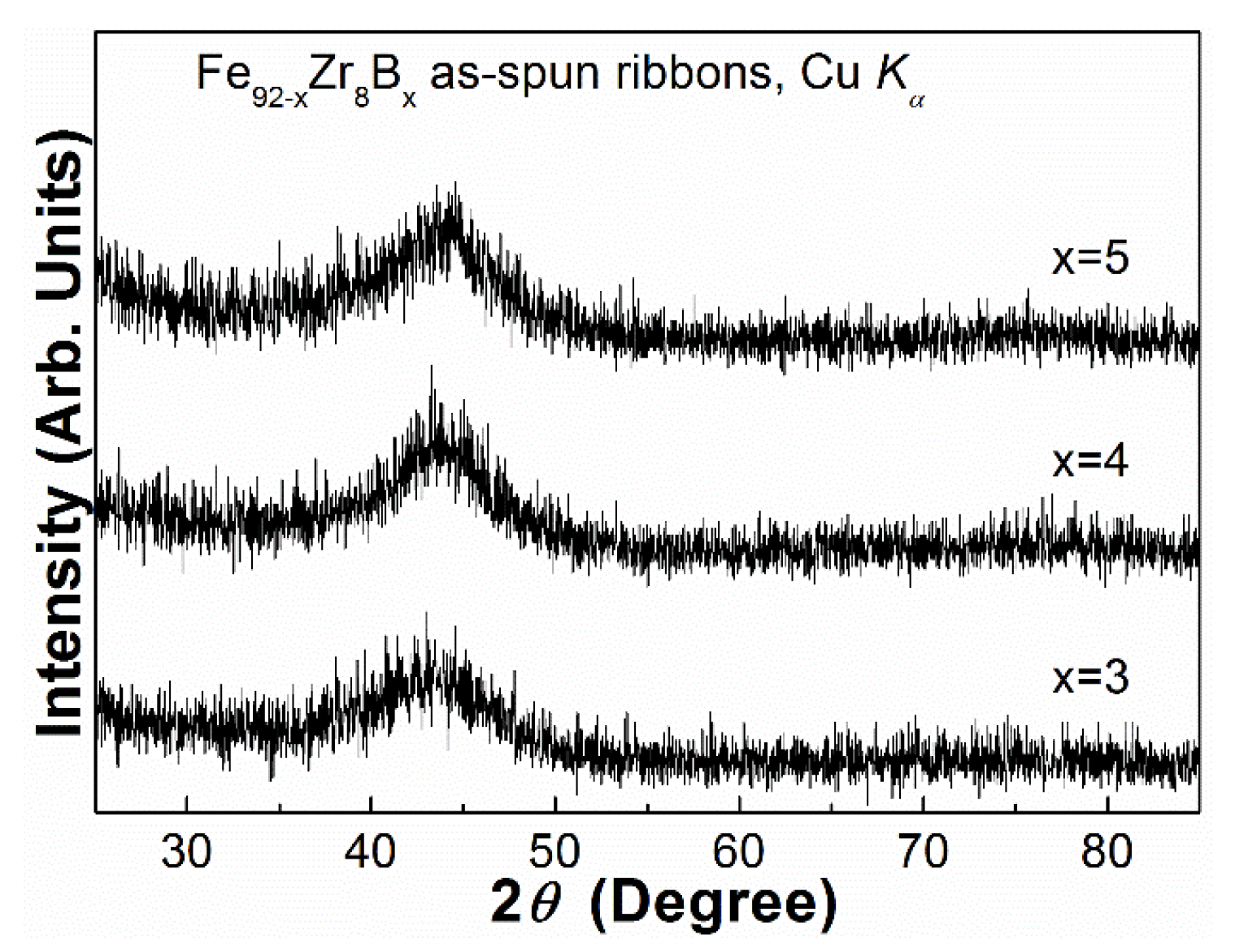

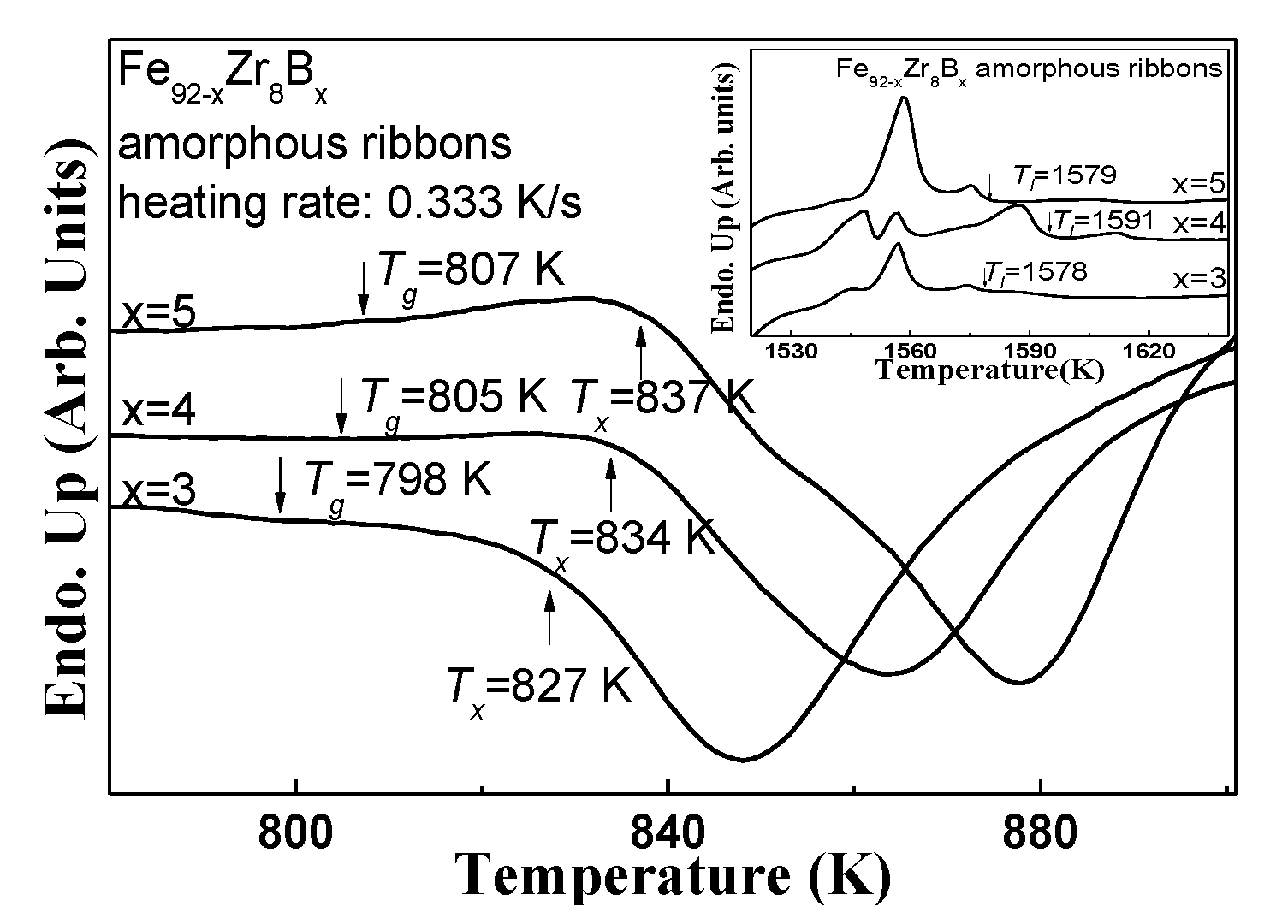

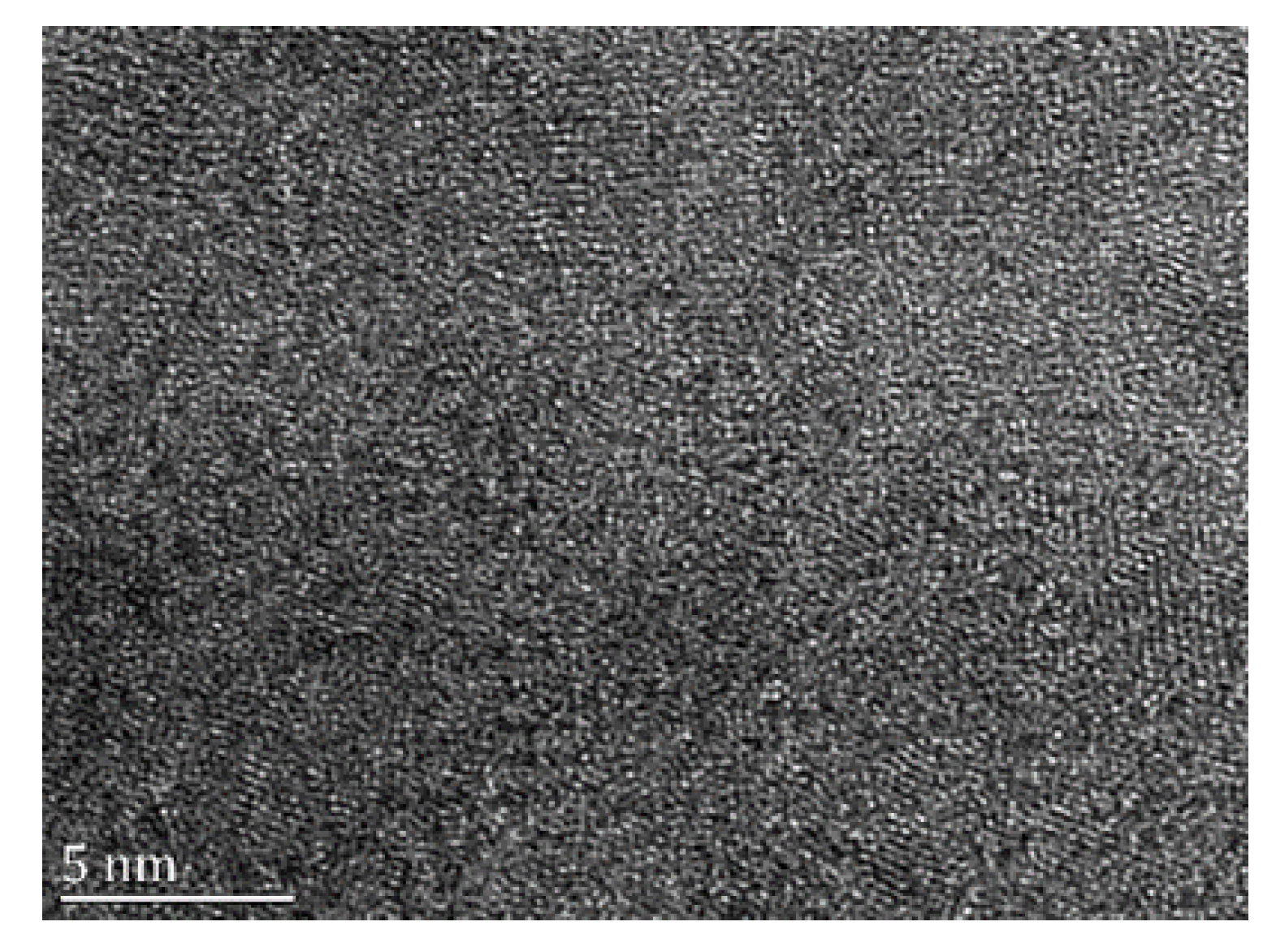

2. Experiments

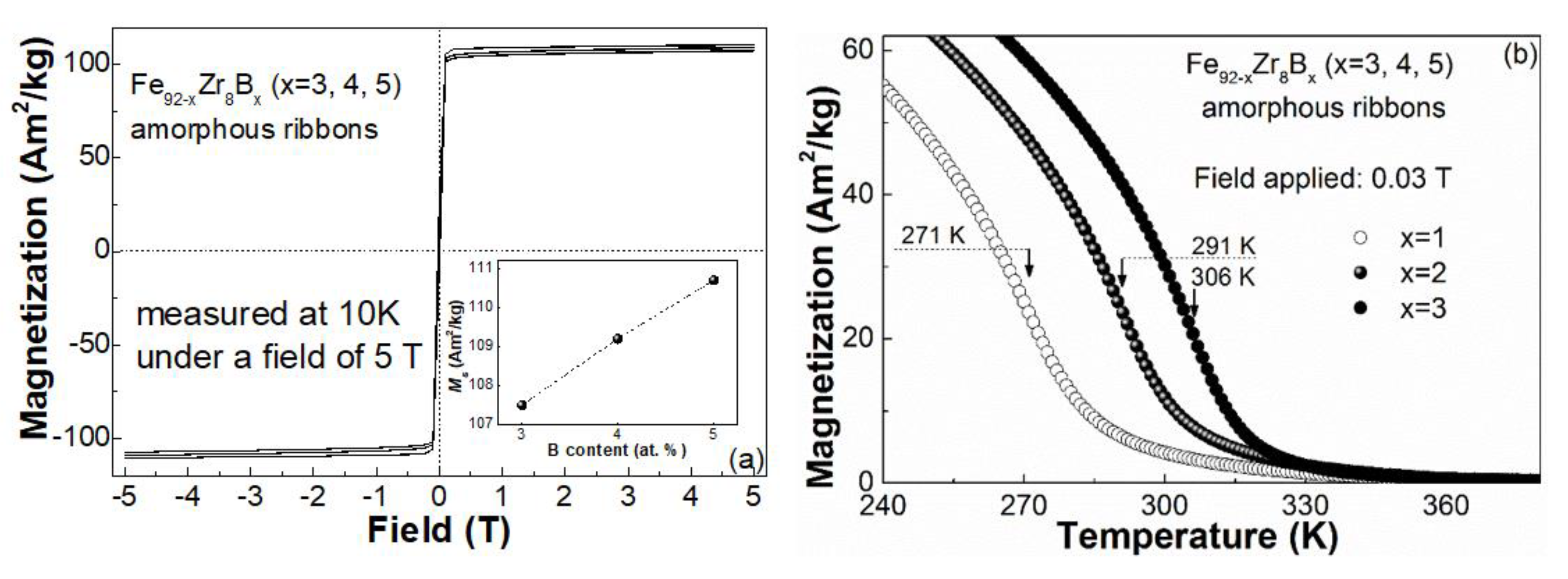

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shen, X.; Liu, H.; Cheng, X.B.; Yan, C.; Huang, J.Q. Beyond lithium ion batteries: Higher energy density battery systems based on lithium metal anodes. Energy Storage Mater. 2018, 12, 161–175. [Google Scholar] [CrossRef]

- Gschneider, K.A.; Pecharsky, V.K. Magnetocaloric Materials. Annu. Rev. Mater. Sci. 2000, 30, 387–429. [Google Scholar] [CrossRef] [Green Version]

- Phan, M.H.; Peng, H.X. Giant magnetoimpedance materials: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 323–420. [Google Scholar] [CrossRef]

- Yang, L.; Chen, Z.G.; Dargusch, M.S.; Zou, J. High Performance Thermoelectric Materials: Progress and Their Applications. Adv. Energy Mater. 2018, 8, 1701797. [Google Scholar] [CrossRef]

- Tang, B.Z.; Guo, D.Q.; Xia, L.; Ding, D.; Chan, K.C. Magnetoelastic and magnetocaloric properties of Tb62.5Co37.5 amorphous alloy. J. Alloys Compd. 2017, 728, 747–751. [Google Scholar] [CrossRef]

- Tishin, A.M.; Spichkin, Y.I. The magnetocaloric effect and its applications. Inst. Phys. Bristol. 2003. [Google Scholar] [CrossRef]

- de Oliveira, N.A.; von Ranke, P.J. Theoretical aspects of the magnetocaloric effect. Phys. Rep. 2010, 489, 89–160. [Google Scholar] [CrossRef]

- Gschneider, K.A.; Pecharsky, V.K.; Tsokol, A.O. Recent developments in magnetocaloric materials. Rep. Prog. Phys. 2005, 68, 1479–1539. [Google Scholar] [CrossRef]

- Franco, V.; Blázquez, J.S.; Ipus, J.J.; Law, J.Y.; Moreno-Ramírez, L.M.; Conde, A. Magnetocaloric effect: From materials research to refrigeration devices. Prog. Mater. Sci. 2018, 93, 112–232. [Google Scholar] [CrossRef]

- Chaudhary, V.; Chen, X.; Ramanujan, R.V. Iron and manganese based magnetocaloric materials for near room temperature thermal management. Prog. Mater. Sci. 2019, 100, 64–98. [Google Scholar] [CrossRef]

- Franco, V.; Conde, A. Magnetic refrigerants with continuous phase transitions: Amorphous and nanostructured materials. Scr. Mater. 2012, 69, 594–599. [Google Scholar] [CrossRef]

- Brück, E. Developments in magnetocaloric refrigeration. J. Phys. D Appl. Phys. 2005, 38, R381–R391. [Google Scholar] [CrossRef]

- Hashimoto, T.; Kuzuhara, T.; Matsumoto, K.; Sahashi, M.; Inomata, K.; Tomokiyo, A.; Yayama, H. New application of complex magnetic materials to the magnetic refrigerant in an Ericsson magnetic refrigerator. J. Appl. Phys. 1987, 62, 3873–3878. [Google Scholar] [CrossRef]

- Luo, Q.; Wang, W.H. Rare earth based bulk metallic glasses. J. Non-Cryst. Solids 2009, 355, 759–775. [Google Scholar] [CrossRef]

- Xia, L.; Tang, M.B.; Chan, K.C.; Dong, Y.D. Large magnetic entropy change and adiabatic temperature rise of a Gd55Al20Co20Ni5 bulk metallic glass. J. Appl. Phys. 2014, 115, 223904. [Google Scholar] [CrossRef]

- Tang, B.Z.; Huang, L.W.; Song, M.N.; Ding, D.; Wang, X.; Xia, L. Compositional dependence of magnetic and magnetocaloric properties of the Gd-Ni binary amorphous alloys. J. Non-Cryst. Solids. 2019, 522, 119589. [Google Scholar] [CrossRef]

- Huo, J.T.; Huo, L.H.; Li, J.W.; Men, H.; Wang, X.M.; Inoue, A.; Chang, C.T.; Wang, J.Q.; Li, R.W. High-entropy bulk metallic glasses as promising magnetic refrigerants. J. Appl. Phys. 2015, 117, 073902. [Google Scholar] [CrossRef]

- Tang, B.Z.; Xie, H.X.; Li, D.M.; Xia, L.; Yu, P. Microstructure and its effect on magnetic and magnetocaloric properties of the Co50Gd50−xFex glassy ribbons. J. Non-Cryst. Solids 2020, 533, 119935. [Google Scholar] [CrossRef]

- Wang, X.; Tang, B.Z.; Wang, Q.; Yu, P.; Ding, D.; Xia, L. Co50Gd48−xFe2Nix amorphous alloys with high adiabatic temperature rise near the hot end of a domestic magnetic refrigerator. J. Non-Cryst. Solids 2020, 544, 120146. [Google Scholar] [CrossRef]

- Hasegawa, R.; Ray, R. Iron-boron metallic glasses. J. Appl. Phys. 1978, 49, 4174–4179. [Google Scholar] [CrossRef]

- O’Handley, R.C. Physics of ferromagnetic amorphous alloys. J. Appl. Phys. 1987, 62, R15. [Google Scholar] [CrossRef]

- Waske, A.; Schwarz, B.; Mattern, N.; Eckert, J. Magnetocaloric (Fe–B)-based amorphous alloys. J. Magn. Magn. Mater. 2013, 329, 101–104. [Google Scholar] [CrossRef]

- Maeda, H.; Sato, M.; Uehara, M. Fe-Zr Amorphous Alloys for Magnetic Refrigerants near Room Temperature. J. Jpn. Inst. Met. 1983, 47, 688–691. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.Y.; Hou, K.; Bi, X. Hydrogenated Fe90M10 (M: Zr and Sc) amorphous alloys with enhanced room-temperature magnetocaloric effect. J. Alloys Compd. 2016, 689, 564–569. [Google Scholar] [CrossRef]

- Min, S.G.; Kim, K.S.; Yu, S.C.; Suh, H.S.; Lee, S.W. Analysis of magnetization and magnetocaloric effect in amorphous FeZrMn ribbons. J. Appl. Phys. 2005, 97, 10M310. [Google Scholar] [CrossRef]

- Kim, K.S.; Min, S.G.; Yu, S.C.; Oh, S.K.; Kim, Y.C.; Kim, K.Y. The large magnetocaloric effect in amorphous Fe91−xYxZr9 (x=0, 5, 10) alloys. J. Magn. Magn. Mater. 2006, 304, E642–E644. [Google Scholar] [CrossRef]

- Mishra, D.; Gurram, M.; Reddy, A.; Perumal, A.; Saravanan, P.; Srinivasan, A. Enhanced soft magnetic properties and magnetocaloric effect in B substituted amorphous Fe-Zr alloy ribbons. Mater. Sci. Eng. B 2010, 175, 253–260. [Google Scholar] [CrossRef]

- Guo, D.Q.; Chan, K.C.; Xia, L.; Yu, P. Magneto-caloric effect of FexZryB100−x−y metallic ribbons for room temperature magnetic refrigeration. J. Magn. Magn. Mater. 2017, 423, 379–385. [Google Scholar] [CrossRef]

- Yu, P.; Zhang, J.Z.; Xia, L. Effect of boron on the magneto-caloric effect in Fe91−xZr9Bx (x= 3, 4, 5) amorphous alloys. J. Mater. Sci. 2017, 52, 13948–13955. [Google Scholar] [CrossRef]

- Alvarez-Alonso, P.; Sánchez Llamazares, J.L.; Sánchez-Valdés, C.F.; Fdez-Gubieda, M.L.; Gorria, P.; Blanco, J.A. High-magnetic field characterization of magnetocaloric effect in FeZrB(Cu) amorphous ribbons. J. Appl. Phys. 2015, 117, 17A710. [Google Scholar] [CrossRef] [Green Version]

- Li, X.Z.; Pan, Y. Magnetocaloric effect in Fe-Zr-B-M (M = Ni, Co, Al, and Ti) amorphous alloys. J. Appl. Phys. 2014, 116, 093910. [Google Scholar] [CrossRef]

- Kiss, L.F.; Kemeny, T.; Franco, V.; Conde, A. Enhancement of magnetocaloric effect in B-rich FeZrBCu amorphous alloys. J. Alloys Compd. 2015, 622, 756–760. [Google Scholar] [CrossRef]

- Fang, Y.K.; Yeh, C.C.; Hsieh, C.C.; Chang, C.W.; Chang, H.W.; Chang, W.C.; Li, X.M.; Li, W. Magnetocaloric effect in Fe-Zr-B-M (M=Mn, Cr, and Co) amorphous systems. J. Appl. Phys. 2009, 105, 07A910. [Google Scholar] [CrossRef]

- Gan, L.H.; Ma, L.Y.; Tang, B.Z.; Ding, D.; Xia, L. Effect of Co substitution on the glass forming ability and magnetocaloric effect of Fe88Zr8B4 amorphous alloys. Sci. China Phys. Mech. Astro. 2017, 60, 076121. [Google Scholar] [CrossRef]

- Chen, L.S.; Zhang, J.Z.; Lin, W.; Yu, P.; Xia, L. Outstanding magnetocaloric effect of Fe88−xZr8B4Smx (x=0, 1, 2, 3) amorphous alloys. Sci. China-Phys. Mech. Astro. 2018, 61, 056121. [Google Scholar] [CrossRef]

- Yu, P.; Zhang, J.Z.; Xia, L. Fe87Zr7B4Co2 amorphous alloy with excellent magneto-caloric effect near room temperature. Intermetallics 2018, 95, 85–88. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Fornell, J.; Feng, Y.P.; Golvano, I.; Barób, M.D.; Pellicer, E.; Sort, J. Inducing surface nanoporosity on Fe-based metallic glass matrix composites by selective dealloying. Mater. Charact. 2019, 153, 46–51. [Google Scholar] [CrossRef]

- Nagase, T.; Yokoyama, A.; Umakoshi, Y. In situ TEM observation of the glass-to-liquid transition of metallic glass in Fe-Zr-B-Cu alloy. Scr. Mater. 2010, 63, 1020–1023. [Google Scholar] [CrossRef]

- Álvarez, P.; Gorria, P.; Marcos, J.S.; Barquín, L.F.; Blanco, J.A. The role of boron on the magneto-caloric effect of FeZrB metallic glasses. Intermetallics 2010, 18, 2464–2467. [Google Scholar] [CrossRef]

- Álvarez, P.; Marcos, J.S.; Gorria, P.; Barquín, L.F.; Blanco, J.A. Magneto-caloric effect in FeZrB amorphous alloys near room temperature. J. Alloys. Compd. 2010, 504, S150–S154. [Google Scholar] [CrossRef]

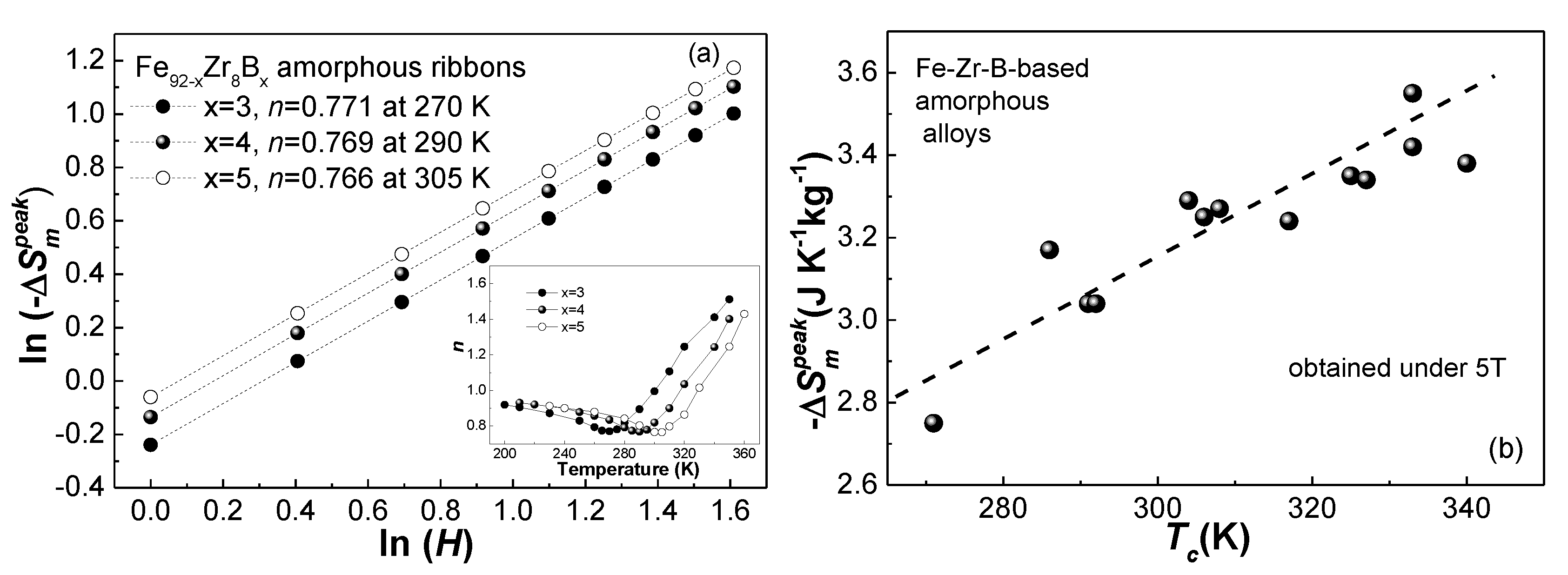

- Franco, V.; Blázquez, J.S.; Conde, A. The influence of Co addition on the magnetocaloric effect of Nanoperm-type amorphous alloys. J. Appl. Phys. 2006, 100, 064307. [Google Scholar] [CrossRef]

- Banerjee, S.K. On a generalized approach to first and second order magnetic transitions. Phys. Lett. 1964, 12, 16–17. [Google Scholar] [CrossRef]

- Law, J.Y.; Franco, V.; Moreno-Ramírez, L.M.; Conde, A.; Karpenkov, D.Y.; Radulov, I.; Skokov, K.P.; Gutfleisch, O. A quantitative criterion for determining the order of magnetic phase transitions using the magnetocaloric effect. Nat. Commun. 2018, 9, 2680. [Google Scholar] [CrossRef] [PubMed]

- Bloe, J.H.; Amaral, J.S.; Pereira, A.M.; Amaral, V.S.; Araujo, J.P. On the Curie temperature dependency of the magnetocaloric effect. Appl. Phys. Lett. 2012, 100, 242407. [Google Scholar] [CrossRef]

| Composition | −ΔSmpeak * (J kg−1 K−1) | Tc (K) | Ref. | ||||

|---|---|---|---|---|---|---|---|

| 1 T | 1.5 T | 2 T | 3 T | 5 T | |||

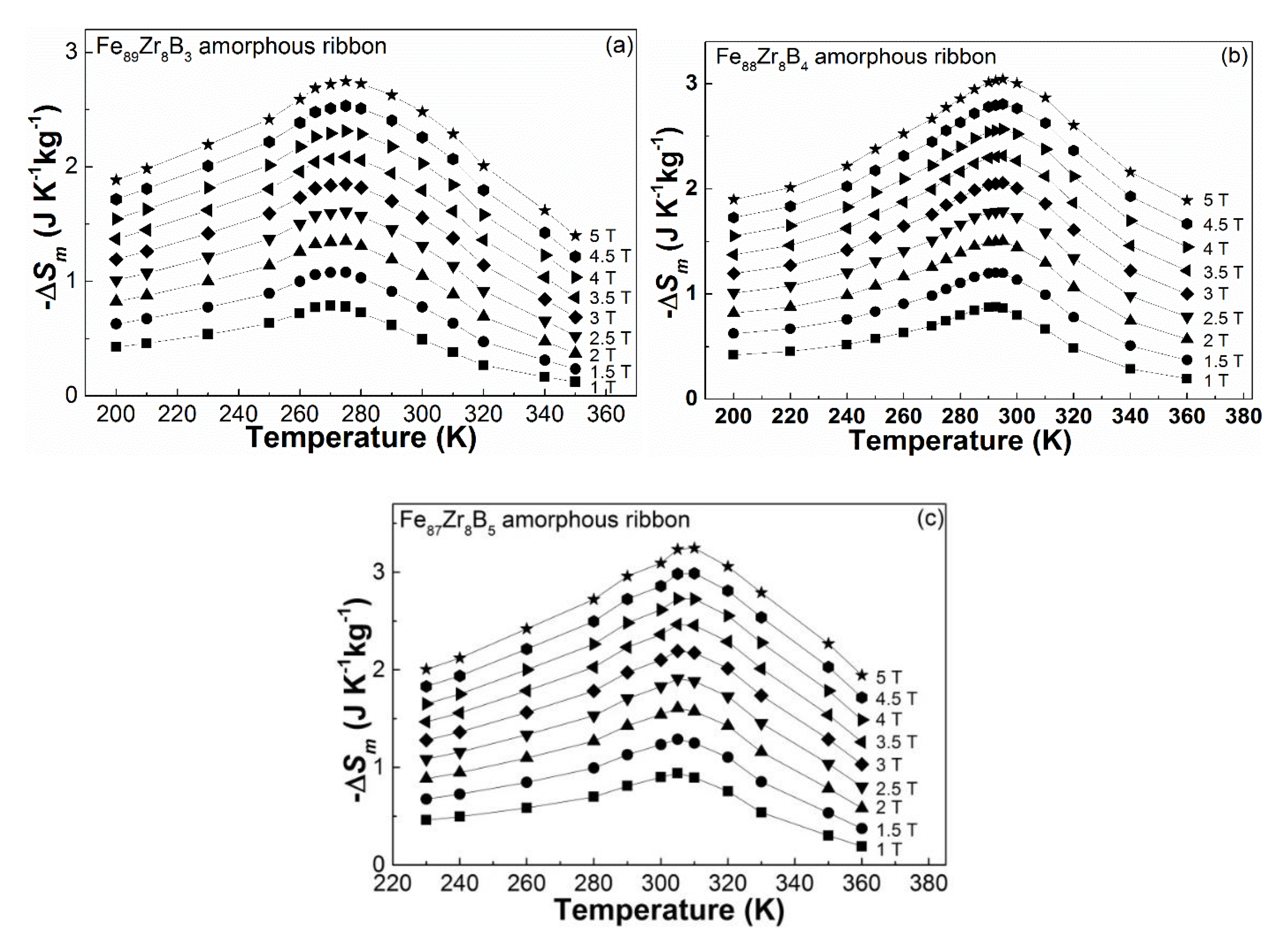

| Fe89Zr8B3 | 0.79 | 1.08 | 1.35 | 1.85 | 2.75 | 271 | Present work |

| Fe88Zr8B4 | 0.88 | 1.20 | 1.50 | 2.06 | 3.04 | 291 | |

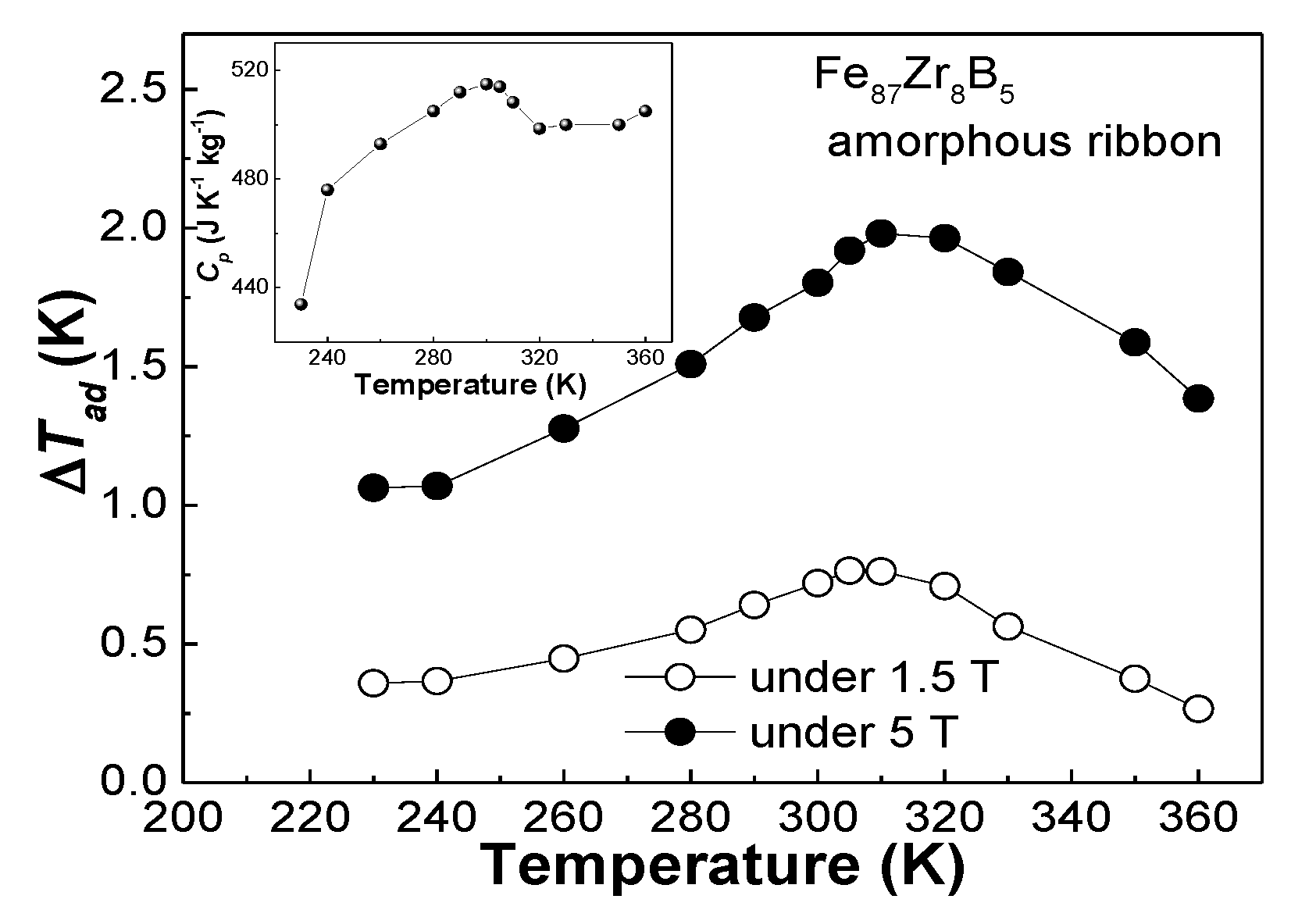

| Fe87Zr8B5 | 0.94 | 1.29 | 1.61 | 2.19 | 3.25 | 306 | |

| Fe88Zr9B3 | 0.94 | 1.28 | 1.59 | 2.16 | 3.17 | 286 | [29] |

| Fe87Zr9B4 | 0.99 | 1.35 | 1.67 | 2.26 | 3.29 | 304 | |

| Fe86Zr9B5 | 1.02 | 1.39 | 1.72 | 2.3 | 3.34 | 327 | |

| Fe88Zr8B4 | 0.87 | 1.2 | 1.5 | 2.06 | 3.04 | 292 | [34] |

| Fe87Co1Zr8B4 | 0.93 | 1.29 | 1.61 | 2.2 | 3.24 | 317 | |

| Fe86Co2Zr8B4 | 0.98 | 1.35 | 1.69 | 2.31 | 3.38 | 340 | |

| Fe87Zr8B4Sm1 | 0.98 | 1.33 | 1.65 | 2.24 | 3.27 | 308 | [35] |

| Fe86Zr8B4Sm2 | 1.04 | 1.41 | 1.73 | 2.32 | 3.35 | 325 | |

| Fe85Zr8B4Sm3 | 1.09 | 1.47 | 1.81 | 2.44 | 3.55 | 333 | |

| Fe87Zr7B4Co2 | 1.01 | 1.38 | 1.72 | 2.34 | 3.42 | 333 | [36] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Wang, Q.; Tang, B.Z.; Ding, D.; Cui, L.; Xia, L. Magnetic and Magneto-Caloric Properties of the Amorphous Fe92−xZr8Bx Ribbons. Materials 2020, 13, 5334. https://doi.org/10.3390/ma13235334

Wang X, Wang Q, Tang BZ, Ding D, Cui L, Xia L. Magnetic and Magneto-Caloric Properties of the Amorphous Fe92−xZr8Bx Ribbons. Materials. 2020; 13(23):5334. https://doi.org/10.3390/ma13235334

Chicago/Turabian StyleWang, Xin, Qiang Wang, Ben Zhen Tang, Ding Ding, Li Cui, and Lei Xia. 2020. "Magnetic and Magneto-Caloric Properties of the Amorphous Fe92−xZr8Bx Ribbons" Materials 13, no. 23: 5334. https://doi.org/10.3390/ma13235334