Realization of a Dental Framework by 3D Printing in Material Cobalt-Chromium with Superior Precision and Fitting Accuracy

Abstract

1. Introduction

2. Materials and Methods

2.1. Selective Laser Melting Conditions

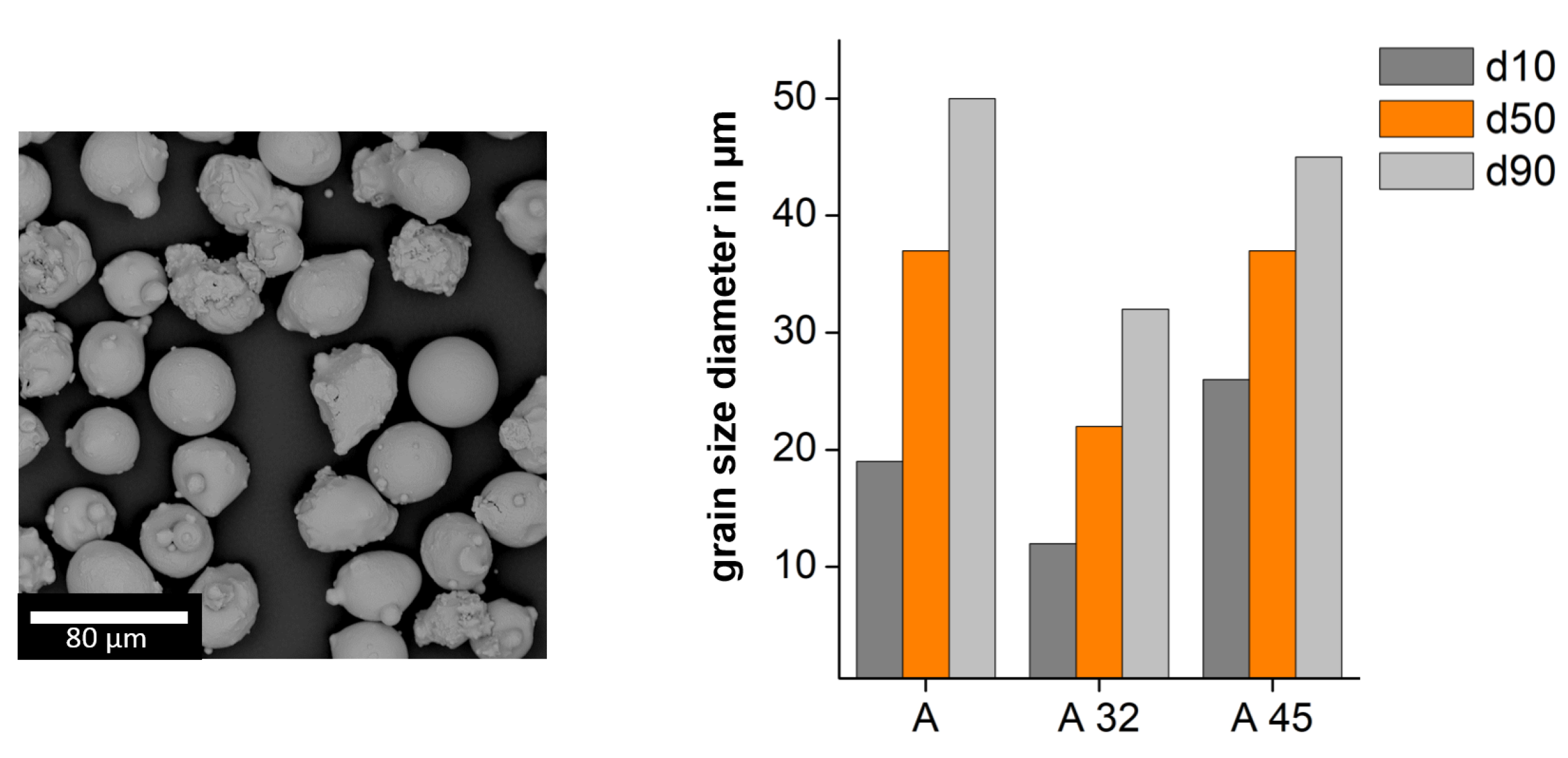

2.2. Powder Characterization

2.3. Mechanical Properties

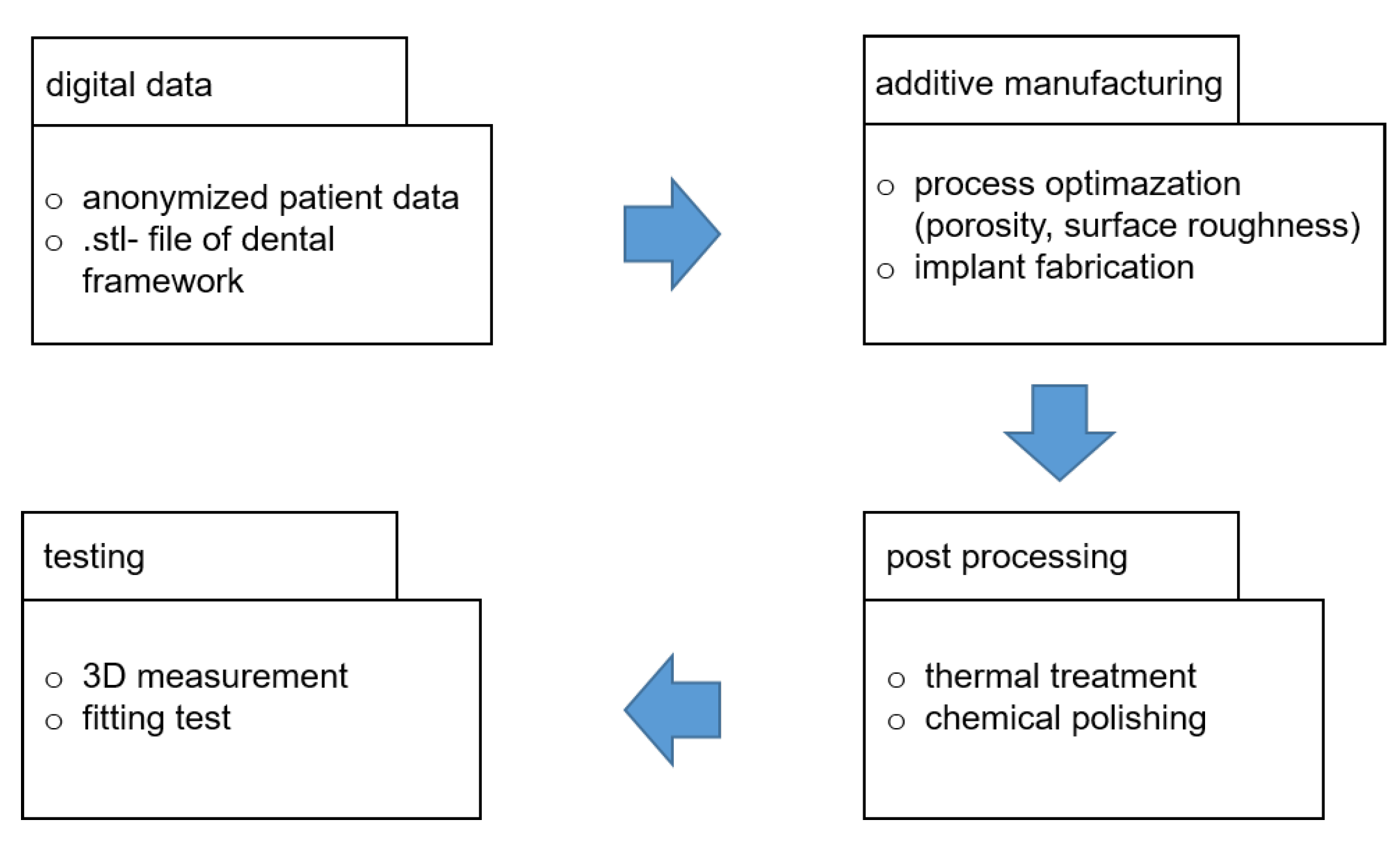

2.4. Experimental Flow Chart

3. Results and Discussion

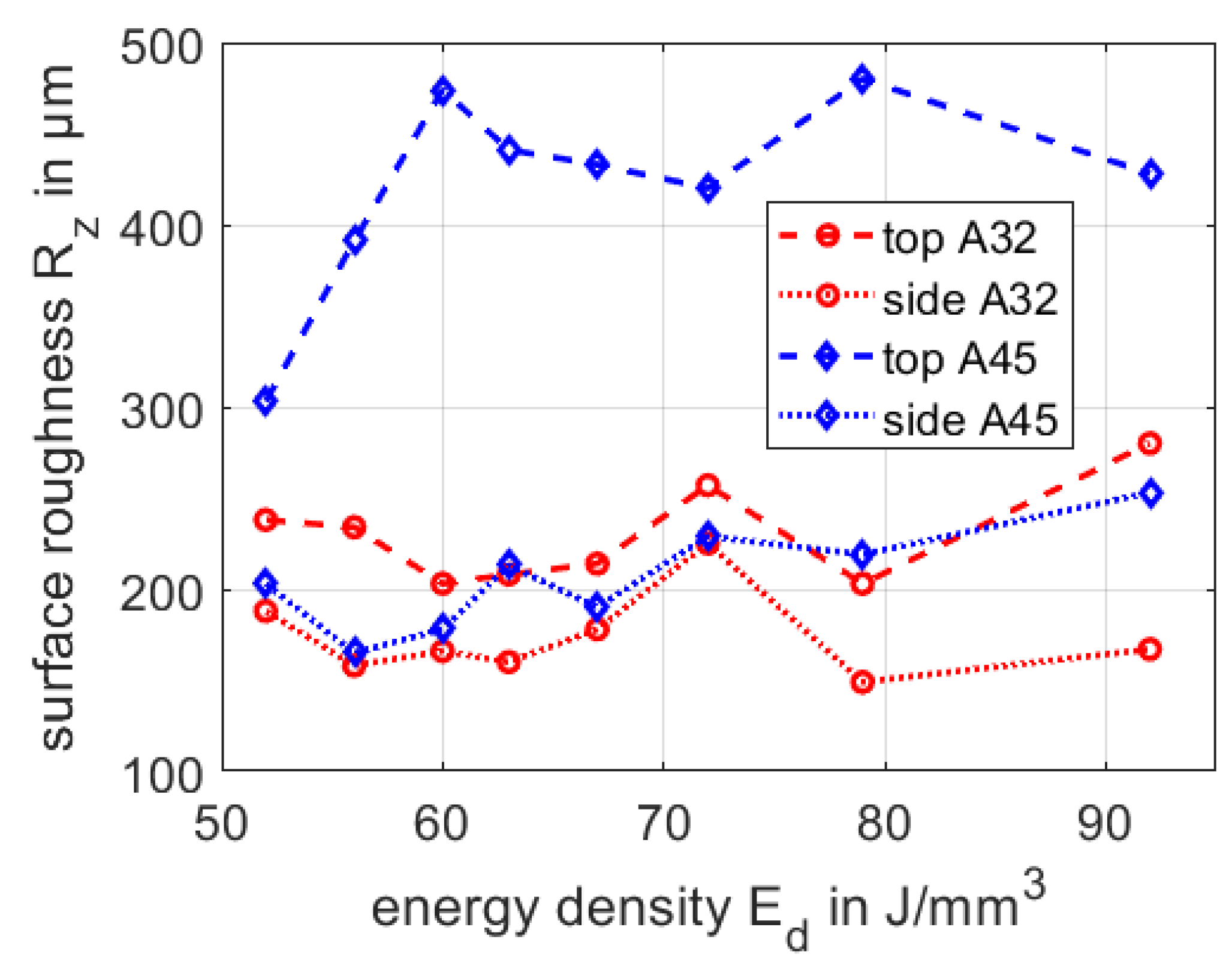

3.1. Optimization of Density and Roughness

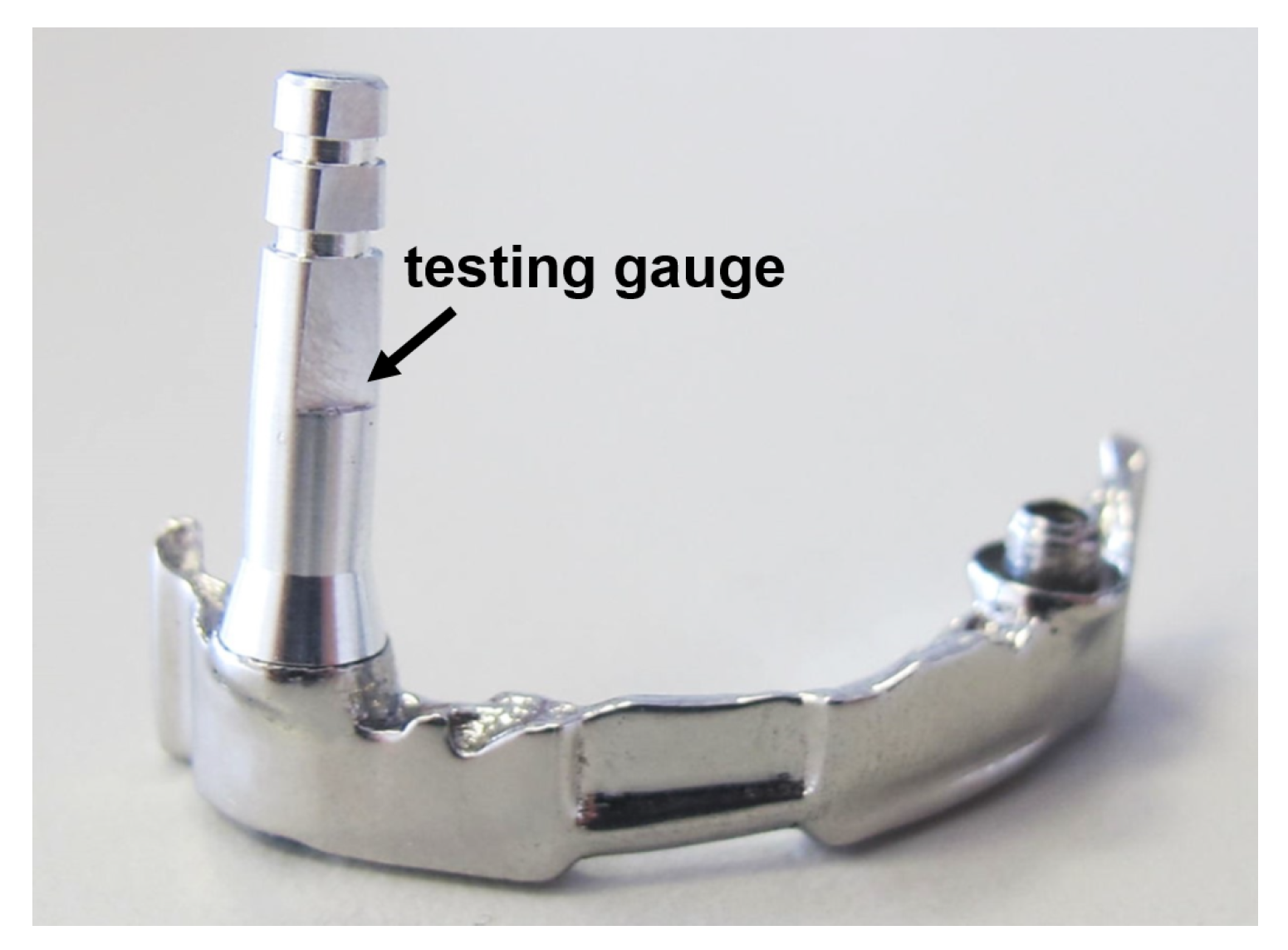

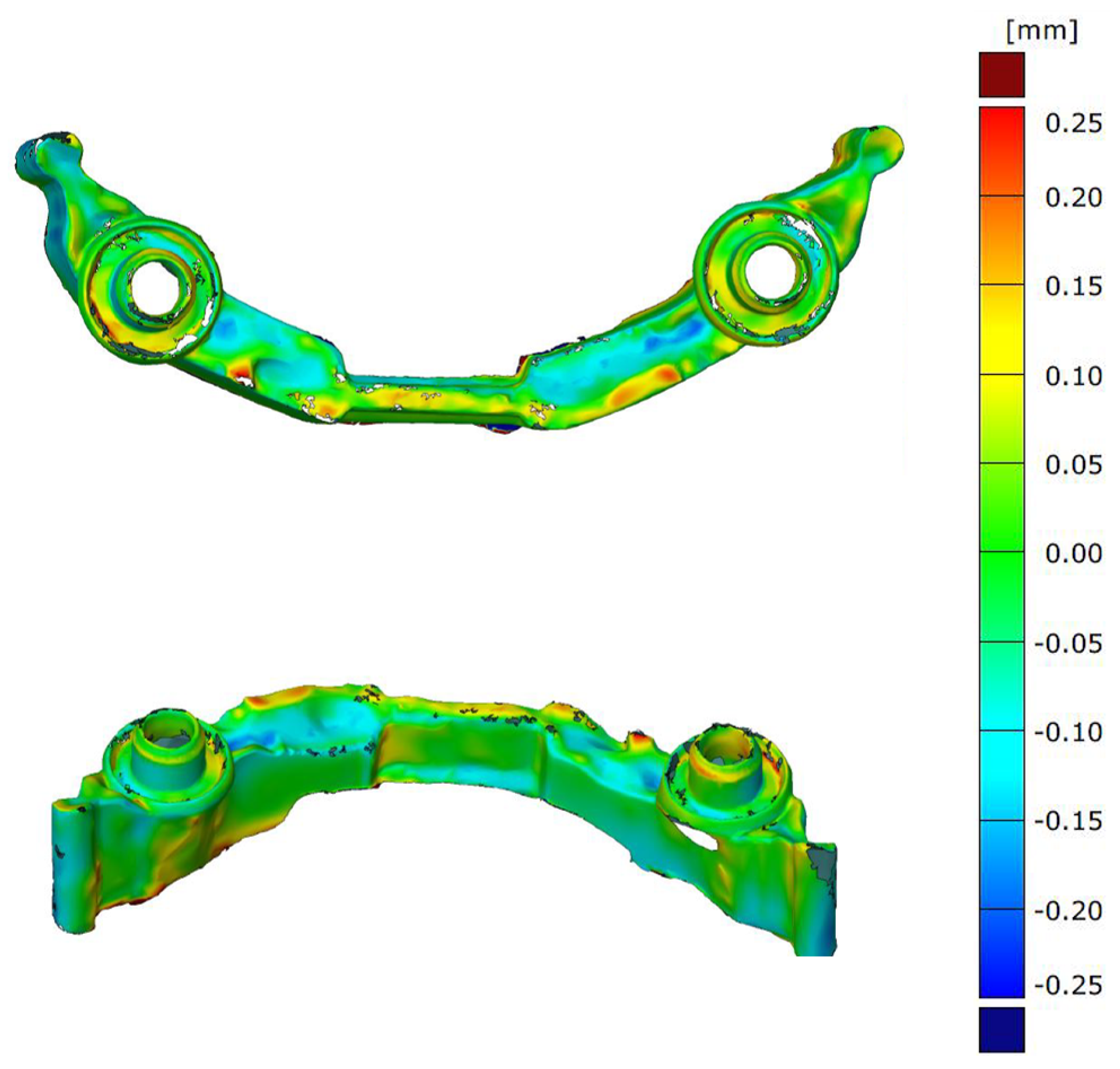

3.2. Fabrication of Dental Framework

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| SLM | selective laser melting |

| AM | additive manufacturing |

References

- Jemt, T. Failures and complications in 391 consecutively inserted fixed prostheses supported by Brånemark implants in edentulous jaws: A study of treatment from the time of prosthesis placement to the first annual checkup. Int. J. Oral Maxillofac. Implants 1991, 6, 270–276. [Google Scholar]

- Wee, A.G.; Aquilino, S.A.; Schneider, R.L. Strategies to achieve fit in implant prosthodontics: A review of the literature. Int. J. Prosthodont. 1999, 12, 167–178. [Google Scholar] [PubMed]

- Kalpana, D.; Sanjana, J.R.; Kumara Raju Kurapati, S.; Joel Koshy, J. Comparative evaluation of one piece and two piece dental implants—A review. Int. J. Sci. Res. 2017, 6, 49–50. [Google Scholar]

- Pjetursson, B.E.; Asgeirsson, A.G.; Zwahlen, M.; Sailer, I. Improvements in implant dentistry over the last decade: Comparison of survival and complication rates in older and newer publications. Int. J. Oral Maxillofac. Implants 2014, 29, 308–324. [Google Scholar] [CrossRef] [PubMed]

- Devaraju, K.; Rao, S.J.; Joseph, J.K.; Kurapati, S.K. Comparison of biomechanical properties of different implant-abutment connections. Indian J. Dent. Sci. 2018, 10, 180–183. [Google Scholar]

- Thalji, G.; McGraw, K.; Cooper, L.F. Maxillary Complete Denture Outcomes: A Systematic Review of Patient-Based Outcomes. Int. J. Oral Maxillofac. Implants 2016, 31, 169–181. [Google Scholar] [CrossRef]

- Örtorp, A.; Jemt, T. CNC-milled titanium frameworks supported by implants in the edentulous jaw: A 10-year comparative clinical study. Clin. Implant Dent. Relat. Res. 2012, 14, 88–99. [Google Scholar] [CrossRef]

- Lowe, L.G.; Shcherbukhin, V.M. An implant-supported, cobalt-chromium milled bar and nonflanged attachment-retained overdenture to rehabilitate the edentulous mandible. J. Prosthet. Dent. 2009, 102, 46–51. [Google Scholar] [CrossRef]

- Kioleoglou, I.; Pissiotis, A.; Konstantinos, M. Accuracy of fit of implant-supported bars favricated on definitive casts made of different dental stones. J. Clin. Exp. Dent. 2018, 10, 252–263. [Google Scholar]

- Rinke, S.; Rasing, H.; Gersdorff, N.; Buergers, R.; Roediger, M. Implant supported over dentures with different bar designs: A retrospective evaluation after 5–19 years of clinical function. J. Adv. Prosthodont. 2015, 7, 338–343. [Google Scholar] [CrossRef]

- Gehrke, P.; Dinkel, J.; Fischer, C.; Schmenger, K.; Sader, R. Surface roughness and necessity of manual refinishing requirements of CAD/CAM-manufatured titanium and cobalt-chrome bars—A pilot study. Open Dent. J. 2019, 13, 316–326. [Google Scholar] [CrossRef]

- Chen, G.; Zeng, X.; Wang, Z.; Guan, K.; Peng, C. Fabrication of removable partial denture framework by selective laser melting. Adv. Mater. Res. 2011, 317–319, 174–178. [Google Scholar] [CrossRef]

- Hong, M.-H.; Ki Min, B.; Kwon, T.-Y. The influence of process parameters on the surface roughness of a 3D-printed CoCr Dental alloy produced via selective laser melting. Appl. Sci. 2016, 6, 401–411. [Google Scholar] [CrossRef]

- Kanazawa, M.; Iwaki, M.; Shunsuke, M.; Naoyuki, N. Fabrication of titanium alloy framework for complete dentures by selective laser melting. J. Prosthet. Dent. 2014, 112, 1441–1447. [Google Scholar] [CrossRef] [PubMed]

- Konieczny, B.; Szczesio-Wlodarczyk, A.; Sokolowski, J.; Bociong, K. Challenges of Co–Cr Alloy Additive Manufacturing Methods in Dentistry—The Current State of Knowledge (Systematic Review). Materials 2020, 13, 3524. [Google Scholar] [CrossRef]

- Weinländer, M.; Piehslinger, E.; Krennmair, G. Removable implant prosthodontic rehabilitation of the edentulous mandible: Five-year results of different prosthetic anchorage concepts. Int. J. Oral Maxillofac. Implants 2010, 25, 589–597. [Google Scholar]

- Mericske-Stern, R. Prosthetic considerations. Aust. Dent. J. 2008, 53, 49–59. [Google Scholar] [CrossRef]

- Waddell, J.N.; Payne, A.G.; Swain, M.V.; Kieser, J.A. Scanning electron microscopy observations of failures of implant overdenture bars: A case series report. Clin. Implant Dent. Relat. Res. 2010, 12, 26–38. [Google Scholar] [CrossRef]

- Abduo, J.; Lyons, K.; Bennani, V.; Waddell, N.; Swain, M. Fit of screwretained fixed implant frameworks fabricated by different methods: A systematic review. Int. J. Prosthodont. 2011, 24, 207–220. [Google Scholar]

- Paniz, G.; Stellini, E.; Meneghello, R.; Cerardi, A.; Gobbato, E.A.; Bressan, E. The precision of fit of cast and milled full-arch implant-supported restorations. Int. J. Oral Maxillofac. Implants 2013, 28, 687–693. [Google Scholar] [CrossRef]

- Katsoulis, J.; Mericske-Stern, R.; Yates, D.M.; Izutani, N.; Enkling, N.; Blatz, M.B. In vitro precision of fit of computer-aided design and computeraided manufacturing titanium and zirconium dioxide bars. Dent. Mater. 2013, 29, 945–953. [Google Scholar] [CrossRef] [PubMed]

- Miyazaki, T.; Hotta, Y.; Kunii, J.; Kuriyama, S.; Tamaki, Y. A review of dental CAD/CAM: Current status and future perspectives from 20 years of experience. Dent. Mater. J. 2009, 28, 44–56. [Google Scholar] [CrossRef] [PubMed]

- Bollen, C.M.; Lambrechts, P.; Quirynen, M. Comparison of surface roughness of oral hard materials to the threshold surface roughness for bacterial plaque retention: A review of the literature. Dent. Mater. 1997, 13, 258–269. [Google Scholar] [CrossRef]

- Romero, G.G.; Engelmeier, R.; Powers, J.M.; Canterbury, A. Accuracy of three corrective techniques for implant bar fabrication. J. Prosthet. Dent. 2000, 84, 602–607. [Google Scholar] [CrossRef] [PubMed]

- Abduo, J.A.; Lyons, K.L. Effect of vertical misfit on strain within screw-retained implant titanium and zirconia frameworks. J. Prosthodont Res. 2012, 56, 102–109. [Google Scholar] [CrossRef]

- Karl, M.; Winter, W.; Taylor, T.D.; Heckmann, S.M. In vitro study on passive fit in implant-supported 5-unit fixed partial dentures. Int. J. Oral Maxillofac. Implants 2004, 19, 30–37. [Google Scholar]

- Hanif, A.; Qureshi, S.; Sheikh, Z.; Rashid, H. Complications in implant dentistry. Eur. J. Dent. 2017, 11, 135–140. [Google Scholar] [CrossRef]

- Clelland, N.L.; Papazoglou, E.; Carr, A.B.; Gilat, A. Comparison of strains transferred to a bone sumulant among implant overdenture bars with various levels of misfir. J. Prosthodont. 1995, 4, 243–250. [Google Scholar] [CrossRef]

- Torsello, F.; di Torresanto, V.M.; Ercoli, C.; Cordaro, L. Evaluation of the marginal precision of one-piece complete arch titanium frameworks fabricated using five different methods for implant-supported restorations. Clin. Oral Implant. Res. 2008, 19, 772–779. [Google Scholar] [CrossRef]

- Takahashi, T.; Gunne, J. Fit of implant frameworks: An in vitro comparison between two fabrication techniques. J. Prosthet. Dent. 2003, 89, 256–260. [Google Scholar] [CrossRef]

- Buzayan, M.M.; Yunus, N.B. Passive fit in screw retained multi-unit implant prosthesis understanding and achieving: A review of the literature. J. Indian Prosthodont. Soc. 2014, 14, 16–23. [Google Scholar] [CrossRef] [PubMed]

- Di Giacomo, A.P.; Cury, P.R.; Airton, D.; DaSilva, M.; DaSilva, V.L.; Sergio, D.; Ajzen, A. A selective laser sintering prototype guide used to fabricate immediate interim fixed complete arch prostheses in flapless dental implant surgery: Technique description and clinical results. J. Prosthet. Dent. 2016, 116, 874–879. [Google Scholar] [CrossRef] [PubMed]

- Jamshidinia, M.; Wang, L.; Tong, W.; Ajlouni, R.; Kovacevic, R. Fatigue properties of a dental implant produced by electron beam melting. J. Mater. Process. Technol. 2015, 226, 255–263. [Google Scholar] [CrossRef]

- Lima, J.; Anami, L.; Araujo, R.; Pavanelli, C. Removable Partial Dentures: Use of Rapid Prototyping. J. Prosthodont. 2014, 23, 588. [Google Scholar] [CrossRef]

- Cherry, J.; Davies, H.; Mehmood, S.; Lavery, N.; Brown, S.; Sienz, J. Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int. J. Adv. Manuf. Technol. 2015, 76, 869–879. [Google Scholar] [CrossRef]

- Spierings, A.B.; Levy, G. Comparision of density of stainless steel parts produced with selective laser melting using different powder grades. In Proceedings of the Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 3–5 August 2009. [Google Scholar]

- Nguyen, Q.B.; Nai, M.L.S.; Zhu, Z.; Sun, C.N.; Wei, J.; Zhou, W. Characteristics of Inconel Powders for Powder-Bed Additive Manufacturing. Engineering 2017, 3, 695–700. [Google Scholar] [CrossRef]

- Clayton, J. Optimising metal powders for additive manufacturing. Met. Powder Rep. 2014, 69, 14–17. [Google Scholar] [CrossRef]

- Lee, Y.S.; Zhang, W. Mesoscopic simulation of heat transfer and fluid flow in laser powder bed additive manufacturing. In Proceedings of the International Solid Free Form Fabrication Symposium, Austin, TX, USA, 12 August 2015. [Google Scholar]

- Karapatis, N.P.; Egger, G.; Gygax, P.E.; Glardon, R. Optimization of powder layer density in selective laser sintering. In Proceedings of the 1999 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 25 April 1999. [Google Scholar]

- Eisenbacher Dentalwaren ED GmbH. Product Specification of Kera S-Powder; Eisenbacher Dentalwaren ED GmbH: Wörth am Main, Germany, 2015. [Google Scholar]

- Maamoun, A.H.; Xue, Y.F.; Elbestawi, M.A.; Veldhuis, S.C. Effect of Selective Laser Melting Process Parameters on the Quality of Al Alloy Parts: Powder Characterization, Density, Surface Roughness, and Dimensional Accuracy. Materials 2018, 11, 2343. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Maity, T.; Das, J.; Eckert, J. Is the energy density a reliable parameter for materials synthesis by selective laser melting? Mater. Res. Lett. 2017, 5, 386–390. [Google Scholar] [CrossRef]

- Aboulkhaira, N.T.; Everitt, N.M.; Ashcroft, I.; Tuck, C. Reducing porosity in AlSi10Mg parts processed by selective laser melting. Addit. Manuf. 2014, 1–4, 77–86. [Google Scholar] [CrossRef]

- Zhang, L.-C.; Attar, H. Selective Laser Melting of Titanium Alloys and Titanium Matrix Composites for Biomedical Applications: A Review. Adv. Eng. Mater. 2016, 18, 463–475. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; Van Humbeeck, J.; Kruth, J.-P. Mechanical properties of AlSi10Mg produced by Selective Laser Melting. Phys. Procedia 2012, 39, 439–446. [Google Scholar] [CrossRef]

- Pleass, C.; Jothi, S. Influence of powder characteristics and additive manufacturing process parameters on the microstructure and mechanical behaviour of Inconel 625 fabricated by Selective Laser Melting. Addit. Manuf. 2018, 24, 419–431. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Hao, L.; Jerrard, P.G.E.; Zhang, D.Z. Experimental investigation on selective laser melting behaviour and processing windows of in situ reacted Al/Fe2O3 powder mixture. Powder Technol. 2012, 231, 112–121. [Google Scholar] [CrossRef]

- Calignano, F.; Manfredi, D.; Ambrosio, E.P.; Iuliano, L.; Fino, P. Influence of process parameters on surface roughness of aluminum parts produced by DMLS. Int. J. Adv. Manuf. Technol. 2013, 67, 2743–2751. [Google Scholar] [CrossRef]

- Yang, T.; Liu, T.; Liao, W.; MacDonald, E.; Wei, H.; Chen, X.; Jiang, L. The influence of process parameters on vertical surface roughness of the AlSi10Mg parts fabricated by selective laser melting. J. Mater. Process. Technol. 2019, 266, 26–36. [Google Scholar] [CrossRef]

| wt% | Cobalt | Chromium | Tungsten | Silicon | Manganous | Iron | Others |

|---|---|---|---|---|---|---|---|

| Powder | 62.44 | 27.50 | 8.09 | 1.52 | 0.2 | 0.11 | <0.1 |

| A 32 | A45 | |

|---|---|---|

| flow time (s) | 19.1 ± 0.1 | 14.5 ± 0.3 |

| powder density (g/) | 3.6 ± 0.1 | 3.1 ± 0.1 |

| Tensile Strength | Young’s Modulus | Elongation | Yield Strength | |

|---|---|---|---|---|

| SLM | 969 MPa | 170 GPa | 18% | 567 MPa |

| reference [41] | 1021 MPa | 196 GPa | 8% | 642 MPa |

| Hardness | Thermal Expansion | |

|---|---|---|

| SLM | 365 HV | |

| reference [41] | 356 HV | 14.25 × |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Edelmann, A.; Riedel, L.; Hellmann, R. Realization of a Dental Framework by 3D Printing in Material Cobalt-Chromium with Superior Precision and Fitting Accuracy. Materials 2020, 13, 5390. https://doi.org/10.3390/ma13235390

Edelmann A, Riedel L, Hellmann R. Realization of a Dental Framework by 3D Printing in Material Cobalt-Chromium with Superior Precision and Fitting Accuracy. Materials. 2020; 13(23):5390. https://doi.org/10.3390/ma13235390

Chicago/Turabian StyleEdelmann, André, Lisa Riedel, and Ralf Hellmann. 2020. "Realization of a Dental Framework by 3D Printing in Material Cobalt-Chromium with Superior Precision and Fitting Accuracy" Materials 13, no. 23: 5390. https://doi.org/10.3390/ma13235390

APA StyleEdelmann, A., Riedel, L., & Hellmann, R. (2020). Realization of a Dental Framework by 3D Printing in Material Cobalt-Chromium with Superior Precision and Fitting Accuracy. Materials, 13(23), 5390. https://doi.org/10.3390/ma13235390