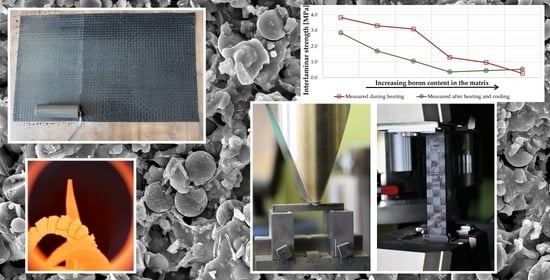

Effect of Boric Acid Content in Aluminosilicate Matrix on Mechanical Properties of Carbon Prepreg Composites

Abstract

Share and Cite

Haincová, E.; Hájková, P. Effect of Boric Acid Content in Aluminosilicate Matrix on Mechanical Properties of Carbon Prepreg Composites. Materials 2020, 13, 5409. https://doi.org/10.3390/ma13235409

Haincová E, Hájková P. Effect of Boric Acid Content in Aluminosilicate Matrix on Mechanical Properties of Carbon Prepreg Composites. Materials. 2020; 13(23):5409. https://doi.org/10.3390/ma13235409

Chicago/Turabian StyleHaincová, Eliška, and Pavlína Hájková. 2020. "Effect of Boric Acid Content in Aluminosilicate Matrix on Mechanical Properties of Carbon Prepreg Composites" Materials 13, no. 23: 5409. https://doi.org/10.3390/ma13235409

APA StyleHaincová, E., & Hájková, P. (2020). Effect of Boric Acid Content in Aluminosilicate Matrix on Mechanical Properties of Carbon Prepreg Composites. Materials, 13(23), 5409. https://doi.org/10.3390/ma13235409