Estimation of Coal’s Sorption Parameters Using Artificial Neural Networks

Abstract

1. Introduction

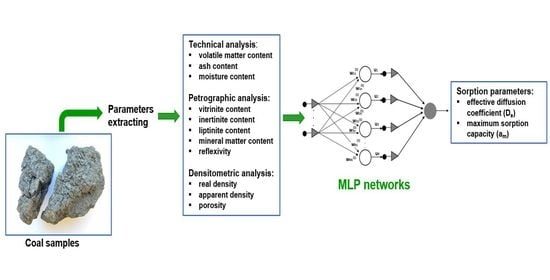

2. Materials and Methods

- R—equivalent radius: ;

- d1—minimal grain diameter (lower sieve size, cm),

- d2—maximal grain diameter (upper sieve size, cm),

- t1/2—sorption half-time (s); and

- a—amount of sorbed methane under given equilibrium pressure p (m3CH4/Mg),

- am—maximal sorption capacity when p→∞ (m3CH4/Mg),

- b—constant peculiar of coal–methane system (MPa−1), and

- p—free gas pressure (in volume stage, MPa).

- Obtained parameters in the course of technical analysis:

- volatile matter content—Vdaf (%),

- ash content—Aa (%),

- moisture content—Wa (%).

- Obtained parameters in the course of petrographic analysis:

- vitrinite content—W (%),

- inertinite content—I (%),

- liptinite content—L (%),

- mineral matter content—M (%),

- reflexivity—Ro (%),

- Parameters obtained in the course of densitometric analysis:

- real density—ρr (g/cm3),

- apparent density—ρp (g/cm3),

- porosity—ε (%).

3. Prediction Model

- —prediction value,

- —observed (measured) value,

- Xi—test-set element, and

- n—number of elements in the test set.

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dutka, B.; Godyń, K. Predicting variability of methane pressure with depth of coal seam. Przem. Chem. 2018, 97, 1344–1348. [Google Scholar] [CrossRef]

- Lama, R.D.; Bodziony, J. Management of outburst in underground coal mines. Int. J. Coal Geol. 1998, 35, 83–115. [Google Scholar] [CrossRef]

- Godyń, K. Structurally Altered Hard Coal in the Areas of Tectonic Disturbances-An Initial Attempt at Classification. Arch. Min. Sci. 2016, 61, 677–694. [Google Scholar] [CrossRef]

- Godyń, K.; Kožušníková, A. Microhardness of Coal from Near-Fault Zones in Coal Seams Threatened with Gas-Geodynamic Phenomena, Upper Silesian Coal Basin, Poland. Energies 2019, 12, 1756. [Google Scholar] [CrossRef]

- Zhang, L.; Ren, T.X.; Aziz, N. A stydy of laboratory testing and calculation methods for coal sorption isotherms. J. Coal Sci. Eng. 2013, 19, 193–202. [Google Scholar] [CrossRef]

- Levine, J.R. Influences of coal composition on coal seam reservoir quality. A review. In Symposium on Coalbed Methane Research and Development in Australia; Coalseam Gas Research Institute–James Cook University: Townsville, Australia, 1992; Volume 1. [Google Scholar]

- Saghafi, A.; Faiz, M.; Roberts, D. CO2 storage and gas diffusivity properties of coals from Sydney Basin, Australia. Int. J. Coal Geol. 2007, 70, 240–254. [Google Scholar] [CrossRef]

- Kawabata, D.; Bandibas, J. Landslide susceptibility mapping using geological data, a DEM from ASTER images and an Artificial Neural Network (ANN). Geomorphology 2009, 113, 97–109. [Google Scholar] [CrossRef]

- Lee, W.; Jang, H.; Lee, J. Development and application of the artificial neural network based technical screening guide system to select production methods in a coalbed methane reservoir. Energy Explor. Exploit. 2014, 32, 791–804. [Google Scholar] [CrossRef]

- Skiba, M. The influence of the discrepancies in the observers’ decisions on the process of identification of maceral groups using artificial neural networks. J. Sustain. Min. 2016, 15, 151–155. [Google Scholar] [CrossRef]

- Młynarczuk, M.; Skiba, M. The application of artificial intelligence for the identification of the maceral groups and mineral components of coal. Comput. Geosci. 2017, 103, 133–141. [Google Scholar] [CrossRef]

- Juliani, C. Automated discrimination of fault scarps along an Arctic mid-ocean ridge using neural networks. Comput. Geosci. 2019, 124, 27–36. [Google Scholar] [CrossRef]

- Ruilin, Z.; Lowndes, I.S. The application of a coupled artificial neural network and fault tree analysis model to predict coal and gas outbursts. Int. J. Coal Geol. 2010, 84, 141–152. [Google Scholar] [CrossRef]

- Tadeusiewicz, R. Neural networks in Mining sciences—General overview and some representative examples. Arch. Min. Sci. 2015, 60, 971–984. [Google Scholar] [CrossRef]

- Skiba, M.; Młynarczuk, M. Identification of macerals of the inertinite group using neural classifiers, based on selected textural features. Arch. Min. Sci. 2018, 63, 827–837. [Google Scholar] [CrossRef]

- Çelekli, A.; Hüseyin, B.; Geyik, F. Use of artificial neural networks and genetic algorithms for prediction of sorption of an azo-metal complex dye onto lentil straw. Bioresour. Technol. 2013, 129, 396–401. [Google Scholar] [CrossRef]

- Trivedi, R.; Singh, T.N.; Raina, A.K. Prediction of blast-induced flyrock in Indian limestone mines using neural networks. J. Rock Mech. Geotech. Eng. 2014, 6, 447–454. [Google Scholar] [CrossRef]

- Jiang, C.; Jiang, M.; Xu, Q.; Huang, X. Expectile regression neural network model with applications. Neurocomputing 2017, 247, 73–86. [Google Scholar] [CrossRef]

- Wen, J.; Han, P.F.; Zhou, Z.; Wang, X.S. Lake level dynamics exploration using deep learning, artificial neural network, and multiple linear regression techniques. Environ. Earth Sci. 2019, 78, 222. [Google Scholar] [CrossRef]

- Specht, D.F. A general regression neural network. IEEE Trans. Neural Netw. 1991, 2, 568. [Google Scholar] [CrossRef]

- Bianchini, M.; Frasconi, P.; Gori, M. Learning without local minima in radial basis function networks. IEEE Trans. Neural Netw. 1995, 6, 749. [Google Scholar] [CrossRef]

- Bataineh, M.; Marler, T. Neural network for regression problems with reduced training sets. Neural Netw. 2017, 95, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Godyń, K.; Dutka, B. The impact of the degree of coalification on the sorption capacity of coals from the Zofiówka Monocline. Arch. Min. Sci. 2018, 63, 727–746. [Google Scholar] [CrossRef]

- ISO 7404-2. Methods for the Petrographic Analysis of Coals, Part 2: Methods of Preparing Coal Samples; International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar] [CrossRef]

- ISO 7404-3. Methods for the Petrographic Analysis of Coals, Part 3: Method of Determining Maceral Group Composition; International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar] [CrossRef]

- ISO 7404-5. Methods for the Petrographic Analysis of Coals, Part 5: Method of Determining Microscopically the Reflectance of Vitrinite; International Organization for Standardization: Geneva, Switzerland, 2002. [Google Scholar] [CrossRef]

- ISO 562. Hard Coal and Coke—Determination of Volatile Matter; International Organization for Standardization: Geneva, Switzerland, 2010. [Google Scholar] [CrossRef]

- ISO 1171. Solid Mineral Fuels—Determination of Ash; International Organization for Standardization: Geneva, Switzerland, 2002. [Google Scholar] [CrossRef]

- Timofiejew, D.P. Adsorptionkinetik; Veb: Leipzig, Germany, 1967. [Google Scholar]

- Langmuir, I. The adsorption of gases on plane surfaces of glass, mica and Platinum. J. Am. Chem. Soc. 1918, 40, 1361–1403. [Google Scholar] [CrossRef]

- Kudasik, M.; Skoczylas, N.; Pajdak, A. The Repeatability of Sorption Processes Occurring in the Coal-Methane System during Multiple Measurement Series. Energies 2017, 10, 661. [Google Scholar] [CrossRef]

- Dutka, B. Evaluation of the Impact of the Geothermal Gradient on the Process of Methane Sorption in Hard Coal. Ph.D. Thesis, Strata Mechanics Research Institute of the Polish Academy of Sciences, Cracow, Poland, October 2017. (In Polish). [Google Scholar]

- Godyń, K.; Dutka, B.; Chuchro, M.; Młynarczuk, M. Synergy of Parameters Determining the Optimal Properties of Coal as a Natural Sorbent. Energies 2020, 13, 1967. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A.; Chen, Q. Neural network and particle swarm optimization for predicting the unconfined compressive strength of cemented paste backfill. Constr. Build. Mater. 2018, 159, 473–478. [Google Scholar] [CrossRef]

- Cybenko, G. Approximation by superpositions of a sigmoidal function. Math. Control Signal. 1989, 2, 303–314. [Google Scholar] [CrossRef]

- Hornik, K.; Stinchcombe, M.; White, H. Multilayer feedforward networks are universal approximators. Neural Netw. 1989, 2, 359–366. [Google Scholar] [CrossRef]

- Hagan, M.T.; Menhaj, M.B. Training Feedforward Networks with the Marquardt Algorithm. IEEE Trans. Neural Netw. 1994, 5, 989–993. [Google Scholar] [CrossRef]

| Hidden-Layer Size | Logistic Activation Function | Hyperbolic Tangent Activation Function |

|---|---|---|

| C (RE, %) | ||

| 4 | 29.41 | 32.98 |

| 5 | 26.13 | 30.95 |

| 6 | 22.86 | 26.32 |

| 7 | 23.37 | 24.34 |

| 8 | 23.40 | 25.90 |

| 9 | 25.39 | 29.43 |

| 10 | 26.25 | 31.28 |

| Hidden-Layer Size | Logistic Activation Function | Hyperbolic Tangent Activation Function |

|---|---|---|

| C (RE, %) | ||

| 4 | 1.94 | 1.98 |

| 5 | 1.42 | 1.41 |

| 6 | 1.34 | 1.39 |

| 7 | 1.30 | 0.89 |

| 8 | 1.13 | 1.09 |

| 9 | 0.97 | 1.16 |

| 10 | 1.06 | 1.26 |

| Observed Value × 10−9 (cm2/s) | 1.12 | 3.04 | 0.95 | 2.87 | 0.61 | 1.32 | 3.70 | 3.56 | 1.29 | 0.97 | 2.63 | 1.76 | 0.94 | 1.59 |

| Predicted Value × 10−9 (cm2/s) | 1.15 | 3.12 | 1.08 | 2.96 | 0.62 | 1.28 | 3.89 | 3.24 | 1.20 | 1.06 | 2.88 | 1.83 | 0.88 | 1.73 |

| Prediction Error (%) | 2.68 | 2.63 | 13.68 | 3.14 | 1.64 | 3.03 | 5.14 | 8.99 | 6.98 | 9.28 | 9.51 | 3.98 | 6.38 | 8.81 |

| Observed Value (m3CH4/MgCSW) | 16.89 | 17.96 | 14.84 | 15.74 | 14.69 | 13.35 | 13.99 | 17.50 | 15.95 | 14.07 | 16.68 | 16.26 | 14.41 | 13.72 |

| Predicted Value (m3CH4/MgCSW) | 16.87 | 17.86 | 14.88 | 15.70 | 14.65 | 13.28 | 13.97 | 17.54 | 15.99 | 14.04 | 16.70 | 16.29 | 14.41 | 13.72 |

| Prediction Error (%) | 0.12 | 0.56 | 0.27 | 0.25 | 0.27 | 0.52 | 0.14 | 0.23 | 0.25 | 0.21 | 0.12 | 0.18 | 0.00 | 0.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skiba, M.; Młynarczuk, M. Estimation of Coal’s Sorption Parameters Using Artificial Neural Networks. Materials 2020, 13, 5422. https://doi.org/10.3390/ma13235422

Skiba M, Młynarczuk M. Estimation of Coal’s Sorption Parameters Using Artificial Neural Networks. Materials. 2020; 13(23):5422. https://doi.org/10.3390/ma13235422

Chicago/Turabian StyleSkiba, Marta, and Mariusz Młynarczuk. 2020. "Estimation of Coal’s Sorption Parameters Using Artificial Neural Networks" Materials 13, no. 23: 5422. https://doi.org/10.3390/ma13235422

APA StyleSkiba, M., & Młynarczuk, M. (2020). Estimation of Coal’s Sorption Parameters Using Artificial Neural Networks. Materials, 13(23), 5422. https://doi.org/10.3390/ma13235422