Stress-Induced In Situ Modification of Transition Temperature in VO2 Films Capped by Chalcogenide

Abstract

1. Introduction

2. Experimental

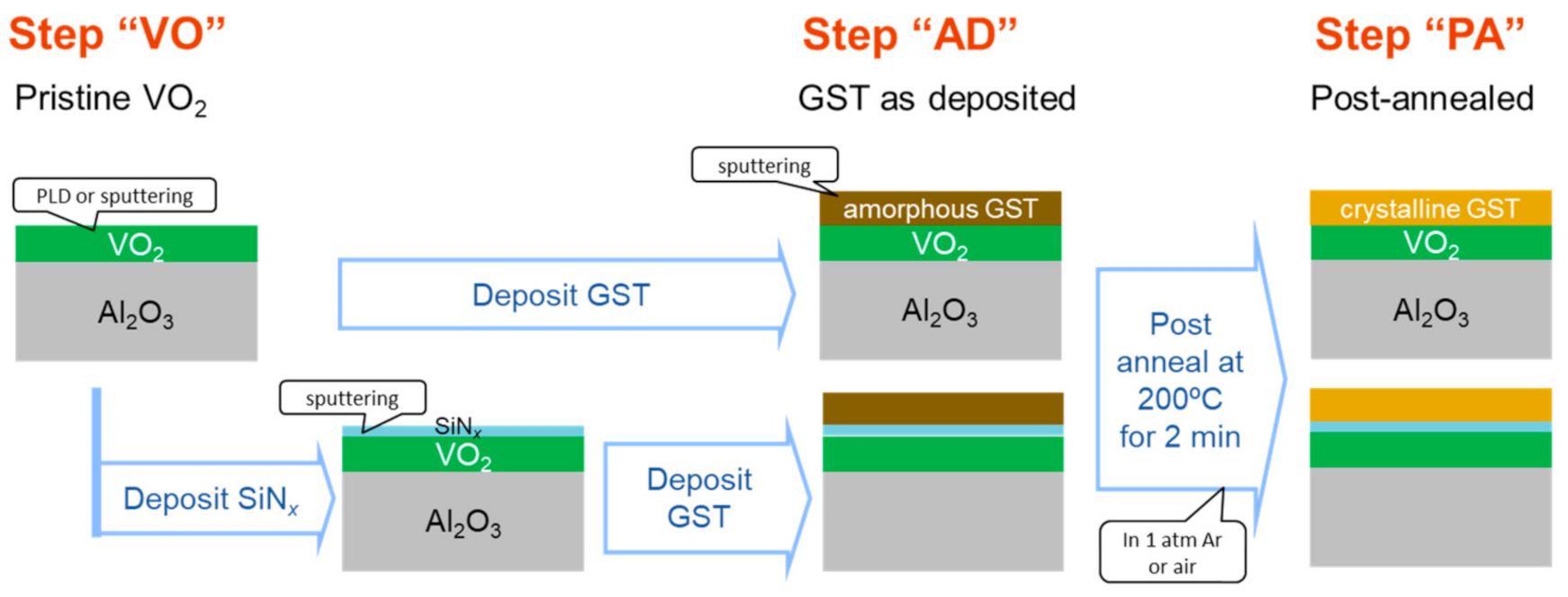

2.1. Sample Preparation

2.2. Characterization

3. Results

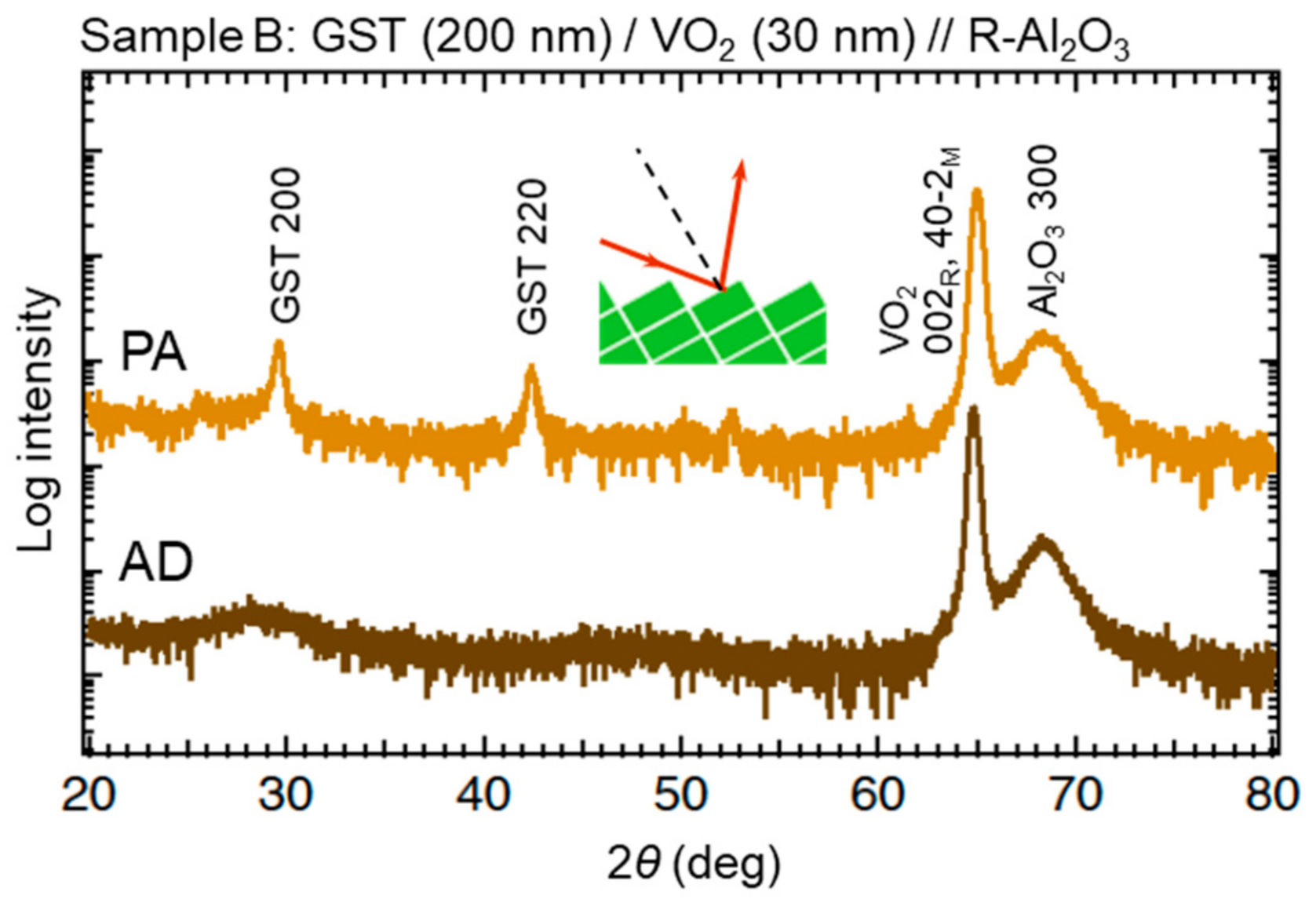

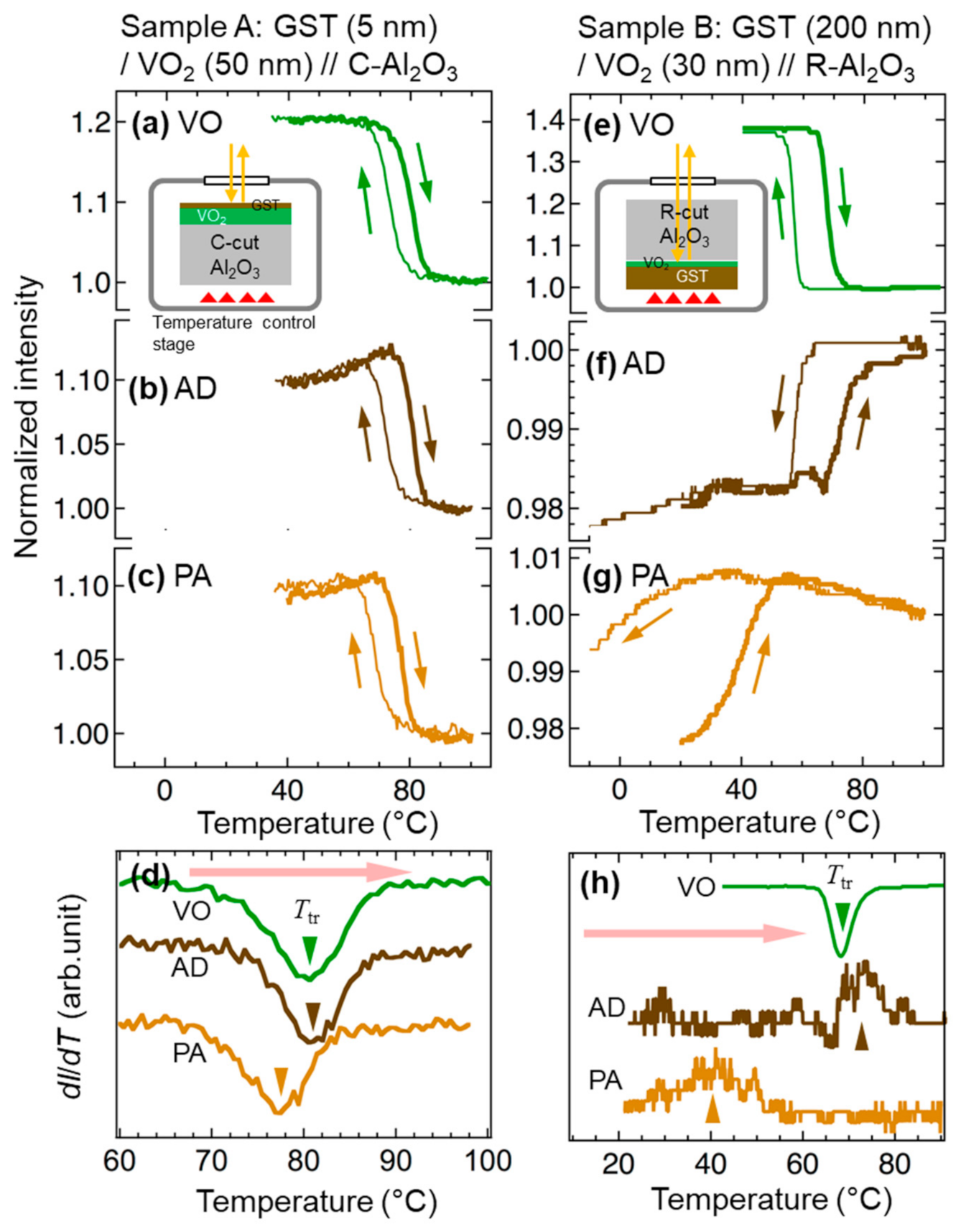

3.1. Optical Reflection

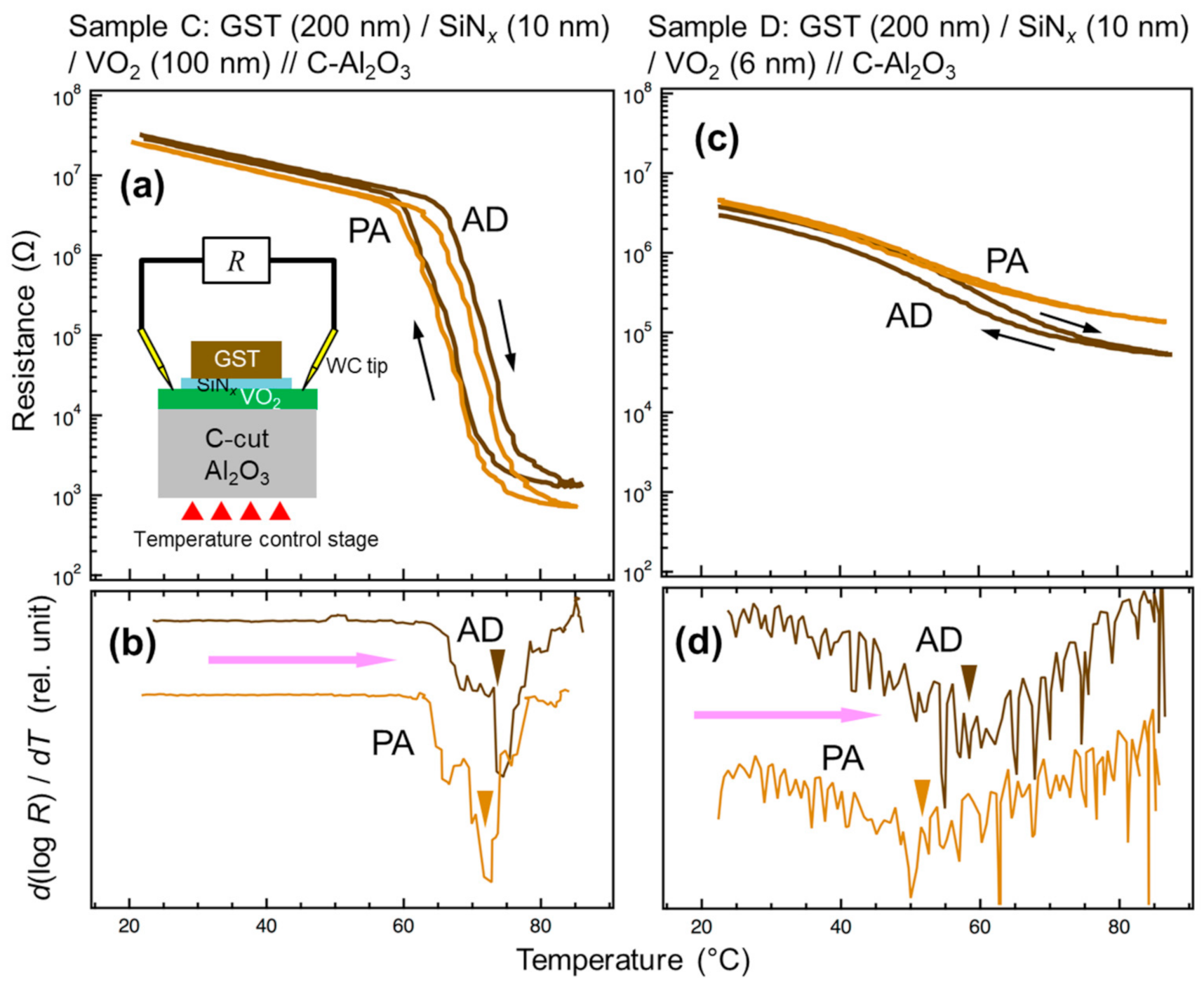

3.2. Electrical Resistance

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Morin, F.J. Oxides Which Show a Metal-to-Insulator Transition at the Neel Temperature. Phys. Rev. Lett. 1959, 3, 34–36. [Google Scholar] [CrossRef]

- Westman, S.; Lindqvist, I.; Sparrman, B.; Nielsen, G.B.; Nord, H.; Jart, A. Note on a Phase Transition in VO2. Acta Chem. Scand. 1961, 15, 217. [Google Scholar] [CrossRef]

- Van Steensel, K.; van de Burg, F.; Kooy, C. Thin-film switching elements of VO2. Philips Res. Repts. 1967, 22, 170–177. [Google Scholar]

- Berglund, C.; Walden, R. A thin-film inductance using thermal filaments. IEEE Trans. Electron. Devices 1970, 17, 137–148. [Google Scholar] [CrossRef]

- Cavalleri, A.; Tóth, C.; Siders, C.W.; Squier, J.A.; Ráksi, F.; Forget, P.; Kieffer, J.C. Femtosecond Structural Dynamics in VO2 during an Ultrafast Solid-Solid Phase Transition. Phys. Rev. Lett. 2001, 87, 237401. [Google Scholar] [CrossRef]

- Baum, P.; Yang, D.-S.; Zewail, A.H. 4D Visualization of Transitional Structures in Phase Transformations by Electron Diffraction. Science 2007, 318, 788–792. [Google Scholar] [CrossRef]

- Cao, J.; Gu, Y.; Fan, W.; Chen, L.Q.; Ogletree, D.F.; Chen, K.; Tamura, N.; Kunz, M.; Barrett, C.; Seidel, J.; et al. Extended Mapping and Exploration of the Vanadium Dioxide Stress-Temperature Phase Diagram. Nano Lett. 2010, 10, 2667–2673. [Google Scholar] [CrossRef]

- Pellegrino, L.; Manca, N.; Kanki, T.; Tanaka, H.; Biasotti, M.; Bellingeri, E.; Siri, A.S.; Marré, D. Multistate memory devices based on free-standing VO2/TiO2 microstructures driven by Joule self-heating. Adv. Mater. 2012, 24, 2929–2934. [Google Scholar] [CrossRef]

- Bae, S.-H.; Lee, S.; Koo, H.; Lin, L.; Jo, B.H.; Park, C.; Wang, Z.L. The Memristive Properties of a Single VO2 Nanowire with Switching Controlled by Self-Heating. Adv. Mater. 2013, 25, 5098–5103. [Google Scholar] [CrossRef]

- Jeong, J.; Aetukuri, N.; Graf, T.; Schladt, T.D.; Samant, M.G.; Parkin, S.S.P. Suppression of Metal-Insulator Transition in VO2 by Electric Field-Induced Oxygen Vacancy Formation. Science 2013, 339, 1402–1405. [Google Scholar] [CrossRef]

- Muraoka, Y.; Hiroi, Z. Metal—Insulator transition of VO2 thin films grown on TiO2 (001) and (110) substrates. Appl. Phys. Lett. 2002, 80, 583–585. [Google Scholar] [CrossRef]

- Fan, L.L.; Chen, S.; Luo, Z.L.; Liu, Q.H.; Wu, Y.F.; Song, L.; Ji, D.X.; Wang, P.; Chu, W.S.; Gao, C.; et al. Strain dynamics of ultrathin VO2 film grown on TiO2 (001) and the associated phase transition modulation. Nano Lett. 2014, 14, 4036–4043. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Charipar, N.; Figueroa, J.; Bingham, N.S.; Piqué, A. Control of metal-insulator transition temperature in VO2 thin films grown on RuO2/TiO2 templates by strain modification. AIP Adv. 2019, 9, 015302. [Google Scholar] [CrossRef]

- Jia, Q.; Grenzer, J.; He, H.; Anwand, W.; Ji, Y.; Yuan, Y.; Huang, K.; You, T.; Yu, W.; Ren, W.; et al. 3D Local Manipulation of the Metal-Insulator Transition Behavior in VO2 Thin Film by Defect-Induced Lattice Engineering. Adv. Mater. Interfaces 2018, 5. [Google Scholar] [CrossRef]

- Gu, D.-E.; Zheng, H.; Ma, Y.; Xu, S.; Zhou, X. A highly-efficient approach for reducing phase transition temperature of VO2 polycrystalline thin films through Ru4+-doping. J. Alloys Compd. 2019, 790, 602–609. [Google Scholar] [CrossRef]

- Molegraaf, H.J.A.; Hoffman, J.; Vaz, C.A.F.; Gariglio, S.; Van Der Marel, D.; Ahn, C.H.; Triscone, J.-M. Magnetoelectric Effects in Complex Oxides with Competing Ground States. Adv. Mater. 2009, 21, 3470–3474. [Google Scholar] [CrossRef]

- Zheng, R.K.; Wang, Y.; Liu, Y.K.; Gao, G.Y.; Fei, L.F.; Jiang, Y.; Chan, H.L.W.; Li, X.M.; Luo, H.S.; Li, X.G. Epitaxial growth and interface strain coupling effects in manganite film/piezoelectric-crystal multiferroic heterostructures. Mater. Chem. Phys. 2012, 133, 42–46. [Google Scholar] [CrossRef]

- Leufke, P.M.; Kruk, R.; Brand, R.A.; Hahn, H. In situ magnetometry studies of magnetoelectric LSMO/PZT heterostructures. Phys. Rev. B 2013, 87, 094416. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, Y.G.; Li, P.S.; Yang, J.J.; Rizwan, S.; Zhang, J.X.; Seidel, J.; Qu, T.L.; Yang, Y.J.; Luo, Z.L.; et al. Electric-field control of nonvolatile magnetization in Co40Fe40B20/Pb(Mg1/3Nb2/3)0.7Ti0.3O3 structure at room temperature. Phys. Rev. Lett. 2012, 108, 137203. [Google Scholar] [CrossRef]

- Brandlmaier, A.; Geprägs, S.; Woltersdorf, G.; Gross, R.; Goennenwein, S.T.B. Nonvolatile, reversible electric-field controlled switching of remanent magnetization in multifunctional ferromagnetic/ferroelectric hybrids. J. Appl. Phys. 2011, 110, 043913. [Google Scholar] [CrossRef]

- Chen, A.T.; Zhao, Y. Research Update: Electrical manipulation of magnetism through strain-mediated magnetoelectric coupling in multiferroic heterostructures. APL Mater. 2016, 4, 032303. [Google Scholar] [CrossRef]

- Sakai, J.; Bavencoffe, M.; Negulescu, B.; Limelette, P.; Wolfman, J.; Tateyama, A.; Funakubo, H. Strain-induced resistance change in V2O3 films on piezoelectric ceramic disks. J. Appl. Phys. 2019, 125, 115102. [Google Scholar] [CrossRef]

- Petraru, A.; Soni, R.; Kohlstedt, H. Voltage controlled biaxial strain in VO2 films grown on 0.72Pb(Mg1/3Nb2/3)-0.28PbTiO3 crystals and its effect on the transition temperature. Appl. Phys. Lett. 2014, 105, 092902. [Google Scholar] [CrossRef]

- Nan, T.; Liu, M.; Ren, W.; Ye, Z.G.; Sun, N.X. Voltage control of metal-insulator transition and non-volatile ferroelastic switching of resistance in VOx/PMN-PT Heterostructures. Sci. Rep. 2014, 4, 5931. [Google Scholar] [CrossRef]

- Zhi, B.; Gao, G.; Xu, H.; Chen, F.; Tan, X.; Chen, P.; Wang, L.; Wu, W. Electric-field-modulated nonvolatile resistance switching in VO2/PMN-PT (111) heterostructures. Appl. Mater. Interfaces 2014, 6, 4603–4608. [Google Scholar] [CrossRef]

- Zhang, J.; Kong, W.; Liu, L.; Li, C.; Fang, L.; Feng, Y.P.; Tang, R.; Su, X.; Chen, J. Piezoelectric control of resistance switching in VO2/Pb(Zr0.52Ti0.48)O3 heterostructure. Appl. Phys. Lett. 2019, 114, 061603. [Google Scholar] [CrossRef]

- Verdaguer, A.; López-Mir, L.; Paradinas, M.; Holý, V.; Železný, J.; Yi, D.; Suresha, S.J.; Liu, J.; Serrao, C.R.; Ramesh, R.; et al. Giant reversible nanoscale piezoresistance at room temperature in Sr2IrO4 thin films. Nanoscale 2015, 7, 3453–3459. [Google Scholar] [CrossRef]

- Alyabyeva, N.; Sakai, J.; Bavencoffe, M.; Wolfman, J.; Limelette, P.; Funakubo, H.; Ruyter, A. Metal-insulator transition in V2O3 thin film caused by tip-induced strain. Appl. Phys. Lett. 2018, 113, 241603. [Google Scholar] [CrossRef]

- Kuwahara, M.; Suzuki, O.; Taketoshi, N.; Yamakawa, Y.; Yagi, T.; Fons, P.; Tsutsumi, K.; Suzuki, M.; Fukaya, T.; Tominaga, J.; et al. Measurements of Temperature Dependence of Optical and Thermal Properties of Optical Disk Materials. Jpn. J. Appl. Phys. 2006, 45, 1419–1421. [Google Scholar] [CrossRef]

- Kuwahara, M.; Suzuki, O.; Yamakawa, Y.; Taketoshi, N.; Yagi, T.; Fons, P.; Fukaya, T.; Tominaga, J.; Baba, T. Temperature Dependence of the Thermal Properties of Optical Memory Materials. Jpn. J. Appl. Phys. 2007, 46, 3909–3911. [Google Scholar] [CrossRef]

- Endo, R.; Maeda, S.; Jinnai, Y.; Lan, R.; Kuwahara, M.; Kobayashi, Y.; Susa, M. Electric Resistivity Measurements of Sb2Te3 and Ge2Sb2Te5 Melts Using Four-Terminal Method. Jpn. J. Appl. Phys. 2010, 49. [Google Scholar] [CrossRef]

- Hada, M.; Oba, W.; Kuwahara, M.; Katayama, I.; Saiki, T.; Takeda, J.; Nakamura, K.G. Ultrafast time-resolved electron diffraction revealing the nonthermal dynamics of near-UV photoexcitation-induced amorphization in Ge2Sb2Te5. Sci. Rep. 2015, 5, 13530. [Google Scholar] [CrossRef] [PubMed]

- Ikuma, Y.; Shoji, Y.; Kuwahara, M.; Wang, X.; Kintaka, K.; Kawashima, H.; Tanaka, D.; Tsuda, H. Small-sized optical gate switch using Ge2Sb2Te5 phase-change material integrated with silicon waveguide. Electron. Lett. 2010, 46, 368. [Google Scholar] [CrossRef]

- Tanaka, D.; Ikuma, Y.; Shoji, Y.; Kuwahara, M.; Wang, X.; Kintaka, K.; Kawashima, H.; Toyosaki, T.; Tsuda, H. Demonstration of 1000-times switching of phase-change optical gate with Is wire waveguides. Electron. Lett. 2011, 47, 268–269. [Google Scholar] [CrossRef]

- Tanaka, D.; Shoji, Y.; Kuwahara, M.; Wang, X.; Kintaka, K.; Kawashima, H.; Toyosaki, T.; Ikuma, Y.; Tsuda, H. Ultra-small, self-holding, optical gate switch using Ge2Sb2Te5 with a multi-mode Si waveguide. Opt. Express 2012, 20, 10283–10294. [Google Scholar] [CrossRef]

- Moriyama, T.; Tanaka, D.; Jain, P.; Kawashima, H.; Kuwahara, M.; Wang, X.; Tsuda, H. Ultra-compact, self-holding asymmetric Mach-Zehnder interferometer switch using Ge2Sb2Te5 phase-change material. IEICE Electron. Express 2014, 11, 20140538. [Google Scholar] [CrossRef]

- Kato, K.; Kuwahara, M.; Kawashima, H.; Tsuruoka, T.; Tsuda, H. Current-driven phase-change optical gate switch using indium—Tin-oxide heater. Appl. Phys. Express 2017, 10, 072201. [Google Scholar] [CrossRef]

- Njoroge, W.K.; Wöltgens, H.-W.; Wuttig, M. Density changes upon crystallization of Ge2Sb2.04Te4.74 films. J. Vac. Sci. Technol. A 2002, 20, 230–233. [Google Scholar] [CrossRef]

- Nagashima, K.; Yanagida, T.; Tanaka, H.; Kawai, T. Influence of ambient atmosphere on metal-insulator transition of strained vanadium dioxide ultrathin films. J. Appl. Phys. 2006, 100, 063714. [Google Scholar] [CrossRef]

- Meng, Y.; Behera, J.K.; Ke, Y.; Chew, L.; Wang, Y.; Long, Y.; Simpson, R.E. Design of a 4-level active photonics phase change switch using VO2 and Ge2Sb2Te5. Appl. Phys. Lett. 2018, 113, 071901. [Google Scholar] [CrossRef]

- Hu, Y.; Zou, H.; Zhang, J.; Xue, J.; Sui, Y.; Wu, W.; Yuan, L.; Zhu, X.; Song, S.; Song, Z. Ge2Sb2Te5/Sb superlattice-like thin fil for high speed change memory application. Appl. Phys. Lett. 2015, 107, 263105. [Google Scholar] [CrossRef]

- Sakai, J.; Kuwahara, M.; Hotsuki, M.; Katano, S.; Uehara, Y. Selective scanning tunneling microscope light emission from rutile phase of VO2. J. Phys. Condens. Matter 2016, 28, 385002. [Google Scholar] [CrossRef] [PubMed]

- Azhan, N.H.; Su, K.; Okimura, K.; Zaghrioui, M.; Sakai, J. Appearance of large crystalline domains in VO2 films grown on sapphire (001) and their phase transition characteristics. J. Appl. Phys. 2015, 117, 245314. [Google Scholar] [CrossRef]

- Kurosawa, K.; Pierce, R.M.; Ushioda, S.; Hemminger, J.C. Raman scattering and attenuated-total-reflection studies of surface-plasmon polaritons. Phys. Rev. B 1986, 33, 789–798. [Google Scholar] [CrossRef] [PubMed]

- Philipp, H.R. Silicon dioxide (SiO2) (Glass). In Handbook of Optical Constants of Solids; Palik, E.D., Ed.; Academic Press: New York, NY, USA, 1985; p. 749. [Google Scholar]

- Lamsal, C.; Ravindra, N.M. Optical properties of vanadium oxides-an analysis. J. Mater. Sci. 2013, 48, 6341–6351. [Google Scholar] [CrossRef]

- Krammer, A.; Magrez, A.; Vitale, W.A.; Mocny, P.; Jeanneret, P.; Guibert, E.; Whitlow, H.J.; Ionescu, A.M.; Schüler, A. Elevated transition temperature in Ge doped VO2 thin films. J. Appl. Phys. 2017, 122, 045304. [Google Scholar] [CrossRef]

- Liu, S.-J.; Su, Y.-T.; Hsieh, J.-H. Effects of postdeposition annealing on the metal–insulator transition of VO2−x thin films prepared by RF magnetron sputtering. Jpn. J. Appl. Phys. 2014, 53, 33201. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, Z.; Li, J.; Jin, H.; Rehman, F.; Chen, P.; Jiang, Y.; Chen, C.; Cao, M.; Zhao, Y. Evolution of Structural and Electrical Properties of Oxygen-Deficient VO2 under Low Temperature Heating Process. ACS Appl. Mater. Interfaces 2017, 9, 27135–27141. [Google Scholar] [CrossRef]

- Uchino, K. Electrostrictive actuators: Materials and applications. Am. Ceram. Soc. Bull. 1986, 65, 647–652. [Google Scholar]

- Marchant, A.B. Optical Recording: A Technical Overview; Addison-Wesley Publishing: Boston, MA, USA, 1990; pp. 84–88. [Google Scholar]

| Sample | VO2 Thickness (nm) | GST Thickness (nm) | SiNx Layer | Substrate | AD | PA | ||

|---|---|---|---|---|---|---|---|---|

| Meas. | Ttr (°C) | Meas. | Ttr (°C) | |||||

| A | 50 | 5 | No | C-cut Al2O3 | Refl. | 81 | Refl. | 77 |

| B | 30 | 200 | No | R-cut Al2O3 | Refl. | 72 | Refl. | 41 |

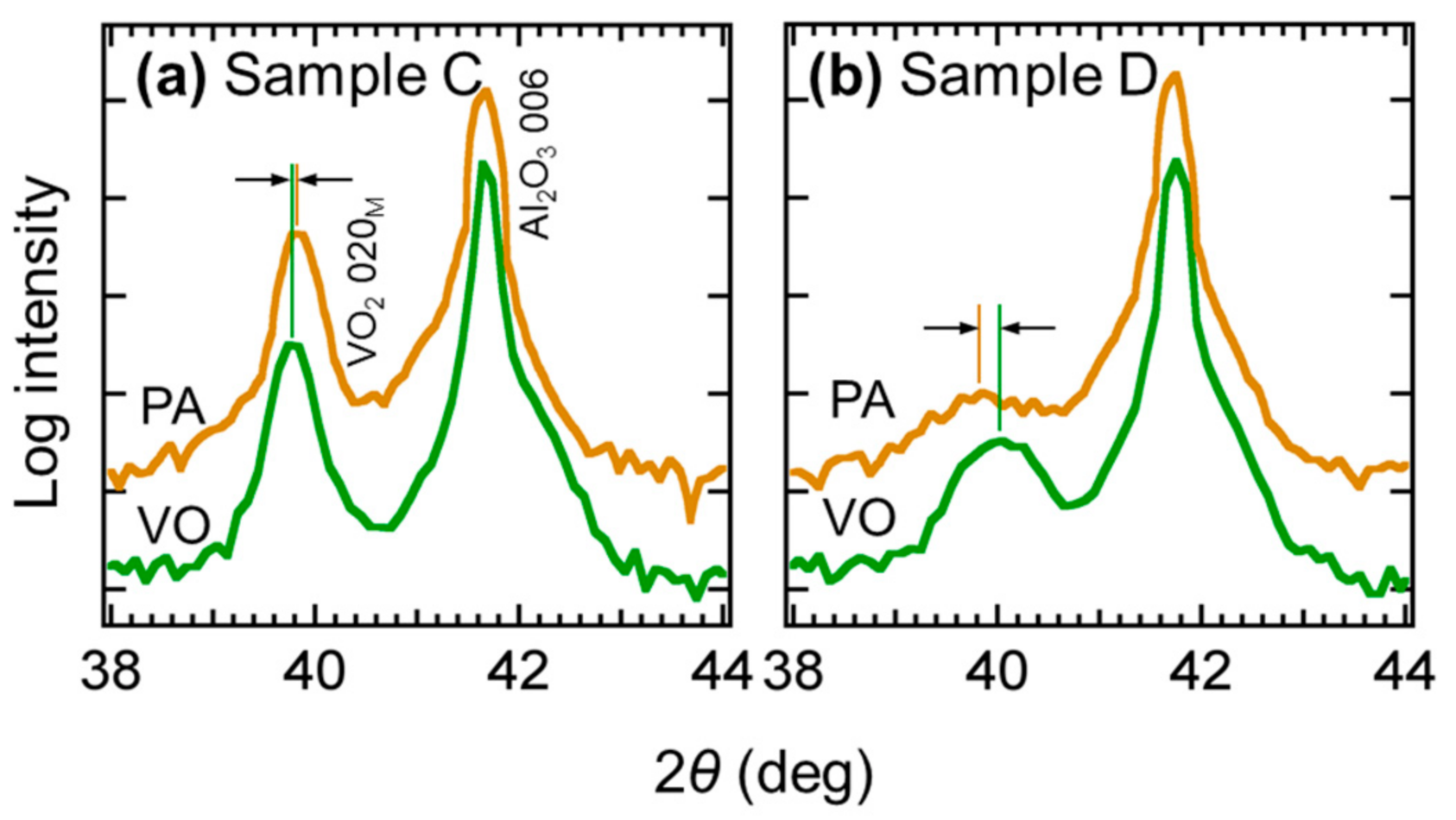

| C | 100 | 200 | Yes | C-cut Al2O3 | R–T | 74 | R–T | 72 |

| D | 6 | 200 | Yes | C-cut Al2O3 | R–T | 58 | R–T | 52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sakai, J.; Kuwahara, M.; Okimura, K.; Uehara, Y. Stress-Induced In Situ Modification of Transition Temperature in VO2 Films Capped by Chalcogenide. Materials 2020, 13, 5541. https://doi.org/10.3390/ma13235541

Sakai J, Kuwahara M, Okimura K, Uehara Y. Stress-Induced In Situ Modification of Transition Temperature in VO2 Films Capped by Chalcogenide. Materials. 2020; 13(23):5541. https://doi.org/10.3390/ma13235541

Chicago/Turabian StyleSakai, Joe, Masashi Kuwahara, Kunio Okimura, and Yoichi Uehara. 2020. "Stress-Induced In Situ Modification of Transition Temperature in VO2 Films Capped by Chalcogenide" Materials 13, no. 23: 5541. https://doi.org/10.3390/ma13235541

APA StyleSakai, J., Kuwahara, M., Okimura, K., & Uehara, Y. (2020). Stress-Induced In Situ Modification of Transition Temperature in VO2 Films Capped by Chalcogenide. Materials, 13(23), 5541. https://doi.org/10.3390/ma13235541