Review on Adhesives and Surface Treatments for Structural Applications: Recent Developments on Sustainability and Implementation for Metal and Composite Substrates

Abstract

1. Introduction

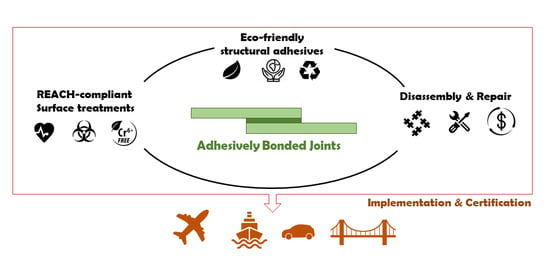

1.1. Overview

1.2. Well-Established Industrial Adhesives

1.3. Opportunities and Challenges in the Adhesives Sector

1.3.1. Replacement of Mechanical Fasteners by Adhesives: A Reality?

1.3.2. REACH Evolution and Its Impact on Adhesives Industry

1.3.3. Adhesives from Renewable Resources

2. Eco-Friendly Emergent Structural Adhesives

2.1. Renewable/Bio-Derived Adhesives

2.1.1. Utilization of Vegetable Oils

2.1.2. Utilization of Wood Derivates (Lignin, Tannin, Cellulose)

2.1.3. Utilization of Polysaccharides

2.1.4. The Role of Nanoparticles in Bio-Based and Commercial Adhesive Formulations

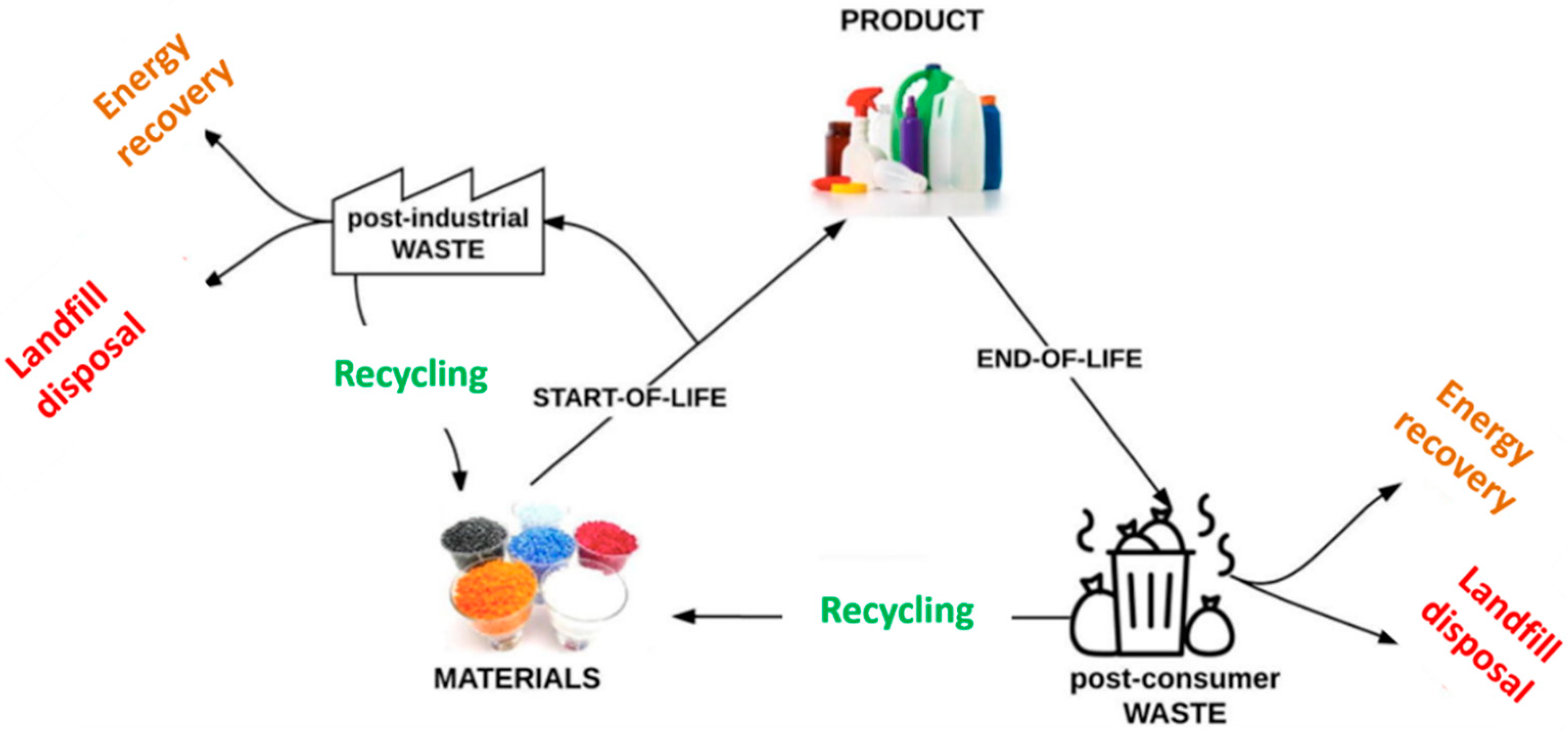

2.2. New Trends in Polymer Waste Management for Adhesive Formulations

2.2.1. Chemical Recycling of Polymers for Adhesive Formulations

2.2.2. Mechanical Recycling of Polymers for Adhesive Formulations

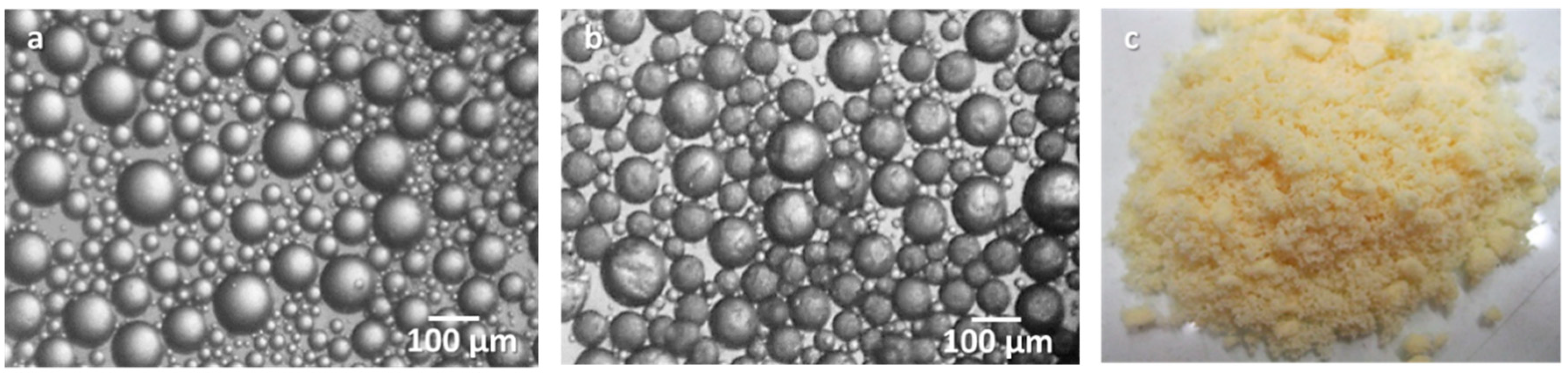

2.3. Microencapsulation of Isocyanate Species for Eco-Innovative Adhesives Formulations

2.4. Final Considerations on the State of the Art of Eco-Friendly Structural Adhesives

3. Surface Treatments to Enable Emergent Technologies

- Surface pre-treatment, which can be physical-mechanical, physical, and chemical;

- Surface post-treatment, which contains the application of primers and the climatization.

3.1. REACH in Surface Pre-Treatments

3.2. Surface Preparation

3.2.1. Cleaning

3.2.2. Cleaning with Laser

3.3. Surface Pre-Treatment: Physical (Mechanical) Treatment

3.3.1. Grinding

- (a)

- In a direction convenient to the performer, sand straight across the surface until the entire surface is lightly and evenly roughened;

- (b)

- In the same way, sand at right angles until all traces (of (a)) are removed;

- (c)

- Using a circular motion (with a diameter of: <100 mm), grind until all traces of the previous step (see (b)) have been removed and the surface appears uniform;

- (d)

- The grinding residues shall be removed. If dry sanding has been carried out, use a vacuum extractor, if applicable. Otherwise, clean, oil-free and dry air must be blown into a suitably ventilated environment. If wet sanding has been used, wipe the solvent off the object with a clean, lint-free piece of cloth and let it dry;

- (e)

- Followed by either gluing or another surface modification procedure.

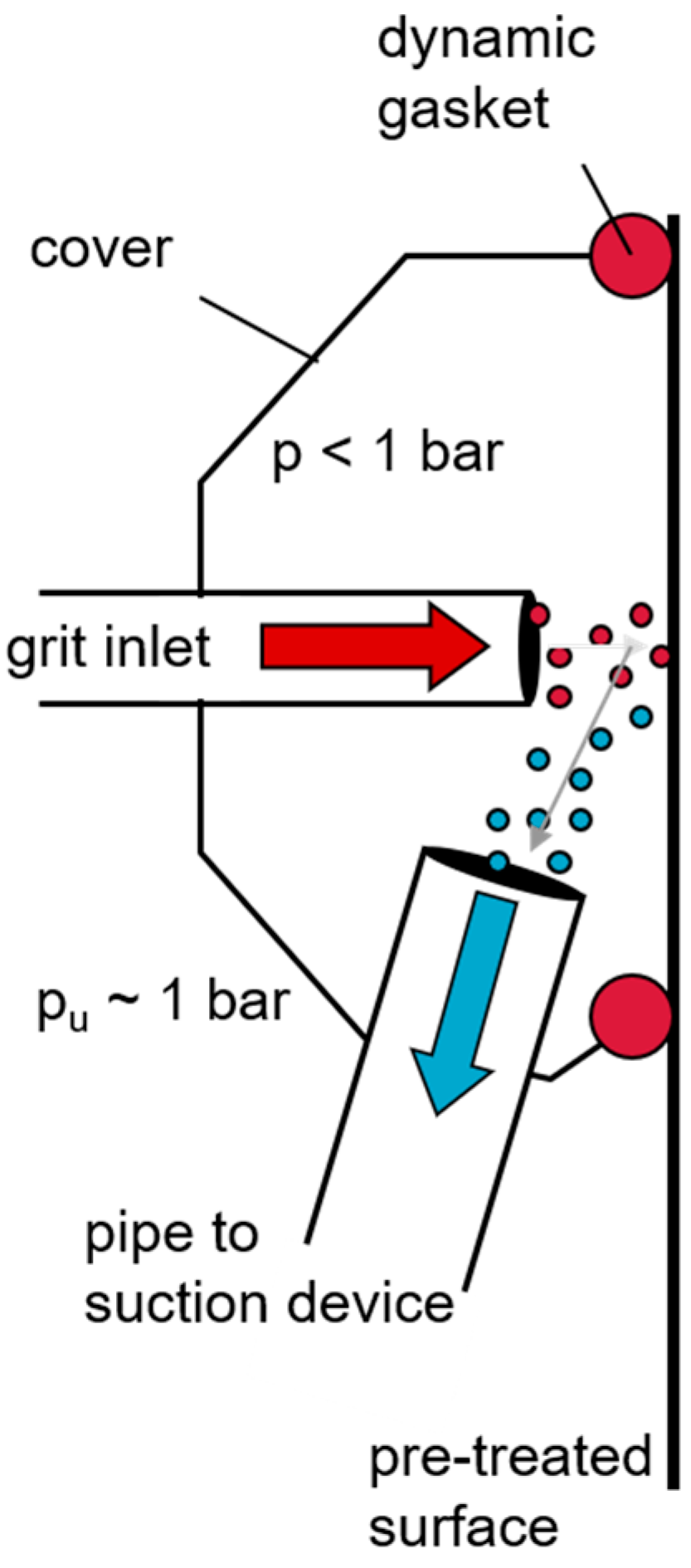

3.3.2. Blasting

3.3.3. Low-Pressure Blasting

3.3.4. Peel Ply

3.4. Surface Pre-Treatment: Other Physical Treatments

3.4.1. Surface Modification by Oxidizing Flame

- (a)

- The gaseous fuel used;

- (b)

- The residual oxygen content of the flame;

- (c)

- The distance between flame and surface;

- (d)

- The speed with which the flame moves over the surface;

- (e)

- The standardization of the time sequence before gluing.

3.4.2. Atmospheric Pressure Plasma

3.4.3. Corona Discharge

3.4.4. Low-Pressure Plasma Discharge

3.4.5. Laser

3.5. Surface Pre-Treatment: Chemical Treatment

3.5.1. Etching, Pickling

3.5.2. Conversion Coating

3.5.3. Anodizing

3.6. Surface Post-Treatment

3.6.1. Coupling Agents

3.6.2. Primer

3.6.3. Climatization

3.7. Final Considerations on the State of the Art of Surface Treatments

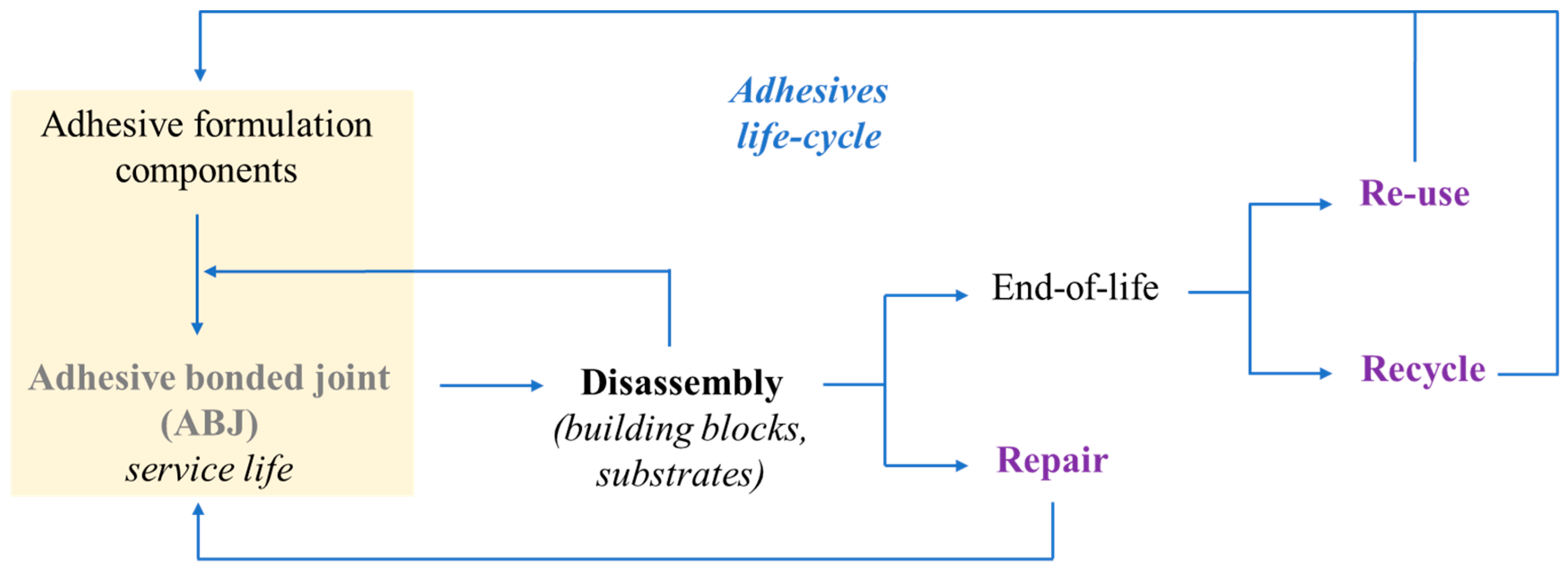

4. Disassembling Strategies for Maintenance and End-of-Life of Structural Adhesives

4.1. Traditional Approaches: Using Force/Degradation of the Adhesive

4.2. Debonding on-Demand

4.2.1. Incorporation of Nanoparticles into the Primer Layer

4.2.2. Incorporation of Microparticles into the Adhesive

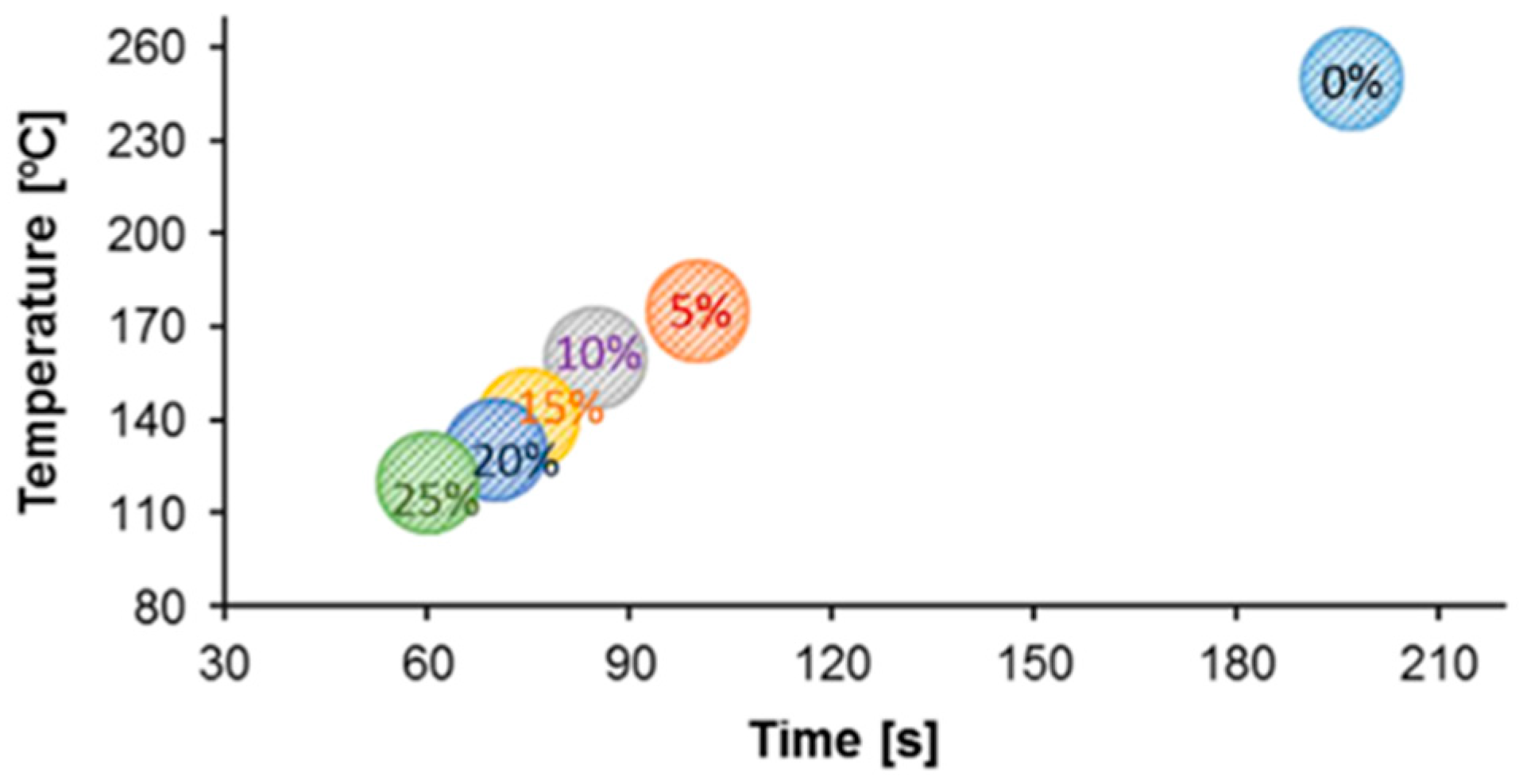

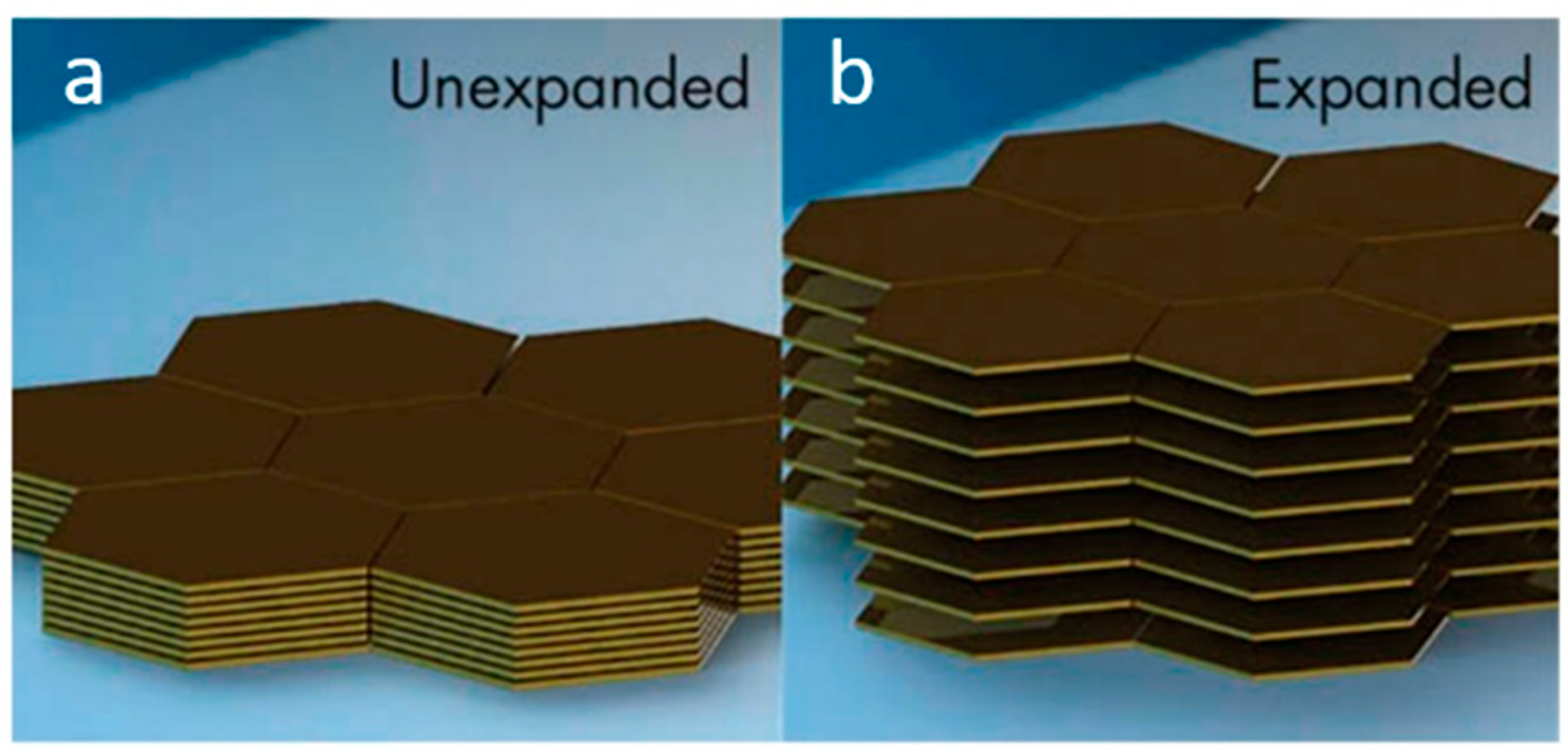

Thermally-Expanding Particles

INDAR Inside

Expandable Graphite

4.3. Final Considerations on the State of the Art about Debonding

5. Critical Overview of the Connection between R&D Efforts and Industry Standards

- (1)

- “The method of fabrication used must produce a consistently sound structure. If a fabrication process (such as gluing (bonding), spot welding, or heat-treating) requires close control to reach this objective, the process must be performed under an approved process specification.”

- (2)

- “Each new aircraft fabrication method must be substantiated by a test program.”

- (a)

- Good durable adhesion;

- (b)

- Capability for the transfer of a (limited) load;

- (c)

- Cohesive fracture of the adhesive (better: no adhesion fracture).

- (a)

- New substrates (mostly new metal or new composite material);

- (b)

- New surface treatment;

- (c)

- New bond primer;

- (d)

- New adhesive material.

- (a)

- Show compliance with the process specification;

- (b)

- Demonstrate effectivity of the implemented fabrication method in industrial environment;

- (c)

- Demonstrate homogeneity of the process on full industrial scale:

- Homogeneity of process baths and solutions (concentration/temperature);

- Homogeneity of the surface characteristics over the entire working area of process baths, or realistic product dimensions. For example, with aluminum a uniform coating weight over the entire range of the anodizing baths [15];

- Homogeneity of the adhesion over the entire working area of process baths, or realistic product dimensions;

- Homogeneity of the bond primer characteristics and adhesion over the entire area of realistic product dimensions;

- Homogeneity of oven or autoclaves over the entire working area with realistic products;

- Compliance to the required bond line quality of relevant products.

- (d)

- Demonstrate reproducibility of recurring process control tests:

- Peel tests for multiple pre-treatment runs;

- Lap shear test for multiple autoclave runs.

6. Concluding Remarks

- The need for eco-innovative adhesive materials stimulates the investment on efficient and sustainable production routes of new polymers from non-virgin petrochemical and bio-based raw materials, creating new “green” businesses opportunities. Alternative feedstocks, such as recycled plastics, industrial wastes—e.g., vegetable oils, sustainable biomass, and modified biopolymers like cellulose and starch—have been investigated. Their penetration in the adhesives industry are in different development stages, with cardanol-derived resins being one example of a commercially available product.

- Mechanical properties of the adhesive materials are often compromised when moving away from conventional, well established petrochemical-derived polymers, however, the incorporation of nanoparticles, or the microencapsulation of hazardous, but efficient, cross-linkers are potential strategies to achieve eco-friendly structural adhesives.

- REACH regulations have stimulated the development of a new range of surface pre-treatments. However, the complete replacement of the hazard materials has proved to be challenging, especially when durability needs to be assured.

- Many REACH-compliant surface pre-treatments have been adopted by many sectors, however, an analogue replacement in the aerospace industry, with its high level of performance and safety, proved to be a very challenging task. In addition, the time to test and qualify new systems for aviation is much longer compared to other industries. Therefore, some Cr(VI)-based substances are still used to date to assure the required level of performance in ABJs, while many other steps of the pre-treatment process already employ environmentally-friendlier alternatives.

- For structural adhesive bonds, complete debonding is not reachable, but a weakening of the ABJ can be enabled, so a reduced mechanical force is necessary to debond the joint.

- The majority of debonding technologies involve the use of functional additives that are mixed into the adhesive (or primer layer) in quantities of up to 20 wt%. In all those cases, the mechanical properties of the adhesive are compromised. New debonding methods must be developed for specific applications.

Author Contributions

Funding

Conflicts of Interest

References

- Shadlou, S.; Ahmadi-Moghadam, B.; Taheri, F. Nano-Enhanced Adhesives. Rev. Adhes. Adhes. 2014, 2, 371–412. [Google Scholar] [CrossRef]

- Kaybal, H.B.; Ulus, H.; Avcı, A. Influence of Nano-CaCO3 Particles on Shear Strength of Epoxy Resin Adhesives. Int. J. Eng. Res. Dev. 2017, 9, 29–35. [Google Scholar] [CrossRef]

- Science to Enable Sustainable Plastics—A White Paper from the 8th Chemical Sciences and Society Summit (CS3). 2020. Available online: https://www.rsc.org/globalassets/22-new-perspectives/sustainability/progressive-plastics/c19_tl_sustainability_cs3_whitepaper_a4_web_final.pdf (accessed on 28 June 2020).

- Heinrich, L.A. Future opportunities for bio-based adhesives-advantages beyond renewability. Green Chem. 2019, 21, 1866–1888. [Google Scholar] [CrossRef]

- Jeevi, G.; Nayak, S.K.; Kader, M.A. Review on adhesive joints and their application in hybrid composite structures. J. Adhes. Sci. Technol. 2019, 33, 1497–1520. [Google Scholar] [CrossRef]

- Banea, M.D.; Da Silva, L.F.M. Adhesively bonded joints in composite materials: An overview. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2009, 223, 1–18. [Google Scholar] [CrossRef]

- Budhe, S.; Banea, M.D.; De Barros, S. Bonded repair of composite structures in aerospace application: A review on environmental issues. Appl. Adhes. Sci. 2018, 6, 3. [Google Scholar] [CrossRef]

- Hemmilä, V.; Adamopoulos, S.; Karlsson, O.; Kumar, A. Development of sustainable bio-adhesives for engineered wood panels—A Review. RSC Adv. 2017, 7, 38604–38630. [Google Scholar] [CrossRef]

- Gadhave, R.V.; Mahanwar, P.A.; Gadekar, P.T. Bio-Renewable Sources for Synthesis of Eco-Friendly Polyurethane Adhesives—Review. Open J. Polym. Chem. 2017, 7, 57–75. [Google Scholar] [CrossRef]

- Magalhães, S.; Alves, L.; Medronho, B.; Fonseca, A.C.; Romano, A.; Coelho, J.; Norgren, M. Brief overview on bio-based adhesives and sealants. Polymers 2019, 11, 1685. [Google Scholar] [CrossRef]

- Messler, R.W., Jr. Joining of Materials and Structures—From Pragmatic Process to Enabling Technology; Elsevier Butterworth-Heinemann: Oxford, UK, 2004. [Google Scholar]

- Wahab, M.A. JOINING COMPOSITES with ADHESIVES Theory and Applications; DEStech Publications, Inc.: Lancaster, PA, USA, 2016; Available online: https://books.google.dk/books?id=ZmOrCgAAQBAJ&pg=PA2&lpg=PA2&dq=composites+in+ancient+times&source=bl&ots=4idu7Fxl93&sig=ZT5RkfD3LrOB0KQZ7cAzxycZewU&hl=da&sa=X&ved=0ahUKEwjZk5vC_L3NAhUFkywKHfdFCqYQ6AEIbDAM#v=onepage&q=composites (accessed on 15 June 2020).

- Ebnesajjad, S. Handbook of Adhesives and Surface Preparation: Technology, Applications and Manufacturing; Elsevier: Oxford, UK, 2011. [Google Scholar]

- Baudrit, J.R.V.; Camacho, N.C.; Urena, Y.C. Basis and Applications of Silicon Reinforced Adhesives. Org. Med. Chem. Int. J. 2018, 5, 1–12. [Google Scholar] [CrossRef]

- Adhesive Bonding of Composites. 2020. Available online: https://compositesuk.co.uk/system/files/documents/Adhesive (accessed on 19 March 2020).

- Cârciumaru, M.; Ion, R.M.; Niţu, E.C.; Ştefânescu, R. New evidence of adhesive as hafting material on Middle and Upper Palaeolithic artefacts from Gura Cheii-Râşnov Cave (Romania). J. Archaeol. Sci. 2012, 39, 1942–1950. [Google Scholar] [CrossRef]

- Karpowicz, A. Ottoman Turkish Bows, Manufacture and Design; The Lyons Press: Guilford, NC, USA, 1992. [Google Scholar]

- Packham, D.E. Adhesive technology and sustainability. Int. J. Adhes. Adhes. 2009, 29, 248–252. [Google Scholar] [CrossRef]

- Isa, Y.M.; Ganda, E.T. Bio-oil as a potential source of petroleum range fuels. Renew. Sustain. Energy Rev. 2018, 81, 69–75. [Google Scholar] [CrossRef]

- Sharma, V.; Getahun, T.; Verma, M.; Villa, A.; Gupta, N. Carbon based catalysts for the hydrodeoxygenation of lignin and related molecules: A powerful tool for the generation of non-petroleum chemical products including hydrocarbons. Renew. Sustain. Energy Rev. 2020, 133, 110280. [Google Scholar] [CrossRef]

- Dessbesell, L.; Paleologou, M.; Leitch, M.; Pulkki, R.C.; Xu, C. Global lignin supply overview and kraft lignin potential as an alternative for petroleum-based polymers. Renew. Sustain. Energy Rev. 2020, 123, 109768. [Google Scholar] [CrossRef]

- Vnučec, D.; Kutnar, A.; Goršek, A. Soy-based adhesives for wood-bonding—A review. J. Adhes. Sci. Technol. 2017, 31, 910–931. [Google Scholar] [CrossRef]

- Siracusa, V. Microbial degradation of synthetic biopolymers waste. Polymers 2019, 11, 1066. [Google Scholar] [CrossRef]

- Ashter, S.A. Mechanisms of Polymer Degradation. In Introduction to Bioplastics Engineering; Elsevier: Amsterdam, The Netherlands, 2016; pp. 31–59. [Google Scholar] [CrossRef]

- Vroman, I.; Tighzert, L. Biodegradable polymers. Materials 2009, 2, 307–344. [Google Scholar] [CrossRef]

- Lligadas, G.; Ronda, J.C.; Galià, M.; Cádiz, V. Renewable polymeric materials from vegetable oils: A perspective. Mater. Today 2013, 16, 337–343. [Google Scholar] [CrossRef]

- Vendamme, R.; Olaerts, K.; Gomes, M.; Degens, M.; Shigematsu, T.; Eevers, W. Interplay Between Viscoelastic and Chemical Tunings in Fatty-Acid-Based Polyester Adhesives: Engineering Biomass toward Functionalized Step-Growth Polymers and Soft Networks. Biomacromolecules 2012, 13, 1933–1944. [Google Scholar] [CrossRef]

- Patel, A.; Mekala, S.; Kravchenko, O.G.; Yilmaz, T.; Yuan, D.; Yue, L.; Gross, R.A.; Manas-Zloczower, I. Design and Formulation of a Completely Biobased Epoxy Structural Adhesive. ACS Sustain. Chem. Eng. 2019, 7, 16382–16391. [Google Scholar] [CrossRef]

- Maiorana, A.; Spinella, S.; Gross, R.A. Bio-Based Alternative to the Diglycidyl Ether of Bisphenol A with Controlled Materials Properties. Biomacromolecules 2015, 16, 1021–1031. [Google Scholar] [CrossRef] [PubMed]

- Patel, A.; Maiorana, A.; Yue, L.; Gross, R.A.; Manas-Zloczower, I. Curing Kinetics of Biobased Epoxies for Tailored Applications. Macromolecules 2016, 49, 5315–5324. [Google Scholar] [CrossRef]

- Maiorana, A.; Ren, L.; Re, G.L.; Spinella, S.; Ryu, C.Y.; Dubois, P.; Gross, R.A. Bio-based epoxy resin toughening with cashew nut shell liquid-derived resin. Green Mater. 2015, 3, 80–92. [Google Scholar] [CrossRef]

- el Mansouri, N.E.; Yuan, Q.; Huang, F. Characterization of Alkaline Lignins for Use in Phenol-Formaldehyde and Epoxy Resins. BioResources 2011, 6, 2647–2662. [Google Scholar]

- Zhang, W.; Ma, Y.; Wang, C.; Li, S.; Zhang, M.; Chu, F. Preparation and properties of lignin–phenol–formaldehyde resins based on different biorefinery residues of agricultural biomass. Ind. Crop. Prod. 2013, 43, 326–333. [Google Scholar] [CrossRef]

- Wang, S.; Yu, Y.; Di, M. Green Modification of Corn Stalk Lignin and Preparation of Environmentally Friendly Lignin-Based Wood Adhesive. Polymers 2018, 10, 631. [Google Scholar] [CrossRef]

- Jacob, S.; Misra, M.; Mohanty, A. Green Synthesis for Lignin Plasticization. J. Renew. Mater. 2013, 1, 154–165. [Google Scholar] [CrossRef]

- Panesar, S.S.; Jacob, S.; Misra, M.; Mohanty, A.K. Functionalization of lignin: Fundamental studies on aqueous graft copolymerization with vinyl acetate. Ind. Crop. Prod. 2013, 46, 191–196. [Google Scholar] [CrossRef]

- Zhao, S.; Abu-Omar, M.M. Biobased Epoxy Nanocomposites Derived from Lignin-Based Monomers. Biomacromolecules 2015, 16, 2025–2031. [Google Scholar] [CrossRef]

- Zhao, S.; Abu-Omar, M.M. Renewable Epoxy Networks Derived from Lignin-Based Monomers: Effect of Cross-Linking Density. ACS Sustain. Chem. Eng. 2016, 4, 6082–6089. [Google Scholar] [CrossRef]

- Yin, Q.; Yang, W.; Sun, C.; Di, M. Preparation and Properties of Lignin-Epoxy Resin Composite. BioResources 2012, 7, 5737–5748. [Google Scholar] [CrossRef]

- Nacas, A.M.; Ito, N.M.; de Sousa, R.R.; Spinacé, M.A.; Santos, D.J.D. Effects of NCO:OH ratio on the mechanical properties and chemical structure of Kraft lignin–based polyurethane adhesive. J. Adhes. 2017, 93, 18–29. [Google Scholar] [CrossRef]

- Hemingway, R.W.; Karchesy, J.J. Chemistryand Significance of Condensed Tannins; Plenum Press: New York, NY, USA, 1989. [Google Scholar]

- Pizzi, A. Advanced Wood Adhesives Technology; Marcel Dekker Inc.: New York, NY, USA, 1994. [Google Scholar]

- Li, K.; Geng, X.; Simonsen, J.; Karchesy, J. Novel wood adhesives from condensed tannins and polyethylenimine. Int. J. Adhes. Adhes. 2004, 24, 327–333. [Google Scholar] [CrossRef]

- Amini, E.; Tajvidi, M.; Gardner, D.J.; Bousfield, D.W. Utilization of cellulose nanofibrils as a binder for particleboard manufacture. BioResources 2017, 12, 4093–4110. [Google Scholar] [CrossRef]

- Lindman, B.; Medronho, B.; Alves, L.; Costa, C.; Edlund, H.; Norgren, M. The relevance of cellulose structural features and interactions on dissolution, regeneration, gelation and plasticization phenomena. Phys. Chem. Chem. Phys. 2017, 19, 23704–23718. [Google Scholar] [CrossRef]

- Carapeto, A.P.; Ferraria, A.M.; Botelho do Rego, A.M. Trimethylsilylcellulose synthesis revisited. Polym. Test. 2017, 58, 236–240. [Google Scholar] [CrossRef]

- Stiubianu, G.; Racles, C.; Cazacu, M.; Simionescu, B.C. Silicone-modified cellulose. Crosslinking of cellulose acetate with poly[dimethyl(methyl-H)siloxane] by Pt-catalyzed dehydrogenative coupling. J. Mater. Sci. 2010, 45, 4141–4150. [Google Scholar] [CrossRef]

- Klemm, D.; Stein, A. Silylated Cellulose Materials in Design of Supramolecular Structures of Ultrathin Cellulose Films. J. Macromol. Sci. Part A 1995, 32, 899–904. [Google Scholar] [CrossRef]

- Robles, E.; Csóka, L.; Labidi, J. Effect of Reaction Conditions on the Surface Modification of Cellulose Nanofibrils with Aminopropyl Triethoxysilane. Coatings 2018, 8, 139. [Google Scholar] [CrossRef]

- Eslah, F.; Jonoobi, M.; Faezipour, M.; Ashori, A. Chemical modification of soybean flour-based adhesives using acetylated cellulose nanocrystals. Polym. Compos. 2018, 39, 3618–3625. [Google Scholar] [CrossRef]

- Qu, P.; Huang, H.; Wu, G.; Sun, E.; Chang, Z. The effect of hydrolyzed soy protein isolate on the structure and biodegradability of urea–formaldehyde adhesives. J. Adhes. Sci. Technol. 2015, 29, 502–517. [Google Scholar] [CrossRef]

- Khanjanzadeh, H.; Behrooz, R.; Bahramifar, N.; Gindl-Altmutter, W.; Bacher, M.; Edler, M.; Griesser, T. Surface chemical functionalization of cellulose nanocrystals by 3-aminopropyltriethoxysilane. Int. J. Biol. Macromol. 2018, 106, 1288–1296. [Google Scholar] [CrossRef] [PubMed]

- Khanjanzadeh, H.; Behrooz, R.; Bahramifar, N.; Pinkl, S.; Gindl-Altmutter, W. Application of surface chemical functionalized cellulose nanocrystals to improve the performance of UF adhesives used in wood based composites—MDF type. Carbohydr. Polym. 2019, 206, 11–20. [Google Scholar] [CrossRef] [PubMed]

- Jaillet, F.; Darroman, E.; Boutevin, B.; Caillol, S. A chemical platform approach on cardanol oil: From the synthesis of building blocks to polymer synthesis. OCL Oilseeds Fats Crop Lipids 2016, 23, D511. [Google Scholar] [CrossRef]

- Desai, S.D.; Patel, J.V.; Sinha, V.K. Polyurethane adhesive system from biomaterial-based polyol for bonding wood. Int. J. Adhes. Adhes. 2003, 23, 393–399. [Google Scholar] [CrossRef]

- Mati-Baouche, N.; Elchinger, P.-H.; de Baynast, H.; Pierre, G.; Delattre, C.; Michaud, P. Chitosan as an adhesive. Eur. Polym. J. 2014, 60, 198–212. [Google Scholar] [CrossRef]

- Shah, N.V.; Meislin, R. Current State and Use of Biological Adhesives in Orthopedic Surgery. Orthopedics 2013, 36, 945–956. [Google Scholar] [CrossRef]

- Ibrahim, V.; Mamo, G.; Gustafsson, P.-J.; Hatti-Kaul, R. Production and properties of adhesives formulated from laccase modified Kraft lignin. Ind. Crop. Prod. 2013, 45, 343–348. [Google Scholar] [CrossRef]

- Peshkova, S.; Li, K. Investigation of chitosan–phenolics systems as wood adhesives. J. Biotechnol. 2003, 102, 199–207. [Google Scholar] [CrossRef]

- Patel, A.K.; Michaud, P.; de Baynast, H.; Grédiac, M.; Mathias, J.-D. Preparation of chitosan-based adhesives and assessment of their mechanical properties. J. Appl. Polym. Sci. 2012, 127, 3869–3876. [Google Scholar] [CrossRef]

- Li, Z.; Wang, J.; Li, C.; Gu, Z.; Cheng, L.; Hong, Y. Effects of montmorillonite addition on the performance of starch-based wood adhesive. Carbohydr. Polym. 2015, 115, 394–400. [Google Scholar] [CrossRef]

- Chen, L.; Xiong, Z.; Xiong, H.; Wang, Z.; Din, Z.; Nawaz, A.; Wang, P.; Hu, C. Effects of nano-TiO2 on bonding performance, structure stability and film-forming properties of starch-g-VAc based wood adhesive. Carbohydr. Polym. 2018, 200, 477–486. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Rallini, M.; Natali, M.; Kenny, J.; Ma, P.; Dong, W.; Torre, L.; Puglia, D. Preparation and properties of adhesives based on phenolic resin containing lignin micro and nanoparticles: A comparative study. Mater. Des. 2018, 161, 55–63. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, D.; Li, N.; Sun, X.S. Bio-Based Wood Adhesive from Camelina Protein (a Biodiesel Residue) and Depolymerized Lignin with Improved Water Resistance. ACS Omega 2017, 2, 7996–8004. [Google Scholar] [CrossRef] [PubMed]

- Saraç, İ.; Adin, H.; Temiz, Ş. Investigation of the effect of use of Nano-Al2O3, Nano-TiO2 and Nano-SiO2 powders on strength of single lap joints bonded with epoxy adhesive. Compos. Part B Eng. 2019, 166, 472–482. [Google Scholar] [CrossRef]

- Saraç, İ.; Adin, H.; Temiz, Ş. Experimental determination of the static and fatigue strength of the adhesive joints bonded by epoxy adhesive including different particles. Compos. Part B Eng. 2018, 155, 92–103. [Google Scholar] [CrossRef]

- Zhou, H.; Liu, H.-Y.; Zhou, H.; Zhang, Y.; Gao, X.; Mai, Y.-W. On adhesive properties of nano-silica/epoxy bonded single-lap joints. Mater. Des. 2016, 95, 212–218. [Google Scholar] [CrossRef]

- Li, Y.; Li, C.; He, J.; Gao, Y.; Hu, Z. Effect of functionalized nano-SiO2 addition on bond behavior of adhesively bonded CFRP-steel double-lap joint. Constr. Build. Mater. 2020, 244, 118400. [Google Scholar] [CrossRef]

- Fu, H.; Yan, C.; Zhou, W.; Huang, H. Nano-SiO2/fluorinated waterborne polyurethane nanocomposite adhesive for laminated films. J. Ind. Eng. Chem. 2014, 20, 1623–1632. [Google Scholar] [CrossRef]

- Khare, H.S.; Burris, D.L. A quantitative method for measuring nanocomposite dispersion. Polymer 2010, 51, 719–729. [Google Scholar] [CrossRef]

- Alhareb, A.O.; Akil, H.M.; Ahmad, Z.A. Impact strength, fracture toughness and hardness improvement of PMMA denture base through addition of nitrile rubber/ceramic fillers. Saudi J. Dent. Res. 2017, 8, 26–34. [Google Scholar] [CrossRef]

- Balos, S.; Pilic, B.; Markovic, D.; Pavlicevic, J.; Luzanin, O. Poly(methyl-methacrylate) nanocomposites with low silica addition. J. Prosthet. Dent. 2014, 111, 327–334. [Google Scholar] [CrossRef] [PubMed]

- Dramicanin, M.; Balos, S.; Janjatovic, P.; Zabunov, I.; Grabulov, V. Activated flux TIG welding of stainless steel pipes. Chem. Ind. Chem. Eng. Q. 2019, 25, 353–360. [Google Scholar] [CrossRef]

- Dorigato, A.; Pegoretti, A.; Bondioli, F.; Messori, M. Improving Epoxy Adhesives with Zirconia Nanoparticles. Compos. Interfaces 2010, 17, 873–892. [Google Scholar] [CrossRef]

- Petriccione, A.; Zarrelli, M.; Antonucci, V.; Giordano, M. Aggregates of Chemically Functionalized Multiwalled Carbon Nanotubes as Viscosity Reducers. Materials 2014, 7, 3251–3261. [Google Scholar] [CrossRef]

- Balos, S.; Pilic, B.; Petronijevic, B.; Markovic, D.; Mirkovic, S.; Sarcev, I. Improving mechanical properties of flowable dental composite resin by adding silica nanoparticles. Vojn. Pregl. 2013, 70, 477–483. [Google Scholar] [CrossRef]

- Butac, L.-M.; Mărculescu, B.; Stancu, I.-C. Adhesives and Film-Forming Materials; ARS DOCENDI: Bucharest, Romania, 2010. [Google Scholar]

- Ciardiello, R. Mechanical characterization and separation tests of a thermoplastic reinforced adhesive used for automotive applications. Procedia Struct. Integr. 2019, 24, 155–166. [Google Scholar] [CrossRef]

- Onusseit, H. The influence of adhesives on recycling. Resour. Conserv. Recycl. 2006, 46, 168–181. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Iacovidou, E. An overview of the challenges and trade-offs in closing the loop of post-consumer plastic waste (PCPW): Focus on recycling. J. Hazard. Mater. 2019, 380, 120887. [Google Scholar] [CrossRef]

- G.M.R. Plastics Europe, Conversio Market & Strategy GmbH, Plastics—The Facts 2019. 2019. Available online: https://www.plasticseurope.org/en/resources/market-data (accessed on 28 June 2020).

- Ragaert, K.; Delva, L.; van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef]

- European Strategy for Plastics in a Circular Economy. 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1584021684730&uri=CELEX:52018IP0352 (accessed on 16 July 2020).

- Jasiukaitytė-Grojzdek, E.; Kunaver, M.; Kukanja, D.; Moderc, D. Renewable (waste) material based polyesters as plasticizers for adhesives. Int. J. Adhes. Adhes. 2013, 46, 56–61. [Google Scholar] [CrossRef]

- Al-Sabagh, A.M.; Yehia, F.Z.; Eshaq, G.; Rabie, A.M.; ElMetwally, A.E. Greener routes for recycling of polyethylene terephthalate. Egypt. J. Pet. 2016, 25, 53–64. [Google Scholar] [CrossRef]

- Awaja, F.; Pavel, D. Recycling of PET. Eur. Polym. J. 2005, 41, 1453–1477. [Google Scholar] [CrossRef]

- Achilias, D.S.; Karayannidis, G.P. The Chemical Recycling of PET in the Framework of Sustainable Development. Water Air Soil Pollut. Focus 2004, 4, 385–396. [Google Scholar] [CrossRef]

- Siddiqui, M.N.; Redhwi, H.H.; Achilias, D.S. Recycling of poly(ethylene terephthalate) waste through methanolic pyrolysis in a microwave reactor. J. Anal. Appl. Pyrolysis 2012, 98, 214–220. [Google Scholar] [CrossRef]

- Dimitrov, N.; Krehula, L.K.; Siročić, A.P.; Hrnjak-Murgić, Z. Analysis of recycled PET bottles products by pyrolysis-gas chromatography. Polym. Degrad. Stab. 2013, 98, 972–979. [Google Scholar] [CrossRef]

- Han, M. Depolymerization of PET Bottle via Methanolysis and Hydrolysis. In Recycling of Polyethylene Terephthalate Bottles; Elsevier: Amsterdam, The Netherlands, 2019; pp. 85–108. [Google Scholar] [CrossRef]

- Fukushima, K.; Lecuyer, J.M.; Wei, D.S.; Horn, H.W.; Jones, G.O.; Al-Megren, H.A.; Alabdulrahman, A.M.; Alsewailem, F.D.; McNeil, M.A.; Rice, J.E.; et al. Advanced chemical recycling of poly(ethylene terephthalate) through organocatalytic aminolysis. Polym. Chem. 2012, 4, 1610–1616. [Google Scholar] [CrossRef]

- Rusen, E.; Mocanu, A.; Fiat, D.; Dumitrescu, A.M.; Stanescu, P.O.; Diacon, A. Straightforward manufacturing of polyurethane adhesives and foams from post-consumer poly(ethylene terephthalate) (PET) bottles. Mater. Plast. 2015, 52, 209–213. [Google Scholar]

- López-Fonseca, R.; Duque-Ingunza, I.; de Rivas, B.; Arnaiz, S.; Gutiérrez-Ortiz, J.I. Chemical recycling of post-consumer PET wastes by glycolysis in the presence of metal salts. Polym. Degrad. Stab. 2010, 95, 1022–1028. [Google Scholar] [CrossRef]

- Abdelaal, M.Y.; Sobahi, T.R.; Makki, M.S.I. Chemical transformation of pet waste through glycolysis. Constr. Build. Mater. 2011, 25, 3267–3271. [Google Scholar] [CrossRef]

- Rusen, E.; Mocanu, A.; Rizea, F.; Diacon, A.; Calinescu, I.; Mititeanu, L.; Dumitrescu, D.; Popa, A.-M. Poly(ethylene terephtalate) recycled from post-consumer soft-drinks bottles: I.Poly(ethylene terephtalate) depolymerization by glycolysis process. Mater. Plast. 2013, 50, 130–133. [Google Scholar]

- Rusen, E.; Mocanu, A.; Rizea, F.; Diacon, A.; Calinescu, I.; Mititeanu, L.; Dumitrescu, D.; Popa, A.-M. Post-consumer PET bottles recycling: II. PET depolymerization using microwaves. Mater. Plast. 2013, 50, 201–207. [Google Scholar]

- Rusen, E.; Mocanu, A.; Rizea, F.; Stanescu, P.; Diacon, A.; Calinescu, I.; Dragoescu, M. Post-consumer PET Bottles Recycling III. Obtaining of unsaturated polyester resins and mechanical characterization of cross-linked materials with styrene. Mater. Plast. 2014, 51, 185–189. [Google Scholar]

- Hoang, C.N.; Pham, C.T.; Dang, T.M.; Hoang, D.; Lee, P.-C.; Kang, S.-J.; Kim, J. Novel Oligo-Ester-Ether-Diol Prepared by Waste Poly(ethylene terephthalate) Glycolysis and Its Use in Preparing Thermally Stable and Flame Retardant Polyurethane Foam. Polymers 2019, 11, 236. [Google Scholar] [CrossRef]

- Fink, J.K. Reactive Polymers, Fundamentals and Applications, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- George, N.; Sharmila, T.K.B.; Kurian, T. Preparation of a one-component epoxy adhesive using PET bottle waste derived terephthalic dihydrazide as latent curing agent. Int. J. Adhes. Adhes. 2020, 98, 102524. [Google Scholar] [CrossRef]

- Aliakbari, M.; Jazani, O.M.; Sohrabian, M. Epoxy adhesives toughened with waste tire powder, nanoclay, and phenolic resin for metal-polymer lap-joint applications. Prog. Org. Coat. 2019, 136, 105291. [Google Scholar] [CrossRef]

- Pizzi, K.L.; Mittal, A. Handbook of Adhesive Technology; CRC Press: New York, NY, USA, 2017. [Google Scholar]

- Registry of Restriction Intentions Until Outcome. 2019. Available online: https://echa.europa.eu/ro/registry-of-restriction-intentions/-/dislist/details/0b0236e180876053 (accessed on 25 June 2020).

- Yang, J.; Keller, M.W.; Moore, J.S.; White, S.R.; Sottos, N.R. Microencapsulation of Isocyanates for Self-Healing Polymers. Macromolecules 2008, 41, 9650–9655. [Google Scholar] [CrossRef]

- Attaei, M.; Loureiro, M.; Vale, M.d.; Condeço, J.; Pinho, I.; Bordado, J.; Marques, A. Isophorone Diisocyanate (IPDI) Microencapsulation for Mono-Component Adhesives: Effect of the Active H and NCO Sources. Polymers 2018, 10, 825. [Google Scholar] [CrossRef]

- Costa, M.; Dias, J.P.; Pinho, I.; Loureiro, M.V.; Marques, A.C.; Simoes, R. Development of a Microfluidic Device to Encapsulate Isocyanate for Autoreactive and Ecological Adhesives. IOP Conf. Ser. Mater. Sci. Eng. 2019, 520, 012007. [Google Scholar] [CrossRef]

- Loureiro, M.V.; Attaei, M.; Rocha, S.; Vale, M.; Bordado, J.C.; Simões, R.; Pinho, I.; Marques, A.C. The role played by different active hydrogen sources in the microencapsulation of a commercial oligomeric diisocyanate. J. Mater. Sci. 2019, 55, 4607–4623. [Google Scholar] [CrossRef]

- Attaei, M.; Vale, M.; Shakoor, A.; Kahraman, R.; Montemor, M.F.; Marques, A.C. Hybrid shell microcapsules containing isophorone diisocyanate with high thermal and chemical stability for autonomous self-healing of epoxy coatings. J. Appl. Polym. Sci. 2019, 137, 48751. [Google Scholar] [CrossRef]

- Attaei, M.; Calado, L.M.; Taryba, M.G.; Morozov, Y.; Shakoor, R.A.; Kahraman, R.; Marques, A.C.; Montemor, M.F. Autonomous self-healing in epoxy coatings provided by high efficiency isophorone diisocyanate (IPDI) microcapsules for protection of carbon steel. Prog. Org. Coat. 2020, 139, 105445. [Google Scholar] [CrossRef]

- Duan, B. Microencapsulation via In Situ Polymerization. In Handbook of Encapsulation and Controlled Release; CRC Press: Boca Raton, FL, USA, 2015; pp. 307–314. [Google Scholar] [CrossRef]

- Arias, A.; González-García, S.; González-Rodríguez, S.; Feijoo, G.; Moreira, M.T. Cradle-to-gate Life Cycle Assessment of bio-adhesives for the wood panel industry. A comparison with petrochemical alternatives. Sci. Total. Environ. 2020, 738, 140357. [Google Scholar] [CrossRef]

- McDevitt, J.E.; Grigsby, W.J. Life Cycle Assessment of Bio- and Petro-Chemical Adhesives Used in Fiberboard Production. J. Polym. Environ. 2014, 22, 537–544. [Google Scholar] [CrossRef]

- Ferrari, A.M.; Spinelli, R.; Gamberini, R.; Neri, P.; Pini, M.; Rimini, B. Comparative life cycle assessment of innovative and traditional adhesives for the laying of ceramic tiles. Int. J. Oper. Quant. Manag. 2014, 20, 227–241. [Google Scholar]

- la Rosa, A.D.; Ursan, G.A.; Aradoaei, M.; Ursan, M.; Schreiner, C. Life Cycle Assessment of Microwave Activated Hot-Melt Adhesives. In Proceedings of the EPE 2018—2018 10th International Conference and Exposition on Electrical and Power Engineering, Iaşi, Romania, 18–19 October 2018; pp. 658–661. [Google Scholar] [CrossRef]

- Yang, M.; Rosentrater, K.A. Cradle-to-gate life cycle assessment of structural bio-adhesives derived from glycerol. Int. J. Life Cycle Assess 2020. [Google Scholar] [CrossRef]

- Yang, M.; Rosentrater, K.A. Life Cycle Assessment and Techno-Economic Analysis of Pressure Sensitive Bio-Adhesive Production. Energies 2019, 12, 4502. [Google Scholar] [CrossRef]

- Rodriguez, L.J.; Peças, P.; Carvalho, H.; Orrego, C.E. A literature review on life cycle tools fostering holistic sustainability assessment: An application in biocomposite materials. J. Environ. Manag. 2020, 262, 110308. [Google Scholar] [CrossRef]

- Habenicht, G. Applied Adhesive Bonding; WILEY VCH: Weinheim, German, 2009. [Google Scholar]

- Packham, D.E. Theories of fundamental adhesion. In Handbook of Adhesion Technology, 2nd ed.; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Rider, A.N.; Olsson-Jacques, C.L.; Arnott, D.R. Influence of adherend surface preparation on bond durability. Surf. Interface Anal. 1999, 27, 1055–1063. [Google Scholar] [CrossRef]

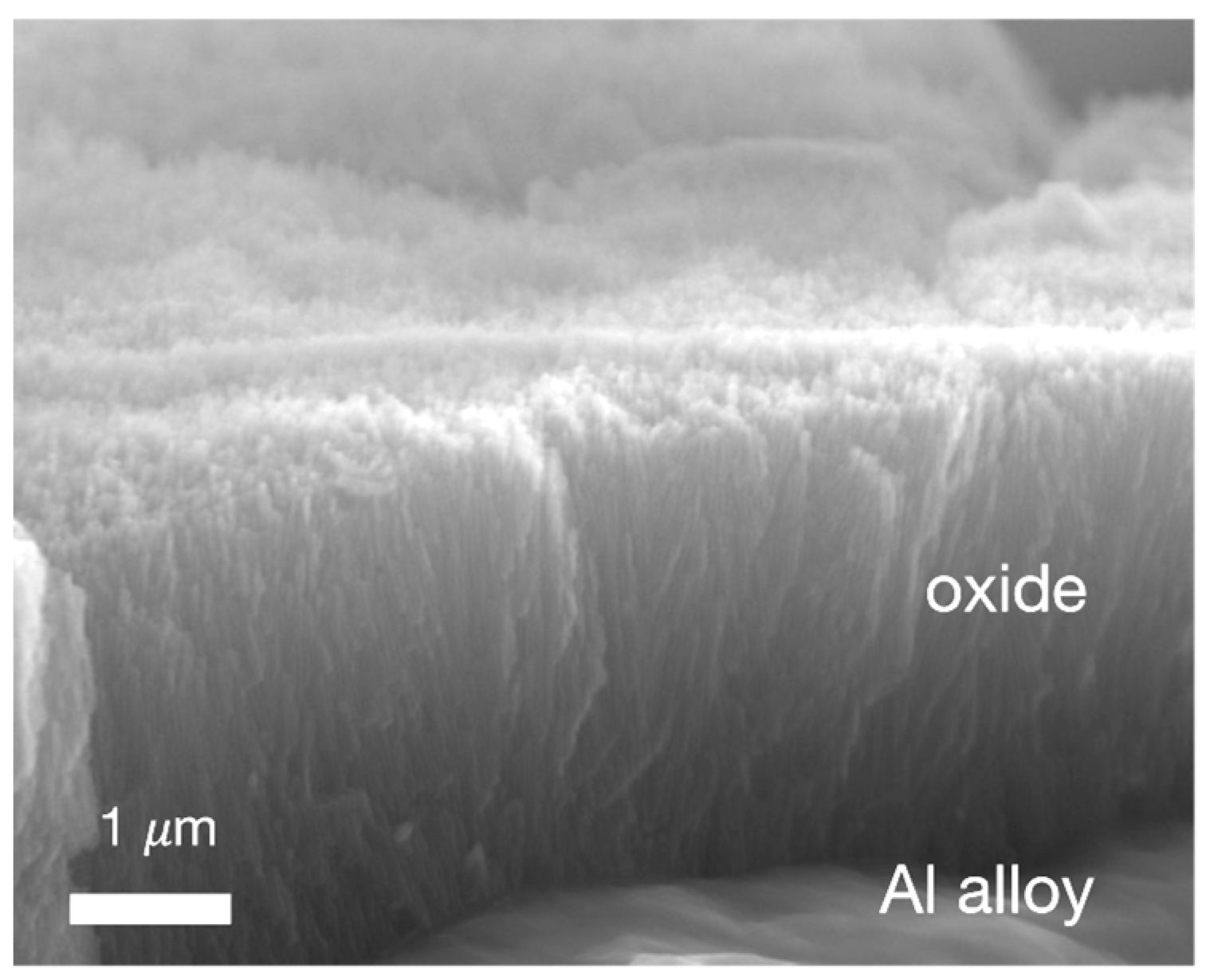

- Abrahami, S.T.; de Kok, J.M.M.; Gudla, V.C.; Ambat, R.; Terryn, H.; Mol, J.M.C. Interface strength and degradation of adhesively bonded porous aluminum oxides. NPJ Mater. Degrad. 2017, 1, 8. [Google Scholar] [CrossRef]

- ISO 17212. Structural Adhesives—Guidelines for the Surface Preparation of Metals and Plastics Prior to Adhesive Bonding. 2012. Available online: https://www.iso.org/standard/50596.html (accessed on 18 June 2020).

- Industry Projects, IFS TU Braunschweig, Technical Report. Unpublished Result.

- Büchter, E. A Green Way to Clean—Laser Cleaning. Laser Tech. J. 2012, 9, 36–38. [Google Scholar] [CrossRef]

- Büchter, E. Cleaning with Light. Laser Tech. J. 2018, 15, 36–39. [Google Scholar] [CrossRef][Green Version]

- ISO 8501-1. Preparation of Steel Substrates before Application of Paints and Related Products—Visual Assessment of Surface Cleanliness—Part 1: Rust Grades and Preparation Grades of Uncoated Steel Substrates and of Steel Substrates after Overall Removal. 2007. Available online: https://www.iso.org/standard/43426.html (accessed on 6 July 2020).

- Ciupack, Y.; Pasternak, H.; Mette, C.; Stammen, E.; Dilger, K. Adhesive Bonding in Steel Construction-Challenge and Innovation. Procedia Eng. 2017, 172, 186–193. [Google Scholar] [CrossRef]

- Ledecky, L.; Ciupack, Y.; Pasternak, H.; Fischer, V.; Stammen, E.; Dilger, K. Service life of cyclic loaded adhesively bonded connections in steel construction—Part 1: Influences on the carrying behavior. Bauingenieur 2019, 94, 29–35. [Google Scholar]

- Uhlmann, E.; el Mernissi, A. Pre-treatment by dry ice blasting for adhesive bonding. Prod. Eng. 2008, 2, 133–138. [Google Scholar] [CrossRef]

- Uhlmann, E.; Jaczkowski, R. Mechanical pretreatment before electroplating of aluminium alloy AlSi12. Surf. Coat. Technol. 2018, 352, 483–488. [Google Scholar] [CrossRef]

- Anagreh, N.; al Robaidi, A. Improvement of adhesion of high-strength steel sheets by surface pretreatment with dry ice blasting and self-indicating pretreatment (SIP*) adhesion mediators. Mater. Manuf. Process. 2011, 26, 84–92. [Google Scholar] [CrossRef]

- Brandt, J. Verbesserung der Beständigkeit Geklebter Verbunde Durch Oberflächenfunktionalisierung Nach dem CRYOSIL®-Verfahren; TU Kaiserslautern: Kaiserslautern, Germany, 2015. [Google Scholar]

- Geiss, P.L.; Götz, L. Cleaning and activating adherend surfaces by Cryosil® Carbon Dioxide Snow Blasting with coupling agents. In Proceedings of the In-Adhesives, Symposium on Innovations in Adhesives and Their Applications 2019, Munich, Germany, 25–26 January 2019; pp. 93–97. [Google Scholar]

- Doobe, M. (Ed.) Kunststoffe Erfolgreich Kleben; Springer Fachmedien Wiesbaden GmbH: Wiesbaden, Germany, 2018; pp. 104–121. [Google Scholar]

- Reincke, T.; Kreling, S.; Dilger, K. Adhesion of continuously manufactured fusion bonded multi-material structures consisting of steel and carbon fibre reinforced Polyamide 6. Int. J. Adhes. Adhes. 2017, 79, 73–82. [Google Scholar] [CrossRef]

- Kern, M.; Thompson, V.P. Effects of sandblasting and silica-coating procedures on pure titanium. J. Dent. 1994, 22, 300–306. [Google Scholar] [CrossRef]

- Ho, B.J.; Tsoi, J.K.H.; Liu, D.; Lung, C.Y.K.; Wong, H.M.; Matinlinna, J.P. Effects of sandblasting distance and angles on resin cement bonding to zirconia and titanium. Int. J. Adhes. Adhes. 2015, 62, 25–31. [Google Scholar] [CrossRef]

- Kreling, S.; Fischer, F.; Dilger, K. Pre-treatment of CFRP for adhesive bonding using low-pressure blasting. In Proceedings of the ICCM International Conference on Composite Materials., Montreal, QC, Canada, 28 July–2 August 2013. [Google Scholar]

- Schweizer, M.; Meinhard, D.; Ruck, S.; Riegel, H.; Knoblauch, V. Adhesive bonding of CFRP: A comparison of different surface pre-treatment strategies and their effect on the bonding shear strength. J. Adhes. Sci. Technol. 2017, 31, 104–121. [Google Scholar] [CrossRef]

- Kanerva, M.; Saarela, O. The peel ply surface treatment for adhesive bonding of composites: A review. Int. J. Adhes. Adhes. 2013, 43, 60–69. [Google Scholar] [CrossRef]

- Holtmannspötter, J.; Czarnecki, J.V.; Wetzel, M.; Dolderer, D.; Eisenschink, C. The use of peel ply as a method to create reproduceable but contaminated surfaces for structural adhesive bonding of carbon fiber reinforced plastics. J. Adhes. 2013, 89, 96–110. [Google Scholar] [CrossRef]

- Molitor, P.; Barron, V.; Young, T. Surface treatment of titanium for adhesive bonding to polymer composites: A review. Int. J. Adhes. Adhes. 2001, 21, 129–136. [Google Scholar] [CrossRef]

- Iqbal, H.M.S.; Bhowmik, S.; Benedictus, R. Surface modification of high performance polymers by atmospheric pressure plasma and failure mechanism of adhesive bonded joints. Int. J. Adhes. Adhes. 2010, 30, 418–424. [Google Scholar] [CrossRef]

- Noeske, M.; Degenhardt, J.; Strudthoff, S.; Lommatzsch, U. Plasma jet treatment of five polymers at atmospheric pressure: Surface modifications and the relevance for adhesion. Int. J. Adhes. Adhes. 2004, 24, 171–177. [Google Scholar] [CrossRef]

- Ward, L.J.; Schofield, W.C.E.; Badyal, J.P.S.; Goodwin, A.J.; Merlin, P.J. Atmospheric pressure plasma deposition of structurally well-defined polyacrylic acid films. Chem. Mater. 2003, 15, 1466–1469. [Google Scholar] [CrossRef]

- Fischer, V.; Stammen, E.; Dilger, K.; Eichler, M.; Paulmann, S.; Klages, C. Promotion of Adhesive Polymer Bonding by Plasma Modification Using Defined Ambient Conditions and Process Gases. J. Energy Power Eng. 2017, 11. [Google Scholar] [CrossRef]

- Romero-Sánchez, M.D.; Pastor-Blas, M.M.; Martín-Martínez, J.M. Treatment of a styrene-butadiene-styrene rubber with corona discharge to improve the adhesion to polyurethane adhesive. Int. J. Adhes. Adhes. 2003, 23, 49–57. [Google Scholar] [CrossRef]

- Sanchis, R.; Fenollar, O.; García, D.; Sánchez, L.; Balart, R. Improved adhesion of LDPE films to polyolefin foams for automotive industry using low-pressure plasma. Int. J. Adhes. Adhes. 2008, 28, 445–451. [Google Scholar] [CrossRef]

- Anagreh, N.; Dorn, L.; Bilke-Krause, C. Low-pressure plasma pretreatment of polyphenylene sulfide (PPS) surfaces for adhesive bonding. Int. J. Adhes. Adhes. 2008, 28, 16–22. [Google Scholar] [CrossRef]

- Mandolfino, C.; Lertora, E.; Genna, S.; Leone, C.; Gambaro, C. Effect of laser and plasma surface cleaning on mechanical properties of adhesive bonded joints. Procedia CIRP 2015, 33, 458–563. [Google Scholar] [CrossRef]

- Arikan, E.; Holtmannspötter, J.; Zimmer, F.; Hofmann, T.; Gudladt, H.J. The role of chemical surface modification for structural adhesive bonding on polymers—Washability of chemical functionalization without reducing adhesion. Int. J. Adhes. Adhes. 2019, 95, 102409. [Google Scholar] [CrossRef]

- Dodiuk, H.; Buchman, A.; Kenig, S.; Rotel, M.; Zahavi, J.; Reinhart, T.J. Preadhesion Laser Treatment of Aluminum Surfaces. J. Adhes. 1993, 41, 93–112. [Google Scholar] [CrossRef]

- Zhang, Z.; Shan, J.; Tan, X.; Zhang, J. Improvement of the laser joining of CFRP and aluminum via laser pre-treatment. Int. J. Adv. Manuf. Technol. 2017, 90, 3465–3472. [Google Scholar] [CrossRef]

- Molitor, P.; Young, T. Adhesives bonding of a titanium alloy to a glass fibre reinforced composite material. Int. J. Adhes. Adhes. 2002, 22, 101–107. [Google Scholar] [CrossRef]

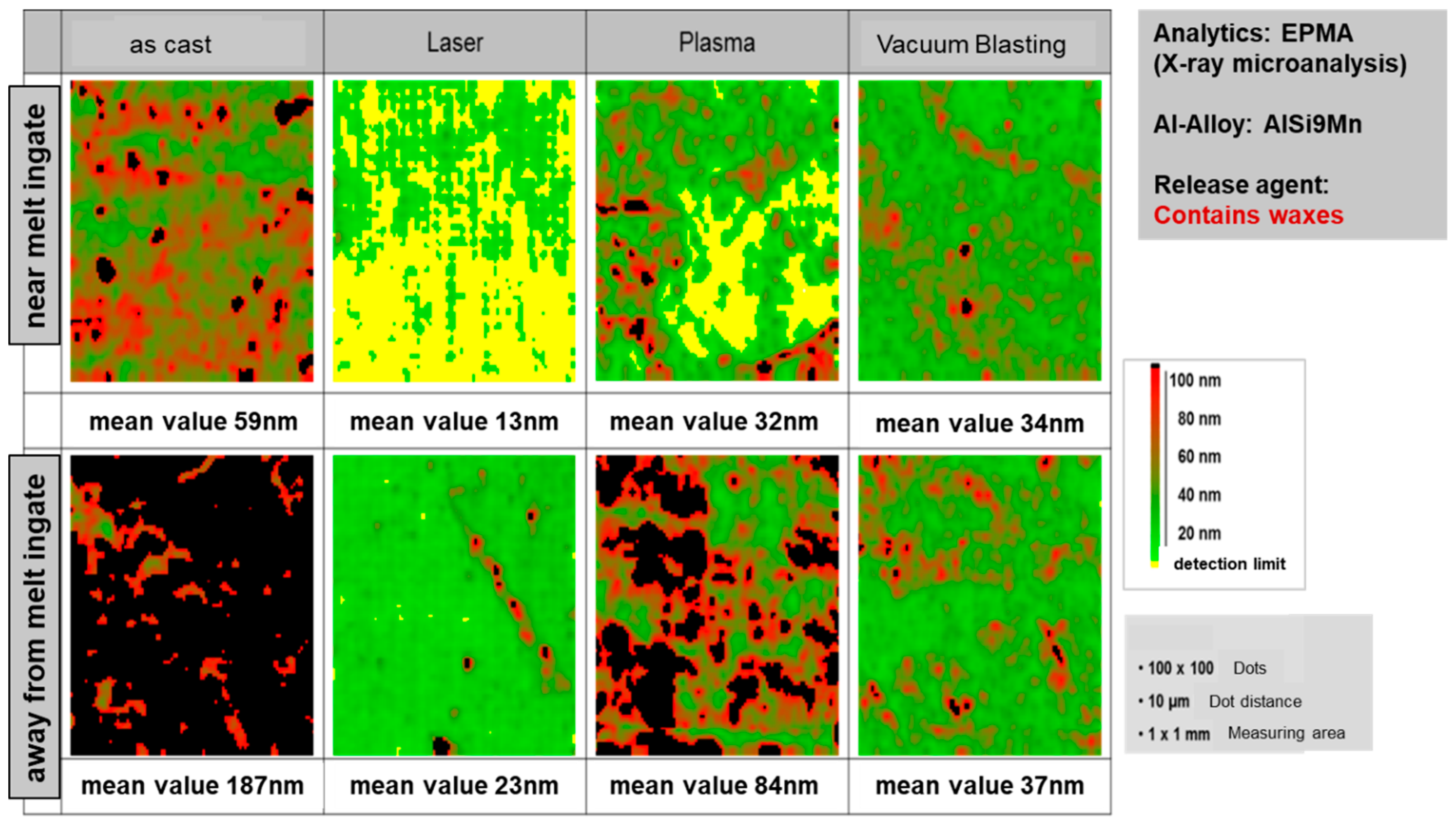

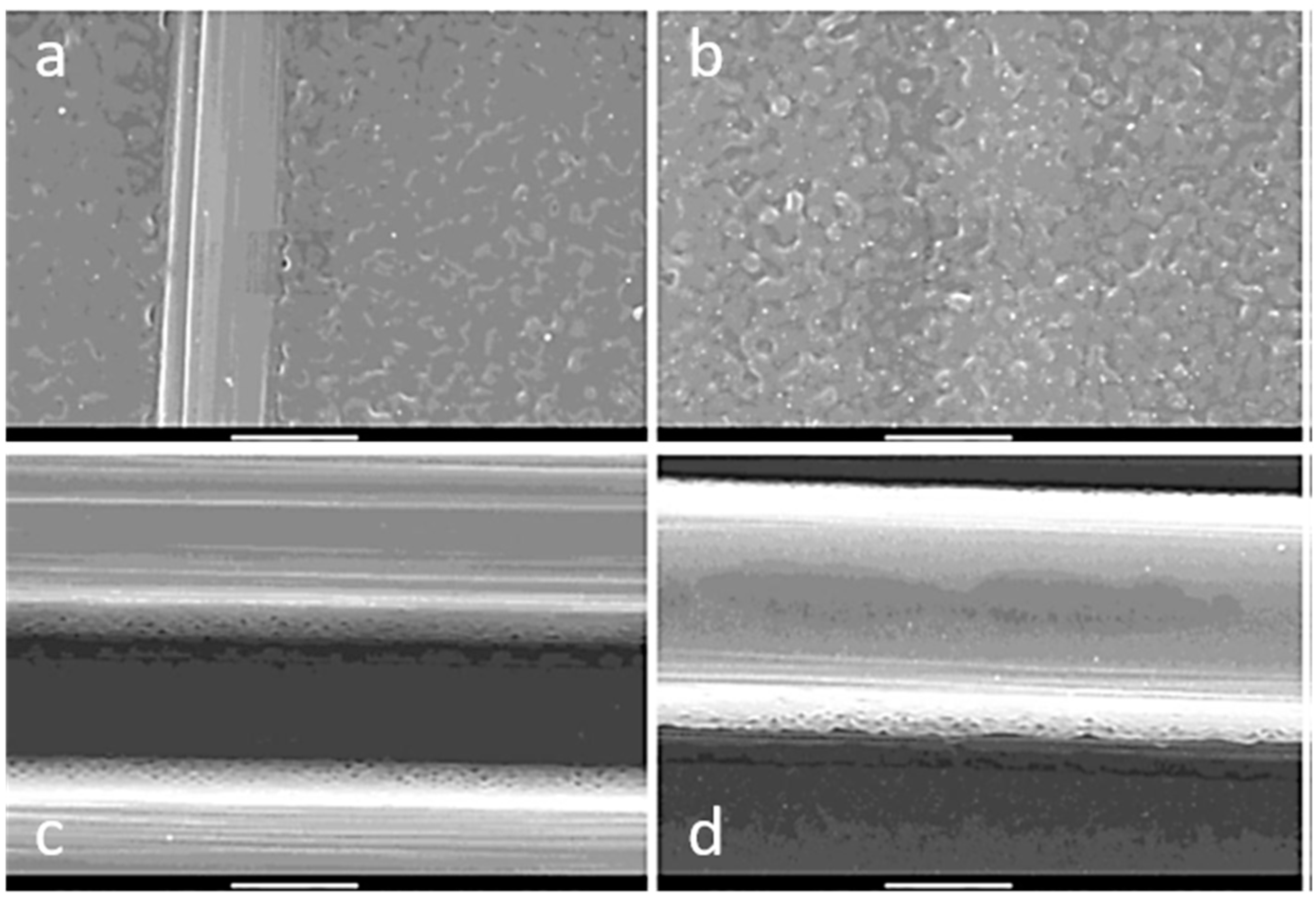

- Stammen, E.; Dilger, K.; Böhm, S.; Hose, R. Surface Modification with Laser: Pretreatment of Aluminium Alloys for Adhesive Bonding. Plasma Process. Polym. 2007, 4, 39–43. [Google Scholar] [CrossRef]

- Hartwig, A.; Hunnekuhl, J.; Vitr, G.; Dieckhoff, S.; Vohwinkel, F.; Hennemann, O.-D. Influence of CO2 laser radiation on the surface properties of poly(ether ether ketone). J. Appl. Polym. Sci. 1997, 64, 1091–1096. [Google Scholar] [CrossRef]

- Kreling, S.; Fischer, F.; Delmdahl, R.; Gäbler, F.; Dilger, K. Analytical characterization of CFRP laser treated by excimer laser radiation. Phys. Procedia 2013, 41, 282–290. [Google Scholar] [CrossRef]

- Rotel, M.; Zahavi, J.; Buchman, A.; Dodiuk, H. Preadhesion Laser Surface Treatment of Carbon Fiber Reinforced Peek Composite. J. Adhes. 1995, 55, 77–97. [Google Scholar] [CrossRef]

- Fischer, F.; Kreling, S.; Jäschke, P.; Frauenhofer, M.; Kracht, D.; Dilger, K. Laser surface pre-treatment of CFRP for adhesive bonding in consideration of the absorption behaviour. J. Adhes. 2012, 88, 350–363. [Google Scholar] [CrossRef]

- Rechner, R.; Jansen, I.; Beyer, E. Influence on the strength and aging resistance of aluminium joints by laser pre-treatment and surface modification. Int. J. Adhes. Adhes. 2010, 30, 595–601. [Google Scholar] [CrossRef]

- Alfano, M.; Lubineau, G.; Furgiuele, F.; Paulino, G.H. Study on the role of laser surface irradiation on damage and decohesion of Al/epoxy joints. Int. J. Adhes. Adhes. 2012, 39, 33–41. [Google Scholar] [CrossRef]

- Kurtovic, A.; Brandl, E.; Mertens, T.; Maier, H.J. Laser induced surface nano-structuring of Ti-6Al-4V for adhesive bonding. Int. J. Adhes. Adhes. 2013, 45, 112–117. [Google Scholar] [CrossRef]

- Palmieri, F.L.; Belcher, M.A.; Wohl, C.J.; Blohowiak, K.Y.; Connell, J.W. Laser ablation surface preparation for adhesive bonding of carbon fiber reinforced epoxy composites. Int. J. Adhes. Adhes. 2016, 68, 95–101. [Google Scholar] [CrossRef]

- Stammen, E.; Pries, H.; Klaus, D. Systemintegrativer Multi-Material-Leichtbau für die Elektromobilität. In Schlussbericht Des Verbundprojektes SMiLE, 1st ed.; Deinzer, G., Kothmann, M.H., Eds.; Shaker Verlag: Herzogenrath, Germany, 2020; p. 456. [Google Scholar]

- Rotella, G.; Alfano, M.; Schiefer, T.; Jansen, I. Evaluation of mechanical and laser surface pre-treatments on the strength of adhesive bonded steel joints for the automotive industry. J. Adhes. Sci. Technol. 2016, 30–37, 747–758. [Google Scholar] [CrossRef]

- Shi, J.; Pries, H.; Stammen, E.; Dilger, K. Chemical pretreatment and adhesive bonding properties of high-pressure die cast aluminum alloy: AlSi10MnMg. Int. J. Adhes. Adhes. 2015, 61, 112–121. [Google Scholar] [CrossRef]

- Milošev, I.; Frankel, G. Review—Conversion Coatings Based on Zirconium and/or Titanium. J. Electrochem. Soc. 2018, 165, C127–C144. [Google Scholar] [CrossRef]

- Wegman, R.F.; van Twisk, J. 2—Aluminum and Aluminum Alloys. In Surface Preparation Techniques for Adhesive Bonding, 2nd ed.; William Andrew: Norwich, NY, USA, 2013; pp. 9–37. [Google Scholar]

- Abrahami, S.T.; de Kok, J.M.M.; Terryn, H.; Mol, J.M.C. Towards Cr(VI)-free anodization of aluminum alloys for aerospace adhesive bonding applications: A review. Front. Chem. Sci. Eng. 2017, 11, 465–482. [Google Scholar] [CrossRef]

- Williams, D.F. The Use of Cold Atmospheric Plasma (CAP) Treatment for the Structural Adhesive Bonding of Metals; University of Surrey: Guildford, UK, 2017. [Google Scholar]

- Maciel, V.G.; Bockorny, G.; Domingues, N.; Scherer, M.B.; Zortea, R.B.; Seferin, M. Comparative Life Cycle Assessment among Three Polyurethane Adhesive Technologies for the Footwear Industry. ACS Sustain. Chem. Eng. 2017, 5, 8464–8472. [Google Scholar] [CrossRef]

- SIKA, Pre-treatment Agents. Webpage. Available online: https://web.archive.org/save/https://www.sika.com/en/about-us/sustainability/sustainable-solutions/projects/automotive/pretreatment-agents.html (accessed on 29 October 2020).

- Vidal, R.; Alberola-Borràs, J.A.; Gómez-Cordón, J.; Moliner, E.; Ortega, A.; Verdejo, E. LCA to Evaluate the Environmental Impact for Chemical Pre-treatment in Plastics Metallization. J. Polym. Environ. 2017, 25, 961–972. [Google Scholar] [CrossRef]

- Harscoet, E.; Froelich, D. Use of LCA to evaluate the environmental benefits of substituting chromic acid anodizing (CAA). J. Clean. Prod. 2008, 16, 1294–1305. [Google Scholar] [CrossRef][Green Version]

- Banea, M.D. Debonding on Demand of Adhesively Bonded Joints: A Critical Review. Rev. Adhes. Adhes. 2019, 7, 33–50. [Google Scholar] [CrossRef]

- EC. Directive 200053EC of the European Parliament and of the Council on End-of Life vehicles. Off. J. Eur. Communities L 2000, 269, 1–15. [Google Scholar]

- Hutchinson, A.; Liu, Y.; Lu, Y. Overview of disbonding technologies for adhesive bonded joints. J. Adhes. 2017, 93, 737–755. [Google Scholar] [CrossRef]

- Heucher, R.; Kopannia, S.; Mcardle, C.; Stuve, M.; Kolbe, J. Electrically Divisible Polyamide Adhesive. KR20140133606A, 12 March 2013. [Google Scholar]

- Kristen, C. Process for Adhesive Separation of Bonded Joints. US20050039848A1, 5 August 2008. [Google Scholar]

- Markle, I.R.A.; Phyllis, L.; George, E.; Elhard, J.D.; Bigg, D.M. Thermally Reversible Isocyanate-Based Polymers. U.S. Patent 5470945A, 28 November 1995. [Google Scholar]

- Alcorta, J.; Papon, E.; Villenave, J.-J. Destructuring Agent for an Adhesive Composition, and Glue and Primer Forming Said Composition. WO2005028583A1, 31 May 2005. [Google Scholar]

- Licari, J.J.; Bakhit, G.G. Reworkable Epoxy Die-Attach Adhesive. U.S. Patent US5002818A, 26 March 1991. [Google Scholar]

- Foulc, M.; Bergara, T.; Olive, M. Assembly of Two Substrates Bonded by a Rigid Polymer, and Methods for Assembly and Dismantling by Means of Migration of Said Bonded Assembly. U.S. Patent 20120258315A1, 11 October 2012. [Google Scholar]

- Becher, P.; Flegel, H.; Hermann, M.; Kurzmann, P.; Bauer, J.; Bauer, M.; Krüger, H.; Neumann-Rodekrich, J.; Schneider, J.; Hirthhammer, M. Adhesive System for Form Reversible Glued Joints. Eur. Pat. EP1115770B1, 10 November 2004. [Google Scholar]

- Gilbert, M.D. Electrically Disbonding Materials. U.S. Patent 7968188B2, 28 June 2011. [Google Scholar]

- Gilbert, M.D. Electrically Disbonding Adhesive Compositions and Related Methods. U.S. Patent 7465492B2, 16 December 2008. [Google Scholar]

- Friese, C.; Unger, L.; Kirsten, C.; Huver, T.; Ferencz, A. Lösbare Klebeverbindungen. Eur. Pat. EP1111020A2, 27 June 2001. [Google Scholar]

- Morehouse, D.S.; Tetreault, R.J. Expansible Thermoplastic Polymer Particles Containing Volatile Fluid Foaming Agent and Method of Foaming the Same. U.S. Patent 3615972A, 28 April 1967. [Google Scholar]

- Bain, P.; Giovanni, M. Method and apparatus for bonding and debonding adhesive interface surfaces. WO2004087826A3, 13 January 2011. [Google Scholar]

- Aubert, J. Method of Making Thermally Removable Adhesives. U.S. Patent 20030116272A1, 26 June 2003. [Google Scholar]

- Afzali-Ardakani, A.; Buchwalter, S.; Gelorme, J.; Kosbar, L.; Newman, B.; Pompeo, F. Cleavable Diepoxide for Removable Epoxy Compositions. U.S. Patent 5560934A, 1 October 1996. [Google Scholar]

- Concord, A. Debonding Technologies for Adhesive Bonded Structures. Ph.D. Thesis, Brandenburgischen Technischen Universität Cottbus, Cottbus, Germany, March 2012. [Google Scholar]

- Kolbe, J.; Kowalik, T.; Popp, M.; Sebald, M.; Schorsch, O.; Heberer, S.; Pridoehl, M.; Zimmermann, G.; Hartwig, A.; Born, E. Curable Bonded Assemblies Capable of Being Dissociated. U.S. Patent 7569624B2, 4 August 2009. [Google Scholar]

- Ciardiello, R.; Martorana, B.; Lambertini, V.G.; Brunella, V. Iron-based reversible adhesives: Effect of particles size on mechanical properties. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 232, 1446–1455. [Google Scholar] [CrossRef]

- Ciardiello, R.; Tridello, A.; Brunella, V.; Martorana, B.; Paolino, D.S.; Belingardi, G. Impact response of adhesive reversible joints made of thermoplastic nanomodified adhesive. J. Adhes. 2018, 94, 1051–1066. [Google Scholar] [CrossRef]

- Lee, B.; Son, I.; Kim, J.H.; Kim, C.; Yoo, J.Y.; Ahn, B.W.; Hwang, J.; Lee, J.; Lee, J.H. Polymeric nanocapsules containing methylcyclohexane for improving thermally induced debonding of thin adhesive films. J. Appl. Polym. Sci. 2018, 135, 1–9. [Google Scholar] [CrossRef]

- Nishiyama, Y.; Uto, N.; Sato, C.; Sakurai, H. Dismantlement behavior and strength of dismantlable adhesive including thermally expansive particles. Int. J. Adhes. Adhes. 2003, 23, 377–382. [Google Scholar] [CrossRef]

- Nishiyama, Y.; Sato, C. Behavior of Dismantlable Adhesives Including Thermally Expansive Microcapsules. Adhes. Curr. Res. Appl. 2006, 555–568. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M.; Carbas, R.J.C. Debonding on command of adhesive joints for the automotive industry. Int. J. Adhes. Adhes. 2015, 59, 14–20. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M.; Carbas, R.J.C.; de Barros, S. Debonding on command of multi-material adhesive joints. J. Adhes. 2017, 93, 756–770. [Google Scholar] [CrossRef]

- Rahmani, H.; Najafi, S.H.M.; Saffarzadeh-Matin, S.; Ashori, A. Effect of No of plies, Angle ply layers. Fiber 2013, 2–9. [Google Scholar] [CrossRef]

- Tomalino, M.; Bianchini, G. Heat-expandable microspheres for car protection production. Prog. Org. Coat. 1997, 32, 17–24. [Google Scholar] [CrossRef]

- Naganuma, T.; Kagawa, Y. Effect of particle size on the optically transparent nano meter-order glass particle-dispersed epoxy matrix composites. Compos. Sci. Technol. 2002, 62, 1187–1189. [Google Scholar] [CrossRef]

- Andersson, L.; Bergström, L. Gas-filled microspheres as an expandable sacrificial template for direct casting of complex-shaped macroporous ceramics. J. Eur. Ceram. Soc. 2008, 28, 2815–2821. [Google Scholar] [CrossRef]

- Chen, S.Y.; Sun, Z.C.; Li, L.H.; Xiao, Y.H.; Yu, Y.M. Preparation and characterization of conducting polymer-coated thermally expandable microspheres. Chin. Chem. Lett. 2017, 28, 658–662. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M.; Carbas, R.J.C.; Campilho, R.D.S.G. Mechanical and thermal characterization of a structural polyurethane adhesive modified with thermally expandable particles. Int. J. Adhes. Adhes. 2014, 54, 191–199. [Google Scholar] [CrossRef]

- Rescoll Research Company, Fields of Application: Industrial Structural Adhesives with Innovative Functionality: DISASSEMBLING. Available online: https://rescoll.fr/wp-content/uploads/2011/07/Indar.pdf (accessed on 5 December 2020).

- Kishi, H.; Inada, Y.; Imade, J.; Uesawa, K.; Matsuda, S.; Sato, C.; Atsushi, M. Design of Dismantlable Structural Adhesives with High Temperature Performance. J. Adhes. Soc. Jpn. 2006, 42, 356–363. [Google Scholar] [CrossRef][Green Version]

- EN 22432. Aerospace Series—Non-Metallic Materials—Structural Adhesives—Test Method—Part 2: Peel Metal-Metal; BSI: London, UK, 2005. [Google Scholar]

- ASTM D3167. Standard Test Method for Floating Roller Peel Resistance of Adhesives; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- EN 22433. Aerospace Series—Non-Metallic Materials—Structural Adhesives—Test Method—Part 3: Peeling Test Metal-Honeycomb Core; BSI: London, UK, 2005. [Google Scholar]

- de Freitas, S.T.; Sinke, J. Test method to assess interface adhesion in composite bonding. Appl. Adhes. Sci. 2015, 3, 1–13. [Google Scholar] [CrossRef]

- de Freitas, S.T.; Sinke, J. Adhesion Properties of Bonded Composite-to-Aluminium Joints Using Peel Tests. J. Adhes. 2014, 90, 511–525. [Google Scholar] [CrossRef]

- EN 1464. Adhesives—Determination of Peel Resistance of Adhesive Bonds—Floating Roller Method; BSI: London, UK, 2010. [Google Scholar]

- EN 1967. Structural Adhesives—Evaluation of the Effectiveness of Surface Treatment Techniques for Aluminium Using a Wet Peel Test in Association with the Floating Roller Method; BSI: London, UK, 2002. [Google Scholar]

- ASTM D3762. Standard Test Method for Adhesive-Bonded Surface Durability of Aluminum (Wedge Test); ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- EN 22431. Aerospace Series—Non-Metallic Materials—Structural Adhesives—Test Method—Part 1: Single Lap Shear; BSI: London, UK, 2005. [Google Scholar]

- ASTM International. D6465-99(2016) Standard Guide for Selecting Aerospace and General Purpose Adhesives and Sealants; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar] [CrossRef]

- Hart-Smith, L.J. Peel-type durability test coupon to assess interfaces in bonded, co-bonded, and co-cured composite structures. Int. J. Adhes. Adhes. 1999, 19, 181–191. [Google Scholar] [CrossRef]

- EN 22431. Aerospace Series—Non-Metallic Materials—Structural Adhesives—Test Method—Part 5: Ageing Tests; BSI: London, UK, 2005. [Google Scholar]

- ISO 9227. Corrosion Tests in Artificial Atmospheres—Salt Spray Tests. 2017. Available online: https://www.iso.org/standard/63543.html (accessed on 17 July 2020).

- ASTM B117. Standard Practice for Operating Salt Spray (Fog) Apparatus; ASTM: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Arouche, M.M.; Budhe, S.; Alves, L.A.; de Freitas, S.T.; Banea, M.D.; de Barros, S. Effect of moisture on the adhesion of CFRP-to-steel bonded joints using peel tests. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 10. [Google Scholar] [CrossRef]

- de Freitas, S.T.; Banea, M.D.; Budhe, S.; de Barros, S. Interface adhesion assessment of composite-to-metal bonded joints under salt spray conditions using peel tests. Compos. Struct. 2017, 164, 68–75. [Google Scholar] [CrossRef]

- EN 6072. Aerospace series—Metallic Materials—Test Methods—Constant Amplitude Fatigue Testing; BSI: London, UK, 2010. [Google Scholar]

- EN 2379. Aerospace series—Fluids for Assessment of Non-Metallic Materials; BSI: London, UK, 2018. [Google Scholar]

| Adhesive | Properties | Applications (Adherends) |

|---|---|---|

| Epoxy | High strength and temperature resistance, good durability and resistance to environmental extremes, relatively low cure temperatures (for two-component formulation (2K)), easy to use, low cost. | Most materials, metals, ceramics, polymers |

| Acrylics | Versatile (design flexibility), high strength, fast curing, tolerates less prepared surfaces | Cloth, plastics, metals |

| Polyurethanes | Good flexibility at low temperatures, resistant to fatigue, impact and durability, ideal for creating strong flexible bonds between dissimilar materials. | Plastics, metals, rubber |

| Cyanoacrylates (superglues) | Fast bonding capability to plastic and rubber but poor to moisture and temperature | Almost any adherends |

| Anaerobics | Fastening and sealing without light, heat or oxygen, suitable for cylindrical shapes | Metals |

| Silicones | Excellent sealant for low stress applications, high flexibility, very high temperature resistance, long cure times (for one-component formulations (1K)), low strength | Metals, glass, paper, plastics, rubber, fluorocarbons |

| Phenolics | Good strength retention for short periods of time, limited resistance to thermal shock, low cost | Metals, wood |

| Polyimides | Thermal stability, dependent on a number of factors, difficult process ability, expensive | Cloth, plastics |

| Bismaleimides | Very rigid, low peel properties | Metals, glass, ceramics, plastics |

| Amino resins (e.g., urea-formaldehyde) | High strength, rigidity, cost effectiveness, and fast cure | Wood |

| Adhesively Bonded Joint Advantages | Adhesively Bonded Joint Disadvantages |

|---|---|

| Expressive weight savings, as there are no rivets (points of stress concentration) | Requires surface preparation—thorough cleaning/degreasing |

| More evenly distributed stresses | Curing times can be significant |

| Cost savings: hole fabrication is not needed | For curing, heat and pressure may be needed |

| Excellent fatigue resistance | Strength consistency is highly dependent on rigid process control |

| Increased vibration and shock resistance | Conventional techniques of non-destructive inspection of ABJs is difficult |

| Increased compliance to critical tolerances | Adhesive shelf-life is limited; thus, special storage conditions are required |

| Provides a way to seal the entire bonding area | Lower humidity and temperature resistance |

| Enables joining of dissimilar base materials | |

| Smooth contours and sections around joint areas |

| Crosslinker Added to the OH Pre-Polymer | Average Load per Unit Width of Bond | Type of Failure Observed in the Peeling Strength Test |

|---|---|---|

| None | <2 N/mm | Adhesive, at the substrate/adhesive interface |

| IPDI | 2.97 N/mm | Cohesive, through the adhesive |

| Microencapsulated IPDI (I MCs) | 2.99 N/mm | Structural and cohesive rupture |

| Creation of Performance and Reproducibility | Validation of Process and Performance by Quality Control | |||

|---|---|---|---|---|

| Qualified/Approved Process | Workmanship/Execution of the Process | Examples of Process Inspection | Examples of Accompanying Tests | Non-Destructive Testing |

| Surface pre-treatment | In pre-treatment line | Racking of metal parts, process parameters | Chemical analyses of solutions Oxide weights Peel test | Visual, and presence of oxide |

| Bond primer application | In contamination and humidity-controlled primer shop | Primer composition, process parameters, working method | Peel test | Primer thickness, and visual inspection |

| Adhesive joining | In contamination and humidity-controlled lay-up area | Adhesive quality, correct assembly, cure pressure, temperature, and time | Lap shear | Visual check of the adhesive squeeze-out; non-destructive testing for contact with bond surface, inclusions, local pressure variations, and adhesive quality (porosity) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marques, A.C.; Mocanu, A.; Tomić, N.Z.; Balos, S.; Stammen, E.; Lundevall, A.; Abrahami, S.T.; Günther, R.; de Kok, J.M.M.; Teixeira de Freitas, S. Review on Adhesives and Surface Treatments for Structural Applications: Recent Developments on Sustainability and Implementation for Metal and Composite Substrates. Materials 2020, 13, 5590. https://doi.org/10.3390/ma13245590

Marques AC, Mocanu A, Tomić NZ, Balos S, Stammen E, Lundevall A, Abrahami ST, Günther R, de Kok JMM, Teixeira de Freitas S. Review on Adhesives and Surface Treatments for Structural Applications: Recent Developments on Sustainability and Implementation for Metal and Composite Substrates. Materials. 2020; 13(24):5590. https://doi.org/10.3390/ma13245590

Chicago/Turabian StyleMarques, Ana C., Alexandra Mocanu, Nataša Z. Tomić, Sebastian Balos, Elisabeth Stammen, Asa Lundevall, Shoshan T. Abrahami, Roman Günther, John M. M. de Kok, and Sofia Teixeira de Freitas. 2020. "Review on Adhesives and Surface Treatments for Structural Applications: Recent Developments on Sustainability and Implementation for Metal and Composite Substrates" Materials 13, no. 24: 5590. https://doi.org/10.3390/ma13245590

APA StyleMarques, A. C., Mocanu, A., Tomić, N. Z., Balos, S., Stammen, E., Lundevall, A., Abrahami, S. T., Günther, R., de Kok, J. M. M., & Teixeira de Freitas, S. (2020). Review on Adhesives and Surface Treatments for Structural Applications: Recent Developments on Sustainability and Implementation for Metal and Composite Substrates. Materials, 13(24), 5590. https://doi.org/10.3390/ma13245590