Comparison of Long-Term Strength Development of Steel Fiber Shotcrete with Cast Concrete Based on Accelerator Type

Abstract

1. Introduction

2. Test Process and Methods

2.1. Materials

2.1.1. Cement

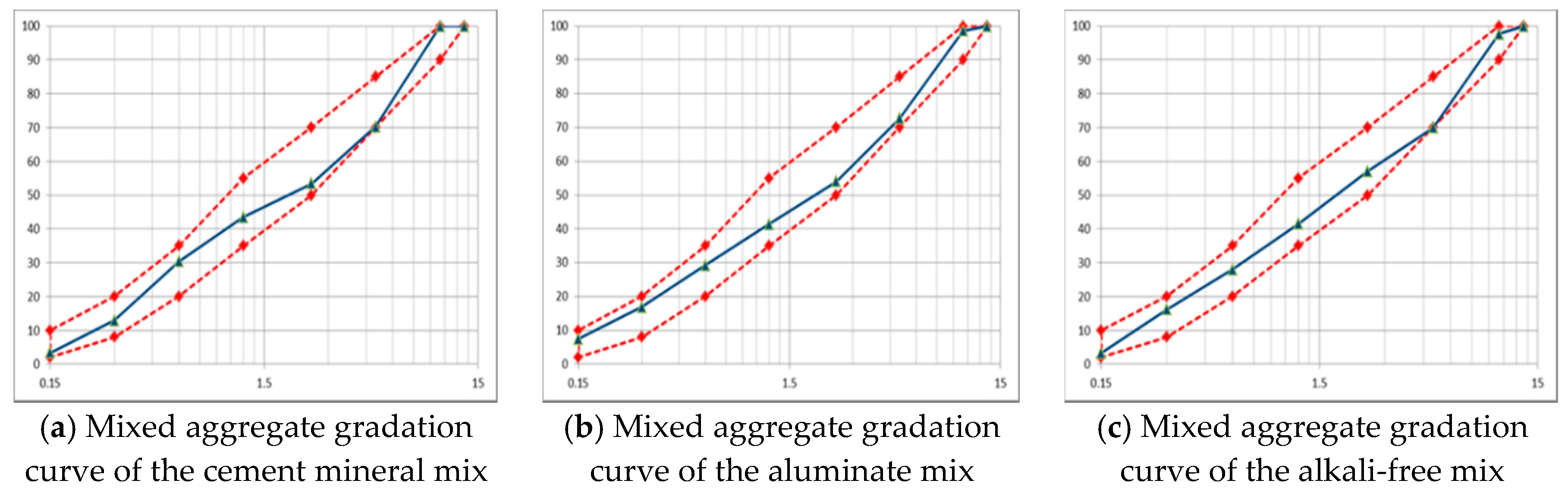

2.1.2. Aggregate

2.1.3. Accelerators

2.1.4. Steel Fiber

2.2. Mix Design

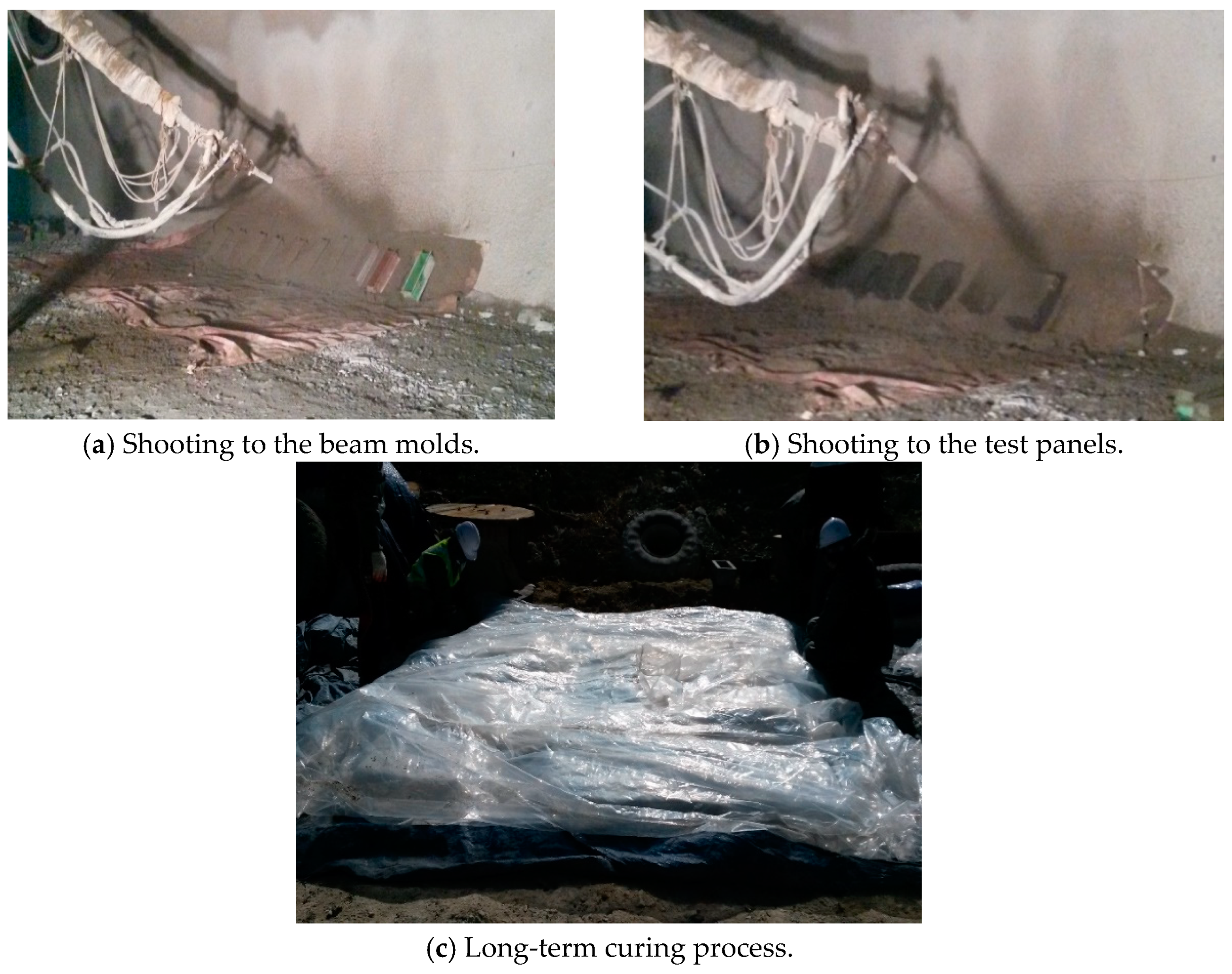

2.3. Specimen Preparation

2.4. Slump and Air Content Test

2.5. Compressive Strength Test

2.6. Flexural Strength Test

3. Result and Analysis

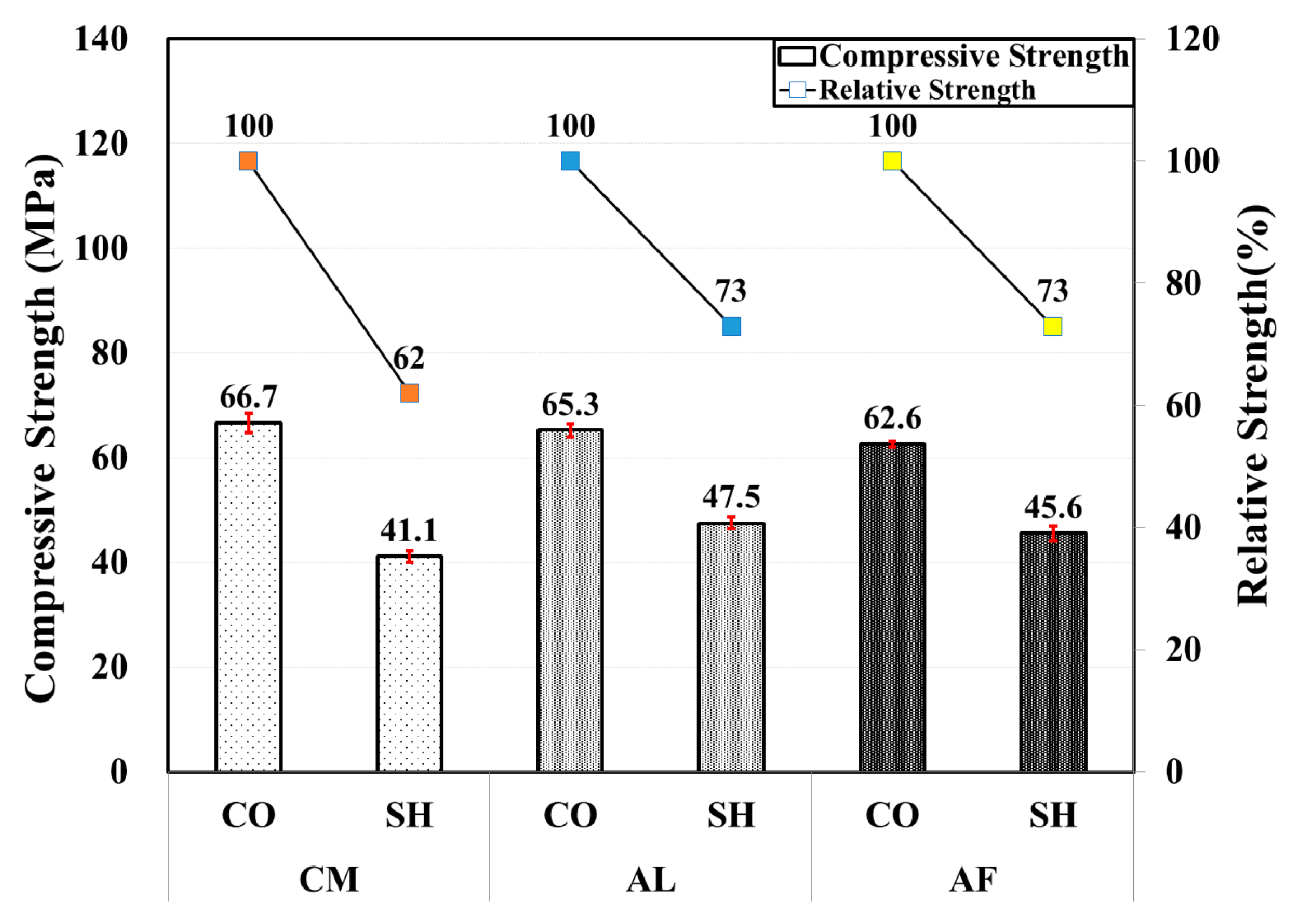

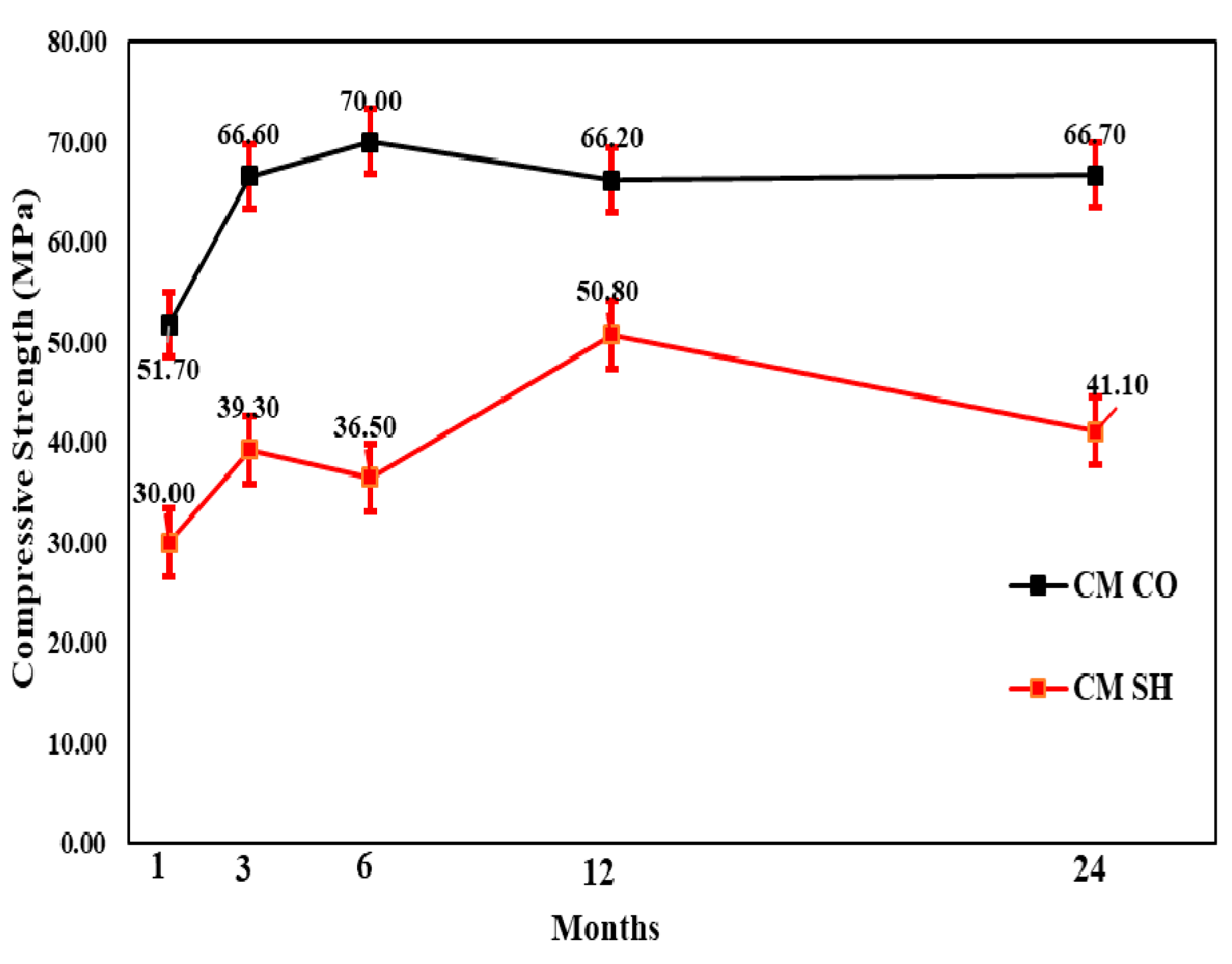

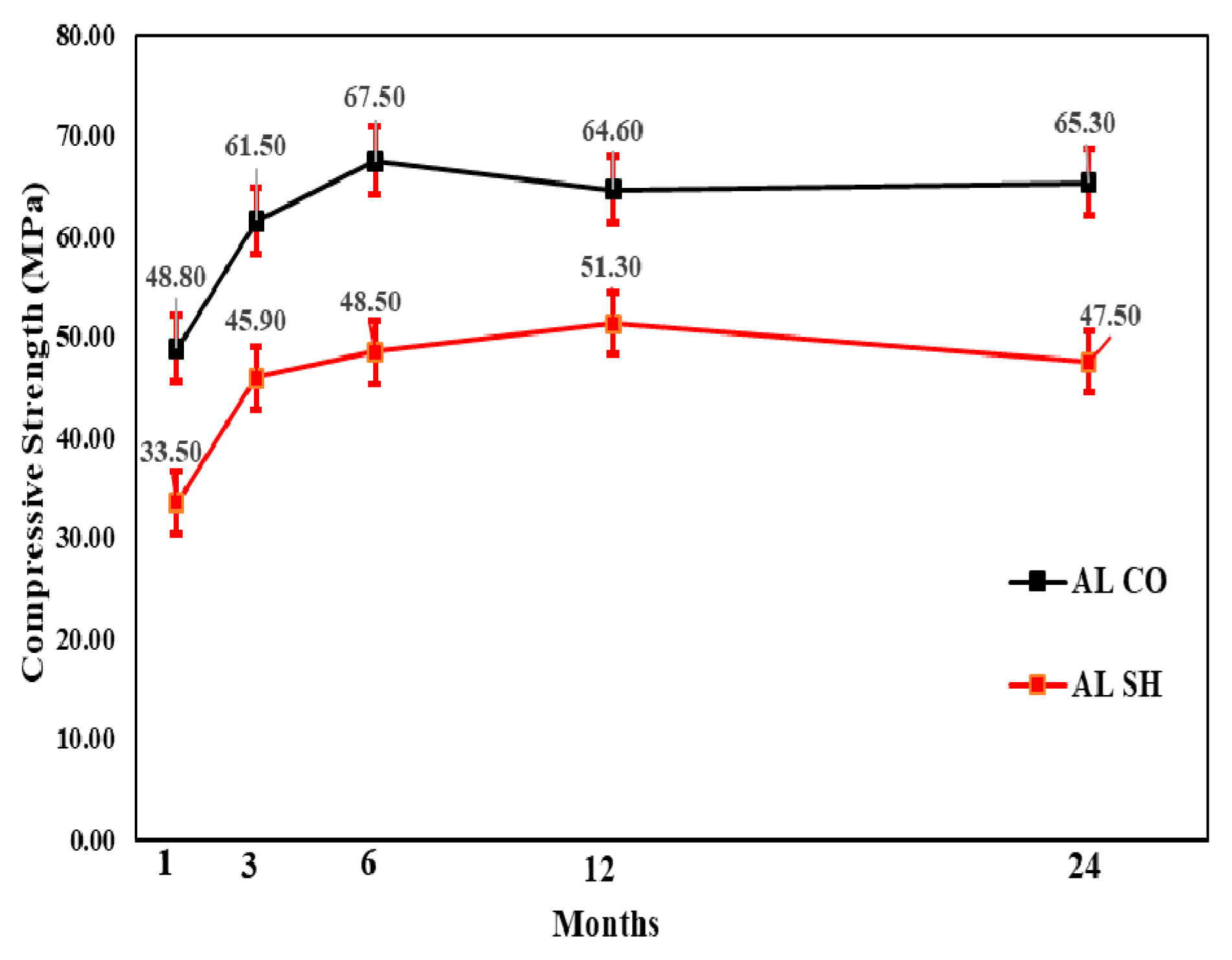

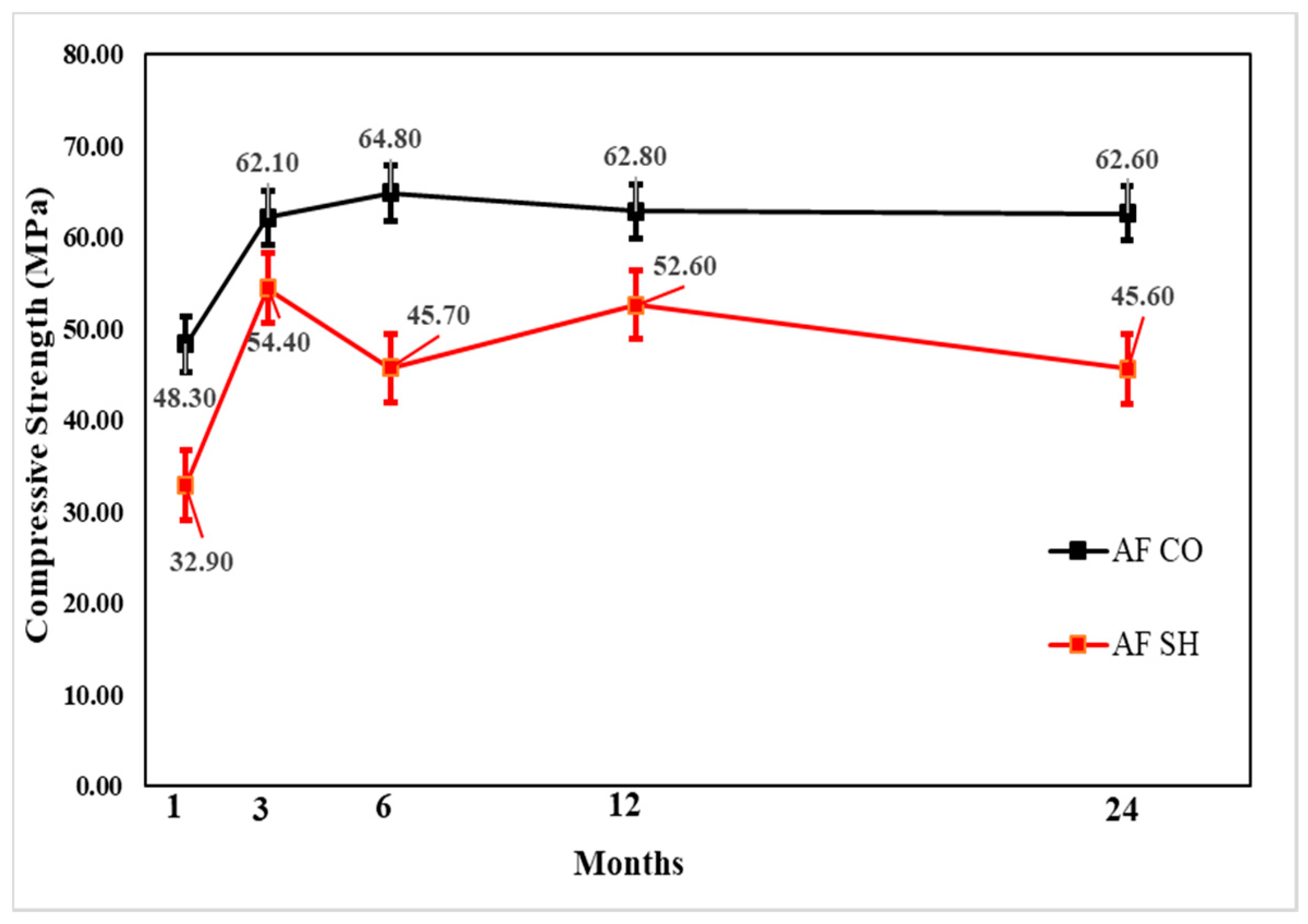

3.1. Effect of Accelerator Types on the Compressive Strength Results

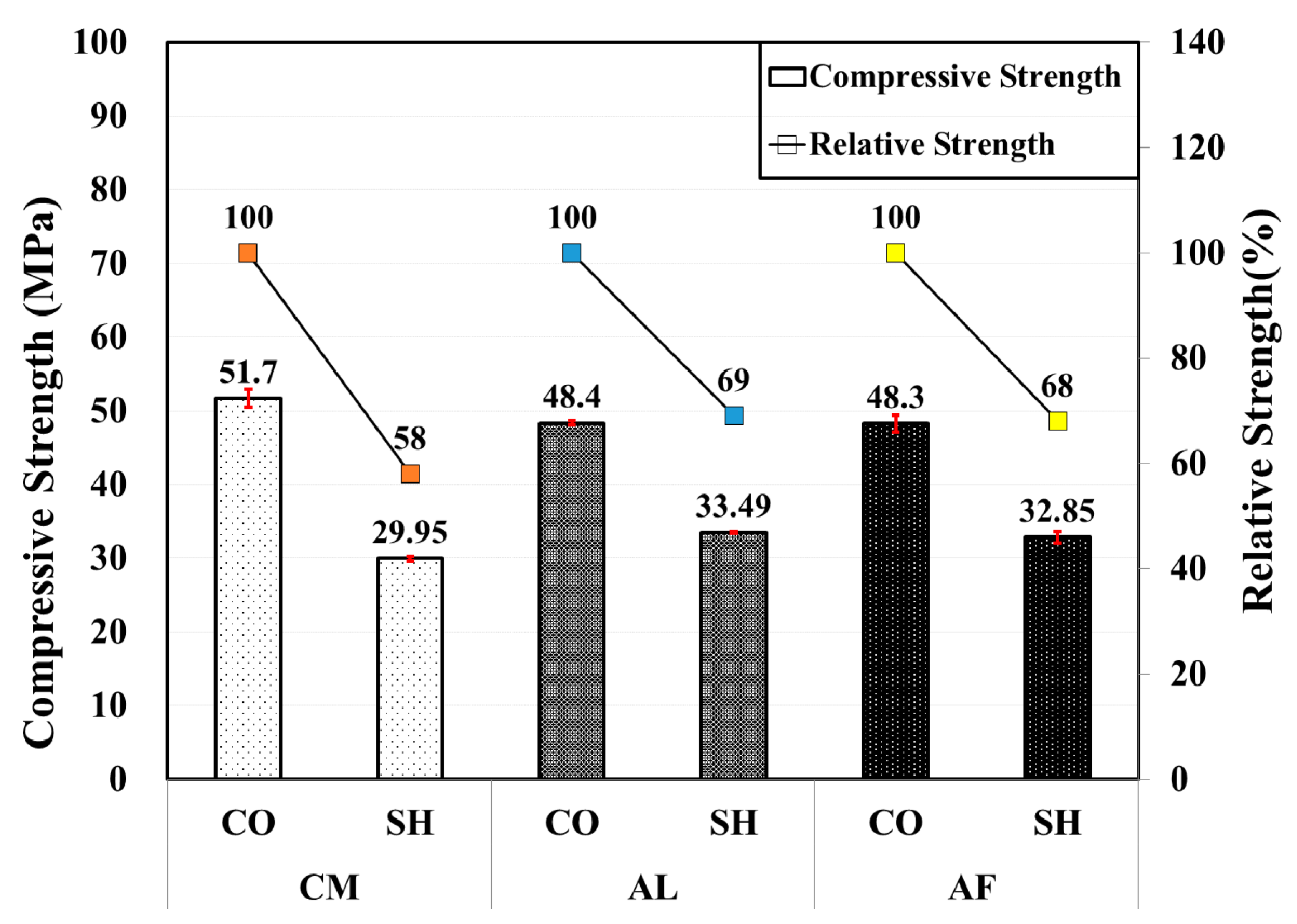

3.1.1. One-Month Compressive Strength Results

3.1.2. Three-Months Compressive Strength Results

3.1.3. Six-Months Compressive Strength Results

3.1.4. Twelve-Month Compressive Strength Results

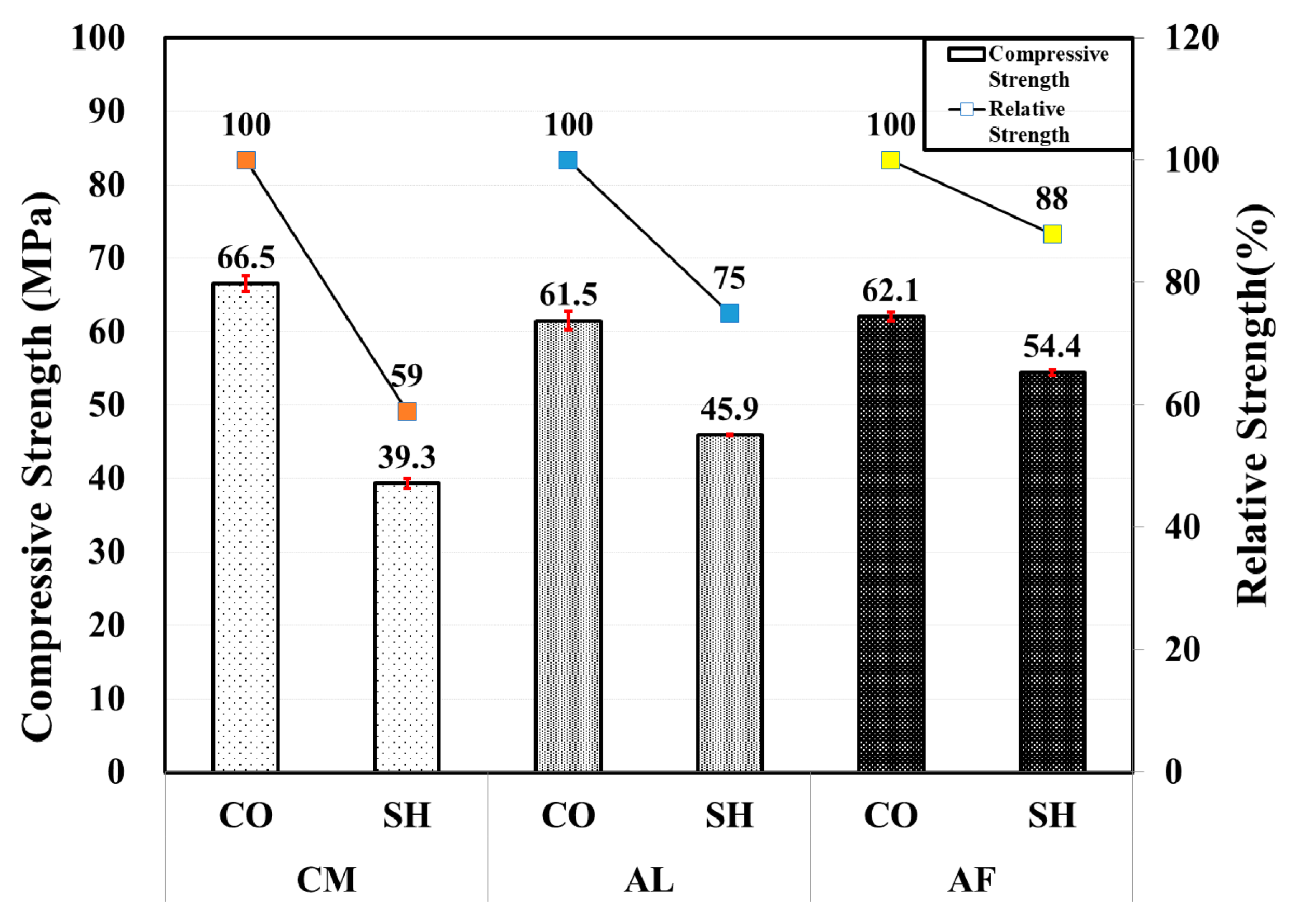

3.1.5. Twenty-Four-Months Compressive Strength Results

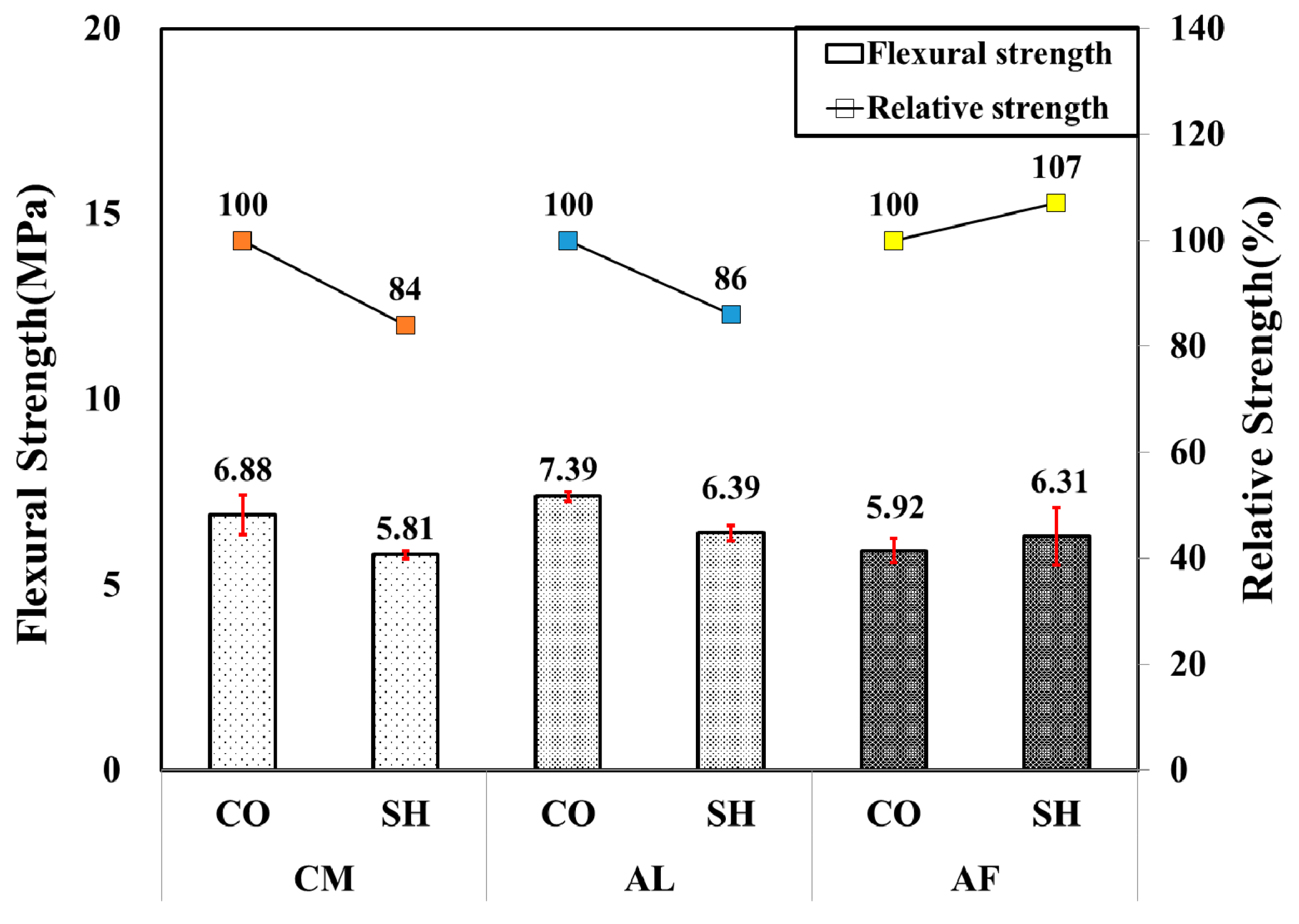

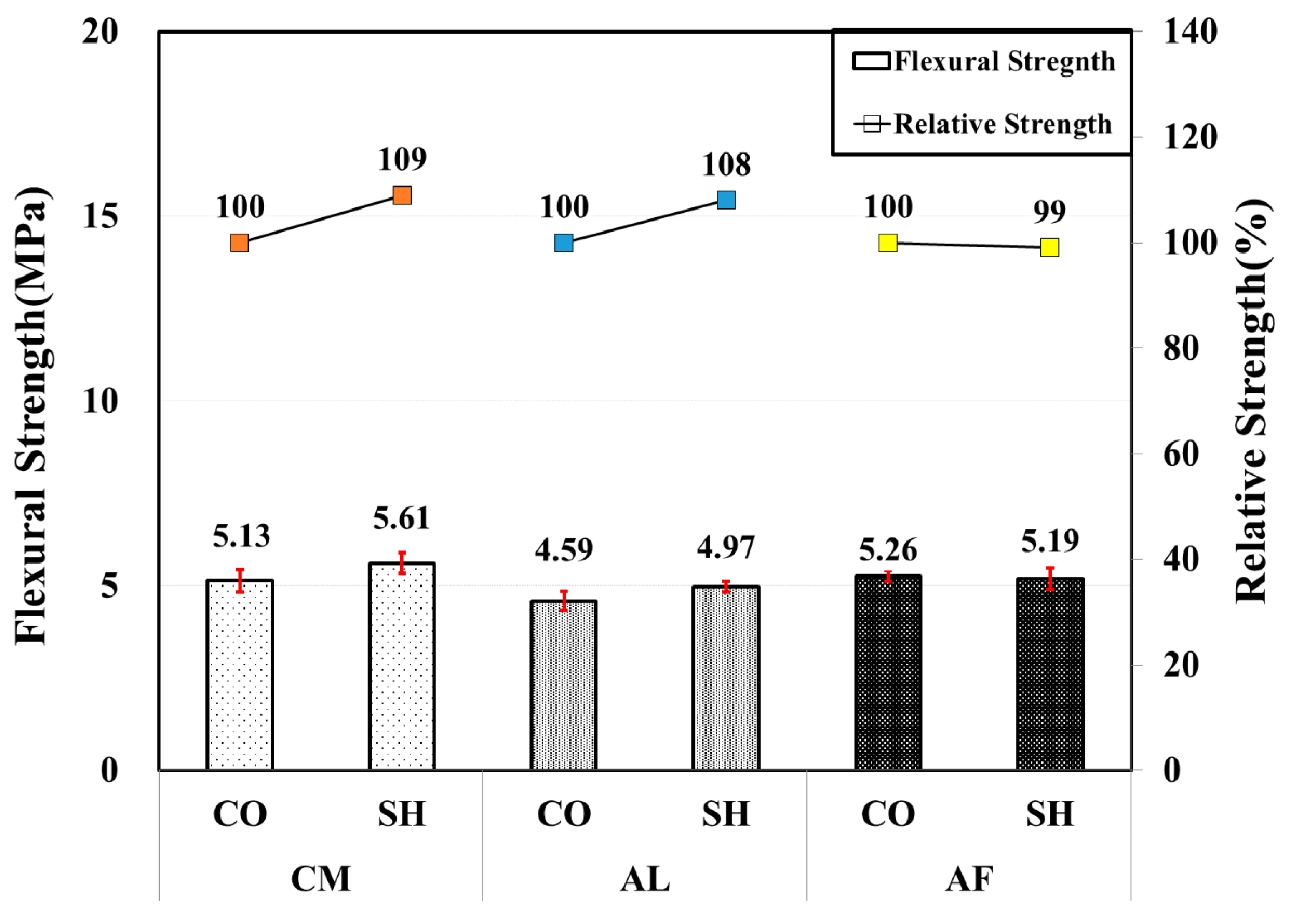

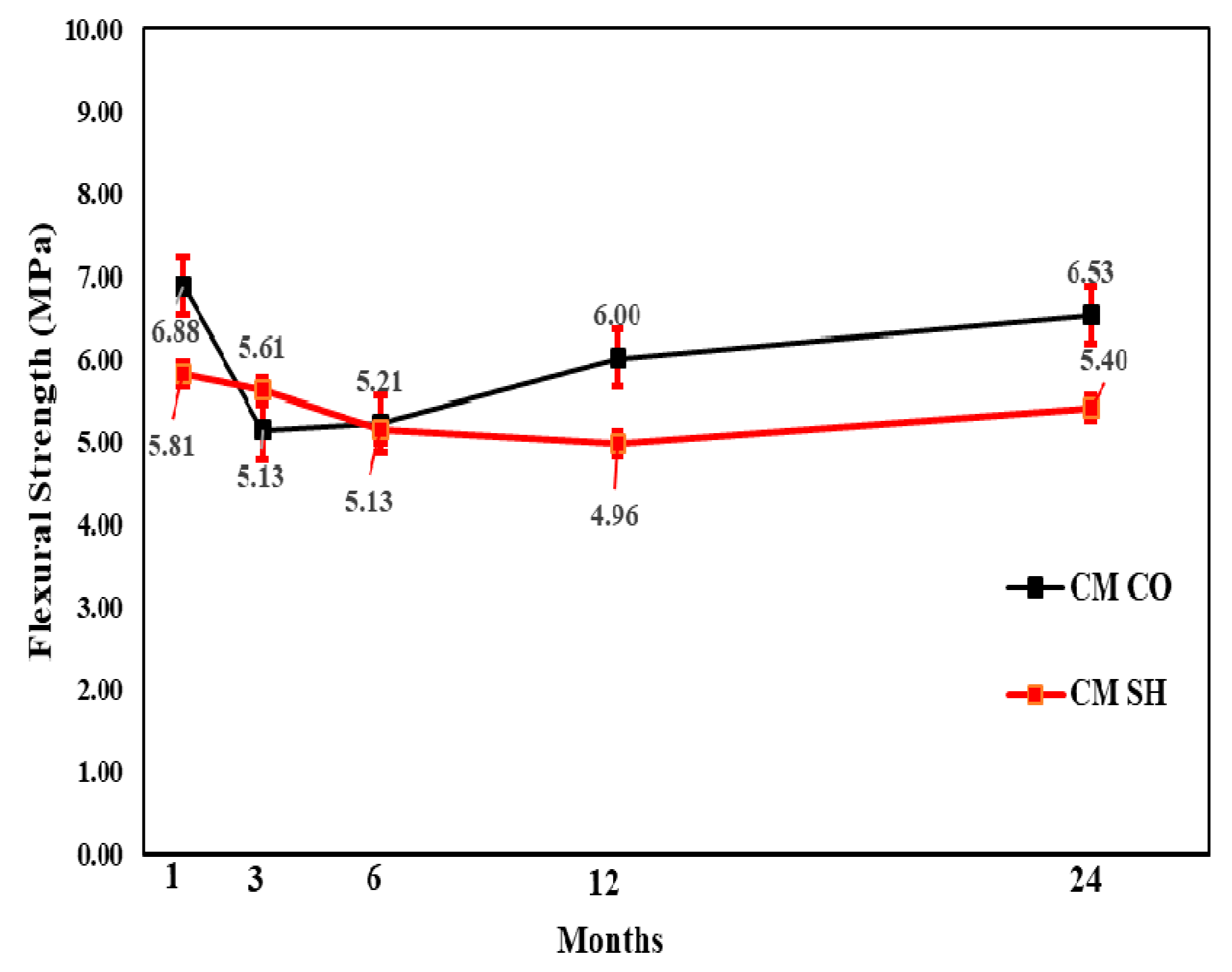

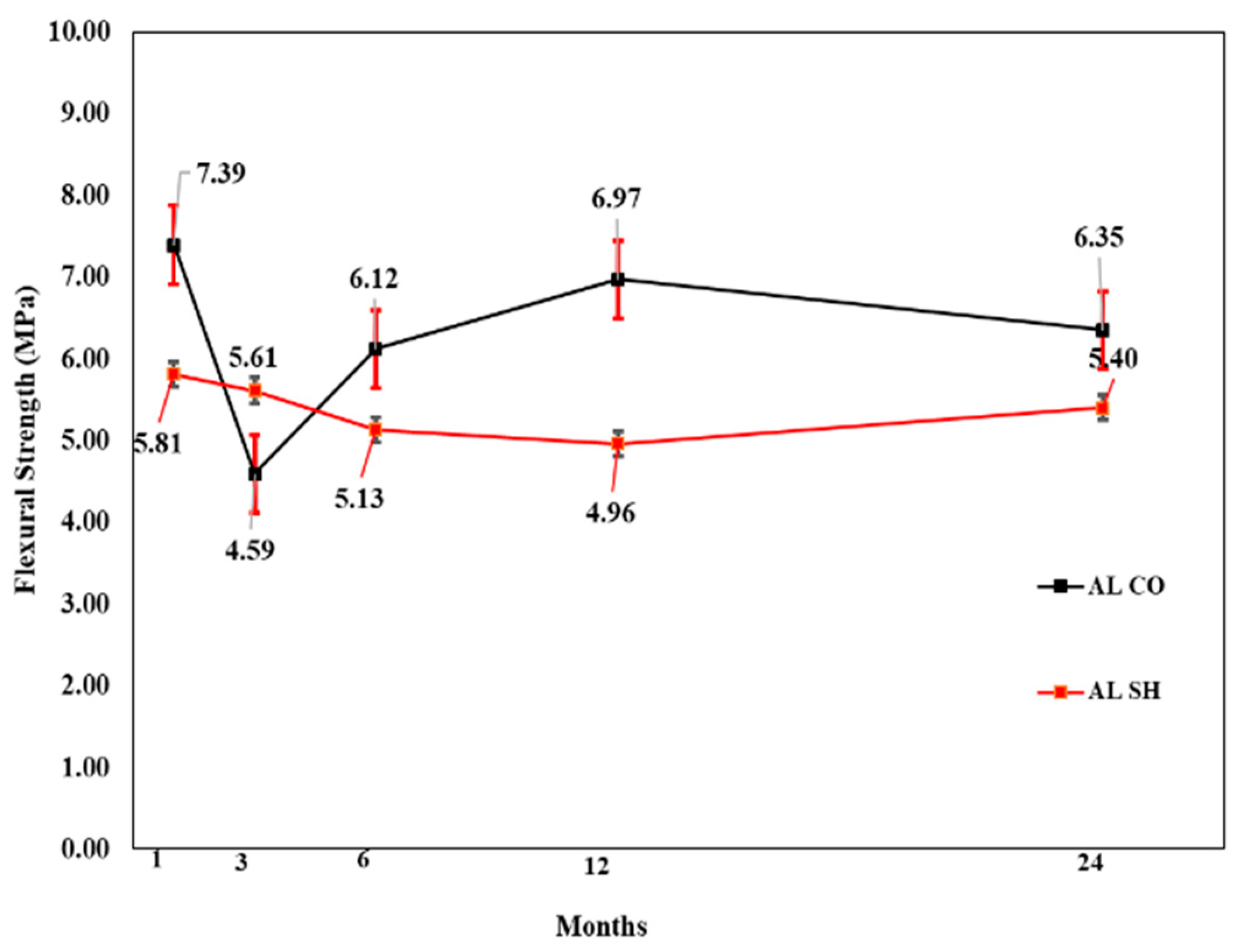

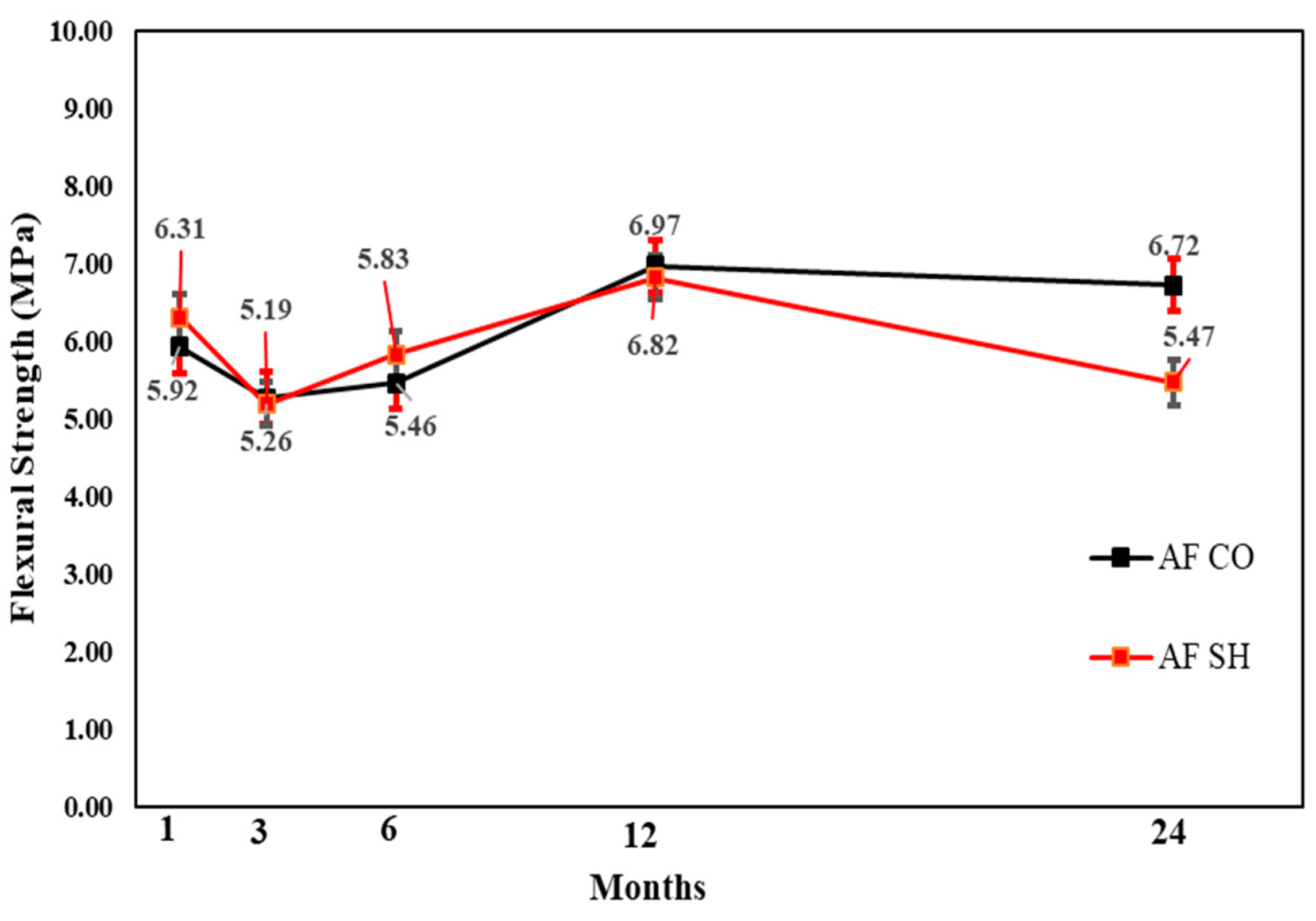

3.2. Effect of Accelerator Types on Flexural Strength Results

3.2.1. One-Month Flexural Strength Results

3.2.2. Three-Month Flexural Strength Results

3.2.3. Six-Months Flexural Strength Results

3.2.4. Twelve-Months Flexural Strength Results

3.2.5. Twenty-Four-Months Flexural Strength Results

3.3. Comprehensive Review of Shotcrete Long-Term Performance Test Results

3.3.1. Compressive Strength Test Results

3.3.2. Flexural Strength Test Results

3.4. ANOVA Test Result

ANOVA Test of Compressive Strength

4. Conclusions

- In the SH long-term performance test based on the type of accelerating agent, CM, AL, and AF accelerators were used, and 37 kg steel fiber was added to the CM and AL mix, and 40 kg of steel fiber was used in the AF mix. The performance tests were performed on 1-, 3-, 6-, 12-, and 24-month-old specimens to determine the long-term performance of SH. The following conclusions are drawn based on the results.

- The compressive and flexural strength test results showed that the CO specimens exhibit a higher strength than that of the SH specimens for all types of accelerators, and both specimens demonstrated a significant strength reduction after 12 months. In the 1-month-old compressive strength test, the Korea Expressway Corporation standard of 21 MPa was satisfied for all test variables. The low compressive and flexural strength for the 24-month-old specimen indicates that accelerating agents reduce the long-term performance; however, the compressive and flexural strength results were not steady in AF. Moreover, the AL mixtures showed steady results in terms of compressive and flexural behavior. They also exhibited the highest compressive strength for the SH, which was 47.5 MPa; however, based on the relative strength results in comparison with those in the CO, both AL and AF were the same at 73%. Furthermore, in terms of flexural strength, the SH of the AF mixtures was highly unsteady. According to the 12-month-old specimen results, the AL SH flexural strength was 7.15 MPa, and that for the 24-month-old specimens was 5.44 MPa. Thus, this study showed that a drastic change occurred in AL flexural strength, which was not seen for the tunnel shotcrete. In contrast, the AF SH showed slightly less flexural strength, 6.82 MPa, than that of the AL SH. However, after 24 months, the flexural strength was slightly high, 5.47 MPa, indicating a greater load-carrying capacity in the long-term. Moreover, the AF accelerator is safer than the AL accelerator for the environment and workers due to the absence of alkali content. Thus, AF is concluded to be more useful than AL and CM for tunnel shotcrete based on the aspects discussed above. Also, the statically significant analysis by the ANOVA test showed that most combinations are statically significant.

Author Contributions

Funding

Conflicts of Interest

References

- Bernard, E.S. Shotcrete: Engineering Developments; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Prudencio, L.R., Jr. Accelerating admixtures for shotcrete. Cem. Concr. Compos. 1998, 20, 213–219. [Google Scholar] [CrossRef]

- De Belie, N.; Grosse, C.U.; Kurz, J.; Reinhardt, H.W. Ultrasound monitoring of the influence of different accelerating admixtures and cement types for shotcrete on setting and hardening behaviour. Cem. Concr. Compos. 2005, 35, 2087–2094. [Google Scholar] [CrossRef]

- Nordström, E. Durability of Sprayed Concrete: Steel Fiber Corrosion in Cracks. Ph.D. Thesis, Luleå Tekniska Universitet, Luleå, Sweden, 2005. [Google Scholar]

- Won, J.P.; Hwang, U.J.; Kim, C.K.; Lee, S.J. Mechanical performance of shotcrete made with a high-strength cement-based mineral accelerator. Constr. Build. Mater. 2013, 49, 175–183. [Google Scholar] [CrossRef]

- Galobardes, I.; Picolo, R.; de Figueiredo, A.D.; Cavalaro, S.H.; Rueda, Á. Wet mix sprayed concrete set accelerating admixtures: Comparison between traditional aluminate based accelerators and new formulations of alkali free accelerators. In Proceedings of the 56 Congresso Brasileiro do Concreto, Natal, Brasil, 7–10 October 2014. [Google Scholar]

- Paglia, C.; Wombacher, F.; Böhni, H. The influence of alkali-free and alkaline shotcrete accelerators within cement systems: Influence of the temperature on the sulfate attack mechanisms and damage. Cem. Concr. Compos. 2003, 33, 387–395. [Google Scholar] [CrossRef]

- Won, J.P.; Hwang, U.J.; Lee, S.J. Enhanced long-term strength and durability of shotcrete with high-strength C12A7 mineral-based accelerator. Cem. Concr. Compos. 2015, 76, 121–129. [Google Scholar] [CrossRef]

- Wang, J.; Xie, Y.; Zhong, X.; Li, L. Test and simulation of cement hydration degree for shotcrete with alkaline and alkali-free accelerators. Cem. Concr. Compos. 2020, 112, 103684. [Google Scholar] [CrossRef]

- Bentur, A.; Mindess, S. Fiber Reinforced Cementitious Composites; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Jadhav, H.S.; Koli, M.D. Flexural behavior of hybrid fiber reinforced concrete beams. Int. J. Struct. Civ. Eng. Res. 2013, 2, 210–218. [Google Scholar]

- ASTM International. Standard Specification for Steel Fibers for Fiber-Reinforced Concrete. 2006. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/A820A820M-06.htm (accessed on 1 October 2020).

- KS F 2781. Steel Fiber Reinforced Wet-Mix Shotcrete. 2007. Available online: http://www.ks.or.kr/library/search/stddetail.do?itemNo=K001010114416&itemCd=K00101# (accessed on 1 October 2020).

- Song, P.S.; Hwang, S. Mechanical properties of high-strength steel fiber-reinforced concrete. Constr. Build. Mater. 2004, 18, 669–673. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of steel fiber content and shape on mechanical properties of ultra high performance concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Lantsoght, E.O. How do steel fibers improve the shear capacity of reinforced concrete beams without stirrups? Compos. Part B Eng. 2019, 175, 107079. [Google Scholar] [CrossRef]

- Fan, L.; Bao, Y.; Meng, W.; Chen, G. In-situ monitoring of corrosion-induced expansion and mass loss of steel bar in steel fiber reinforced concrete using a distributed fiber optic sensor. Compos. Part B Eng. 2019, 165, 679–689. [Google Scholar] [CrossRef]

- Korea Highway Corporation Road Research Institute. Enhancement and Quality Control of Steel Fiber Reinforced Shotcrete (II); Korea Highway Corporation Road Research Institute: Hallim-myeon, Korea, 2000. [Google Scholar]

- Maltese, C.; Pistolesi, C.; Bravo, A.; Cella, F.; Cerulli, T.; Salvioni, D. A case history: Effect of moisture on the setting behaviour of a Portland cement reacting with an alkali-free accelerator. Cem. Concr. Res. 2007, 37, 856–865. [Google Scholar] [CrossRef]

- KS F 2566. Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete; Korean Standards Association: Seoul, Korea, 2014. [Google Scholar]

| Test | Aggregate | Density (g/cm3) | Fineness Modulus | Division | Standard |

|---|---|---|---|---|---|

| Cement mineral mix | Fine | 2.61 | 3.86 | Aggregate for shotcrete | Mixed aggregate |

| Coarse | 2.70 | ||||

| Aluminate mix | Fine | 2.61 | 3.84 | ||

| Coarse | 2.70 | ||||

| Alkali mix | Fine | 2.61 | 3.78 | ||

| Coarse | 2.70 |

| Accelerator | Type | Specific Gravity | pH | Solid Content | Initial Set (Hours) | Final Set (Hours) |

|---|---|---|---|---|---|---|

| Cement mineral | powder | 2.76 | 10~12 | 99.2 | 2:00 | 13:00 |

| Aluminate | liquid | 1.45 | 13 ± 2 | 45.7 | 3:30 | 13:20 |

| Alkali-free | liquid | 1.36 | 2.6 | 42.0 | 2:45 | 12:35 |

| Test | Material | Aspect Ratio | Tensile Strength |

|---|---|---|---|

| Cement mineral mix | Steel fiber | 62.0 | 1123 N/mm2 |

| Aluminate mix | Steel fiber | 60.1 | 1043 N/mm2 |

| Alkali-free mix | Steel fiber | 60.9 | 977 N/mm2 |

| Accelerator | Gmax (mm) | Slump (mm) | W/C | S/a (%) | Unit Content (kg/m3) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Water | Cement | Sand | Gravel | High-Range Water-Reducing Agent | Steel Fiber (kg/m3) | |||||

| CM * | 10 | 100 | 0.44 | 65 | 210 | 480 | 1047 | 568 | 4.80 (1.0%) | 37 |

| AL * | 0.43 | 64.7 | 213 | 492 | 1074 | 608 | 3.936(0.8%) | 37 | ||

| AF * | 0.44 | 62.1 | 206 | 465 | 1011 | 622 | 4.65 (1.0%) | 40 | ||

| Mean Squared | F Value | p-Value | R2 | |||||

|---|---|---|---|---|---|---|---|---|

| CO | SH | CO | SH | CO | SH | CO | SH | |

| Intercept | 57598.0167 | 28654.0906 | 383.71391 | 186.563 | 4.005 × 10−5 | 0.000 | 0.9896831 | 0.979 |

| Accelerators | 21.6326666 | 66.1166666 | 27.035201 | 5.778 | 0.0002759 | 0.028 | 0.8711141 | 0.591 |

| Long term | 150.106666 | 153.589 | 187.59425 | 13.423 | 6.139 × 10−8 | 0.001 | 0.9894512 | 0.870 |

| Mean Squared | F Value | p-Value | R2 | |||||

|---|---|---|---|---|---|---|---|---|

| CO | SH | CO | SH | CO | SH | CO | SH | |

| Intercept | 562.67367 | 489.63267 | 333.497 | 685.78 | 0.000 | 0.000 | 0.988 | 0.994 |

| Accelerators | 0.14032667 | 0.41588666 | 0.507 | 1.341 | 0.620 | 0.315 | 0.113 | 0.251 |

| Long term | 1.68719333 | 0.71403333 | 6.097 | 2.303 | 0.015 | 0.147 | 0.753 | 0.535 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yun, K.K.; Choi, S.; Ha, T.; Hossain, M.S.; Han, S. Comparison of Long-Term Strength Development of Steel Fiber Shotcrete with Cast Concrete Based on Accelerator Type. Materials 2020, 13, 5599. https://doi.org/10.3390/ma13245599

Yun KK, Choi S, Ha T, Hossain MS, Han S. Comparison of Long-Term Strength Development of Steel Fiber Shotcrete with Cast Concrete Based on Accelerator Type. Materials. 2020; 13(24):5599. https://doi.org/10.3390/ma13245599

Chicago/Turabian StyleYun, Kyong Ku, Seunghak Choi, Taeho Ha, Mohammad Shakhawat Hossain, and Seungyeon Han. 2020. "Comparison of Long-Term Strength Development of Steel Fiber Shotcrete with Cast Concrete Based on Accelerator Type" Materials 13, no. 24: 5599. https://doi.org/10.3390/ma13245599

APA StyleYun, K. K., Choi, S., Ha, T., Hossain, M. S., & Han, S. (2020). Comparison of Long-Term Strength Development of Steel Fiber Shotcrete with Cast Concrete Based on Accelerator Type. Materials, 13(24), 5599. https://doi.org/10.3390/ma13245599