Utilization of Iron Tailings Sand as an Environmentally Friendly Alternative to Natural River Sand in High-Strength Concrete: Shrinkage Characterization and Mitigation Strategies

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.1.1. Cement and Aggregate

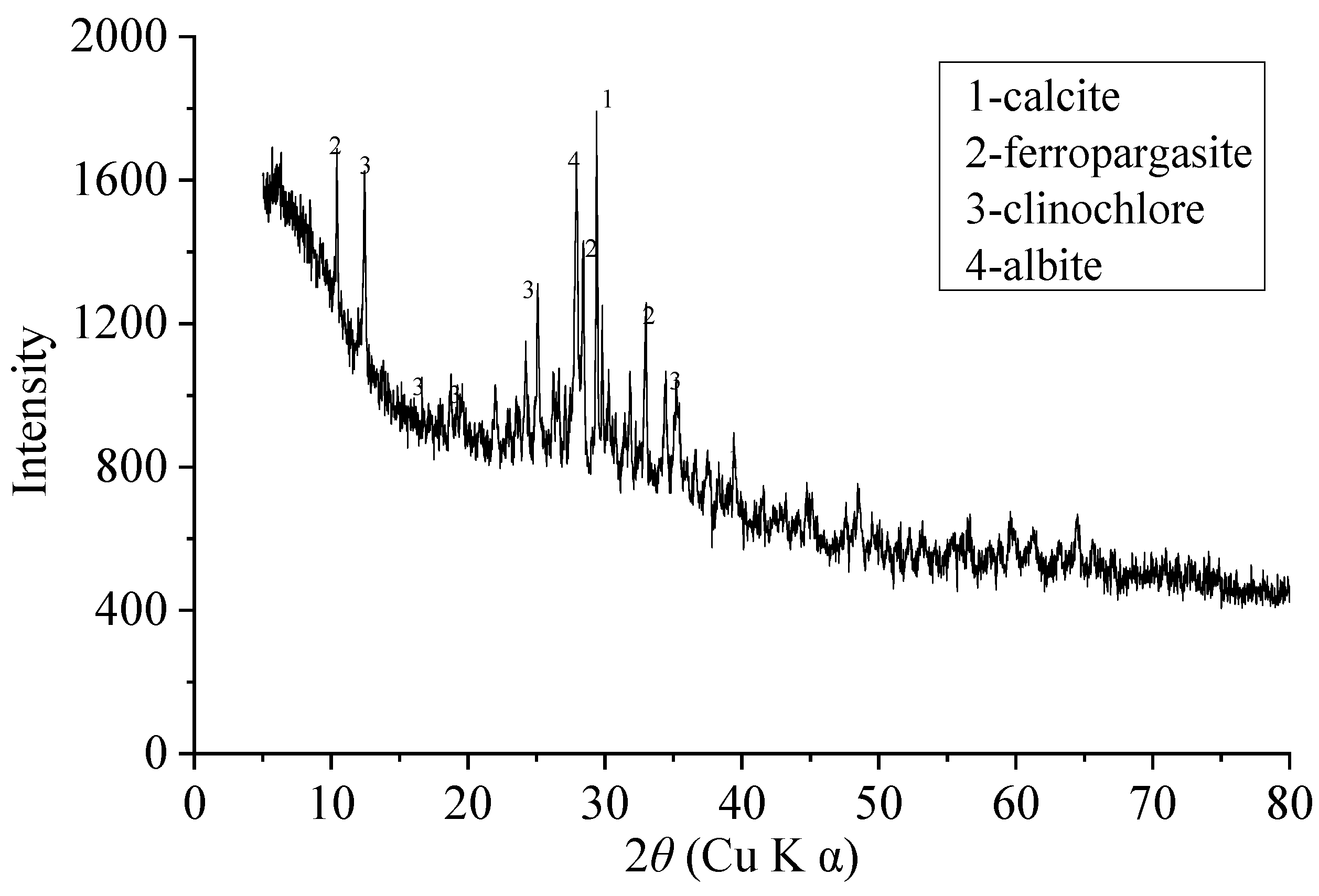

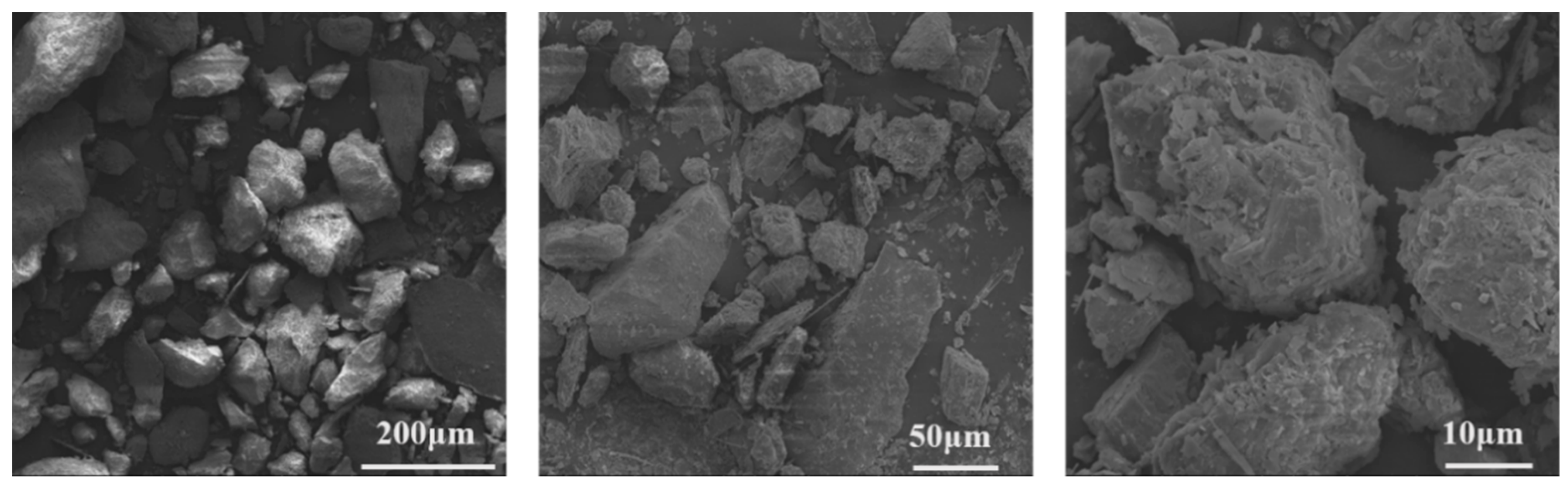

2.1.2. Iron Tailings Sand

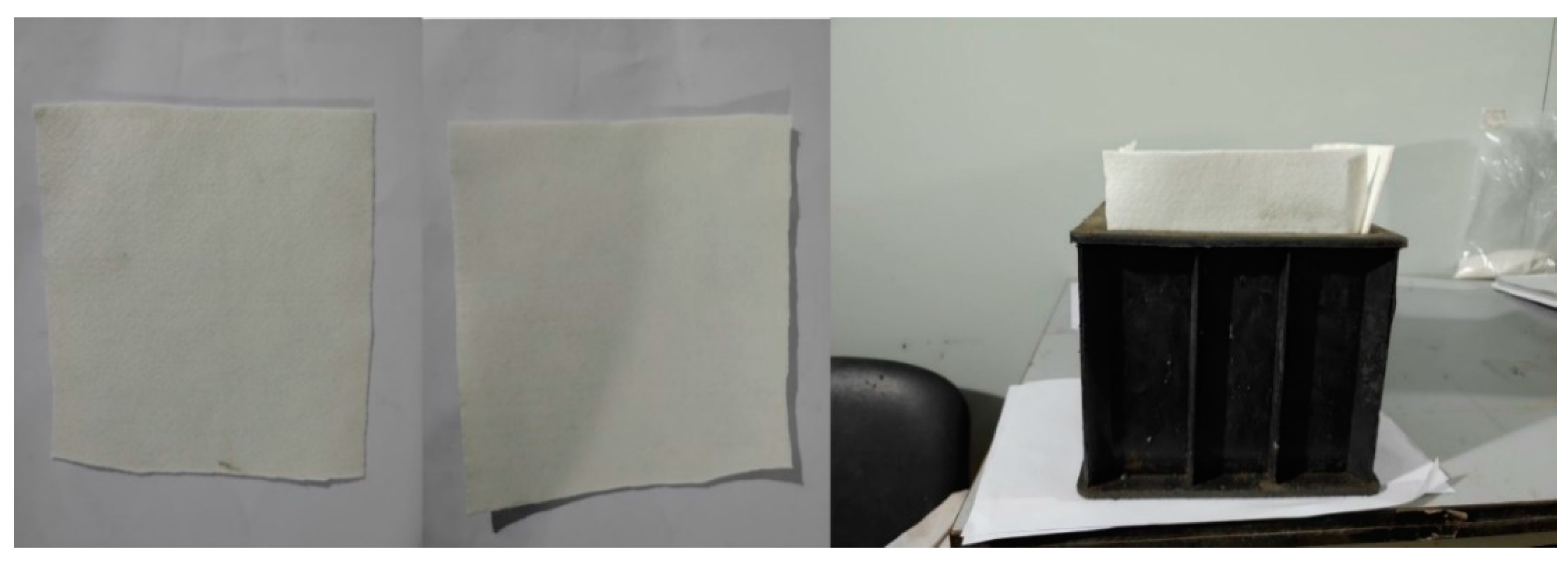

2.1.3. Shrinkage Reducing Methods

2.2. Mix Proportions

2.3. Test Methods

2.3.1. Mechanical Properties

2.3.2. Drying and Autogenous Shrinkage

2.3.3. Internal Relative Humidity

2.3.4. Chloride Penetration Test

3. Results and Discussion

3.1. General Properties

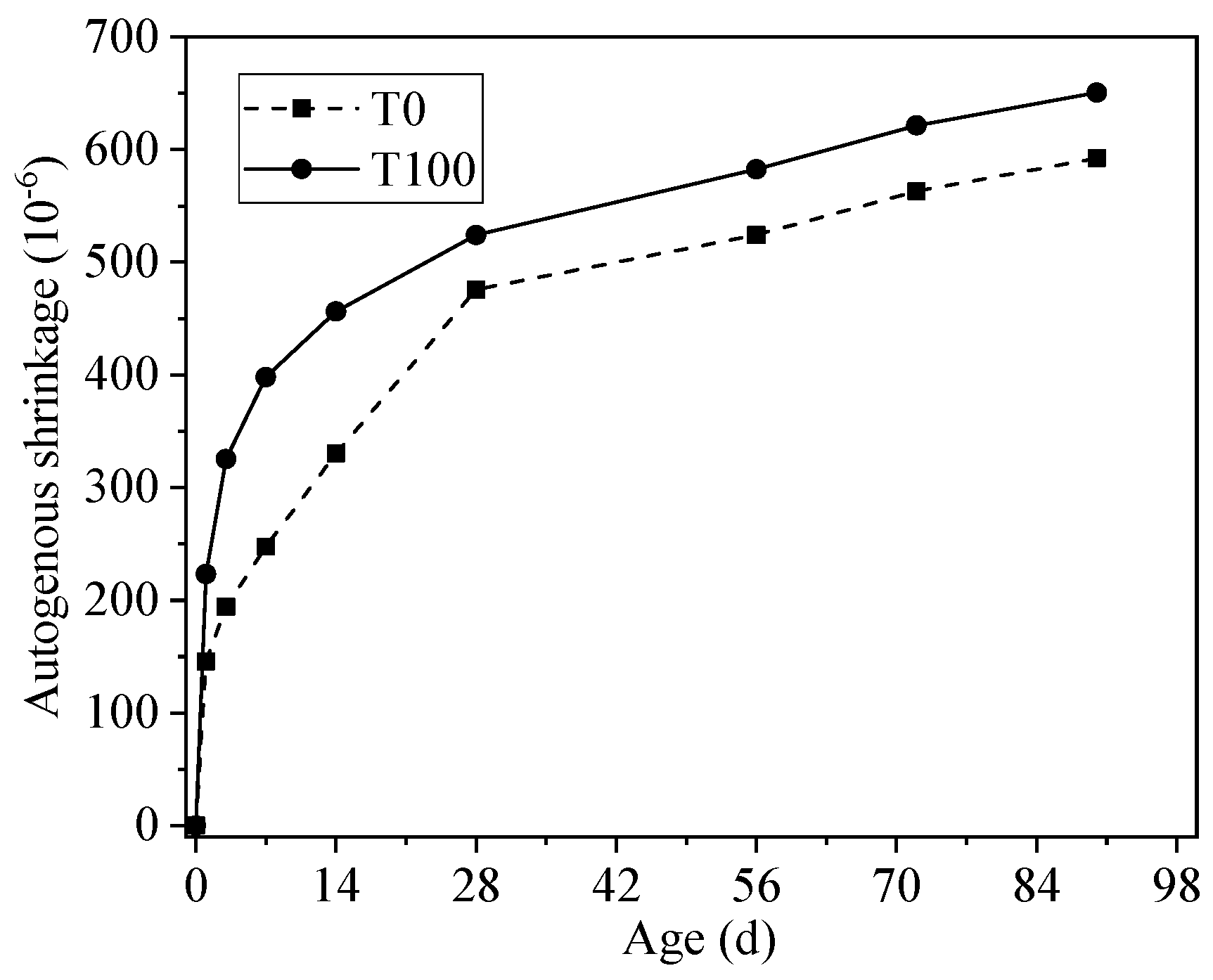

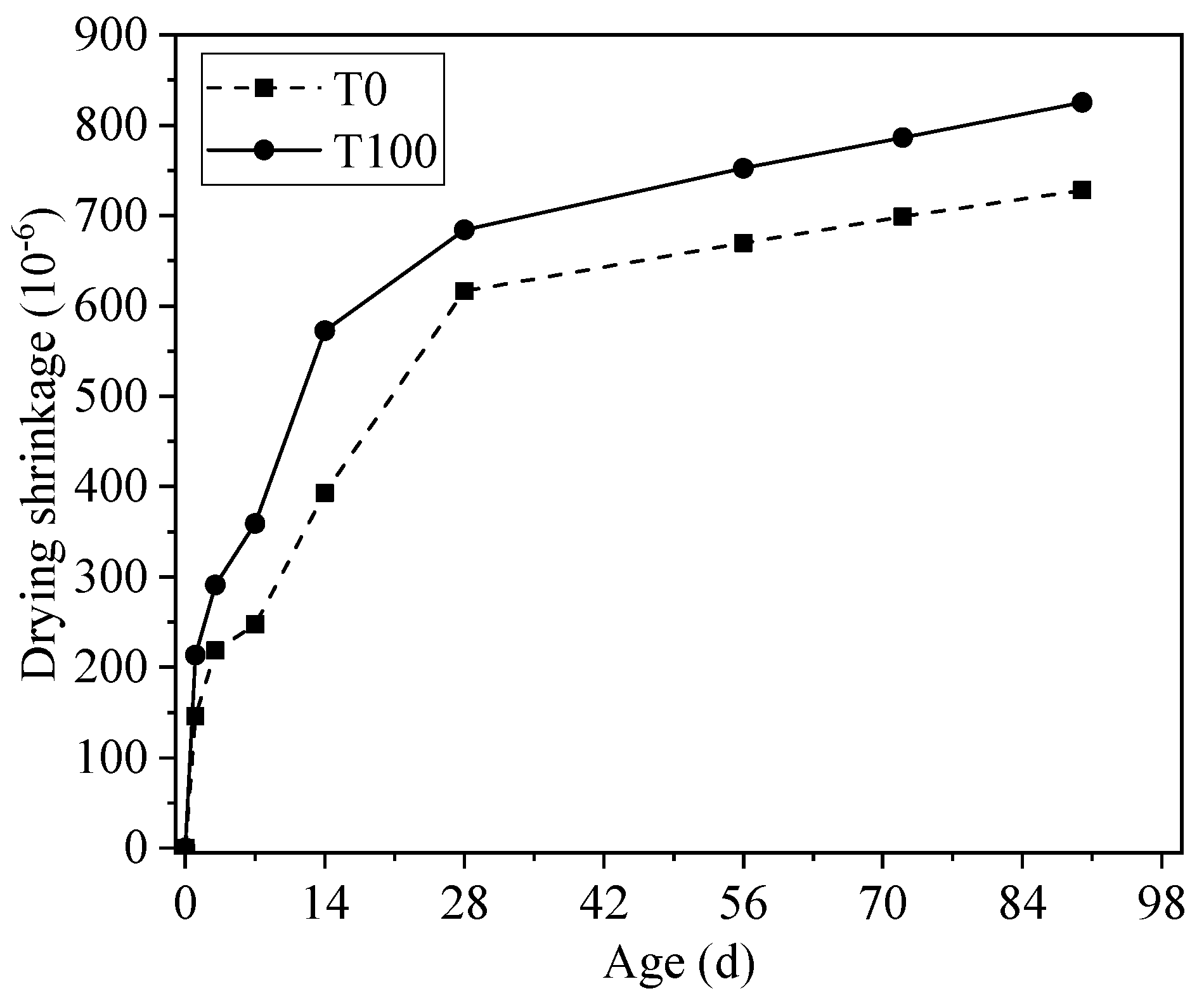

3.2. Autogenous and Total Shrinkage

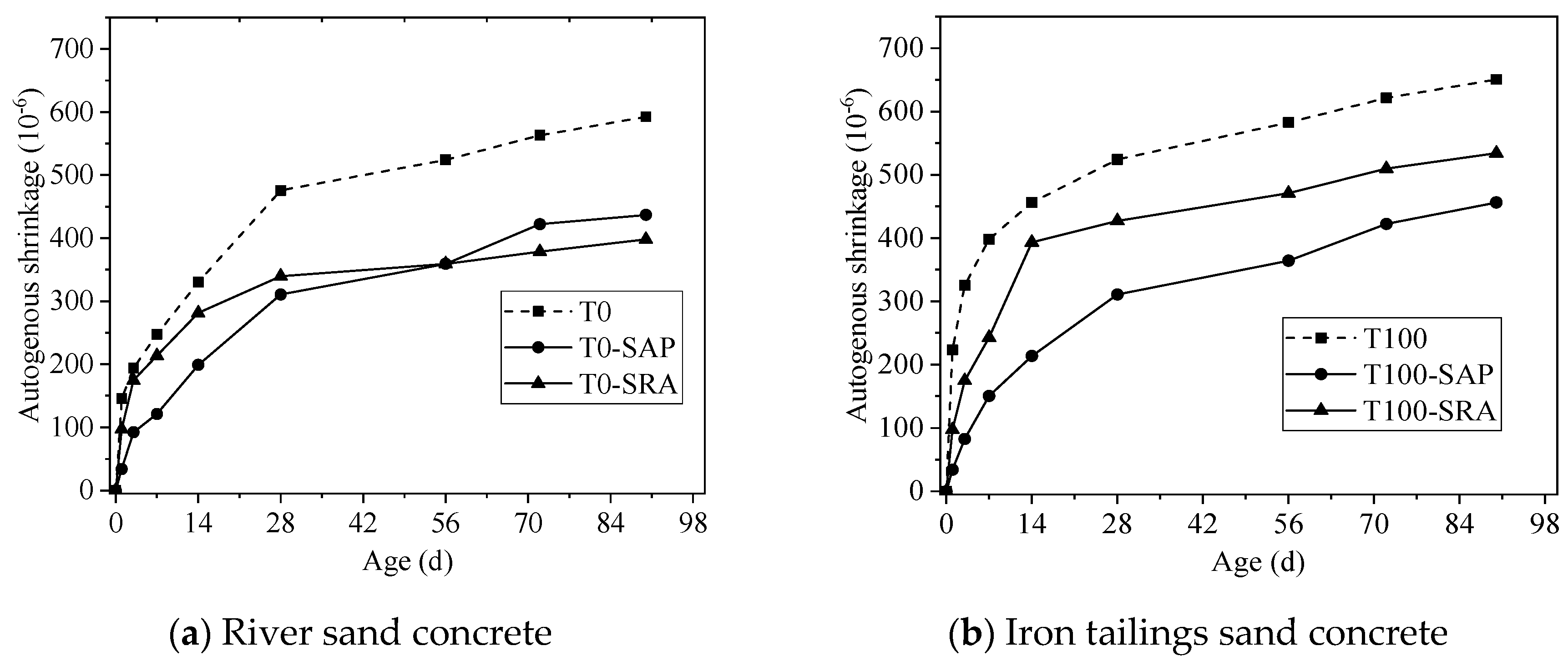

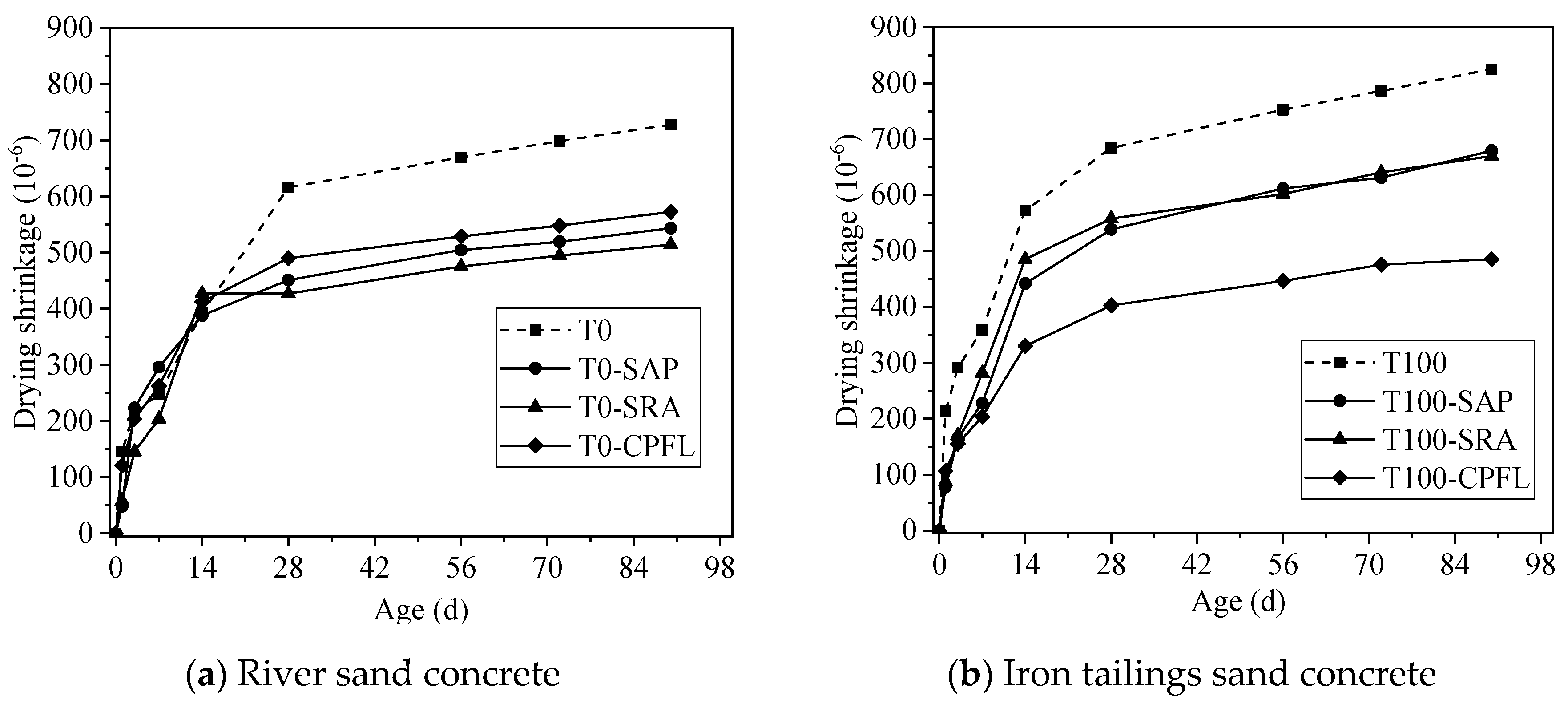

3.3. Effects of Shrinkage Mitigation Methods on Shrinkage Properties of Concrete

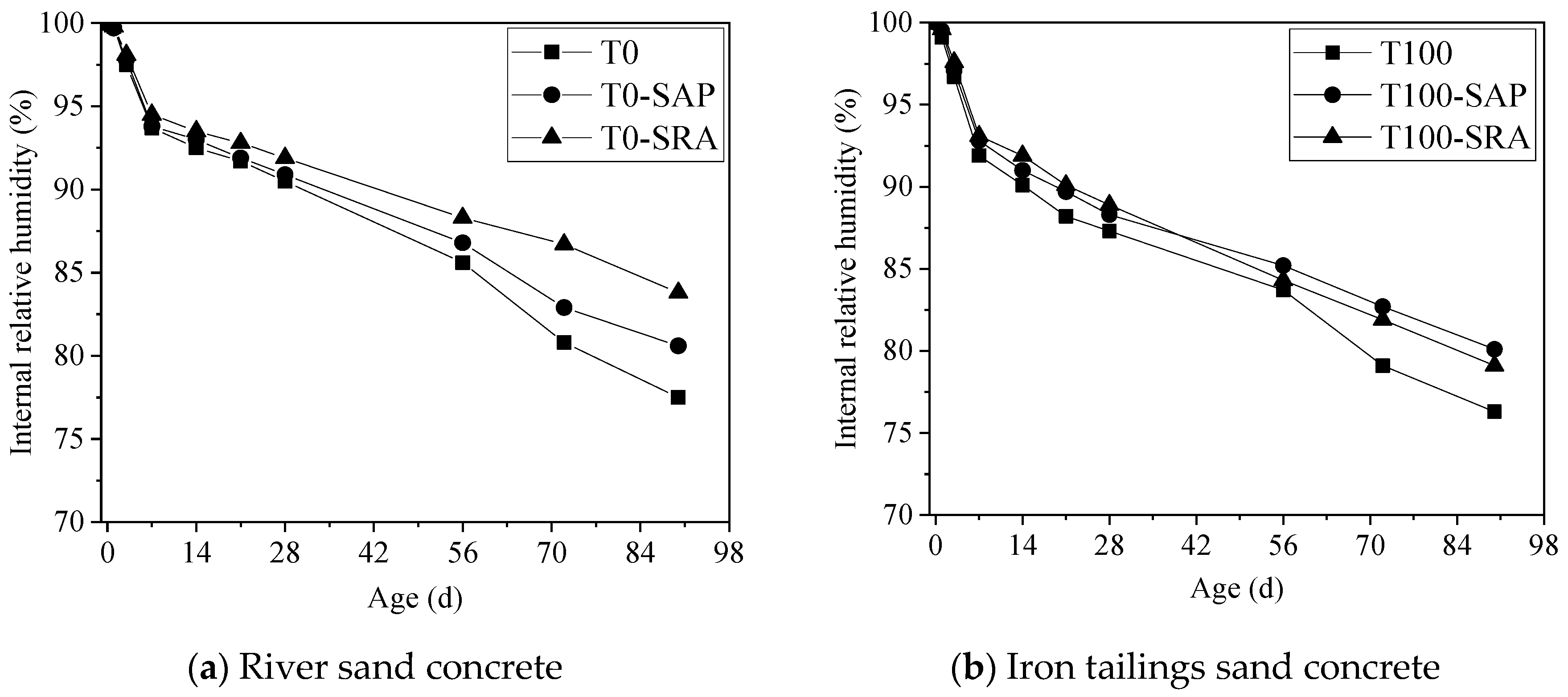

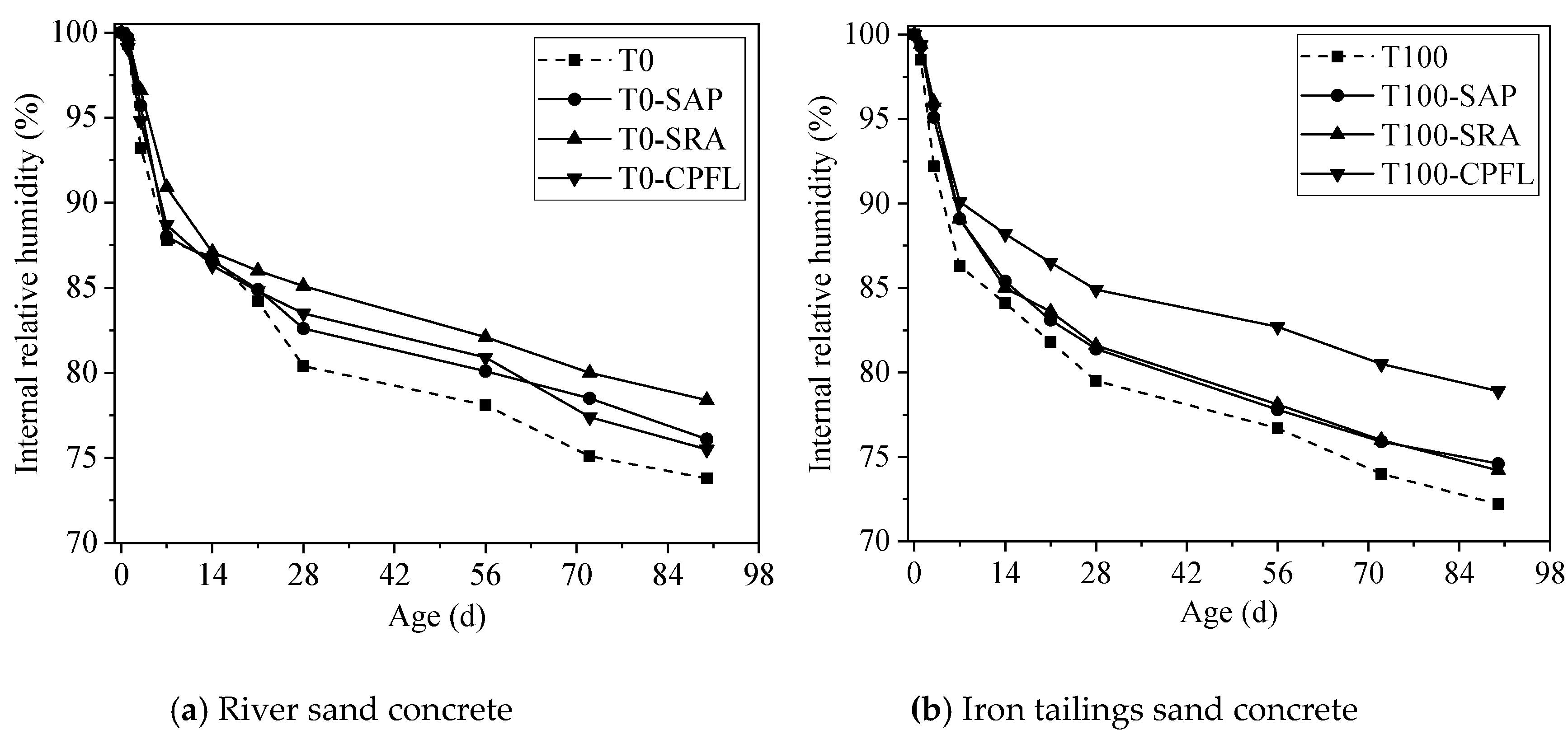

3.4. Effects of Shrinkage Mitigation Methods on Internal Relative Humidity of Concrete

3.5. Effects of Shrinkage-Reducing Methods on Properties of Concrete

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dauce, P.D.; De Castro, G.B.; Lima, M.M.F.; Lima, R.M.F. Characterisation and magnetic concentration of an iron ore tailings. J. Mater. Res. Technol. 2019, 8, 1052–1059. [Google Scholar] [CrossRef]

- Kuranchie, F.A.; Shukla, S.K.; Habibi, D.; Alireza, M. Utilisation of iron ore tailings as aggregates in concrete. Cogent Eng. 2015, 2, 1083137. [Google Scholar] [CrossRef]

- Wong, M.; Tam, F.; Tam, N.F.Y. Soil and vegetation contamination by iron-ore tailings. Environ. Pollut. 1977, 14, 241–254. [Google Scholar] [CrossRef]

- Zhang, S.; Xue, X.; Liu, X.; Duan, P.; Yang, H.; Jiang, T.; Wang, D.; Liu, R. Current situation and comprehensive utilization of iron ore tailing resources. J. Min. Sci. 2006, 42, 403–408. [Google Scholar] [CrossRef]

- Liu, Y.; Du, F.; Yuan, L.; Zeng, H.; Kong, S. Production of lightweight ceramisite from iron ore tailings and its performance investigation in a biological aerated filter (BAF) reactor. J. Hazard. Mater. 2010, 178, 999–1006. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Sun, H.; Bai, J.; Li, L. Innovative methodology for comprehensive utilization of iron ore tailings: Part 1. The recovery of iron from iron ore tailings using magnetic separation after magnetizing roasting. J. Hazard. Mater. 2010, 174, 71–77. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Fan, J.; Sun, W. Utilization of iron ore tailings as fine aggregate in ultra-high performance concrete. Constr. Build. Mater. 2014, 50, 540–548. [Google Scholar] [CrossRef]

- Xu, W.; Wen, X.; Wei, J.; Xu, P.; Zhang, B.; Yu, Q.; Ma, H. Feasibility of kaolin tailing sand to be as an environmentally friendly alternative to river sand in construction applications. J. Clean. Prod. 2018, 205, 1114–1126. [Google Scholar] [CrossRef]

- Ugama, T.I.; Ejeh, S.P.; Amartey, D.Y. Effect of iron ore tailing on the properties of concrete. Civ. Environ. Res. 2014, 6, 7. [Google Scholar]

- Liu, W.Y.; Xu, X.L.; An, Y.Y. Study on the sprayed concrete with iron tailings. Adv. Mater. Res. 2011, 347, 1939–1943. [Google Scholar] [CrossRef]

- Wang, C.L.; Ni, W.; Zhang, S.Q.; Wang, S.; Gai, G.S.; Wang, W.K. Preparation and properties of autoclaved aerated concrete using coal gangue and iron ore tailings. Constr. Build. Mater. 2016, 104, 109–115. [Google Scholar] [CrossRef]

- Ma, B.G.; Cai, L.X.; Li, X.; Jian, S.W. Utilization of iron tailings as substitute in autoclaved aerated concrete: Physico-mechanical and microstructure of hydration products. J. Clean. Prod. 2016, 127, 162–171. [Google Scholar] [CrossRef]

- Zhang, G.D.; Zhang, X.Z.; Zhou, Z.H.; Cheng, X. Preparation and properties of concrete containing iron tailings/manufactured sand as fine aggregate. Adv. Mater. Res. 2013, 838, 152–155. [Google Scholar] [CrossRef]

- Shettima, A.U.; Hussin, M.W.; Ahmad, Y.; Mirza, J. Evaluation of iron ore tailings as replacement for fine aggregate in concrete. Constr. Build. Mater. 2016, 120, 72–79. [Google Scholar] [CrossRef]

- Lura, P.; Jensen, O.M.; Van Breugel, K. Autogenous shrinkage in high-performance cement paste: An evaluation of basic mechanisms. Cem. Concr. Res. 2003, 33, 223–232. [Google Scholar] [CrossRef]

- Zhu, X.; Tang, D.; Yang, K.; Zhang, Z.; Li, Q.; Pan, Q.; Yang, C. Effect of Ca(OH)2 on shrinkage characteristics and microstructures of alkali-activated slag concrete. Constr. Build. Mater. 2018, 175, 467–482. [Google Scholar] [CrossRef] [Green Version]

- Gilbert, R.I. Shrinkage, cracking and deflection-the serviceability of concrete structures. Electron. J. Struct. Eng. 2001, 1, 2–14. [Google Scholar]

- Folliard, K.J.; Berke, N.S. Properties of high-performance concrete containing shrinkage-reducing admixture. Cem. Concr. Res. 1997, 27, 1357–1364. [Google Scholar] [CrossRef]

- Tian, Z.; Liu, H.; Wu, Y. Effect of shrinkage-reducing on early-age concrete poured with controlled permeability formwork. In Earth and Space 2012; American Society of Civil Engineers: Reston, VA, USA, 2012; pp. 647–654. [Google Scholar]

- Schröfl, C.; Mechtcherine, V.; Gorges, M. Relation between the molecular structure and the efficiency of superabsorbent polymers (SAP) as concrete admixture to mitigate autogenous shrinkage. Cem. Concr. Res. 2012, 42, 865–873. [Google Scholar] [CrossRef]

- Figueiras, H.; Nunes, S.; Sousa-Coutinho, J.; A Figueiras, J. Combined effect of two sustainable technologies: Self-compacting concrete (SCC) and controlled permeability formwork (CPF). Constr. Build. Mater. 2009, 23, 2518–2526. [Google Scholar] [CrossRef]

- Liu, J.; Miao, C.; Chen, C.; Liu, J.; Cui, G. Effect and mechanism of controlled permeable formwork on concrete water adsorption. Constr. Build. Mater. 2013, 39, 129–133. [Google Scholar] [CrossRef]

- Ye, J.; Yu, L.; Chen, Y. Study on the mitigative effect of controlled permeable formwork (CPF) liner on early-age shrinkage of box-girder concrete. Adv. Mater. Sci. Eng. 2019, 2019, 4150279. [Google Scholar] [CrossRef] [Green Version]

- Kang, S.H.; Hong, S.G.; Moon, J. Absorption kinetics of superabsorbent polymers (SAP) in various cement-based solutions. Cem. Concr. Res. 2017, 97, 73–83. [Google Scholar] [CrossRef]

- Hou, Y.F. Comparison of effect of iron tailing sand and natural sand on concrete properties. Key Eng. Mater. 2014, 599, 11–14. [Google Scholar] [CrossRef]

- Arum, C.; Owolabi, A.O. Suitability of iron ore tailings and quarry dust as fine aggregates for concrete production. J. Appl. Sci. Technol. 2012, 17, 46–52. [Google Scholar]

- Jensen, O.M.; Hansen, P.F. Water-entrained cement-based materials: I. Principles and theoretical background. Cem. Concr. Res. 2001, 31, 647–654. [Google Scholar] [CrossRef]

- Poppe, A.M.; De Schutter, G. Cement hydration in the presence of high filler contents. Cem. Concr. Res. 2005, 35, 2290–2299. [Google Scholar] [CrossRef]

- Bentz, D.P.; Ardani, A.; Barrett, T.; Jones, S.Z.; Lootens, D.; Peltz, M.A.; Sato, T.; Stutzman, P.E.; Tanesi, J.; Weiss, W.J. Multi-scale investigation of the performance of limestone in concrete. Constr. Build. Mater. 2015, 75, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Lothenbach, B.; Le Saout, G.; Gallucci, E.; Scrivener, K. Influence of limestone on the hydration of Portland cements. Cem. Concr. Res. 2008, 38, 848–860. [Google Scholar] [CrossRef]

- Liu, J.; Farzadnia, N.; Shi, C.; Ma, X. Shrinkage and strength development of UHSC incorporating a hybrid system of SAP and SRA. Cem. Concr. Compos. 2019, 97, 175–189. [Google Scholar] [CrossRef]

- Tu, W.; Zhu, Y.; Fang, G.; Wang, X.; Zhang, M. Internal curing of alkali-activated fly ash-slag pastes using superabsorbent polymer. Cem. Concr. Res. 2019, 116, 179–190. [Google Scholar] [CrossRef] [Green Version]

- Kang, S.H.; Hong, S.G.; Moon, J. Importance of drying to control internal curing effects on field casting ultra-high performance concrete. Cem. Concr. Res. 2018, 108, 20–30. [Google Scholar] [CrossRef]

- Rajabipour, F.; Sant, G.; Weiss, J. Interactions between shrinkage reducing admixtures (SRA) and cement paste’s pore solution. Cem. Concr. Res. 2008, 38, 606–615. [Google Scholar] [CrossRef]

- Bentz, D.; Jensen, O. Mitigation strategies for autogenous shrinkage cracking. Cem. Concr. Compos. 2004, 26, 677–685. [Google Scholar] [CrossRef]

- Bentz, D.P.; Geiker, M.R.; Hansen, K.K. Shrinkage-reducing admixtures and early-age desiccation in cement pastes and mortars. Cem. Concr. Res. 2001, 31, 1075–1085. [Google Scholar] [CrossRef]

- Kothandaraman, S.; Kandasamy, S.; Sivaraman, K. The effect of controlled permeable formwork liner on the mechanical and durability properties of self compacting concrete. Constr. Build. Mater. 2016, 118, 319–326. [Google Scholar] [CrossRef]

- Kothandaraman, S.; Kandasamy, S. The effect of controlled permeable formwork (CPF) liner on the surface quality of concretes. Cem. Concr. Compos. 2017, 76, 48–56. [Google Scholar] [CrossRef]

- Kumarappa, D.B.; Peethamparan, S.; Ngami, M. Autogenous shrinkage of alkali activated slag mortars: Basic mechanisms and mitigation methods. Cem. Concr. Res. 2018, 109, 1–9. [Google Scholar] [CrossRef]

- Sant, G.; Kumar, A.; Patapy, C.; Le Saout, G.; Scrivener, K.L. The influence of sodium and potassium hydroxide on volume changes in cementitious materials. Cem. Concr. Res. 2012, 42, 1447–1455. [Google Scholar] [CrossRef]

- Chen, H.; Wyrzykowski, M.; Scrivener, K.L.; Lura, P. Prediction of self-desiccation in low water-to-cement ratio pastes based on pore structure evolution. Cem. Concr. Res. 2013, 49, 38–47. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Longman: London, UK, 1995. [Google Scholar]

- Choi, S. Internal relative humidity and drying shrinkage of hardening concrete containing lightweight and normal-weight coarse aggregates: A comparative experimental study and modeling. Constr. Build. Mater. 2017, 148, 288–296. [Google Scholar] [CrossRef]

- Hasholt, M.T.; Jespersen, M.H.S.; Jensen, O.M. Mechanical properties of concrete with SAP. Part I: Development of compressive strength. In Proceedings of the International RILEM Conference on Use of Superabsorbent Polymers and Other New Additives in Concrete, Lyngby, Denmark, 15–18 August 2010; p. 10. [Google Scholar]

- Hasholt, M.T.; Jensen, O.M. Chloride migration in concrete with superabsorbent polymers. Cem. Concr. Compos. 2015, 55, 290–297. [Google Scholar] [CrossRef] [Green Version]

- Assmann, A. Physical Properties of Concrete Modified with Superabsorbent Polymers. Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 2013. [Google Scholar]

- Bentz, D.P.; Peltz, M.A.; Snyder, K.A.; Davis, J.M. VERDiCT: Viscosity enhancers reducing diffusion in concrete technology. Concr. Int. 2009, 31, 31–36. [Google Scholar]

- Sant, G.; Eberhardt, B.A.; Bentz, D.P.; Weiss, J. Influence of shrinkage-reducing admixtures on moisture absorption in cementitious materials at early ages. J. Mater. Civ. Eng. 2010, 22, 277–286. [Google Scholar] [CrossRef]

| Composition | SiO2 | Al2O3 | Fe2O3 | K2O | CaO | MgO | TiO2 | Na2O | SO3 | LOI |

|---|---|---|---|---|---|---|---|---|---|---|

| PC | 21.54 | 6.22 | 4.47 | 0.84 | 59.21 | 2.61 | 0.51 | 0.23 | 2.32 | 1.57 |

| GGBFS | 33.04 | 14.48 | 0.44 | 0.34 | 37.40 | 9.63 | 1.33 | 0.27 | 2.56 | 0.84 |

| Fly ash | 46.02 | 25.46 | 16.46 | 0.22 | 1.27 | 0.53 | 0.12 | 1.57 | 1.58 | 4.50 |

| Composition | SiO2 | Al2O3 | Fe2O3 | K2O | CaO | MgO | TiO2 | Na2O | SO3 | P2O5 | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Content | 36.94 | 10.38 | 16.96 | 0.37 | 11.04 | 7.94 | 5.97 | 1.19 | 0.22 | 3.38 | 4.53 |

| Thickness/mm | Width/m | Fracture Strength | |

|---|---|---|---|

| Longitudinal/kN·m−1 | Transverse/kN·m−1 | ||

| 3 | 2 | 8.2 | 6.2 |

| Group | Cement | Fly Ash | Slag | River Sand | Tailings Sand | Gravel | Water | Super-Plasticizer | SAP | SRA | Wa/B |

|---|---|---|---|---|---|---|---|---|---|---|---|

| T0 | 294 | 63 | 63 | 743.8 | 0 | 1093.7 | 147 | 4.2 | - | - | - |

| T100 | 294 | 63 | 63 | 0 | 743.8 | 1093.7 | 147 | 4.2 | - | - | - |

| T0-SAP | 294 | 63 | 63 | 743.8 | 0 | 1093.7 | 147 | 4.2 | 2.52 | - | 0.05 |

| T100-SAP | 294 | 63 | 63 | 0 | 743.8 | 1093.7 | 147 | 4.2 | 2.52 | - | 0.05 |

| T0-SRA | 294 | 63 | 63 | 743.8 | 0 | 1093.7 | 147 | 4.2 | - | 4.2 | - |

| T100-SRA | 294 | 63 | 63 | 0 | 743.8 | 1093.7 | 147 | 4.2 | - | 4.2 | - |

| T0-CPFL | 294 | 63 | 63 | 743.8 | 0 | 1093.7 | 147 | 4.2 | - | - | - |

| T100-CPFL | 294 | 63 | 63 | 0 | 743.8 | 1093.7 | 147 | 4.2 | - | - | - |

| Groups | Slump (mm) | Slump Flow (mm) | Compressive Strength (MPa) | Flexural Strength (MPa) | Modulus of Elasticity at 28 d (GPa) | ||

|---|---|---|---|---|---|---|---|

| 7 d | 28 d | 7 d | 28 d | ||||

| T0 | 200 | 510 | 46.9 ± 1.8 | 60.4 ± 2.3 | 4.8 ± 0.3 | 8.0 ± 0.6 | 51.6 ± 3.1 |

| T100 | 190 | 510 | 49.3 ± 2.0 | 62.4 ± 2.6 | 5.5 ± 0.3 | 8.5 ± 0.5 | 54.4 ± 3.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Zhang, Z.; Yin, S.; Yu, L. Utilization of Iron Tailings Sand as an Environmentally Friendly Alternative to Natural River Sand in High-Strength Concrete: Shrinkage Characterization and Mitigation Strategies. Materials 2020, 13, 5614. https://doi.org/10.3390/ma13245614

Zhang Z, Zhang Z, Yin S, Yu L. Utilization of Iron Tailings Sand as an Environmentally Friendly Alternative to Natural River Sand in High-Strength Concrete: Shrinkage Characterization and Mitigation Strategies. Materials. 2020; 13(24):5614. https://doi.org/10.3390/ma13245614

Chicago/Turabian StyleZhang, Zhiqiang, Zhilu Zhang, Shaoning Yin, and Linwen Yu. 2020. "Utilization of Iron Tailings Sand as an Environmentally Friendly Alternative to Natural River Sand in High-Strength Concrete: Shrinkage Characterization and Mitigation Strategies" Materials 13, no. 24: 5614. https://doi.org/10.3390/ma13245614