Influence of Sandblasting Particle Size and Pressure on Resin Bonding Durability to Zirconia: A Residual Stress Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specimen Preparation

2.2. SEM and EDS Analyses

2.3. Surface Roughness and Contact Angle (CA) Measurements

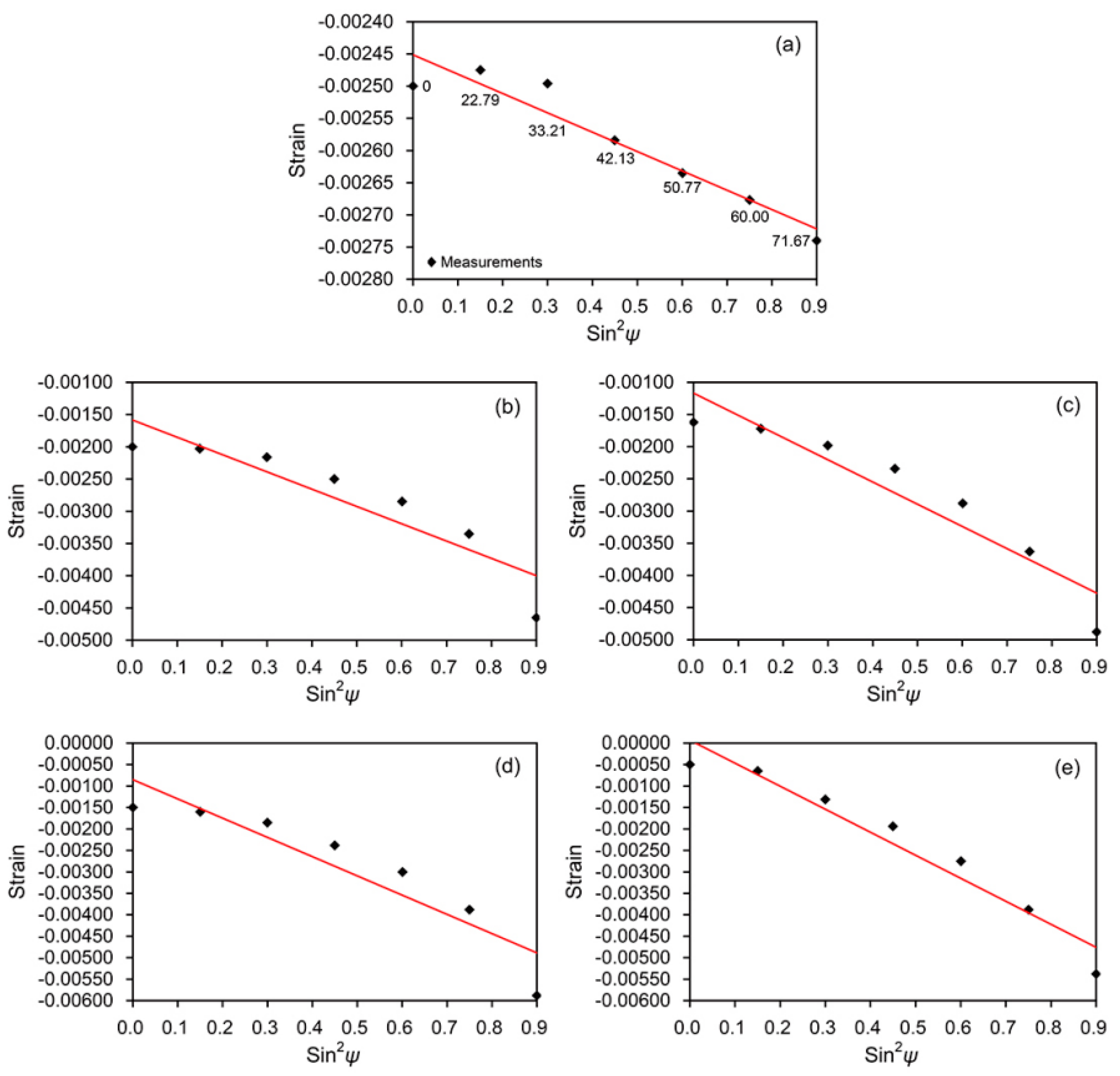

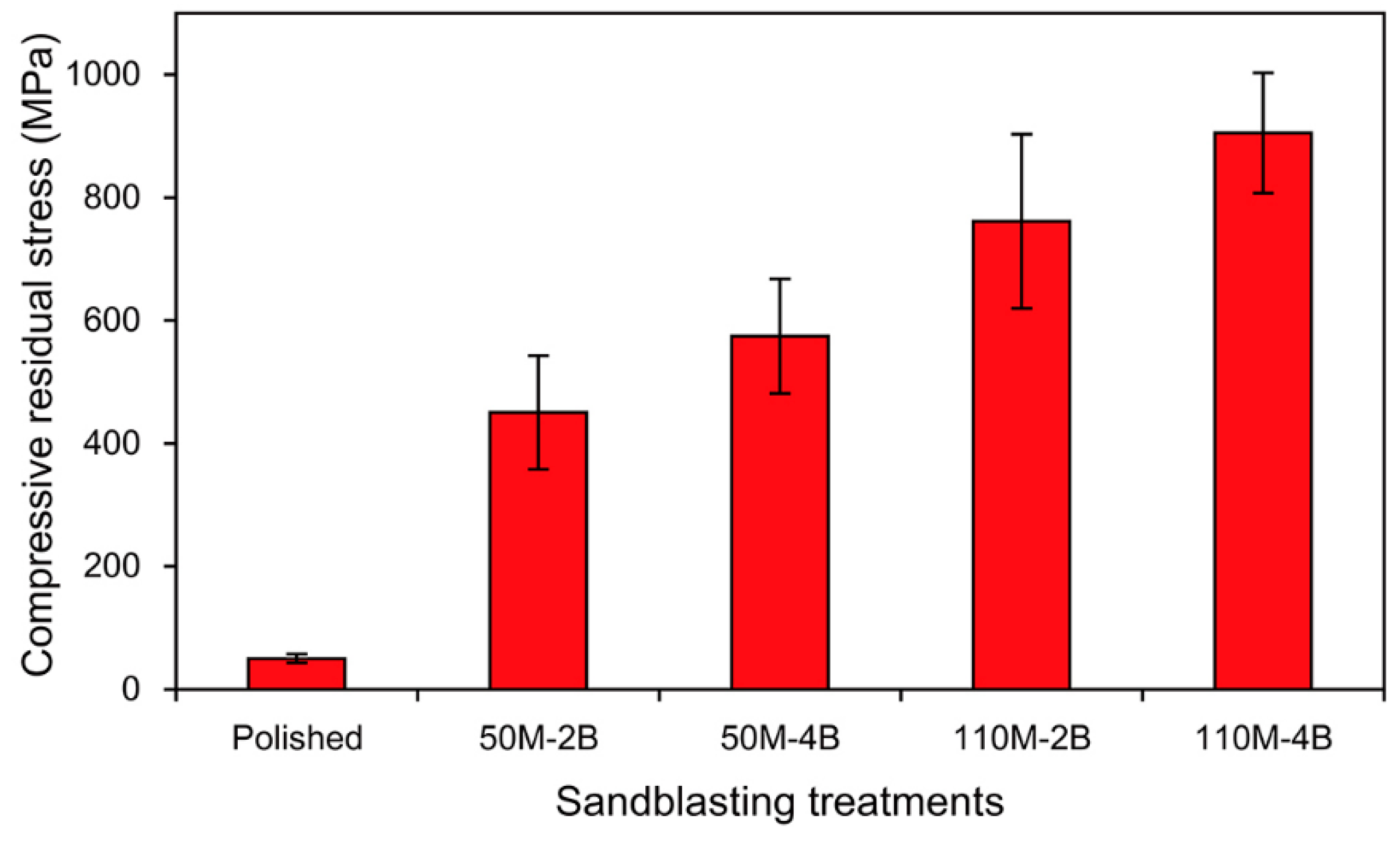

2.4. X-ray Diffraction (XRD) Analysis

2.5. Shear Bond Strength (SBS) Test

2.6. Statistical Analysis

3. Results

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Silva, G.A.F.; da Luza, E.C.; dos Reis Goyatá, F.; da Silva Concilio, L.R.; Neves, A.C.C.; Vitti, R.P.; Cunha, L.G. Influence of surface treatments on topography and bond strength of densely-sintered zirconium-oxide ceramic. Ceram. Int. 2016, 42, 8136–8139. [Google Scholar] [CrossRef]

- de Oyagüe, R.C.; Monticelli, F.; Toledano, M.; Osorio, E.; Ferrari, M.; Osorio, R. Influence of surface treatments and resin cement selection on bonding to densely-sintered zirconium-oxide ceramic. Dent. Mater. 2009, 25, 172–179. [Google Scholar] [CrossRef]

- Zhang, Y.; Lawn, B.R. Novel zirconia materials in dentistry. J. Dent. Res. 2018, 97, 140–147. [Google Scholar] [CrossRef] [PubMed]

- Craciunescu, E.; Sinescu, C.; Negrutiu, M.L.; Pop, D.M.; Lauer, H.C.; Rominu, M.; Hutiu, G.; Bunoiu, M.; Duma, V.F.; Antoniac, I. Shear bond strength tests of zirconia veneering ceramics after chipping repair. J. Adhes. Sci. Technol. 2016, 30, 666–676. [Google Scholar] [CrossRef]

- Gomes, A.L.; Castillo-Oyague, R.; Lynch, C.D.; Montero, J.; Albaladejo, A. Influence of sandblasting granulometry and resin cement composition on microtensile bond strength to zirconia ceramic for dental prosthetic frameworks. J. Dent. 2013, 41, 31–41. [Google Scholar] [CrossRef]

- Wolfart, M.; Lehmann, F.; Wolfart, S.; Kern, M. Durability of the resin bond strength to zirconia ceramic after using different surface conditioning methods. Dent. Mater. 2007, 23, 45–50. [Google Scholar] [CrossRef]

- Yang, B.; Barloi, A.; Kern, M. Influence of air-abrasion on zirconia ceramic bonding using an adhesive composite resin. Dent. Mater. 2010, 26, 44–50. [Google Scholar] [CrossRef]

- Matinlinna, J.P.; Heikkinen, T.; Özcan, M.; Lassila, L.V.J.; Vallittu, P.K. Evaluation of resin adhesion to zirconia ceramic using some organosilanes. Dent. Mater. 2006, 22, 824–831. [Google Scholar] [CrossRef]

- Hallmann, L.; Ulmer, P.; Reusser, E.; Hämmerle, C.H.F. Effect of blasting pressure, abrasive particle size and grade on phase transformation and morphological change of dental zirconia surface. Surf. Coat. Technol. 2012, 206, 4293–4302. [Google Scholar] [CrossRef]

- Chintapalli, R.K.; Rodriguez, A.M.; Marro, F.G.; Anglada, M. Effect of sandblasting and residual stress on strength of zirconia for restorative dentistry applications. J. Mech. Behav. Biomed. Mater. 2014, 29, 126–137. [Google Scholar] [CrossRef]

- Chintapalli, R.K.; Marro, F.G.; Jimenez-Pique, E.; Anglada, M. Phase transformation and subsurface damage in 3Y-TZP after sandblasting. Dent. Mater. 2013, 29, 566–572. [Google Scholar] [CrossRef] [PubMed]

- Okada, M.; Taketa, H.; Torii, Y.; Irie, M.; Matsumoto, T. Optimal sandblasting conditions for conventional-type yttria-stabilized tetragonal zirconia polycrystals. Dent. Mater. 2019, 35, 169–175. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.C.; Chang, E. Influence of residual stress on bonding strength and fracture of plasma-sprayed hydroxyapatite coatings on Ti-6Al-4V substrate. Biomaterials 2001, 22, 1827–1836. [Google Scholar] [CrossRef]

- Peltonen, J.; Järn, M.; Areva, S.; Linden, M.; Rosenholm, J.B. Topographical parameters for specifying a three-dimensional surface. Langmuir 2004, 20, 9428–9431. [Google Scholar] [CrossRef] [PubMed]

- Kwon, S.M.; Min, B.K.; Son, J.S.; Kim, K.H.; Kwon, T.Y. Durability of resin bond strength to dental noble metal–ceramic alloys conditioned with novel mercapto silane-based primer systems. J. Adhes. Sci. Technol. 2016, 30, 506–519. [Google Scholar] [CrossRef]

- Kwon, S.M.; Kim, Y.K.; Kwon, T.Y. Challenging the resin-zirconia interface by thermal cycling or mechanical load cycling or their combinations. Appl. Sci. 2020, 10, 7352. [Google Scholar] [CrossRef]

- Gale, M.S.; Darvell, B.W. Thermal cycling procedures for laboratory testing of dental restorations. J. Dent. 1999, 27, 89–99. [Google Scholar] [CrossRef]

- Lorente, C.M.; Scherrer, S.S.; Richard, J.; Demellayer, R.; Amez-Droz, M.; Wiskott, A.W.H. Surface roughness and EDS characterization of a Y-TZP dental ceramic treated with the CoJetTM Sand. Dent. Mater. 2010, 26, 1035–1042. [Google Scholar] [CrossRef]

- Wang, H.; Aboushelib, M.N.; Feilzer, A.J. Strength influencing variables on CAD/CAM zirconia frameworks. Dent. Mater. 2008, 24, 633–638. [Google Scholar] [CrossRef]

- Blatz, M.B.; Sadan, A.; Kern, M. Resin-ceramic bonding: A review of the literature. J. Prosthet. Dent. 2003, 89, 268–274. [Google Scholar] [CrossRef] [Green Version]

- Xie, H.; Tay, F.R.; Zhang, F.; Lu, Y.; Shen, S.; Chen, C. Coupling of 10-methacryloyloxydecyldihydrogenphosphate to tetragonal zirconia: Effect of pH reaction conditions on coordinate bonding. Dent. Mater. 2015, 31, e218–e225. [Google Scholar] [CrossRef] [PubMed]

- Nagaoka, N.; Yoshihara, K.; Feitosa, V.P.; Tamada, Y.; Irie, M.; Yoshida, Y.; Van Meerbeek, B.; Hayakawa, S. Chemical interaction mechanism of 10-MDP with zirconia. Sci. Rep. 2017, 7, 45563. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Attia, A. Bond strength of three luting agents to zirconia ceramic—Influence of surface treatment and thermocycling. J. Appl. Oral Sci. 2011, 19, 388–395. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kern, M.; Barloi, A.; Yang, B. Surface conditioning influences zirconia ceramic bonding. J. Dent. Res. 2009, 88, 817–822. [Google Scholar] [CrossRef]

- Casucci, A.; Osorio, E.; Osorio, R.; Monticelli, F.; Toledano, M.; Mazzitelli, C.; Ferrari, M. Influence of different surface treatments on surface zirconia frameworks. J. Dent. 2009, 37, 891–897. [Google Scholar] [CrossRef] [PubMed]

- Sciasci, P.; Abi-Rached, F.O.; Adabo, G.L.; Baldissara, P.; Fonseca, R.G. Effect of surface treatments on the shear bond strength of luting cements to Y-TZP ceramic. J. Prosthet. Dent. 2015, 113, 212–219. [Google Scholar] [CrossRef]

- Dündar, M.; Özcan, M.; Gökçe, B.; Cömlekoğlu, E.; Leite, F.; Valandro, L.F. Comparison of two bond strength testing methodologies for bilayered all-ceramics. Dent. Mater. 2007, 23, 630–636. [Google Scholar] [CrossRef] [PubMed]

| Groups | Surface Roughness (μm) | Water Contact Angle (Degrees) | ||

|---|---|---|---|---|

| Ra | Rz | Measured | Roughness-Corrected | |

| Polished | 0.04 (0.003) a,1 | 0.29 (0.03) a | 59.7 (3.2) a | 60.7 (3.1) a |

| 50M-2B | 0.63 (0.03) b | 4.52 (0.17) b | 44.1 (1.3) b | 49.2 (1.1) b |

| 50M-4B | 0.75 (0.04) c | 5.16 (0.20) c | 43.5 (1.4) b | 49.3 (1.2) b |

| 110M-2B | 0.84 (0.03) d | 6.01 (0.28) d | 42.4 (1.7) b,c | 48.7 (1.4) b |

| 110M-4B | 1.06 (0.07) e | 7.53 (0.26) e | 40.9 (1.2) c | 48.5 (0.9) b |

| Groups | 0 Thermocycles (1-Day Water Immersion) | 10,000 Thermocycles (after 7-Day Water Immersion) | 30,000 Thermocycles (after 7-Day Water Immersion) |

|---|---|---|---|

| Polished | 6.2 (1.4) A,a,1 | 1.9 (0.7) A,b | 0.0 (0.0) A,c |

| 50M-2B | 16.9 (3.3) B,a,2 | 14.6 (2.2) B,a | 11.5 (3.0) B,b |

| 50M-4B | 20.8 (2.7) C,a | 17.2 (2.9) B,b | 11.1 (2.9) B,c |

| 110M-2B | 17.3 (2.5) B,a | 15.1 (2.0) B,a | 10.4 (2.3) B,b |

| 110M-4B | 21.4 (2.6) C,a | 16.4 (1.9) B,b | 10.5 (2.5) B,c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwon, S.-M.; Min, B.K.; Kim, Y.K.; Kwon, T.-Y. Influence of Sandblasting Particle Size and Pressure on Resin Bonding Durability to Zirconia: A Residual Stress Study. Materials 2020, 13, 5629. https://doi.org/10.3390/ma13245629

Kwon S-M, Min BK, Kim YK, Kwon T-Y. Influence of Sandblasting Particle Size and Pressure on Resin Bonding Durability to Zirconia: A Residual Stress Study. Materials. 2020; 13(24):5629. https://doi.org/10.3390/ma13245629

Chicago/Turabian StyleKwon, Sung-Min, Bong Ki Min, Young Kyung Kim, and Tae-Yub Kwon. 2020. "Influence of Sandblasting Particle Size and Pressure on Resin Bonding Durability to Zirconia: A Residual Stress Study" Materials 13, no. 24: 5629. https://doi.org/10.3390/ma13245629

APA StyleKwon, S.-M., Min, B. K., Kim, Y. K., & Kwon, T.-Y. (2020). Influence of Sandblasting Particle Size and Pressure on Resin Bonding Durability to Zirconia: A Residual Stress Study. Materials, 13(24), 5629. https://doi.org/10.3390/ma13245629