Crack Detection during Laser Metal Deposition by Infrared Monochrome Pyrometer

Abstract

1. Introduction

2. Crack Detection Principles

2.1. Crack Detection Principles Using an Infrared Monochrome Pyrometer

- ❖

- Step 1: In the first-layer, the LMD nozzle is directly behind the IMP, and the shaded part in Figure 3a is not scanned.

- ❖

- Step 2: In the second-layer, the LMD nozzle scans perpendicular to the scanning direction of the previous layer. The fixture rotates 90° clockwise. The LMD nozzle is still directly behind the IMP optical head; thus, the shaded part of Figure 3b is not scanned. After scanning the two layers, only the small square at the lower left corner of Figure 3c has not been scanned.

- ❖

- Step 3: During the production of the third layer, the LMD nozzle returns to the original position of the first layer, and the fixture continues to rotate 90° clockwise so that the IMP is in front of the nozzle. After the third layer has been completed, it can be seen that the small square at the lower left corner has been completely covered. When scanning the third layer, the shadow part of Figure 3d is not scanned by the IMP.

- ❖

- Step 4: The fixture continues to rotate 90° clockwise, and the fourth layer is formed. The IMP is still in front of the LMD nozzle, scanning perpendicular to the scanning direction of the previous layer. The shaded part of Figure 3e is not scanned. Therefore, after scanning the third and the fourth layers, only the small square at the upper left corner of Figure 3f has not been scanned. The fixture continues to rotate 90° clockwise, and it can be seen that the nozzle has returned to the initial state when the first layer was made, and the IPM is directly behind the LMD nozzle.

- ❖

- Step 5: The first four steps are repeated until the part processed by LMD is completed. The scanning of the entire area by the IMP can be realized by the sequential scanning of the four layers.

2.2. Plane Wall Heat Conduction

- (i)

- The thermal conductivity λ is constant (only one nozzle).

- (ii)

- The heat loss from the plane wall edge can be ignored.

- (iii)

- The temperature of the plane wall varies only along the vertical wall surface direction rather than time.

- Single-layer conduction (Figure 4a)

- Multi-layer conduction (Figure 4b)

3. Experimental Methods

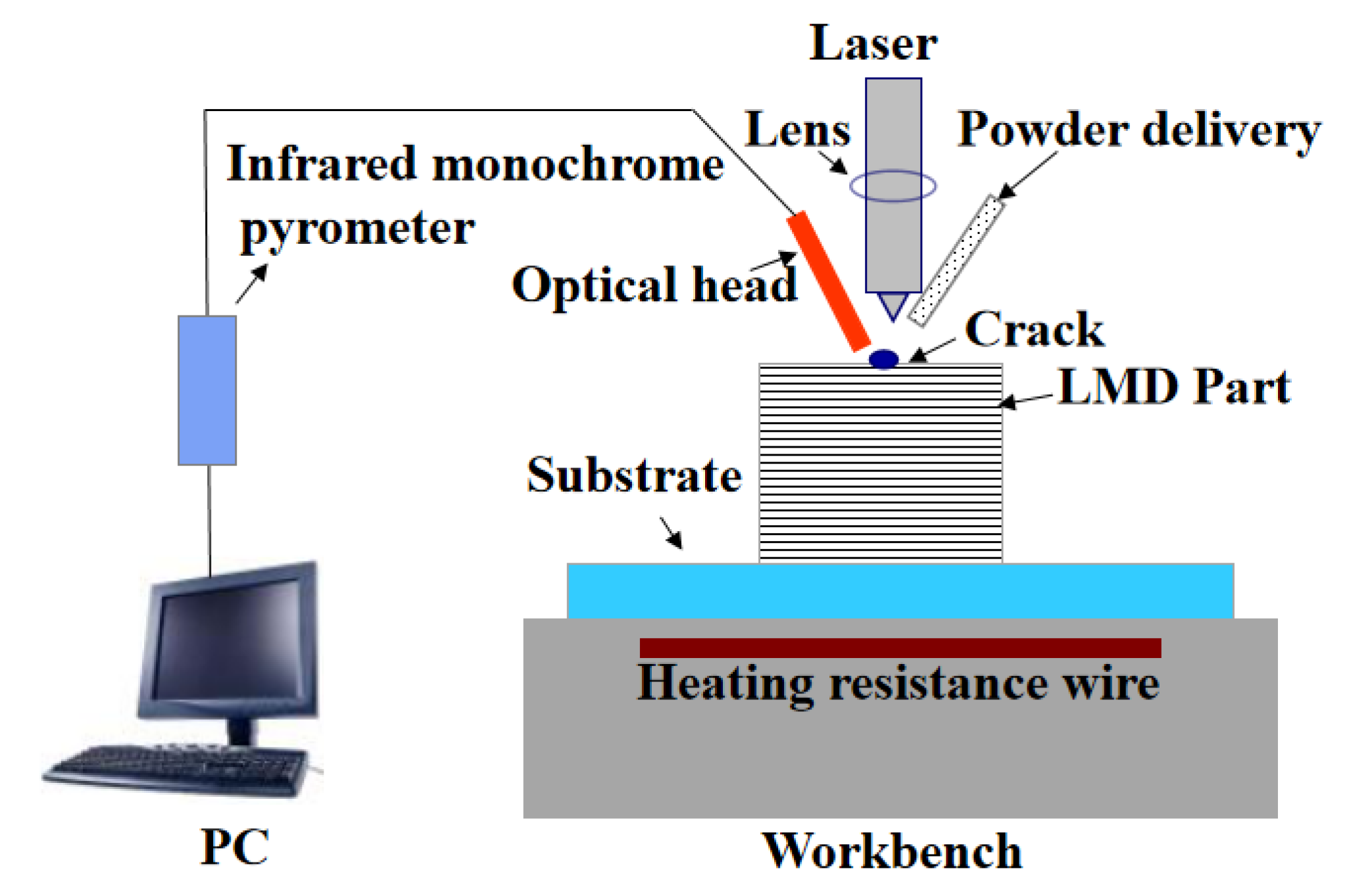

3.1. Experimental Set-up

3.2. Crack Simulation Experiments

4. Results and Discussion

4.1. Confirmation Cracks

4.2. Cracks Influencing Factors

- ❖

- According to Equation (9), if Φ, A, λ, and δ are the same, the fluctuation of the curve would be small, and Tn+1 would be on the same plane (isothermal surface) even if there are no cracks on the LMD workpiece.

- ❖

- If the height of the LMD specimen (Figure 14) was a, the distance between point Q and the substrate would be s in Crack 1, and the distance between point O and the substrate would be m in Crack 2. The depth of Crack 1 would be hs = (a − s) and that of Crack 2 would be hm = (a − m). In the heat transfer process of the LMD-316L austenitic stainless-steel cuboid sample, the values of Φ and λ would be similar.

- Q point:

- O point:

5. Conclusions

- The evaluation of surface cracks on a 316L austenitic stainless-steel sample prepared by LMD using an IMP indicated that the absence of cracks on the specimen surface induced smaller temperature changes with stable trends. In other words, if there are cracks on the LMD sample surface, the temperature changes at the crack would be significant. Remarkably, it was found that the temperature peaks in the plots were located at the exact same position with the defects.

- When the heat transfer rate in the test piece remained unchanged, the IMP was able to rapidly detect the cracks and determine their sizes. In addition, it was able to scan the cracks at different speeds and various directions. For curves with similar trend and stability, the up or down trends in the surface temperature curves of the LMD sample were unrelated to the optical head scanning speed. The changes in the temperature curve were related only to the crack depth of the LMD workpiece. Deeper depths induced larger temperature changes.

- The combination of additive manufacturing and subtractive manufacturing can guarantee the high quality of LMD samples. When defects appear in the cladding layer, they can be accurately located using the proposed real-time online defect detection method and be removed in time through the subtractive manufacturing mechanism. After all defects have been completely removed, the processing can continue through the additive manufacturing mechanism.

Author Contributions

Funding

Conflicts of Interest

References

- Azarniya, A.; Colera, X.G.; Mirzaali, M.J.; Sovizi, S.; Bartolomeu, F.; Wits, W.W.; Yap, C.Y.; Ahn, J.; Miranda, G.; Silva, F.S.; et al. Additive manufacturing of Ti–6Al–4V parts through laser metal deposition (LMD): Process, microstructure, and mechanical properties. J. Alloy. Compd. 2019, 804, 163–191. [Google Scholar] [CrossRef]

- Geyer, F. Powder based additive manufacturing methods LMF/LMD–requirements, comparison and applications. ICALEO Int. Congr. Appl. Laser. Electro-Opt. 2016, 2016, 701. [Google Scholar] [CrossRef]

- Panadeiro-Castro, V.; Rodriguez-ARAÚJO, J.; Garcia-DÍAZ, A.; Vergara, G. Medium Wavelength Infrared (MWIR) Imaging for High Speed Control of Laser Metal Deposition (LMD). Lasers Eng. (Old City Publ.) 2018, 39, 67–75. [Google Scholar]

- Zhang, D.; Xiao, J.; Bai, Y.; Guo, Q.; Zheng, M.; Liu, M.; Moorlag, C.; Yang, J. Introducing Bioinspired Initiator into Resins for In-situ Repairing of 3D Printed Metallic Structures. ACS Appl. Mater. Interfaces 2020. [Google Scholar] [CrossRef] [PubMed]

- Sun, G.F.; Shen, X.T.; Wang, Z.D.; Zhan, M.J.; Yao, S.; Zhou, R.; Ni, Z.H. Laser metal deposition as repair technology for 316L stainless steel: Influence of feeding powder compositions on microstructure and mechanical properties. Opt. Laser Technol. 2019, 109, 71–83. [Google Scholar] [CrossRef]

- Wu, Y.; Cao, Y.; Wu, Y.; Li, D. Mechanical Properties and Gamma-Ray Shielding Performance of 3D-Printed Poly-Ether-Ether-Ketone/Tungsten Composites. Materials 2020, 13, 4475. [Google Scholar] [CrossRef] [PubMed]

- Liang, S.; Rajora, M.; Liu, X.; Yue, C.; Zou, P.; Wang, L. Intelligent manufacturing systems: A review. Int. J. Mech. Eng. Robot. Res. 2018, 7, 324–330. [Google Scholar] [CrossRef]

- Mohd Yusuf, S.; Cutler, S.; Gao, N. Review: The Impact of Metal Additive Manufacturing on the Aerospace Industry. Metals 2019, 9, 1286. [Google Scholar] [CrossRef]

- Yusuf, S.M.; Chen, Y.; Boardman, R.; Yang, S.; Gao, N. Investigation on Porosity and Microhardness of 316L Stainless Steel Fabricated by Selective Laser Melting. Metals 2017, 7, 64. [Google Scholar] [CrossRef]

- Carluccio, D.; Bermingham, M.; Kent, D.; Demir, A.G.; Previtali, B.; Dargusch, M.S. Comparative study of pure iron manufactured by selective laser melting, laser metal deposition, and casting processes. Adv. Eng. Mater. 2019, 21, 1900049. [Google Scholar] [CrossRef]

- Pöhl, F.; Hardes, C.; Scholz, F.; Frenzel, J. Orientation-Dependent Deformation Behavior of 316L Steel Manufactured by Laser Metal Deposition and Casting under Local Scratch and Indentation Load. Materials 2020, 13, 1765. [Google Scholar] [CrossRef]

- Wu, Y.; Cao, Y.; Wu, Y.; Li, D. Neutron Shielding Performance of 3D-Printed Boron Carbide PEEK Composites. Materials 2020, 13, 2314. [Google Scholar] [CrossRef]

- Yu, J.H.; Choi, Y.S.; Shim, D.S.; Park, S.H. Repairing casting part using laser assisted additive metal-layer deposition and its mechanical properties. Opt. Laser Technol. 2018, 106, 87–93. [Google Scholar] [CrossRef]

- Qi, H. Synthesis of Designed Materials by Laser-Based Direct Metal Deposition Technique: Experimental and Theoretical Approaches. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2005; p. 3163915. [Google Scholar]

- Mahamood, R.M.; Akinlabi, E.T.; Shukla, M.; Pityana, S. Improving surface integrity using laser metal deposition process. In Additive Manufacturing: Breakthroughs in Research and Practice; IGI Globle: Hershey, PA, USA, 2020; pp. 220–244. [Google Scholar] [CrossRef]

- Mahamood, R.M.; Shukla, M.; Pityana, S. Laser Additive Manufacturing in Surface Modification of Metals. In Surface Engineering Techniques and Applications: Research Advancements; IGI Globle: Hershey, PA, USA, 2014; pp. 222–248. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Koutsomichalis, A.; Vaxevanidis, N. Laser-Based Manufacturing Processes for Aerospace Applications. In Materials Science and Engineering: Concepts, Methodologies, Tools, and Applications; IGI Globle: Hershey, PA, USA, 2017; pp. 374–391. [Google Scholar] [CrossRef]

- Nowotny, S.; Scharek, S.; Beyer, E.; Richter, K.H. Laser beam build-up welding: Precision in repair, surface cladding, and direct 3D metal deposition. J. Therm. Spray Technol. 2007, 16, 344–348. [Google Scholar] [CrossRef]

- Gasser, A.; Backes, G.; Kelbassa, I.; Weisheit, A.; Wissenbach, K. Laser Additive Manufacturing: Laser Metal Deposition (LMD) and Selective Laser Melting (SLM) in Turbo-Engine Applications. Laser Tech. J. 2010, 7, 58–63. [Google Scholar] [CrossRef]

- Kumar, L.J.; Nair, G.K. Laser Metal Deposition Repair Applications for Ti-6Al-4V Alloy. Mech. Mater. Sci. Eng. J. 2017, 7, 13–22. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, D.; Liu, X.; Zhang, D.; Qu, S.; Ma, J.; Liu, W. 3D-imaging of selective laser melting defects in a Co–Cr–Mo alloy by synchrotron radiation micro-CT. Acta Mater. 2015, 98, 1–16. [Google Scholar] [CrossRef]

- Leung, C.L.A.; Marussi, S.; Atwood, R.C.; Towrie, M.; Withers, P.J.; Lee, P.D. In situ X-ray imaging of defect and molten pool dynamics in laser additive manufacturing. Nat. Commun. 2018, 9, 1–9. [Google Scholar]

- Barua, S.; Liou, F.; Newkirk, J.; Sparks, T. Vision-based defect detection in laser metal deposition process. Rapid Prototyp. J. 2014, 20, 77–85. [Google Scholar] [CrossRef]

- Yuan, K.; Guo, W.; Li, P.; Wang, J.; Su, Y.; Lin, X.; Li, Y. Influence of process parameters and heat treatments on the microstructures and dynamic mechanical behaviors of Inconel 718 superalloy manufactured by laser metal deposition. Mater. Sci. Eng. A 2018, 721, 215–225. [Google Scholar] [CrossRef]

- Yuan, K.; Li, X.; Guo, W.; Zhang, Y.; Li, P. Effect of Microstructures and Defects on Dynamic Compression and Shear Performance of Laser Metal—Deposited GH4169 Superalloy. J. Aerosp. Eng. 2020, 33, 04020008. [Google Scholar] [CrossRef]

- Yu, J.; Rombouts, M.; Maes, G. Cracking behavior and mechanical properties of austenitic stainless steel parts produced by laser metal deposition. Mater. Des. 2013, 45, 228–235. [Google Scholar] [CrossRef]

- Caiazzo, F. Laser-aided Directed Metal Deposition of Ni-based superalloy powder. Opt. Laser Technol. 2018, 103, 193–198. [Google Scholar] [CrossRef]

- Song, X.; Lei, J.; Xie, J.; Fang, Y. Microstructure and electrochemical corrosion properties of nickel-plated carbon nanotubes composite Inconel 718 alloy coatings by laser melting deposition. Opt. Laser Technol. 2019, 119, 105593. [Google Scholar] [CrossRef]

- Prakash, D.L.; Walsh, M.J.; Maclachlan, D.; Korsunsky, A.M. Crack growth micro-mechanisms in the IN718 alloy under the combined influence of fatigue, creep and oxidation. Int. J. Fatigue 2009, 31, 1966–1977. [Google Scholar] [CrossRef]

- Li, X.; Jiang, X. Effects of dislocation pile-up and nanocracks on the main crack propagation in crystalline metals under uniaxial tensile load. Eng. Fract. Mech. 2019, 212, 258–268. [Google Scholar] [CrossRef]

- Ciampa, F.; Mahmoodi, P.; Pinto, F.; Meo, M. Recent advances in active infrared thermography for non-destructive testing of aerospace components. Sensors 2018, 18, 609. [Google Scholar] [CrossRef]

- Valeev, S.I.; Kharlamov, I.E. Determination of powerful active zones of petrochemical equipment. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 537, p. 032059. [Google Scholar] [CrossRef]

- Ganapathy, S.; Wu, W.S.; Schmult, B. Analysis and design considerations for a real-time system for non-destructive evaluation in the nuclear industry. Ultrasonics 1982, 20, 249–256. [Google Scholar] [CrossRef]

- Shih, Y.F.; Wang, Y.R.; Lin, K.L.; Chen, C.W. Improving non-destructive concrete strength tests using support vector machines. Materials 2015, 8, 7169–7178. [Google Scholar] [CrossRef]

- Lopez, A.; Bacelar, R.; Pires, I.; Santos, T.G.; Sousa, J.P.; Quintino, L. Non-destructive testing application of radiography and ultrasound for wire and arc additive manufacturing. Addit. Manuf. 2018, 21, 298–306. [Google Scholar] [CrossRef]

- Cho, Y.I.; Shin, S.H.; Kim, J.H. Dose assessment and shielding analysis of the working environments for non-destructive testing. J. Instrum. 2020, 15, P06012. [Google Scholar] [CrossRef]

- Zheng, S.; Vanderstelt, J.; McDermid, J.R.; Kish, J.R. Non-destructive investigation of aluminum alloy hemmed joints using neutron radiography and X-ray computed tomography. NDT E Int. 2017, 91, 32–35. [Google Scholar] [CrossRef]

- Jafari, H.; Dastjerdi, M.C.; Rajabi, S. A Monte Carlo evaluation of neutron images quality in a research reactor based neutron radiography facility. In Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment; Elsevier: New York, NY, USA, 2020; p. 164258. [Google Scholar] [CrossRef]

- Adams, R.; Zboray, R. Gamma radiography and tomography with a CCD camera and Co-60 source. Appl. Radiat. Isot. 2017, 127, 82–86. [Google Scholar] [CrossRef] [PubMed]

- Adam, A.M.B. Radiation Protection in Industrial Radiography. Master’s Thesis, Sudan University of Science and Technology, Khartoum, Sudan, July 2017. Available online: http://repository.sustech.edu/handle/123456789/19091 (accessed on 7 July 2017).

- Guembou Shouop, C.J.; Bak, S.I.; Ndontchueng Moyo, M.; Nguelem Mekongtso, E.J.; Strivay, D. New Cf-252 neutron source shielding design based Monte Carlo simulation using material combination. AIP Adv. 2020, 10, 075203. [Google Scholar] [CrossRef]

- Huang, H.; Qian, Z. Recent advances in magnetic non-destructive testing and the application of this technique to remanufacturing. Insight-Non-Destr. Test. Cond. Monit. 2018, 60, 451–462. [Google Scholar] [CrossRef]

- Hristoforou, E. Advanced Non-Destructive Testing in Steels. Metals 2018, 8, 492. [Google Scholar] [CrossRef]

- Juraszek, J. Residual Magnetic Field Non-Destructive Testing of Gantry Cranes. Materials 2019, 12, 564. [Google Scholar] [CrossRef]

- Al-Obaidi, S.M.A.; Leong, M.S.; Hamzah, R.I.; Abdelrhman, A.M. A review of acoustic emission technique for machinery condition monitoring: Defects detection & diagnostic. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Zurich, Switzerland, 2012; Volume 229, pp. 1476–1480. [Google Scholar]

- Gao, Z.; Wang, X.; Lin, J.; Liao, Y. Online evaluation of metal burn degrees based on acoustic emission and variational mode decomposition. Measurement 2017, 103, 302–310. [Google Scholar] [CrossRef]

- Gaja, H.; Liou, F. Defects monitoring of laser metal deposition using acoustic emission sensor. Int. J. Adv. Manuf. Technol. 2017, 90, 561–574. [Google Scholar] [CrossRef]

- Froend, M.; Riekehr, S.; Kashaev, N.; Klusemann, B.; Enz, J. Process development for wire-based laser metal deposition of 5087 aluminium alloy by using fibre laser. J. Manuf. Process. 2018, 34, 721–732. [Google Scholar] [CrossRef]

- Gao, Z.; Lin, J.; Wang, X.; Xu, X. Bearing fault detection based on empirical wavelet transform and correlated kurtosis by acoustic emission. Materials 2017, 10, 571. [Google Scholar] [CrossRef]

- Jiao, Y.; Fu, L.; Shan, W.; Liu, S. Damage fracture characterization of pervious asphalt considering temperature effect based on acoustic emission parameters. Eng. Fract. Mech. 2019, 210, 147–159. [Google Scholar] [CrossRef]

- Ziegler, B.; Dudzik, K. An overview of different possibilities to master the challenge of coupling an ae-sensor to an object of interest partly using examples of previous investigations. J. Kones 2019, 26, 207–214. [Google Scholar] [CrossRef]

- Kundu, A.; Eaton, M.J.; Al-Jumali, S.; Sikdar, S.; Pullin, R. Acoustic emission based damage localization in composites structures using Bayesian identification. In Proceedings of the 12th International Conference on Damage Assessment of Structures (DAMAS), Kitakyushu, Japan, 10–12 July 2017. [Google Scholar] [CrossRef]

- Madarshahian, R.; Ziehl, P.; Caicedo, J.M. Acoustic emission Bayesian source location: Onset time challenge. Mech. Syst. Signal Process. 2019, 123, 483–495. [Google Scholar] [CrossRef]

- Caso, E.; Fernandez-del-Rincon, A.; Garcia, P.; Diez-Ibarbia, A.; Sanchez-Espiga, J. Acoustic Emission Monitoring of Teeth Surface Damage Process in a Planetary Gearbox. In European Conference on Mechanism Science; Springer: Cham, Switzerland, 2020; pp. 256–264. [Google Scholar] [CrossRef]

- Quy, T.B.; Kim, J.M. Leak localization in industrial-fluid pipelines based on acoustic emission burst monitoring. Measurement 2020, 151, 107150. [Google Scholar] [CrossRef]

- He, Z.; Wang, H.; He, Y.; Zhang, G.; Wang, J.; Zou, G.; Chady, T. Joint scanning laser thermography defect detection method for carbon fiber reinforced polymer. IEEE Sens. J. 2019, 20, 328–336. [Google Scholar] [CrossRef]

- Doshvarpassand, S.; Wu, C.; Wang, X. An overview of corrosion defect characterization using active infrared thermography. Infrared Phys. Technol. 2019, 96, 366–389. [Google Scholar] [CrossRef]

- Ruidong, X.; Dichen, L.; Bin, C.; Lianzhong, Z.; Feng, G. A defects detection method based on infrared scanning in laser metal deposition process. Rapid Prototyp. J. 2018, 24, 945–954. [Google Scholar] [CrossRef]

- Cui, B.; Wu, Y.; Li, D.; Xie, R.; Cao, Y.; Tong, Z. A Defects Detection Device and Repair Method in Laser Metal Cladding Rapid Prototyping. China Patent CN201711448233.8, 20 April 2018. Available online: http://cprs.patentstar.com.cn/Search/Detail?ANE=9GHG7GBA6CDA9FAD8FCA5EAA9FHH6ACA9DBD8CEA9BFABIHA (accessed on 10 December 2020).

- Kreith, F.; Manglik, R.M.; Bohn, M.S. Principles of Heat Transfer; Cengage Learning: Boston, MA, USA, 2012. [Google Scholar]

- Bergman, T.L.; Lavine, A.; Incropera, F.P.; Dewitt, D.P. Fundamentals of Heat and Mass Transfer; John Wiley & Sons: New York, NY, USA, 2017. [Google Scholar]

- Welty, J.; Rorrer, G.L.; Foster, D.G. Fundamentals of Momentum, Heat, and Mass Transfer; John Wiley & Sons: New York, NY, USA, 2020. [Google Scholar]

- Maruyama, S. Heat Transfer; Beijing University Press: Beijng, China, 2011. [Google Scholar]

| Composition | Content (wt.%) |

|---|---|

| C | ≤0.030 |

| Mn | ≤2.00 |

| S | ≤0.01 |

| Si | 0.030 |

| P | 0.045 |

| Cr | 17.5–18 |

| Ni | 12.00 |

| Mo | 3.00 |

| Fe | Bal. |

| Crack No | Width (μm) | Depth (μm) |

|---|---|---|

| Crack 1 | 399.10 | 208.23 |

| Crack 2 | 301.18 | 280.13 |

| Crack 3 | 196.27 | 165.10 |

| Crack 4 | 169.71 | 122.71 |

| Crack No | Scanning Speed | ||

|---|---|---|---|

| 1.0 mm/s | 5.0 mm/s | 10.0 mm/s | |

| Peak Temperature (°C) | |||

| Crack 1 | 197.8 | 211.2 | 213.5 |

| Crack 2 | 200.4 | 212.3 | 213.9 |

| Crack 3 | 197.2 | 208.0 | 209.4 |

| Crack 4 | 195.2 | 204.7 | 206.3 |

| Distance between Peaks (mm) | Scanning Speed | ||

|---|---|---|---|

| 1.0 mm/s | 5.0 mm/s | 10.0 mm/s | |

| |X2 − X1| | 9.6472 | 9.7110 | 9.8320 |

| |X3 − X2| | 9.8891 | 9.7110 | 9.8320 |

| |X4 − X3| | 9.8891 | 9.5766 | 9.8791 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Cui, B.; Xiao, Y. Crack Detection during Laser Metal Deposition by Infrared Monochrome Pyrometer. Materials 2020, 13, 5643. https://doi.org/10.3390/ma13245643

Wu Y, Cui B, Xiao Y. Crack Detection during Laser Metal Deposition by Infrared Monochrome Pyrometer. Materials. 2020; 13(24):5643. https://doi.org/10.3390/ma13245643

Chicago/Turabian StyleWu, Yin, Bin Cui, and Yao Xiao. 2020. "Crack Detection during Laser Metal Deposition by Infrared Monochrome Pyrometer" Materials 13, no. 24: 5643. https://doi.org/10.3390/ma13245643

APA StyleWu, Y., Cui, B., & Xiao, Y. (2020). Crack Detection during Laser Metal Deposition by Infrared Monochrome Pyrometer. Materials, 13(24), 5643. https://doi.org/10.3390/ma13245643