Dependence of the Magnetization Process on the Thickness of Fe70Pd30 Nanostructured Thin Film

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication of Fe–Pd Antidot Thin Films

2.2. Morphological Characterization and Composition

2.3. Magnetic Properties Characterization

3. Results

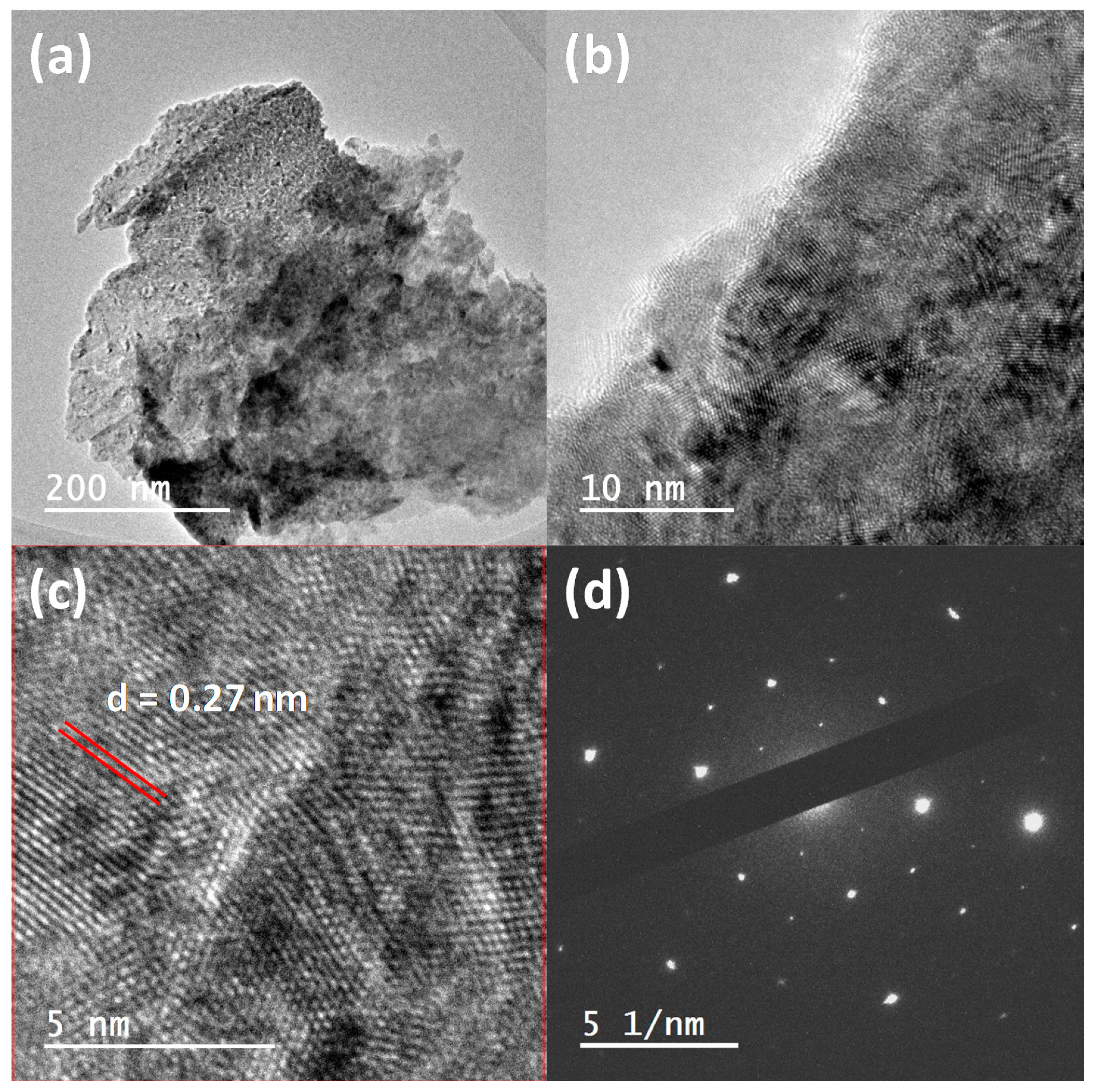

3.1. Morphology and Composition

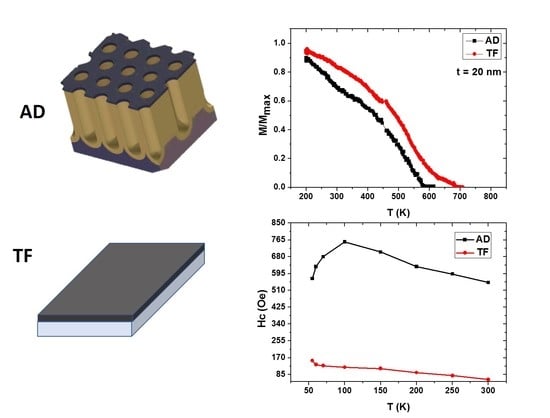

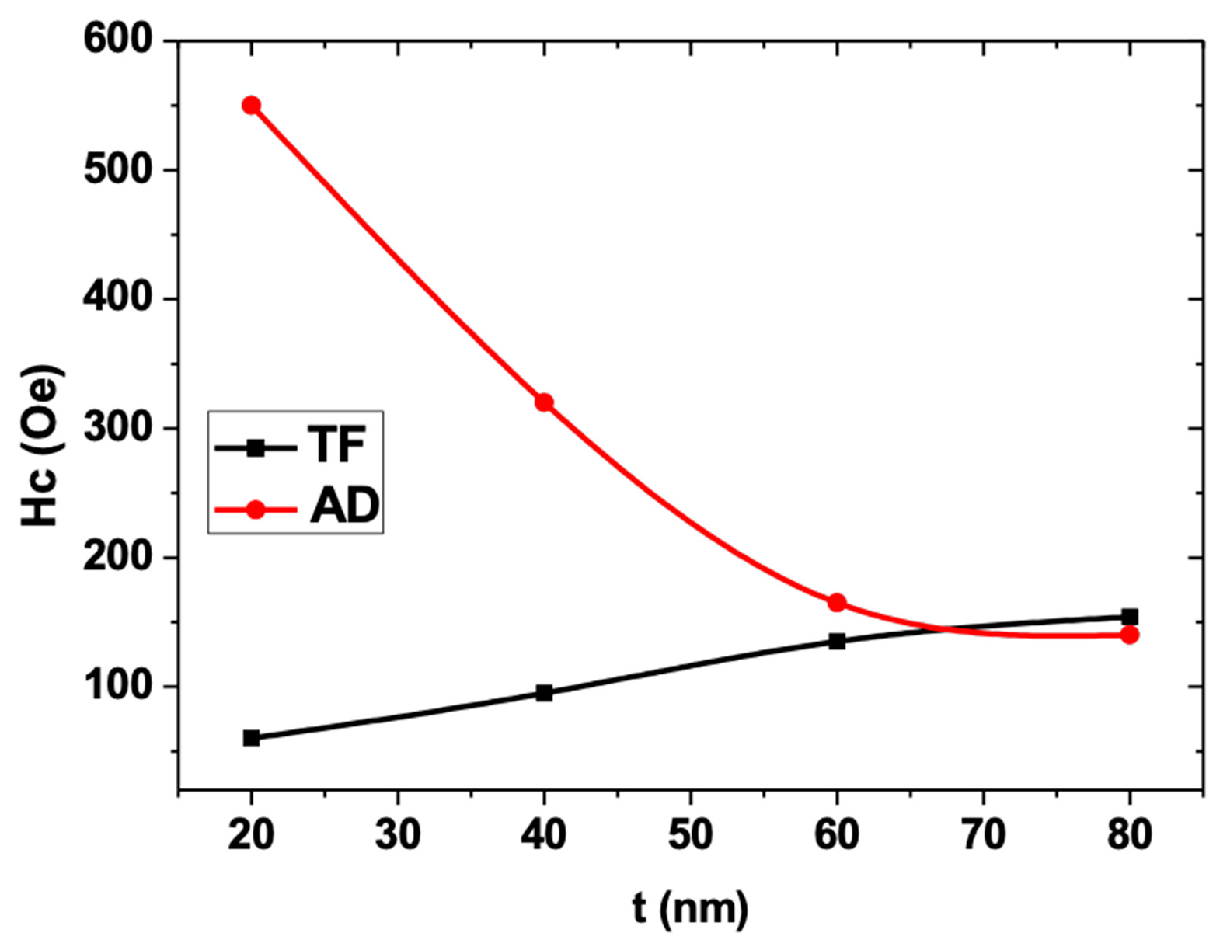

3.2. Magnetic Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, T.; Ma, L.; Zhao, S.Q.; Ma, D.D.; Li, L.; Cheng, G.; Rao, G.H. Crystal structure and magnetic properties of FexPd1−x thin films annealed at 550 °C. J. Mater. Sci. Mater. Electron. 2017, 28, 3616–3620. [Google Scholar] [CrossRef]

- Han, J.H.; Han, T.; Sohn, Y.; Kim, D.I.; Kim, H.S.; Jin, S. Thermo-elastic strain analysis in crystallographic-texture-aligned Fe–Pd magnetic shape memory alloy. Scr. Mater. 2019, 167, 56–60. [Google Scholar] [CrossRef]

- Allenstein, U.; Wisotzki, E.I.; Gräfe, C.; Clement, J.H.; Liu, Y.; Schroers, J.; Mayr, S.G. Binary Fe-Pd submicron structures fabricated through glancing angle deposition (GLAD) for bioapplications. Mater. Des. 2017, 131, 366–374. [Google Scholar] [CrossRef]

- Allenstein, U.; Ma, Y.; Arabi-Hashemi, A.; Zink, M.; Mayr, S.G. Fe-Pd based ferromagnetic shape memory actuators for medical applications: Biocompatibility, effect of surface roughness and protein coatings. Acta Biomater. 2013, 9, 5845–5853. [Google Scholar] [CrossRef]

- Chiu, Y.J.; Shen, C.Y.; Chang, H.W.; Jian, S.R. Characteristics of Iron-Palladium alloy thin films deposited by magnetron sputtering. Results Phys. 2018, 9, 17–22. [Google Scholar] [CrossRef]

- Barrera, G.; Scaglione, F.; Cialone, M.; Celegato, F.; Coïsson, M.; Rizzi, P.; Tiberto, P. Structural and magnetic properties of FePd thin film synthesized by electrodeposition method. Materials 2020, 13, 1454. [Google Scholar] [CrossRef] [Green Version]

- Senthil Kumar, M. Temperature dependence of magnetization in Fe-Pd thin films. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2009, B162, 59–63. [Google Scholar] [CrossRef]

- Sun, W.; Xu, X.; Liu, J.; Xia, W.; Yan, A. An in-situ study of magnetic domain structures in undercooled Fe-29.5 at. %Pd magnetostrictive alloys by Lorentz microscopy and electron holography. J. Appl. Phys. 2015, 177, 163909. [Google Scholar] [CrossRef]

- Kauffmann-Weiss, S.; Hamann, S.; Gruner, M.E.; Buschbeck, J.; Ludwig, A.; Schultz, L.; Fähler, S. Understanding the magnetic shape memory system Fe-Pd-X by thin film experiments and first principle calculations. Adv. Eng. Mater. 2012, 14, 724–749. [Google Scholar] [CrossRef]

- Cialone, M.; Fernandez-Barcia, M.; Celegato, F.; Coisson, M.; Barrera, G.; Uhlemann, M.; Gebert, A.; Sort, J.; Pellicer, E.; Rizzi, P.; et al. A comparative study of the influence of the deposition technique (electrodeposition versus sputtering) on the properties of nanostructured Fe70Pd30 films. Sci. Technol. Adv. Mater. 2020, 21, 424–434. [Google Scholar] [CrossRef] [PubMed]

- Rozman, K.Z.; Pecko, D.; Trafela, S.; Samardzija, Z.; Spreitzer, M.; Jaglicic, Z.; Nadrah, P.; Zorko, M.; Bele, M.; Tisler, T.; et al. Austenite-martensite transformation in electrodeposited Fe70Pd30 NWs: A step towards making bio-nano-actuators tested on in vivo systems. Smart Mater. Struct. 2018, 27, 035018. [Google Scholar] [CrossRef]

- Merkel, D.G.; Bottyán, L.; Tanczik, F.; Zolnai, Z.; Nagy, N.; Vértesy, G.; Waizinger, J.; Bommer, L. Magnetic patterning perpendicular anisotropy FePd alloy films by masked ion irradiation. J. Appl. Phys. 2011, 109, 124302. [Google Scholar] [CrossRef]

- Maximenko, A.; Fedotova, J.; Marszałek, M.; Zarzycki, A.; Zabila, Y. Magnetic characteristics of CoPd and FePd antidot arrays on nanoperforated Al2O3 templates. J. Magn. Magn. Mater. 2016, 400, 200–205. [Google Scholar] [CrossRef]

- Aravind, P.B.; Heigl, M.; Fix, M.; Groß, F.; Grafe, J.; Mary, A.; Rajgowrav, C.R.; Krupiński, M.; Marszałek, M.; Thomas, S.; et al. Bistability of magnetic states in Fe-Pd nanocap arrays. Nanotechnology 2019, 30, 405705. [Google Scholar] [CrossRef] [PubMed]

- Salaheldeen, M.; Vega, V.; Fernández, A.; Prida, V.M. Anomalous in-plane coercivity behaviour in hexagonal arrangements of ferromagnetic antidot thin films. J. Magn. Magn. Mater. 2019, 491, 165572. [Google Scholar] [CrossRef]

- Kaidatzis, A.; Del Real, R.P.; Alvaro, R.; Palma, J.L.; Anguita, J.; Niarchos, D.; Vázquez, M.; Escrig, J.; García-Martín, J.M. Magnetic properties engineering of nanopatterned cobalt antidot arrays. J. Phys. D Appl. Phys. 2016, 49, 5004–5012. [Google Scholar] [CrossRef]

- Perzanowski, M.; Krupinski, M.; Zarzycki, A.; Dziedzic, A.; Zabila, Y.; Marszalek, M. Exchange Bias in the [CoO/Co/Pd]10Antidot Large Area Arrays. ACS Appl. Mater. Interfaces 2017, 9, 33250–33256. [Google Scholar] [CrossRef] [Green Version]

- Salaheldeen, M.; Méndez, M.; Vega, V.; Fernández, A.; Prida, V.M. Tuning Nanohole Sizes in Ni Hexagonal Antidot Arrays: Large Perpendicular Magnetic Anisotropy for Spintronic Applications. ACS Appl. Nano Mater. 2019, 2, 1866–1875. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Martínez-Goyeneche, L.; Álvarez-Alonso, P.; Fernandez, A. Enhancement the perpendicular magnetic anisotropy of nanopatterned hard/soft bilayer magnetic antidot arrays for spintronic application. Nanotechnology 2020, 31, 485708. [Google Scholar] [CrossRef]

- Saavedra, E.; Corona, R.M.; Vidal-Silva, N.; Palma, J.L.; Altbir, D.; Escrig, J. Dynamic and static properties of stadium-shaped antidot arrays. Sci. Rep. 2020, 10, 20024. [Google Scholar] [CrossRef]

- Prida, V.M.; Vega, V.; García, J.; González, L.; Rosa, W.O.; Fernández, A.; Hernando, B. Functional Fe-Pd nanomaterials synthesized by Dynamic and static properties of stadium-shaped antidot arrays template-assisted methods. J. Magn. Magn. Mater. 2012, 324, 3508–3511. [Google Scholar] [CrossRef]

- Béron, F.; Pirota, K.R.; Vega, V.; Prida, V.M.; Fernández, A.; Hernando, B.; Knobel, M. An effective method to probe local magnetostatic properties in a nanometric FePd antidot array. New J. Phys. 2011, 13, 3035–3051. [Google Scholar] [CrossRef]

- Vera-Londono, L.; Ruiz-Clavijo, A.; Caballero-Calero, O.; Martín-González, M. Understanding the thermal conductivity variations in nanoporous anodic aluminum oxide. Nanoscale Adv. 2020, 2, 4591–4603. [Google Scholar] [CrossRef]

- Shaban, M.; Ahmed, A.M.; Abdel-Rahman, E.; Hamdy, H. Fabrication and characterization of micro/nanoporous Cr film for sensing applications. Microporous Mesoporous Mater. 2014, 198, 115–121. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Vega, V.; Ibabe, A.; Jaafar, M.; Asenjo, A.; Fernandez, A.; Prida, V.M. Tailoring of Perpendicular Magnetic Anisotropy in Dy13Fe87 Thin Films with Hexagonal Antidot Lattice Nanostructure. Nanomaterials 2018, 8, 227. [Google Scholar] [CrossRef] [Green Version]

- Prida, V.M.; Salaheldeen, M.; Pfitzer, G.; Hidalgo, A.; Vega, V.; González, S.; Teixeira, J.M.; Fernández, A.; Hernando, B. Template assisted deposition of ferromagnetic nanostructures: From antidot thin films to multisegmented nanowires. Acta Phys. Pol. A 2017, 131, 822–827. [Google Scholar] [CrossRef]

- Svalov, A.V.; Fernandez, A.; Vas’kovskiy, V.O.; Kurlyandskaya, G.V.; Barandiarán, J.M.; Anton, R.L.; Tejedor, M. MOKE study of Co/Ti/(Gd-Co) multilayers near the magnetic compensation state. J. Alloys Compd. 2006, 419, 25–31. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Vega, V.; Caballero-Flores, R.; Prida, V.M.; Fernández, A. Influence of nanoholes array geometrical parameters on magnetic properties of Dy-Fe antidot thin films. Nanotechnology 2019, 30, 455703. [Google Scholar] [CrossRef]

- Abràmoff, M.D.; Magalhães, P.J.; Ram, S.J. Image Processing with ImageJ. Biophotonics Int. 2004, 11, 36–42. [Google Scholar]

- Krupinski, M.; Mitin, D.; Zarzycki, A.; Szkudlarek, A.; Giersig, M.; Albrecht, M.; Marszałek, M. Magnetic transition from dot to antidot regime in large area Co/Pd nanopatterned arrays with perpendicular magnetization. Nanotechnology 2017, 28, 085302. [Google Scholar] [CrossRef]

- Bahamida, S.; Fnidiki, A.; Laggoun, A.; Guittoum, A. A comparative structural and magnetic study of Fe100−xPdx (x = 15, 20 and 36) thin films deposited on Si (100) and glass substrates. J. Magn. Magn. Mater. 2015, 392, 139–147. [Google Scholar] [CrossRef]

- Chang, Y.C.; Hsiao, S.N.; Liu, S.H.; Chen, S.K.; Liu, Y.T.; Lee, H.Y.; Sun, A.C.; Dhu, J.G. Influence of stoichiometry and growth temperature on the crystal structure and magnetic properties of epitaxial L 10 Fe-Pd (001) films. J. Appl. Phys. 2014, 115, 17A740. [Google Scholar] [CrossRef]

- Gates-Rector, S.D.; Blanton, T.N. The Powder Diffraction File: A Quality Materials Characterization Database. Powder Diffr. 2019, 34, 352–360. [Google Scholar] [CrossRef] [Green Version]

- Ko, J.; Bae, T.; Hong, J. Effect of a change in thickness on the structural and perpendicular magnetic properties of L10 ordered FePd ultra-thin films with (001) texture. J. Appl. Phys. 2012, 112, 113919. [Google Scholar] [CrossRef]

- Bensehil, I.; Kharmouche, A.; Bourzami, A. Synthesis, Structural, and Magnetic Properties of Fe Thin Films. J. Supercond. Nov. Magn. 2020, 33, 1521–1526. [Google Scholar] [CrossRef]

- Liu, Q.F.; Jiang, C.J.; Fan, X.L.; Wang, J.B.; Xue, D.S. Low-temperature magnetic properties of Co antidot array. Chin. Phys. Lett. 2006, 23, 1592–1595. [Google Scholar] [CrossRef]

- Castán-Guerrero, C.; Herrero-Albillos, J.; Bartolomé, J.; Bartolomé, F.; Rodríguez, L.A.; Magén, C.; Kronast, F.; Gawronski, P.; Chubykalo-Fesenko, O.; Merazzo, K.J.; et al. Magnetic antidot to dot crossover in Co and Py nanopatterned thin films. Phys. Rev. B Condens. Matter Mater. Phys. 2014, 89, 144405. [Google Scholar] [CrossRef] [Green Version]

- Fettar, F.; Cagnon, L.; Rougemaille, N. Three-dimensional magnetization profile and multiaxes exchange bias in Co antidot arrays. Appl. Phys. Lett. 2010, 97, 192502. [Google Scholar] [CrossRef] [Green Version]

- Jiang, C.; Wei, W.; Liu, Q.; Guo, D.; Xue, D. Magnetic irreversibility of the Fe antidot arrays film by depositing on the porous alumina templates. Appl. Surf. Sci. 2012, 258, 3723–3725. [Google Scholar] [CrossRef]

| Sample | S1 (20 nm) | S2 (40 nm) | S3 (60 nm) | S4 (80 nm) | ||||

|---|---|---|---|---|---|---|---|---|

| Atomic Species | Fe (at.%) | Pd (at.%) | Fe (at.%) | Pd (at.%) | Fe (at.%) | Pd (at.%) | Fe (at.%) | Pd (at.%) |

| Average | 67 ± 2 | 33 ± 2 | 69 ± 3 | 31 ± 3 | 70 ± 3 | 30 ± 3 | 68 ± 3 | 32 ± 3 |

| Sample | Layer Thickness (nm) | (D) (nm) | W = P − D (nm) | (%) [30] |

|---|---|---|---|---|

| S1 | 20 | 69 ± 1 | 36 ± 2 | 61 ± 2 |

| S2 | 40 | 52 ± 3 | 53 ± 4 | 78 ± 3 |

| S3 | 60 | 39 ± 3 | 67 ± 3 | 87 ± 2 |

| S4 | 80 | 18 ± 2 | 88 ± 2 | 97 ± 1 |

| STF | - | - | - | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salaheldeen, M.; Abu-Dief, A.M.; Martínez-Goyeneche, L.; Alzahrani, S.O.; Alkhatib, F.; Álvarez-Alonso, P.; Blanco, J.Á. Dependence of the Magnetization Process on the Thickness of Fe70Pd30 Nanostructured Thin Film. Materials 2020, 13, 5788. https://doi.org/10.3390/ma13245788

Salaheldeen M, Abu-Dief AM, Martínez-Goyeneche L, Alzahrani SO, Alkhatib F, Álvarez-Alonso P, Blanco JÁ. Dependence of the Magnetization Process on the Thickness of Fe70Pd30 Nanostructured Thin Film. Materials. 2020; 13(24):5788. https://doi.org/10.3390/ma13245788

Chicago/Turabian StyleSalaheldeen, Mohamed, Ahmed Mohamed Abu-Dief, Lucía Martínez-Goyeneche, Seraj Omar Alzahrani, Fatmah Alkhatib, Pablo Álvarez-Alonso, and Jesús Ángel Blanco. 2020. "Dependence of the Magnetization Process on the Thickness of Fe70Pd30 Nanostructured Thin Film" Materials 13, no. 24: 5788. https://doi.org/10.3390/ma13245788