Impact of Cryogenic Treatment on HCF and FCP Performance of β-Solution Treated Ti-6Al-4V ELI Biomaterial

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Thermal Treatment

2.3. High Cycle Fatigue and Fatigue Crack Propagation Test

2.4. Microstructure and Fractography

3. Results and Discussions

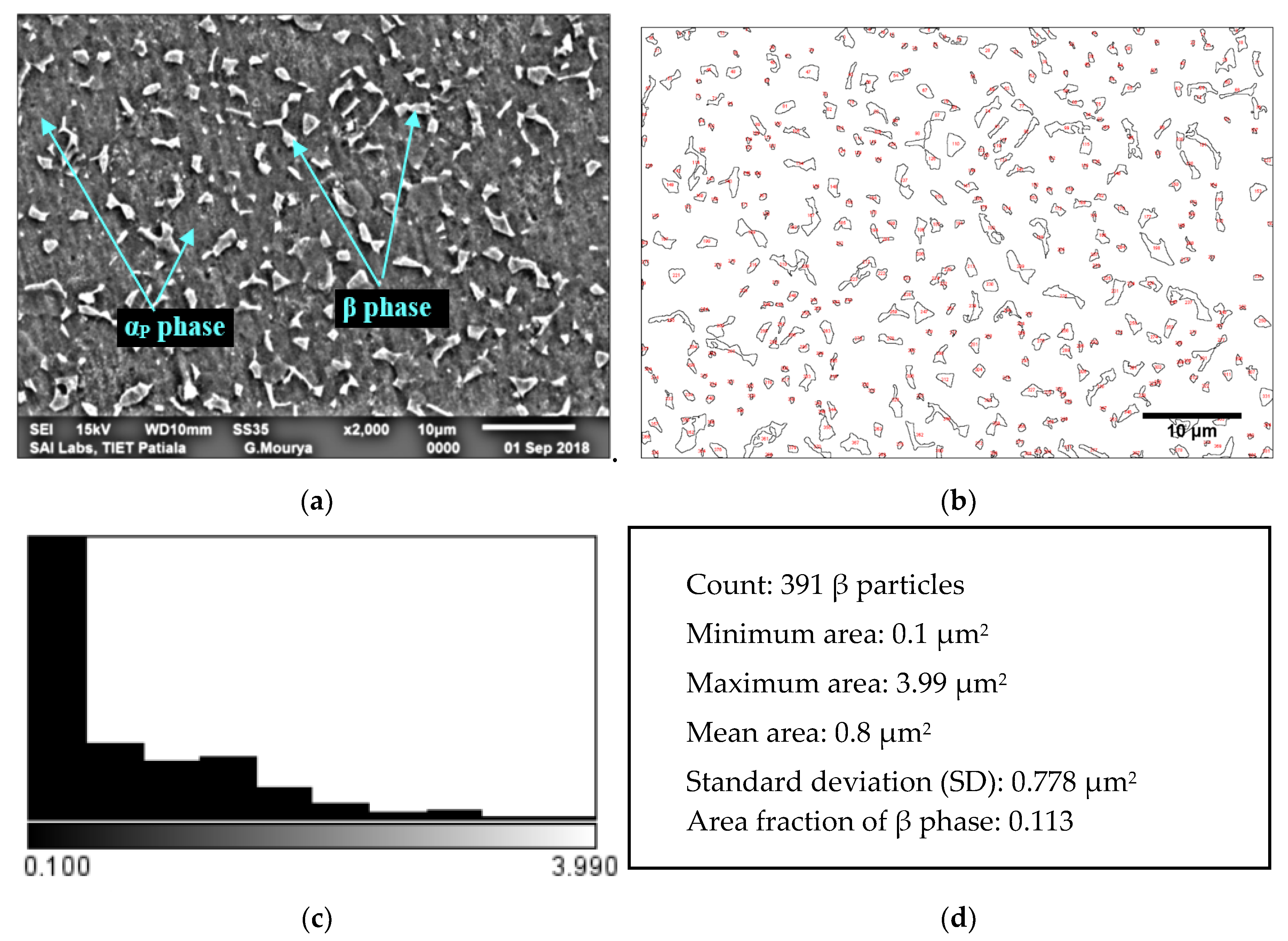

3.1. Microstructure

Microstructure of MA, B1 and B2 Ti-6Al-4V ELI

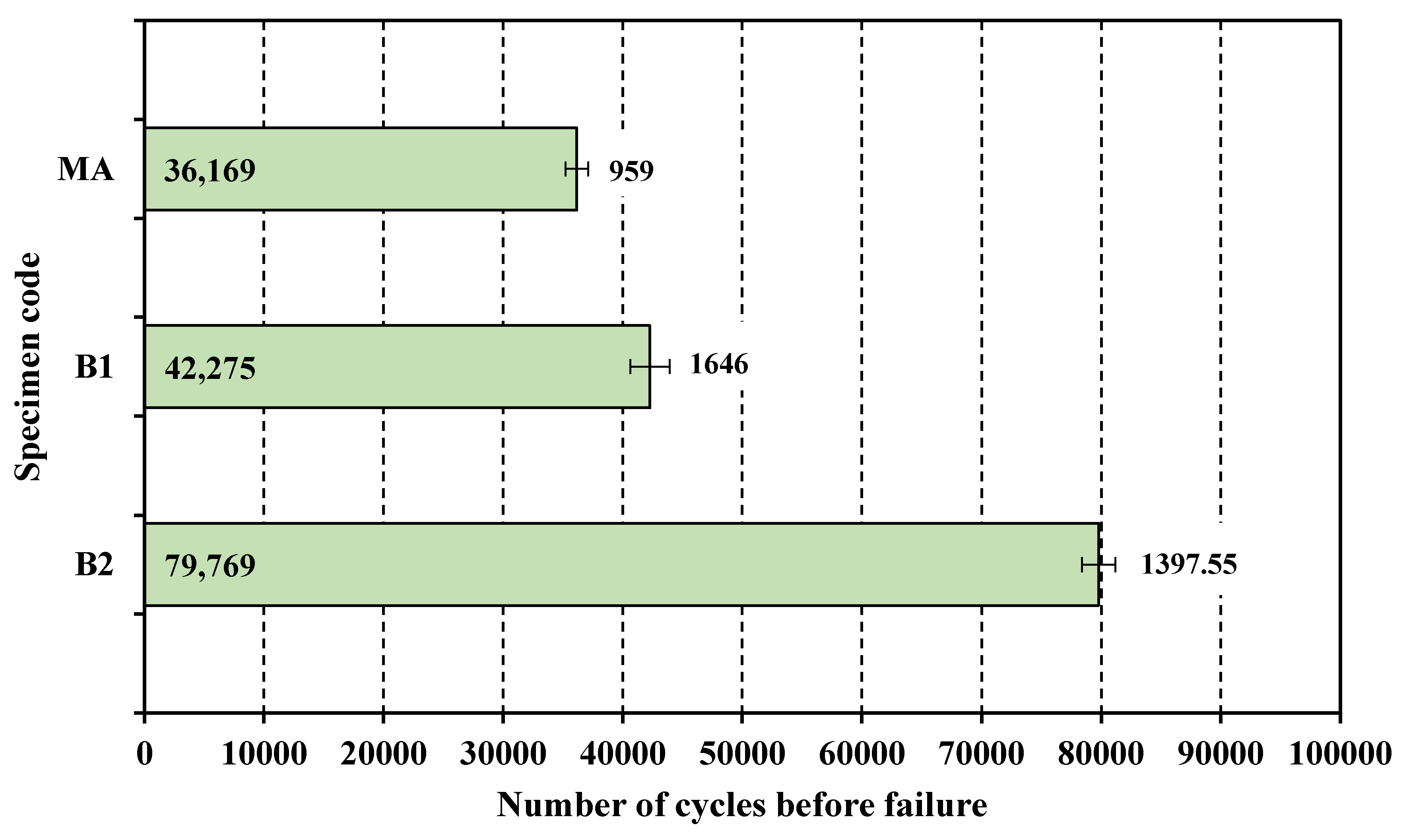

3.2. High Cycle Fatigue

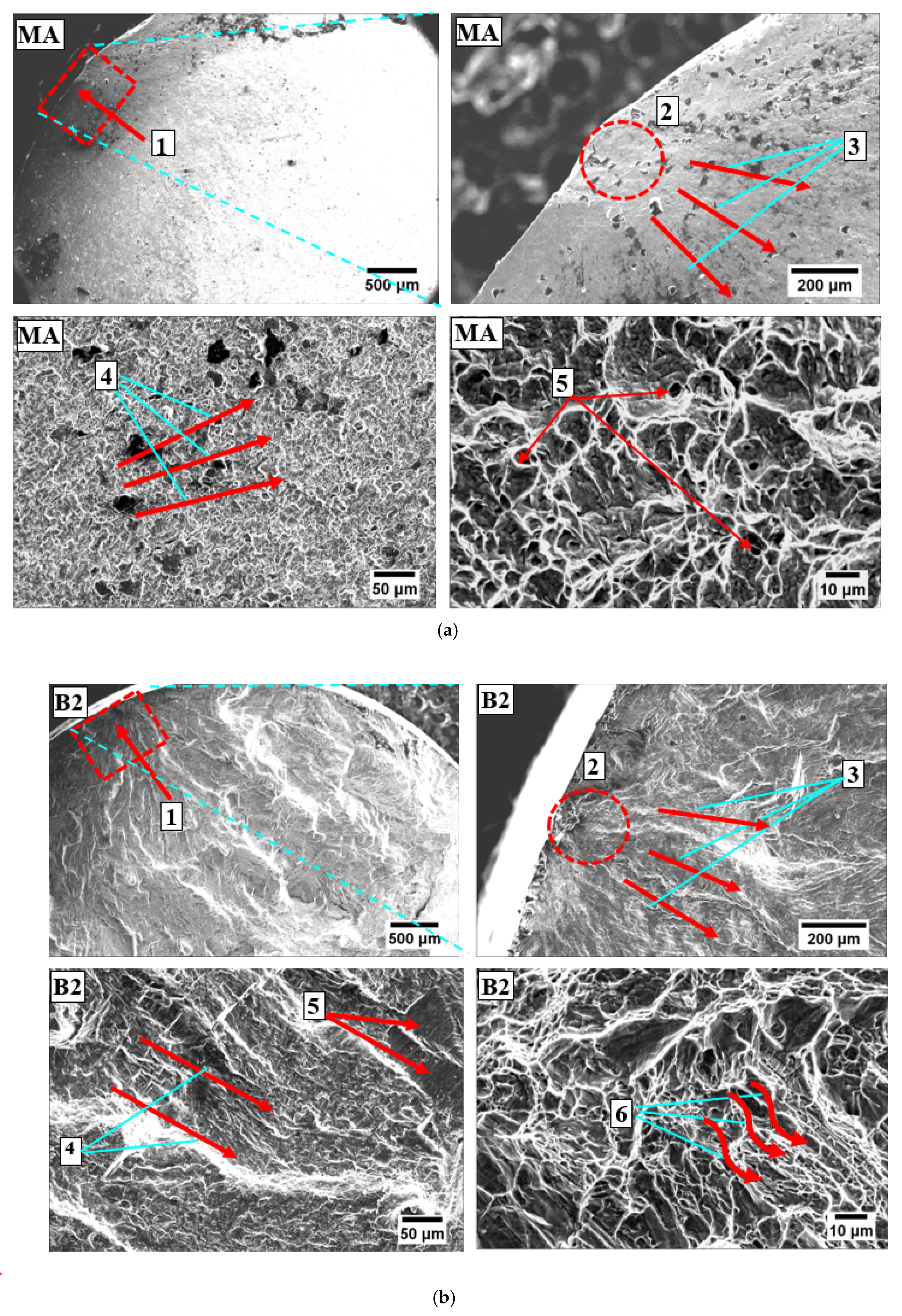

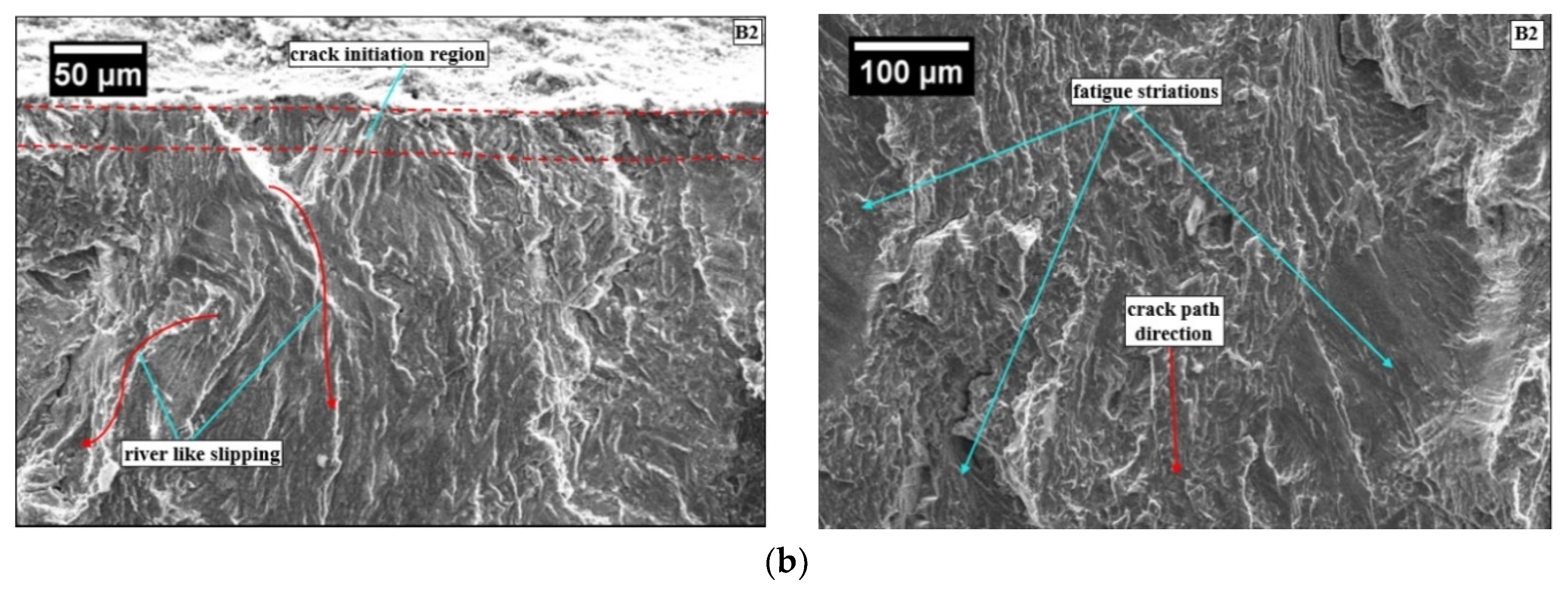

3.3. Fatigue Crack Propagation

4. Conclusions

- Cryogenic treatment had caused refinement in the prior β grain and led to development of massive α and its further transformation into ultrafine α and β during the soaking phase at cryogenic temperature.

- CT had caused improvement (88.69%) in HCF behavior of martensite microstructure attributable to refinement in the prior β grain and development of massive α that was further transformed into ultrafine α and β during the soaking phase at cryogenic temperature.

- Significant improvement in fatigue crack propagation was observed after β-solution treatment due to formation of martensite α’ and prior β grains. Cryogenic treatment post β-solution treatment had not realized any improvement in the FCP behavior of martensite Ti-6Al-4V ELI. However, despite prior β grain reduction after CT, no decline in the FCP performance of martensite Ti-6Al-4V ELI was noticed.

- Cryotreated martensite specimen had displayed significantly improved FCP behavior when compared with MA sample in all the three regions of da/dN vs. ΔK plot attributable to crack tortuosity. Crack deflection is to disperse the strain field energy of the macroscopic crack into multiple secondary microcracks resulting in significant reduction in fatigue crack growth.

Author Contributions

Funding

Conflicts of Interest

Nomenclature and Abbreviation

| da/dN | fatigue crack growth rate |

| σy | yield strength in quasi-static tension |

| σu | ultimate tensile strength in quasi-static tension |

| A | % elongation |

| R | stress ratio |

| Mf | martensite finish temperature |

| ΔK | stress intensity factor range |

| AC | air cooling |

| COD | crack opening displacement |

| CT | cryogenic treatment |

| DCT | deep cryogenic treatment |

| EDS | energy dispersive X-ray spectroscopy |

| FCP | fatigue crack propagation |

| HCF | high cycle fatigue |

| HT | heat treatment |

| MA | mill annealed |

| RT | room temperature |

| SEM | scanning electron microscope |

| WQ | water quenching |

| ASTM | American society for testing and materials |

References

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants-A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Kurtz, S.; Ong, K.; Lau, E.; Mowat, F.; Halpern, M. Projections of Primary and Revision Hip and Knee Arthroplasty in the United States from 2005 to 2030. J. Bone Jt. Surg. 2007, 89, 780–785. [Google Scholar] [CrossRef] [PubMed]

- Rack, H.J.; Qazi, J.I. Titanium alloys for biomedical applications. Mater. Sci. Eng. C 2006, 26, 1269–1277. [Google Scholar] [CrossRef]

- Chen, Q.; George, A. Thouas Metallic implant biomaterials. Mater. Sci. Eng. R 2015, 87, 1–57. [Google Scholar] [CrossRef]

- Carrion, P.E.; Shamsaei, N.; Daniewicz, S.R.; Moser, R.D. Fatigue behavior of Ti-6Al-4V ELI including mean stress effects. Int. J. Fatigue 2017, 99, 87–100. [Google Scholar] [CrossRef]

- Renganathan, G.; Tanneru, N.; Madurai, S.L. Orthopedical and Biomedical Applications of Titanium and Zirconium Metals; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; ISBN 9780081022054. [Google Scholar]

- Teoh, S.H. Fatigue of biomaterials: A review. Int. J. Fatigue 2000, 22, 825–837. [Google Scholar] [CrossRef]

- Boyer, R.; Welsch, G.; Collings, E.W. Materials Properties Handbook: Titanium Alloys; ASM International: Materials Park, OH, USA, 1994. [Google Scholar]

- Ren, X.D.; Zhou, W.F.; Liu, F.F.; Ren, Y.P.; Yuan, S.Q.; Ren, N.F.; Xu, S.D.; Yang, T. Microstructure evolution and grain refinement of Ti-6Al-4V alloy by laser shock processing. Appl. Surf. Sci. 2016, 48, 44–49. [Google Scholar] [CrossRef]

- Magnissalis, E.; Zinelis, S.; Karachalios, T.; Hartofilakidis, G. Failure analysis of two Ti-alloy total hip arthroplasty femoral stems fractured in vivo. J. Biomed. Mater. Res. Part. B Appl. Biomater. 2003, 66B, 299–305. [Google Scholar] [CrossRef]

- Nayar, P.L.; Bohm, E.R.; Petrak, M.J.; Caley, W.F.; Cahoon, J.R. Failure analysis and mechanical testing of Ti-6Al-4V modular revision hip stems. Can. Metall. Q. 2016, 55, 420–428. [Google Scholar] [CrossRef]

- Chao, J.; López, V. Failure analysis of a Ti6Al4V cementless HIP prosthesis. Eng. Fail. Anal. 2007, 14, 822–830. [Google Scholar] [CrossRef]

- Akincioğlu, S.; Gökkaya, H.; Uygur, İ. A review of cryogenic treatment on cutting tools. Int. J. Adv. Manuf. Technol. 2015, 78, 1609–1627. [Google Scholar] [CrossRef]

- Wayne, R.; John, P. Cryoprocessing of Materials: A Review of Current Status. Mater. Manuf. Pr. Cess. 2001, 16, 829–840. [Google Scholar]

- Baldissera, P.; Delprete, C. Deep Cryogenic Treatment: A Bibliographic Review. Open Mech. Eng. J. 2008, 2, 1–11. [Google Scholar] [CrossRef]

- Kumar, T.V.; Thirumurugan, R.; Viswanath, B. Influence of cryogenic treatment on the metallurgy of ferrous alloys: A review. Mater. Manuf. Pr. Cess. 2017, 32, 1789–1805. [Google Scholar] [CrossRef]

- Patil, P.I.; Tated, R.G. Comparison of effects of cryogenic Treatment on different types of steels: A review. IJCA Pr. C. Int. Conf. Comput. Intell. 2012, 9, 10–29. [Google Scholar]

- Kalsi, N.S.; Sehgal, R.; Sharma, V.S. Cryogenic treatment of tool materials: A review. Mater. Manuf. Pr. Cess. 2010, 25, 1077–1100. [Google Scholar] [CrossRef]

- Gill, S.S.; Singh, H.; Singh, R.; Singh, J. Cryopr Cessing of cutting tool materials—A review. Int. J. Adv. Manuf. Technol. 2010, 48, 175–192. [Google Scholar] [CrossRef]

- Shokrani, A.; Dhokia, V.; Muñoz-Escalona, P.; Newman, S.T. State-of-the-art cryogenic machining and pr Cessing. Int. J. Comput. Integr. Manuf. 2013, 26, 616–648. [Google Scholar] [CrossRef]

- Singla, A.K.; Singh, J.; Sharma, V.S. Pr Cessing of materials at cryogenic temperature and its implications in manufacturing: A review. Mater. Manuf. Process. 2018, 33, 1603–1640. [Google Scholar] [CrossRef]

- Akhbarizadeh, A.; Javadpour, S.; Amini, K.; Yaghtin, A.H. Investigating the effect of ball milling during the deep cryogenic heat treatment of the 1.2080 tool steel. Kov. Mater. 2013, 90, 70–74. [Google Scholar] [CrossRef]

- Mohan, K.; Suresh, J.A.; Ramu, P.; Jayaganthan, R. Microstructure and Mechanical Behavior of Al 7075-T6 Subjected to Shallow Cryogenic Treatment. J. Mater. Eng. Perform. 2016, 25, 2185–2194. [Google Scholar] [CrossRef]

- Li, C.; Cheng, N.P.; Chen, Z.Q.; Guo, N.; Zeng, S. min Deep-cryogenic-treatment-induced phase transformation in the Al-Zn-Mg-Cu alloy. Int. J. Miner. Metall. Mater. 2015, 22, 68–77. [Google Scholar] [CrossRef]

- Gu, K.; Wang, J.; Zhou, Y. Effect of cryogenic treatment on wear resistance of Ti-6Al-4V alloy for biomedical applications. J. Mech. Behav. Biomed. Mater. 2014, 30, 131–139. [Google Scholar] [CrossRef] [PubMed]

- Singla, A.K.; Singh, J.; Sharma, V.S. Impact of Cryogenic Treatment on Mechanical Behavior and Microstructure of Ti-6Al-4V ELI Biomaterial. J. Mater. Eng. Perform. 2019, 28, 5931–5945. [Google Scholar] [CrossRef]

- Standard Specification for Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical Implant Applications; UNS R56401; ASTM—American Society for Testing and Materials: West Conshohocken, PA, USA, 2013.

- Matthew, J.; Donachie, J. Titanium A Technical Guide; ASM International: Materials Park, OH, USA, 2004. [Google Scholar]

- Meyer, L.W.; Krüger, L.; Sommer, K.; Halle, T.; H Ckauf, M. Dynamic strength and failure behavior of titanium alloy Ti-6Al-4V for a variation of heat treatments. Mech. Time Depend. Mater. 2008, 12, 237–247. [Google Scholar] [CrossRef]

- Nalla, R.K.; Boyce, B.L.; Campbell, J.P.; Peters, J.O.; Ritchie, R.O. Influence of microstructure on high-cycle fatigue of Ti-6Al-4V: Bimodal vs. lamellar structures. Metall. Mater. Trans. A 2002, 33, 899–918. [Google Scholar] [CrossRef]

- Reda, R.; Nofal, A.A.; Hussein, A.H.A. Effect of Quenching Temperature on the Mechanical Properties of Cast Ti-6Al-4V Alloy. J. Metall. Eng. 2013, 2, 48–54. [Google Scholar]

- Rozumek, D.; Hepner, M. Influence of microstructure on fatigue crack propagation under bending in the alloy Ti-6Al-4V after heat treatment. Materwiss. Werksttech. 2015, 46, 1088–1095. [Google Scholar] [CrossRef]

- Imam, M.A.; Fraker, A.C.; Harris, J.S.; Gilmore, C.M. INFLUENCE OF HEAT TREATMENT ON THE FATIGUE LIVES OF Ti-6Al-4V AND Ti-4.5Al-5Mo-1.5Cr. ASTM Spec. Tech. Publ. 1983, 1, 105–119. [Google Scholar]

- Dumbleton, J.H. Tribology of Natural and Artificial Joints; Elsevier: New York, NY, USA, 1981. [Google Scholar]

- Paul, J.P. Forces transmitted by joints in the human body. SAGE J. 2006, 181, 8–15. [Google Scholar]

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Gu, K.; Zhang, H.; Zhao, B.; Wang, J.; Zhou, Y.; Li, Z. Effect of cryogenic treatment and aging treatment on the tensile properties and microstructure of Ti-6Al-4V alloy. Mater. Sci. Eng. A 2013, 584, 170–176. [Google Scholar] [CrossRef]

- Sallica-leva, E.; Caram, R.; Jardini, A.L.; Fogagnolo, J.B. Ductility improvement due to martensite α’ decomposition in porous Ti-6Al-4V parts produced by selective laser melting for orthopedic implants. J. Mech. Behav. Biomed. Mater. 2016, 54, 149–158. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, T.; Rack, H.J. Phase transformations during cooling in α + β titanium alloys. Mater. Sci. Eng. A 1998, 243, 206–211. [Google Scholar] [CrossRef]

- Lu, S.L.; Qian, M.; Tang, H.P.; Yan, M.; Wang, J.; Stjohn, D.H. Massive transformation in Ti-6Al-4V additively manufactured by selective electron beam melting. Acta Mater. 2016, 104, 303–311. [Google Scholar] [CrossRef]

- Jeong, D.; Kwon, Y.; Goto, M.; Kim, S. High cycle fatigue and fatigue crack propagation behavior of β-annealed Ti-6Al-4V alloy. Int. J. Mech. Mater. Eng. 2017, 12, 1–10. [Google Scholar] [CrossRef]

- Sen, I.; Tamirisakandala, S.; Miracle, D.B.; Ramamurty, U. Microstructural effects on the mechanical behavior of B-modified Ti-6Al-4V alloys. Acta Mater. 2007, 55, 4983–4993. [Google Scholar] [CrossRef]

- Seo, W.; Jeong, D.; Lee, D.; Sung, H.; Kwon, Y.; Kim, S. Effects of cooling rate and stabilization annealing on fatigue behavior of β-processed Ti-6Al-4V alloys. Met. Mater. Int. 2017, 23, 648–659. [Google Scholar] [CrossRef]

- Yoder, G.R.; Gooley, L.A.; Crooker, T.W. Enhancement of fatigue Crack Growth and Fracture Resistance in TI-6AI-4V anl Ti-6AI- 6V-2Sn Through Microstructural Modification. J. Eng. Mater. Technol. 1977, 99, 313–318. [Google Scholar] [CrossRef]

| Ti-6Al-4V ELI | Fe | C | N | H | O | Al | V | Ti |

|---|---|---|---|---|---|---|---|---|

| As per ASTM F136-13 | ≤0.25 | ≤0.08 | ≤0.05 | ≤0.012 | 0.13 | 5.5–6.5 | 3.5–4.5 | balance |

| As received material | 0.04 | 0.02 | 0.01 | 0.001 | 0.10 | 5.9 | 4.2 | balance |

| Material | σy (MPa) | σu (MPa) | A (%) | HRC |

|---|---|---|---|---|

| MA Ti-6Al-4V ELI | 958 | 1040 | 19.6 | 32 |

| Thermal Cycle | Specimen Code |

|---|---|

| β-solution treatment (1035 °C/1 h, WQ) + aging (600 °C/2 h, AC) | B1 |

| β-solution treatment (1035 °C/1 h, WQ) + aging (600 °C/2 h, AC) + DCT(−196 °C/24 h) + tempering (170 °C/4 h, AC) | B2 |

| mill annealed (MA) | MA |

| Parameter | Value of the Parameter |

|---|---|

| Stress ratio R | −1 |

| Stress amplitude | 604 MPa |

| Frequency | 20 Hz |

| Parameters of FCP Test | Value of the Parameter |

|---|---|

| Load | 4 kN |

| Frequency | 10 Hz |

| Stress ratio R | 0.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singla, A.K.; Singh, J.; Sharma, V.S.; Gupta, M.K.; Song, Q.; Rozumek, D.; Krolczyk, G.M. Impact of Cryogenic Treatment on HCF and FCP Performance of β-Solution Treated Ti-6Al-4V ELI Biomaterial. Materials 2020, 13, 500. https://doi.org/10.3390/ma13030500

Singla AK, Singh J, Sharma VS, Gupta MK, Song Q, Rozumek D, Krolczyk GM. Impact of Cryogenic Treatment on HCF and FCP Performance of β-Solution Treated Ti-6Al-4V ELI Biomaterial. Materials. 2020; 13(3):500. https://doi.org/10.3390/ma13030500

Chicago/Turabian StyleSingla, Anil Kumar, Jagtar Singh, Vishal S. Sharma, Munish Kumar Gupta, Qinghua Song, Dariusz Rozumek, and Grzegorz M. Krolczyk. 2020. "Impact of Cryogenic Treatment on HCF and FCP Performance of β-Solution Treated Ti-6Al-4V ELI Biomaterial" Materials 13, no. 3: 500. https://doi.org/10.3390/ma13030500

APA StyleSingla, A. K., Singh, J., Sharma, V. S., Gupta, M. K., Song, Q., Rozumek, D., & Krolczyk, G. M. (2020). Impact of Cryogenic Treatment on HCF and FCP Performance of β-Solution Treated Ti-6Al-4V ELI Biomaterial. Materials, 13(3), 500. https://doi.org/10.3390/ma13030500