Electromechanical Behaviors of Graphene Reinforced Polymer Composites: A Review

Abstract

:1. Introduction

2. Graphene-Reinforced Polymer Composites

2.1. Graphene

- (a)

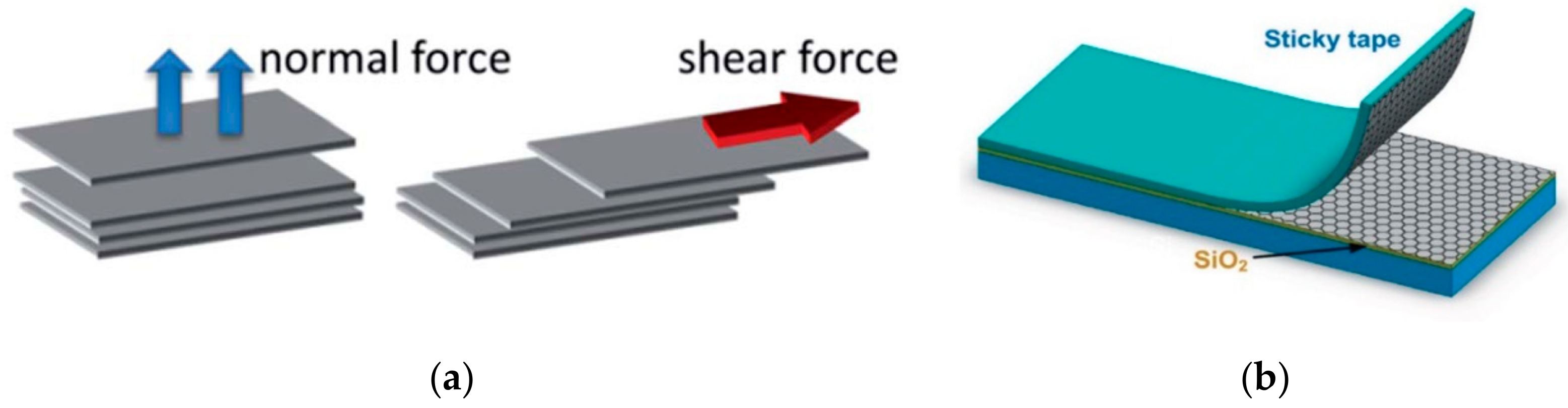

- Mechanical Exfoliation

- (b)

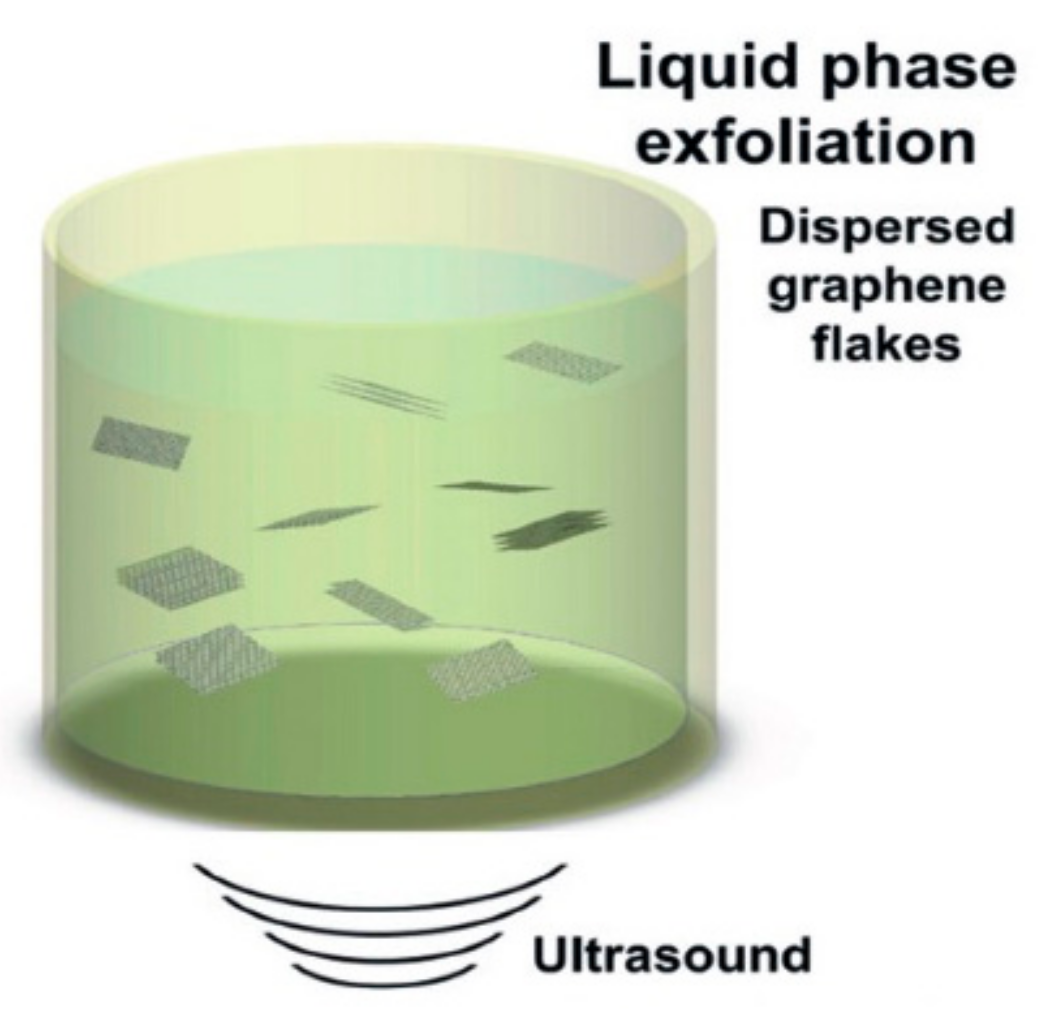

- Liquid Phase Exfoliation

- (c)

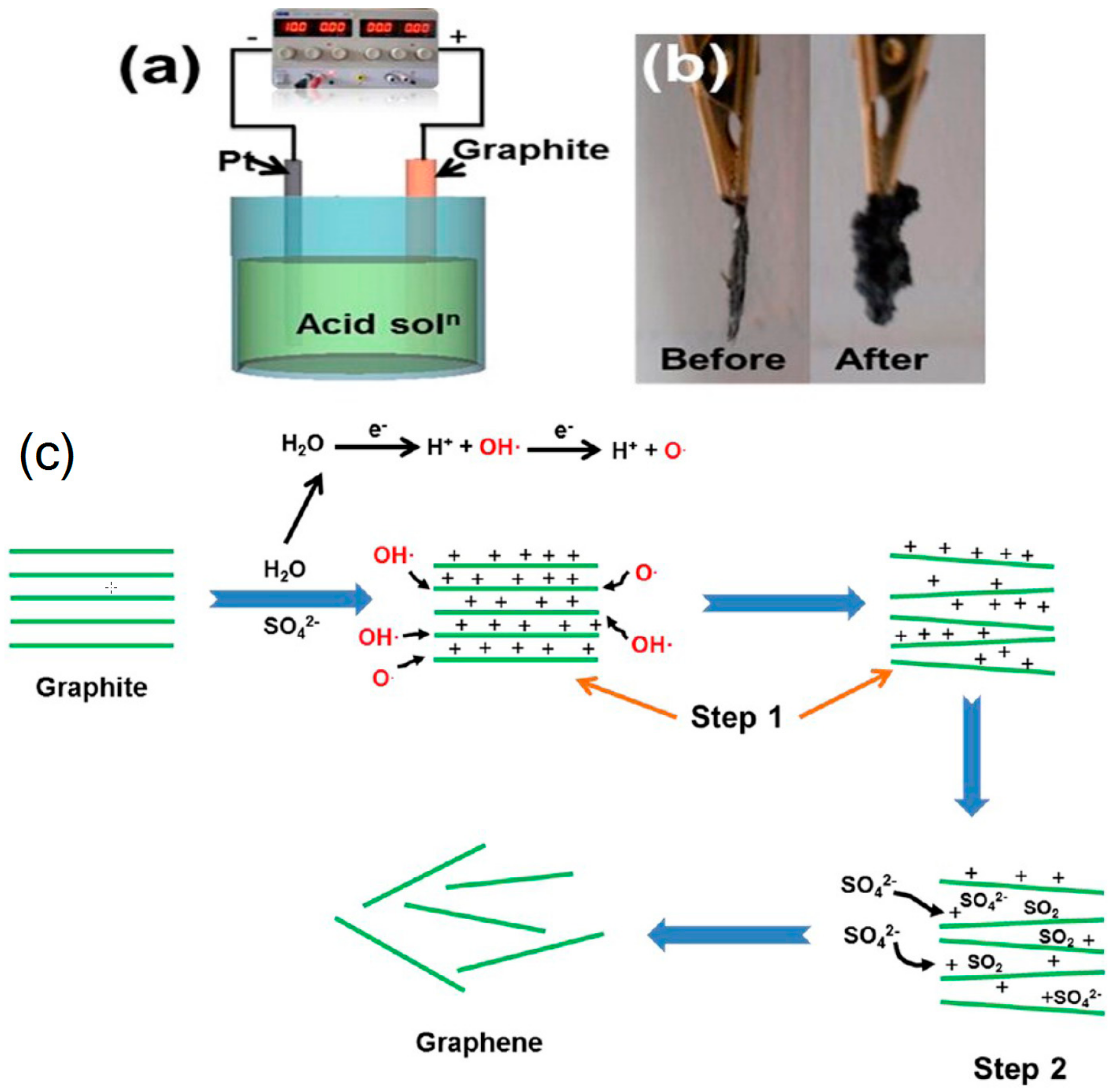

- Electrochemical Exfoliation

- (d)

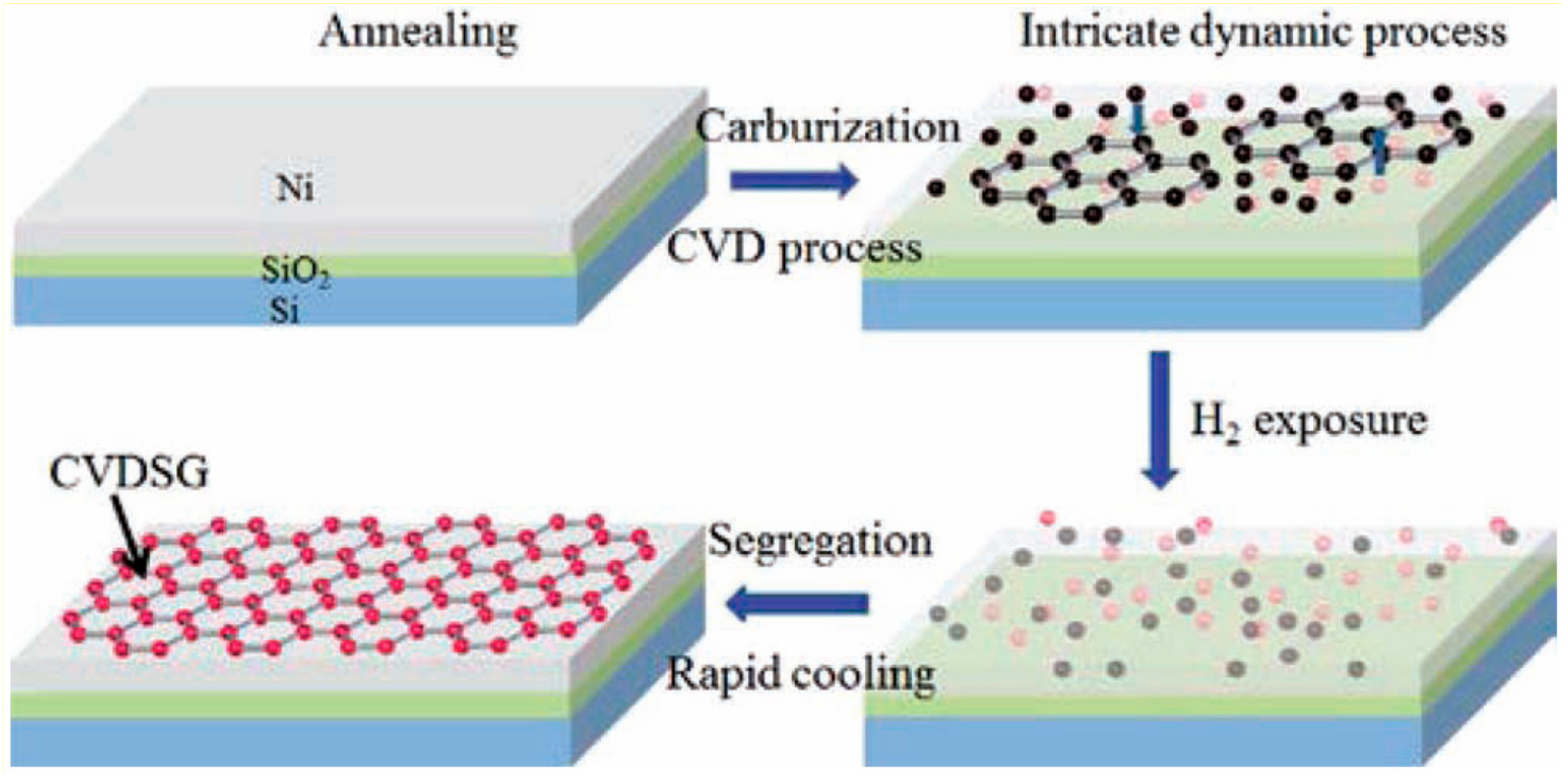

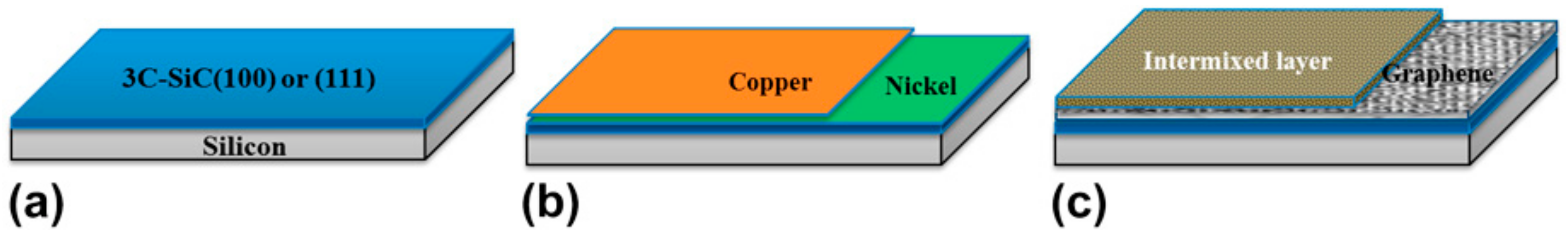

- Chemical Vapor Deposition

- (e)

- Reduction of Graphene Oxide

- (f)

- Epitaxial Growth

2.2. Polymer Matrix

2.3. Graphene Reinforced Polymer Composites

- (a)

- Solution Mixing

- (b)

- Melt Blending

- (c)

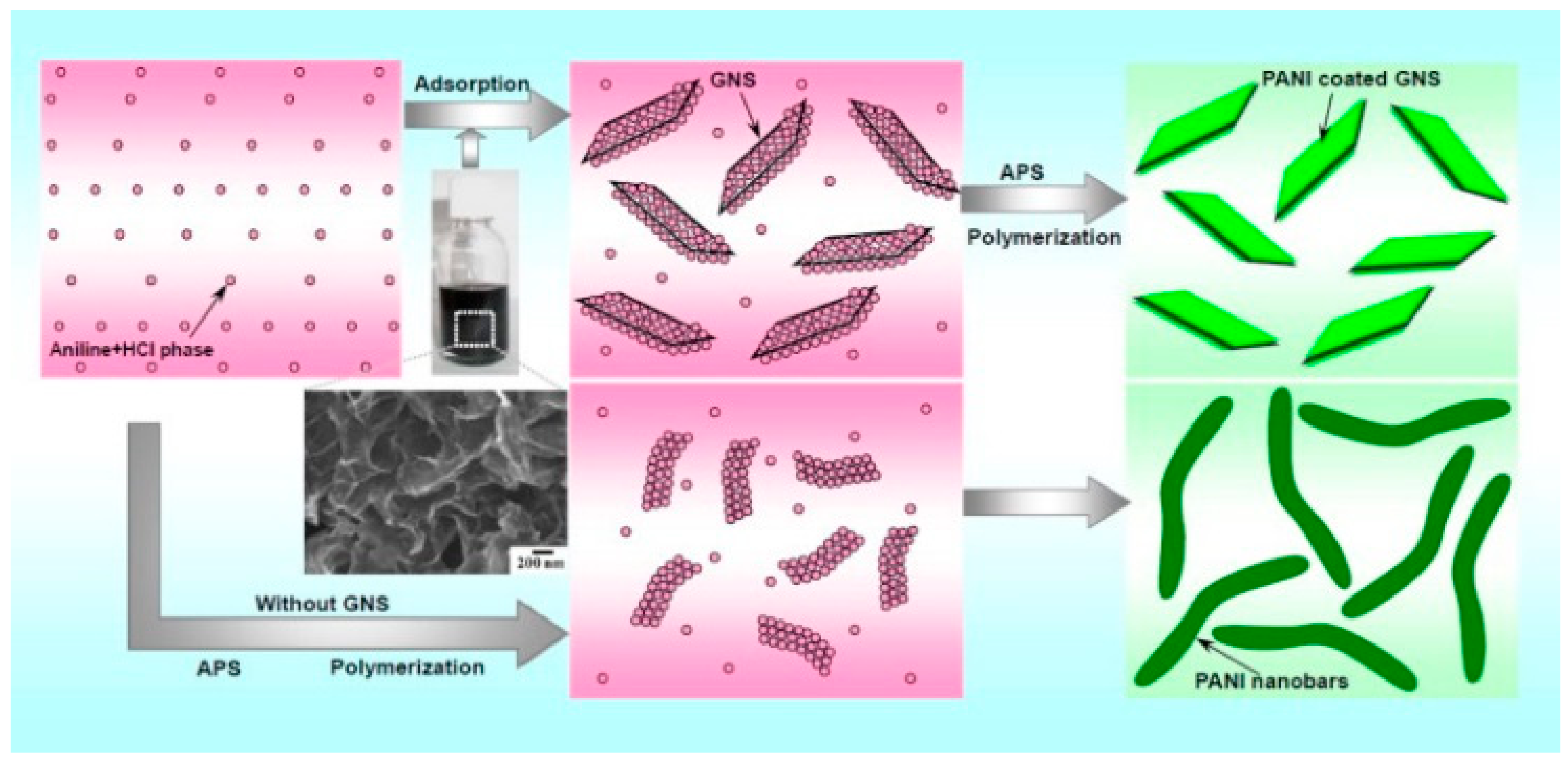

- In Situ Polymerization

- (d)

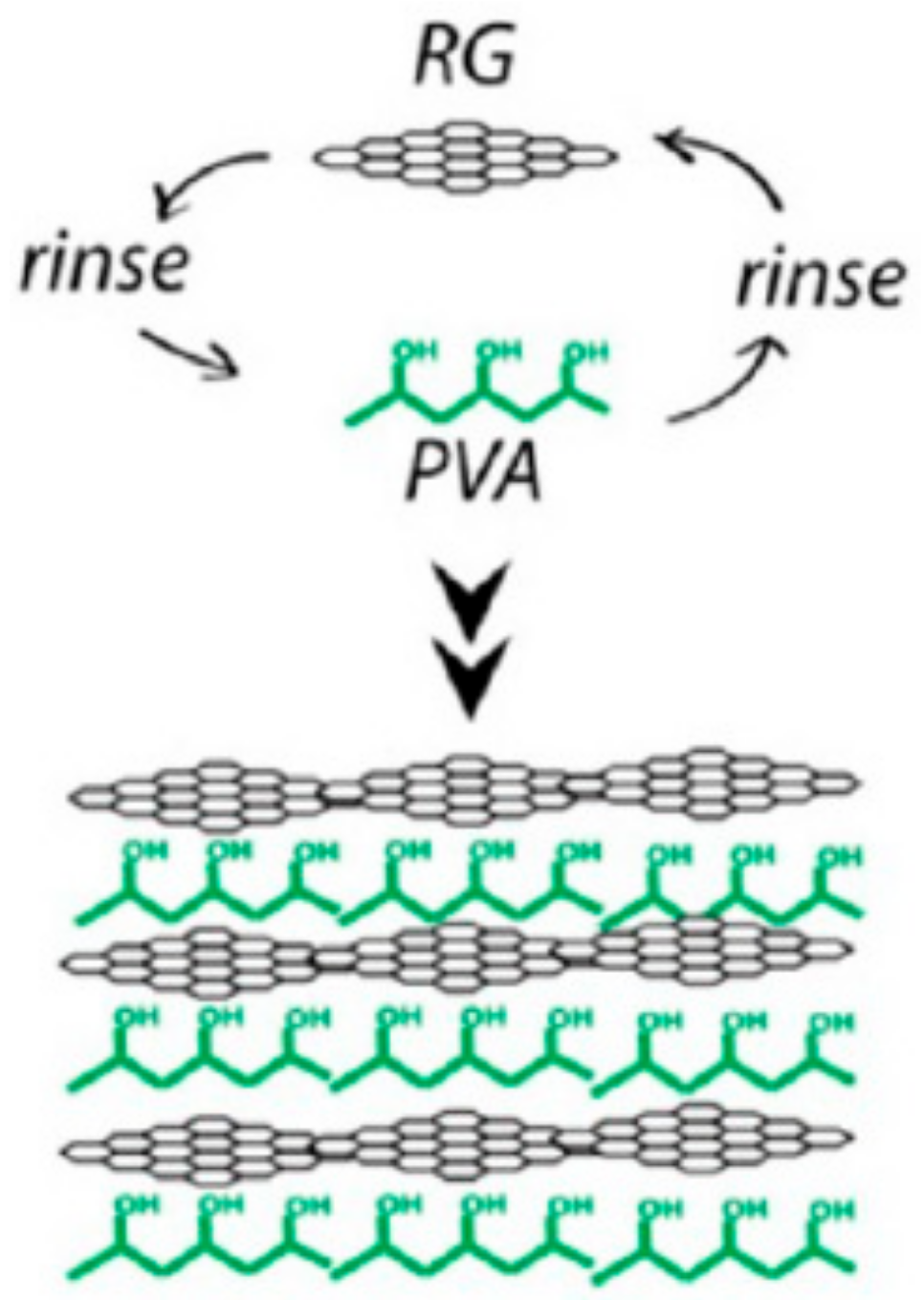

- Layer-by-Layer Assembly

3. Electromechanical Behaviors

3.1. Experiments

3.2. Theoretical Modeling

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef] [PubMed]

- Du, X.; Skachko, I.; Barker, A.; Andrei, E.Y. Approaching ballistic transport in suspended graphene. Nat. Nanotechnol. 2008, 3, 491–495. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Novoselov, K.S.; Fal, V.I.; Colombo, L.; Gellert, P.R.; Schwab, M.G.; Kim, K. A roadmap for graphene. Nature 2012, 490, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Rafiee, M.A.; Rafiee, J.; Wang, Z.; Song, H.; Yu, Z.Z.; Koratkar, N. Enhanced mechanical properties of nanocomposites at low graphene content. ACS Nano 2009, 3, 3884–3890. [Google Scholar] [CrossRef]

- Hernandez, Y.; Nicolosi, V.; Lotya, M.; Blighe, F.M.; Sun, Z.; De, S.; McGovern, I.T.; Holland, B.; Byrne, M.; Gun’Ko, Y.K. High-yield production of graphene by liquid-phase exfoliation of graphite. Nat. Nanotechnol. 2008, 3, 563–568. [Google Scholar] [CrossRef] [Green Version]

- Coleman, J.N. Liquid-phase exfoliation of nanotubes and graphene. Adv. Func. Mater. 2009, 19, 3680–3695. [Google Scholar] [CrossRef]

- Su, C.Y.; Lu, A.Y.; Xu, Y.; Chen, F.R.; Khlobystov, A.N.; Li, L.J. High-quality thin graphene films from fast electrochemical exfoliation. ACS Nano 2011, 5, 2332–2339. [Google Scholar] [CrossRef]

- Wei, D.; Grande, L.; Chundi, V.; White, R.; Bower, C.; Andrew, P.; Ryhänen, T. Graphene from electrochemical exfoliation and its direct applications in enhanced energy storage devices. Chem. Commun. 2012, 48, 1239–1241. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Piner, R.D.; Kohlhaas, K.A.; Kleinhammes, A.; Jia, Y.; Wu, Y.; Nguyen, S.T.; Ruoff, R.S. Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 2007, 45, 1558–1565. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Graphene and graphene oxide: Synthesis, properties, and applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef] [PubMed]

- Obraztsov, A.N. Chemical vapour deposition: Making graphene on a large scale. Nat. Nanotechnol. 2009, 4, 212–213. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.S.; Zhao, Y.; Jang, H.; Lee, S.Y.; Kim, J.M.; Kim, K.S.; Ahn, J.H.; Kim, P.; Choi, J.Y.; Hong, B.H. Large-scale pattern growth of graphene films for stretchable transparent electrodes. Nature 2009, 457, 706–710. [Google Scholar] [CrossRef] [PubMed]

- Hass, J.; De Heer, W.A.; Conrad, E.H. The growth and morphology of epitaxial multilayer graphene. J. Phys. Condens. Matter. 2008, 20, 323202. [Google Scholar] [CrossRef]

- Lalmi, B.; Oughaddou, H.; Enriquez, H.; Kara, A.; Vizzini, S.; Ealet, B.; Aufray, B. Epitaxial growth of a silicene sheet. J. Appl. Phys. Lett. 2010, 97, 223109. [Google Scholar] [CrossRef] [Green Version]

- Araby, S.; Meng, Q.; Zhang, L.; Kang, H.; Majewski, P.; Tang, Y.; Ma, J. Electrically and thermally conductive elastomer/graphene nanocomposites by solution mixing. Polymer 2014, 55, 201–210. [Google Scholar] [CrossRef]

- Liu, J.; Chen, G.; Jiang, M. Supramolecular hybrid hydrogels from noncovalently functionalized graphene with block copolymers. Macromolecules 2011, 44, 7682–7691. [Google Scholar] [CrossRef]

- Shen, X.J.; Liu, Y.; Xiao, H.M.; Feng, Q.P.; Yu, Z.Z.; Fu, S.Y. The reinforcing effect of graphene nanosheets on the cryogenic mechanical properties of epoxy resins. Compos. Sci. Technol. 2012, 72, 1581–1587. [Google Scholar] [CrossRef]

- Eswaraiah, V.; Balasubramaniam, K.; Ramaprabhu, S. Functionalized graphene reinforced thermoplastic nanocomposites as strain sensors in structural health monitoring. J. Mater. Chem. 2011, 21, 12626–12628. [Google Scholar] [CrossRef]

- Nguyen, D.A.; Lee, Y.R.; Raghu, A.V.; Jeong, H.M.; Shin, C.M.; Kim, B.K. Morphological and physical properties of a thermoplastic polyurethane reinforced with functionalized graphene sheet. Polym. Int. 2009, 58, 412–417. [Google Scholar] [CrossRef]

- Hsiao, S.-T.; Ma, C.-C.M.; Tien, H.-W.; Liao, W.-H.; Wang, Y.-S.; Li, S.-M.; Huang, Y.-C. Using a non-covalent modification to prepare a high electromagnetic interference shielding performance graphene nanosheet/water-borne polyurethane composite. Carbon 2013, 60, 57–66. [Google Scholar] [CrossRef]

- Cong, H.-P.; Ren, X.-C.; Wang, P.; Yu, S.-H. Macroscopic multifunctional graphene-based hydrogels and aerogels by a metal ion induced self-assembly process. ACS Nano 2012, 6, 2693–2703. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Zhang, Q.; Chen, D.; Lu, P. Enhanced mechanical properties of graphene-based poly (vinyl alcohol) composites. Macromolecules 2010, 43, 2357–2363. [Google Scholar] [CrossRef]

- Sun, R.; Li, L.; Feng, C.; Kitipornchai, S.; Yang, J. Tensile behavior of polymer nanocomposite reinforced with graphene containing defects. Eur. Polym. J. 2018, 98, 475–482. [Google Scholar] [CrossRef]

- Sun, R.; Li, L.; Feng, C.; Kitipornchai, S.; Yang, J. Tensile property enhancement of defective graphene/epoxy nanocomposite by hydrogen functionalization. Compos. Struct. 2019, 224, 111079. [Google Scholar] [CrossRef]

- Sun, R.; Li, L.; Zhao, S.; Feng, C.; Kitipornchai, S.; Yang, J. Temperature-dependent mechanical properties of defective graphene reinforced polymer nanocomposite. Mech. Adv. Mater. Struct. 2019, 1–10. [Google Scholar] [CrossRef]

- Rahman, R.; Haque, A. Molecular modeling of crosslinked graphene-epoxy nanocomposites for characterization of elastic constants and interfacial properties. Compos. Part B Eng. 2013, 54, 353–364. [Google Scholar] [CrossRef]

- Rahman, R. The role of graphene in enhancing the stiffness of polymeric material: A molecular modeling approach. J. Appl. Phys. 2013, 113, 243503. [Google Scholar] [CrossRef]

- Rahman, R.; Foster, J.T. Deformation mechanism of graphene in amorphous polyethylene: A molecular dynamics based study. Comput. Mater. Sci. 2014, 87, 232–240. [Google Scholar] [CrossRef]

- Rahman, R.; Foster, J.T.; Haque, A. Molecular dynamics simulation and characterization of graphene-cellulose nanocomposites. J. Phys. Chem. 2013, 117, 5344–5353. [Google Scholar] [CrossRef]

- Ji, X.Y.; Cao, Y.P.; Feng, X.Q. Micromechanics prediction of the effective elastic moduli of graphene sheet-reinforced polymer nanocomposites. Model. Simul. Mater. Sci. Eng. 2010, 18, 045005. [Google Scholar] [CrossRef]

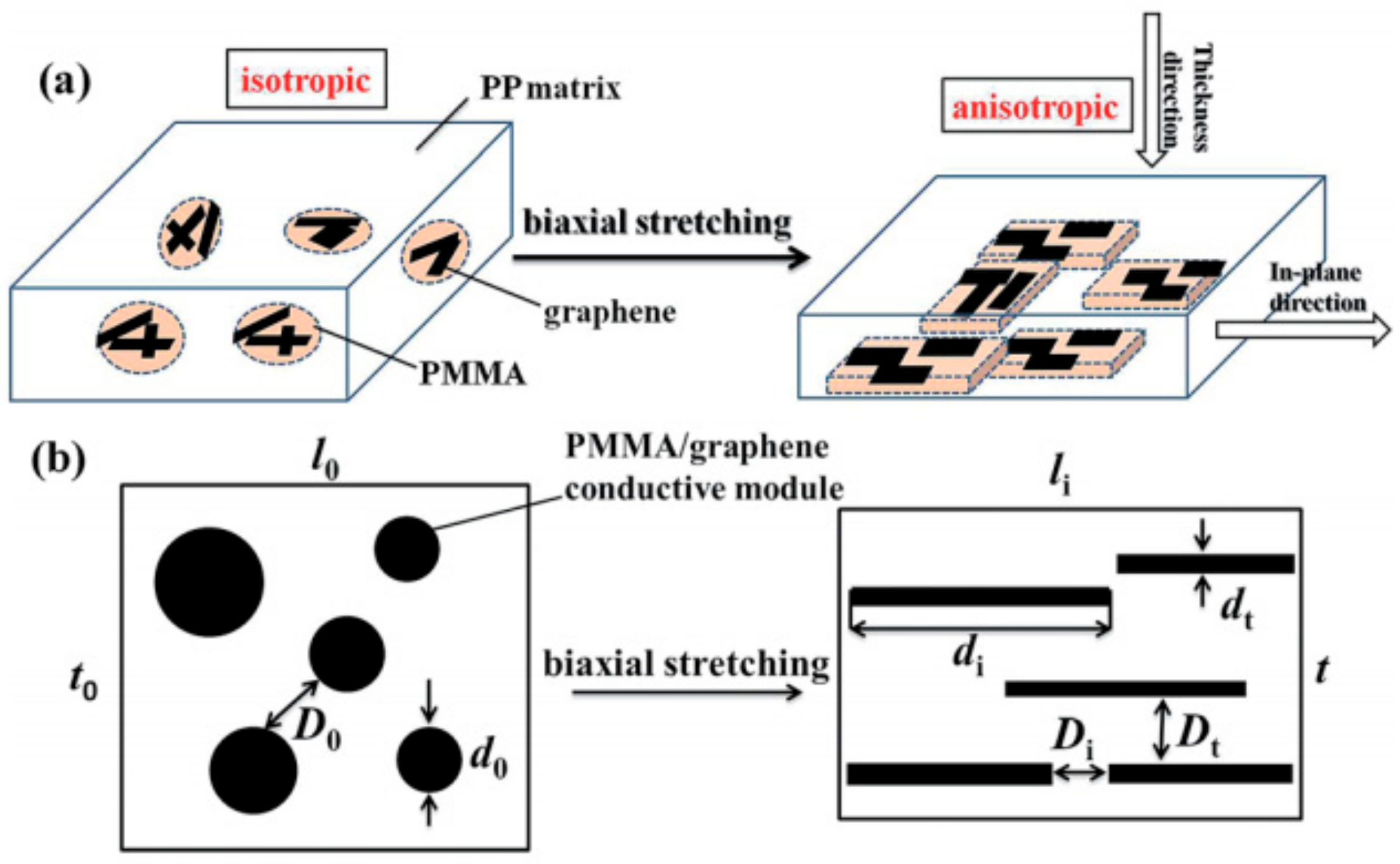

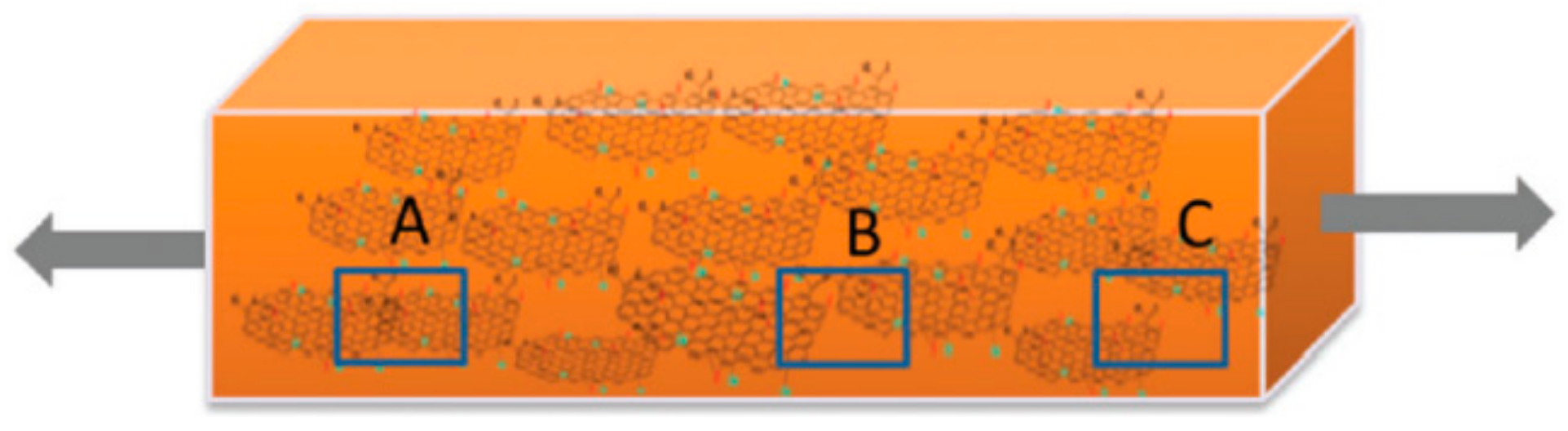

- Feng, C.; Wang, Y.; Kitipornchai, S.; Yang, J. Effects of reorientation of graphene platelets (GPLs) on Young’s modulus of polymer nanocomposites under uni-axial stretching. Polymers 2017, 9, 532. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Spanos, K.; Georgantzinos, S.; Anifantis, N. Mechanical properties of graphene nanocomposites: A multiscale finite element prediction. Compos. Struct. 2015, 132, 536–544. [Google Scholar] [CrossRef]

- Feng, C.; Wang, Y.; Yang, J. Effects of reorientation of graphene platelets (GPLs) on Young’s modulus of polymer composites under bi-axial stretching. Nanomaterials 2018, 8, 27. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tang, L.C.; Wan, Y.J.; Yan, D.; Pei, Y.B.; Zhao, L.; Li, Y.B.; Wu, L.B.; Jiang, J.X.; Lai, G.Q. The effect of graphene dispersion on the mechanical properties of graphene/epoxy composites. Carbon 2013, 60, 16–27. [Google Scholar] [CrossRef]

- Hu, K.; Gupta, M.K.; Kulkarni, D.D.; Tsukruk, V.V. Ultra-robust graphene oxide-silk fibroin nanocomposite membranes. Adv. Mater. 2013, 25, 2301–2307. [Google Scholar] [CrossRef]

- Liang, J.; Huang, Y.; Zhang, L.; Wang, Y.; Ma, Y.; Guo, T.; Chen, Y. Molecular-level dispersion of graphene into poly (vinyl alcohol) and effective reinforcement of their nanocomposites. Adv. Func. Mater. 2009, 19, 2297–2302. [Google Scholar] [CrossRef]

- Lee, J.K.; Song, S.; Kim, B. Functionalized graphene sheets-epoxy based nanocomposite for cryotank composite application. Polym. Compos. 2012, 33, 1263–1273. [Google Scholar] [CrossRef]

- Hu, K.; Kulkarni, D.D.; Choi, I.; Tsukruk, V.V. Graphene-polymer nanocomposites for structural and functional applications. Prog. Polym. Sci. 2014, 39, 1934–1972. [Google Scholar] [CrossRef]

- Shokrieh, M.; Esmkhani, M.; Shahverdi, H.; Vahedi, F. Effect of graphene nanosheets (GNS) and graphite nanoplatelets (GNP) on the mechanical properties of epoxy nanocomposites. Sci. Adv. Mater. 2013, 5, 260–266. [Google Scholar] [CrossRef]

- Imran, K.A.; Shivakumar, K.N. Graphene-modified carbon/epoxy nanocomposites: Electrical, thermal and mechanical properties. J. Compos. Mater. 2019, 53, 93–106. [Google Scholar] [CrossRef]

- Ravindran, A.; Feng, C.; Huang, S.; Wang, Y.; Zhao, Z.; Yang, J. Effects of graphene nanoplatelet size and surface area on the AC electrical conductivity and dielectric constant of epoxy nanocomposites. Polymers 2018, 10, 477. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fan, P.; Wang, L.; Yang, J.; Chen, F.; Zhong, M. Graphene/poly(vinylidene fluoride) composites with high dielectric constant and low percolation threshold. Nanotechnology 2012, 23, 365702. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Zhuang, Q.; Liu, X.; Liu, J.; Lin, S.; Han, Z. Preparation of thermostable PBO/graphene nanocomposites with high dielectric constant. Nanotechnology 2013, 24, 245702. [Google Scholar] [CrossRef] [PubMed]

- He, F.; Lau, S.; Chan, H.L.; Fan, J. High dielectric permittivity and low percolation threshold in nanocomposites based on poly (vinylidene fluoride) and exfoliated graphite nanoplates. Adv. Mater. 2009, 21, 710–715. [Google Scholar] [CrossRef]

- Xia, X.; Wang, Y.; Zhong, Z.; Weng, G.J. A frequency-dependent theory of electrical conductivity and dielectric permittivity for graphene-polymer nanocomposites. Carbon 2017, 111, 221–230. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, C.; Santiuste, C.; Zhao, Z.; Yang, J. Buckling and postbuckling of dielectric composite beam reinforced with Graphene Platelets (GPLs). Aerosp. Sci. Technol. 2019, 91, 208–218. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, C.; Wang, X.; Zhao, Z.; Romero, C.S.; Yang, J. Nonlinear free vibration of graphene platelets (GPLs)/polymer dielectric beam. Smart Mater. Struct. 2019, 28, 055013. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, C.; Wang, X.; Zhao, Z.; Romero, C.S.; Dong, Y.; Yang, J. Nonlinear static and dynamic responses of graphene platelets reinforced composite beam with dielectric permittivity. Appl. Math. Model. 2019, 71, 298–315. [Google Scholar] [CrossRef]

- Wang, W.; Jayatissa, A.H. Computational and experimental study of electrical conductivity of graphene/poly (methyl methacrylate) nanocomposite using Monte Carlo method and percolation theory. Synth. Met. 2015, 204, 141–147. [Google Scholar] [CrossRef]

- Ding, J.; Fan, Y.; Zhao, C.; Liu, Y.; Yu, C.; Yuan, N. Electrical conductivity of waterborne polyurethane/graphene composites prepared by solution mixing. J. Compos. Mater. 2012, 46, 747–752. [Google Scholar] [CrossRef]

- Qi, X.Y.; Yan, D.; Jiang, Z.; Cao, Y.K.; Yu, Z.Z.; Yavari, F.; Koratkar, N. Enhanced electrical conductivity in polystyrene nanocomposites at ultra-low graphene content. ACS Appl. Mater. Interfaces 2011, 3, 3130–3133. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Miura, Y.; Macosko, C.W. Graphene/polyurethane nanocomposites for improved gas barrier and electrical conductivity. Chem. Mater. 2010, 22, 3441–3450. [Google Scholar] [CrossRef]

- Wang, Y.; Shan, J.W.; Weng, G.J. Percolation threshold and electrical conductivity of graphene-based nanocomposites with filler agglomeration and interfacial tunneling. J. Appl. Phys. 2015, 118, 065101. [Google Scholar] [CrossRef]

- Xia, X.; Hao, J.; Wang, Y.; Zhong, Z.; Weng, G.J. Theory of electrical conductivity and dielectric permittivity of highly aligned graphene-based nanocomposites. J. Phys. Condens. Matter. 2017, 29, 205702. [Google Scholar] [CrossRef]

- Yi, M.; Shen, Z.A. Review on mechanical exfoliation for the scalable production of graphene. J. Mater. Chem. A 2015, 3, 11700–11715. [Google Scholar] [CrossRef]

- Bonaccorso, F.; Lombardo, A.; Hasan, T.; Sun, Z.; Colombo, L.; Ferrari, A.C. Production and processing of graphene and 2d crystals. Mater. Today 2012, 15, 564–589. [Google Scholar] [CrossRef]

- Gong, L.; Kinloch, I.A.; Young, R.J.; Riaz, I.; Jalil, R.; Novoselov, K.S. Interfacial stress transfer in a graphene monolayer nanocomposite. Adv. Mater. 2010, 22, 2694–2697. [Google Scholar] [CrossRef] [Green Version]

- Kuila, T.; Khanra, P.; Kim, N.H.; Choi, S.K.; Yun, H.J.; Lee, J.H. One-step electrochemical synthesis of 6-amino-4-hydroxy-2-napthalene-sulfonic acid functionalized graphene for green energy storage electrode materials. Nanotechnology 2013, 24, 365706. [Google Scholar] [CrossRef]

- Wang, J.; Manga, K.K.; Bao, Q.; Loh, K.P. High-yield synthesis of few-layer graphene flakes through electrochemical expansion of graphite in propylene carbonate electrolyte. J. Am. Chem. Soc. 2011, 133, 8888–8891. [Google Scholar] [CrossRef]

- Zhou, M.; Tang, J.; Cheng, Q.; Xu, G.; Cui, P.; Qin, L.C. Few-layer graphene obtained by electrochemical exfoliation of graphite cathode. Chem. Phys. Lett. 2013, 572, 61–65. [Google Scholar] [CrossRef]

- Yang, Y.; Lu, F.; Zhou, Z.; Song, W.; Chen, Q.; Ji, X. Electrochemically cathodic exfoliation of graphene sheets in room temperature ionic liquids N-butyl, methylpyrrolidinium bis (trifluoromethylsulfonyl) imide and their electrochemical properties. Electrochim. Acta 2013, 113, 9–16. [Google Scholar] [CrossRef]

- Parvez, K.; Li, R.; Puniredd, S.R.; Hernandez, Y.; Hinkel, F.; Wang, S.; Feng, X.; Muüllen, K. Electrochemically exfoliated graphene as solution-processable, highly conductive electrodes for organic electronics. ACS Nano 2013, 7, 3598–3606. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gong, Y.; Zhang, X.; Liu, G.; Wu, L.; Geng, X.; Long, M.; Cao, X.; Guo, Y.; Li, W.; Xu, J. Layer-controlled and wafer-scale synthesis of uniform and high-quality graphene films on a polycrystalline nickel catalyst. Adv. Func. Mater. 2012, 22, 3153–3159. [Google Scholar] [CrossRef]

- Iacopi, F.; Mishra, N.; Cunning, B.V.; Goding, D.; Dimitrijev, S.; Brock, R.; Dauskardt, R.H.; Wood, B.; Boeckl, J. A catalytic alloy approach for graphene on epitaxial SiC on silicon wafers. J. Mater. Res. 2015, 30, 609–616. [Google Scholar] [CrossRef] [Green Version]

- Emtsev, K.V.; Bostwick, A.; Horn, K.; Jobst, J.; Kellogg, G.L.; Ley, L.; McChesney, J.L.; Ohta, T.; Reshanov, S.A.; Röhrl, J. Towards wafer-size graphene layers by atmospheric pressure graphitization of silicon carbide. Nat. Mater. 2009, 8, 203–207. [Google Scholar] [CrossRef] [PubMed]

- Cai, D.; Yusoh, K.; Song, M. The mechanical properties and morphology of a graphite oxide nanoplatelet/polyurethane composite. Nanotechnology 2009, 20, 085712. [Google Scholar] [CrossRef]

- Ozbas, B.; O’Neill, C.D.; Register, R.A.; Aksay, I.A.; Prud’homme, R.K.; Adamson, D.H. Multifunctional elastomer nanocomposites with functionalized graphene single sheets. J. Polym. Sci. Part B Polym. Phys. 2012, 50, 910–916. [Google Scholar] [CrossRef]

- Steurer, P.; Wissert, R.; Thomann, R.; Mülhaupt, R. Functionalized graphenes and thermoplastic nanocomposites based upon expanded graphite oxide. Macromol. Rapid Commun. 2009, 30, 316–327. [Google Scholar] [CrossRef]

- Bao, C.; Guo, Y.; Song, L.; Kan, Y.; Qian, X.; Hu, Y. In situ preparation of functionalized graphene oxide/epoxy nanocomposites with effective reinforcements. J. Mater. Chem. 2011, 21, 13290–13298. [Google Scholar] [CrossRef]

- Zaman, I.; Phan, T.T.; Kuan, H.-C.; Meng, Q.; La, L.T.B.; Luong, L.; Youssf, O.; Ma, J. Epoxy/graphene platelets nanocomposites with two levels of interface strength. Polymer 2011, 52, 1603–1611. [Google Scholar] [CrossRef] [Green Version]

- Gröschel, A.H.; Löbling, T.I.; Petrov, P.D.; Müllner, M.; Kuttner, C.; Wieberger, F.; Müller, A.H. Janus micelles as effective supracolloidal dispersants for carbon nanotubes. Angew. Chem. 2013, 52, 3602–3606. [Google Scholar] [CrossRef] [PubMed]

- Bockstaller, M.R.; Mickiewicz, R.A.; Thomas, E.L. Block copolymer nanocomposites: Perspectives for tailored functional materials. Adv. Mater. 2005, 17, 1331–1349. [Google Scholar] [CrossRef]

- Das, P.; Schipmann, S.; Malho, J.M.; Zhu, B.; Klemradt, U.; Walther, A. Facile access to large-scale, self-assembled, nacre-inspired, high-performance materials with tunable nanoscale periodicities. ACS Appl. Mater. Interfaces 2013, 5, 3738–3747. [Google Scholar] [CrossRef] [PubMed]

- Lozano, K.; Barrera, E. Nanofiber-reinforced thermoplastic composites. I. Thermoanalytical and mechanical analyses. J. Appl. Polym. Sci. 2001, 79, 125–133. [Google Scholar] [CrossRef]

- Yu, A.D.; Liu, C.L.; Chen, W.C. Supramolecular block copolymers: Graphene oxide composites for memory device applications. Chem. Commun. 2012, 48, 383–385. [Google Scholar] [CrossRef]

- Seo, J.-W.T.; Green, A.A.; Antaris, A.L.; Hersam, M.C. High-concentration aqueous dispersions of graphene using nonionic, biocompatible block copolymers. J. Phys. Chem. Lett. 2011, 2, 1004–1008. [Google Scholar] [CrossRef]

- Worsley, M.A.; Pauzauskie, P.J.; Olson, T.Y.; Biener, J.; Satcher, J.H., Jr.; Baumann, T.F. Synthesis of graphene aerogel with high electrical conductivity. J. Am. Chem. Soc. 2010, 132, 14067–14069. [Google Scholar] [CrossRef]

- Qi, X.; Yao, X.; Deng, S.; Zhou, T.; Fu, Q. Water-induced shape memory effect of graphene oxide reinforced polyvinyl alcohol nanocomposites. J. Mater. Chem. A 2014, 2, 2240–2249. [Google Scholar] [CrossRef]

- Liu, L.; Gao, Y.; Liu, Q.; Kuang, J.; Zhou, D.; Ju, S.; Han, B.; Zhang, Z. High mechanical performance of layered graphene oxide/poly (vinyl alcohol) nanocomposite films. Small 2013, 9, 2466–2472. [Google Scholar] [CrossRef]

- Jiang, L.; Shen, X.P.; Wu, J.L.; Shen, K.C. Preparation and characterization of graphene/poly (vinyl alcohol) nanocomposites. J. Appl. Polym. Sci. 2010, 118, 275–279. [Google Scholar] [CrossRef]

- Guo, J.; Ren, L.; Wang, R.; Zhang, C.; Yang, Y.; Liu, T. Water dispersible graphene noncovalently functionalized with tryptophan and its poly (vinyl alcohol) nanocomposite. Compos. Part B Eng. 2011, 42, 2130–2135. [Google Scholar] [CrossRef]

- Salavagione, H.J.; Martínez, G.; Gómez, M.A. Synthesis of poly (vinyl alcohol)/reduced graphite oxide nanocomposites with improved thermal and electrical properties. J. Mater. Chem. 2009, 19, 5027–5032. [Google Scholar] [CrossRef]

- Cheng, H.K.F.; Sahoo, N.G.; Tan, Y.P.; Pan, Y.; Bao, H.; Li, L.; Chan, S.H.; Zhao, J. Poly (vinyl alcohol) nanocomposites filled with poly (vinyl alcohol)-grafted graphene oxide. ACS Appl. Mater. Interfaces 2012, 4, 2387–2394. [Google Scholar] [CrossRef] [PubMed]

- Sayyar, S.; Murray, E.; Thompson, B.C.; Gambhir, S.; Officer, D.L.; Wallace, G.G. Covalently linked biocompatible graphene/polycaprolactone composites for tissue engineering. Carbon 2013, 52, 296–304. [Google Scholar] [CrossRef] [Green Version]

- Cai, D.; Song, M. A simple route to enhance the interface between graphite oxide nanoplatelets and a semi-crystalline polymer for stress transfer. Nanotechnology 2009, 20, 315708. [Google Scholar] [CrossRef]

- Gong, L.; Yin, B.; Li, L.P.; Yang, M.B. Nylon-6/Graphene composites modified through polymeric modification of graphene. Compos. Part B Eng. 2015, 73, 49–56. [Google Scholar] [CrossRef]

- Wu, D.; Cheng, Y.; Feng, S.; Yao, Z.; Zhang, M. Crystallization behavior of polylactide/graphene composites. Ind. Eng. Chem. Res. 2013, 52, 6731–6739. [Google Scholar] [CrossRef]

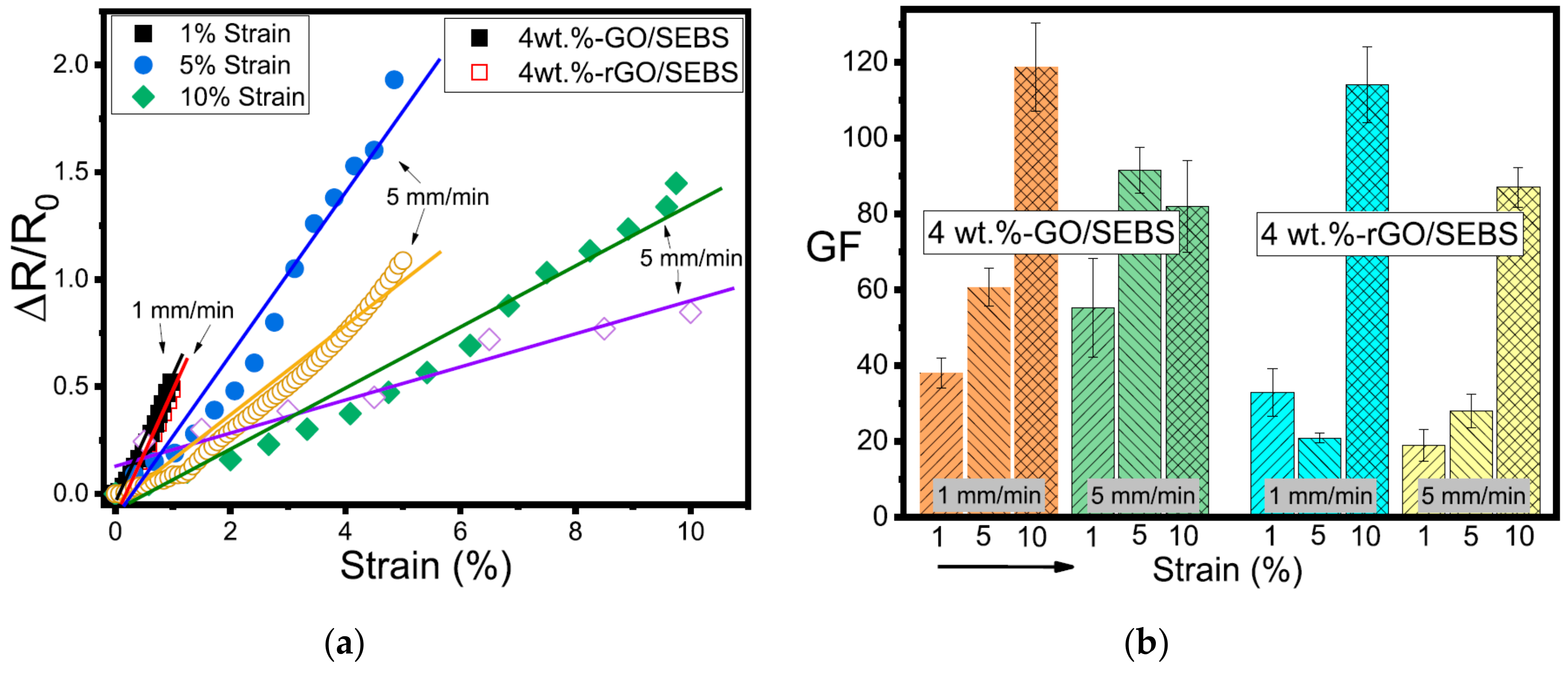

- Costa, P.; Gonçalves, S.; Mora, H.; Carabineiro, S.A.; Viana, J.C.; Lanceros-Mendez, S. Highly sensitive piezoresistive graphene-based stretchable composites for sensing applications. ACS Appl. Mater. Interfaces 2019, 11, 46286–46295. [Google Scholar] [CrossRef]

- Han, Y.; Wu, Y.; Shen, M.; Huang, X.; Zhu, J.; Zhang, X. Preparation and properties of polystyrene nanocomposites with graphite oxide and graphene as flame retardants. J. Mater. Sci. 2013, 48, 4214–4222. [Google Scholar] [CrossRef]

- Shen, B.; Zhai, W.; Chen, C.; Lu, D.; Wang, J.; Zheng, W. Melt blending in situ enhances the interaction between polystyrene and graphene through π–π stacking. ACS Appl. Mater. Interfaces 2011, 3, 3103–3109. [Google Scholar] [CrossRef] [PubMed]

- Istrate, O.M.; Paton, K.R.; Khan, U.; O’Neill, A.; Bell, A.P.; Coleman, J.N. Reinforcement in melt-processed polymer-graphene composites at extremely low graphene loading level. Carbon 2014, 78, 243–249. [Google Scholar] [CrossRef]

- Yuan, B.; Bao, C.; Song, L.; Hong, N.; Liew, K.M.; Hu, Y. Preparation of functionalized graphene oxide/polypropylene nanocomposite with significantly improved thermal stability and studies on the crystallization behavior and mechanical properties. Chem. Eng. J. 2014, 237, 411–420. [Google Scholar] [CrossRef]

- El Achaby, M.; Arrakhiz, F.E.; Vaudreuil, S.; el Kacem Qaiss, A.; Bousmina, M.; Fassi-Fehri, O. Mechanical, thermal, and rheological properties of graphene-based polypropylene nanocomposites prepared by melt mixing. Polym. Compos. 2012, 33, 733–744. [Google Scholar] [CrossRef]

- Shen, B.; Zhai, W.; Tao, M.; Lu, D.; Zheng, W. Enhanced interfacial interaction between polycarbonate and thermally reduced graphene induced by melt blending. Compos. Sci. Technol. 2013, 86, 109–116. [Google Scholar] [CrossRef]

- Kuila, T.; Bose, S.; Khanra, P.; Kim, N.H.; Rhee, K.Y.; Lee, J.H. Characterization and properties of in situ emulsion polymerized poly (methyl methacrylate)/graphene nanocomposites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1856–1861. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, L.L.; Zhao, X.; Wu, J. Graphene/polyaniline nanofiber composites as supercapacitor electrodes. Chem. Mater. 2010, 22, 1392–1401. [Google Scholar] [CrossRef]

- Xu, Z.; Gao, C. In situ polymerization approach to graphene-reinforced nylon-6 composites. Macromolecules 2010, 43, 6716–6723. [Google Scholar] [CrossRef]

- Verdejo, R.; Barroso-Bujans, F.; Rodriguez-Perez, M.A.; de Saja, J.A.; Lopez-Manchado, M.A. Functionalized graphene sheet filled silicone foam nanocomposites. J. Mater. Chem. 2008, 18, 2221–2226. [Google Scholar] [CrossRef]

- Yu, Y.H.; Lin, Y.Y.; Lin, C.H.; Chan, C.C.; Huang, Y.C. High-performance polystyrene/graphene-based nanocomposites with excellent anti-corrosion properties. Polym. Chem. 2014, 5, 535–550. [Google Scholar] [CrossRef]

- Hu, H.; Wang, X.; Wang, J.; Wan, L.; Liu, F.; Zheng, H.; Chen, R.; Xu, C. Preparation and properties of graphene nanosheets-polystyrene nanocomposites via in situ emulsion polymerization. Chem. Phys. Lett. 2010, 484, 247–253. [Google Scholar] [CrossRef]

- Shen, J.; Hu, Y.; Li, C.; Qin, C.; Shi, M.; Ye, M. Layer-by-layer self-assembly of graphene nanoplatelets. Langmuir 2009, 25, 6122–6128. [Google Scholar] [CrossRef]

- Hu, M.; Mi, B. Layer-by-layer assembly of graphene oxide membranes via electrostatic interaction. J. Membr. Sci. 2014, 469, 80–87. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, Q.; Hao, Y.; Li, Y.; Fang, Y.; Chen, D. Alternate multilayer films of poly (vinyl alcohol) and exfoliated graphene oxide fabricated via a facial layer-by-layer assembly. Macromolecules 2010, 43, 9411–9416. [Google Scholar] [CrossRef]

- Vadukumpully, S.; Paul, J.; Mahanta, N.; Valiyaveettil, S. Flexible conductive graphene/poly (vinyl chloride) composite thin films with high mechanical strength and thermal stability. Carbon 2011, 49, 198–205. [Google Scholar] [CrossRef]

- Li, W.; Xu, Z.; Chen, L.; Shan, M.; Tian, X.; Yang, C.; Lv, H.; Qian, X. A facile method to produce graphene oxide-g-poly (L-lactic acid) as an promising reinforcement for PLLA nanocomposites. Chem. Eng. J. 2014, 237, 291–299. [Google Scholar] [CrossRef]

- Kim, I.H.; Jeong, Y.G. Polylactide/exfoliated graphite nanocomposites with enhanced thermal stability, mechanical modulus, and electrical conductivity. J. Polym. Sci. Part B Polym. Phys. 2010, 48, 850–858. [Google Scholar] [CrossRef]

- Yan, J.; Wei, T.; Shao, B.; Fan, Z.; Qian, W.; Zhang, M.; Wei, F. Preparation of a graphene nanosheet/polyaniline composite with high specific capacitance. Carbon 2010, 48, 487–493. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Sato, N.; Tölle, F.; Mülhaupt, R.; Fiedler, B.; Schulte, K. Fracture toughness and failure mechanism of graphene based epoxy composites. Compos. Sci. Technol. 2014, 97, 90–99. [Google Scholar] [CrossRef]

- Wei, T.; Luo, G.; Fan, Z.; Zheng, C.; Yan, J.; Yao, C.; Li, W.; Zhang, C. Preparation of graphene nanosheet/polymer composites using in situ reduction-extractive dispersion. Carbon 2009, 47, 2296–2299. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, H.; Kotov, N.A. Thermodynamic and structural insights into nanocomposites engineering by comparing two materials assembly techniques for graphene. ACS Nano 2013, 7, 4818–4829. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Zhao, Z.; Hu, H.; Liu, Y.; Wang, X.; Zhou, S.; Qiu, J. Highly stretchable and ultrasensitive strain sensor based on reduced graphene oxide microtubes-elastomer composite. ACS Appl. Mater. Interfaces 2015, 7, 27432–27439. [Google Scholar] [CrossRef] [PubMed]

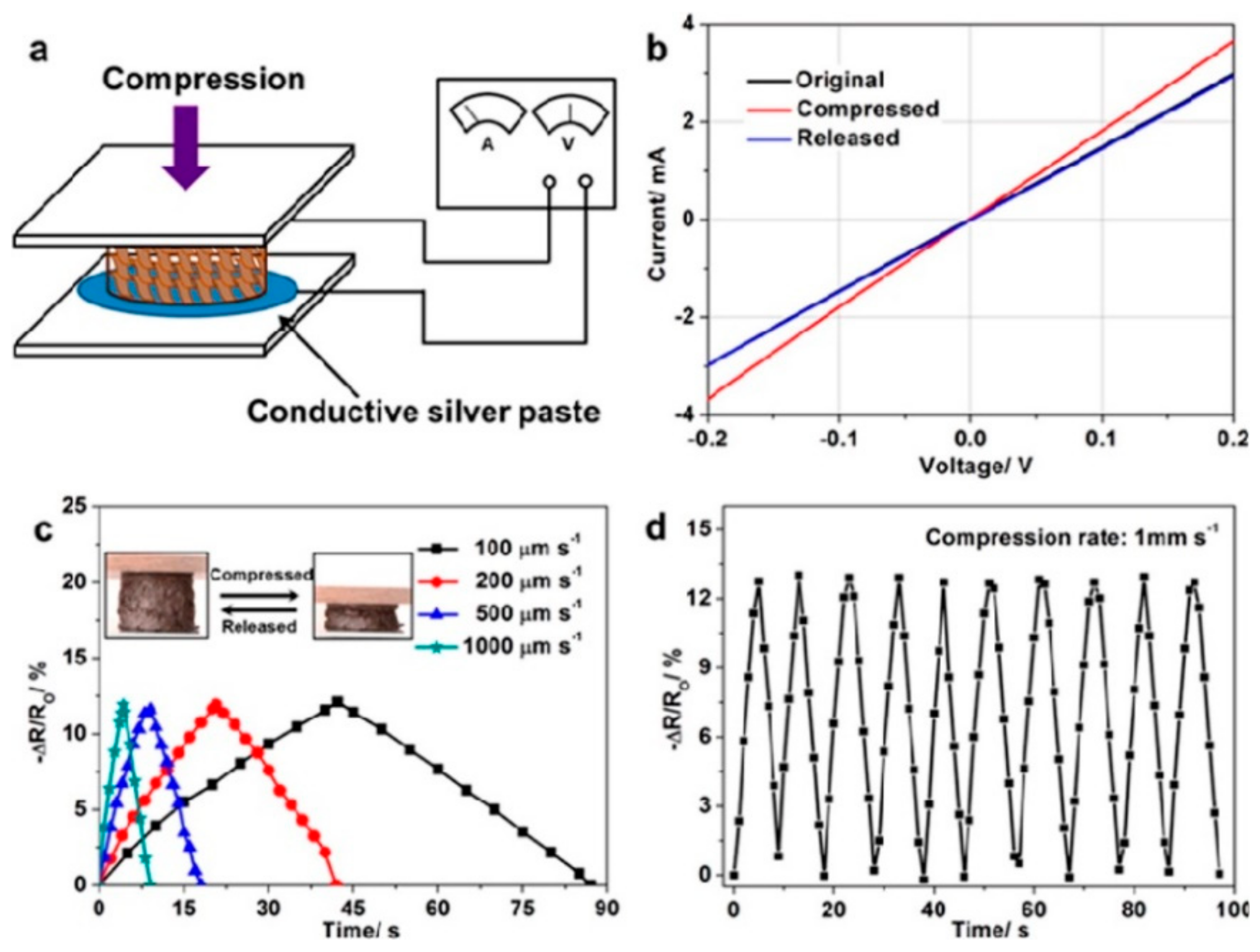

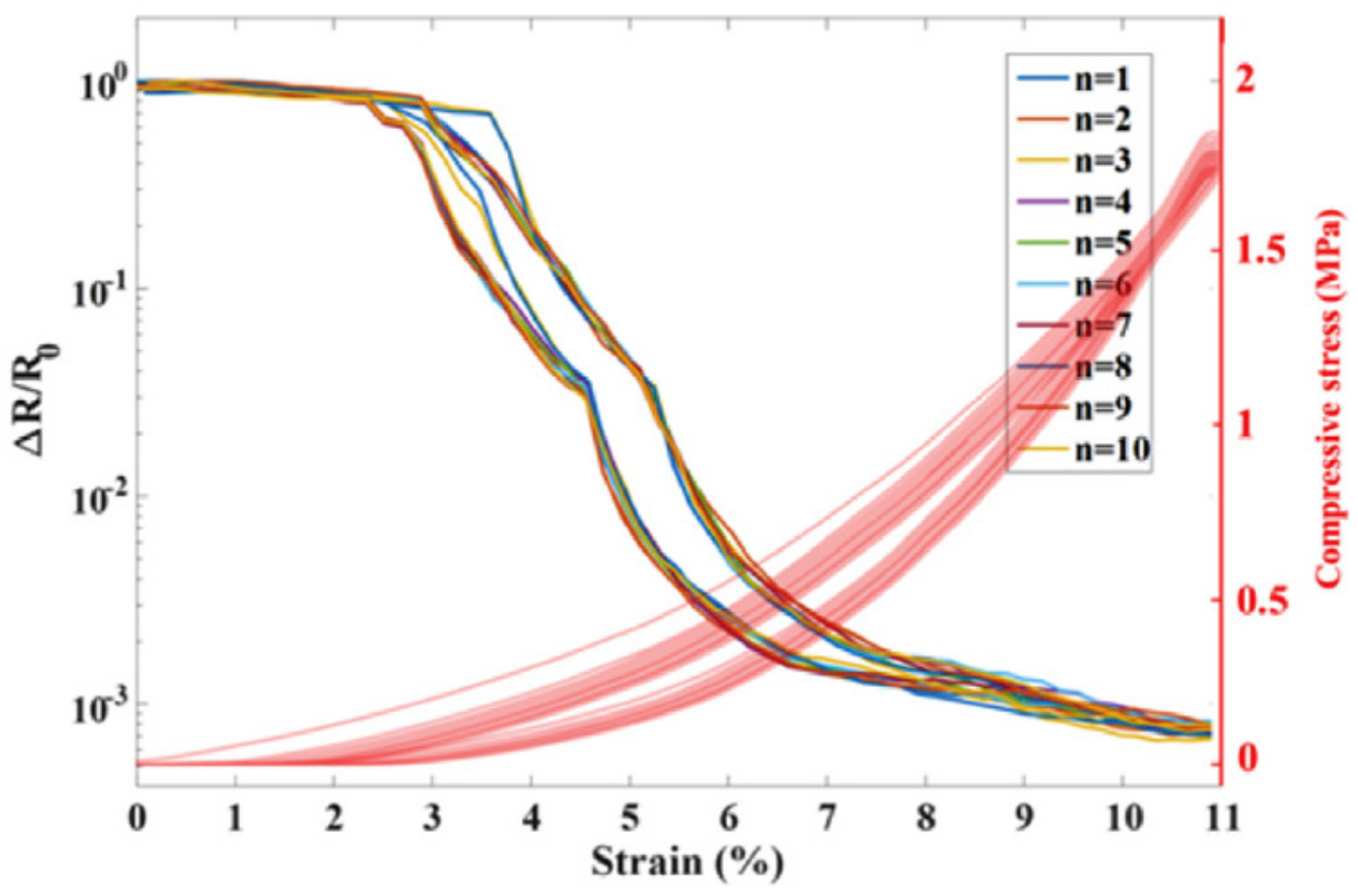

- Liu, H.; Dong, M.; Huang, W.; Gao, J.; Dai, K.; Guo, J.; Zheng, G.; Liu, C.; Shen, C.; Guo, Z. Lightweight conductive graphene/thermoplastic polyurethane foams with ultrahigh compressibility for piezoresistive sensing. J. Mater. Chem. C 2017, 5, 73–83. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Xu, X.; Li, H.; Xiong, G.; Hu, H.; Fisher, T.S. Mechanically robust honeycomb graphene aerogel multifunctional polymer composites. Carbon 2015, 93, 659–670. [Google Scholar] [CrossRef]

- Li, X.; Zhang, R.; Yu, W.; Wang, K.; Wei, J.; Wu, D.; Cao, A.; Li, Z.; Cheng, Y.; Zheng, Q. Stretchable and highly sensitive graphene-on-polymer strain sensors. Sci. Rep. 2012, 2, 870. [Google Scholar] [CrossRef] [Green Version]

- Qin, Y.; Peng, Q.; Ding, Y.; Lin, Z.; Wang, C.; Li, Y.; Xu, F.; Li, J.; Yuan, Y.; He, X. Lightweight, superelastic, and mechanically flexible graphene/polyimide nanocomposite foam for strain sensor application. ACS Nano 2015, 9, 8933–8941. [Google Scholar] [CrossRef]

- Boland, C.S.; Khan, U.; Ryan, G.; Barwich, S.; Charifou, R.; Harvey, A.; Backes, C.; Li, Z.; Ferreira, M.S.; Möbius, M.E. Sensitive electromechanical sensors using viscoelastic graphene-polymer nanocomposites. Science 2016, 354, 1257–1260. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Lo Re, G.; Parisi, A.; Busacca, A. Advanced piezoresistive sensor achieved by amphiphilic nanointerfaces of graphene oxide and biodegradable polymer blends. Compos. Sci. Technol. 2018, 156, 166–176. [Google Scholar] [CrossRef]

- Wu, C.; Huang, X.; Wu, X.; Qian, R.; Jiang, P. Mechanically Flexible and Multifunctional Polymer-Based Graphene Foams for Elastic Conductors and Oil-Water Separators. Adv. Mater. 2013, 25, 5658–5662. [Google Scholar] [CrossRef]

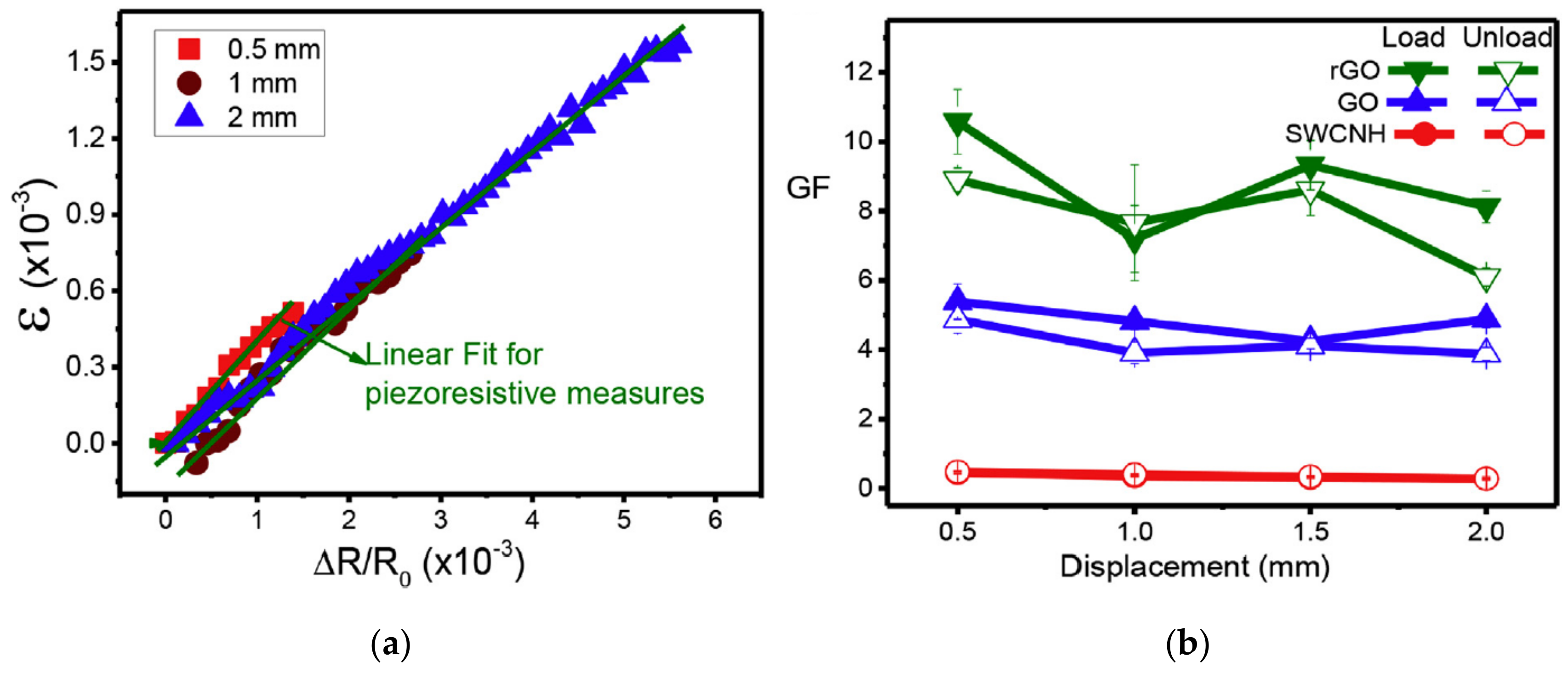

- Costa, P.; Nunes-Pereira, J.; Oliveira, J.; Silva, J.; Moreira, J.A.; Carabineiro, S.; Buijnsters, J.; Lanceros-Mendez, S. High-performance graphene-based carbon nanofiller/polymer composites for piezoresistive sensor applications. Compos. Sci. Technol. 2017, 153, 241–252. [Google Scholar] [CrossRef]

- You, F.; Li, X.; Zhang, L.; Wang, D.; Shi, C.-Y.; Dang, Z.-M. Polypropylene/poly(methyl methacrylate)/graphene composites with high electrical resistivity anisotropy via sequential biaxial stretching. RSC Adv. 2017, 7, 6170–6178. [Google Scholar] [CrossRef] [Green Version]

- Yu, Y.Y.; Bai, X.J.; Kung, M.C.; Xue, Y.; Huang, Y.; Keane, D.T.; Kung, H.H. Electromechanical properties of reduced graphene oxide thin film on 3D elastomeric substrate. Carbon 2017, 115, 380–387. [Google Scholar] [CrossRef] [Green Version]

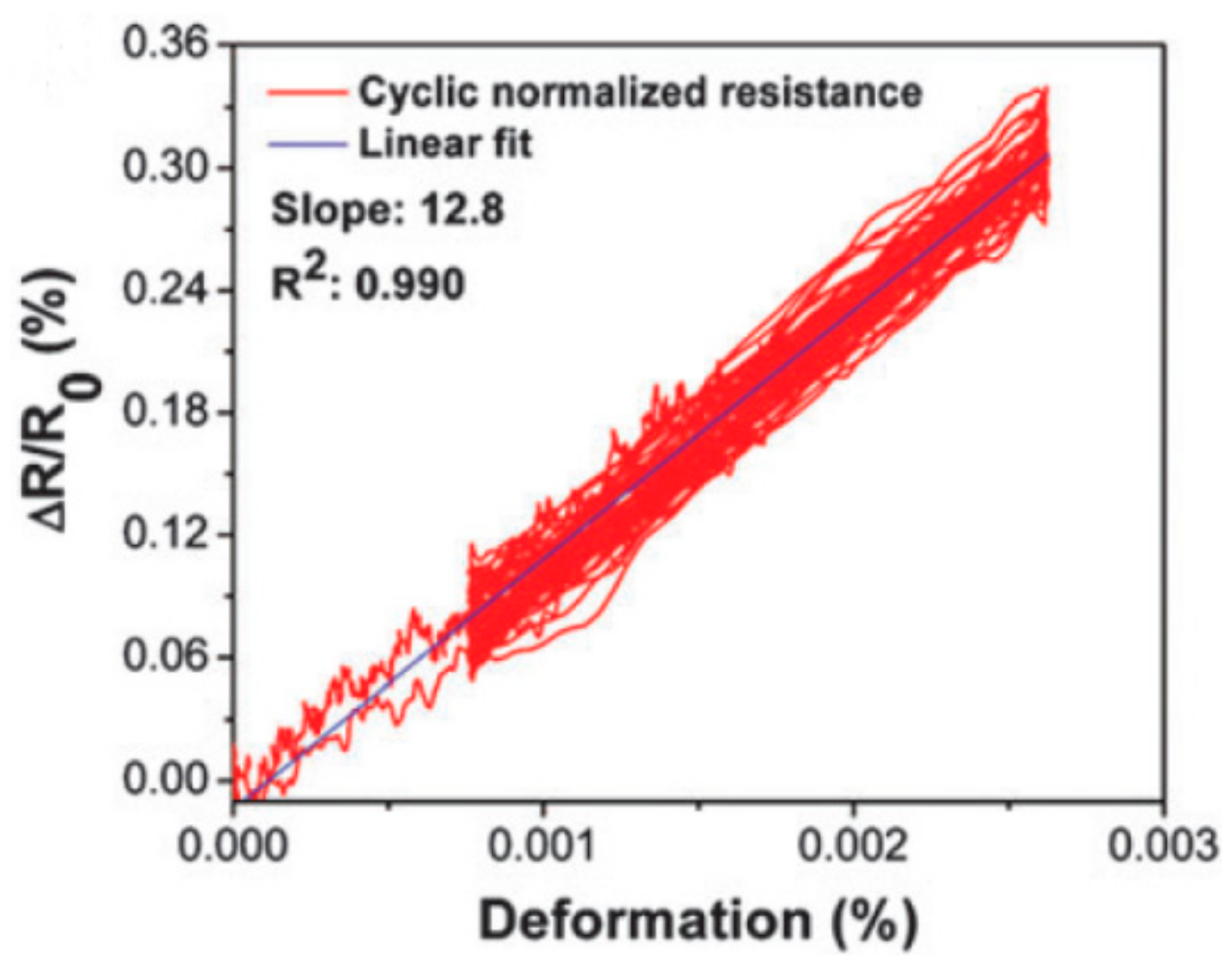

- Lu, S.; Tian, C.; Wang, X.; Zhang, L.; Du, K.; Ma, K.; Xu, T. Strain sensing behaviors of GnPs/epoxy sensor and health monitoring for composite materials under monotonic tensile and cyclic deformation. Compos. Sci. Technol. 2018, 158, 94–100. [Google Scholar] [CrossRef]

- Huang, Z.M.; Liu, X.Y.; Wu, W.G.; Li, Y.Q.; Wang, H. Highly elastic and conductive graphene/carboxymethylcellulose aerogels for flexible strain-sensing materials. J. Mater. Sci. 2017, 52, 12540–12552. [Google Scholar] [CrossRef]

- Zhang, P.; Lv, L.; Cheng, Z.; Liang, Y.; Zhou, Q.; Zhao, Y.; Qu, L. Superelastic, Macroporous Polystyrene-Mediated Graphene Aerogels for Active Pressure Sensing. Chem. Asian J. 2016, 11, 1071–1075. [Google Scholar] [CrossRef]

- Zheng, G.; Jiang, Z.; Han, Z.; Yang, J. Mechanical and electro-mechanical properties of three-dimensional nanoporous graphene-poly (vinylidene fluoride) composites. Express Polym. Lett. 2016, 10, 730. [Google Scholar] [CrossRef]

- Zha, J.-W.; Zhang, B.; Li, R.K.Y.; Dang, Z.-M. High-performance strain sensors based on functionalized graphene nanoplates for damage monitoring. Compos. Sci. Technol. 2016, 123, 32–38. [Google Scholar] [CrossRef]

- Xu, B.; Yang, H.; Dai, K.; Liu, X.; Zhang, L.; Wang, M.; Niu, M.; Duan, R.; Wang, X.; Chen, J. Thermo-compression-aligned functional graphene showing anisotropic response to in-plane stretching and out-of-plane bending. J. Mater. Sci. 2018, 53, 6574–6585. [Google Scholar] [CrossRef]

- Luo, Y.; Xiao, Q.; Li, B. Highly compressible graphene/polyurethane sponge with linear and dynamic piezoresistive behavior. RSC Adv. 2017, 7, 34939–34944. [Google Scholar] [CrossRef] [Green Version]

- Zhang, B.X.; Hou, Z.L.; Yan, W.; Zhao, Q.L.; Zhan, K.T. Multi-dimensional flexible reduced graphene oxide/polymer sponges for multiple forms of strain sensors. Carbon 2017, 125, 199–206. [Google Scholar] [CrossRef]

- Bang, S.; Lim, J.; Chun, S.; Park, W. A Flexible Graphene-Polydimethylsiloxane Nanocomposite Force Sensor with Linear Response Across a Wide Pressure Detection Range. J. Nanosci. Nanotechnol. 2019, 19, 1630–1634. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Peng, S.; Han, Z.J.; Zhu, H.; Wang, C.H. Ultrasensitive and Stretchable Strain Sensors Based on Mazelike Vertical Graphene Network. ACS Appl. Mater. Interfaces 2018, 10, 36312–36322. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.-S.; Gwak, M.-J.; Lee, D.-W. Polymeric cantilever integrated with PDMS/graphene composite strain sensor. Rev. Sci. Instrum. 2016, 87, 105004. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Ren, W.; Gao, L.; Liu, B.; Pei, S.; Cheng, H.-M. Three-dimensional flexible and conductive interconnected graphene networks grown by chemical vapour deposition. Nat. Mater. 2011, 10, 424. [Google Scholar] [CrossRef]

- Park, S.; Nam, G.; Choi, Y.; Woo, S.; Uhm, W.; Park, S.; Yoon, S.-H. Mechanoelectrical properties of a GnF/PDMS composite controlled by the aspect ratio and concentration of GnF. Compos. Sci. Technol. 2018, 159, 77–86. [Google Scholar] [CrossRef]

- Lin, Y.; Liu, S.; Chen, S.; Wei, Y.; Dong, X.; Liu, L. A highly stretchable and sensitive strain sensor based on graphene–elastomer composites with a novel double-interconnected network. J. Mater. Chem. C 2016, 4, 6345–6352. [Google Scholar] [CrossRef]

- Zeng, Z.; Shahabadi, S.I.S.; Che, B.; Zhang, Y.; Zhao, C.; Lu, X. Highly stretchable, sensitive strain sensors with a wide linear sensing region based on compressed anisotropic graphene foam/polymer nanocomposites. Nanoscale 2017, 9, 17396–17404. [Google Scholar] [CrossRef]

- Hu, H.; Zhao, Z.; Wan, W.; Gogotsi, Y.; Qiu, J. Polymer/graphene hybrid aerogel with high compressibility, conductivity, and “sticky” superhydrophobicity. ACS Appl. Mater. Interfaces 2014, 6, 3242–3249. [Google Scholar] [CrossRef]

- Hou, Y.; Wang, D.; Zhang, X.-M.; Zhao, H.; Zha, J.-W.; Dang, Z.-M. Positive piezoresistive behavior of electrically conductive alkyl-functionalized graphene/polydimethylsilicone nanocomposites. J. Mater. Chem. C 2013, 1, 515–521. [Google Scholar] [CrossRef]

- Tung, T.T.; Karunagaran, R.; Tran, D.N.H.; Gao, B.; Nag-Chowdhury, S.; Pillin, I.; Castro, M.; Feller, J.-F.; Losic, D. Engineering of graphene/epoxy nanocomposites with improved distribution of graphene nanosheets for advanced piezo-resistive mechanical sensing. J. Mater. Chem. C 2016, 4, 3422–3430. [Google Scholar] [CrossRef]

- Antunes, M.; Velasco, J.I. Multifunctional polymer foams with carbon nanoparticles. Prog. Polym. Sci. 2014, 39, 486–509. [Google Scholar] [CrossRef]

- Zhao, H.; Bai, J. Highly sensitive piezo-resistive graphite nanoplatelet–carbon nanotube hybrids/polydimethylsilicone composites with improved conductive network construction. ACS Appl. Mater. Interfaces 2015, 7, 9652–9659. [Google Scholar] [CrossRef] [PubMed]

- Sadasivuni, K.K.; Ponnamma, D.; Thomas, S.; Grohens, Y. Evolution from graphite to graphene elastomer composites. Prog. Polym. Sci. 2014, 39, 749–780. [Google Scholar] [CrossRef]

- Wang, X.; Meng, S.; Tebyetekerwa, M.; Li, Y.; Pionteck, J.; Sun, B.; Qin, Z.; Zhu, M. Highly sensitive and stretchable piezoresistive strain sensor based on conductive poly (styrene-butadiene-styrene)/few layer graphene composite fiber. Compos. Part A Appl. Sci. Manuf. 2018, 105, 291–299. [Google Scholar] [CrossRef]

- Gonçalves, B.F.; Costa, P.; Oliveira, J.; Ribeiro, S.; Correia, V.; Botelho, G.; Betelho, G.; Lanceros-Mendez, S. Green solvent approach for printable large deformation thermoplastic elastomer based piezoresistive sensors and their suitability for biomedical applications. J. Polym. Sci. Part B Polym. Phys. 2016, 54, 2092–2103. [Google Scholar] [CrossRef]

- Costa, P.; Ferreira, A.; Sencadas, V.; Viana, J.; Méndez, S.L. Electro-mechanical properties of triblock copolymer styrene–butadiene–styrene/carbon nanotube composites for large deformation sensor applications. Sens. Actuators A Phys. 2013, 201, 458–467. [Google Scholar] [CrossRef]

- Costa, P.; Silvia, C.; Viana, J.; Mendez, S.L. Extruded thermoplastic elastomers styrene–butadiene–styrene/carbon nanotubes composites for strain sensor applications. Compos. Part B Eng. 2014, 57, 242–249. [Google Scholar] [CrossRef]

- Lu, X.; Detrez, F.; Yvonnet, J.; Jinbo, B. Multiscale study of influence of interfacial decohesion on piezoresistivity of graphene/polymer nanocomposites. Model. Simul. Mater. Sci. Eng. 2018, 27, 035001. [Google Scholar] [CrossRef] [Green Version]

- Hwang, J.; Sohn, H.; Lee, S.H. Computational characterization and control of electrical conductivity of nanowire composite network under mechanical deformation. Sci. Rep. 2018, 8, 16617. [Google Scholar] [CrossRef]

- Gbaguidi, A.; Namilae, S.; Kim, D.W. Monte Carlo Model for Piezoresistivity of Hybrid Nanocomposites. J. Eng. Mater. Technol. 2018, 140, 011007. [Google Scholar] [CrossRef]

| Method | Quality | Cost | Scalability | Purity | Yield |

|---|---|---|---|---|---|

| Mechanical Exfoliation | High | Low | Not applicable | Average | Low |

| Liquid Phase Exfoliation | High | Average | High | Average | Low |

| Electrochemical Exfoliation | High | High | Average | Average | Low |

| Chemical Vapor Deposition | High | High | Average | Average | Low |

| Reduction of Graphene Oxide | Low | Average | High | Low | High |

| Epitaxial Growth | High | Low | Low | Average | Low |

| Graphene Type | Polymer Matrix | Preparation Method | Reference |

|---|---|---|---|

| GN, GO, rGO | PVA | Solution mixing | [23,40,79,80,81,82,83,84] |

| GN, GO | Polycaprolactone (PCL) | Solution mixing | [85,86] |

| GN | Polyurethane (PU) | Solution mixing | [21,51] |

| GO, GN | Polyamide (PLA) | Solution mixing | [87,88] |

| GO, rGO, GNP | Styrene-ethylene-butylene-styrene (SEBS) | Solution mixing | [89] |

| GO, GN | Polystyrene (PS) | Melt blending | [90,91] |

| GNP | Polyethylene terephthalate (PET) | Melt blending | [92] |

| GO, GN | Polypropylene (PP) | Melt blending | [93,94] |

| rGO | Polycarbonate (PC) | Melt blending | [95] |

| GN | Polymethyl methacrylate (PMMA) | In situ polymerization | [96] |

| GN | Polyaniline (PANI) | In situ polymerization | [97] |

| GN | Nylon (PA)-6 | In situ polymerization | [98] |

| GN | Silicone | In situ polymerization | [99] |

| GO, GN | PS | In situ polymerization | [100,101] |

| GN | Polydiallyldimethylam monium chloride (PolyDDA) (PDDA) | Layer-by-layer assembly | [102] |

| GO | Polycyclic aromatic hydrocarbons (PAH) | Layer-by-layer assembly | [103] |

| GO | PVA | Layer-by-layer assembly | [104] |

| Graphene Type | Polymer | Electromechanical Behaviors | Reference |

|---|---|---|---|

| GO, rGO, GNP | SEBS | The gauge factor can be as high as 120 under a 10% strain. | [89] |

| rGO | Elastomer | The gauge factor can reach 630 under 21.3% applied strain | [112] |

| GNP | PU | A stable electromechanical sensing signal can be obtained up to 90% strain. | [113] |

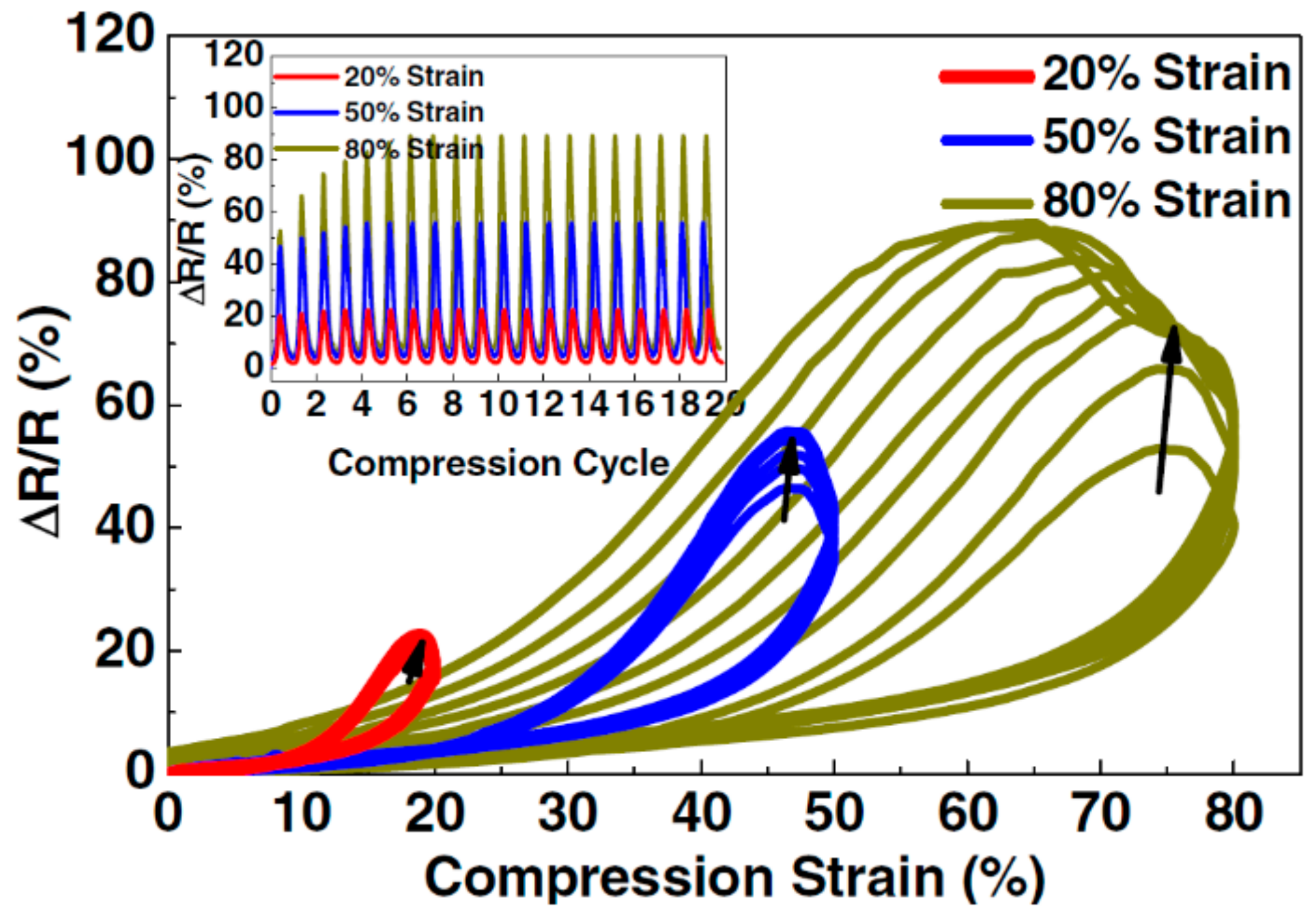

| Graphene Aerogel (GA) | Polydimethylsiloxane (PDMS) | The relative electrical resistivity change increases from 0% to 20% when the compression strain increases from 0% to 20%. | [114] |

| Graphene woven fabric | PDMS | Gauge factors of 103 and 106 can be obtained under strains of 6% and 7%, respectively. | [115] |

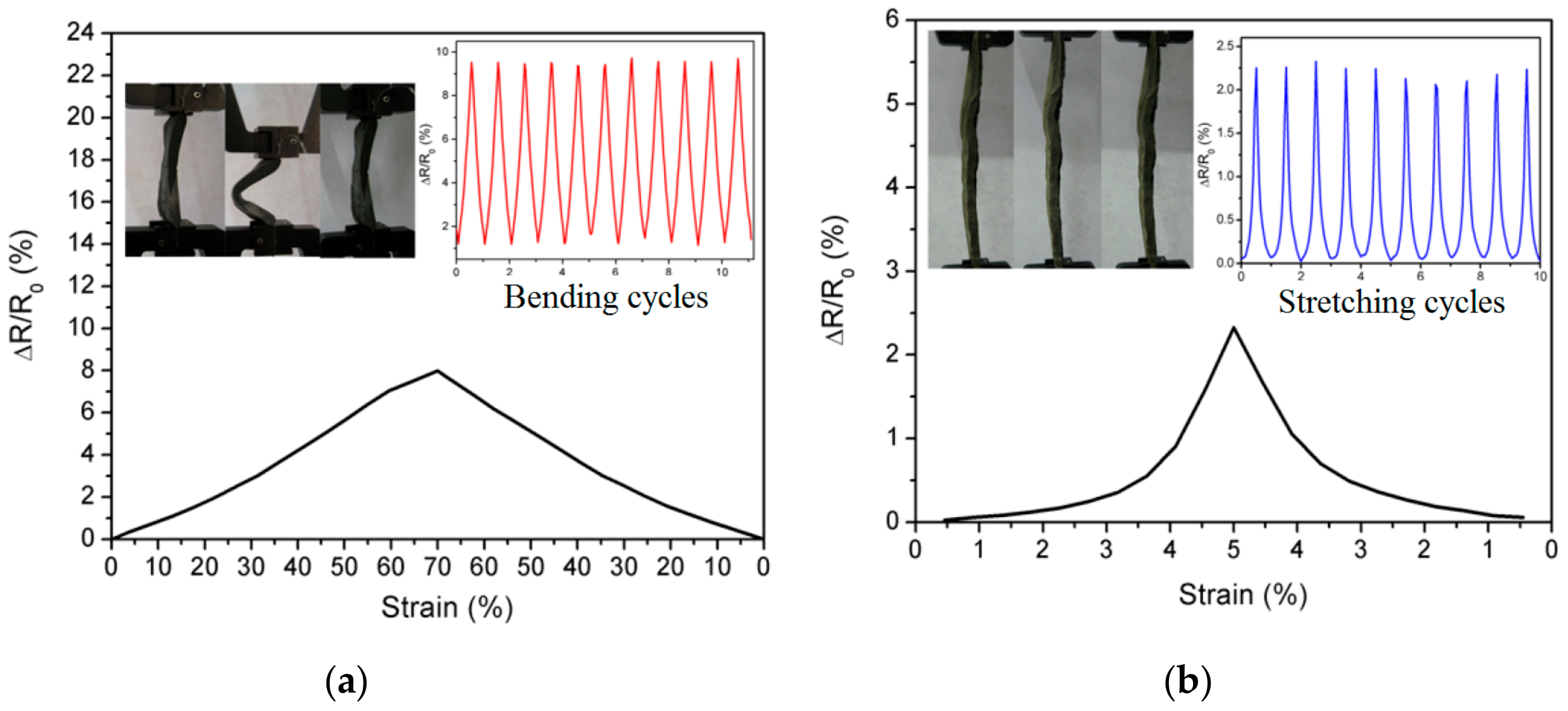

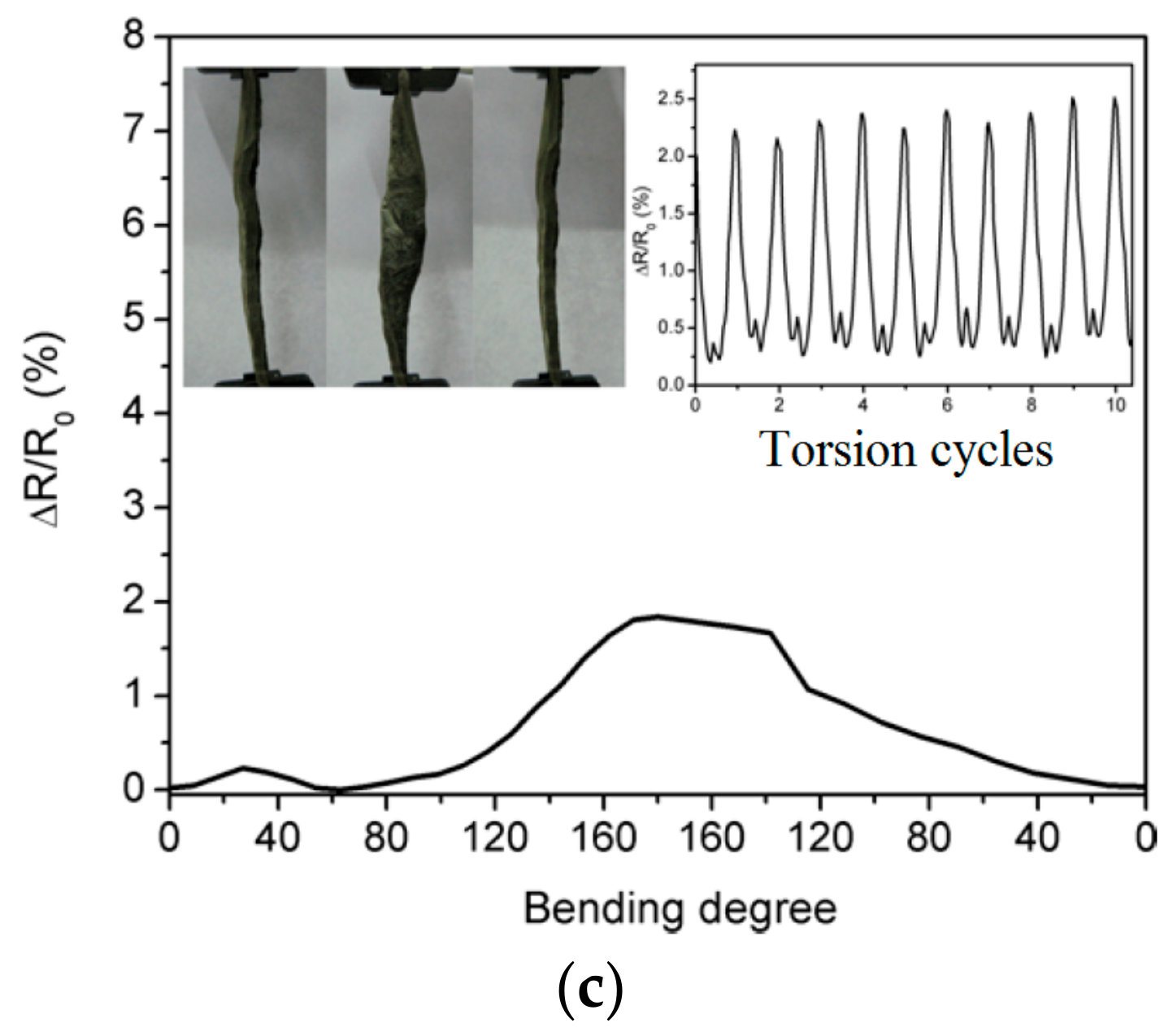

| rGO | Polyimide | The nanocomposites demonstrate excellent electromechanical properties under bending, stretching and torsion deformation, and the resistance variation remained stable during each deformation cycles. | [116] |

| GNs | Polysilicon | The electrical resistivity changes nonmonotonically with a strain and gauge factor of greater than 500 is observed. | [117] |

| GO | PLA/Polyethylene-glycol (PEG) | The electrical properties of the nanocomposites are sensitive to the mechanical deformations. For pressure ranges 0.6 to 8.5 MPa and 8.5 to 25 MPa, the responsivities can reach 35 mA/MPa and 19 mA/MPa, respectively. | [118] |

| GO | PU | The electrical resistance decreases linearly when the strain is approximately less than 60%. However, the strain further increases to be greater than 70%, and the resistance decreases exponentially. After 300 cycles at fixed strain, the electromechanical performances become stable. | [119] |

| rGO | PVDF | Linear fit is found for the relationship between electrical resistance and strain when the nanocomposites are subjected to deformations. The rGO-reinforced composites demonstrate the highest gauge factor among fillers as involved. | [120] |

| GN | PMMA | Through biaxial stretching to orientate the graphene fillers, the electrical conductivity was significantly improved in the stretching direction. | [121] |

| GO | PU | The electrical resistance–strain behavior is repeatable when the nanocomposites are subjected to compression cycles up to 70% strain. | [122] |

| GNP | Epoxy | As the graphene concentration increases, the linear growth rate of the electrical resistance change drops while the linear tendency is enhanced. | [123] |

| GNs | carboxymethylcellulose (CMC) | Under a compression strain of 70%, the electrical conductivity can be as high as 86.73 S/m. The gauge factor can reach 1.58 under 45%–70% compression strain. | [124] |

| GNs | PS | The nanocomposites demonstrate excellent electromechanical performance with sensitive electrical resistance response. | [125] |

| GO | PVDF | The electrical resistance change is about 27% when the nanocomposite is subjected to a strain of 10%. | [126] |

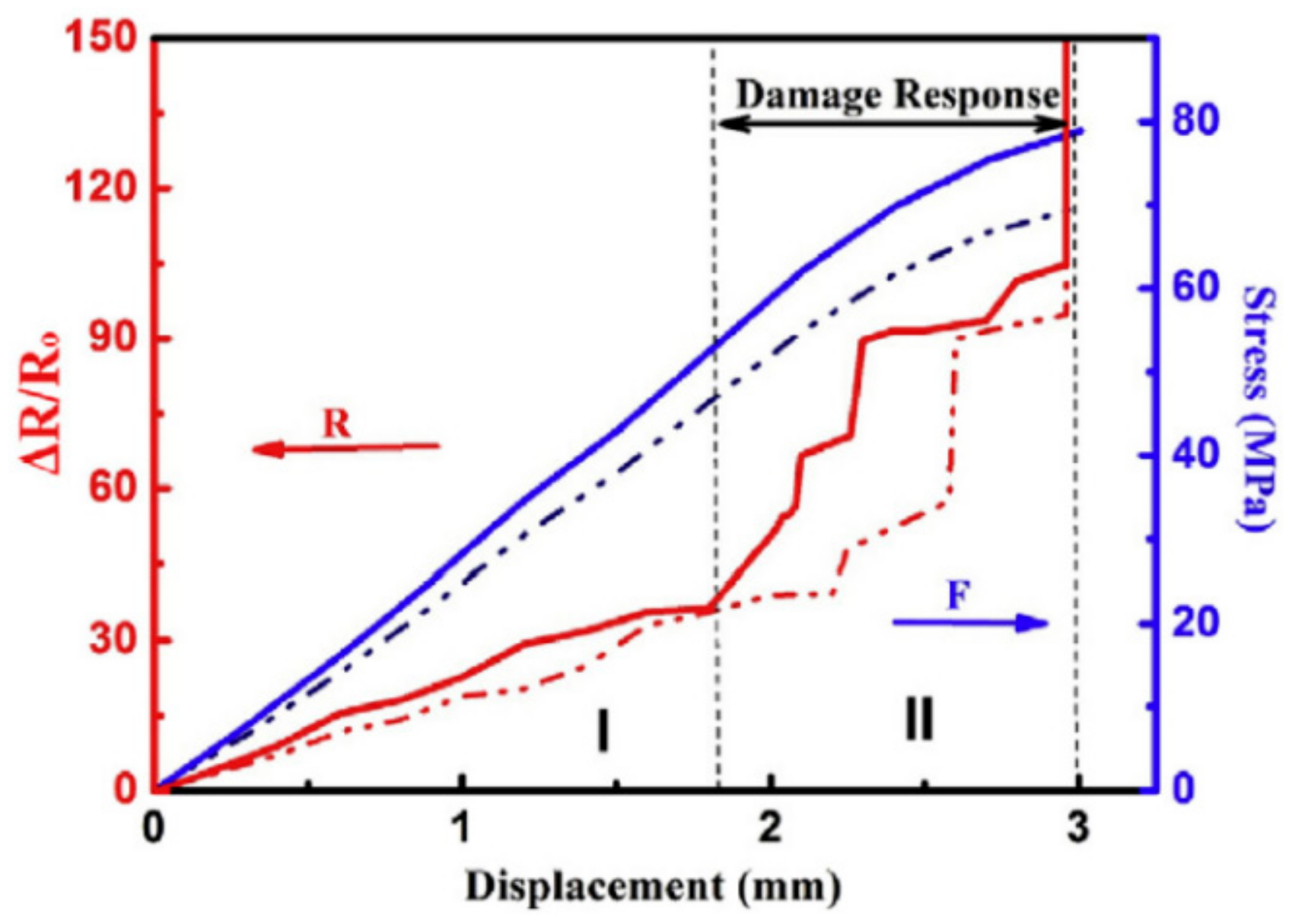

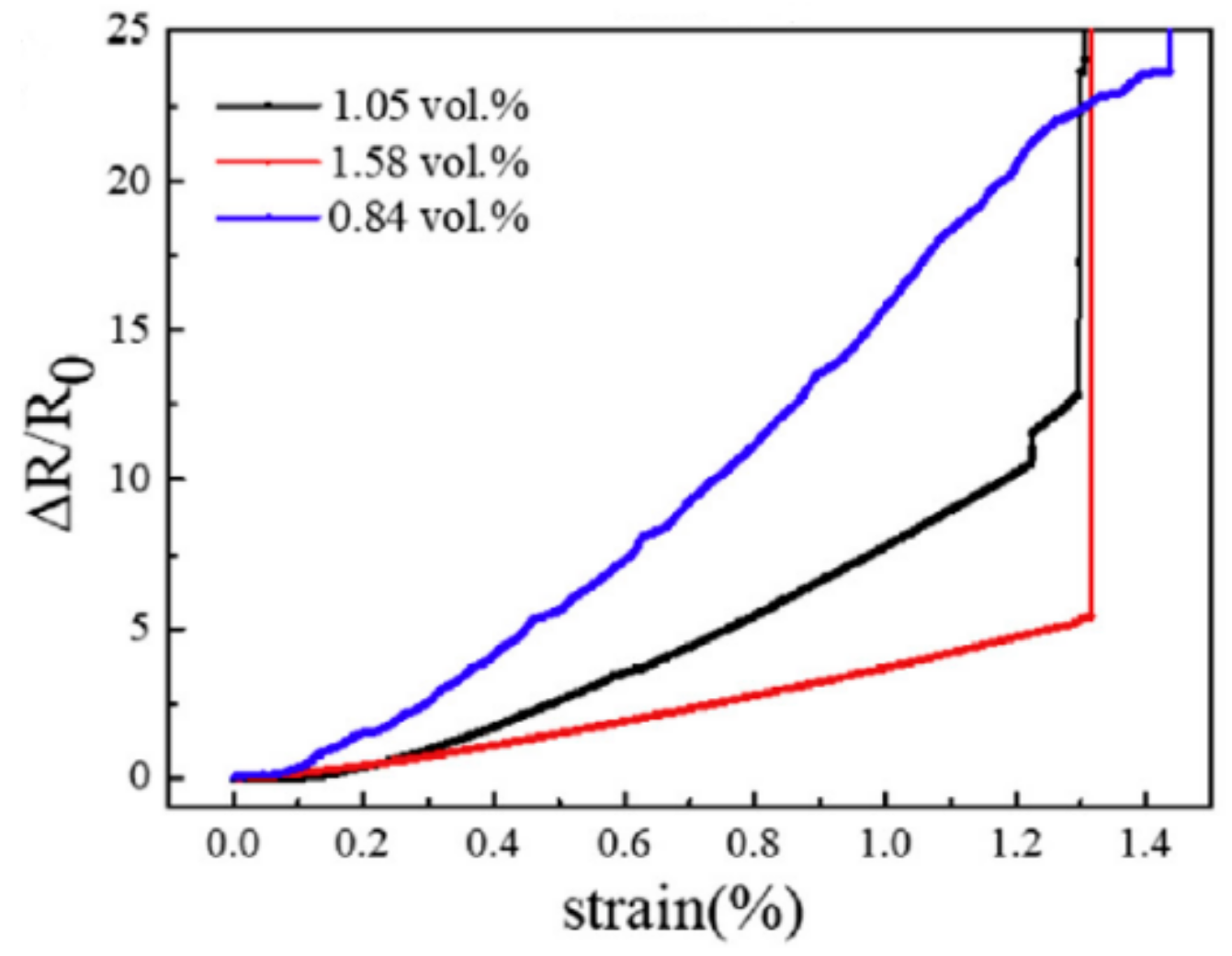

| GN | Epoxy | The electrical resistance changes linearly for smaller strain, and then has nonlinear, ladder-shaped growth, which indicates the irreversible deformation and damage in engineering structures. | [127] |

| GN | Elastomer | The electrical resistance of the nanocomposites is sensitive to the out-of-plane bending, while they are not sensitive to the in-plane stretching. | [128] |

| GNs | PU | When the nanocomposites are subjected to a 99% strain, the electrical resistance decreased from 5 kΩ to 25 kΩ. | [129] |

| rGO | PU/Polyvinyl Chloride (PVC) | The electrical resistivity of the rGO/PU and rGO/PVC composites generally decreases with the strain. However, the resistivity is almost independent on the strain with the strain range 30%–50%. The gauge factors for rGO/PU and rGO/PVC composites are observed to be 16.1 and 14.3 at 2% strain, and are 3.4 and 3.3 at 10% strain, respectively. | [130] |

| Graphene flakes | PDMS | The nanocomposite-based sensors showed sensitive electromechanical response to static and dynamically applied forces, which can be used to develop a force sensor capable of describing human pressure perception ability. | [131] |

| GN | PDMS | The nanocomposite-based sensors demonstrate high stretchability (~120%) and high sensitivity. | [132] |

| Graphene flakes | PDMS | The gauge factor increases with the strain for smaller graphene concentration while it keeps constant when the concentration increases to 30 wt % | [133] |

| Graphene foam | PDMS | With the increase of the stretching cycles, the electrical resistance first increases for the first six cycles. Then the resistance keeps constant when the strain is released. | [134] |

| Graphene flakes | PDMS | The aspect ratio and concentration of the graphene fillers have significant influences on the electromechanical behaviors. Graphene fillers with larger aspect ratio and great concentration are beneficial to enhance the gauge factor of the nanocomposites. | [135] |

| GN | rubber | The nanocomposite-based sensors exhibited a high stretchability, sensitivity (i.e., gauge factor can reach up to 82.5) and good reproducibility (up to 300 cycles) when subjected to a cyclic tensile test. | [136] |

| rGO | PDMS | High strain sensing sensitivity with a gauge factor of about 7.2. | [137] |

| GA | PDMS | The nanocomposites showed excellent electromechanical stability during a repeated compress process. | [138] |

| GN | PDMS | The electrical resistance change increases exponentially with pressure when the composites are under uniaxial compression. After 1000 load-release cycles, the curves remain nearly unchanged, indicating excellent durability and electromechanical stability. | [139] |

| GN | Epoxy | The electromechanical performance of the composites, which are subjected to static and dynamic deformation, demonstrated fast response (20 ms) and excellent sensitivity (gauge factor of 12.8). | [140] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, C.; Zhu, D.; Wang, Y.; Jin, S. Electromechanical Behaviors of Graphene Reinforced Polymer Composites: A Review. Materials 2020, 13, 528. https://doi.org/10.3390/ma13030528

Feng C, Zhu D, Wang Y, Jin S. Electromechanical Behaviors of Graphene Reinforced Polymer Composites: A Review. Materials. 2020; 13(3):528. https://doi.org/10.3390/ma13030528

Chicago/Turabian StyleFeng, Chuang, Dong Zhu, Yu Wang, and Sujing Jin. 2020. "Electromechanical Behaviors of Graphene Reinforced Polymer Composites: A Review" Materials 13, no. 3: 528. https://doi.org/10.3390/ma13030528

APA StyleFeng, C., Zhu, D., Wang, Y., & Jin, S. (2020). Electromechanical Behaviors of Graphene Reinforced Polymer Composites: A Review. Materials, 13(3), 528. https://doi.org/10.3390/ma13030528