Sustainable Test Methods for Construction Materials and Elements

Abstract

1. Introduction

2. Methods

2.1. Bond Strength Tests of Adhesives

- σ—strength result, MPa

- F—breaking force, N

- D—diameter of the stamp in mm.

2.2. Tensile Strength Tests of Plastics

- σ—strength result, MPa

- F—force, N

- a—sample thickness, in mm

- b—sample width, in mm.

3. Estimation of Uncertainty

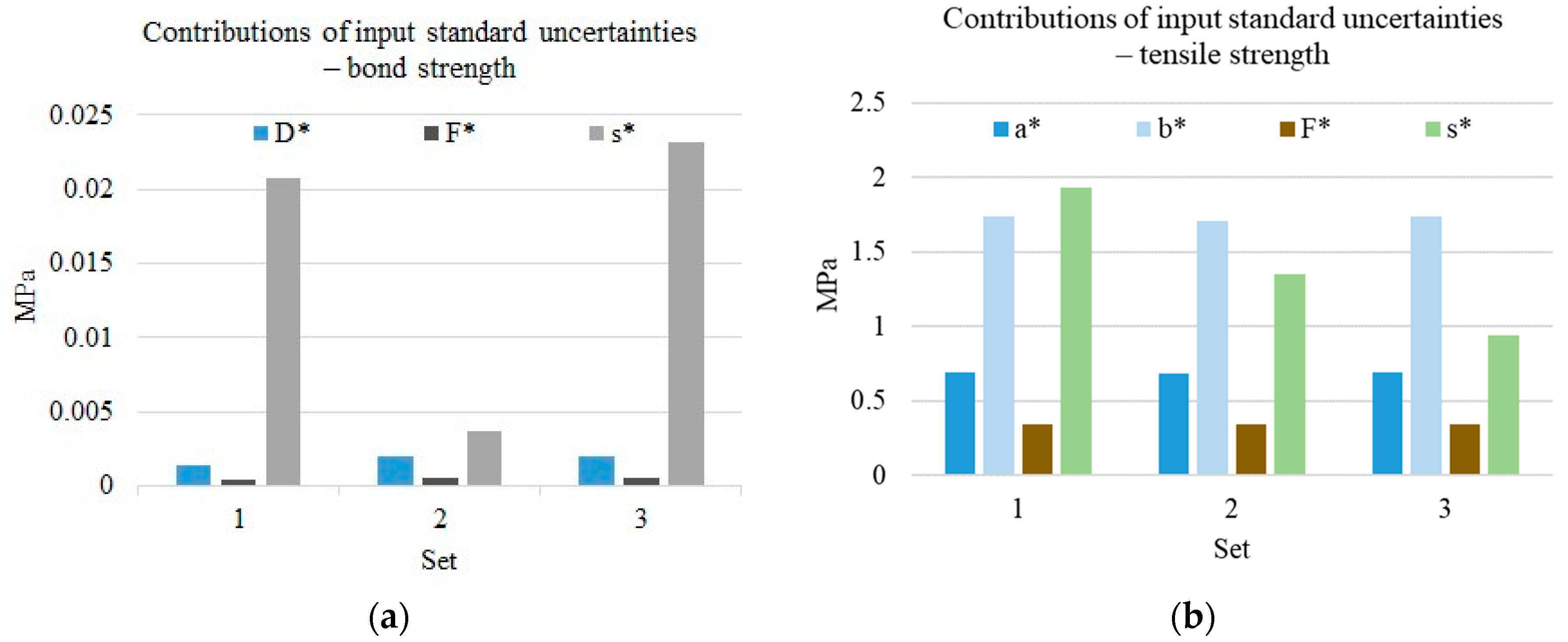

3.1. Bond Strength Tests and Their Influence on the Results

- The test substrate is usually standardised, thus adhesion to some other substrate in actual conditions may significantly vary.

- The sample is subjected to perpendicular force during the test, whilst the system of forces, e.g., on a façade, may differ in real conditions.

- The material is pulled off with a stamp glued to the sample with epoxy glue, which may affect the sample properties.

- Measurements which directly affect the result. According to Equation (1), these are the force measurement at pull-off and the stamp diameter attached to the sample. These measurement uncertainties can be determined in two ways—either in relation to the calibration certificates or in relation to the confirmation of compliance with conditions specified in the standards as uncertainty. For example, if the force ought to be measured with a Class 1 device, it means that the total uncertainty of measurement should not exceed 1% of the measured value.

- Measurements with uncertainties which do not affect the result according to a known relationship; however, they are measured in order to maintain compliance with the tolerance limits given in the standard: ambient temperature, air humidity measurement, force application speed measurement.

- Interactions whose level is not measured: force application direction (some non-perpendicular components of stress) which should be controlled by the construction of the measurement device, but there are always some imperfections, the substrate and stamp surface difference, the epoxy glue chemical and physical influence on the adhesive, repeatability, and reproducibility of sample preparation (the sample preparation process for testing is multi-stage and involves a number of interactions, such as layer thickness, clamping force, conditioning variability, and others that may affect the test result), the material and sample heterogeneity.

3.1.1. Precision of Bond Strength Tests

- s—standard deviation of repeatability or reproducibility

- —mean value of bond strength in the result set with standard deviation calculated.

3.1.2. Estimation of Bond Strength Results Uncertainty

- uD—standard uncertainty of D

- uF—standard uncertainty of F

- —dispersion of σ results.

3.2. Tests of Tensile Strength and Their Influence on the Results

- Measurements which directly affect the result. According to Equation (2), these are the force, thickness and width of the sample measurements.

- Measurements with uncertainties which do not affect the result according to a known relationship; however, they are measured: ambient temperature, sample geometry, and stress increase pace.

- Interactions whose level is not measured yet affects the result, include, but are not limited to, the jaw design which may result in excessive strain exerted on the sample or may cause the sample to slip, heterogeneous sample thickness, and material heterogeneity. The method assumes perpendicular stress, however, the design of the equipment and inaccurate clamping of the sample may imply the formation of tangential and torsional components that may affect the result.

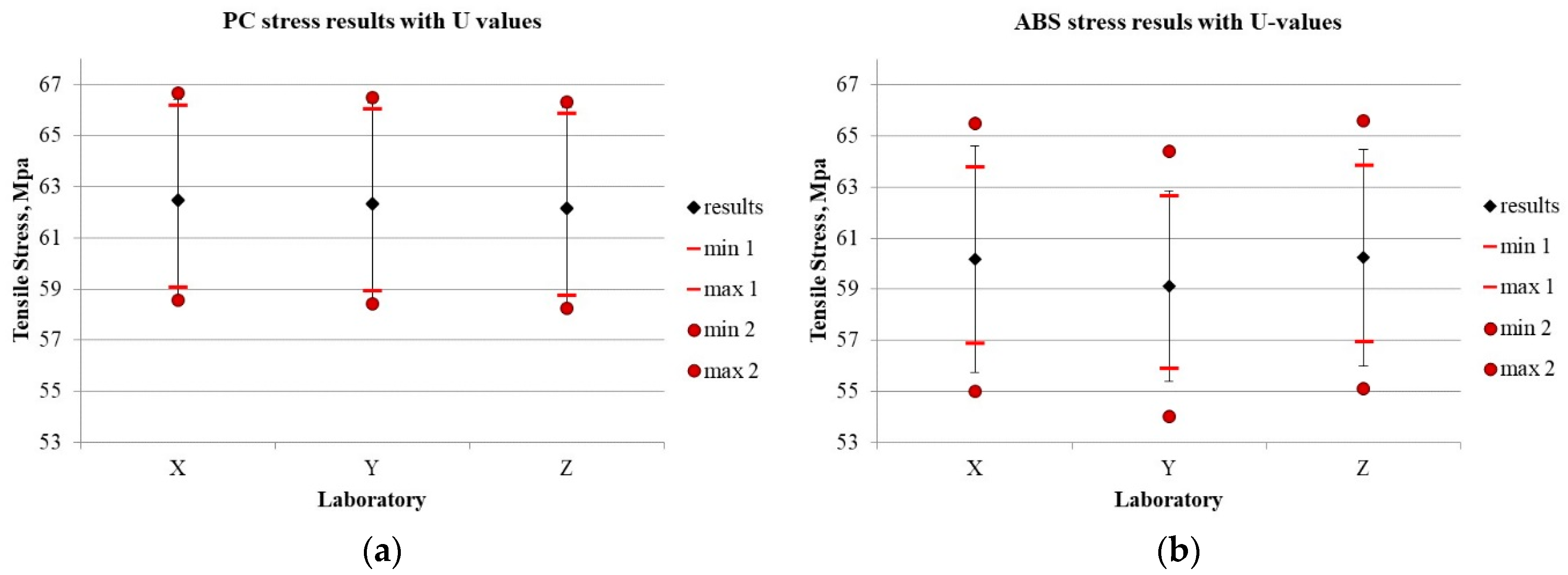

3.2.1. Precision of Tensile Strength Tests

3.2.2. Estimation of Tensile Strength Results Uncertainty

- ua,b,F—standard uncertainty of a, b, F

- —dispersion of σ results.

4. Discussion

4.1. Comparison of Methods in the Context of Uncertainty

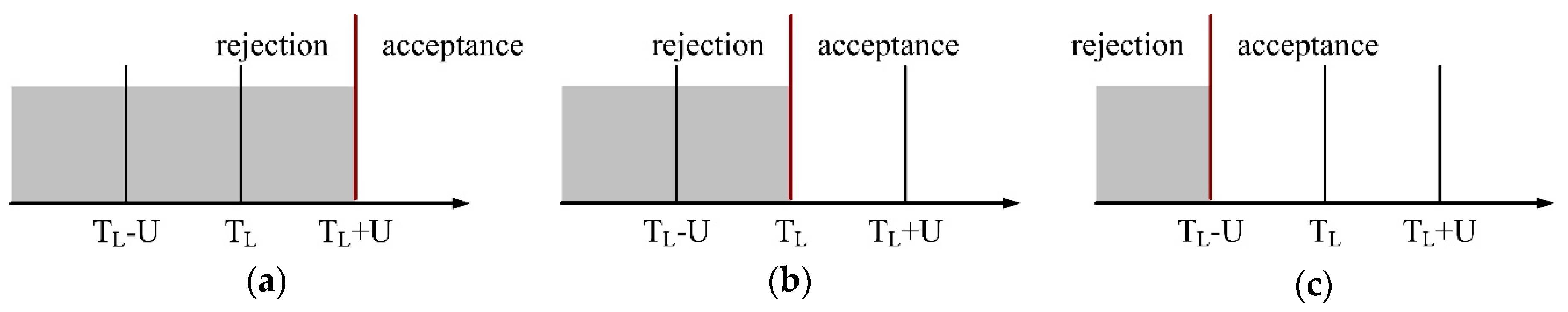

4.2. Effects Related to Material Assessment

- (a)

- Guarded acceptance (as shown in Figure 7, a lower acceptance limit AL = TL+ U, where TL—lower tolerance limit and U—expanded uncertainty)

- (b)

- Simple acceptance (a lower acceptance limit AL = TL)

- (c)

- Guarded rejection (lower acceptance limit AL = TL − U)

4.3. Difference between Initial Performance Tests and Routine Compliance Tests on the Background of Validation of Test Methods

- The test is to be carried out with the use of the substrate which the adhesive will be applied to in regular conditions of use. This solution may prove very costly for adhesives which can be used for a variety of materials.

- The test is to be carried out with the use of a reference substrate (the same for all laboratories which use a particular method, irrespective of subsequent use of the material). This increases the method precision; however, it makes the method-based test results diverge from the actual conditions of use, which in turn increases the type III risk associated with the use of an incorrect assessment criterion.

- α—targeted accuracy factor related to standard uncertainty and tolerance limits

- T—material properties tolerance range

- f—function which describes the measurement model.

4.4. Sustainable Test Methods

4.5. Final Remarks

- a non-compliant material or element is put on the market, which implies broadly defined costs for the producer related to the batch’s withdrawal

- installation of non-compliant materials—this may result in failures, repair mitigation costs, as well as immeasurable costs of impact on health and safety.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Czarnecki, L.; Van Gemert, D. Scientific basis and rules of thumb in civil engineering: conflict or harmony? Bull. Polish Acad. Sci. Tech. Sci. 2016, 64, 665–673. [Google Scholar] [CrossRef]

- Czarnecki, L. Sustainable Concrete; Is Nanotechnology the Future of Concrete Polymer Composites? Adv. Mater. Res. 2013, 687, 3–11. [Google Scholar] [CrossRef]

- Malesa, M.; Malowany, K.; Pawlicki, J.; Kujawinska, M.; Skrzypczak, P.; Piekarczuk, A.; Lusa, T.; Zagorski, A. Non-destructive testing of industrial structures with the use of multi-camera Digital Image Correlation method. Eng. Fail. Anal. 2016, 69, 122–134. [Google Scholar] [CrossRef]

- Piekarczuk, A. Experimental and numerical studies of double corrugated steel arch panels. Thin-Walled Struct. 2019, 140, 60–73. [Google Scholar] [CrossRef]

- Węgrzyński, W.; Turkowski, P.; Roszkowski, P. The discrepancies in energy balance in furnace testing, a bug or a feature? Fire Mater. 2019. [Google Scholar] [CrossRef]

- Rajczakowska, M.; Habermehl-Cwirzen, K.; Hedlund, H.; Cwirzen, A. The Effect of Exposure on the Autogenous Self-Healing of Ordinary Portland Cement Mortars. Materials 2019, 12, 3926. [Google Scholar] [CrossRef]

- Ukrainczyk, N.; Muthu, M.; Vogt, O.; Koenders, E. Geopolymer, Calcium Aluminate, and Portland Cement-Based Mortars: Comparing Degradation Using Acetic Acid. Materials 2019, 12, 3115. [Google Scholar] [CrossRef]

- Gorzelańczyk, T.; Schabowicz, K. Effect of Freeze–Thaw Cycling on the Failure of Fibre-Cement Boards, Assessed Using Acoustic Emission Method and Artificial Neural Network. Materials 2019, 12, 2181. [Google Scholar] [CrossRef]

- Kwan, A.K.H.; Ng, P.L. Building Diagnostic Techniques and Building Diagnosis: The Way Forward. In Engineering Asset Management-Systems, Professional Practices and Certification; Tse, P., Mathew, J., Wong, K., Lam, R., Ko, C.N., Eds.; Springer: Berlin, Germany, 2015. [Google Scholar]

- Schabowicz, K. Non-Destructive Testing of Materials in Civil Engineering. Materials 2019, 12, 3237. [Google Scholar] [CrossRef]

- Piasecki, M. Practical Implementation of the Indoor Environmental Quality Model for the Assessment of Nearly Zero Energy Single-Family Building. Buildings 2019, 9, 214. [Google Scholar] [CrossRef]

- Piasecki, M.; Kostyrko, K.; Pykacz, S. Indoor environmental quality assessment: Part 1: Choice of the indoor environmental quality sub-component models. J. Build. Phys. 2017, 41, 264–289. [Google Scholar] [CrossRef]

- Bragança, L.; Mateus, R.; Koukkari, H. Building Sustainability Assessment. Sustainability 2010, 2, 2010–2023. [Google Scholar] [CrossRef]

- Walker, W.E.; Harremoës, P.; Rotmans, J.; van der Sluijs, J.P.; van Asselt, M.B.A.; Janssen, P.; Krayer von Krauss, M.P. Defining Uncertainty: A Conceptual Basis for Uncertainty Management in Model-Based Decision Support. Integr. Assess. 2003, 4, 5–17. [Google Scholar] [CrossRef]

- Trzpiot, G. Some remarks of type iii error for directional two-tailed test. Stud. Èkon. 2015, 219, 5–16. [Google Scholar]

- Conte, E. The Era of Sustainability: Promises, Pitfalls and Prospects for Sustainable Buildings and the Built Environment. Sustainability 2018, 10, 2092. [Google Scholar] [CrossRef]

- Czarnecki, L.; Van Gemert, D. Innovation in construction materials engineering versus sustainable development. Bull. Polish Acad. Sci. Tech. Sci. 2017, 65, 765–771. [Google Scholar] [CrossRef][Green Version]

- JCGM 106:2012 Evaluation of Measurement Data—The Role of Measurement Uncertainty in Conformity Assessment; JCGM: Sèvres, France, 2012.

- Pendrill, L.R. Using measurement uncertainty in decision-making and conformity assessment. Metrologia 2014, 51, S206–S218. [Google Scholar] [CrossRef]

- JCGM 100:2008 Evaluation of Measurement Data—Guide to the Expression of Uncertainty in Measurement; JCGM: Sèvres, France, 2008.

- JCGM 101:2008 Evaluation of Measurement data—Supplement 1 to the “Guide to the Expression of Uncertainty in Measurement”—Propagation of Distributions using a Monte Carlo Method; JCGM: Sèvres, France, 2008.

- Bich, W. From Errors to Probability Density Functions. Evolution of the Concept of Measurement Uncertainty. IEEE Trans. Instrum. Meas. 2012, 61, 2153–2159. [Google Scholar] [CrossRef]

- Kacker, R.N. Measurement uncertainty and its connection with true value in the GUM versus JCGM documents. Measurement 2018, 127, 525–532. [Google Scholar] [CrossRef]

- Grégis, F. On the meaning of measurement uncertainty. Measurement 2019, 133, 41–46. [Google Scholar] [CrossRef]

- EA-4/16 G:2003 EA Guidelines on the Expression of Uncertainty in Quantitative Testing; EA: Paris, France, 2003.

- JCGM 200:2012 International Vocabulary of Metrology–Basic and General Concepts and Associated Terms (VIM); JCGM: Sèvres, France, 2012.

- Szewczak, E.; Piekarczuk, A. Performance evaluation of the construction products as a research challenge. Small error-Big difference in assessment? Bull. Polish Acad. Sci. Tech. Sci. 2016, 64, 675–686. [Google Scholar] [CrossRef][Green Version]

- Czarnecki, L.; Łukowski, P. Polymer-cement concretes. Cem. Lime Concr. 2010, 5, 243–258. [Google Scholar]

- ÖNORM B 6100:1998 10 01 Außenwand-Wärmedämmverbundsysteme-Prüfverfahren; Austrian Standards: Vienna, Austria, 1998.

- ETAG 004 External Thermal Insulation Composite Systems with Rendering; EOTA: Brussels, Belgium, 2013.

- ISO 527-1,2:2012 Plastics—Determination of Tensile Properties—Part 1: General Principles, Part 2: Test Conditions for Moulding and Extrusion Plastics; ISO: Geneva, Switzerland, 2012.

- Helbig, T.; Beyer, S. DRRR-Proficiency Testing RVEP 16151 Tensile Test (strength/elongation) ISO 527-1/-2. Unpublished work. 2016. [Google Scholar]

- Shang, J.; Hencher, S.R.; West, L.J. Tensile Strength of Geological Discontinuities Including Incipient Bedding, Rock Joints and Mineral Veins. Rock Mech. Rock Eng. 2016, 49, 4213–4225. [Google Scholar] [CrossRef]

- ISO 5725-2:1994 Accuracy (Trueness and Precision) of Measurement Methods and Results—Part 2: Basic Method for the Determination of Repeatability and Reproducibility of a Standard Measurement Method; ISO: Geneva, Switzerland, 1994.

- NIST Uncertainty Machine. Available online: https://uncertainty.nist.gov/ (accessed on 20 December 2019).

- Grégis, F. Assessing accuracy in measurement: The dilemma of safety versus precision in the adjustment of the fundamental physical constants. Stud. Hist. Philos. Sci. Part A 2019, 74, 42–55. [Google Scholar] [CrossRef] [PubMed]

- Czarnecki, L.; Sokołowska, J.J. Material model and revealing the truth. Bull. Polish Acad. Sci. Tech. Sci. 2015, 63, 7–14. [Google Scholar] [CrossRef][Green Version]

- Laying Down Harmonised Conditions for the Marketing of Construction Products and Repealing Council Directive 89/106/EEC; European Union: Brussels, Belgium, 2011.

- Scheiber, F.; Motra, H.B.; Legatiuk, D.; Werner, F. Uncertainty-based evaluation and coupling of mathematical and physical models. Probabilistic Eng. Mech. 2016, 45, 52–60. [Google Scholar] [CrossRef]

- Oberkampf, W.L.; Trucano, T.G.; Hirsch, C. Verification, validation, and predictive capability in computational engineering and physics. Appl. Mech. Rev. 2004, 57, 345–384. [Google Scholar] [CrossRef]

| Laboratory | a | b | c | d | e | f | g | h | i | k | l | m | n | o | p |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bond Strength Results, MPa | |||||||||||||||

| 1 | 0.022 | 0.026 | 0.045 | 0.043 | 0.042 | 0.040 | 0.048 | 0.047 | 0.046 | 0.060 | 0.044 | 0.066 | 0.062 | 0.084 | 0.108 |

| 2 | 0.022 | 0.054 | 0.046 | 0.045 | 0.044 | 0.057 | 0.038 | 0.047 | 0.059 | 0.045 | 0.071 | 0.093 | 0.085 | 0.083 | 0.099 |

| 3 | 0.034 | 0.040 | 0.051 | 0.056 | 0.061 | 0.054 | 0.066 | 0.072 | 0.070 | 0.079 | 0.080 | 0.089 | 0.103 | 0.112 | 0.113 |

| Average Bond Strength for Three Laboratories for Particular Adhesives | |||||||||||||||

| 0.026 | 0.040 | 0.047 | 0.048 | 0.049 | 0.050 | 0.051 | 0.056 | 0.058 | 0.061 | 0.065 | 0.083 | 0.084 | 0.093 | 0.106 | |

| The v Coefficient of Variation of Bond Strength Results for 15 Different Adhesives and Three Laboratories in % | |||||||||||||||

| 1 | 48.7 | 24.5 | 15.6 | 17.8 | 16.6 | 28.4 | 8.9 | 17.1 | 33.1 | 16.9 | 9.1 | 15.4 | 33.4 1 | 18.0 | 11.5 |

| 2 | 64.6 | 14.6 | 53.5 | 12.7 | 55.6 2 | 6.8 | 9.1 | 12.2 | 4.5 | 54.3 | 12.4 | 6.8 | 4.4 | 8.3 | 10.8 |

| 3 | 18.5 | 23.2 | 35.6 | 19.4 | 11.0 | 10.9 | 8.6 | 8.3 | 16.1 | 11.9 | 5.5 | 9.9 | 5.6 | 16.2 | 8.9 |

| Repeatability Expressed as Coefficient of Variation ν for Each Adhesive in % | |||||||||||||||

| 41.9 | 19.8 | 38.4 | 17.4 | 30.9 | 15.3 | 9.0 | 12.1 | 18.9 | 26.5 | 9.5 | 10.4 | 15.1 | 15.3 | 10.4 | |

| Reproducibility Expressed as ν Coefficient of Variation of Each Adhesive in % | |||||||||||||||

| 45.3 | 39.0 | 42.3 | 21.4 | 34.5 | 22.5 | 28.5 | 28.4 | 26.6 | 35.7 | 29.6 | 19.8 | 27.7 | 22.1 | 11.4 | |

| Approach | Force F, N Diameter D, mm | Random Dispersion of σ Results | Coverage Factor, k |

|---|---|---|---|

| I approach | Type B evaluation, based on the standard requirements regarding accuracy: F-force measurement accuracy 1%. Rectangular PDF 1 D-accuracy of the sample preparation 1 mm. Rectangular PDF | No evaluation. Approach based on the assumption that uncertainty relates to the accuracy of the direct measurements only (F and D) | k = 2 (sometimes inappropriate but often used). |

| II approach | Type A evaluation based on the current test results. 4 results, ν = 3 degrees of freedom. | k = t0.95(νeff), where νeff—value of tp from t-distribution with an effective degree of freedom νeff obtained from the Welch-Satterthwaite formula. p-fraction of the distribution | |

| III approach | Type B evaluation, based on historical results (e.g., inter-laboratory tests–reproducibility). Normal PDF. | k = 2, based on the assumption that the sR component with normal distribution is dominant. | |

| IV approach | Type A evaluation based on the current test results. Normal PDF | No k-factor, 95% coverage intervals obtained by the Monte Carlo method [35] |

| Approach | Adhesive ‘n’ | Adhesive ‘o’ | ||||

|---|---|---|---|---|---|---|

| Lab. 1 | Lab. 2 | Lab. 3 | Lab. 1 | Lab. 2 | Lab. 3 | |

| Results, MPa | 0.062 | 0.085 | 0.103 | 0.084 | 0.083 | 0.112 |

| Uncertainties, MPa | ||||||

| I approach | 0.003 | 0.004 | 0.005 | 0.004 | 0.004 | 0.005 |

| II approach | 0.066 | 0.011 | 0.017 | 0.048 | 0.020 | 0.058 |

| III approach | 0.074 | 0.074 | 0.074 | 0.065 | 0.065 | 0.066 |

| IV approach | 0.046 | 0.047 | 0.047 | 0.039 | 0.041 | 0.041 |

| Way of Assessment | Approach for Uncertainty Evaluation | Laboratory 1 | Laboratory 2 | Laboratory 3 |

|---|---|---|---|---|

| Guarded acceptance | I | rejection | acceptance | acceptance |

| II | rejection | rejection | acceptance | |

| III | rejection | rejection | rejection | |

| IV | rejection | rejection | rejection | |

| Simple acceptance | I, II, III, IV | rejection | acceptance | acceptance |

| Guarded rejection | I | rejection | acceptance | acceptance |

| II | acceptance | acceptance | acceptance | |

| III | acceptance | acceptance | acceptance | |

| IV | acceptance | acceptance | acceptance |

| Material | Method 1, Round Stamp, D = 50 mm, Medium Bond Strength, MPa | Method 2, Square Stamp a = 50 mm Medium Bond Strength, MPa |

|---|---|---|

| Adhesive 1 | 0.046 | 0.068 |

| Adhesive 2 | 0.066 | 0.097 |

| Adhesive 3 | 0.051 | 0.085 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szewczak, E.; Winkler-Skalna, A.; Czarnecki, L. Sustainable Test Methods for Construction Materials and Elements. Materials 2020, 13, 606. https://doi.org/10.3390/ma13030606

Szewczak E, Winkler-Skalna A, Czarnecki L. Sustainable Test Methods for Construction Materials and Elements. Materials. 2020; 13(3):606. https://doi.org/10.3390/ma13030606

Chicago/Turabian StyleSzewczak, Ewa, Agnieszka Winkler-Skalna, and Lech Czarnecki. 2020. "Sustainable Test Methods for Construction Materials and Elements" Materials 13, no. 3: 606. https://doi.org/10.3390/ma13030606

APA StyleSzewczak, E., Winkler-Skalna, A., & Czarnecki, L. (2020). Sustainable Test Methods for Construction Materials and Elements. Materials, 13(3), 606. https://doi.org/10.3390/ma13030606