Nanoscale Plasticity Behavior of Additive-Manufactured Zirconia-Toughened Alumina Ceramics during Nanoindentation

Abstract

1. Introduction

2. Materials and Methods

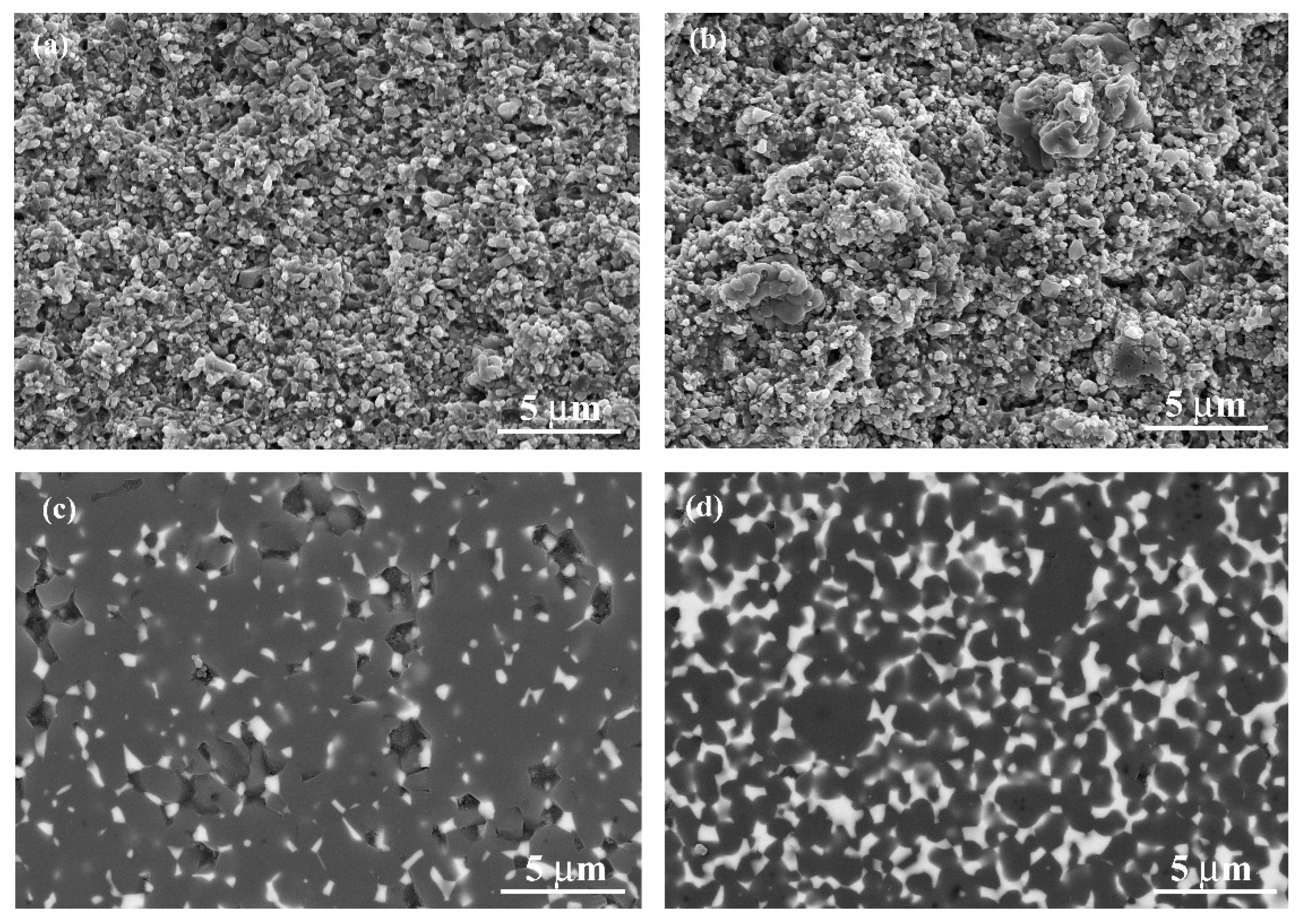

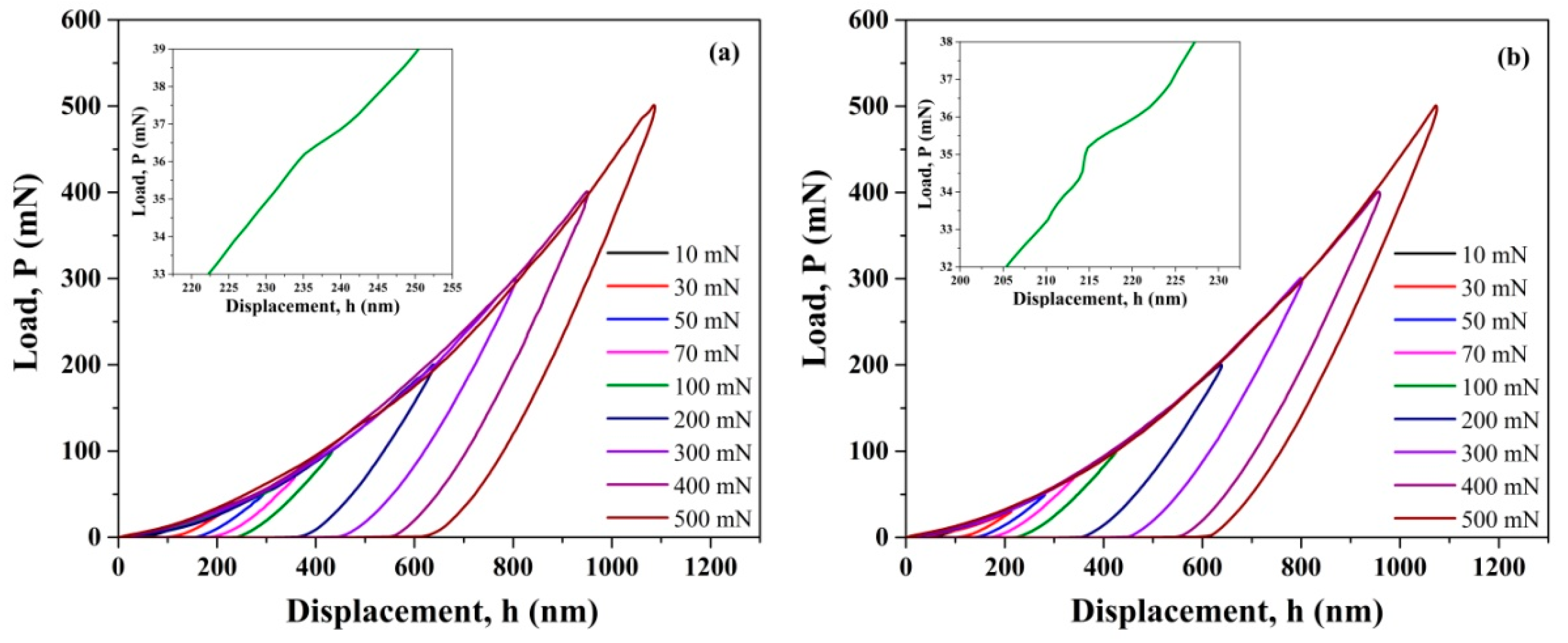

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sequeira, S.; Fernandes, M.H.; Neves, N.; Almeida, M.M. Development and characterization of zirconia-Alumina composites for orthopedic implants. Ceram. Int. 2017, 43, 693–703. [Google Scholar] [CrossRef]

- Maiti, P.; Bhattacharya, M.; Das, P.S.; Devi, P.S.; Mukhopadhyay, A.K. Indentation size effect and energy balance issues in nanomechanical behavior of ZTA ceramics. Ceram. Int. 2018, 44, 9753–9772. [Google Scholar] [CrossRef]

- Aragonduarte, M.C.; Nevarezrascon, A.; Esparzaponce, H.E.; Nevarezrascon, M.M.; Talamantes, R.P.; Ornelas, C.; Mendeznonell, J.; Gonzalezhernandez, J.; Yacaman, M.J.; Hurtadomacias, A. Nanomechanical properties of zirconia-yttria and alumina zirconia-yttria biomedical ceramics, subjected to low temperature aging. Ceram. Int. 2017, 43, 3931–3939. [Google Scholar] [CrossRef]

- Jang, K.; Kang, J.; Fisher, J.G.; Park, S. Effect of the volume fraction of zirconia suspensions on the microstructure and physical properties of products produced by additive manufacturing. Dent. Mater. 2019, 35, E97–E106. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Song, L.; Sun, J.; Ma, J.; Shen, Z. Dental ceramic prostheses by stereolithography–based additive manufacturing: Potentials and challenges. Adv. Appl. Ceram. 2019, 118, 30–36. [Google Scholar] [CrossRef]

- He, R.; Liu, W.; Wu, Z.; An, D.; Huang, M.; Wu, H.; Jiang, Q.; Ji, X.; Wu, S.; Xie, Z. Fabrication of complex-shaped zirconia ceramic parts via a DLP- stereolithography-based 3D printing method. Ceram. Int. 2018, 44, 3412–3416. [Google Scholar] [CrossRef]

- Rueschhoff, L.M.; Costakis, W.; Michie, M.; Youngblood, J.P.; Trice, R.W. Additive manufacturing of dense ceramic parts via direct ink writing of aqueous alumina suspensions. Int. J. Appl. Ceram. Technol. 2016, 13, 821–830. [Google Scholar] [CrossRef]

- Xing, Z.; Liu, W.; Chen, Y.; Li, W. Effect of plasticizer on the fabrication and properties of alumina ceramic by stereolithography-based additive manufacturing. Ceram. Int. 2018, 44, 19939–19944. [Google Scholar] [CrossRef]

- Chen, W.; Kirihara, S.; Miyamoto, Y. Fabrication and characterization of three-dimensional ZrO(2)-toughened Al(2)O(3) ceramic microdevices. Int. J. Appl. Ceram. Technol. 2008, 5, 353–359. [Google Scholar] [CrossRef]

- Wu, H.; Liu, W.; He, R.; Wu, Z.; Jiang, Q.; Song, X.; Chen, Y.; Cheng, L.; Wu, S. Fabrication of dense zirconia-toughened alumina ceramics through a stereolithography-based additive manufacturing. Ceram. Int. 2017, 43, 968–972. [Google Scholar] [CrossRef]

- Bhattacharya, M.; Chakraborty, R.; Dey, A.; Mandal, A.K.; Mukhopadhyay, A.K. Improvement in nanoscale contact resistance of alumina. Appl. Phys. A 2012, 107, 783–788. [Google Scholar] [CrossRef]

- Blaber, J.A.; Ghosh, D.; Subhash, G.; McCumiskey, E.; Taylor, C.R. Determination of post-yield hardening response in a ZrB2 ceramic. Scr. Mater. 2011, 65, 962–965. [Google Scholar] [CrossRef]

- Huang, L.; Zhang, Z.; Zhao, Y.; Yao, W.; Mukherjee, A.K.; Schoenung, J.M. Scratch-induced deformation in fine- and ultrafine-grained bulk alumina. Scr. Mater. 2010, 63, 528–531. [Google Scholar] [CrossRef]

- Staehler, J.M.; Predebon, W.W.; Pletka, B.J.; Subhash, G. Micromechanisms of deformation in high-purity hot-pressed alumina. Mater. Sci. Eng. A 2000, 291, 37–45. [Google Scholar] [CrossRef]

- Scholz, T.; Mclaughlin, K.K.; Giuliani, F.; Clegg, W.; Espinozabeltran, F.J.; Swain, M.V.; Schneider, G.A. Nanoindentation initiated dislocations in barium titanate (BaTiO3). Appl. Phys. Lett. 2007, 91, 062903. [Google Scholar] [CrossRef]

- Shao, H.; Zhao, D.; Lin, T.; He, J.; Wu, J. 3D gel-printing of zirconia ceramic parts. Ceram. Int. 2017, 43, 13938–13942. [Google Scholar] [CrossRef]

- Ghazanfari, A.; Li, W.; Leu, M.C.; Watts, J.L.; Hilmas, G.E. Additive manufacturing and mechanical characterization of high density fully stabilized zirconia. Ceram. Int. 2017, 43, 6082–6088. [Google Scholar] [CrossRef]

- Harrer, W.; Schwentenwein, M.; Lube, T.; Danzer, R. Fractography of zirconia-specimens made using additive manufacturing (LCM) technology. J. Eur. Ceram. Soc. 2017, 37, 4331–4338. [Google Scholar] [CrossRef]

- Bhattacharya, M.; Chakraborty, R.; Dey, A.; Mandal, A.K.; Mukhopadhyay, A.K. New observations in micro-pop-in issues in nanoindentation of coarse grain alumina. Ceram. Int. 2013, 39, 999–1009. [Google Scholar] [CrossRef]

- He, B.; Liang, Z.Y.; Huang, M.X. Nanoindentation investigation on the initiation of yield point phenomenon in a medium Mn steel. Scr. Mater. 2018, 150, 134–138. [Google Scholar] [CrossRef]

- Huang, L.; Yao, W.; Mukherjee, A.K.; Schoenung, J.M. Improved mechanical behavior and plastic deformation capability of ultrafine grain alumina ceramics. J. Am. Ceram. Soc. 2012, 95, 379–385. [Google Scholar] [CrossRef]

- Bhattacharya, M.; Mukhopadhyay, A.K. Interaction of nanoscale damages with static and dynamic contact induced damages in alumina: A novel approach using nanoindentation. Ceram. Int. 2019, 45, 24982–24998. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Meunier, C.; Zuo, F.; Peillon, N.; Saunier, S.; Marinel, S.; Goeuriot, D. In situ study on microwave sintering of ZTA ceramic: Effect of ZrO2 content on densification, hardness, and toughness. J. Am. Ceram. Soc. 2017, 100, 929–936. [Google Scholar] [CrossRef]

- Lian, J.; Garay, J.E.; Wang, J. Grain size and grain boundary effects on the mechanical behavior of fully stabilized zirconia investigated by nanoindentation. Scr. Mater. 2007, 56, 1095–1098. [Google Scholar] [CrossRef]

- Mao, W.; Shen, Y.G. Nanoindentation study of pop-in phenomenon characteristics and mechanical properties of sapphire (1012) Crystal. J. Am. Ceram. Soc. 2012, 95, 3605–3612. [Google Scholar] [CrossRef]

- Swain, M.V. Limitation of maximum strength of zirconia-toughened ceramics by transformation toughening increment. J. Am. Ceram. Soc. 1985, 68, C-97–C-99. [Google Scholar] [CrossRef]

- Mao, W.; Shen, Y.G.; Lu, C. Deformation behavior and mechanical properties of polycrystalline and single crystal alumina during nanoindentation. Scr. Mater. 2011, 65, 127–130. [Google Scholar] [CrossRef]

- An, D.; Li, H.; Xie, Z.; Zhu, T.; Luo, X.; Shen, Z.; Ma, J. Additive manufacturing and characterization of complex Al2O3 parts based on a novel stereolithography method. Int. J. Appl. Ceram. Technol. 2017, 14, 836–844. [Google Scholar] [CrossRef]

- Maiti, P.; Eqbal, A.; Bhattacharya, M.; Das, P.S.; Ghosh, J.; Mukhopadhyay, A. Micro pop-in issues in nanoindentation behaviour of 10 ZTA ceramics. Ceram. Int. 2019, 45, 8204–8215. [Google Scholar] [CrossRef]

- Trejoarroyo, D.; Zaratemedina, J.; Alvaradoorozco, J.M.; Contrerasgarcia, M.E.; Boldrick, M.S.; Munozsaldana, J. Microstructure and mechanical properties of Al2O3-YSZ spherical polycrystalline composites. J. Eur. Ceram. Soc. 2013, 33, 1907–1916. [Google Scholar] [CrossRef]

- Page, T.F.; Oliver, W.C.; Mchargue, C.J. The deformation behavior of ceramic crystals subjected to very low load (nano)indentations. J. Mater. Res. 1992, 7, 450–473. [Google Scholar] [CrossRef]

- Tang, D.; Lim, H.; Lee, K.; Lee, C.; Cho, W. Evaluation of mechanical reliability of zirconia-toughened alumina composites for dental implants. Ceram. Int. 2012, 38, 2429–2436. [Google Scholar] [CrossRef]

| Technology | Material | hc (nm) | Pc (mN) | τmax (GPa) | Ref. |

|---|---|---|---|---|---|

| AM | ZTA10 | 5.06–14.20 | 0.06–1.55 | 8.64–24.66 | This work |

| Uniaxial pressing | 10 ZTA (10 vol. %) | 0.93–3.24 | 0.11–0.16 | 14.59–16.66 | [30] |

| AM | ZTA30 | 2.85–13.42 | 0.04–1.82 | 7.42–24.81 | This work |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Liu, W.; Li, M.; Nie, J.; Chen, Y.; Xing, Z. Nanoscale Plasticity Behavior of Additive-Manufactured Zirconia-Toughened Alumina Ceramics during Nanoindentation. Materials 2020, 13, 1006. https://doi.org/10.3390/ma13041006

Li W, Liu W, Li M, Nie J, Chen Y, Xing Z. Nanoscale Plasticity Behavior of Additive-Manufactured Zirconia-Toughened Alumina Ceramics during Nanoindentation. Materials. 2020; 13(4):1006. https://doi.org/10.3390/ma13041006

Chicago/Turabian StyleLi, Wenli, Weiwei Liu, Maoshan Li, Jianbin Nie, Yao Chen, and Zhanwen Xing. 2020. "Nanoscale Plasticity Behavior of Additive-Manufactured Zirconia-Toughened Alumina Ceramics during Nanoindentation" Materials 13, no. 4: 1006. https://doi.org/10.3390/ma13041006

APA StyleLi, W., Liu, W., Li, M., Nie, J., Chen, Y., & Xing, Z. (2020). Nanoscale Plasticity Behavior of Additive-Manufactured Zirconia-Toughened Alumina Ceramics during Nanoindentation. Materials, 13(4), 1006. https://doi.org/10.3390/ma13041006