An Enhanced Three-Dimensional Auxetic Lattice Structure with Improved Property

Abstract

:1. Introduction

2. Experimental

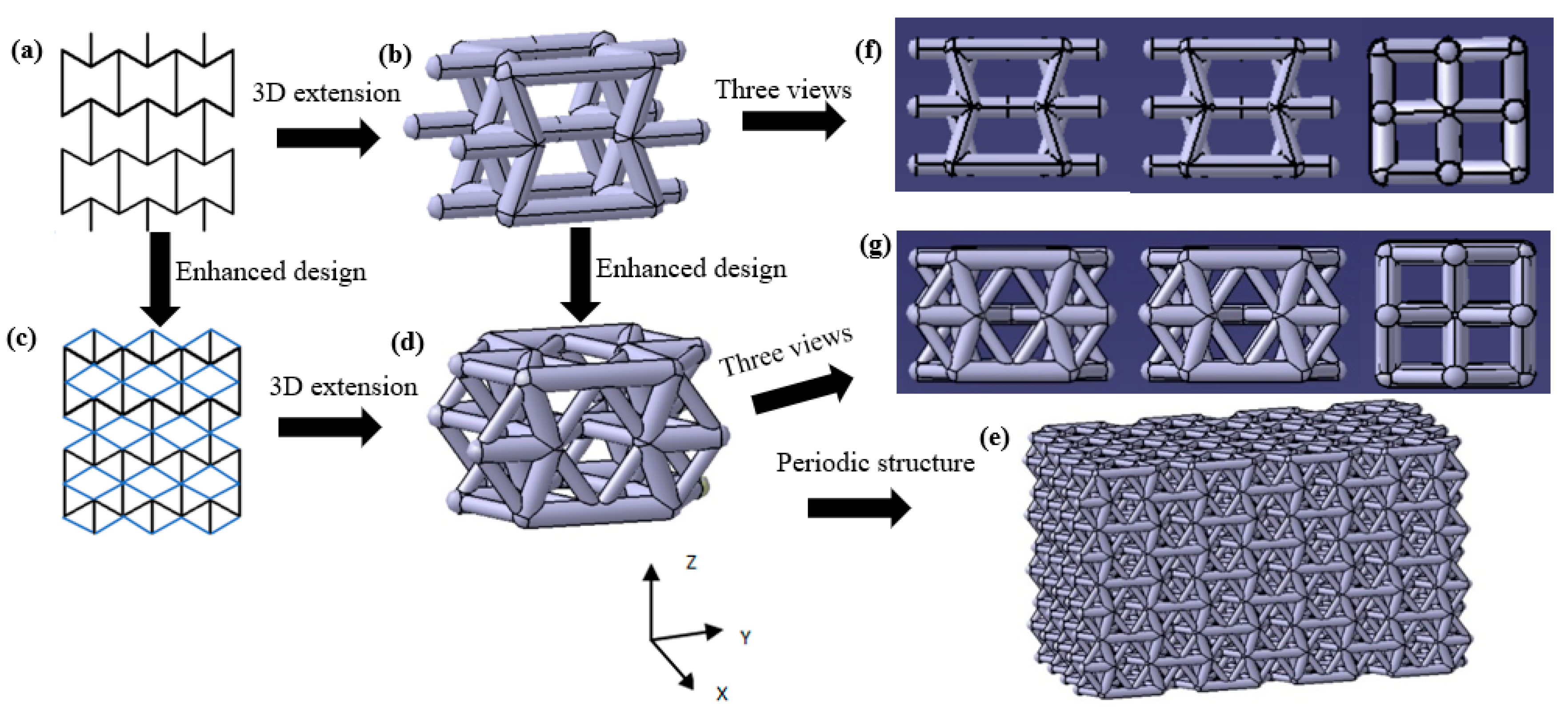

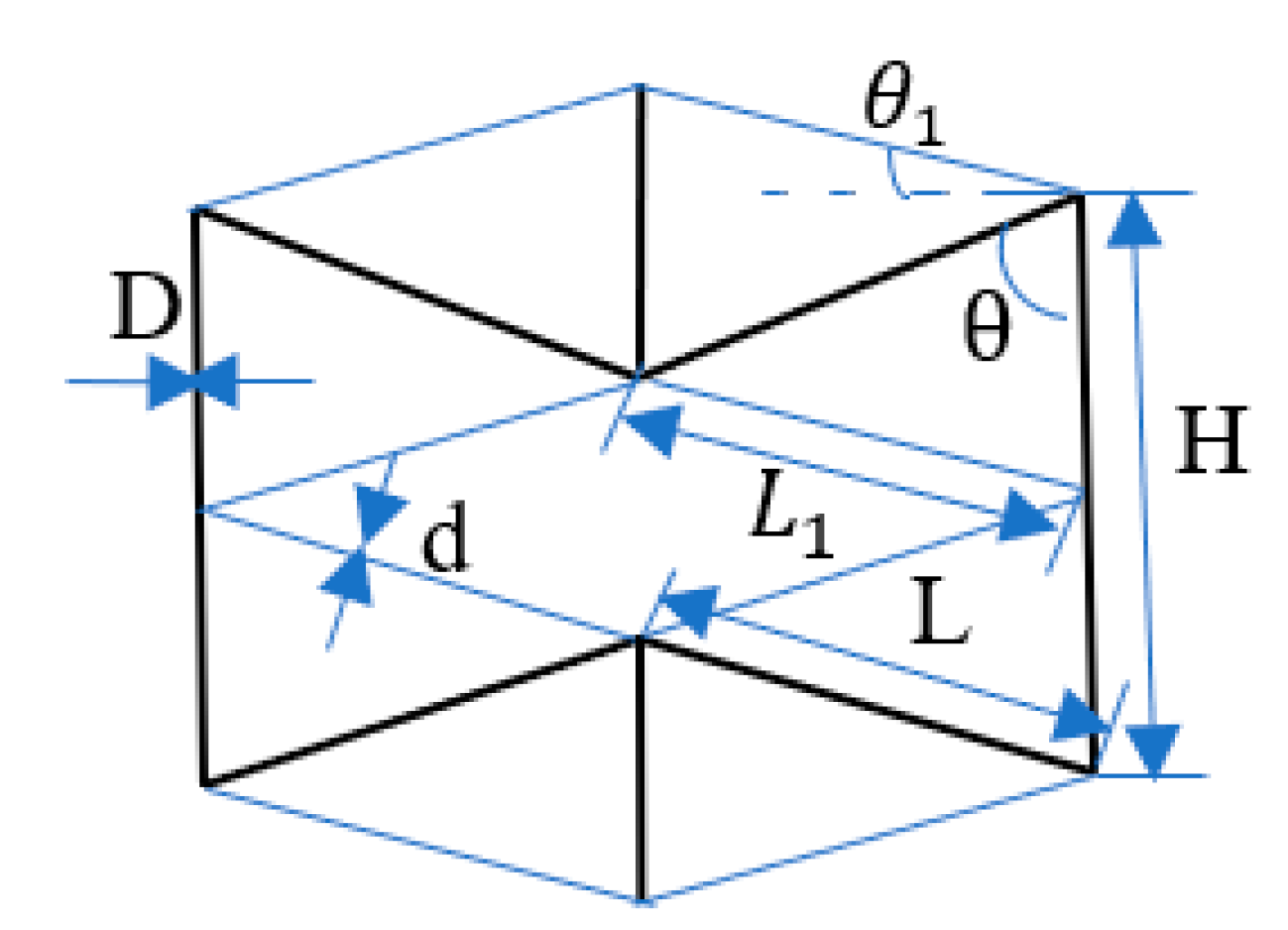

2.1. Structure Design

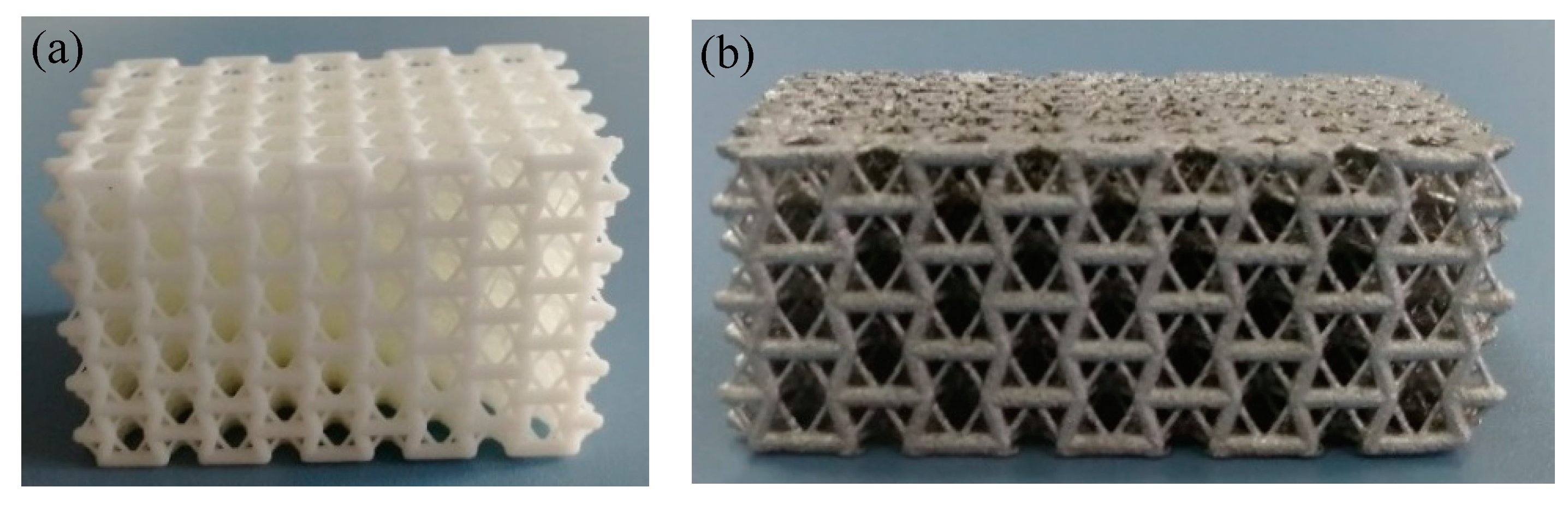

2.2. Fabrication of Lattice Samples

2.3. Mechanical Measurement

3. Results and Discussion

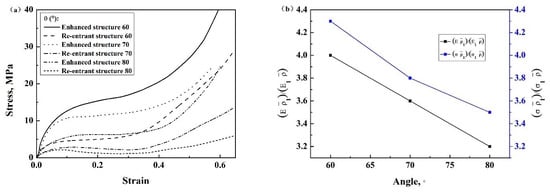

3.1. Parameter Studies of the Structures

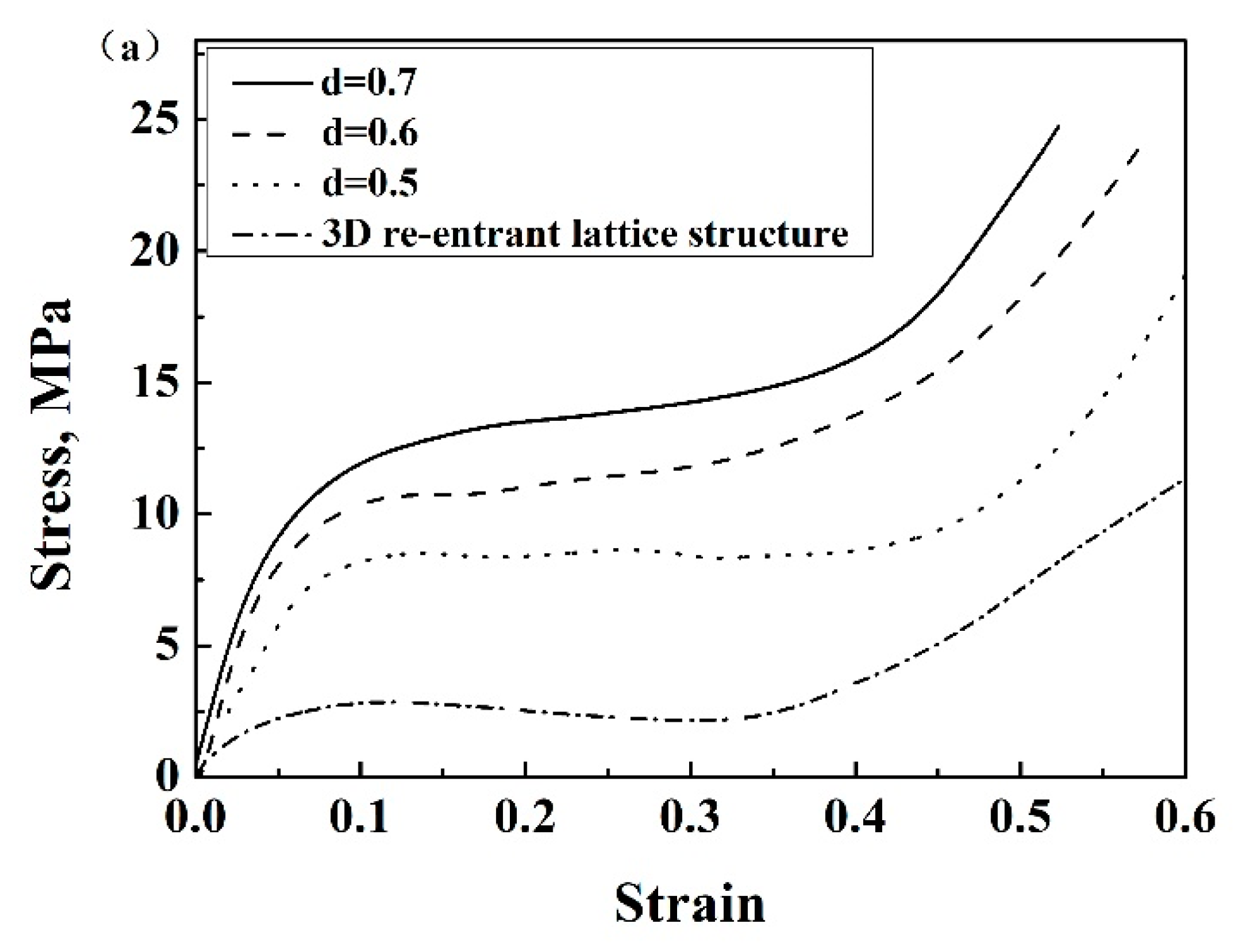

3.1.1. Effect of Strut Diameter d

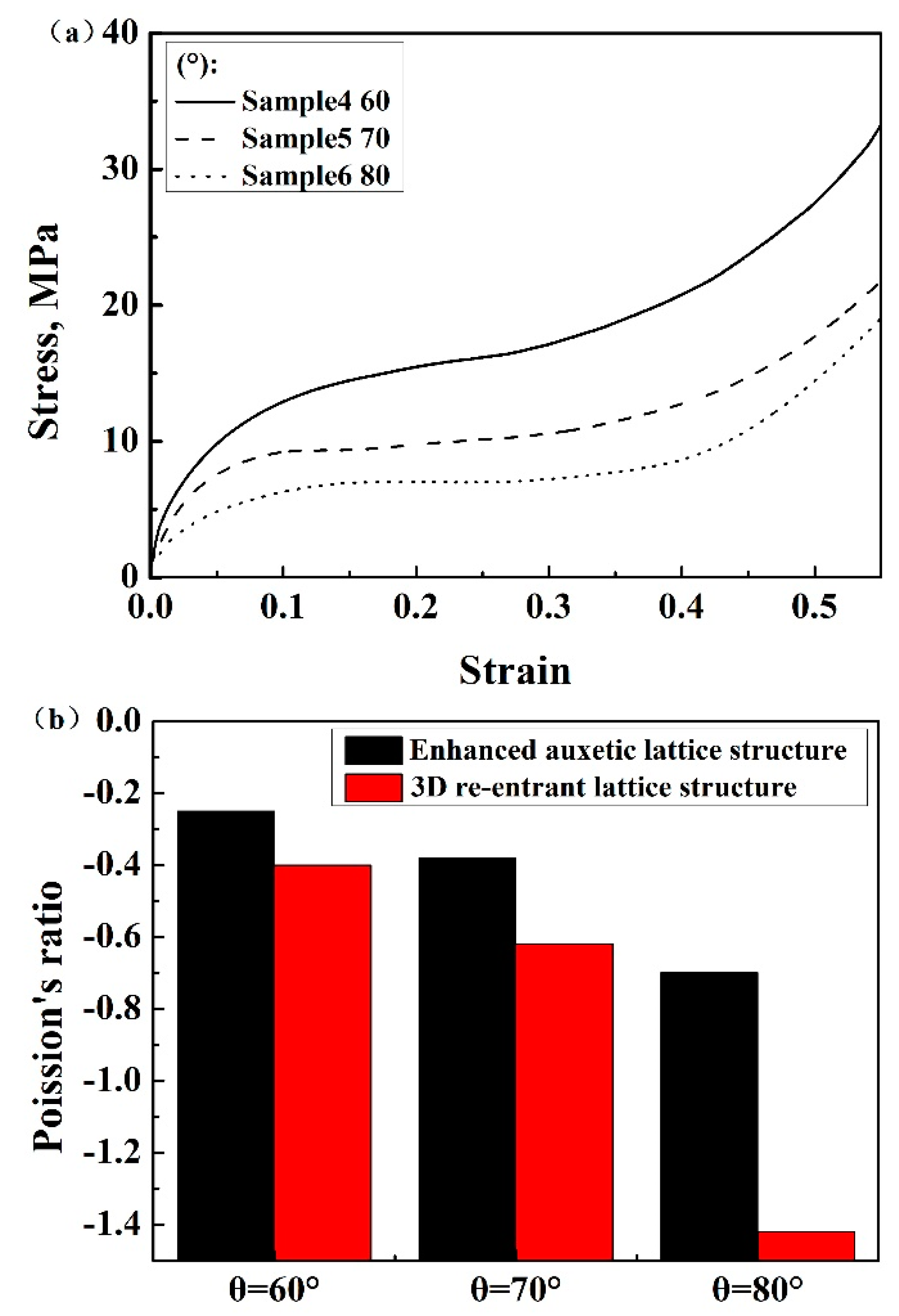

3.1.2. Effect of θ Angle

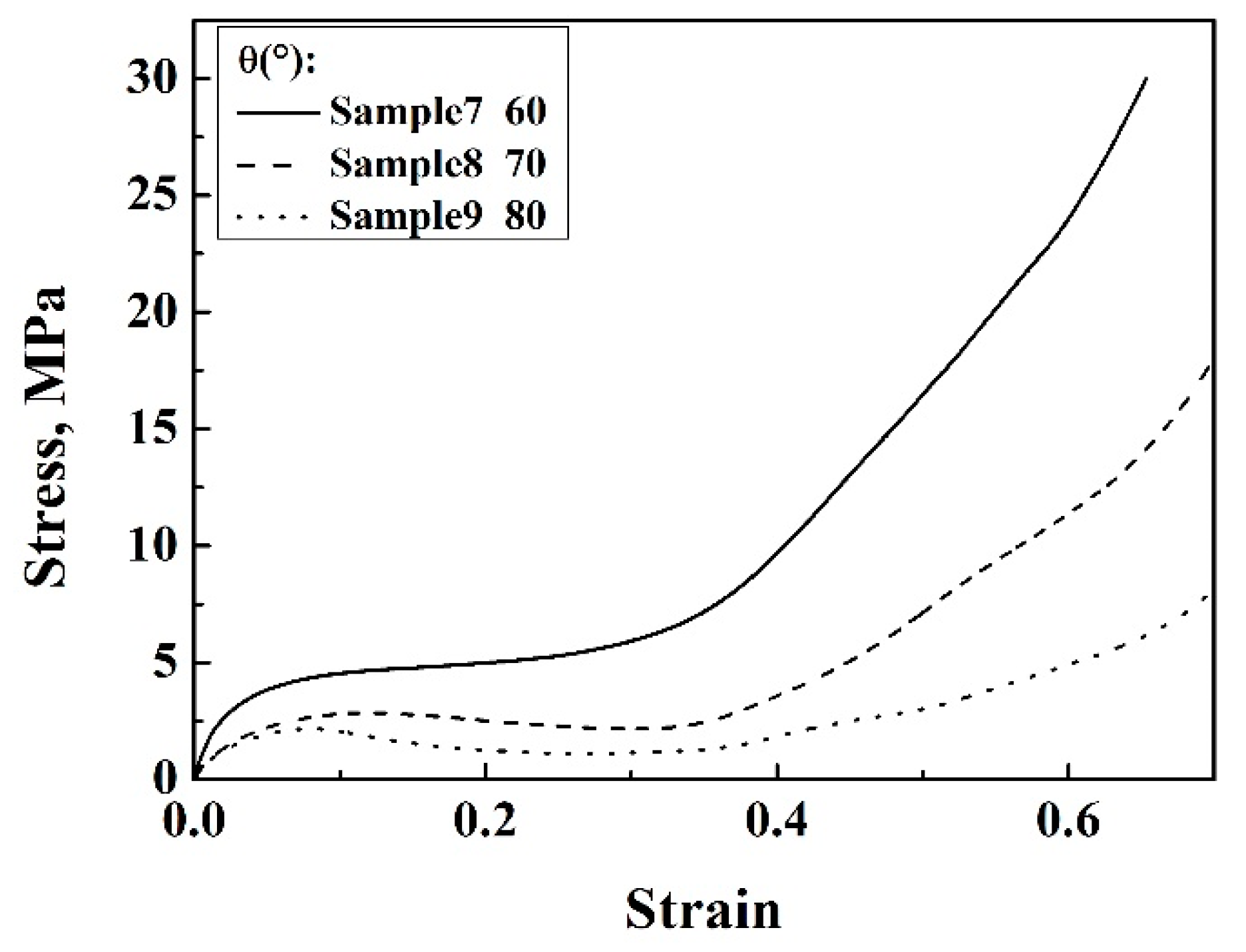

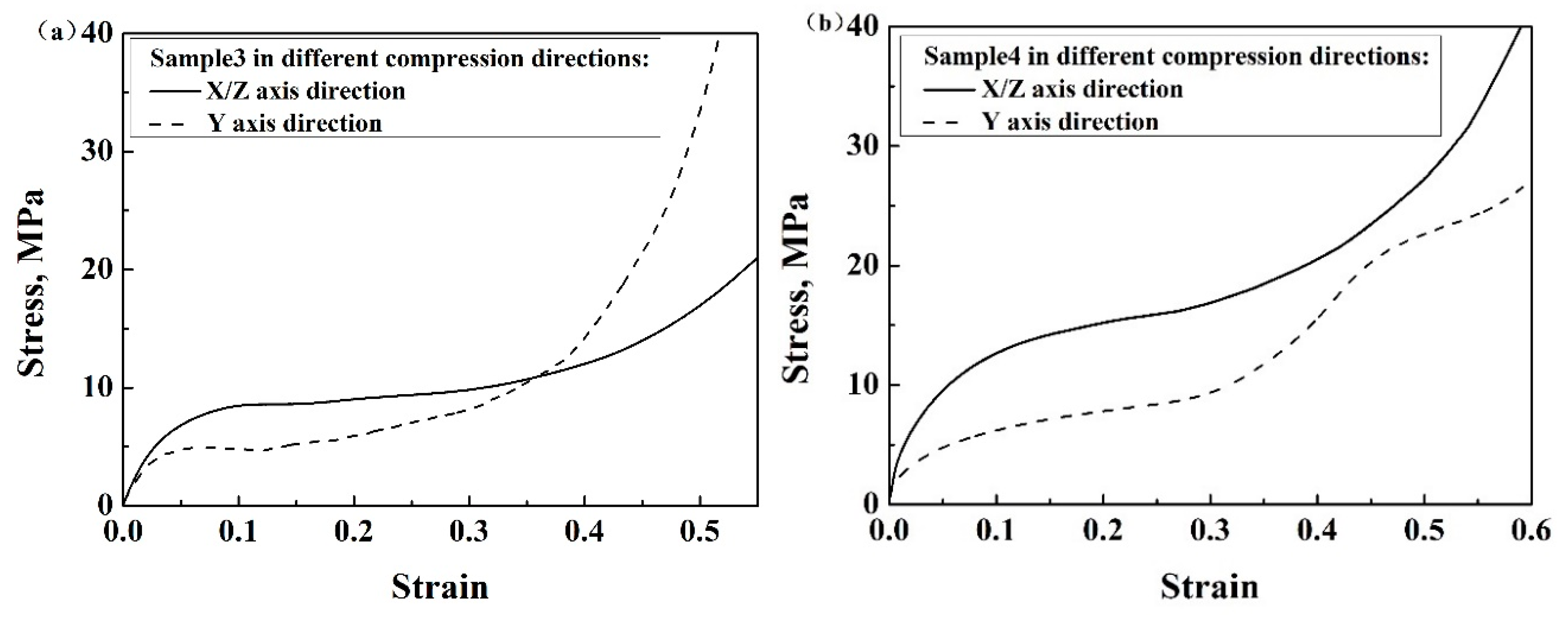

3.2. Effect of Compression Direction

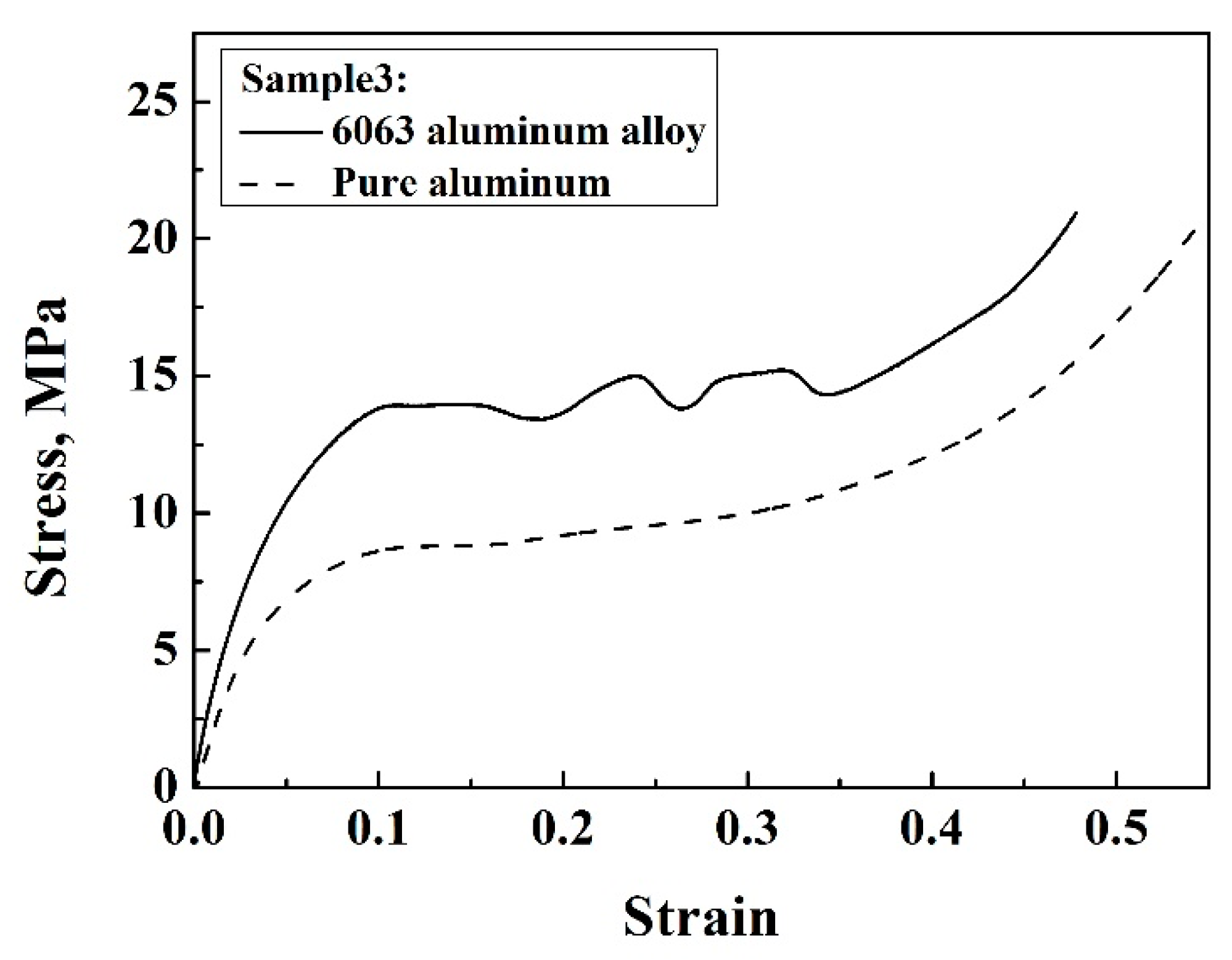

3.3. Effect of Material

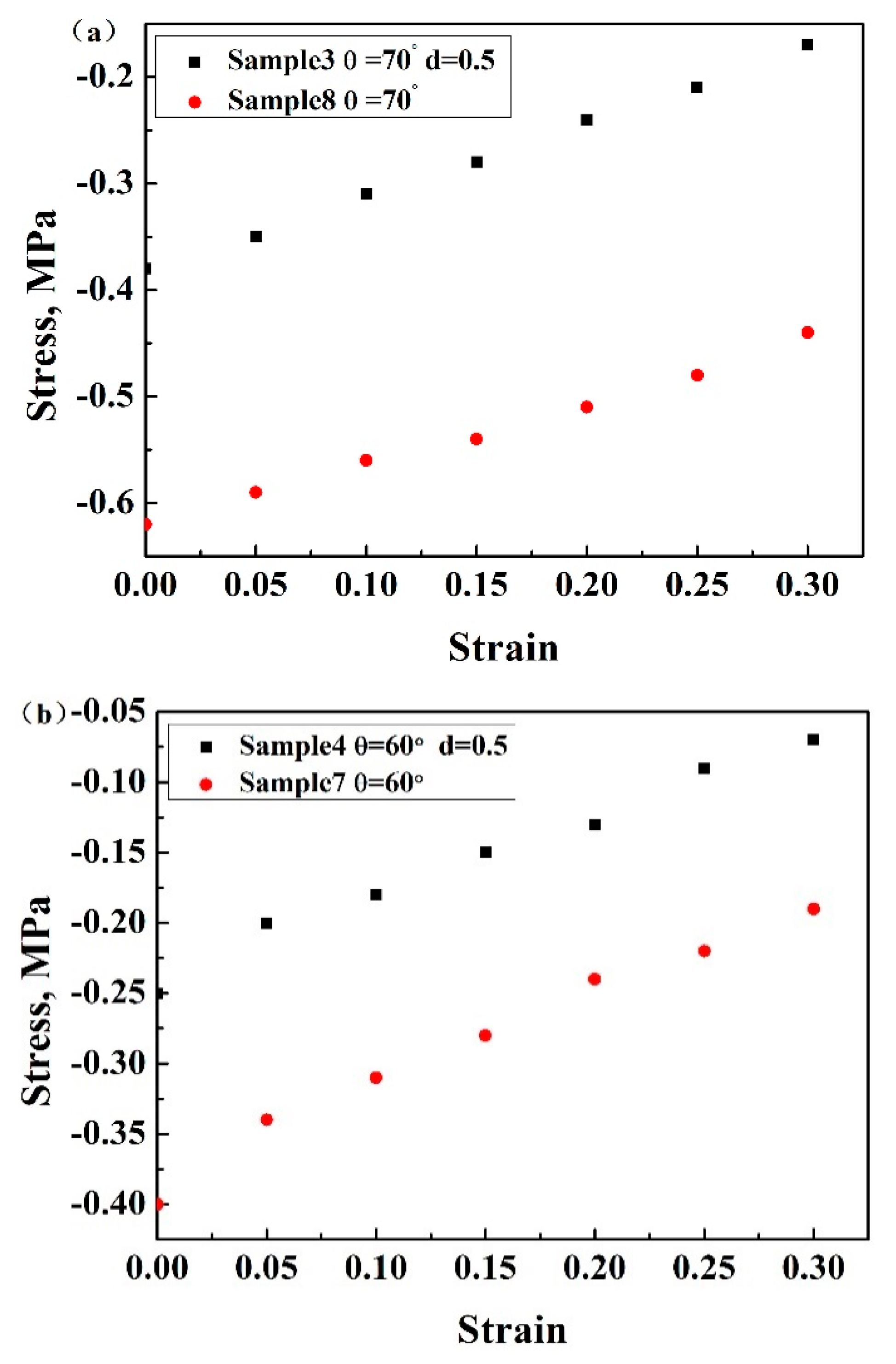

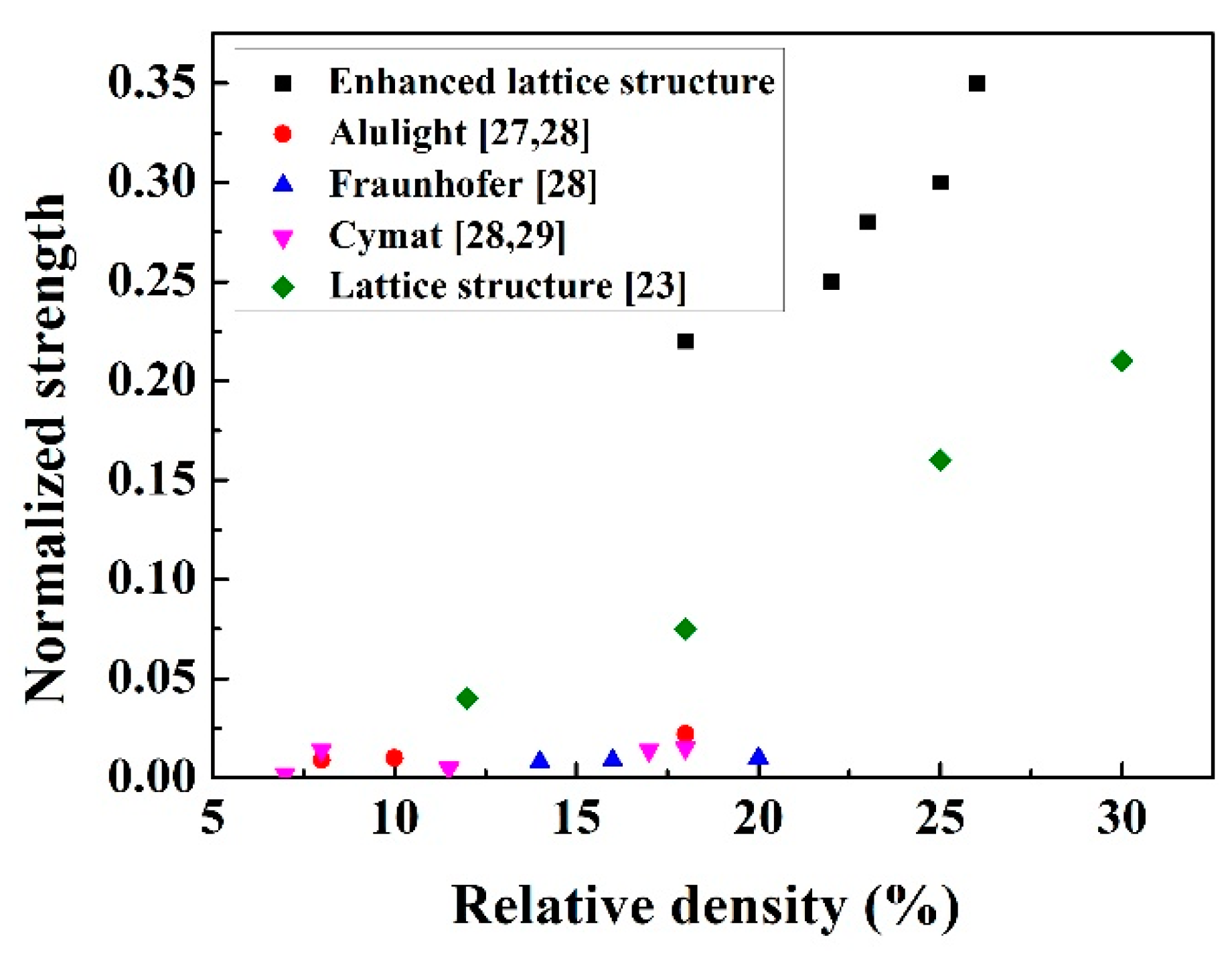

3.4. Analysis of Enhanced Mechanical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Salit, V.; Weller, T. On the feasibility of introducing auxetic behavior into thin-walled structures. Acta Mater. 2009, 57, 125–135. [Google Scholar] [CrossRef]

- Evans, K.E.; Alderson, A. Auxetic materials: Functional materials and structures from lateral thinking! Adv. Mater. 2000, 12, 617–628. [Google Scholar] [CrossRef]

- Lakes, R. Foam structures with a negative Poisson’s ratio. Science 1987, 235, 1038–1041. [Google Scholar] [CrossRef] [PubMed]

- Lakes, R.; Elms, K. Indentability of conventional and negative Poisson’s ratio foams. Compos. Mater. 1993, 27, 1193. [Google Scholar] [CrossRef] [Green Version]

- Scarpa, F.; Yates, J.R.; Ciffo, L.G.; Patsias, S. Dynamic crushing of auxetic open-cell polyurethane foam. J. Mech. Eng. Sci. 2002, 216, 1153–1156. [Google Scholar] [CrossRef]

- Howell, B.; Prendergast, P.; Hansen, L. Examination of acoustic behavior of negative Poisson’s ratio materials. Appl. Acoust. 1996, 43, 141. [Google Scholar] [CrossRef]

- Scarpa, F.; Smith, C. Passive and MR fluid-coated auxetic PU foam–mechanical, acoustic, and electromagnetic properties. J. Intell. Mater. Syst. Struct. 2004, 15, 971. [Google Scholar] [CrossRef]

- Scarpa, F.; Bullough, W.; Lumley, P. Trends in acoustic properties of iron particle seeded auxetic polyurethane foam. Proc. Inst. Mech. Eng. Part. C J. Mech. Eng. Sci. 2004, 218, 241. [Google Scholar] [CrossRef]

- Doyoyo, J.W. Plastic failure analysis of an auxetic foam or inverted strut lattice under longitudinal and shear loads. J. Mech. Phys. Solids 2006, 54, 1479–1492. [Google Scholar] [CrossRef]

- Kuribayashi, K.; Tsuchiya, K.; You, Z.; Tomus, D.; Umemoto, M.; Ito, T.; Sasaki, M. Self-deployable origami stent grafts as a biomedical application of Ni-rich TiNi shape memory alloy foil. Mat. Sci. Eng. A. 2006, 419, 131–137. [Google Scholar] [CrossRef]

- Ali, M.N.; Rehman, I.U. An Auxetic structure conFigured as oesophageal stent with potential to be used for palliative treatment of oesophageal cancer; development and in vitro mechanical analysis. J. Mater. Sci. Mater. Med. 2011, 22, 2573–2581. [Google Scholar] [CrossRef] [PubMed]

- Ko, J.; Bhullar, S.; Cho, Y.; Lee, P.C.; Jun, M.B.G. Design and fabrication of auxetic stretchable force sensor for hand rehabilitation. Smart Mater. Struct. 2015, 24, 075027. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F.; Schajer, G.S.; Robertson, C.I. The mechanics of two-dimensional cellular materials. R. Soc. 1982, 382, 25–42. [Google Scholar]

- Caddock, B.D.; Evans, K.E. Microporous materials with negative Poisson’s ratios. I. Microstructure and mechanical properties. J Appl Phys 1989, 22, 1877. [Google Scholar] [CrossRef]

- Prall, D.; Lakes, R.S. Properties of a chiral honeycomb with a Poisson’s ratio of—1. Int. J. Mech. Sci. 1997, 39, 305–314. [Google Scholar] [CrossRef]

- Yang, L.; Harrysson, O.; West, H.; Cormier, D. Compressive properties of Ti–6Al–4V auxetic mesh structures made by electron beam melting. Acta Mater. 2012, 60, 3370–3379. [Google Scholar] [CrossRef]

- Lira, C.; Scarpa, F. Transverse shear stiffness of thickness gradient honeycombs. Compos. Sci. Technol. 2010, 70, 930–936. [Google Scholar] [CrossRef]

- Hou, Y.; Neville, R.; Scarpa, F. Graded conventional-auxetic Kirigami sandwich structures: Flatwise compression and edgewise loading. Compos. Part B-Eng. 2014, 59, 33–42. [Google Scholar] [CrossRef]

- Boldrin, L.; Hummel, S.; Scarpa, F. Dynamic behaviour of auxetic gradient composite hexagonal honeycombs. Compos. Struct. 2016, 149, 114–124. [Google Scholar] [CrossRef] [Green Version]

- Assidi, M.; Ganghoffer, J.F. Composites with auxetic inclusions showing both an auxetic behavior and enhancement of their mechanical properties. Compos. Struct. 2012, 94, 2373–2382. [Google Scholar] [CrossRef]

- Lu, Z.X.; Li, X.; Yang, Z.Y. Novel structure with negative Poisson’s ratio and enhanced Young’s modulus. Compos. Struct. 2016, 138, 243–252. [Google Scholar] [CrossRef]

- Fu, M.H.; Chen, Y.; Hu, L.L. A novel auxetic honeycomb with enhanced in-plane stiffness and buckling strength. Compos. Struct. 2017, 160, 574–585. [Google Scholar] [CrossRef]

- Huang, Y.J.; Xue, Y.Y.; Wang, X.F. Mechanical behavior of three-dimensional pyramidal aluminum lattice materials. Mat. Sci. Eng. A 2017, 696, 520–528. [Google Scholar] [CrossRef]

- McKown, S.; Shen, Y.; Brookes, W.K.; Sutcliffe, C.J.; Cantwell, W.J.; Langdon, G.S.; Nurick, G.G.; Theobald, M.D. The quasi-static and blast loading response of lattice structures. Int. J. Impact. Eng. 2008, 35, 795–810. [Google Scholar] [CrossRef]

- Gumruk, R.; Mines, R.A.W.; Karadeniz, S. Static mechanical behaviours of stainless steel micro-lattice structures under different loading conditions. Mater. Sci. Eng. A 2013, 586, 392–406. [Google Scholar] [CrossRef]

- Fu, M.H.; Chen, Y.; Hu, L.L. Bilinear elastic characteristic of enhanced auxetic honeycombs. Compos. Struct. 2017, 175, 101–110. [Google Scholar] [CrossRef]

- Schäffler, P.; Hanko, G.; Mitterer, H. Alulight Metal Foam Products. Proc. Porous Metals Metallic Foams Metfoam 2018, 7–10. [Google Scholar]

- Andrews, E.; Sanders, W.; Gibson, L.J. Compressive and tensile behaviour of aluminum foams. Mater. Sci. Eng. A-Struct. 1999, 270, 113–124. [Google Scholar] [CrossRef]

- Ruan, D.; Lu, G.; Chen, F.L.; Siores, E. Compressive behaviour of aluminium foams at low and medium strain rates. Compos. Struct. 2002, 57, 331–336. [Google Scholar] [CrossRef]

| Sample | H (mm) | L (mm) | θ (°) | D (mm) | d (mm) | Relative Density | |

|---|---|---|---|---|---|---|---|

| 1 | 7.0 | 3.5 | 70 | 1.4 | 0.7 | 0.27 | 0.25 |

| 2 | 0.6 | 0.25 | 0.23 | ||||

| 3 | 0.5 | 0.23 | 0.22 | ||||

| 4 | 7.0 | 3.5 | 60 | 1.4 | 0.5 | 0.28 | 0.26 |

| 5 | 70 | 0.25 | 0.22 | ||||

| 6 | 80 | 0.19 | 0.18 | ||||

| Sample | H (mm) | L (mm) | θ (°) | D (mm) | Relative Density | |

|---|---|---|---|---|---|---|

| 7 | 7.0 | 3.5 | 60 | 1.4 | 0.24 | 0.24 |

| 8 | 70 | 0.20 | 0.20 | |||

| 9 | 80 | 0.16 | 0.15 | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, Y.; Gao, P.; Zhou, L.; Han, F. An Enhanced Three-Dimensional Auxetic Lattice Structure with Improved Property. Materials 2020, 13, 1008. https://doi.org/10.3390/ma13041008

Xue Y, Gao P, Zhou L, Han F. An Enhanced Three-Dimensional Auxetic Lattice Structure with Improved Property. Materials. 2020; 13(4):1008. https://doi.org/10.3390/ma13041008

Chicago/Turabian StyleXue, Yingying, Peixin Gao, Li Zhou, and Fusheng Han. 2020. "An Enhanced Three-Dimensional Auxetic Lattice Structure with Improved Property" Materials 13, no. 4: 1008. https://doi.org/10.3390/ma13041008

APA StyleXue, Y., Gao, P., Zhou, L., & Han, F. (2020). An Enhanced Three-Dimensional Auxetic Lattice Structure with Improved Property. Materials, 13(4), 1008. https://doi.org/10.3390/ma13041008