Mechanical Properties of Concrete Containing Liquefied Red Mud Subjected to Uniaxial Compression Loads

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Liquefied Red Mud

2.1.2. Cement

2.1.3. Aggregate

2.2. Experimental Plan and Concrete Mix Proportions

2.3. Specimens

2.4. Test Setup and Test Method

3. Experimental Results and Discussions

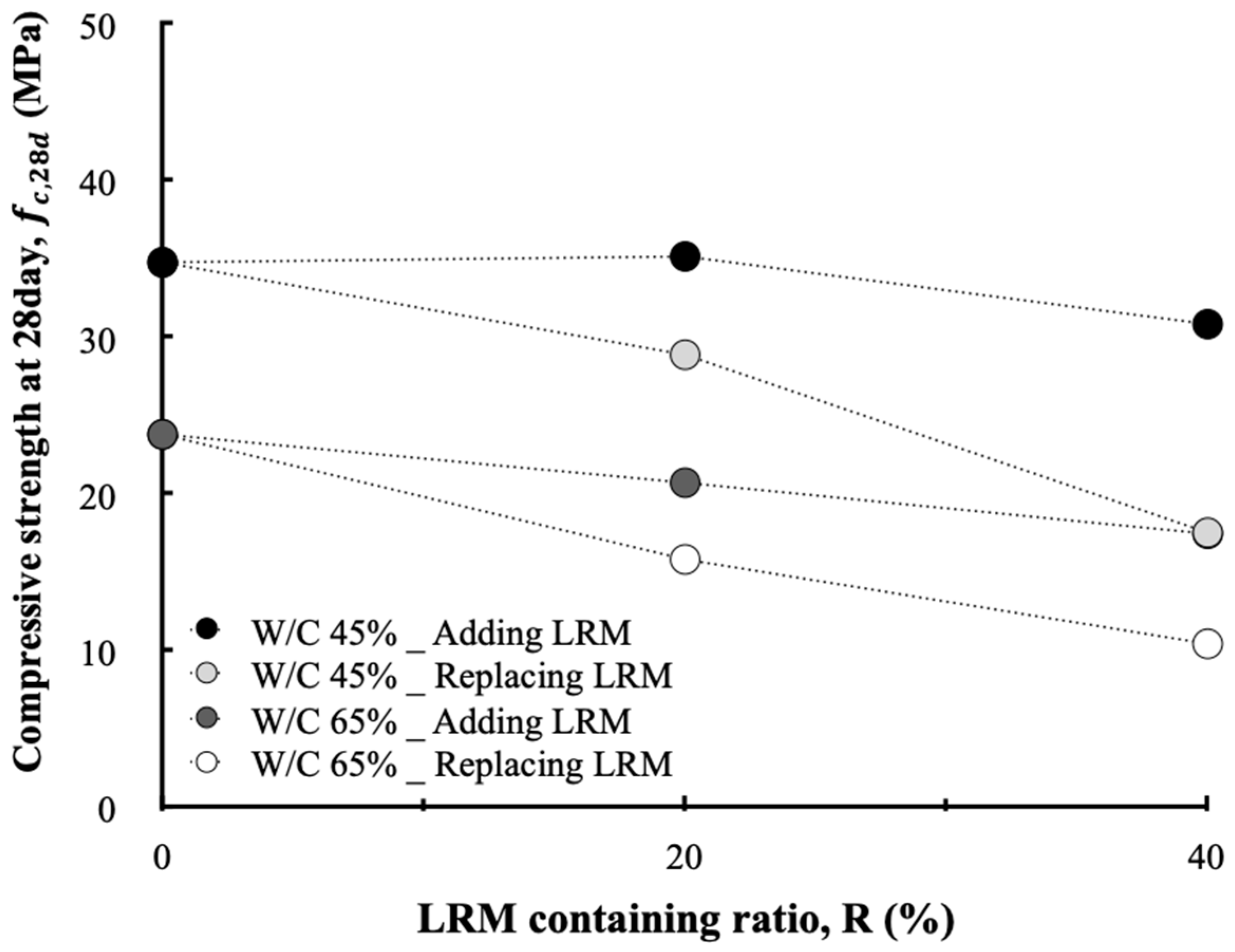

3.1. Properties of Fresh and Hardened Concrete According to the LRM Insertion Method

3.2. Mechanical Properties According to Cement Type

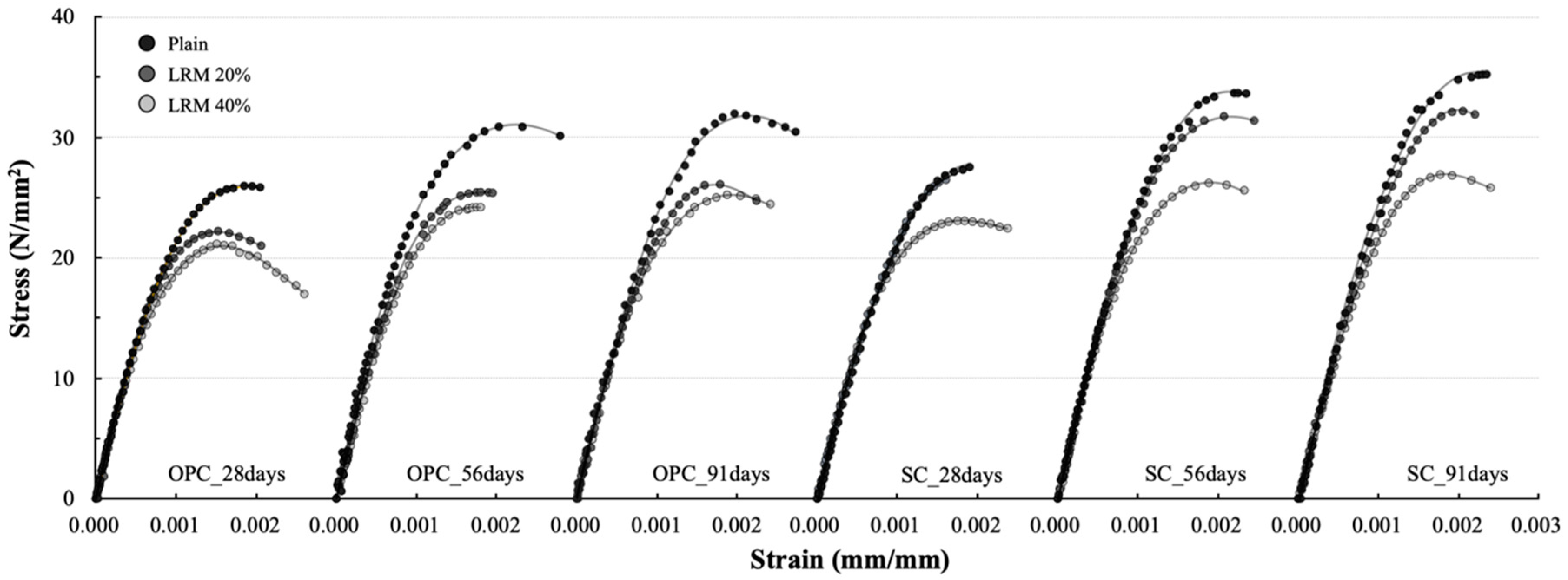

3.2.1. Stress–Strain Curve

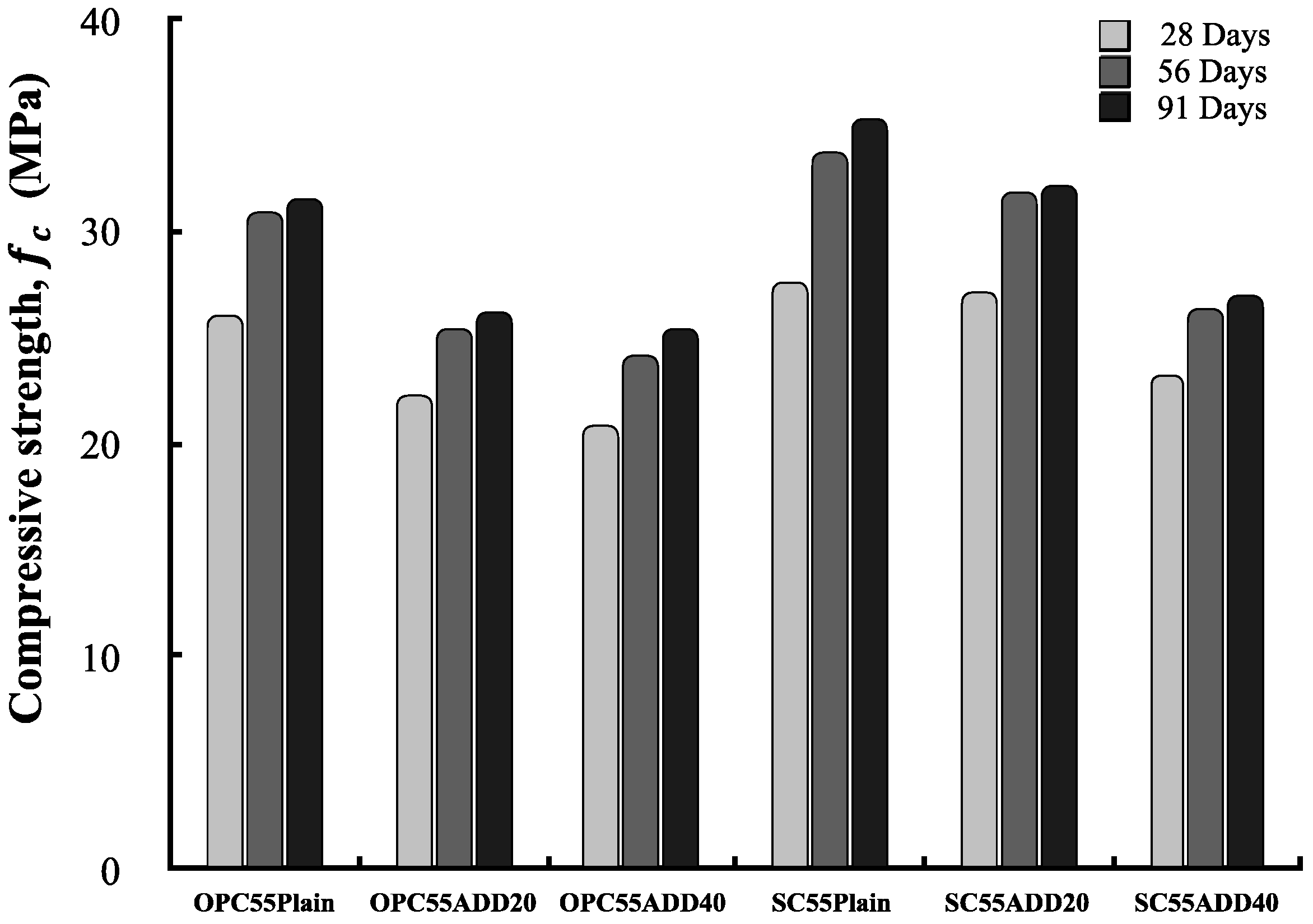

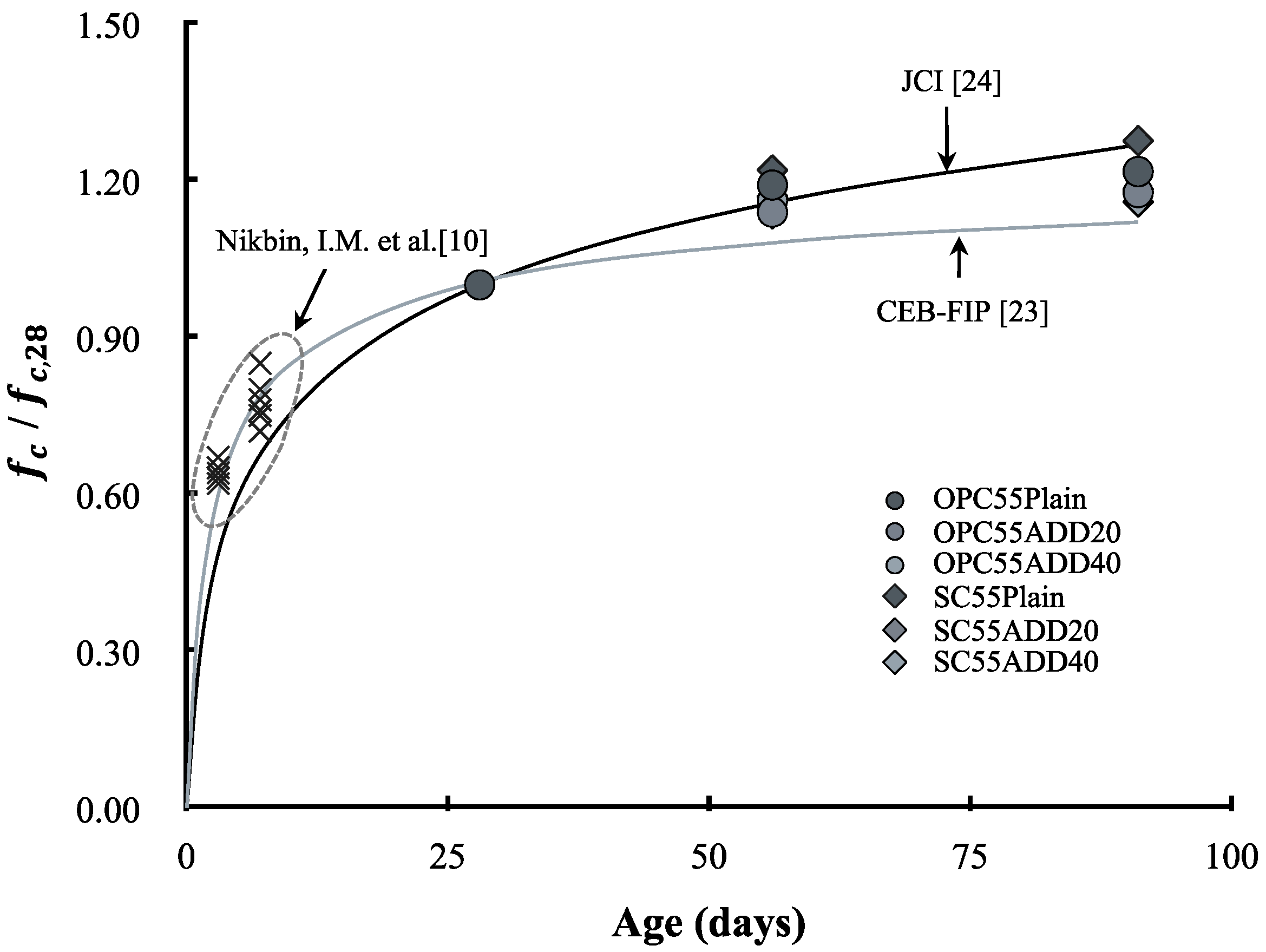

3.2.2. Compressive Strength

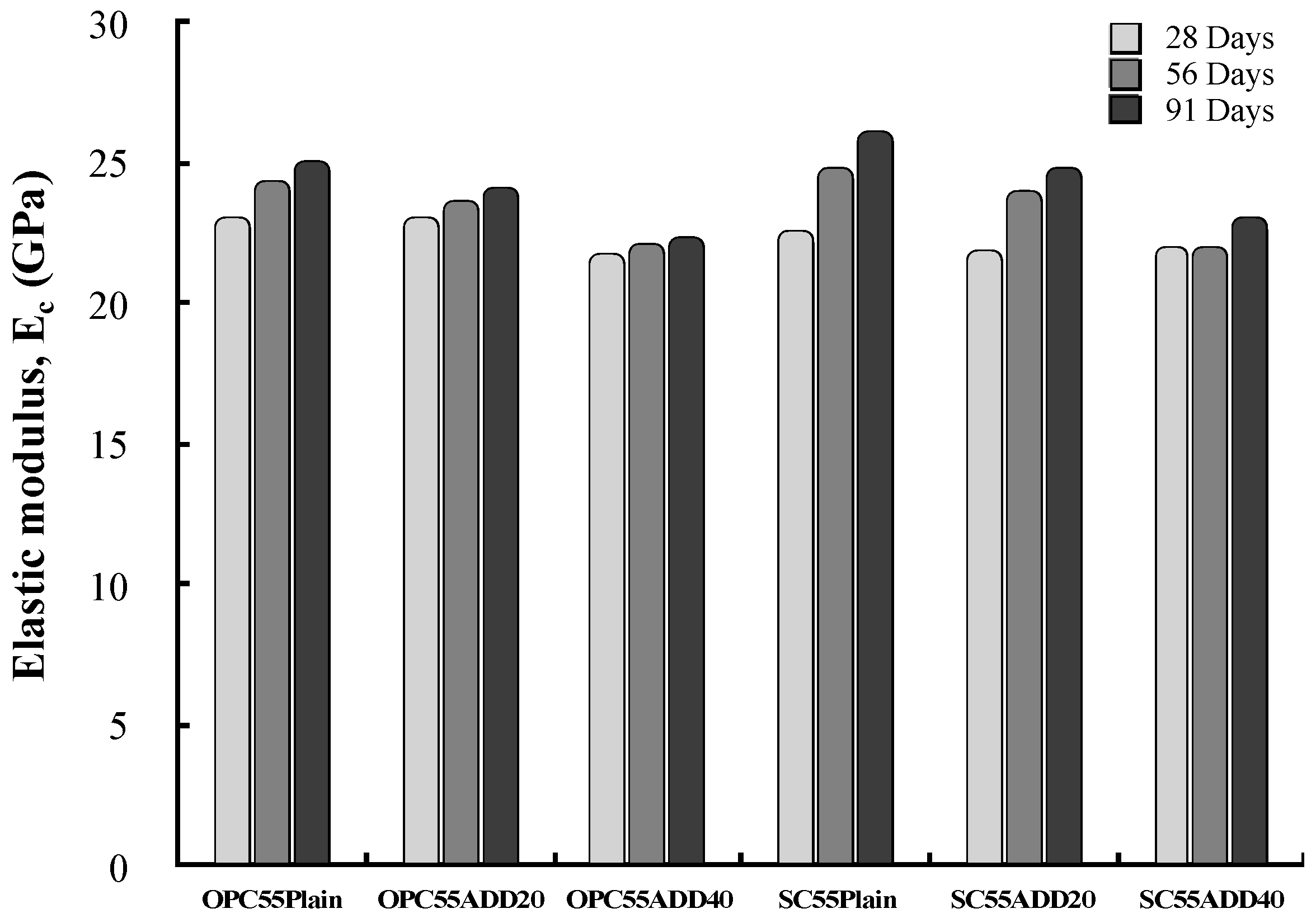

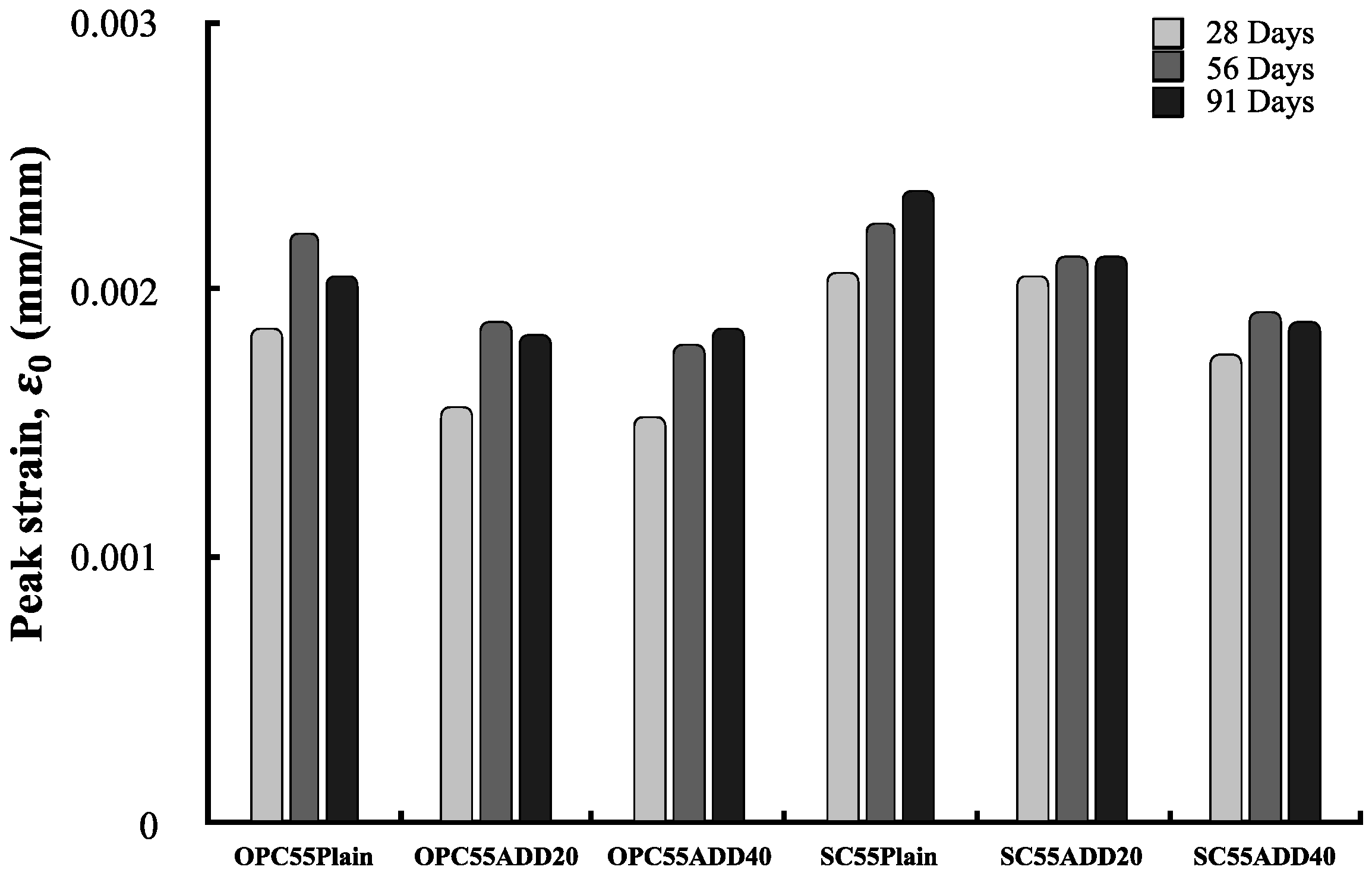

3.2.3. Elastic Modulus and Peak Stress

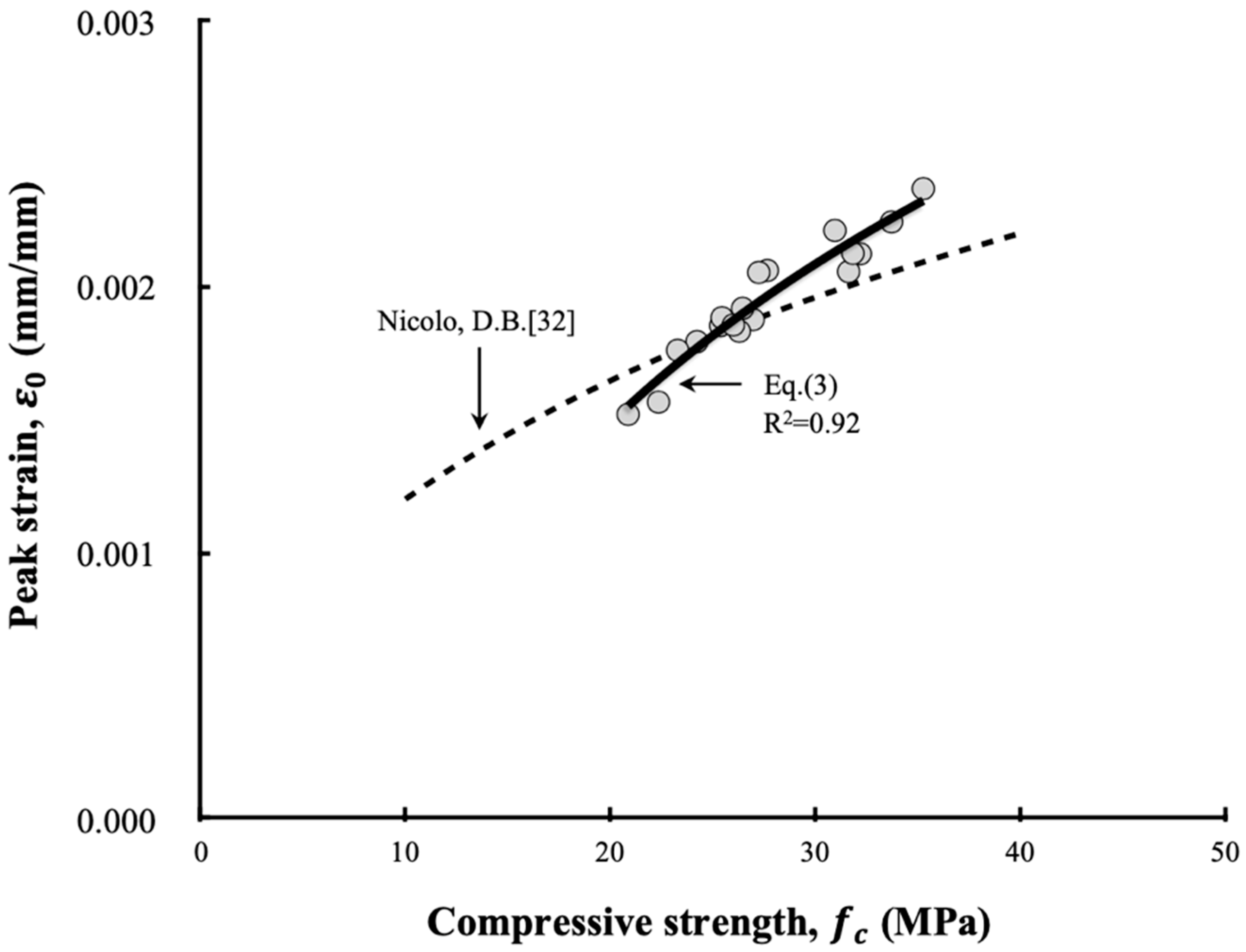

4. Approximation of the Stress–Strain Relations

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mymrin, V.; Guidolin, M.A.; Klitzke, W.; Alekseev, K.; Guidolin, R.H.; Avanci, M.A.; Pawlowsky, U.; Winter, E., Jr.; Catai, R.E. Environmentally clean ceramics from printed circuit board sludge, red mud of bauxite treatment and steel slag. J. Clean. Prod. 2017, 164, 831–839. [Google Scholar] [CrossRef]

- Khairul, M.A.; Zanganeh, J.; Moghtaderi, B. The composition, recycling and utilisation of Bayer red mud. Resour. Conserv. Recycl. 2019, 141, 483–498. [Google Scholar] [CrossRef]

- Li, J.; Xu, L.; Sun, P.; Zhai, P.; Chen, X.; Zhang, H.; Zhang, Z.; Zhu, W. Novel application of red mud: Facile hydrothermal-thermal conversion synthesis of hierarchical porous AlOOH and Al2O3 microspheres as adsorbents for dye removal. Chem. Eng. J. 2017, 321, 622–634. [Google Scholar] [CrossRef]

- Zhang, R.; Zheng, S.; Ma, S.; Zhang, Y. Recovery of alumina and alkali in Bayer red mud by the formation of andradite-grossular hydrogarnet in hydrothermal process. J. Hazard. Mater. 2011, 189, 827–835. [Google Scholar] [CrossRef] [PubMed]

- Alam, S.; Das, S.K.; Rao, B.H. Characterization of coarse fraction of red mud as a civil engineering construction material. J. Clean. Prod. 2017, 168, 679–691. [Google Scholar] [CrossRef]

- Borges, A.J.P.; Hauser-Davis, R.A.; de Oliveira, T.F. Cleaner red mud residue production at an alumina plant by applying experimental design techniques in the filtration stage. J. Clean. Prod. 2011, 19, 1763–1769. [Google Scholar] [CrossRef]

- Ali, M.B.; Saidur, R.; Hossain, M.S. A review on emission analysis in cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2252–2261. [Google Scholar] [CrossRef]

- Yao, Y.; Li, Y.; Liu, X.; Jiang, S.; Feng, C.; Rafanan, E. Characterization on a cementitious material composed of red mud and coal industry byproducts. Constr. Build. Mater. 2013, 47, 496–501. [Google Scholar] [CrossRef]

- Senff, L.; Hotza, D.; Labrincha, J.A. Effect of red mud addition on the rheological behaviour and on hardened state characteristics of cement mortars. Constr. Build. Mater. 2011, 25, 163–170. [Google Scholar] [CrossRef]

- Nikbin, I.M.; Aliaghazadeh, M.; Charkhtab, S.H.; Fathollahpour, A. Environmental impacts and mechanical properties of lightweight concrete containing bauxite residue (red mud). J. Clean. Prod. 2018, 172, 2683–2694. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, N. Utilization of red mud in cement production: A review. Waste Manag. Res. 2011, 29, 1053–1063. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, D.V.; Labrincha, J.A.; Morelli, M.R. Use of Red Mud as Addition for Portland Cement Mortars. J. Mater. Sci. Eng. 2010, 4, 1–9. [Google Scholar]

- Liu, R.-X.; Poon, C.S. Utilization of red mud derived from bauxite in self-compacting concrete. J. Clean. Prod. 2016, 112, 384–391. [Google Scholar] [CrossRef]

- Kang, S.; Kwon, S.-J. Effects of red mud and Alkali-Activated Slag Cement on efflorescence in cement mortar. Constr. Build. Mater. 2017, 133, 459–467. [Google Scholar] [CrossRef]

- Kim, H.; Kang, S.; Choe, G. Effect of Red Mud Content on Strength and Efflorescence in Pavement using Alkali-Activated Slag Cement. Int. J. Concr. Struct. Mater. 2018, 12, 1–9. [Google Scholar]

- Geng, J.; Zhou, M.; Li, Y.; Chen, Y.; Han, Y.; Wan, S.; Zhou, X.; Hou, H. Comparison of red mud and coal gangue blended geopolymers synthesized through thermal activation and mechanical grinding preactivation. Constr. Build. Mater. 2017, 153, 185–192. [Google Scholar] [CrossRef]

- Tang, W.C.; Wang, Z.; Liu, Y.; Cui, H.Z. Influence of red mud on fresh and hardened properties of self-compacting concrete. Constr. Build. Mater. 2018, 178, 288–300. [Google Scholar] [CrossRef]

- Krivenko, P.; Kovalchuk, O.; Pasko, A.; Croymans, T.; Hult, M.; Lutter, G.; Vandevenne, N.; Schreurs, S.; Schroeyers, W. Development of alkali activated cements and concrete mixture design with high volumes of red mud. Constr. Build. Mater. 2017, 151, 819–826. [Google Scholar] [CrossRef]

- Choe, G.; Kang, S.; Kang, H. Characterization of Slag Cement Mortar Containing Nonthermally Treated Dried Red Mud. Appl. Sci. 2019, 9, 2510. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.; Xiao, B. Development of unsintered construction materials from red mud wastes produced in the sintering alumina process. Constr. Build. Mater. 2008, 22, 2299–2307. [Google Scholar] [CrossRef]

- Korean Standards KS F 2403. Standard Test Method for Making and Curing Concrete Specimens; Korean Agency for Technology and Standards (KATS): Seoul, Korea, 2014. [Google Scholar]

- Chen, W.F. Concrete plasticity: Macro-and microapproaches. Int. J. Concr. Struct. Mater. 1993, 35, 1097–1109. [Google Scholar] [CrossRef]

- Du, B. Fib Model Code for Concrete Structures 2010; Wiley-vch Verlag Gmbh: Weinheim, Germany, 2013. [Google Scholar]

- JCI. Guidelines for Control of Cracking of Mass Concrete; Japan Concrete Institute, JCI: Tokyo, Japan, August 2011. [Google Scholar]

- Smaoui, N.; Bérubé, M.A.; Fournier, B.; Bissonnette, B.; Durand, B. Effects of alkali addition on the mechanical properties and durability of concrete. Cem. Concr. Res. 2005, 35, 203–212. [Google Scholar] [CrossRef]

- ACI Committee; American Concrete Institute. Building Code Requirements for Structural Concrete (ACI 318-08) and Commentary, 1st ed.; American Concrete Institute: Farmington Hills, MI, USA, 2008. [Google Scholar]

- Klieger, P.; Isberne, A.W. Laboratory Studies of Blended Cement Portland Blast—Furnace Slag Cements. J. PCA Res. Dev. Lab. 1967, 9, 2–22. [Google Scholar]

- Fulton, F.S. The Properties of Portland Cement Containing Milled Granulated Blast-Furnace Slag; Portland Cement Institute: Skokie, IL, USA, 1974. [Google Scholar]

- Xiao, J.; Li, J.; Zhang, C. Mechanical properties of recycled aggregate concrete under uniaxial loading. Cem. Concr. Res. 2005, 35, 1187–1194. [Google Scholar] [CrossRef]

- Ispir, M.; Dalgic, K.D.; Sengul, C.; Kuran, F.; Ilki, A.; Tasdemir, M.A. Modulus of elasticity of low strength concrete. In Proceedings of the 9th International Congress on Advances in Civil Engineering, Trabzon, Turkey, 27–30 Septembe 2010. [Google Scholar]

- Tasdemir, M.A.; Tasdemir, C.; Akyüz, S.; Jefferson, A.D.; Lydon, F.D.; Barr, B.I.G. Evaluation of strains at peak stresses in concrete: A three-phase composite model approach. Cem. Concr. Compos. 1998, 20, 301–318. [Google Scholar] [CrossRef]

- De Nicolo, B.; Pani, L.; Pozzo, E. Strain of concrete at peak compressive stress for a wide range of compressive strengths. Mater. Struct. 1994, 27, 206–210. [Google Scholar] [CrossRef]

- Carreira, D.J.; Chu, K.H. Stress-strain relationship for plain concrete in compression. J. Mater. Sci. Eng. 1985, 82, 797–804. [Google Scholar]

| Material | Density (g/cm3) | Average Diameter (μm) | Viscosity (cP) | Water Content (%) | Chemical Composition (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | K2O | |||||

| RM sludge | 2.0 | 4.31 | 20,000 | 50.2 | 38.8 | 16.1 | 22.8 | 3.4 | 0.2 | 10.0 | 0.4 |

| Materials | Type | Color | Viscosity (cPs) | Water Content (%) | pH | Density (g/cm3) |

|---|---|---|---|---|---|---|

| Thickener | Methyl Cellulose | White | 32,900 | 1.4 | - | - |

| Antifoamer | Polyoxyalkylene alkylether | - | - | - | 4.5~7.5 | 0.9884 |

| Material | RM sludge | Water | Thickener | Antifoamer |

|---|---|---|---|---|

| Proportion (by weight for RM sludge) | 1 | 0.5 | 0.0036 | 0.0014 |

| Type of Cement | Specific Surface Area (cm2/g) | Density (g/cm3) | Lg. Loss (%) | Chemical Composition (%) | |||||

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | ||||

| OPC | 3140 | 3.15 | 1.01 | 21.3 | 5.4 | 3.5 | 62.0 | 3.3 | 1.64 |

| SC | 3959 | 3.06 | 1.49 | 27.2 | 9.4 | 2.2 | 52.0 | 3.6 | 2.10 |

| Type of Aggregate | Type | Maximum Size (mm) | Density (g/cm3) | Absorption (%) |

|---|---|---|---|---|

| Fine aggregate | Crushed sand | 5 | 2.56 | 1.01 |

| Coarse aggregate | Granite | 20 | 2.67 | 1.39 |

| Specimen | Cement Type | W/B (1) (%) | LRM Addition (2) | S/A (%) | Water (kg/m3) | Unit Weight(kg/m3) | LRM (kg/m3) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Method | R(%) | Binder | S | G | ||||||||

| OPC | SC | LRM | ||||||||||

| SC45Plain | SC | 45 | - | 0 | 50 | 135 | 0 | 300 | 0 | 961 | 995 | 0 |

| SC45REP20 | SC | 45 | REP. | 20 | 50 | 135 | 0 | 240 | 60 | 935 | 968 | 0 |

| SC45REP40 | SC | 45 | REP. | 40 | 50 | 135 | 0 | 180 | 120 | 908 | 940 | 0 |

| SC45ADD20 | SC | 45 | Add. | 20 | 50 | 135 | 0 | 300 | 0 | 961 | 995 | 60 |

| SC45ADD40 | SC | 45 | Add. | 40 | 50 | 135 | 0 | 300 | 0 | 961 | 995 | 120 |

| SC65Plain | SC | 65 | - | 0 | 50 | 195 | 0 | 300 | 0 | 884 | 915 | 0 |

| SC65REP20 | SC | 65 | REP. | 20 | 50 | 195 | 0 | 240 | 60 | 858 | 888 | 0 |

| SC65REP40 | SC | 65 | REP. | 40 | 50 | 195 | 0 | 180 | 120 | 832 | 861 | 0 |

| SC65ADD20 | SC | 65 | ADD. | 20 | 50 | 195 | 0 | 300 | 0 | 884 | 915 | 60 |

| SC65ADD40 | SC | 65 | ADD. | 40 | 50 | 195 | 0 | 300 | 0 | 884 | 915 | 120 |

| OPC55Plain | OPC | 55 | - | 0 | 50 | 135 | 300 | 0 | 0 | 934 | 967 | 0 |

| OPC55ADD20 | OPC | 55 | ADD. | 20 | 50 | 135 | 300 | 0 | 0 | 934 | 967 | 60 |

| OPC55ADD40 | OPC | 55 | ADD. | 40 | 50 | 135 | 300 | 0 | 0 | 934 | 967 | 120 |

| SC55Plain | SC | 55 | - | 0 | 50 | 135 | 0 | 300 | 0 | 923 | 955 | 0 |

| SC5ADD20 | SC | 55 | ADD. | 20 | 50 | 135 | 0 | 300 | 0 | 923 | 955 | 60 |

| SC55ADD40 | SC | 55 | ADD. | 40 | 50 | 135 | 0 | 300 | 0 | 923 | 955 | 120 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choe, G.; Kang, S.; Kang, H. Mechanical Properties of Concrete Containing Liquefied Red Mud Subjected to Uniaxial Compression Loads. Materials 2020, 13, 854. https://doi.org/10.3390/ma13040854

Choe G, Kang S, Kang H. Mechanical Properties of Concrete Containing Liquefied Red Mud Subjected to Uniaxial Compression Loads. Materials. 2020; 13(4):854. https://doi.org/10.3390/ma13040854

Chicago/Turabian StyleChoe, Gyeongcheol, Sukpyo Kang, and Hyeju Kang. 2020. "Mechanical Properties of Concrete Containing Liquefied Red Mud Subjected to Uniaxial Compression Loads" Materials 13, no. 4: 854. https://doi.org/10.3390/ma13040854

APA StyleChoe, G., Kang, S., & Kang, H. (2020). Mechanical Properties of Concrete Containing Liquefied Red Mud Subjected to Uniaxial Compression Loads. Materials, 13(4), 854. https://doi.org/10.3390/ma13040854