Mechanical and Electrical Characteristics of WB2 Synthesized at High Pressure and High Temperature

Abstract

:1. Introduction

2. Materials and Methods

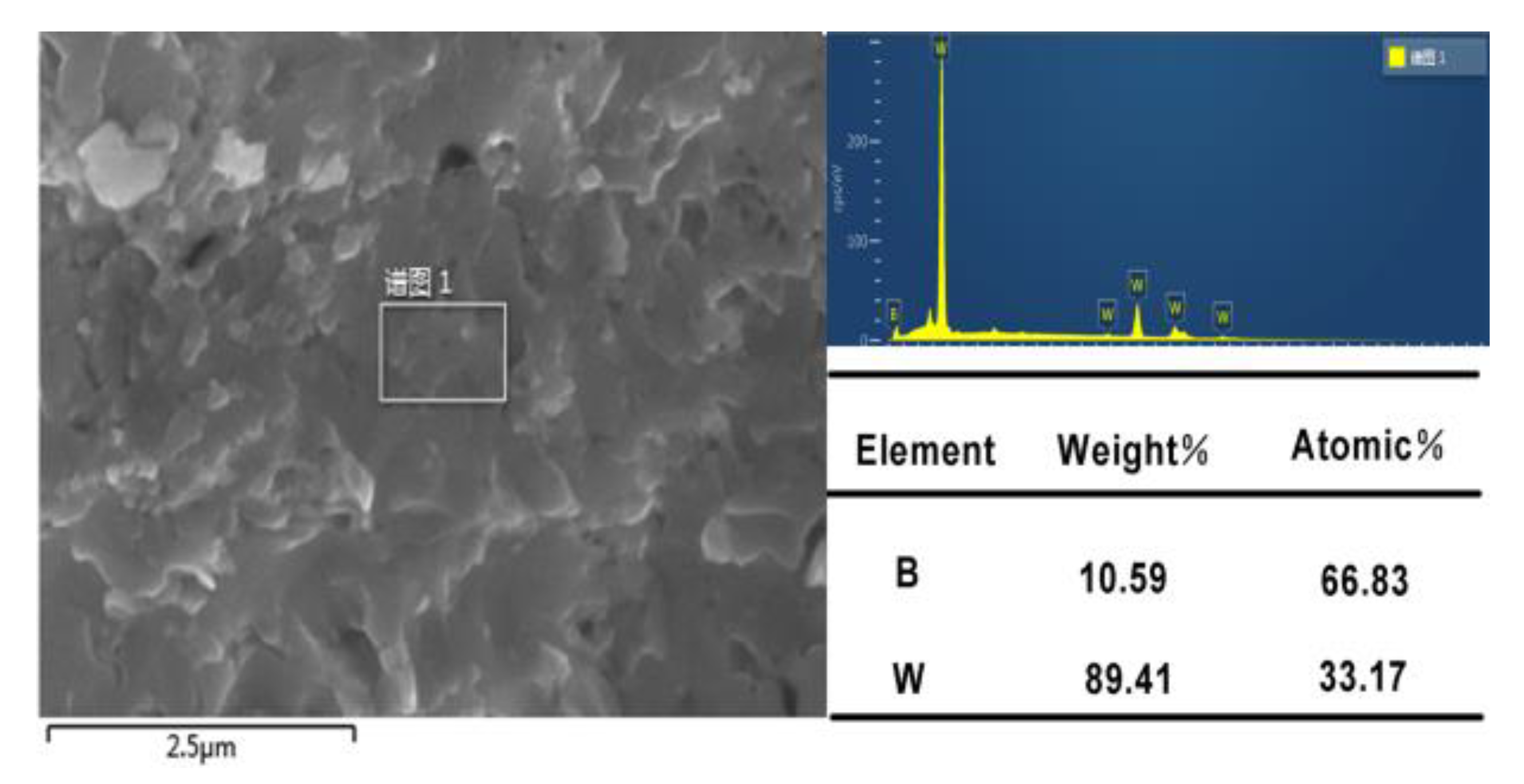

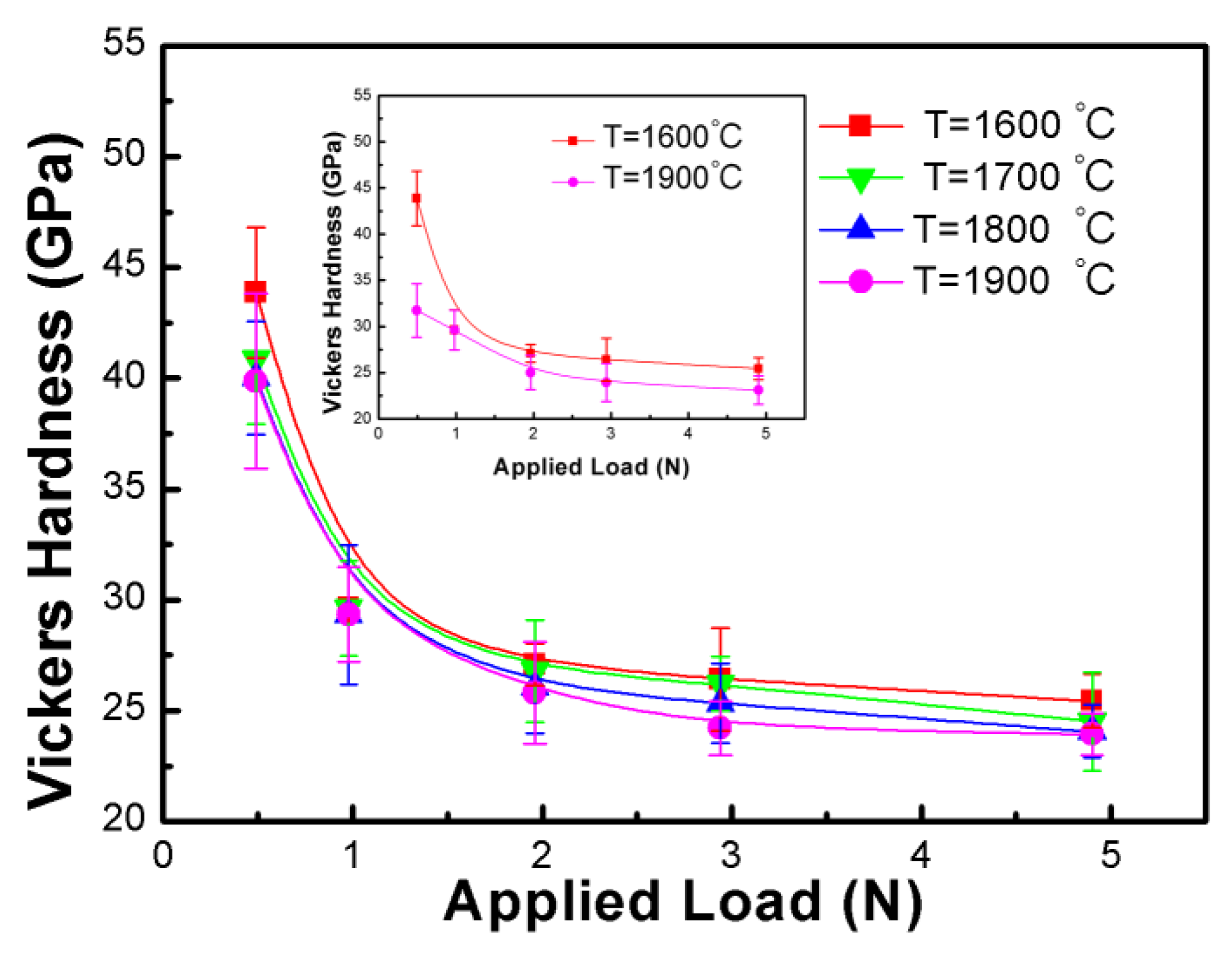

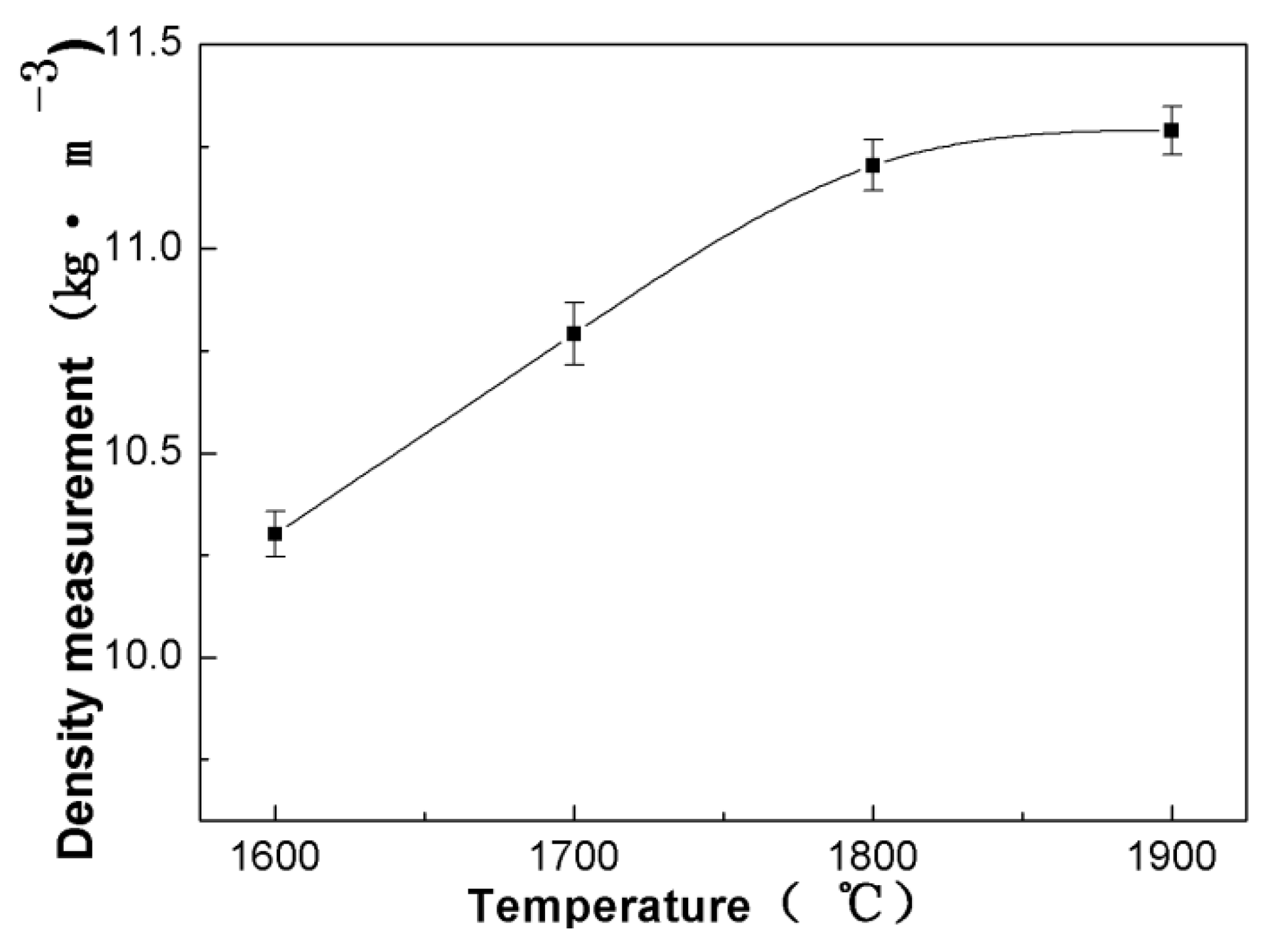

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chung, H.Y.; Weinberger, M.B.; Levine, J.B.; Kavner, A.; Yang, J.M.; Tolbert, S.H.; Kaner, R.B. Synthesis of Ultra-Incompressible Superhard Rhenium Diboride at Ambient Pressure. Science 2007, 316, 436–439. [Google Scholar] [CrossRef] [PubMed]

- Latini, A.; Rau, J.V.; Ferro, D.; Teghil, R.; Albertini, V.R.; Barinov, S.M. ChemInform Abstract: Superhard Rhenium Diboride Films: Preparation and Characterization. Cheminform 2010, 39. [Google Scholar] [CrossRef]

- Wang, C.; Song, L. Exploring the effects of interlamellar binding modes on the hardness of ReB2 and MoB2 with laminar structure. Can. J. Phys. 2017, 95. [Google Scholar] [CrossRef] [Green Version]

- Weinberger, M.B.; Levine, J.B.; Chung, H.Y.; Cumberland, R.W.; Rasool, H.I.; Yang, J.M.; Kaner, R.B.; Tolbert, S.H. Incompressibility and Hardness of Solid Solution Transition Metal Diborides: Os1−xRuxB2. Cheminform 2010, 40, 1915–1921. [Google Scholar] [CrossRef]

- Ingole, S.; Liang, H.; Usta, M.; Bindal, C.; Ucisik, A.H. Multi-scale wear of a boride coating on tungsten. Wear 2005, 259, 849–860. [Google Scholar] [CrossRef]

- Kawanowa, H.; Gotoh, Y.; Otani, S.; Souda, R. Structure analysis of the WB 2 (0001) surface. Surf. Sci. 1999, 433–435, 661–665. [Google Scholar] [CrossRef]

- Khor, K.A.; Yu, L.G.; Sundararajan, G. Formation of hard tungsten boride layer by spark plasma sintering boriding. Thin Solid Films 2005, 478, 232–237. [Google Scholar] [CrossRef]

- Usta, M. The characterization of borided pure niobium. Surf. Coat. Technol. 2005, 194, 330–334. [Google Scholar] [CrossRef]

- Xing-Qiu, C.; Fu, C.L.; Krcmar, M.; Painter, G.S. Electronic and structural origin of ultraincompressibility of 5d transition-metal diborides MB (2) (M=W, Re, Os). Phys. Rev. Lett. 2008, 100, 196403. [Google Scholar]

- Yeh, C.L.; Chen, W.H. Preparation of niobium borides NbB and NbB 2 by self-propagating combustion synthesis. J. Alloys Compd. 2006, 420, 111–116. [Google Scholar] [CrossRef]

- Brandstötter, J.; Lengauer, W. Multiphase reaction diffusion in transition metal-boron systems. J. Alloys Compd. 1997, 229, 390–396. [Google Scholar] [CrossRef]

- Locci, A.M.; Licheri, R.; Orrù, R.; Cao, G. Reactive Spark Plasma Sintering of rhenium diboride. Ceram. Int. 2009, 35, 397–400. [Google Scholar] [CrossRef]

- Shibuya, M.; Ohyanagi, M. Effect of nickel boride additive on simultaneous densification and phase decomposition of TiB-WB solid solutions by pressureless sintering using induction heating. J. Eur. Ceram. Soc. 2007, 27, 301–306. [Google Scholar] [CrossRef]

- Li, B.; Sun, H.; Chen, C. First-principles calculation of the indentation strength ofFeB4. Phys. Rev. B 2014, 90. [Google Scholar] [CrossRef]

- Brazhkin, V.; Dubrovinskaia, N.; Nicol, M.; Novikov, N.; Riedel, R.; Solozhenko, V.; Zhao, Y. From our readers: What does ‘harder than diamond’ mean? Nat. Mater. 2004, 3, 576–577. [Google Scholar] [CrossRef] [PubMed]

- Qin, J.; He, D.; Wang, J.; Fang, L.; Lei, L.; Li, Y.; Hu, J.; Kou, Z.; Bi, Y. Is Rhenium Diboride a Superhard Material? Adv. Mater. 2010, 20, 4780–4783. [Google Scholar] [CrossRef]

- Kodas, T. Handbook of Chemical vapor Deposition (CVD), Principles, Technology, and Applications; By Hugh O. Pierson, Noyes: Park Ridge, NJ, USA, 1992. 436 pp., hardback, $ 68, ISBN 0-8155-1300-3. Adv. Mater. 1993, 5, 401–402. [Google Scholar] [CrossRef]

- Gou, H.; Hou, L.; Zhang, J.; Li, H.; Sun, G.; Gao, F. First-principles study of low compressibility osmium borides. Appl. Phys. Lett. 2006, 88, 1268. [Google Scholar] [CrossRef]

- Kaner, R.B.; Gilman, J.J.; Tolbert, S.H. Materials science. Designing superhard materials. Science 2005, 308, 1268. [Google Scholar] [CrossRef] [Green Version]

- Schumacher, S.; Birringer, R.; Strauβ, R.; Gleiter, H. Diffusion of silver in nanocrystalline copper between 303 and 373 K. Acta Metall. 1989, 37, 2485–2488. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Song, L.; Xie, Y. Mechanical and Electrical Characteristics of WB2 Synthesized at High Pressure and High Temperature. Materials 2020, 13, 1212. https://doi.org/10.3390/ma13051212

Wang C, Song L, Xie Y. Mechanical and Electrical Characteristics of WB2 Synthesized at High Pressure and High Temperature. Materials. 2020; 13(5):1212. https://doi.org/10.3390/ma13051212

Chicago/Turabian StyleWang, Changchun, Lele Song, and Yupeng Xie. 2020. "Mechanical and Electrical Characteristics of WB2 Synthesized at High Pressure and High Temperature" Materials 13, no. 5: 1212. https://doi.org/10.3390/ma13051212