Post-Fire Characteristics of Concrete Beams Reinforced with Hybrid FRP Bars

Abstract

1. Introduction

2. Novelty and Purpose of the Work

3. The Concept of Hybrid FRP Bars

4. Experimental Program

4.1. Materials

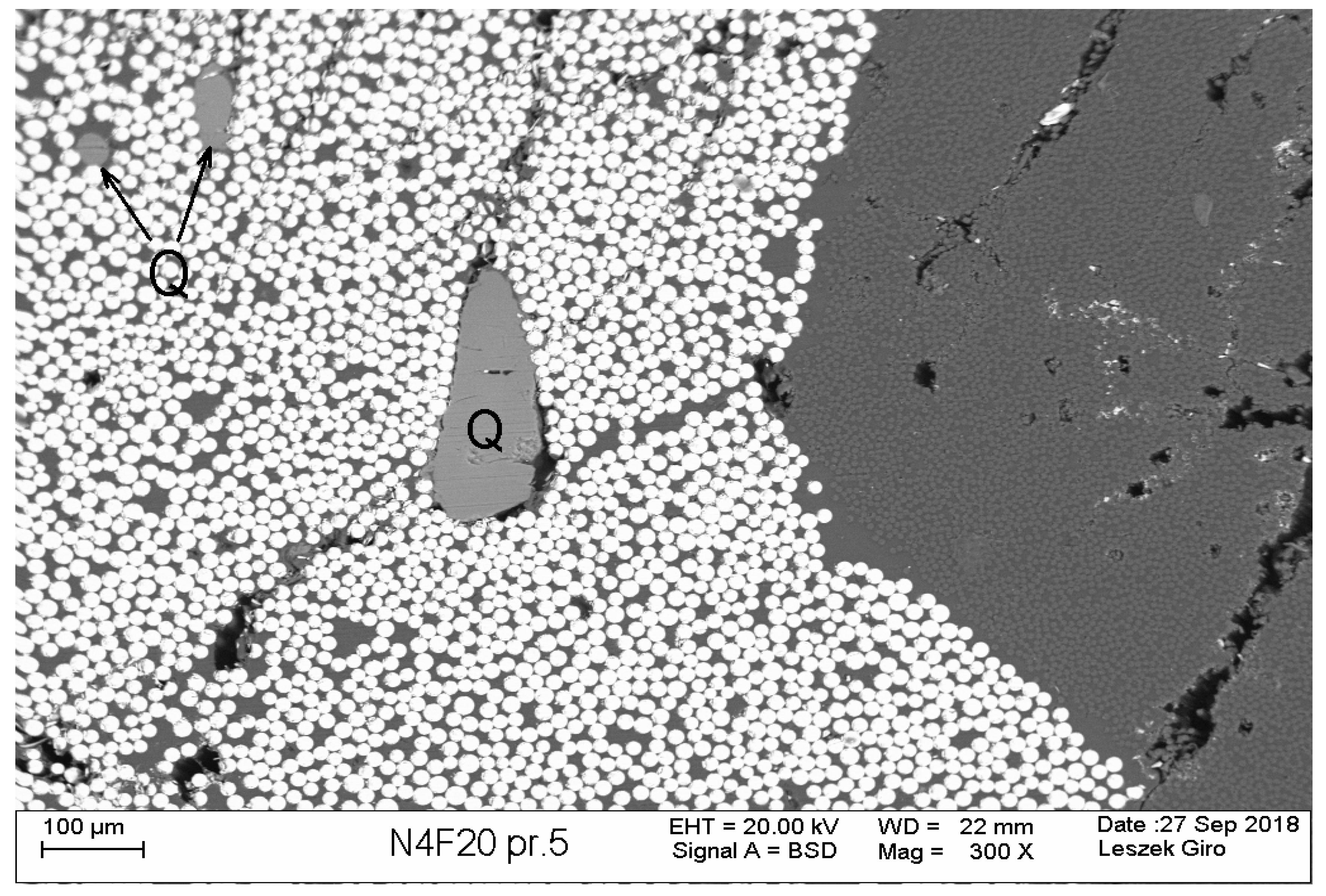

4.1.1. Concrete

4.1.2. Bars

4.2. Specimen Dimensions and Reinforcement Configuration

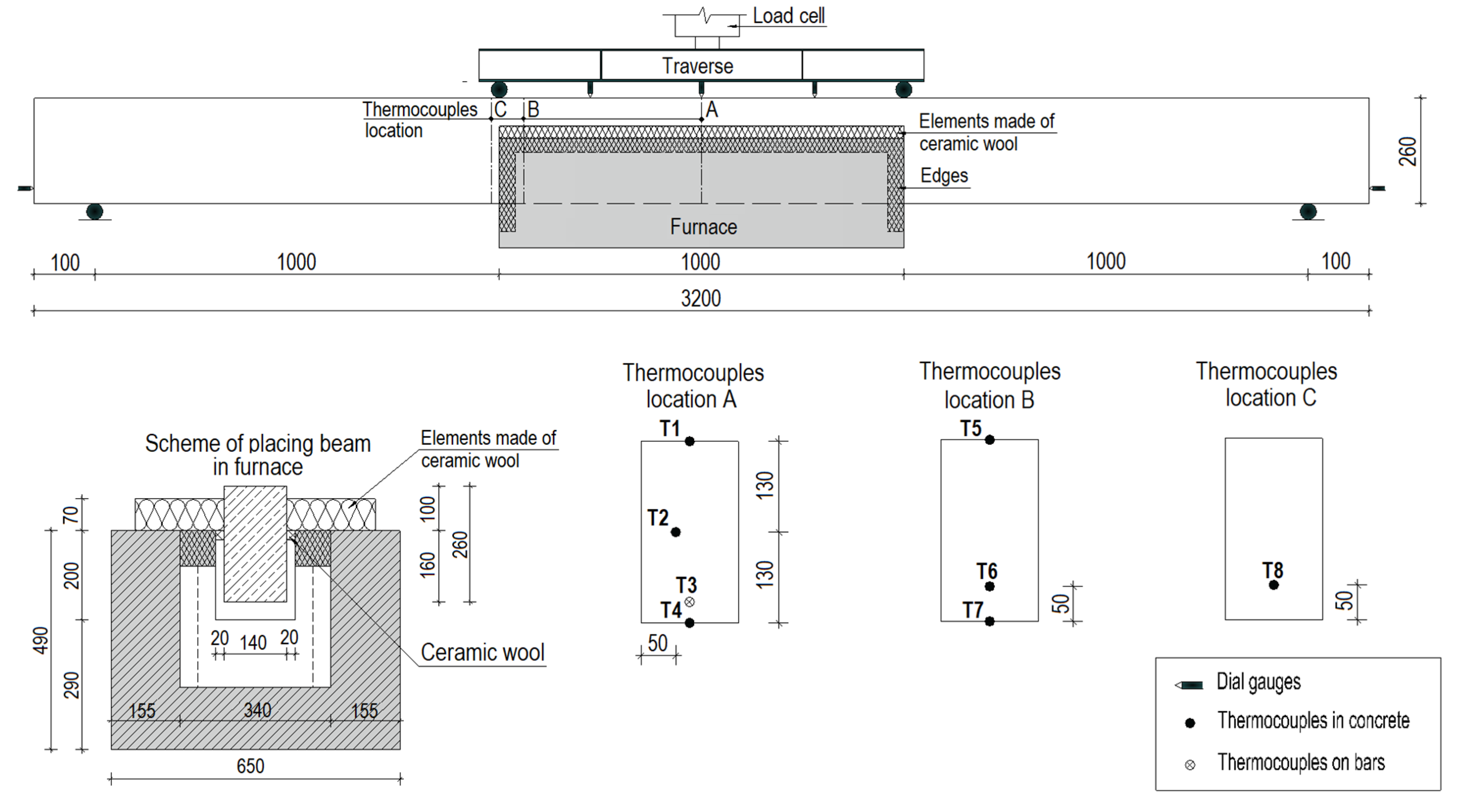

4.3. Test Setup

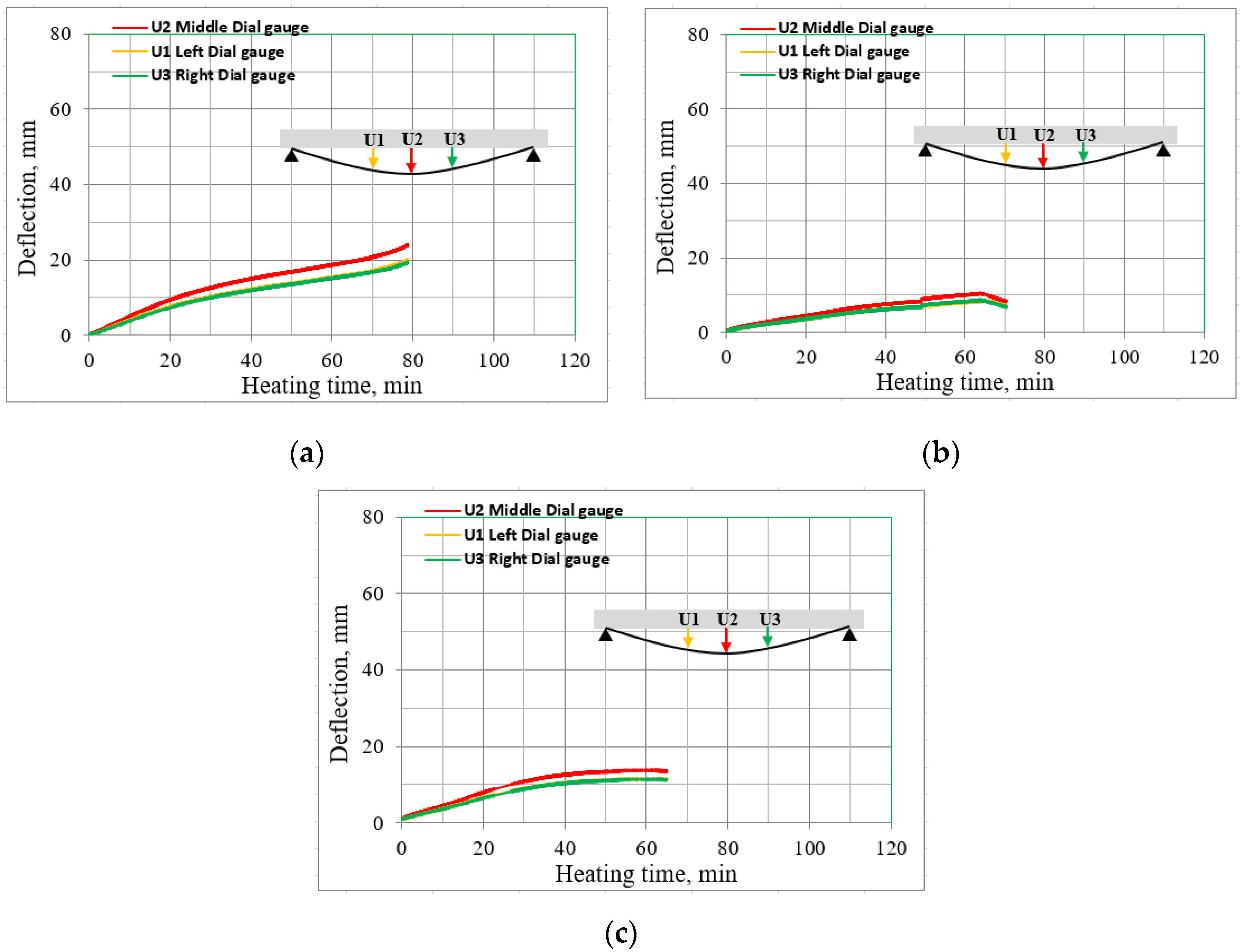

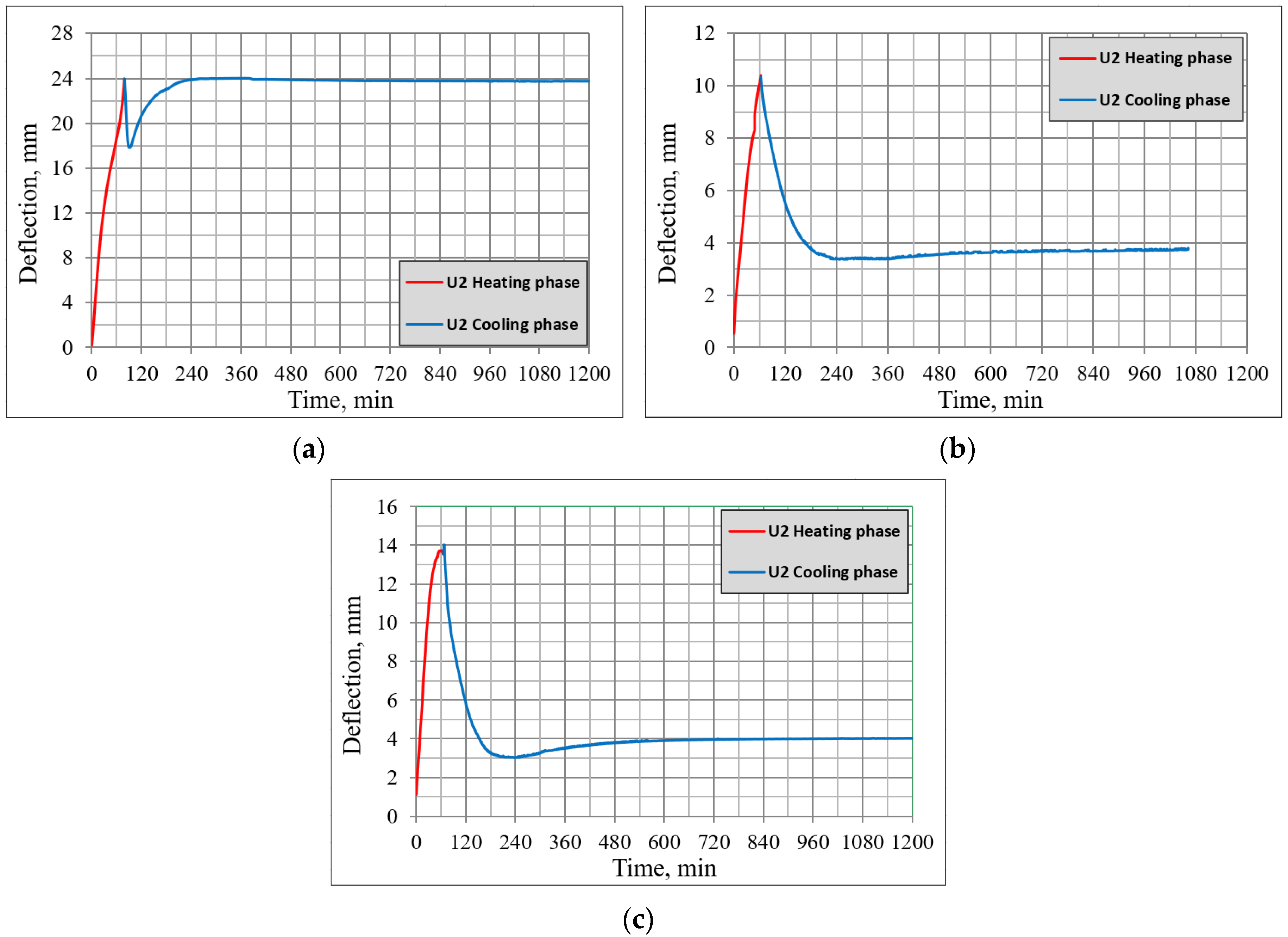

5. Results and Discussion

6. Conclusions

- All tested samples subjected to elevated temperatures were destroyed due to the tensile zone reaching its ultimate strength capacity. The authors suggest that this issue can be related to the reduction of mechanical properties experienced by the bars after being subjected to fire actions.

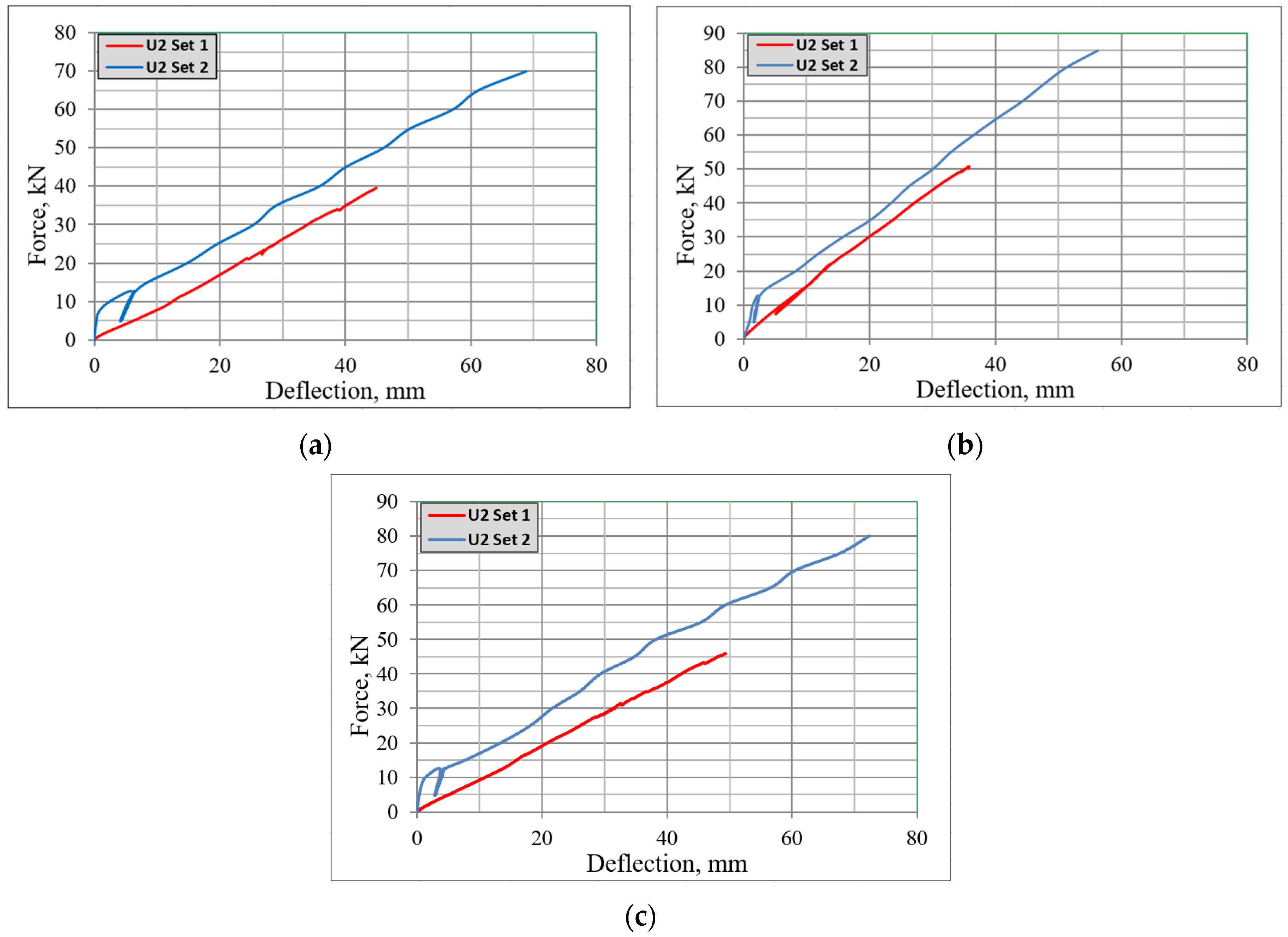

- The overall strength capacity of the FRP reinforced beams after being subjected to fire exposure was reduced; by approx. 43% for beams with the tensile zone reinforced with BFRP bars, 40% and 43% for beams reinforced with HFRP and nHFRP bars, correspondingly.

- The highest strength capacity was obtained by beams reinforced with HFRP bars. The strength capacity of the beams reinforced with HFRP bars after applying elevated temperatures was reduced by approximately 40% and was equal to 51 kN. As it can be seen from the force-deflection plots; the post-fire behavior of FRP-RC beams (Set 1) was similar to beams not subjected to fire exposure (Set 2) until failure. Nevertheless, the reduction in strength is significant.

- When the temperature on the bars reached the range of 550–570 °C, and the bottom edge of beams were heated to around 700 °C, the deflections of the beams reinforced with hybrid FRP bars, i.e., for HFRP and nHFRP reinforced beams) started to decrease. This behavior was different for the BFRP reinforced beam, which was more similar to typical steel reinforced beams.

Author Contributions

Funding

Conflicts of Interest

References

- Aslam, M.; Shafigh, P.; Jumaat, M.Z.; Shah, S.N.R. Strengthening of RC beams using prestressed fiber reinforced polymers—A review. Constr. Build. Mater. 2015, 82, 235–256. [Google Scholar] [CrossRef]

- Zhang, S.S.; Yu, T.; Chen, G.M. Reinforced concrete beams strengthened in flexure with near-surface mounted (NSM) CFRP strips: Current status and research needs. Compos. Part B Eng. 2017, 131, 30–42. [Google Scholar] [CrossRef]

- Szmigiera, E.D.; Urbański, M.; Protchenko, K. Strength Performance of Concrete Beams Reinforced with BFRP Bars. In International Congress on Polymers in Concrete (ICPIC 2018); Springer: Cham, Switzerland, 2018; pp. 667–674. [Google Scholar] [CrossRef]

- Balendran, R.V.; Rana, T.M.; Maqsood, T.; Tang, W.C. Application of FRP bars as reinforcement in civil engineering structures. Struct. Surv. 2002, 20, 62–72. [Google Scholar] [CrossRef]

- Kashwani, G.A.; Al-Tamimi, A.K. Evaluation of FRP bars performance under high temperature. Phys. Proc. 2014, 55, 296–300. [Google Scholar] [CrossRef]

- Yehia, S.; Kashwani, G. Performance of Structures Exposed to Extreme High Temperature—An Overview. Open J. Civ. Eng. 2013, 3, 154–161. [Google Scholar] [CrossRef]

- Hollaway, L.C. Polymer Composites for Civil. and Structural Engineering; Blackie Academic and Professional: Glasgow, UK, 1993; pp. 12–62. [Google Scholar]

- Szmigiera, E.; Protchenko, K.; Urbański, M.; Garbacz, A. Mechanical Properties of Hybrid FRP Bars and Nano-Hybrid FRP Bars. Arch. Civ. Eng. 2019, 65, 97–110. [Google Scholar] [CrossRef]

- Garbacz, A.; Radomski, W.A.; Mossakowski, P. Alternatywne zbrojenie betonu kompozytami FRP—Zagadnienie kompatybilności (in English—Alternative reinforcement of concrete using FRP composites—compatibility issues). Mosty 2015, 73, 42–45. [Google Scholar]

- Elsayed, T.A.; Elhefnawy, A.A.; Eldaly, A.A.; Ghanem, G.M. Hybrid fiber reinforced polymers rebars. J. Adv. Mater. 2011, 43, 65–75. [Google Scholar] [CrossRef]

- Nanni, A.; De Luca, A.; Jawaheri Zadeh, H. Reinforced Concrete with FRP Bars: Mechanics and Design; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Abbasi, A.; Hogg, P.J. Fire testing of concrete beams with fibre reinforced plastic rebar. In Advanced Polymer Composites for Structural Applications in Construction; Hollaway, L.C., Chryssanthopoulos, M.K., Moy, S.S.J., Eds.; Woodhead Publishing Limited: Cambridge, UK, 2005; pp. 445–456. [Google Scholar]

- Kowalski, R.; Głowacki, M.J. On the experimental analysis of temperature influence on stiffness of reinforced concrete beams. J. Struct. Fire Eng. 2015, 6, 49–57. [Google Scholar] [CrossRef]

- ACI. Guide for the Design and Construction of Concrete Reinforced with FRP Bars; ACI 440.1R-15; American Concrete Institute: Farmington Hills, MI, USA, 2015. [Google Scholar]

- CSA. Design and Construction of Building Structures with Fibre-Reinforced Polymers; CAN/CSA S806-12; Canadian Standards Association: Mississauga, ON, Canada, 2012; p. 206. [Google Scholar]

- Nigro, E.; Cefarelli, G.; Bilotta, A.; Manfredi, G.; Cosenza, E. Fire resistance of concrete slabs reinforced with FRP bars part II: Experimental results and numerical simulations on the thermal field. Compos. Part B Eng. 2011, 42, 1751–1763. [Google Scholar] [CrossRef]

- Wang, K.; Young, B.; Smith, S.T. Mechanical properties of pultruded carbon fibre-reinforced polymer (CFRP) plates at elevated temperatures. Eng. Struct. 2011, 33, 2154–2161. [Google Scholar] [CrossRef]

- Hu, Y.-J.; Jiang, C.; Liu, W.; Yu, Q.-Q.; Zhou, Y.-L. Degradation of the In-plane Shear Modulus of Structural BFRP Laminates Due to High Temperature. Sensors 2018, 18, 3361. [Google Scholar] [CrossRef]

- Bellakehal, H.; Zaidi, A.; Masmoudi, R.; Bouhicha, M. Behavior of FRP Bars-Reinforced Concrete Slabs under Temperature and Sustained Load Effects. Polymers 2014, 6, 873–889. [Google Scholar] [CrossRef]

- Scholzen, A.; Chudoba, R.; Hegger, J. Dünnwandiges schalentragwerk aus textilbewehrtem Beton. Beton Stahlbetonbau 2012, 107, 767–776. [Google Scholar] [CrossRef]

- Mechtcherine, V. Novel cement-based composites for the strengthening and repair of concrete structures. Constr. Build. Mater. 2013, 41, 365–373. [Google Scholar] [CrossRef]

- Hajiloo, H.; Green, M.F.; Noël, M.; Bénichou, N.; Sultan, M. Fire tests on full-scale FRP reinforced concrete slabs. Comp. Struct. 2017, 179, 705–719. [Google Scholar] [CrossRef]

- Nigro, E.; Cefarelli, G.; Bilotta, A.; Manfredi, G.; Cosenza, E. Fire resistance of concrete slabs reinforced with FRP bars part I: Experimental investigations on the mechanical behavior. Compos. Part B Eng. 2011, 42, 1739–1750. [Google Scholar] [CrossRef]

- Nigro, E.; Cefarelli, G.; Bilotta, A.; Manfredi, G.; Cosenza, E. Tests at high temperatures on concrete slabs reinforced with bent FRP bars. Spec. Publ. 2011, 275, 1–20. [Google Scholar]

- Kodur, V.K.R.; Bisby, L.A.; Foo, S. Thermal behaviour of fire-exposed concrete slabs reinforced with fibre reinforced polymer bars. ACI Struct. J. 2005, 102, 799–807. [Google Scholar]

- Sadek, A.; El-Hawary, M.; El-Deeb, A. Fire Resistance Testing of Concrete Beams Reinforced by GFRP Rebars. Eur. J. Sci. Res. 2006, 15, 190–200. [Google Scholar] [CrossRef]

- Saafi, M. Effect of fire on FRP reinforced concrete members. Comp. Struct. 2002, 58, 11–20. [Google Scholar] [CrossRef]

- Palmieri, A.; Matthys, S.; Taerwe, L. Experimental investigation on fire endurance of insulated concrete beams strengthened with near surface mounted FRP bar reinforcement. J. Compos. Part B Eng. 2012, 43, 885–895. [Google Scholar] [CrossRef]

- Palmieri, A.; Matthys, S.; Taerwe, L. Fire endurance and residual strength of insulated concrete beams strengthened with near surface mounted reinforcement. J. Compos. Constr. 2013, 17, 454–462. [Google Scholar] [CrossRef]

- Bootle, J.; Burzesi, F.; Fiorini, L. Design guidelines. In ASM handbook; ASM International: Material Park, OH, USA, 2001; pp. 388–395. [Google Scholar]

- Schneider, K.; Michel, A.; Liebscher, M.; Terreri, L.; Hempel, S.; Mechtcherine, V. Mineral-impregnated carbon fibre reinforcement for high temperature resistance of thin-walled concrete structures. Cem. Concr. Compos. 2019, 97, 68–77. [Google Scholar] [CrossRef]

- Kowalski, R.; Głowacki, M.J.; Abramowicz, M. Premature destruction of two-span RC beams exposed to high temperature caused by a redistribution of shear forces. J. Civ. Eng. Manag. 2017, 23, 431–439. [Google Scholar] [CrossRef][Green Version]

- Barbero, E.J. Introduction to Composite Materials Design, 2nd ed.; Taylor & Francis Group: Boca Raton, FL, USA, 2011; pp. 91–100. [Google Scholar]

- Black, T.; Kosher, R. Non Metallic Materials: Plastic, Elastomers, Ceramics and Composites. In Materials and Processing in Manufacturing, 10th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2008; pp. 162–194. [Google Scholar]

- Voigt, W. Uber die beziehung zwischen den beiden elasticitatsconstanten isotroperkorper. Ann. Phys. 1889, 274, 573–587. [Google Scholar] [CrossRef]

- Ashton, J.E.; Halpin, J.C.; Petit, P.H. Primer on Composite Materials: Analysis; Technomic Publishing Company: Stamford, CT, USA, 1969. [Google Scholar]

- Halpin, J.C. Stiffness and expansion estimates for oriented short fiber composites. J. Compos. Mater. 1969, 3, 732–734. [Google Scholar] [CrossRef]

- ANSYS® Academic Research Mechanical, Release 16.2, Help System, Coupled Field Analysis Guide; ANSYS, Inc.: Canonsburg, PA, USA, 2016.

- Baur, J.W.; Chen, C.; Justice, R.S.; Schaefer, D.W. Highly dispersed nanosilica-epoxy resins with enhanced mechanical properties. Polymer 2008, 49, 3805–3815. [Google Scholar] [CrossRef]

- Jesionowski, T.; Pilawka, R. Kompozycje epoksydowe z krzemionką (Epoxy composites with silica). Kompozyty 2009, 9, 112–116. [Google Scholar]

- Jesionowski, T.; Pilawka, R. Kompozyty epoksydowe z krzemionką sieciowane 1-etylomimidazolem [Epoxy composites with silica crosslinked with 1-ethylimidazole]. Kompozyty 2011, 11, 14–17. [Google Scholar]

- Garbacz, A.; Szmigiera, E.D.; Protchenko, K.; Urbański, M. On Mechanical Characteristics of HFRP Bars with Various Types of Hybridization. In International Congress on Polymers in Concrete (ICPIC 2018); Springer: Cham, Switzerland, 2018; pp. 653–658. [Google Scholar] [CrossRef]

- Protchenko, K.; Dobosz, J.; Urbański, M.; Garbacz, A. Wpływ substytucji włókien bazaltowych przez włókna węglowe na właściwości mechaniczne prętów B/CFRP (HFRP) (Influence of the substitution of basalt fibres by carbon fibres on the mechanical behavior of B/CFRP (HFRP) bars). Czas. Inżynierii Lądowej Środowiska Archit. JCEEA 2016, 63, 149–156. [Google Scholar]

- Protchenko, K.; Szmigiera, E.D.; Urbański, M.; Garbacz, A. Development of Innovative HFRP Bars. MATEC Web Conf. 2018, 196, 04087. [Google Scholar] [CrossRef][Green Version]

- Fire Resistance Tests. General Requirements; EN 1363-1:2012; British Standards Institution: London, UK, 2012.

- ISO 834-1. Fire Resistance Tests—Elements of Buildings Construction, Part-1 General Requirements; International Organization for Standardization: Geneva, Switzerland, 1999. [Google Scholar]

| Volume Fraction Dependence C:B 1 | Modulus of Elasticity of Hybrid Fiber-Reinforced Polymer (HFRP) Bars, GPa | ||

|---|---|---|---|

| ROM The Location of Fibers Is Neglected | FEM Carbon Fibers Location | ||

|  | ||

| 1:9 | 83.3 | 83.0 | 82.9 |

| 1:4 | 94.8 | 93.6 | 93.6 |

| 1:3 | 100.5 | 101.1 | 100.1 |

| 1:2 | 110.0 | 110.5 | 109.1 |

| 1:1 | 129.1 | 127.8 | 129.2 |

| Set No. | Beam Designation 1 | Reinforcement Ratio | Reinforcement Type (Tension Zone) | Preliminary Loaded (50% of the Ultimate Load) |

|---|---|---|---|---|

| - | - | (%) | Number/dia/type | (kN) |

| 1 | B2Ø14 | 0.98 | 2/14/BFRP | 30 |

| H2Ø14 | 2/14/HFRP | 40 | ||

| N2Ø14 | 2/14/nHFRP | 40 | ||

| 2 | B2Ø14 | 2/14/BFRP | 0 | |

| H2Ø14 | 2/14/HFRP | 0 | ||

| N2Ø14 | 2/14/nHFRP | 0 |

| Type of Bars Type/Dia | Maximum Tensile Force Fu (kN) | Tensile Strength fu (MPa) | Tensile Strength at Rupture εu (%) | Modulus of Elasticity E11 (GPa) |

|---|---|---|---|---|

| BFRP Ø6 | 37.07 | 1148.81 | 2.48 | 46. 47 |

| BFRP Ø8 | 60.03 | 1103.30 | 2.52 | 43.87 |

| BFRP Ø14 | 179.26 | 1101.94 | 2.39 | 46.02 |

| HFRP Ø14 | 206.57 | 1160.06 | 1.61 | 72.12 |

| nHFRP Ø14 | 150.54 | 958.00 | 1.58 | 60.44 |

| Type of Bars | BFRP | HFRP | nHFRP | |||

|---|---|---|---|---|---|---|

| Fu, tested (kN) | Fu, reference (kN) | Fu, tested (kN) | Fu, reference (kN) | Fu, tested (kN) | Fu, reference (kN) | |

| Ultimate force | 40.00 | 70.00 | 51.00 | 85.00 | 46.00 | 81.00 |

| Fu,tested/Fu,reference (%) | 57 | 60 | 57 | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Protchenko, K.; Szmigiera, E. Post-Fire Characteristics of Concrete Beams Reinforced with Hybrid FRP Bars. Materials 2020, 13, 1248. https://doi.org/10.3390/ma13051248

Protchenko K, Szmigiera E. Post-Fire Characteristics of Concrete Beams Reinforced with Hybrid FRP Bars. Materials. 2020; 13(5):1248. https://doi.org/10.3390/ma13051248

Chicago/Turabian StyleProtchenko, Kostiantyn, and Elżbieta Szmigiera. 2020. "Post-Fire Characteristics of Concrete Beams Reinforced with Hybrid FRP Bars" Materials 13, no. 5: 1248. https://doi.org/10.3390/ma13051248

APA StyleProtchenko, K., & Szmigiera, E. (2020). Post-Fire Characteristics of Concrete Beams Reinforced with Hybrid FRP Bars. Materials, 13(5), 1248. https://doi.org/10.3390/ma13051248