Effect of Single-Walled Carbon Nanotubes on Strength Properties of Cement Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

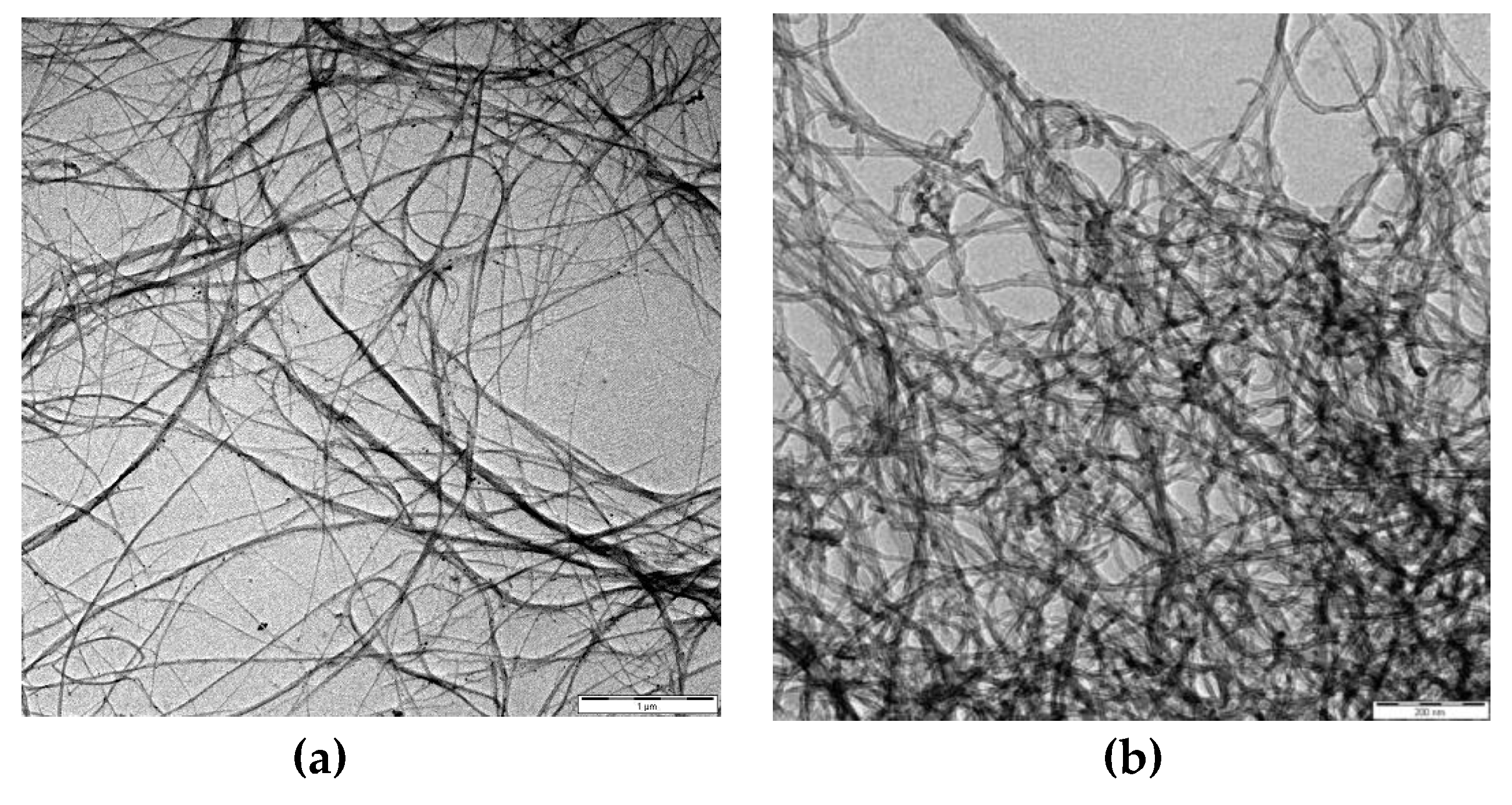

2.1.1. Carbon Nanotubes

2.1.2. Cement and Sand

2.1.3. Surfactant (SAA)

2.2. Specimens Preparation

2.2.1. Mortar Mix Ratio

2.2.2. Concentration of SWCNTs in Mortar Preparation

2.2.3. Mortar Mix Design without TX10 Treatment

2.2.4. Mortar Mix Design with TX10 Treatment

2.2.5. Mixing Process

- Certain quantities of water and Rhenofit® CNT-3/CNT-2 suspension were mixed as Solution A, and were stirred.

- All sand and half of Solution A were poured into the stir machine and stirred.

- All cement was poured into the stir machine and stirred.

- The rest of Solution A was poured into the stir machine.

- Certain quantities of water, Rhenofit® CNT-3/CNT-2, and TX10 were mixed as Solution B, and were stirred.

- All sand and half Solution B were poured into the stir machine and stirred.

- All cement was poured into the stir machine.

- The rest of Solution B was poured into the mixing machine.

2.3. Test Methods

2.3.1. Compressive Test

2.3.2. Flexural Test

3. Results and Discussion

3.1. Comparison of Strength Properties of SWCNTs and MWCNTs Added Specimens

3.2. Compressive Strength Test Results

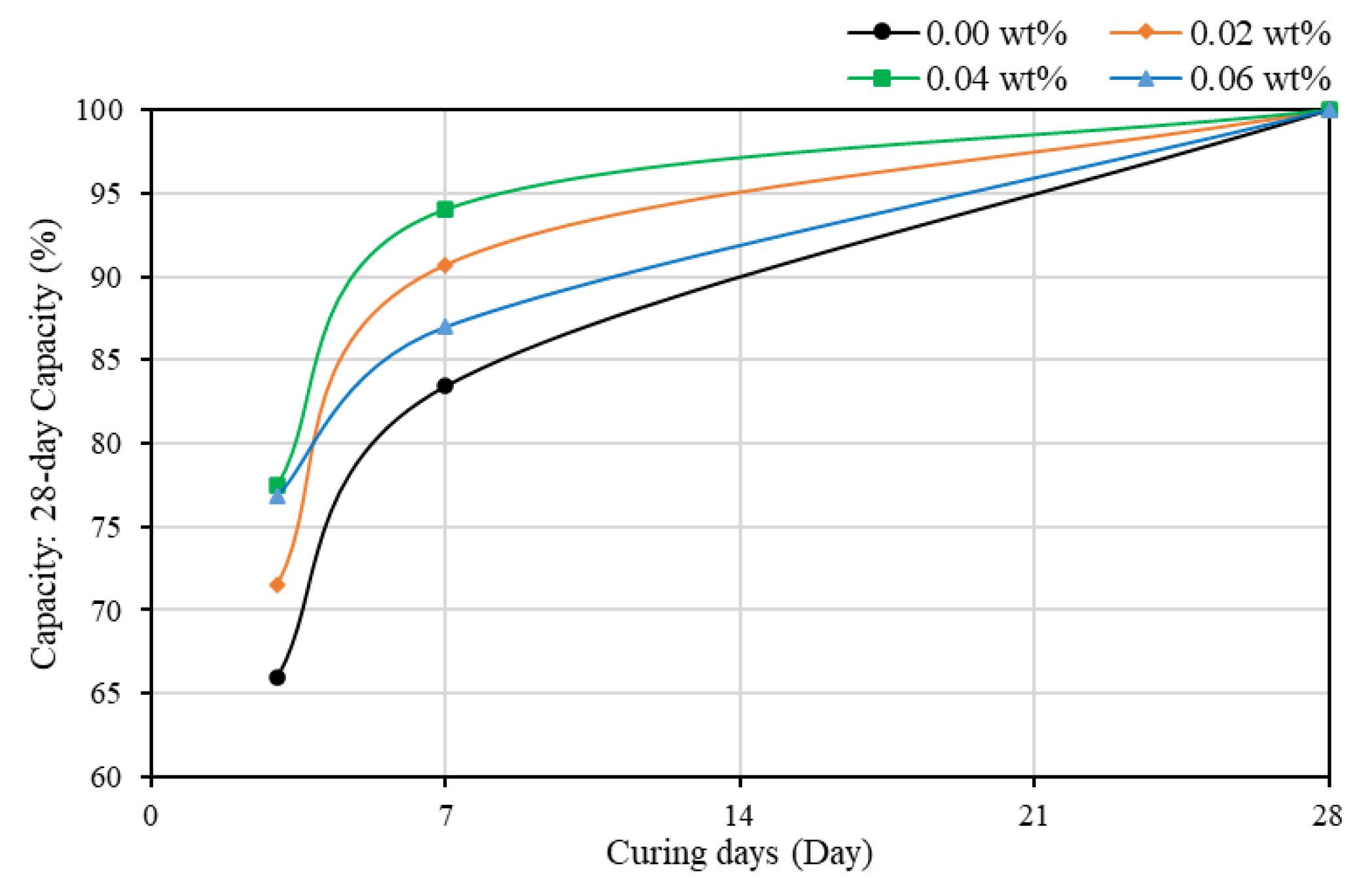

3.2.1. Specimens without Treatment of TX10

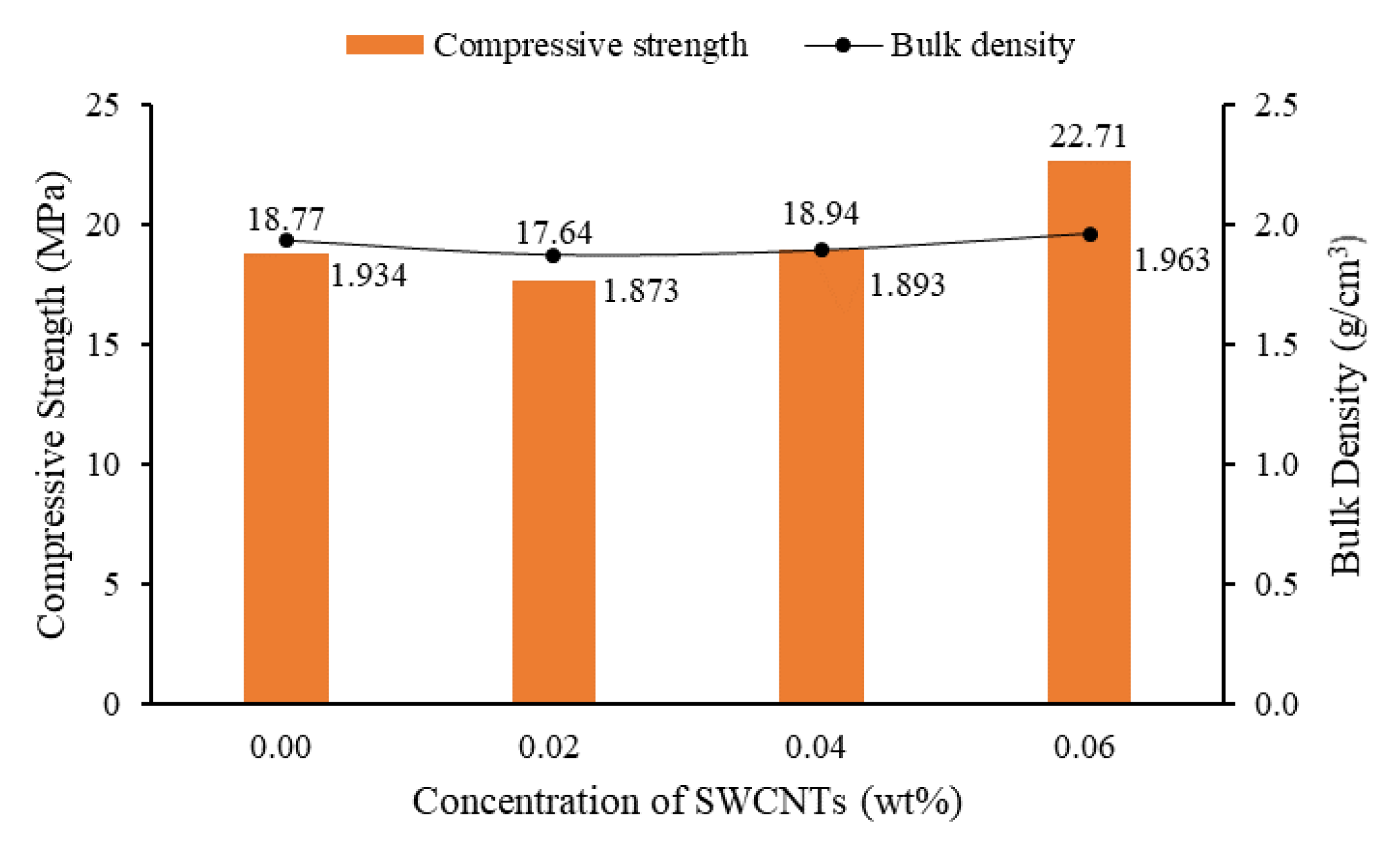

3.2.2. Specimens with Treatment of TX10

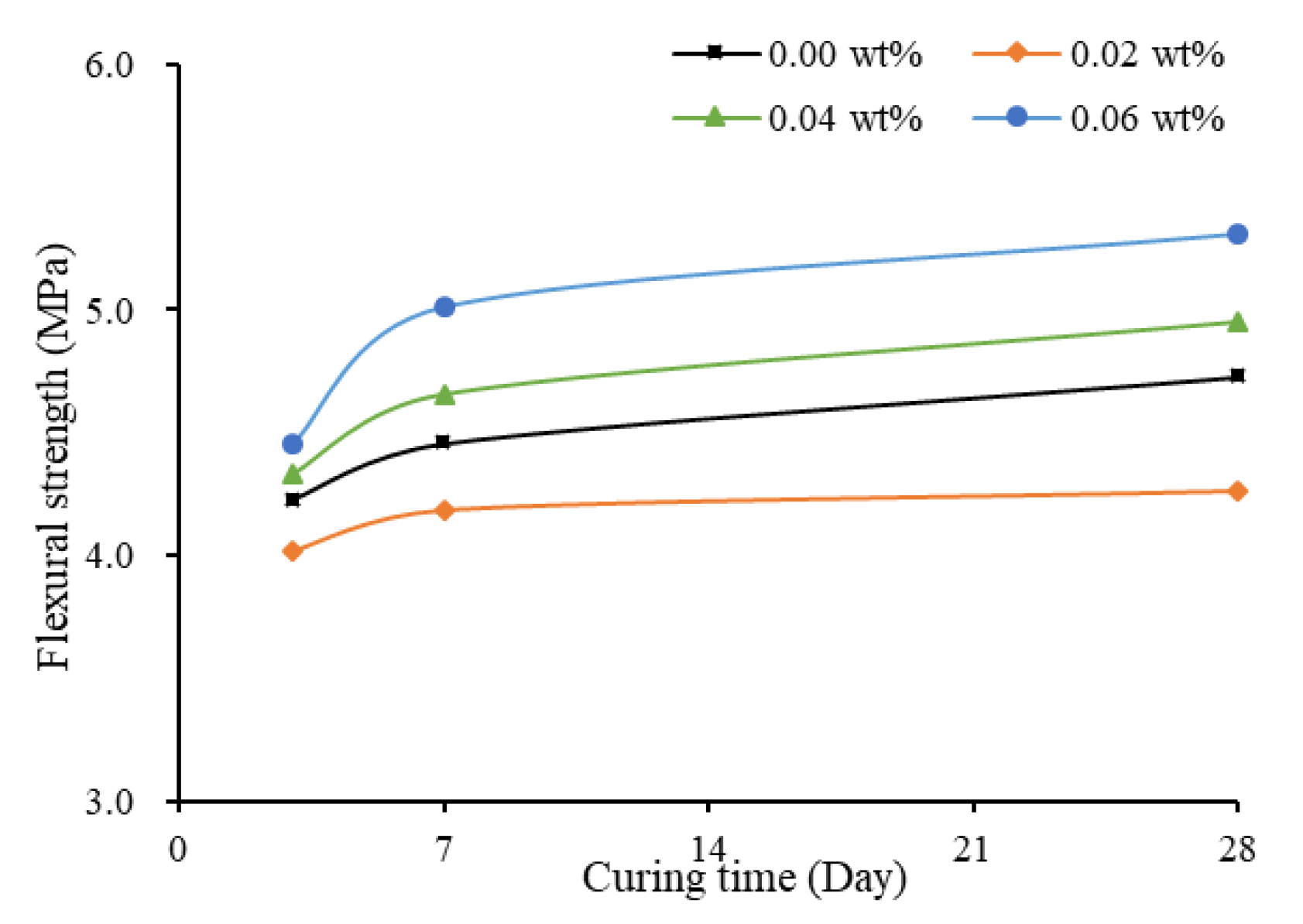

3.3. Flexural Strength Test Results

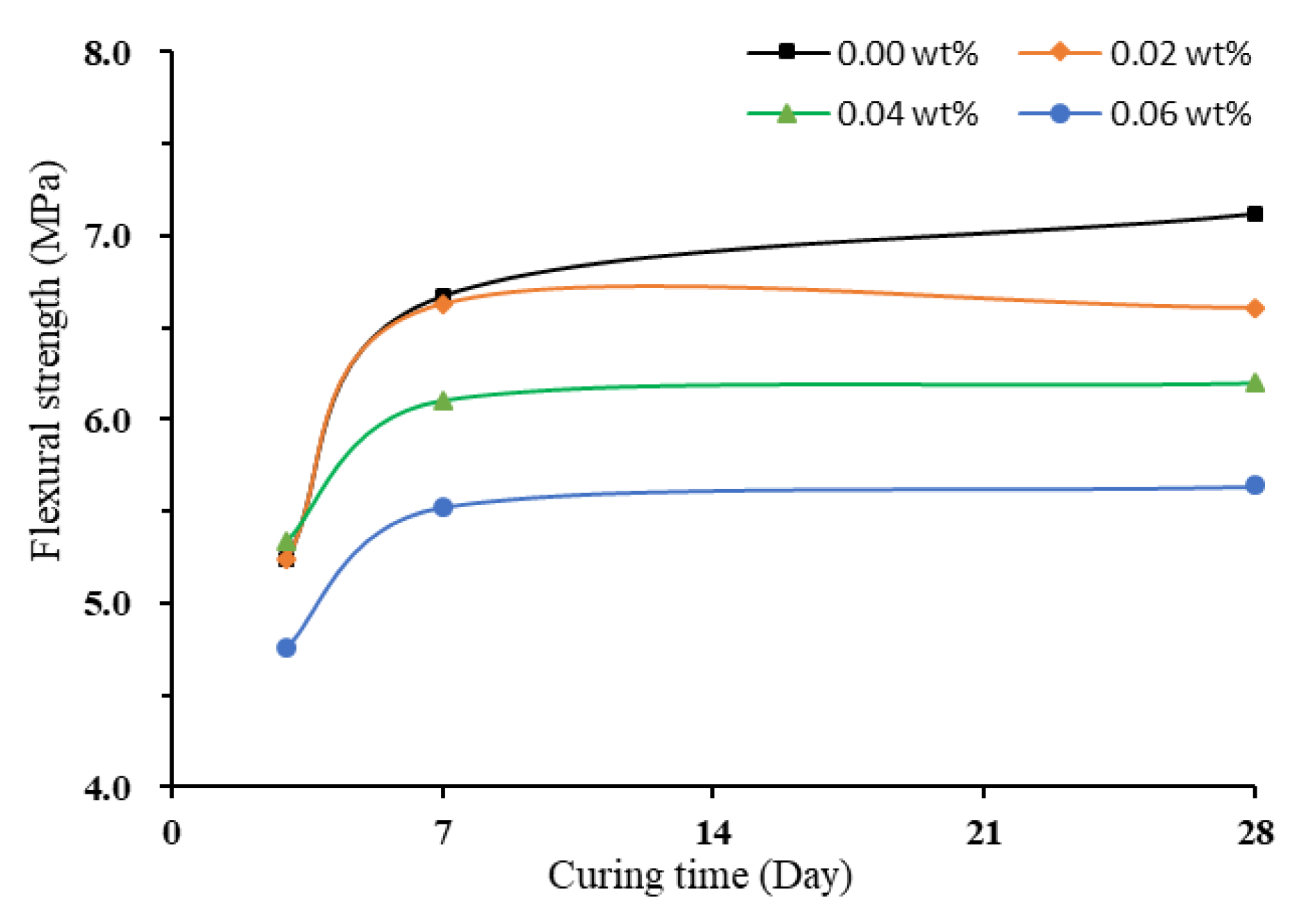

3.3.1. Specimens without Treatment of TX10

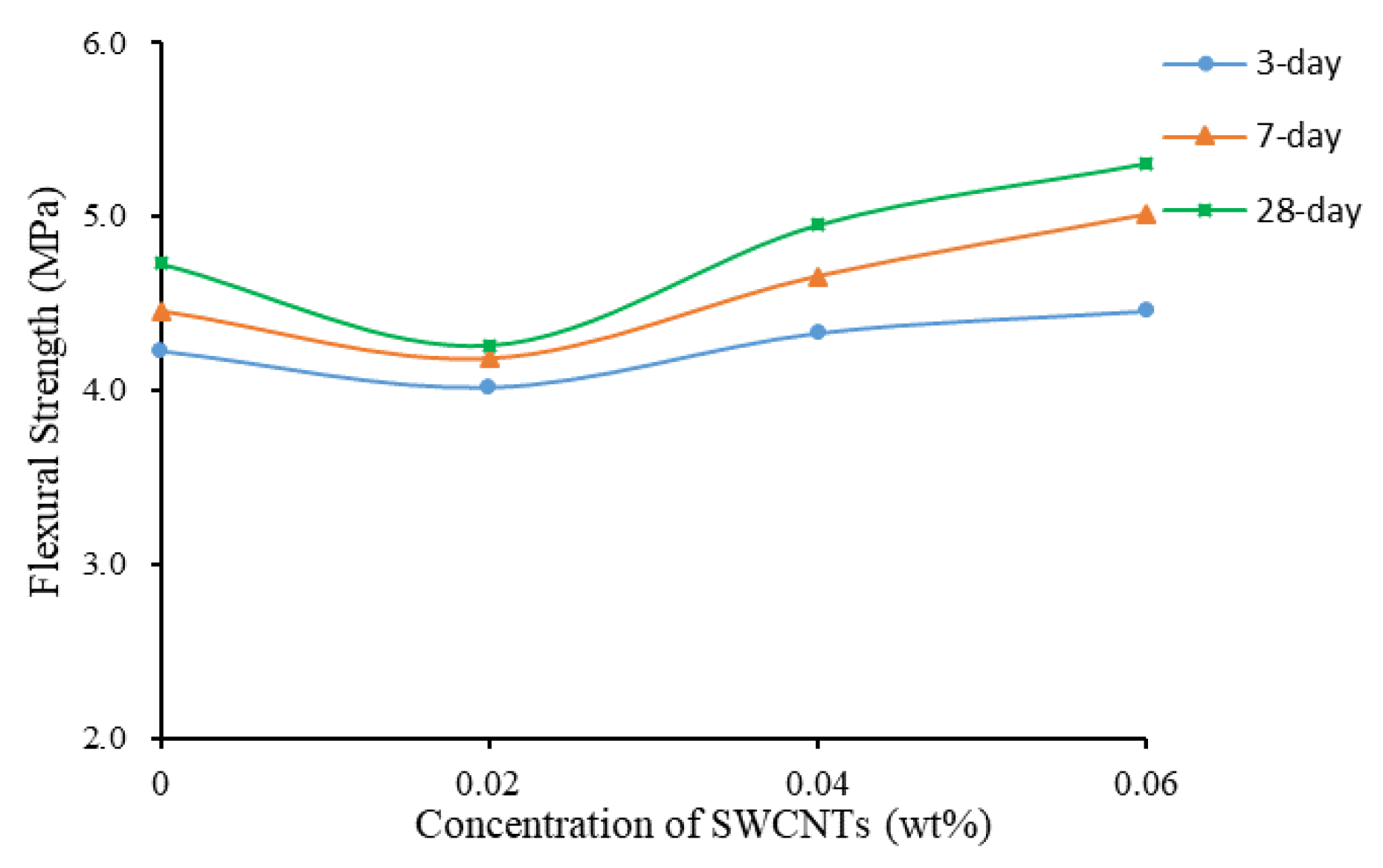

3.3.2. Specimens with Treatment of TX10

3.4. Relationship between Strength and Bulk Density of Cement Based Specimens

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jose, N.-C.; Ariel, C.; Irene, G.-T.; Manuel, C.; Antonios, K. Effect of Metallic Waste Addition on the Physical and Mechanical Properties of Cement-Based Mortars. Appl. Sci. 2018, 8, 929. [Google Scholar]

- Jang, J.G.; Kim, H.K.; Kim, T.S.; Min, B.J.; Lee, H.K. Improved flexural fatigue resistance of pva fiber-reinforced concrete subjected to freezing and thawing cycles. Constr. Build. Mater. 2014, 59, 129–135. [Google Scholar] [CrossRef]

- Liang, N.H.; Liu, X.R.; Sun, J. Experimental study of compression for multi-scale polypropylene fiber concrete. Appl. Mech. Mater. 2012, 174–177, 1584–1588. [Google Scholar] [CrossRef]

- Nuruddin, M.F.; Khan, S.U.; Shafiq, N.; Ayub, T. Strength development of high-strength ductile concrete incorporating metakaolin and pva fibers. Sci. World J. 2014, 2014, 387259. [Google Scholar] [CrossRef] [Green Version]

- Shi, Z.Q.; Chung, D.D.L. Carbon fiber-reinforced concrete for traffic monitoring and weighing in motion. Cem. Concr. Res. 1999, 29, 435–439. [Google Scholar] [CrossRef]

- de Sena Cruz, J.M.; Oliveira de Barros, J.A. Bond between near-surface mounted carbon-fiber-reinforced polymer laminate strips and concrete. J. Compos. Constr. 2004, 8, 519–527. [Google Scholar] [CrossRef] [Green Version]

- Nelson, P.K.; Li, V.C.; Kamada, T. Fracture toughness of microfiber reinforced cement composites. J. Mater. Civ. Eng. 2002, 14, 384–391. [Google Scholar] [CrossRef] [Green Version]

- Tesárek, P.; Holub, P.; Havrda, J.; Fládr, J.; Proek, Z.; Trejbal, J.; Plachy, T. Mechanical properties of cement composites reinforced by carbon microfibers: Compressive and bending strength. Key Eng. Mater. 2016, 722, 351–356. [Google Scholar] [CrossRef]

- Arash, B.; Wang, Q.; Varadan, V.K. Mechanical properties of carbon nanotube/polymer composites. Sci. Rep. 2014, 4, 6479. [Google Scholar] [CrossRef]

- Sinha, S.; Barjami, S.; Iannacchione, G.; Schwab, A.; Muench, G. Off-axis Thermal Properties of Carbon Nanotube Films. J. Nanopart. Res. 2005, 7, 651–657. [Google Scholar] [CrossRef]

- Mahar, B.; Laslan, C.; Yip, R.; Sun, Y. Development of carbon nanotube-based sensors—A review. IEEE Sens. J. 2007, 7, 266–284. [Google Scholar] [CrossRef]

- Rashad, A.M. Effect of carbon nanotubes (CNTs) on the properties of traditional cementitious materials. Constr. Build. Mater. 2017, 153, 81–101. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Birgisson, B.; Taylor, P.; Attoh-Okine, N. Nano-Technology in Civil. Infrastructure; Springer: Berlin/Heidelberg, Germany, 2011; pp. 1–1272. [Google Scholar]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Highly dispersed carbon nanotube reinforced cement based materials. Cem. Concr. Res. 2010, 40, 1052–1059. [Google Scholar] [CrossRef]

- O’Connell, M. Carbon Nanotubes: Properties and Applications; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Salvetat-Delmotte, J.; Rubio, A. Mechanical properties of carbon nanotubes: A fiber digest for beginners. Carbon 2002, 40, 1729–1734. [Google Scholar] [CrossRef]

- Saether, E.; Frankland, S.J.V.; Pipes, R.B. Transverse mechanical properties of single-walled carbon nanotube crystals. Part I: Determination of elastic moduli. Compos. Sci. Technol. 2003, 63, 1543–1550. [Google Scholar] [CrossRef]

- Wang, X.; Li, Q.; Xie, J.; Jin, Z.; Wang, J.; Li, Y.; Jiang, K.; Fan, S. Fabrication of ultralong and electrically uniform single-walled carbon nanotubes on clean substrates. Nano Lett. 2009, 9, 3137–3141. [Google Scholar] [CrossRef]

- Yu, M.F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile loading. Science 2000, 287, 637–640. [Google Scholar] [CrossRef] [Green Version]

- Lisuzzo, L.; Cavallaro, G.; Lazzara, G.; Milioto, S.; Parisi, F.; Stetsyshyn, Y. Stability of Halloysite, Imogolite, and Boron Nitride Nanotubes in Solvent Media. Appl. Sci. 2018, 8, 1068. [Google Scholar] [CrossRef] [Green Version]

- Oscar, A.M.R.; Romildo, D.T.F. A review on the chemical, mechanical and microstructural characterization of carbon nanotubes-cement based composites. Constr. Build. Mater. 2017, 154, 697–710. [Google Scholar]

- Khare, R.; Bose, S. Carbon nanotube based composites—A review. J. Miner. Mater. Charact. Eng. 2005, 4, 31–46. [Google Scholar] [CrossRef]

- Liew, K.M.; Kai, M.F.; Zhang, L.W. Carbon nanotube reinforced cement composites: An overview. Compos. Part A 2016, 91, 301–323. [Google Scholar] [CrossRef]

- Lourie, O.; Cox, D.; Wagner, H. Buckling and collapse of embedded carbon nanotubes. Phys. Rev. Lett. 1998, 81, 1638. [Google Scholar] [CrossRef]

- Saez de Ibarra, Y.; Gaitero, J.; Erkizia, E.; Campillo, I. Atomic force microscopy and nanoindentation of cement pastes with nanotube dispersions. Phys. Status Solidi (a) 2006, 203, 1076–1081. [Google Scholar] [CrossRef]

- Cavallaro, G.; Lazzara, G.; Lisuzzo, L.; Milioto, S.; Parisi, F. Filling of Mater-Bi with Nanoclays to Enhance the Biofilm Rigidity. J. Funct. Biomater. 2018, 9, 60. [Google Scholar] [CrossRef] [Green Version]

- Lisuzzo, L.; Cavallaro, G.; Milioto, S.; Lazzara, G. Effects of halloysite content on the thermo-mechanical performances of composite bioplastics. Appl. Clay Sci. 2020, 185, 105416. [Google Scholar] [CrossRef] [Green Version]

- Cota, F.P.; Panzera, T.H.; Schiavon, M.A.; Christoforo, A.L.; Borges, P.H.R.; Bowen, C.; Scarpa, F. Full factorial design analysis of carbon nanotube polymer-cement composites. Mater. Res. 2012, 15, 573–580. [Google Scholar] [CrossRef] [Green Version]

- Gopalakrishnan, K.; Birgisson, B.; Taylor, P.; Attoh Okine, N.O. Nanotechnology in Civil. Infrastructure a Paradigm Shift; Springer: Heidelberg, Germany, 2011. [Google Scholar]

- Yazdanbakhsh, A.; Grasley, Z.; Tyson, B.; Abu Al Rub, R.K. Distribution of carbon nanofibers and nanotubes in cement composites. Transport. Res. Rec. 2010, 2142, 89–95. [Google Scholar] [CrossRef] [Green Version]

- Parveen, S.; Rana, S.; Fangueiro, R. A review on nanomaterial dispersion, microstructure, and mechanical properties of carbon nanotube and nanofiber reinforced cement composites. J. Nanomater. 2013, 2013, 710175. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Pressure-sensitive properties and microstructure of carbon nanotube reinforced cement composites. Cem. Concr. Compos. 2007, 29, 377–382. [Google Scholar] [CrossRef]

- Collins, F.; Lambert, J.; Duan, W.H. The influences of admixtures on the dispersion, workability, and strength of carbon nanotube–OPC paste mixtures. Cem. Concr. Compos. 2012, 34, 201–207. [Google Scholar] [CrossRef]

- Cwirzen, A.; Habermehl-Cwirzen, K.; Penttala, V. Surface decoration of carbon nanotubes and mechanical properties of cement/carbon nanotube composites. Adv. Cem. Res. 2008, 20, 65–73. [Google Scholar] [CrossRef]

- Wang, B.; Han, Y.; Liu, S. Effect of highly dispersed carbon nanotubes on the flexural toughness of cement-based composites. Constr. Build. Mater. 2013, 46, 8–12. [Google Scholar] [CrossRef]

- Sindu, B.S.; Sasmal, S. Properties of carbon nanotube reinforced cement composite synthesized using different types of surfactants. Constr. Build. Mater. 2017, 155, 389–399. [Google Scholar] [CrossRef]

- Wu, X.; Dai, L. Carbon nano-tubes in improving the mechanical property of cement-based composite materials. Frat. Integritá Strutt. 2017, 11, 388–395. [Google Scholar] [CrossRef] [Green Version]

- Fatemi, S.M.; Foroutan, M. Study of dispersion of carbon nanotubes by Triton X-100 surfactant using molecular dynamics simulation. J. Iran. Chem. Soc. 2015, 12, 1905–1913. [Google Scholar] [CrossRef]

- Luo, J.; Duan, Z.; Li, H. The influence of surfactants on the processing of multi-walled carbon nanotubes in reinforced cement matrix composites. Phys. Status Solidi 2009, 206, 8. [Google Scholar] [CrossRef]

- Mohsen, M.O.; Taha, R.; Abu Taqa, A.; Al-Nuaimi, N.; Al-Rub, R.A.; Bani-Hani, K.A. Effect of Nanotube Geometry on the Strength and Dispersion of CNT-Cement Composites. J. Nanomater. 2017, 2017, 6927416. [Google Scholar] [CrossRef] [Green Version]

- Evangelista, A.C.J.; de Morais, J.F.; Tam, V.; Soomro, M.; Di Gregorio, L.T.; Haddad, A.N. Evaluation of Carbon Nanotube Incorporation in Cementitious composites Materials. Materials 2019, 12, 1504. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Wei, W.; Qin, H.; Hu, Y.H. Co-effects of graphene oxide sheets and single wall carbon nanotubes on mechanical properties of cement. J. Phys. Chem. Solids 2015, 85, 39–43. [Google Scholar] [CrossRef]

- Parveen, S.; Rana, S.; Fangueiro, R.; Paiva, M.C. Microstructure and mechanical properties of carbon nanotube reinforced cementitious composites developed using a novel dispersion technique. Cem. Concr. Res. 2015, 73, 215–227. [Google Scholar] [CrossRef]

- del Carmen Camacho, M.; Galao, O.; Baeza, F.J.; Zornoza, E.; Garcés, P. Mechanical properties and durability of cnt cement composites. Materials 2014, 7, 1640–1651. [Google Scholar] [CrossRef] [PubMed]

- Shao, H.; Chen, B.; Li, B.; Tang, S.; Li, Z. Influence of dispersants on the properties of CNTs reinforced cement-based materials. Constr. Build. Mater. 2017, 131, 186–194. [Google Scholar] [CrossRef]

- Sobolkina, A.; Mechtcherine, V.; Khavrus, V.; Maier, D.; Mende, M.; Ritschel, M.; Leonhardt, A. Dispersion of carbon nanotubes and its influence on the mechanical properties of the cement matrix. Cem. Concr. Compos. 2012, 34, 1104–1113. [Google Scholar] [CrossRef]

- Kim, J.-H.; Chung, C.-W. Rheological Properties of Cement Paste Mixed with Aqueously Dispersed Single-Walled Carbon Nanotubes. J. Korea Inst. Build. Constr. 2019, 19, 113–121. [Google Scholar]

- Bharj, J.; Singh, S.; Chander, S.; Rabinder, S. Experimental study on compressive strength of cement-CNT composite paste. Indian J. Pure Appl. Phys. 2014, 52, 35–38. [Google Scholar]

- Rastogi, R.; Kaushal, R.; Tripathi, S.K.; Sharma, A.L.; Kaur, I.; Bharadwaj, L.M. Comparative study of carbon nanotube dispersion using surfactants. J. Colloid Interface Sci. 2018, 328, 421–428. [Google Scholar] [CrossRef]

- Nadiv, R.; Vasilyev, G.; Shtein, M.; Peled, A.; Zussman, E.; Regev, O. The multiple roles of a dispersant in nanocomposite systems. Compos. Sci. Technol. 2016, 133, 192–199. [Google Scholar] [CrossRef]

- Yamada, K.; Takahashi, T.; Hanehara, S.; Matsuhisa, M. Effects of the chemical structure on the properties of polycarboxylate-type superplasticizer. Cem. Concr. Res. 2000, 30, 197–207. [Google Scholar] [CrossRef]

- Han, B.; Sun, S.; Ding, S.; Zhang, L.; Yu, X.; Ou, J. Review of nanocarbon-engineered multifunctional cementitious composites. Compos. Part A Appl. Sci. Manuf. 2015, 70, 69–81. [Google Scholar] [CrossRef]

- Salvetat, J.P.; Bonard, J.M.; Thomson, N.H.; Kulik, A.J.; Forró, L.; Benoit, W.; Zuppiroli, L. Mechanical properties of carbon nanotubes. Appl. Phys. A 1999, 69, 255–260. [Google Scholar] [CrossRef]

- Lee, J.I.; Jung, H.T. Technical status of carbon nanotubes composites. Korean Chem. Eng. Res. 2008, 46, 7–14. [Google Scholar]

- Bandaru, P.R. Electrical Properties and Applications of Carbon Nanotube Structures. J. Nanosci. Nanotechnol. 2007, 7, 1239–1267. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Kang, D.; Song, Y.M.; Chung, W. Heating Experiment of CNT Cementitious Composites with Single-Walled and Multiwalled Carbon Nanotubes. J. Nanomater. 2017, 2017, 3691509. [Google Scholar] [CrossRef] [Green Version]

- Luigi, C.; Alessandra, B.; Fabio, C. Electrical properties of carbon nanotubes cement composites for monitoring stress conditions in concrete structures. Appl. Mech. Mater. 2011, 82, 118–123. [Google Scholar]

- Lee, H.; Kang, D.; Kim, J.; Choi, K.; Chung, W. Void detection of cementitious grout composite using single-walled and multi-walled carbon nanotubes. Cem. Concr. Compos. 2019, 95, 237–246. [Google Scholar] [CrossRef]

- Kim, J.H.; Rhee, I.; Jung, Y.C.; Ha, S.; Kim, Y.A. Optical sensitivity of DNA-dispersed single-walled carbon nanotubes within cement composites under mechanical load. Carbon Lett. 2017, 24, 90–96. [Google Scholar]

- Image of Rhenofit ® CNT-3/CNT-2 from Transmission Electron Microscope, 16th ed.; RheinChemie Additives: Mannheim, Germany, November 2018; Available online: http://cnt.lanxess.com (accessed on 28 February 2020).

- D’Souza, O.J.; Mascarenhas, R.J.; Thomas, T.; Basavaraja, B.M.; Saxena, A.K.; Mukhopadhyay, K.; Roy, D. Platinum decorated multi-walled carbon nanotubes/Triton X-100 modified carbon paste electrode for the sensitive amperometric determination of Paracetamol. J. Electroanal. Chem. 2015, 739, 49–57. [Google Scholar] [CrossRef]

- Carriço, A.; Bogas, J.A.; Hawreen, A.; Guedes, M. Durability of multi-walled carbon nanotube reinforced concrete. Constr. Build. Mater. 2018, 164, 121–133. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, W.; Ho, D.L.; Winey, K.I.; Fischer, J.E.; Glinka, C.J.; Hobbie, E.K. Dispersing single-walled carbon nanotubes with surfactants: A small angle neutron scattering study. Nano Lett. 2004, 4, 1789–1793. [Google Scholar] [CrossRef]

- Jensen, R.E.; O’Brien, E.; Wang, J.; Bryant, J.; Lewis, D.A. Characterization of epoxy-surfactant interactions. J. Polym. Sci. Part B Polym. Phys. 1998, 36, 2781–2792. [Google Scholar] [CrossRef]

- Ferro, G.; Tulliani, J.M.; Musso, S. Carbon nanotubes cement composites. Frat. Integrità Strutt. 2011, 18, 34–44. [Google Scholar] [CrossRef] [Green Version]

- Suprompituk, W.; Jaroenapibal, P. Improvement of Early Compressive Strength in Belite Cement by Incorporating Silica Coated Single-Walled Carbon Nanotubes. Key Eng. Mater. 2016, 718, 157–162. [Google Scholar] [CrossRef]

- Markar, J.M.; Beaudoin, J.J. Carbon nanotubes and their applications in the construction industry. Spec. Publ. Roy. Soc. Chem. 2004, 331–341. [Google Scholar]

- Markar, J.M.; Margeson, J.C.; Luh, J. Carbon nanotube/cement composites early results and potential applications. In Proceedings of the NRC Publications Record, 3rd International Conference on Construction Materails: Performaing Innovations and Structural Implications, Vancouver, BC, Canada, 22–24 August 2005; pp. 1–10. [Google Scholar]

- Raki, L.; Beaudoin, J.; Aali, R.A.; Makar, J. Cement and concrete nanoscience and nanotechnology. Materials 2010, 3, 918–942. [Google Scholar] [CrossRef] [Green Version]

| SWCNT | MWCNT | |

|---|---|---|

| Structure | Diameter: 0.5–3.0 nm | Diameter: 5–100 nm |

| Length: 100 nm–1 cm | Length: 100 nm–1 cm | |

| Typical Young’s modulus | 1.3 TPa | 1.8 TPa |

| Tensile strength | Up to 53 GPa | Up to 63 GPa |

| Electrical conductivity | 10,000 S/cm | 6000 S/cm |

| Heat conductivity | Max. 6000 W/m·k | Max. 3000 W/m·k |

| Rhenofit® CNT-3 | Rhenofit® CNT-2 | |

|---|---|---|

| Composition | 0.2 wt% single wall carbon nanotubes | 2 wt% Multi wall carbon nanotubes |

| 0.4 wt% dispersant agent in water | 4 wt% dispersant agent in water | |

| Appearance | stable black suspension | stable black suspension |

| Odor | no odor | no odor |

| Compatibility | can be mixed with liquid systems and some polar organic solvents | can be mixed with liquid systems and some polar organic solvents |

| pH Value | 7.7 | 8–10 |

| 1:3:0.7 Mix Ratio of Mass | ||

|---|---|---|

| Cement | Sand | Water |

| 1 | 3 | 0.70 |

| 1:3:0.55 Mix Ratio of Mass | ||

|---|---|---|

| Cement | Sand | Water |

| 1 | 3 | 0.55 |

| Classification of Workability | Slump (mm) |

|---|---|

| S1 | 10–40 |

| S2 | 50–90 |

| S3 | 100–150 |

| S4 | ≥160 |

| Mix Name | Cement (g) | Sand (g) | Water (g) | SWCNT (%wt, cement) | Rhenofit® CNT-3 (g) | Total Mass of Solution (g) |

|---|---|---|---|---|---|---|

| SWCNT0N | 1833 | 5499 | 1283.1 | 0.00 | 0.0 | 1283.1 |

| SWCNT2N | 1833 | 5499 | 1099.8 | 0.02 | 183.3 | 1283.1 |

| SWCNT4N | 1833 | 5499 | 916.4 | 0.04 | 366.7 | 1283.1 |

| SWCNT6N | 1833 | 5499 | 733.2 | 0.06 | 549.9 | 1283.1 |

| Mix Name | Cement (g) | Sand (g) | Water (g) | MWCNT (%wt, cement) | Rhenofit® CNT-2 (g) | Total Mass of Solution (g) |

|---|---|---|---|---|---|---|

| MWCNT0N | 1842 | 5529 | 1289.4 | 0.00 | 0.0 | 1289.4 |

| MWCNT4N | 1842 | 5529 | 1106.1 | 0.04 | 36.8 | 1289.4 |

| MWCNT8N | 1842 | 5529 | 922.8 | 0.08 | 73.6 | 1289.4 |

| MWCNT12N | 1842 | 5529 | 739.5 | 0.12 | 110.4 | 1289.4 |

| Mix Name | Cement (g) | Sand (g) | Water (g) | SWCNT (%wt, cement) | Rhenofit® CNT-3 (g) | TX10 (g) |

|---|---|---|---|---|---|---|

| SWCNT0S | 1833 | 5499 | 1008.2 | 0.00 | 0.0 | 2.75 |

| SWCNT2S | 1833 | 5499 | 824.85 | 0.02 | 183.3 | 2.75 |

| SWCNT4S | 1833 | 5499 | 641.55 | 0.04 | 366.6 | 2.75 |

| SWCNT6S | 1833 | 5499 | 458.25 | 0.06 | 549.9 | 2.75 |

| Mix Name | Cement (g) | Sand (g) | Water (g) | SWCNT (%wt, cement) | Rhenofit® CNT-3 (g) | TX10 (g) |

|---|---|---|---|---|---|---|

| MWCNT0S | 1842 | 5529 | 1013.1 | 0.00 | 0.0 | 2.76 |

| MWCNT2S | 1842 | 5529 | 976.3 | 0.04 | 36.8 | 2.76 |

| MWCNT4S | 1842 | 5529 | 939.5 | 0.08 | 73.6 | 2.76 |

| MWCNT6S | 1842 | 5529 | 902.7 | 0.12 | 110.4 | 2.76 |

| SWCNTs | MWCNTs | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| SWCNTs Concentration | No TX10 | TX10 Added | MWCNTs Concentration | No TX10 | TX10 Added | ||||

| Com | Fle | Com | Fle | Com | Fle | Com | Fle | ||

| 0.00 wt% | 30.15 | 7.12 | 18.77 | 4.73 | 0.00 wt% | 30.57 | 7.08 | 18.12 | 4.59 |

| 0.02 wt% | 28.21 | 6.66 | 17.64 | 4.26 | 0.04 wt% | 29.26 | 6.96 | 18.46 | 4.79 |

| 0.04 wt% | 25.79 | 6.20 | 18.94 | 4.95 | 0.08 wt% | 27.46 | 6.94 | 21.71 | 4.91 |

| 0.06 wt% | 25.58 | 5.64 | 22.71 | 5.31 | 0.12 wt% | 24.86 | 6.62 | 21.65 | 5.06 |

| Compressive Strength (MPa) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mix Name | 3 Days | Mean | 7 Days | Mean | 28 Days | Mean | ||||||

| SWCNT0N | 18.70 | 19.24 | 21.71 | 19.88 | 25.01 | 25.16 | 25.28 | 25.15 | 29.45 | 29.73 | 31.26 | 30.15 |

| SWCNT2N | 19.03 | 20.46 | 21.06 | 20.18 | 25.34 | 25.55 | 25.89 | 25.59 | 28.07 | 28.09 | 28.48 | 28.21 |

| SWCNT4N | 18.73 | 20.47 | 20.75 | 19.98 | 23.13 | 24.74 | 24.89 | 24.25 | 24.94 | 25.68 | 26.76 | 25.79 |

| SWCNT6N | 17.84 | 18.92 | 22.22 | 19.66 | 21.51 | 22.54 | 22.70 | 22.25 | 25.42 | 25.65 | 25.67 | 25.58 |

| SWCNT0S | 13.98 | 14.44 | 14.46 | 14.29 | 15.84 | 16.24 | 16.55 | 16.21 | 18.56 | 18.86 | 18.89 | 18.77 |

| SWCNT2S | 13.66 | 13.88 | 14.45 | 13.99 | 15.76 | 15.85 | 16.67 | 16.09 | 17.55 | 17.64 | 17.72 | 17.64 |

| SWCNT4S | 15.97 | 16.12 | 16.37 | 16.15 | 18.43 | 18.71 | 18.72 | 18.62 | 18.64 | 18.96 | 19.22 | 18.94 |

| SWCNT6S | 18.88 | 18.98 | 19.23 | 19.03 | 20.76 | 21.09 | 22.43 | 21.43 | 21.87 | 22.94 | 23.32 | 22.71 |

| Flexural Strength (MPa) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mix Name | 3 Days | Mean | 7 Days | Mean | 28 Days | Mean | ||||||

| SWCNT0N | 5.02 | 5.34 | 5.35 | 5.24 | 6.47 | 6.70 | 6.84 | 6.67 | 6.76 | 7.11 | 7.52 | 7.12 |

| SWCNT2N | 5.12 | 5.25 | 5.35 | 5.24 | 6.46 | 6.71 | 6.73 | 6.63 | 6.08 | 6.60 | 7.15 | 6.66 |

| SWCNT4N | 5.13 | 5.41 | 5.46 | 5.34 | 5.94 | 6.12 | 6.27 | 6.11 | 6.12 | 6.24 | 6.25 | 6.20 |

| SWCNT6N | 4.55 | 4.63 | 5.10 | 4.76 | 5.19 | 5.57 | 5.79 | 5.52 | 5.29 | 5.48 | 6.14 | 5.64 |

| SWCNT0S | 4.11 | 4.25 | 4.32 | 4.23 | 4.31 | 4.40 | 4.66 | 4.46 | 4.69 | 4.71 | 4.78 | 4.73 |

| SWCNT2S | 4.00 | 4.02 | 4.03 | 4.02 | 3.99 | 4.25 | 4.31 | 4.18 | 4.20 | 4.27 | 4.32 | 4.26 |

| SWCNT4S | 4.27 | 4.32 | 4.40 | 4.33 | 4.54 | 4.64 | 4.79 | 4.66 | 4.68 | 4.97 | 5.21 | 4.95 |

| SWCNT6S | 4.16 | 4.58 | 4.63 | 4.46 | 4.66 | 4.88 | 5.50 | 5.01 | 5.21 | 5.29 | 5.42 | 5.31 |

| Types | Curing Days | 0.00 wt% | 0.02 wt% | 0.04 wt% | 0.06 wt% | ||||

|---|---|---|---|---|---|---|---|---|---|

| Cubes | Prisms | Cubes | Prisms | Cubes | Prisms | Cubes | Prisms | ||

| Non-TX10-treated | 3 | 2.094 | 2.164 | 2.122 | 2.164 | 2.115 | 2.082 | 2.107 | 2.129 |

| 7 | 2.106 | 2.164 | 2.114 | 2.082 | 2.109 | 2.152 | 2.115 | 2.156 | |

| 28 | 2.105 | 2.074 | 2.114 | 2.176 | 2.108 | 2.121 | 2.105 | 2.078 | |

| Mean | 2.102 | 2.134 | 2.117 | 2.141 | 2.111 | 2.118 | 2.109 | 2.121 | |

| TX10-treated | 3 | 1.882 | 1.891 | 1.902 | 1.871 | 1.939 | 1.867 | 1.999 | 2.000 |

| 7 | 1.887 | 1.875 | 1.878 | 1.902 | 1.943 | 1.918 | 2.024 | 2.031 | |

| 28 | 1.934 | 1.871 | 1.873 | 1.855 | 1.893 | 1.852 | 1.963 | 1.965 | |

| Mean | 1.901 | 1.879 | 1.884 | 1.876 | 1.925 | 1.879 | 1.995 | 1.998 | |

| Mix Name | Cube Mass (g) | Comp (MPa) | Prism Mass (g) | Flex (MPa) | Comp/ Mass | Flex/ Mass | Difference |

|---|---|---|---|---|---|---|---|

| SWCNT0N | 2106 | 25.15 | 554 | 6.67 | 0.01194 | 0.01205 | 0.921% |

| SWCNT2N | 2114 | 25.59 | 533 | 6.63 | 0.01211 | 0.01244 | 2.725% |

| SWCNT4N | 2109 | 24.25 | 551 | 6.11 | 0.01149 | 0.01108 | 3.568% |

| SWCNT6N | 2115 | 22.25 | 552 | 5.52 | 0.01052 | 0.01000 | 4.943% |

| SWCNT0S | 1887 | 16.21 | 480 | 4.46 | 0.00859 | 0.00928 | 8.032% |

| SWCNT2S | 1878 | 16.09 | 487 | 4.18 | 0.00857 | 0.00859 | 0.233% |

| SWCNT4S | 1943 | 18.62 | 491 | 4.66 | 0.00949 | 0.00949 | 0.000% |

| SWCNT6S | 2024 | 21.43 | 498 | 5.01 | 0.01059 | 0.01006 | 5.005% |

| Mix Name | Cube Mass (g) | Comp (MPa) | Prism Mass (g) | Flex (MPa) | Comp/ Mass | Flex/ Mass | Difference |

|---|---|---|---|---|---|---|---|

| SWCNT0S | 1882 | 14.29 | 484 | 4.23 | 0.00759 | 0.00874 | 15.152% |

| SWCNT2S | 1902 | 14.00 | 479 | 4.02 | 0.00736 | 0.00839 | 13.995% |

| SWCNT4S | 1939 | 16.15 | 478 | 4.33 | 0.00833 | 0.00906 | 8.764% |

| SWCNT6S | 1999 | 19.03 | 512 | 4.46 | 0.00952 | 0.00871 | 8.508% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, J.; Al-Sabah, S.; Théo, R. Effect of Single-Walled Carbon Nanotubes on Strength Properties of Cement Composites. Materials 2020, 13, 1305. https://doi.org/10.3390/ma13061305

Kang J, Al-Sabah S, Théo R. Effect of Single-Walled Carbon Nanotubes on Strength Properties of Cement Composites. Materials. 2020; 13(6):1305. https://doi.org/10.3390/ma13061305

Chicago/Turabian StyleKang, Jiayuan, Salam Al-Sabah, and Roger Théo. 2020. "Effect of Single-Walled Carbon Nanotubes on Strength Properties of Cement Composites" Materials 13, no. 6: 1305. https://doi.org/10.3390/ma13061305