Assessment of the Effect of Laser Welding on the Properties and Structure of TMCP Steel Butt Joints

Abstract

:1. Introduction

2. Own Research

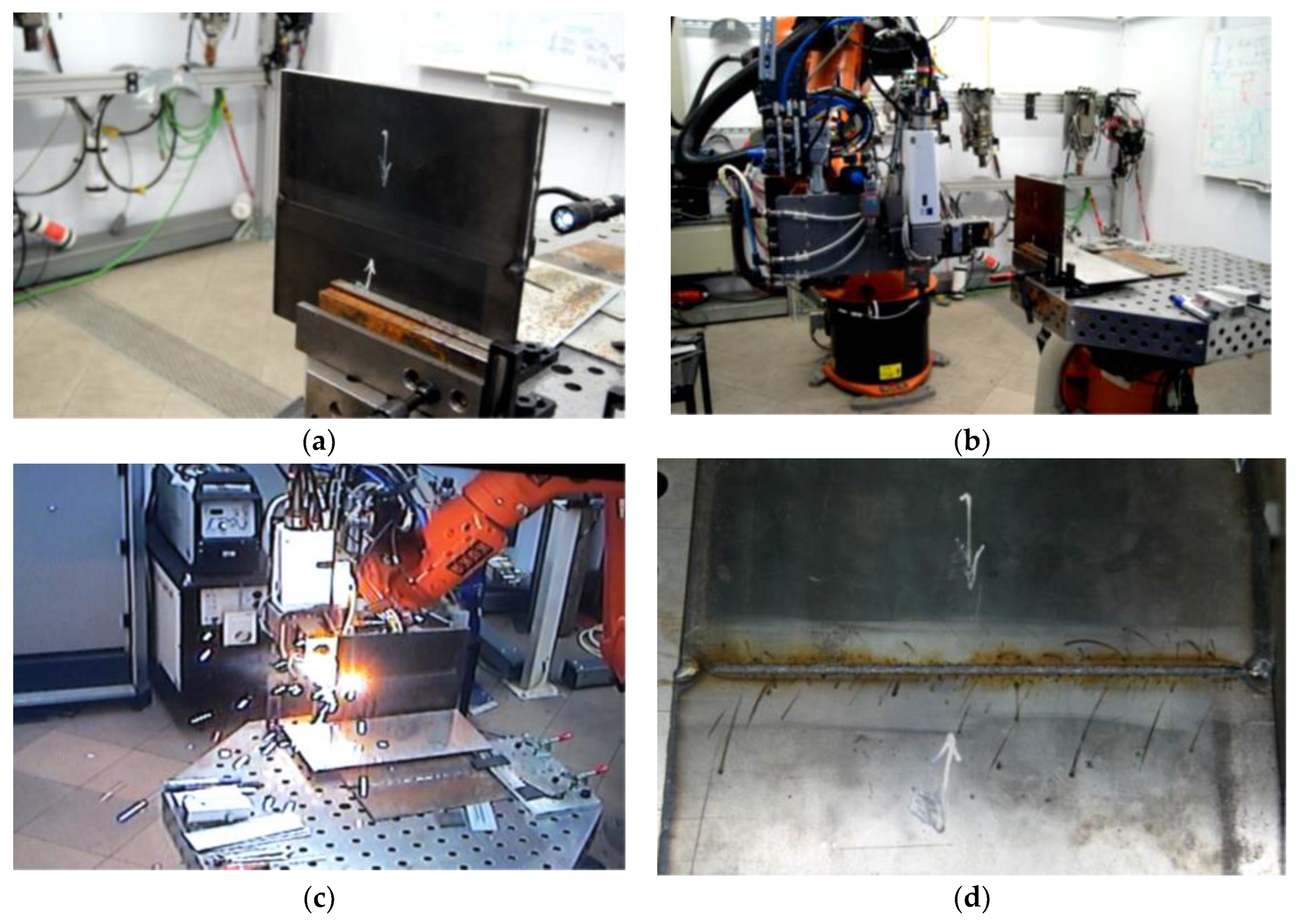

2.1. Welding Process

2.2. The Study of Welded Joints

- ⮚

- visual tests,

- ⮚

- magnetic-particle tests,

- ⮚

- radiographic tests.

- ⮚

- static tensile strength test,

- ⮚

- technological face bend test,

- ⮚

- impact tests (tests were carried out at a temperature of −30 °C),

- ⮚

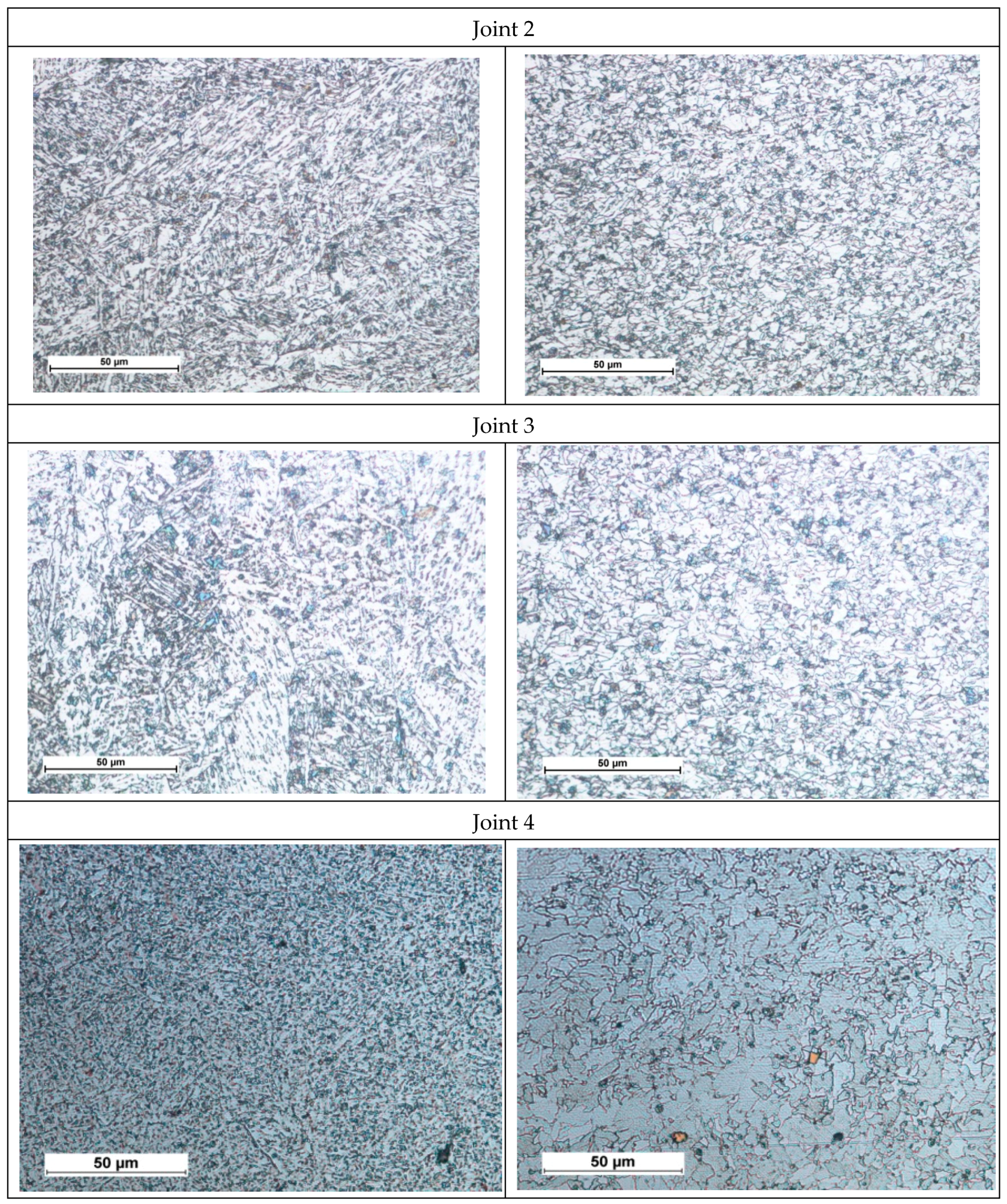

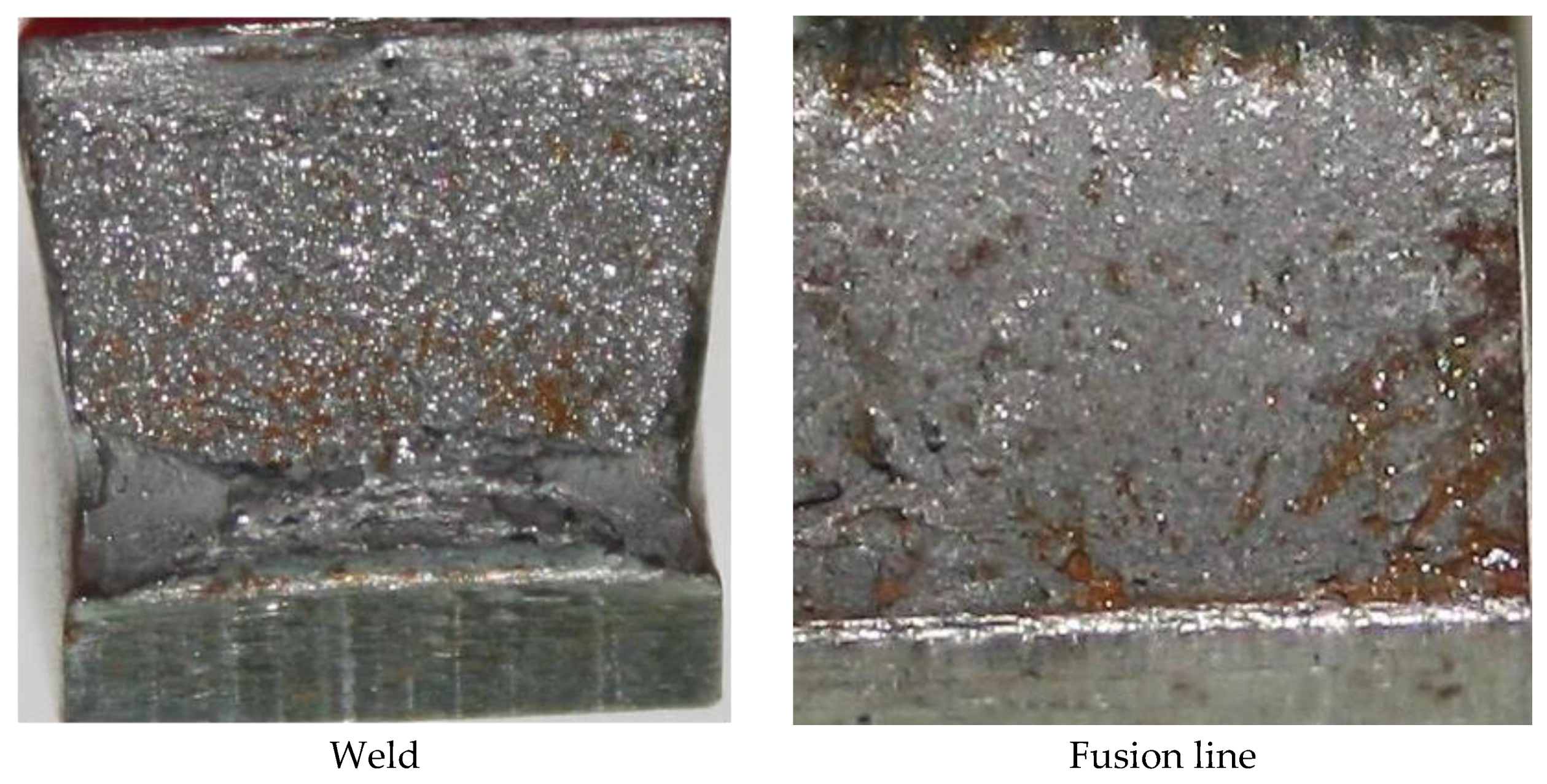

- macro and microscopic metallographic tests, ent,

- ⮚

- Vickers hardness tests,

- ⮚

- analysis of the chemical composition using a Magellan Q8 Bruker (Bruker Austria GmbH, Vienna, Austria) and optical emission spectroscopy,

- ⮚

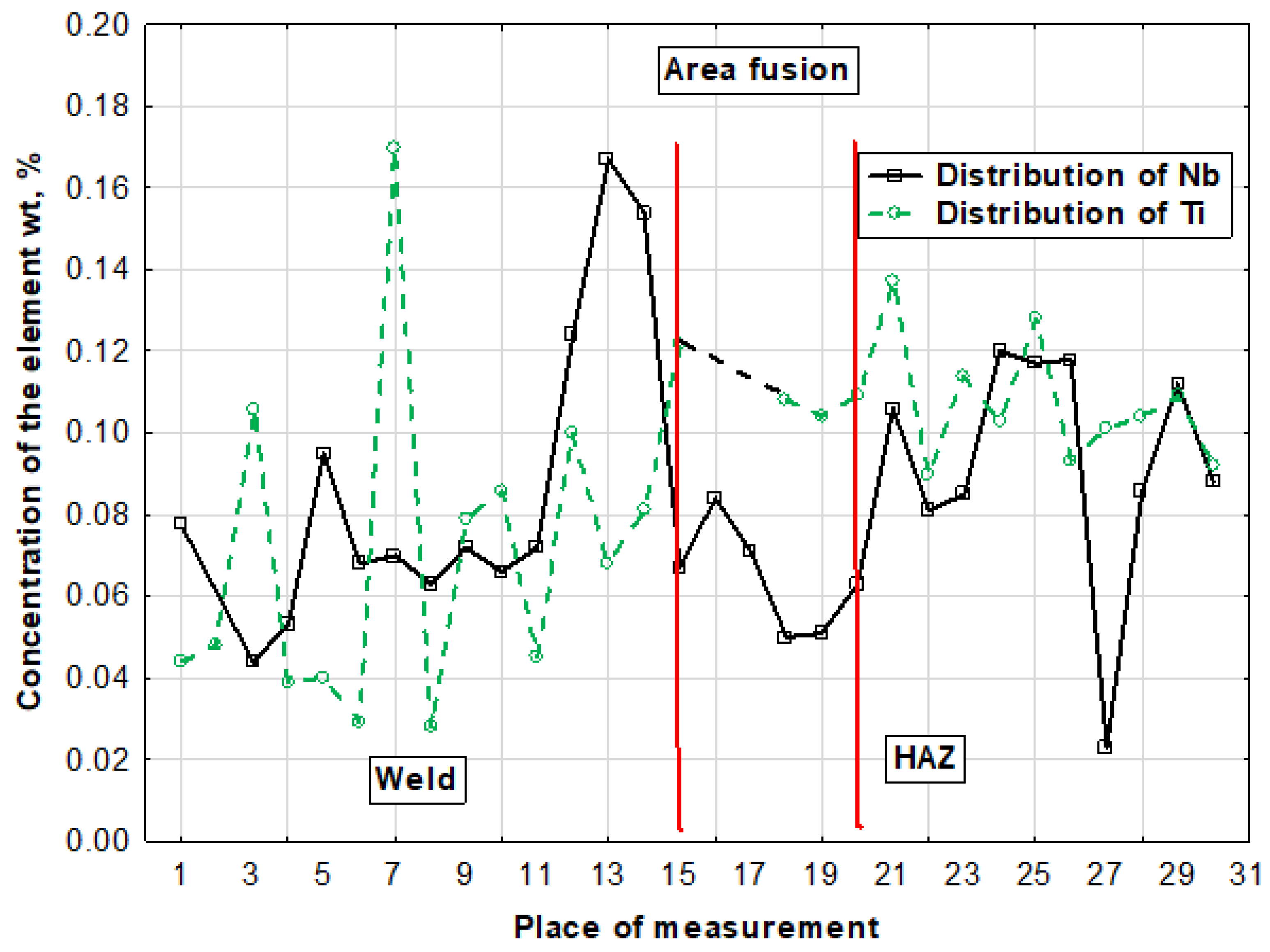

- microanalysis of the chemical composition, performed using a JOEL JSM-5800LV EDX Penta FETx3 scanning microscope (JEOL Ltd., Akishima, Japan) and an accelerating voltage of 13 kV and 20 kV,

- ⮚

- tests of the chemical composition in the micro-areas of the welded joints performed using a SUPRA 35 scanning electron microscope (Zeiss, Jena, Germany) equipped with an EDS attachment (EDAX) and the back-scattered electron observation technique (BSE),

- ⮚

- quantitative composition measured using a JXA-8230 electron probe microanalyser (JEOL Ltd., Akishima, Japan) and wavelength dispersion spectroscopy. In relation to the above-named method, the limit of detectability of heavy elements amounts to approximately 100 ppm. Images of the tested areas (with marked areas subjected to analysis) were made in light of back-scattered electrons (composition-contrast depending on the average atomic number),

- ⮚

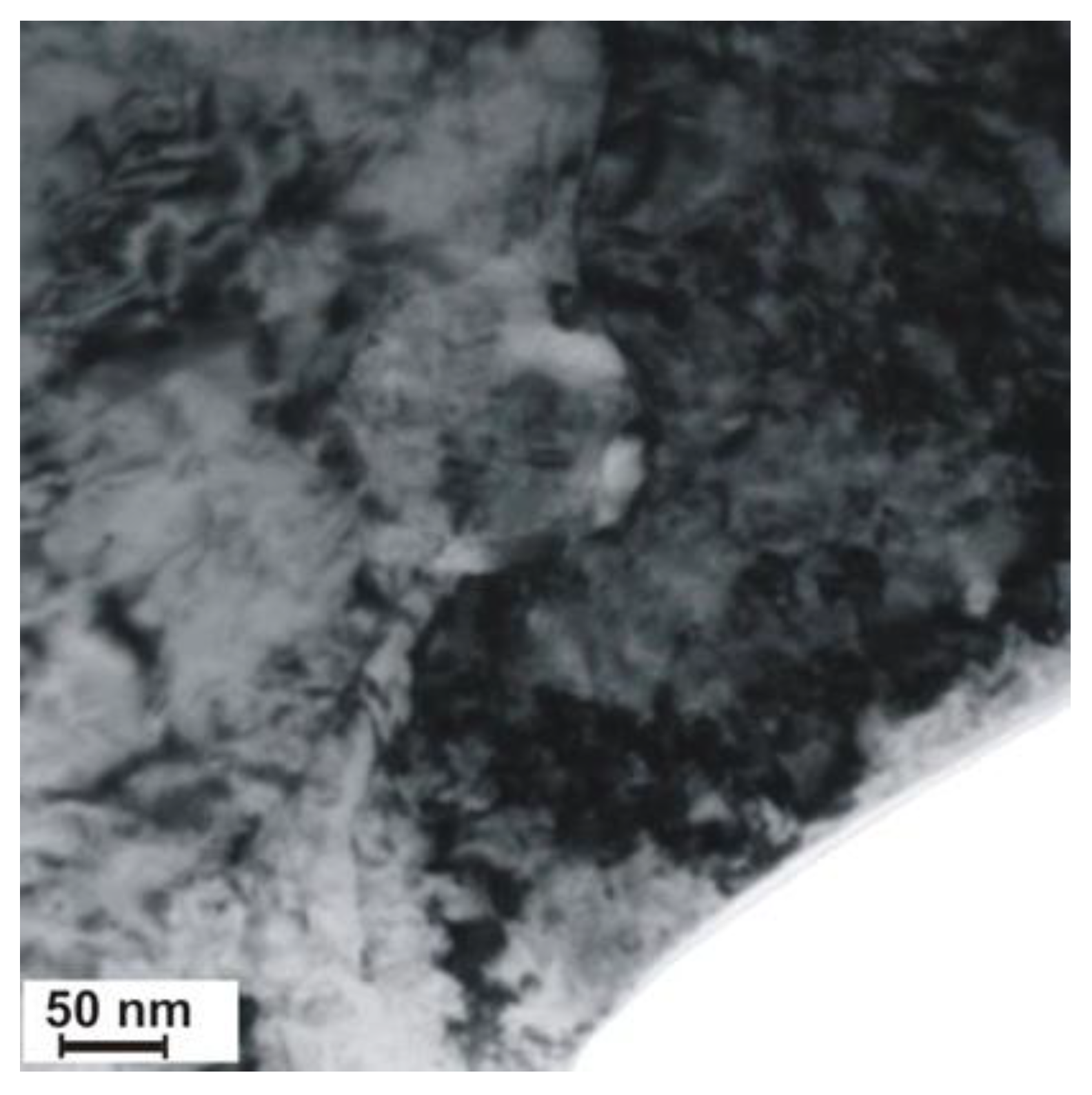

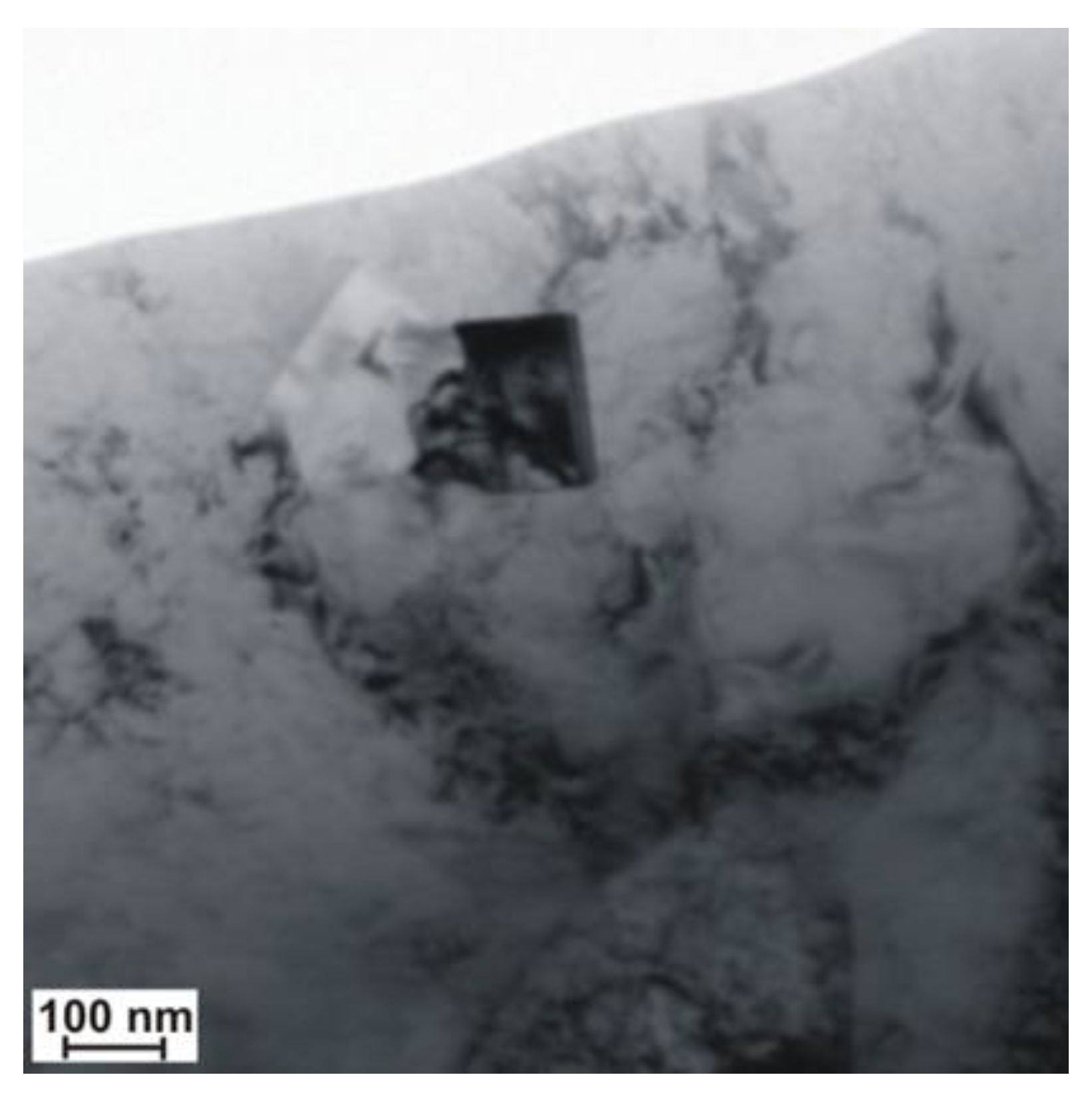

- tests of thin films performed using a Titan 80–300 kV high-resolution scanning transmission electron microscope (HR S/TEM, Thermo Fisher Scientific, Waltham, MA, USA), the diffraction solution was based on the publication [39],

- ⮚

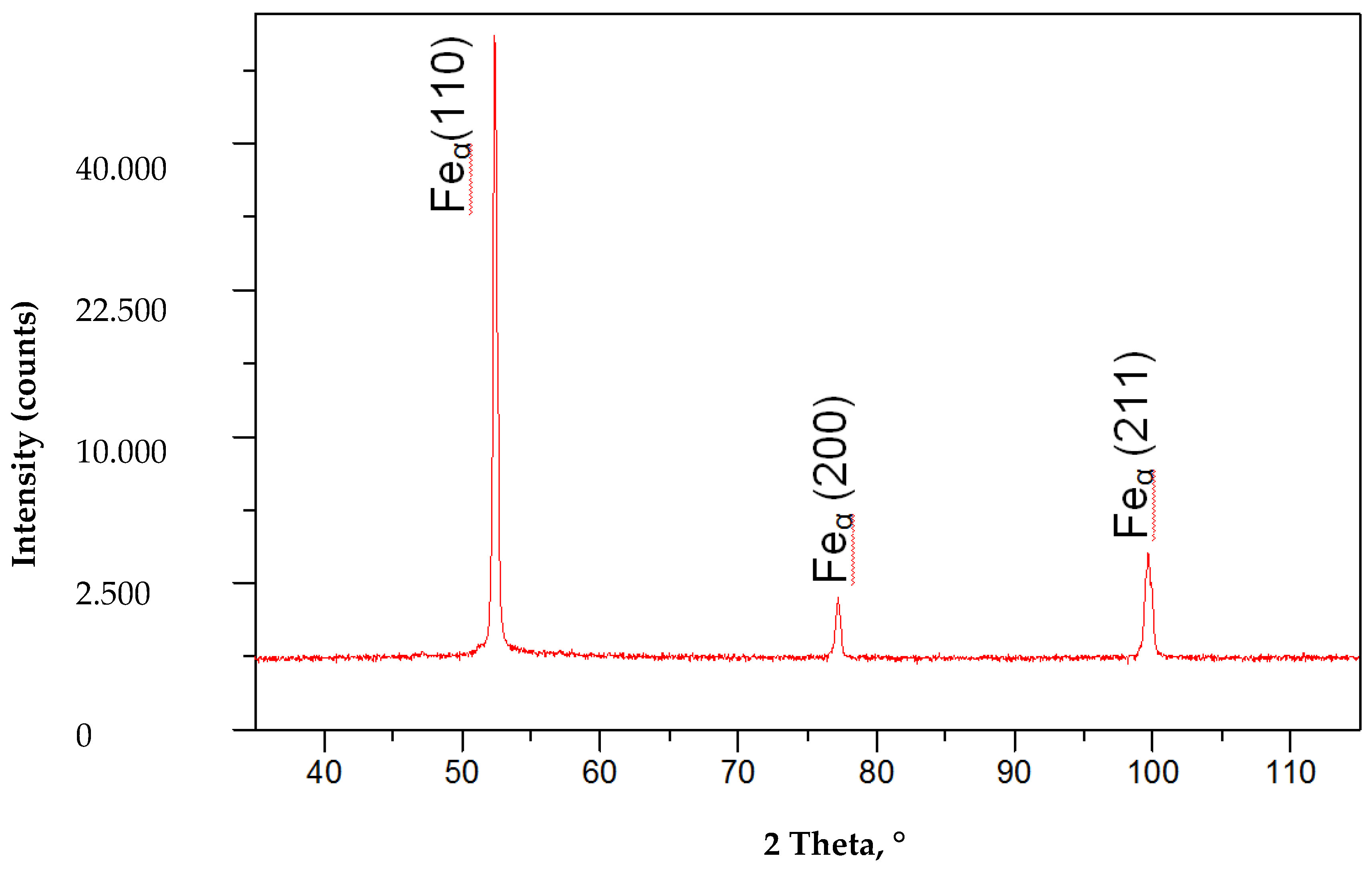

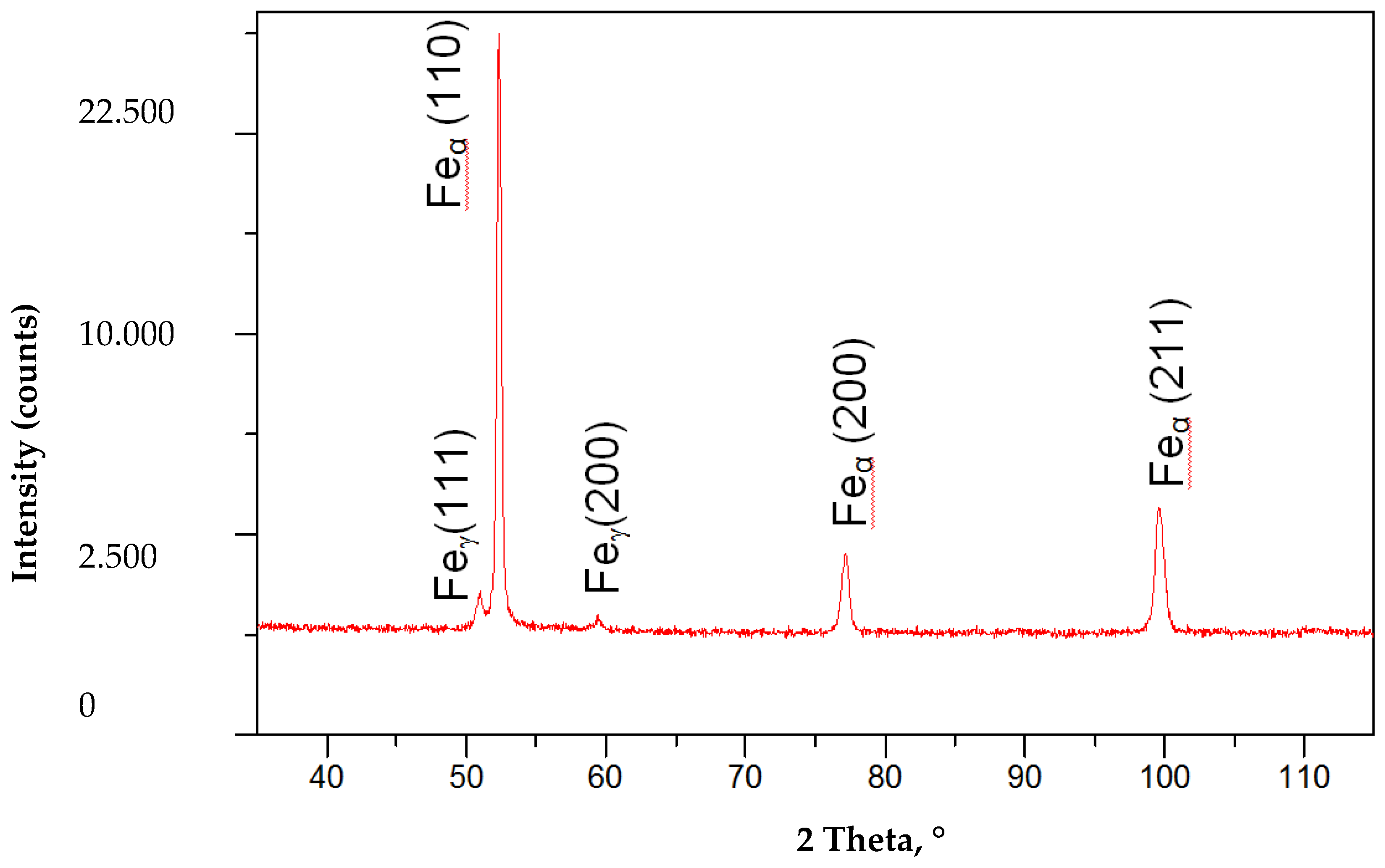

- X-ray phase analysis performed using an X’Pert PRO diffractometer (PANalytical, Almelo, The Netherlands) an X’Celerator strip detector (PANalytical, Almelo, The Netherlands), and a lamp equipped with a cobalt anode.

3. Results and Discussion

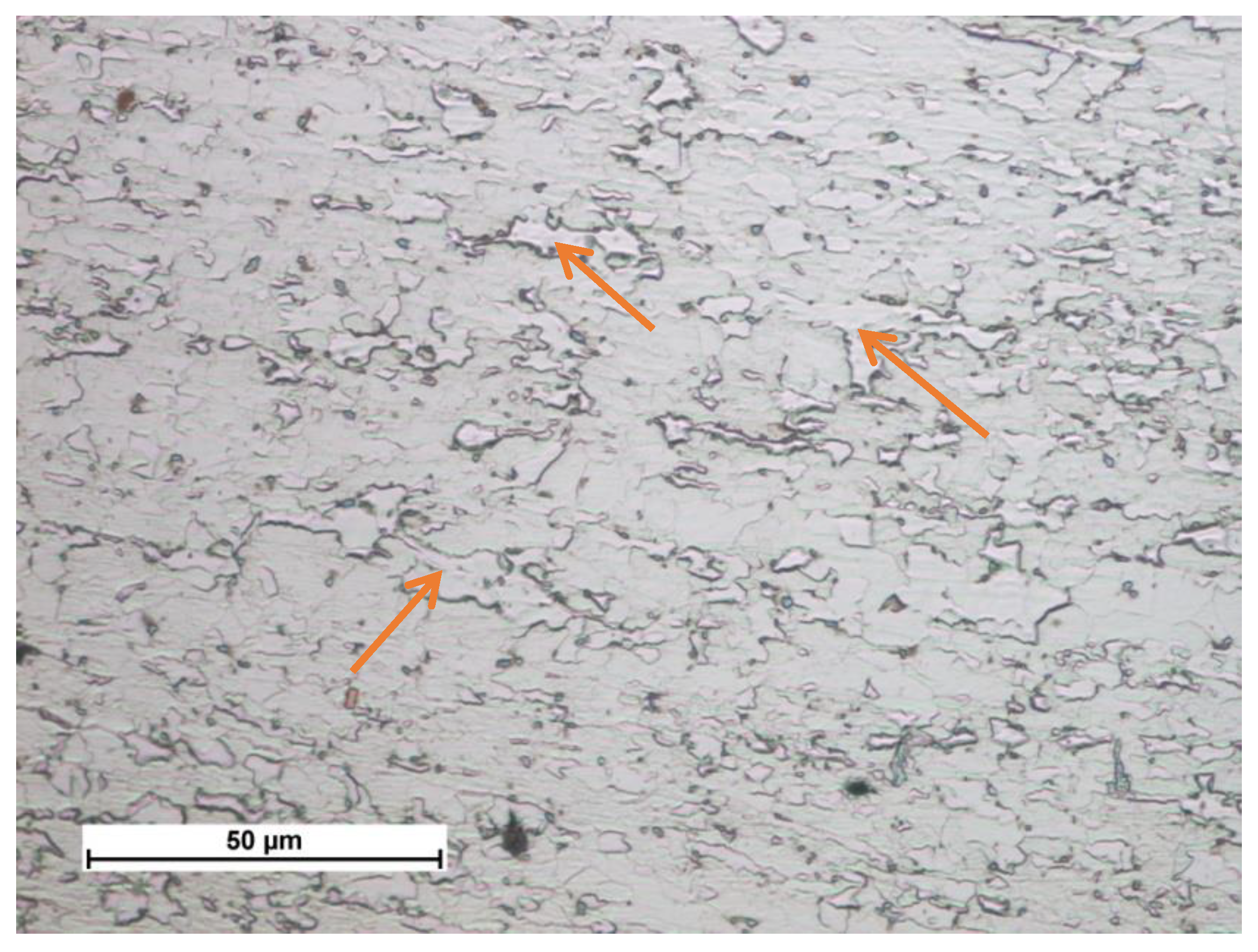

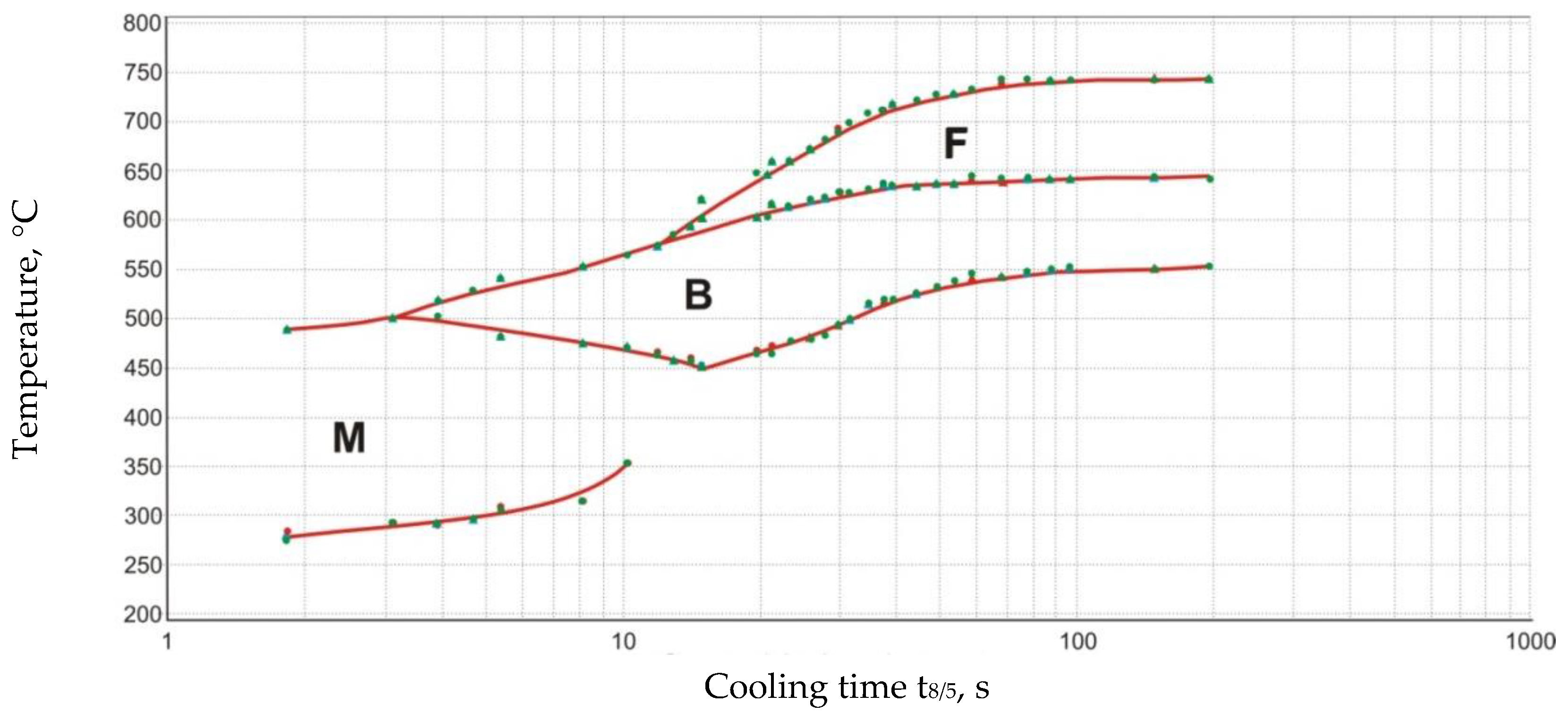

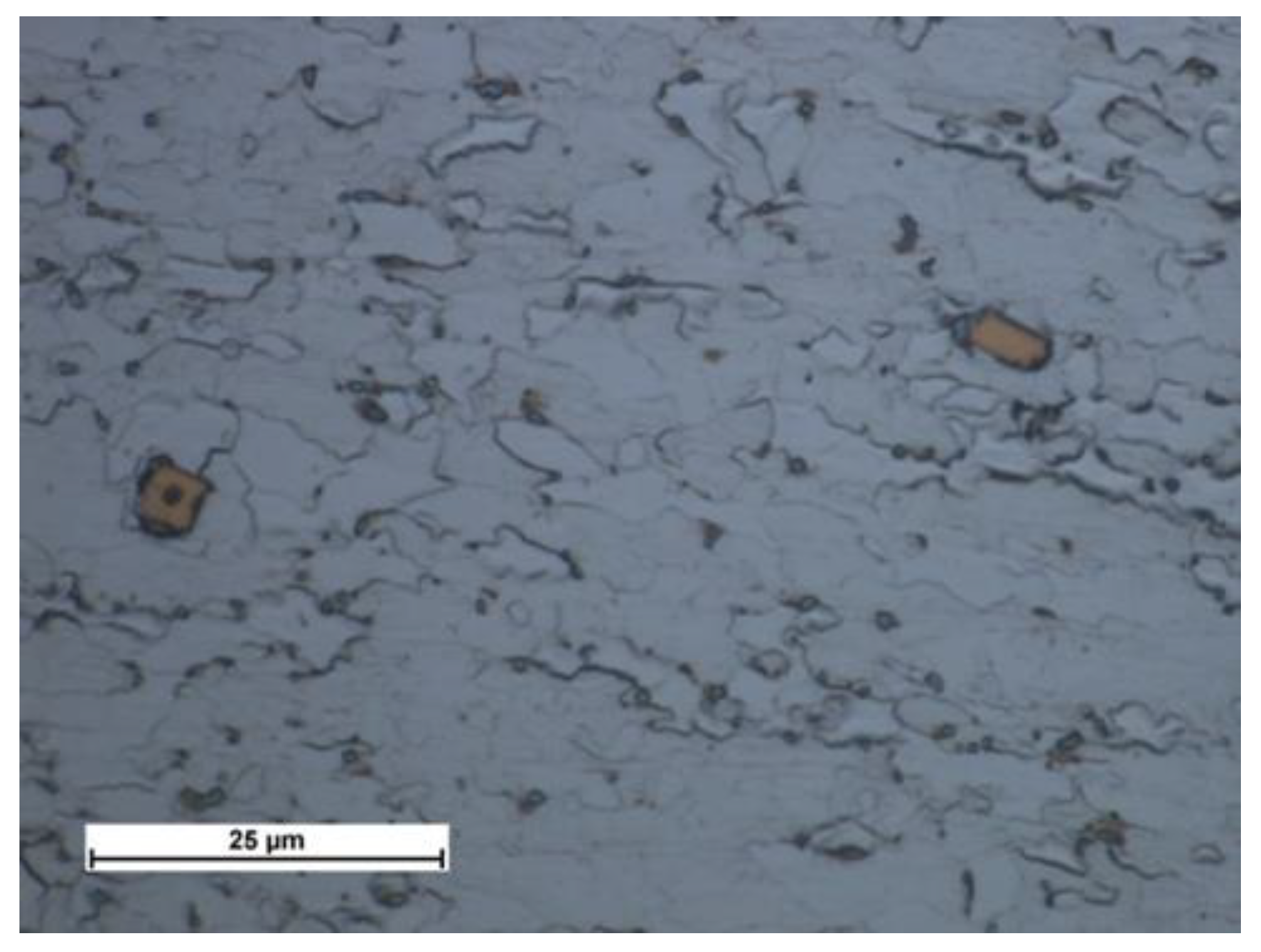

3.1. Analysis of the Base Material

3.2. Analysis of the Welded Joints

4. Conclusions

Funding

Conflicts of Interest

References

- Rajashekhar, S.; Pal, M. Weldability of advanced high strength steels using an Yb:YAG disk laser. J. Mater. Process. Technol. 2011, 211, 1888–1897. [Google Scholar]

- Gao, M.; Zeng, X.; Hu, Q.; Yan, J. Laser-TIG hybrid welding of ultra-fine grained steel. J. Mater. Process. Technol. 2009, 209, 785–791. [Google Scholar] [CrossRef]

- Grajcar, A.; Różański, M.; Stano, S.; Kowalski, A.; Grzegorczyk, B. Effect of heat input on microstructure and hardness distribution of laser welded Si-Al TRIP-Type steel. Adv. Mater. Sci. Eng. 2014, 2014, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Górka, J. Microstructure and properties of the high-temperature (HAZ) of thermo-mechanically treated S700MC high-yield-strength steel. Mater. technol. 2016, 50, 616–621. [Google Scholar] [CrossRef]

- Bang, K.S.; Kim, W.Y. Estimation and prediction of HAZ softening in thermomechanically controlled–rolled and accelerated–cooled steel. Weld. J. N. Y. 2002, 81, 174-S. [Google Scholar]

- Żuk, M.; Górka, J.; Czupryński, A.; Adamiak, M. Properties and structure of the weld joints of quench and tempered 4330V steel. Metalurgija 2016, 55, 613–616. [Google Scholar]

- Hildebrand, J.; Werner, F. Change of structural condition of welded joints between high-strength fine-grained and structural steels. J. Civ. Eng. Manag. 2004, 10, 87–95. [Google Scholar] [CrossRef]

- Porter, D.; Laukkanen, A.; Nevasmaa, P.; Rahka, K.; Wallin, K. Performance of TMCP steel with respect to mechanical properties after cold forming and post-forming heat treatment. Int. J. Press. Vessels Pip. 2004, 81, 867–877. [Google Scholar] [CrossRef]

- Górka, J.; Janicki, D.; Fidali, M.; Jamrozik, W. Thermographic Assessment of the HAZ Properties and Structure of Thermomechanically Treated Steel. Int. J. Thermophys. 2017, 38, 183. [Google Scholar] [CrossRef] [Green Version]

- Fydrych, D.; Labanowski, J.; Rogalski, G. Weldability of high strength steels in wet welding conditions. Pol. Marit. Res. 2013, 20, 67–73. [Google Scholar] [CrossRef] [Green Version]

- Kurc-Lisiecka, A.; Lisiecki, A. Laser welding of the new grade of advanced high-strength steel Domex 960. Mater. Technol. 2017, 51, 199–204. [Google Scholar] [CrossRef]

- Janicki, D. “Disk laser welding of armor steel”. Arch. Metall. Mater. 2014, 59, 1641–1646. [Google Scholar] [CrossRef] [Green Version]

- Grajcar, A.; Różański, M.; Kamińska, M.; Grzegorczyk, B. Effect of gas atmosphere on the non-metallic inclusions in laser-welded TRIP steel with Al and Si additions. Mater. Tehnol. 2016, 50, 945–950. [Google Scholar] [CrossRef]

- Suder, W.; Ganguly, S.; Williams, S.; Yudodibroto, B. Root stability in hybrid laser welding. J. Laser Appl. 2017, 29, 022410. [Google Scholar] [CrossRef] [Green Version]

- Janicki, D. Fiber laser welding of nickel based superalloy Rene 77. In Proceedings of the Laser Technology 2012: Applications of Lasers, Szczecin, Poland, 22 January 2013; Volume 8703, p. 87030Q. [Google Scholar]

- Węgrzyn, T.; Piwnik, J.; Hadryś, D.; Wszołek, Ł. Low alloy steel structures after welding with micro-jet cooling. Arch. Metall. Mater. 2017, 62, 115–118. [Google Scholar] [CrossRef]

- Górka, J. Welding Thermal Cycle-Triggered Precipitation Processes in Steel S700MC Subjected to the Thermo-Mechanical Control Processing. Arch. Metall. Mater. 2017, 62, 331–336. [Google Scholar] [CrossRef] [Green Version]

- Yurioka, M. TMCP steel and their welding. Weld. World 1995, 35, 375–390. [Google Scholar]

- Bajić, N.; Šijački-Žeravčić, V.; Rakin, M.; Kovačević, K. Effect of the welding mode and filler content on the structure of microalloyed Nb/Ti steel weldments. Mater. Sci. 2010, 46, 124–133. [Google Scholar] [CrossRef]

- Winczek, J.; Modrzycka, A.; Gawrońska, E. Analytical description of the temperature field induced by laser heat source with any trajectory. Procedia Eng. 2016, 149, 553–558. [Google Scholar] [CrossRef] [Green Version]

- Kik, T.; Górka, J. Numerical Simulations of Laser and Hybrid S700MC T-Joint Welding. Materials 2019, 12, 516. [Google Scholar] [CrossRef] [Green Version]

- Skowrońska, B.; Szulc, J.; Chmielewski, T.; Sałaciński, T.; Swiercz, R. Properties and microstructure of hybride Plasma + MAG welded joints of thermomechanically treated S700MC steel. In Proceedings of the 27th Anniversary International Conference on Metallurgy and Materials (METAL), Brno, Czech Republik, 23–25 May 2018. [Google Scholar]

- Shin, Y.T.; Kang, S.W.; Lee, H.W. Fracture characteristics of TMCP and QT steel weldments with respect to crack length. Mater. Sci. Eng. A 2006, 434, 365–371. [Google Scholar] [CrossRef]

- Kim, Y.; Kwon, J.; Lee, H.; Jang, W. Effect of microstructure on fatigue crack propagation and S–N fatigue behaviours of TMCP steels with yield strengths of approximately 450 MPa. Metall. Mater. Trans. 2011, 42, 986–999. [Google Scholar] [CrossRef]

- Altuna, M.A.; Iza-Mendia, A.; Guitierrez, I. Precipitation strengthening by formationin ferrite of Nb carbides. In Proceedings of the 3rd International Conference on Thermomechanical Processing of Steels, Padua, Italy, 10–12 September 2008; pp. 1–12. [Google Scholar]

- Kik, T.; Moravec, J.; Novakova, I. New method of processing heat treatment experiments with numerical simulation support. In IOP Conference Series-Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 227. [Google Scholar]

- Hashimoto, S.; Ikeda, S.; Sugimoto, K.; Miyake, S. Effects of Nb and Mo addition to 0.2%C–1.5%Mn steel on mechanical properties of hot rolled TRIP-aided steel sheets. ISIJ Int. 2004, 44, 1590–1598. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.D.; Huang, B.X.; Wang, L.; Rong, Y.H. Microstructure and mechanical properties of microalloyed high-strength transformation-induced plasticity steels. Metall. Mater. Trans. A 2008, 39, 1–7. [Google Scholar] [CrossRef]

- Yasuharu, S.; Osamu, M.; Hiroshi, T. Mechanical properties and retained austenite in intercritically heat-treated bainite-transformed steel and their variation with Si and Mn additions. Metall. Trans. A 1991, 22, 489–498. [Google Scholar]

- Wang, S.H.; Chiang, C.C.; Chan, L.I. Effect of initial microstructure on the creep behaviour of TMCP EH36 and S490MC steels. Mater. Sci. Eng. A 2003, 344, 288–295. [Google Scholar] [CrossRef]

- Timokhaina, I.B.; Hodgson, P.D.; Pereloma, E.V. Effect of microstructure on the stability of retained austenite in transformation-induced-plasticity steels. Metall. Mater. Trans. A 2004, 35, 2331–2341. [Google Scholar] [CrossRef] [Green Version]

- Barin, I. Thermochemical Data of Pure Substances; VCH: Weinheim, Germany, 1995. [Google Scholar]

- Bhadeshia, H.K. Bainite in Steels, 2nd ed.; Institute of Materials, Minerals and Mining: London, UK, 2001; pp. 265–268. [Google Scholar]

- Opiela, M. Thermodynamic analysis of the precipitation of carbonitrides in microalloyed steels. Mater. Technol. 2015, 49, 395–401. [Google Scholar] [CrossRef]

- Xue, E.; Shan, Y.; Zheng, S.; Lou, S. Microstructural characteristic of low carbon microalloyed steels produced by termomechanical controlled process. Mater. Sci. Eng. 2006, 438, 285–287. [Google Scholar] [CrossRef]

- Medina, S.F.; Gomez, M.; Gomez, P. Effects of V and Nb on static recrystallization of austenite and precipitate size in microalloyed steels. J. Mater. Sci. 2010, 45, 5553–5557. [Google Scholar] [CrossRef]

- Nishioka, K.; Ichikawa, K. Progress in termomechanical control of steel plates and their commercialization. Sci. Technol. Adv. Mater. 2012, 13, 023001. [Google Scholar] [CrossRef] [PubMed]

- Górka, J. Assessment of Steel Subjected to the Thermomechanical Control Process with Respect to Weldability. Metals 2018, 8, 169. [Google Scholar] [CrossRef] [Green Version]

- Hirsch, P.B.; Howie, B.; Nicholson, A.M.; Pasheley, D.W.; Whelan, M.J. Electron Microscopy of Thin Crystals; Butterworths: London, UK, 1965. [Google Scholar]

- ISO 13919-1:2002 Welding-Electrons and Laser Beam Welded Joints-Guidance on Quality Levels for Imperfections-Part 1: Steel; ISO: Geneva, Switzerland, 2002.

| Chemical Composition, % by Weight | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | S | P | Al | Nb | Ti | V | N | Ce | |||

| 0.056 | 1.68 | 0.16 | 0.005 | 0.01 | 0.027 | 0.044 | 0.12 | 0.006 | 72 | 0.33 | |||

| Mechanical properties | |||||||||||||

| Tensile strength Rm, MPa | Yield point Re, MPa | Elongation A5, % | Toughness, J/cm2 (−30 °C) | ||||||||||

| 820 | 700 | 17 | 50 | ||||||||||

| Specimen Test No. | Beam Power, W | Melting Rate, mm/min | Linear Energy, J/mm | Position of Focus in Relation to the Plate Surface, mm |

|---|---|---|---|---|

| 1 | 4000 | 2000 | 120 | 0 |

| 2 | 4000 | 2000 | 120 | −3 |

| 3 | 4000 | 1000 | 240 | 0 |

| 4 | 4000 | 1000 | 240 | −3 |

| 5 | 6000 | 2000 | 180 | 0 |

| 6 | 6000 | 2000 | 180 | −3 |

| 7 | 6000 | 1000 | 360 | 0 |

| 8 | 6000 | 1000 | 360 | −3 |

| 9 | 8000 | 2000 | 240 | 0 |

| 10 | 8000 | 2000 | 240 | −3 |

| 11 | 8000 | 1000 | 480 | 0 |

| 12 | 8000 | 1000 | 480 | −3 |

| 13 | 10,000 | 2000 | 300 | 0 |

| 14 | 10,000 | 2000 | 300 | −3 |

| 15 | 10,000 | 1000 | 600 | 0 |

| 16 | 10,000 | 1000 | 600 | −3 |

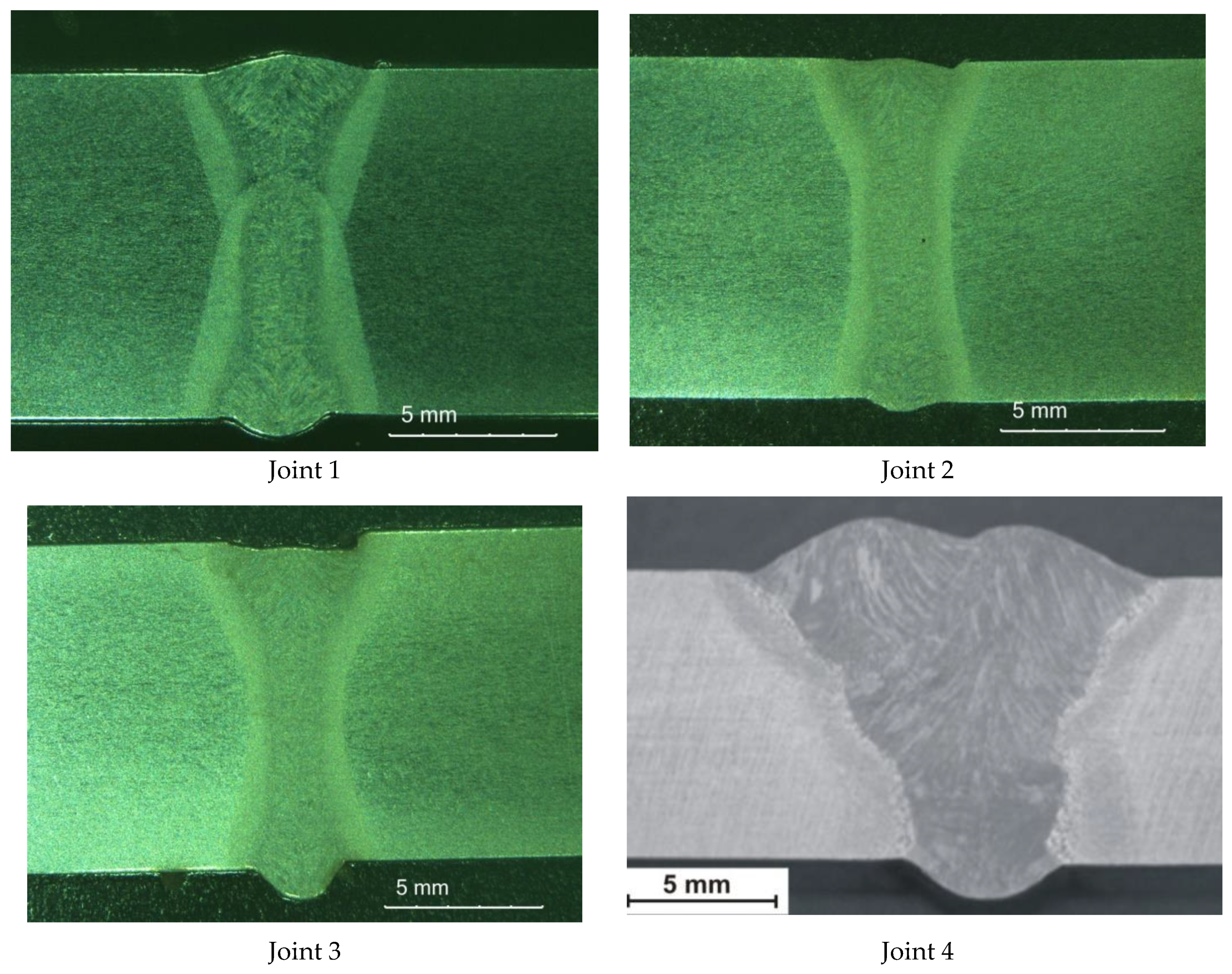

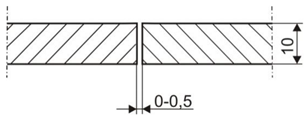

| Preparing Metal Welding | The Stacking Order of the Bead | ||||

|---|---|---|---|---|---|

|  | ||||

| Bead | Beam Power, W | Focus Position Relative to the Surface of the Plate, mm | Welding Position | Welding Speed v, m/min | Energy Linear Welding E, kJ/cm |

| Joint 1 | |||||

| 2 | 3500 | 0 | PC | 1 | 4 |

| Joint 2 | |||||

| 1 | 8400 | 0 | PC | 1 | 5 |

| Joint 3 | |||||

| 1 | 8400 | 0 | PA | 1 | 5 |

| Helium with a flow rate of 20 dm3/min was used as the shielding gas. The joints were heated to a temperature before welding at 65 °C. | |||||

| Designation of the Welded Joint | Tensile Strength | Bending, Bending Angle, ° | Impact Strength KCV, J/cm2 (Test Temperature −30 °C) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Rm, MPa | Place Breaking | Place of Rupture | Face of Weld | Weld | FL | HAZ | ||||

| KCV, J/cm2 | Fracture | KCV, J/cm2 | Fracture | KCV, J/cm2 | Fracture | |||||

| Joint 1 | 785 | FL | 180 | 180 | 20 | fragile | 23 | fragile | 41 | mixed |

| Joint 2 | 790 | Weld | 180 | 180 | 25 | fragile | 22 | fragile | 38 | mixed |

| Joint 3 | 792 | Weld | 180 | 180 | 22 | fragile | 27 | fragile | 39 | mixed |

| Joint 4 * | 810 | BM | 180 | 180 | 94 | mixed | 82 | mixed | 86 | mixed |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Górka, J. Assessment of the Effect of Laser Welding on the Properties and Structure of TMCP Steel Butt Joints. Materials 2020, 13, 1312. https://doi.org/10.3390/ma13061312

Górka J. Assessment of the Effect of Laser Welding on the Properties and Structure of TMCP Steel Butt Joints. Materials. 2020; 13(6):1312. https://doi.org/10.3390/ma13061312

Chicago/Turabian StyleGórka, Jacek. 2020. "Assessment of the Effect of Laser Welding on the Properties and Structure of TMCP Steel Butt Joints" Materials 13, no. 6: 1312. https://doi.org/10.3390/ma13061312