Modifications of the HJC (Holmquist–Johnson–Cook) Model for an Improved Numerical Simulation of Roller Compacted Concrete (RCC) Structures Subjected to Impact Loadings

Abstract

1. Introduction

2. Experimental Observations for RCC Materials

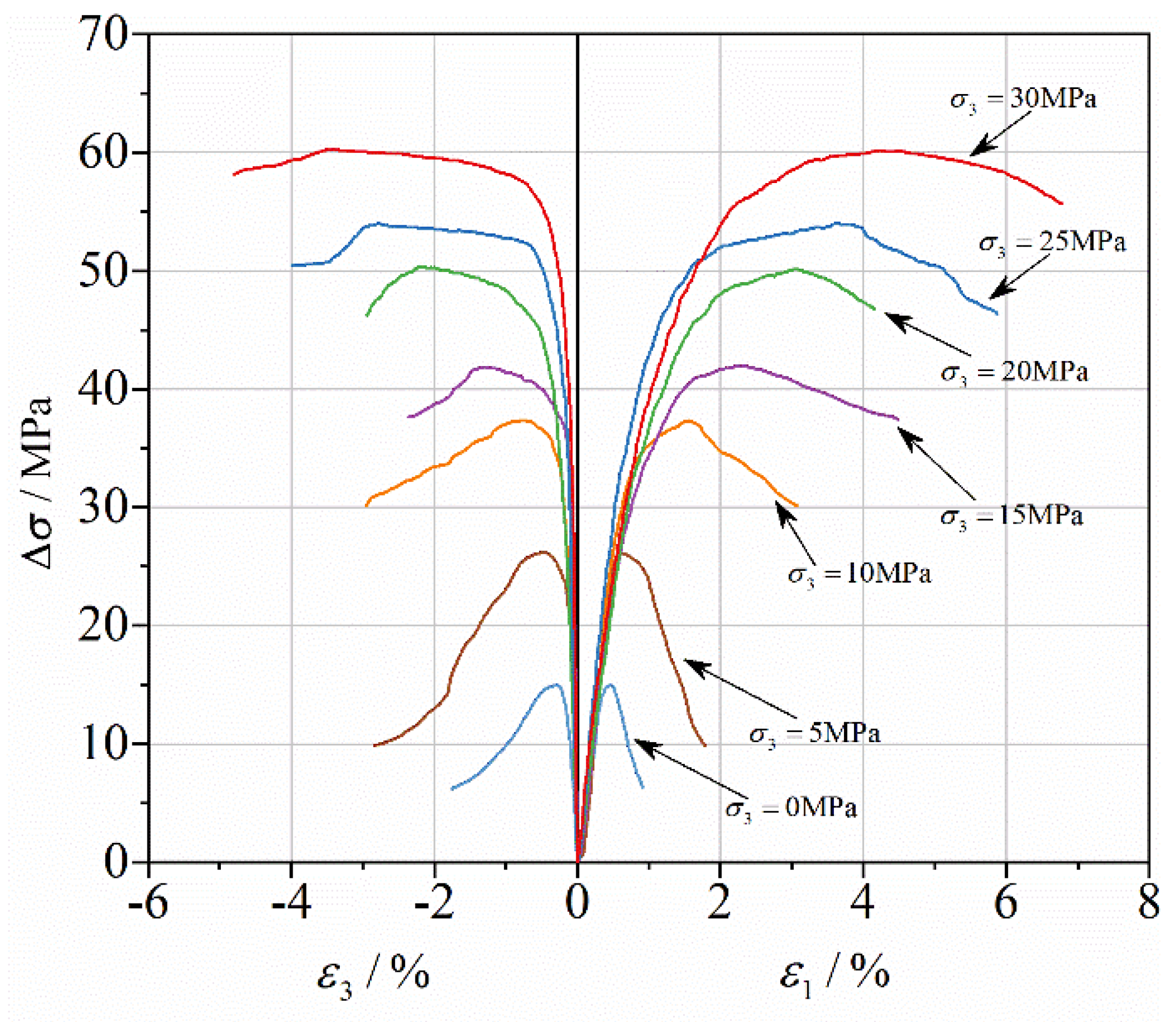

2.1. Uniaxial and Triaxial Compressive Results

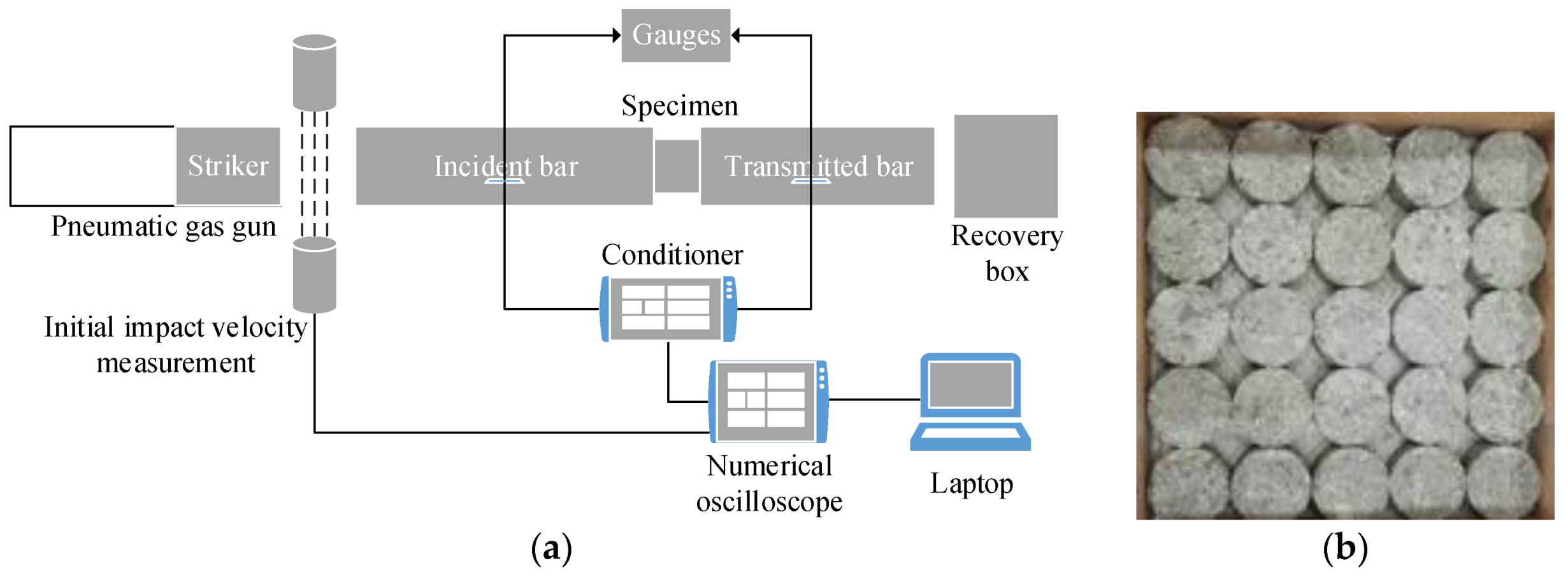

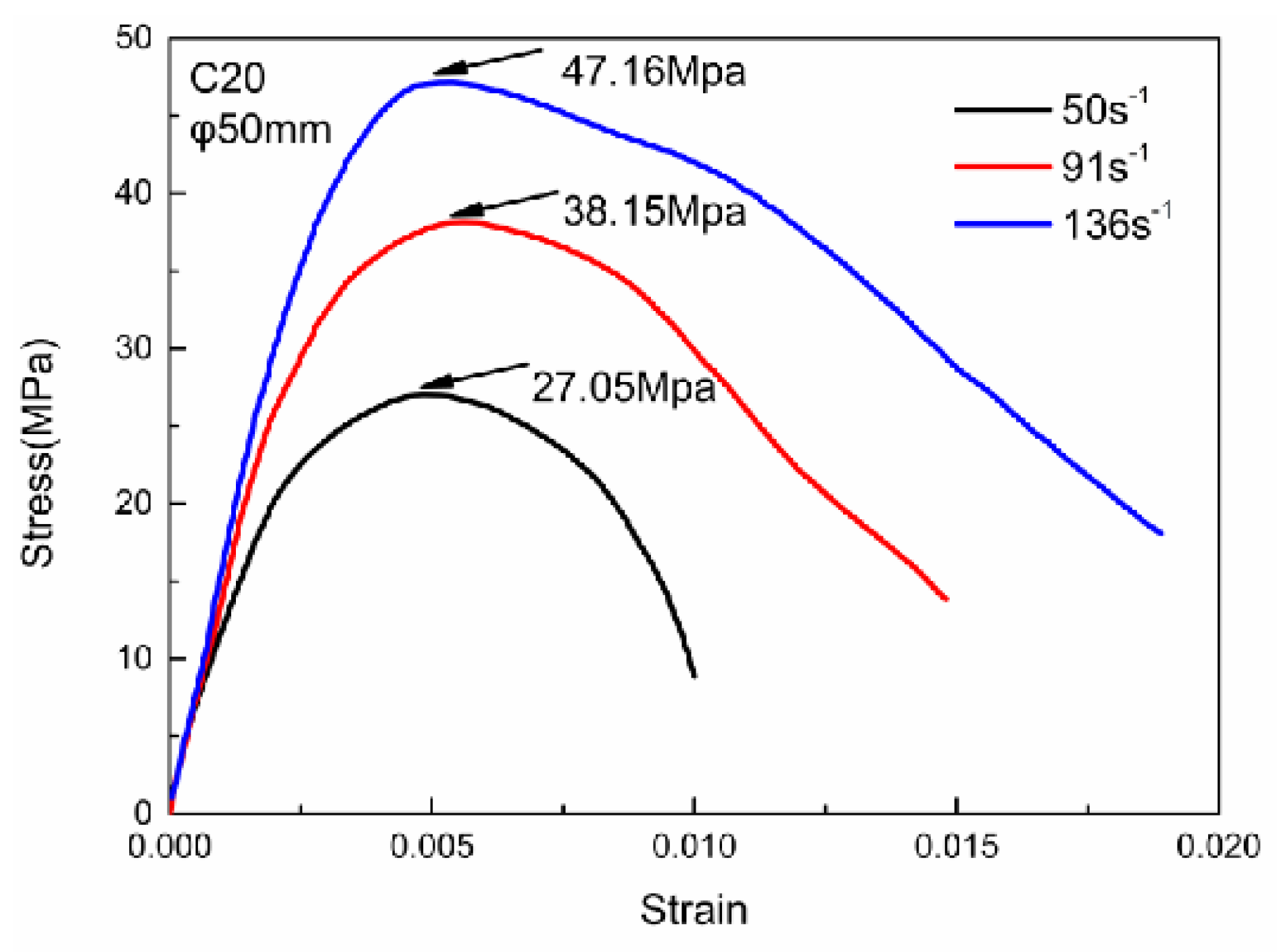

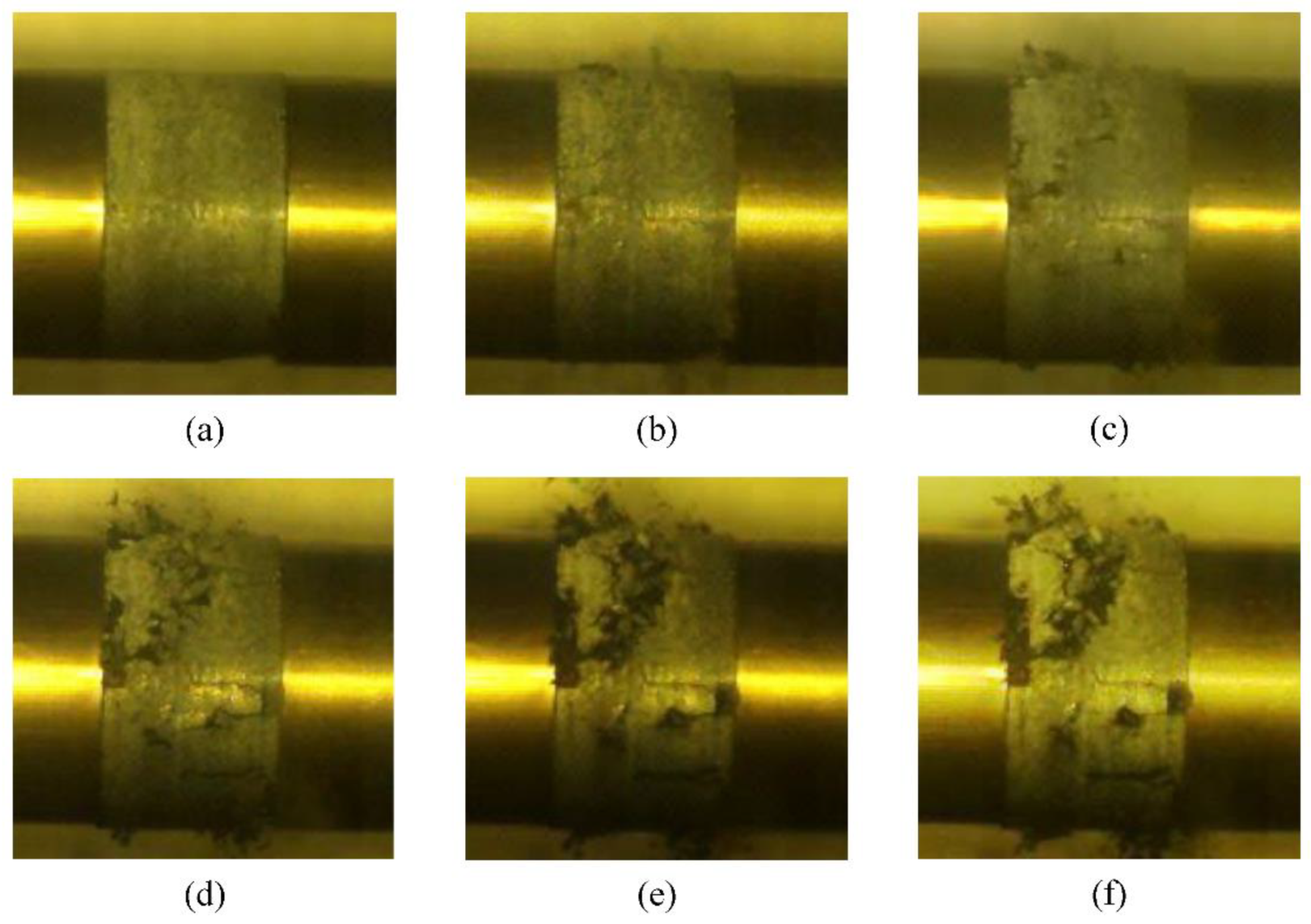

2.2. Split Hopkinson Pressure Bar (SHPB) Experimental Results

3. The Modified HJC Model

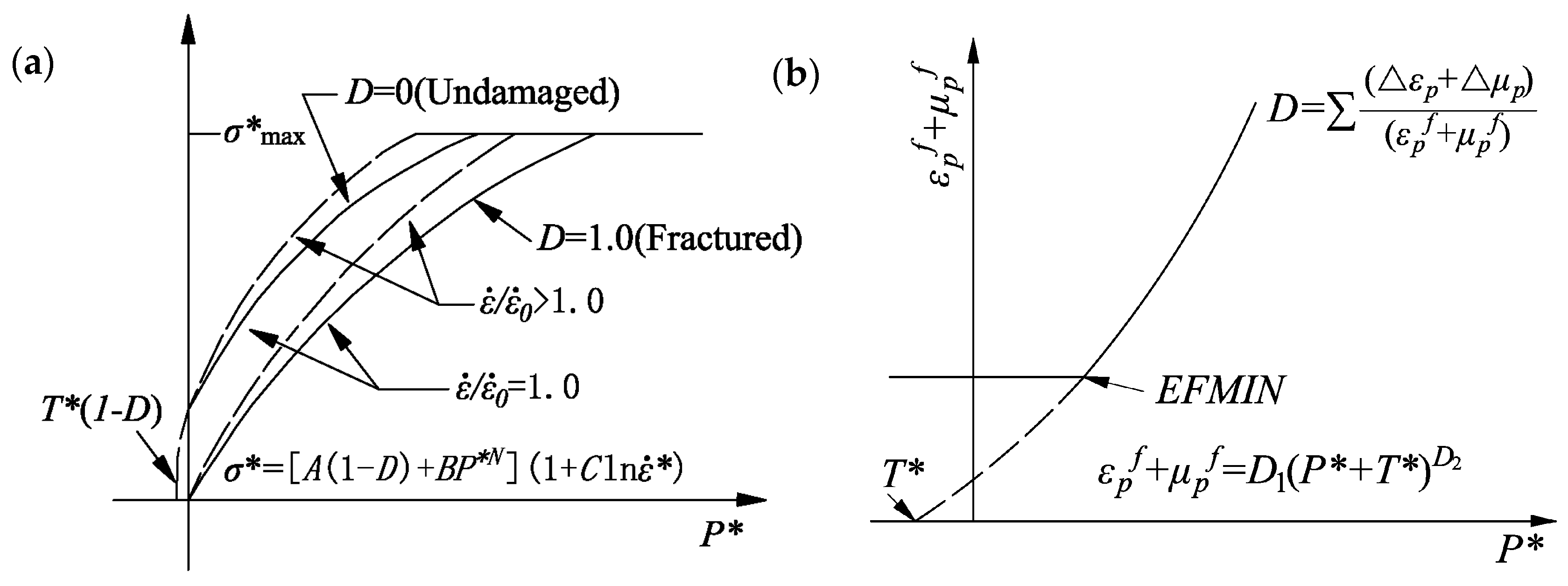

3.1. The Original HJC Model

3.1.1. Yield Function

3.1.2. Damage Evolution

3.1.3. Equation of State

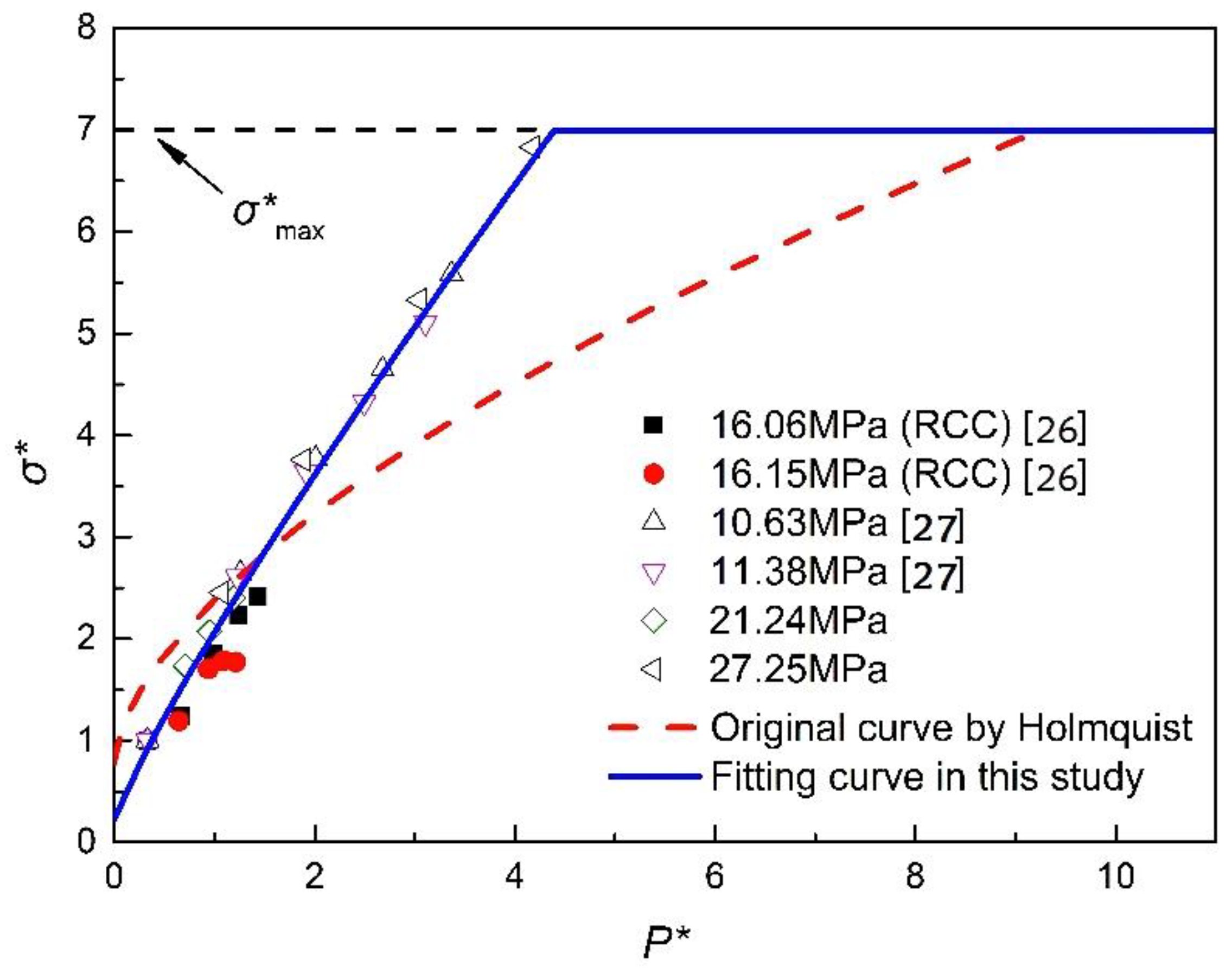

3.2. Modified Strength Yield Surface

3.3. Modified Strain Rate Effect

3.4. Parameter Calibration for the Modified HJC Model

4. Numerical Verification

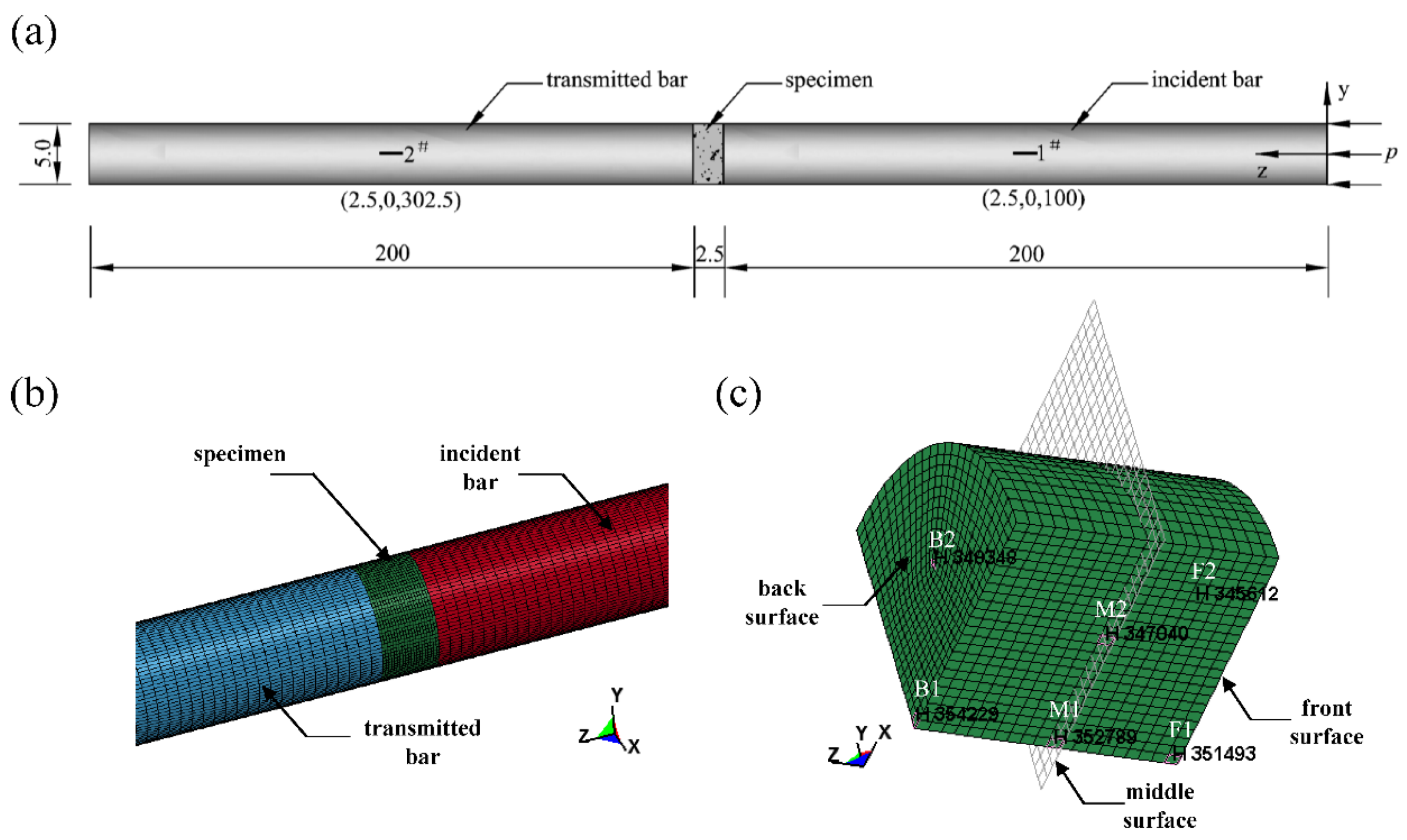

4.1. Numerical Model

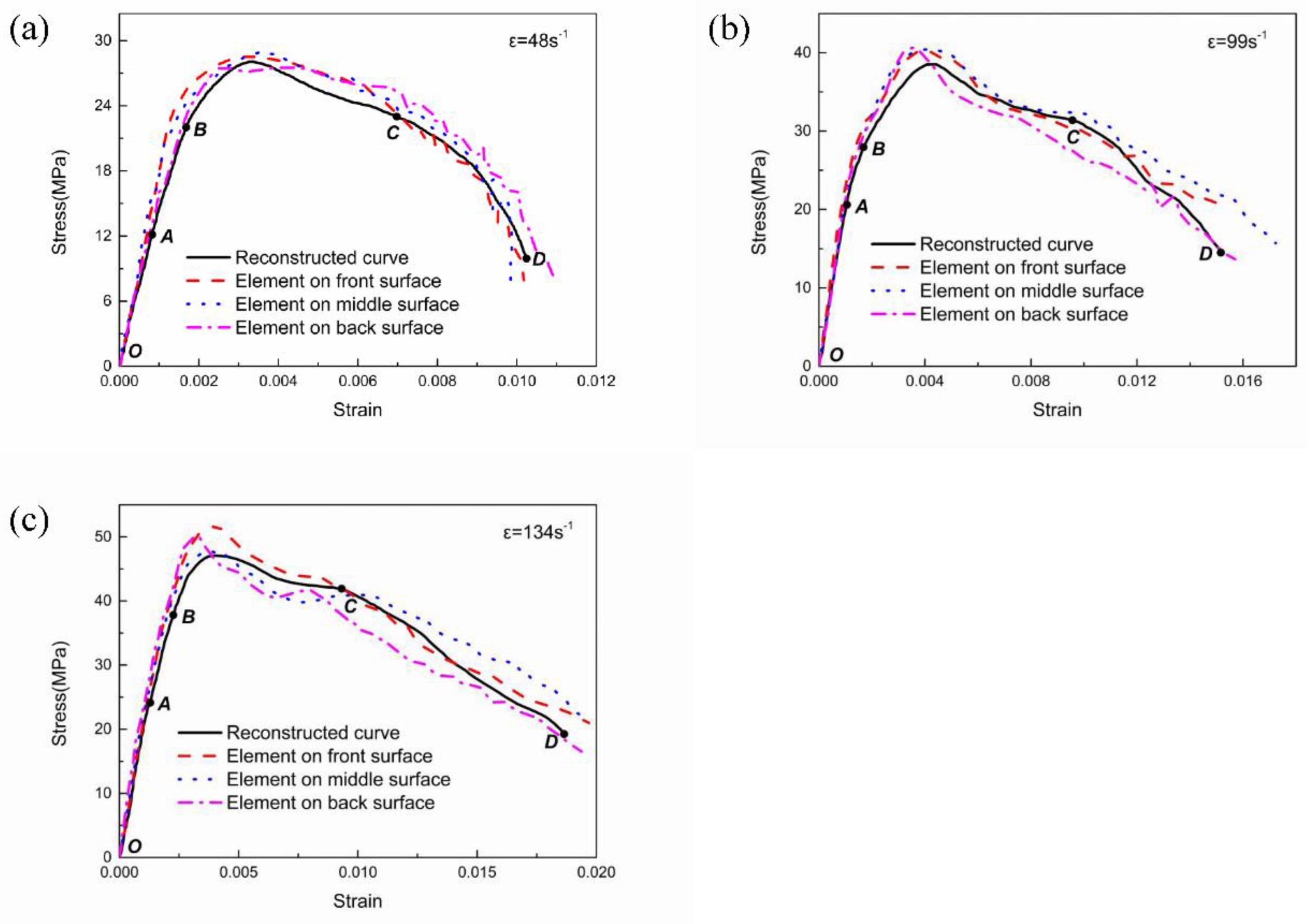

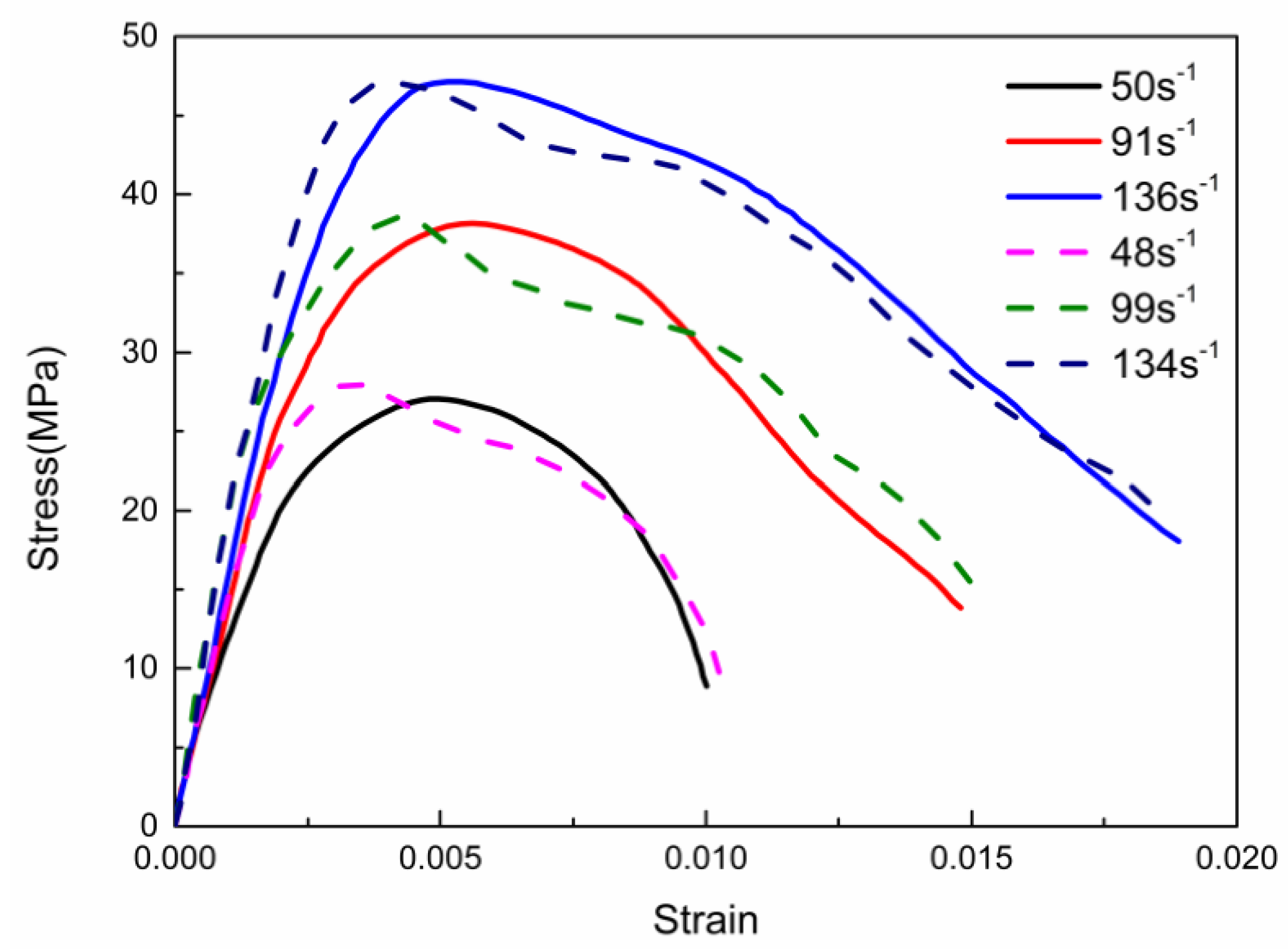

4.2. Stress–Strain Curve

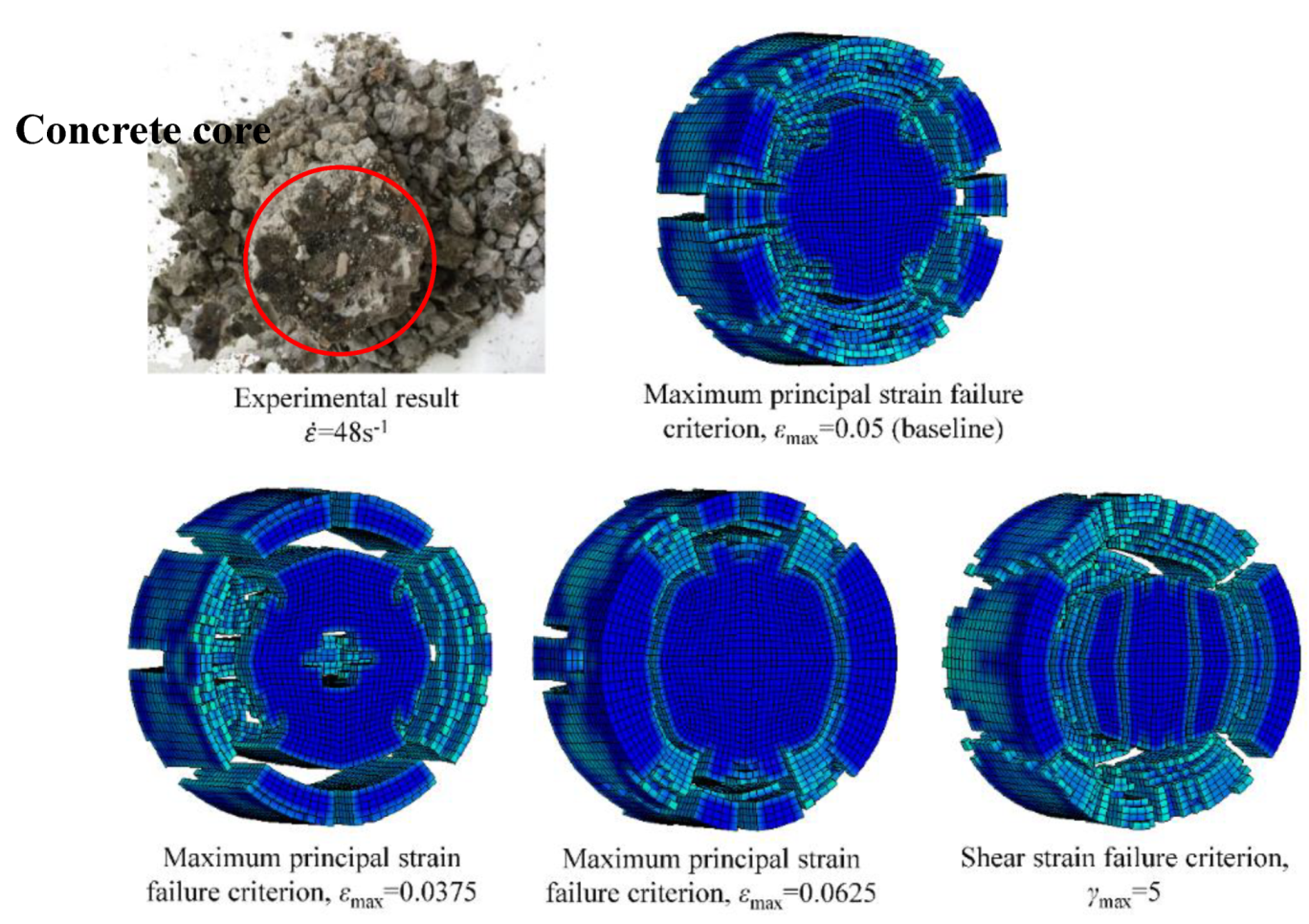

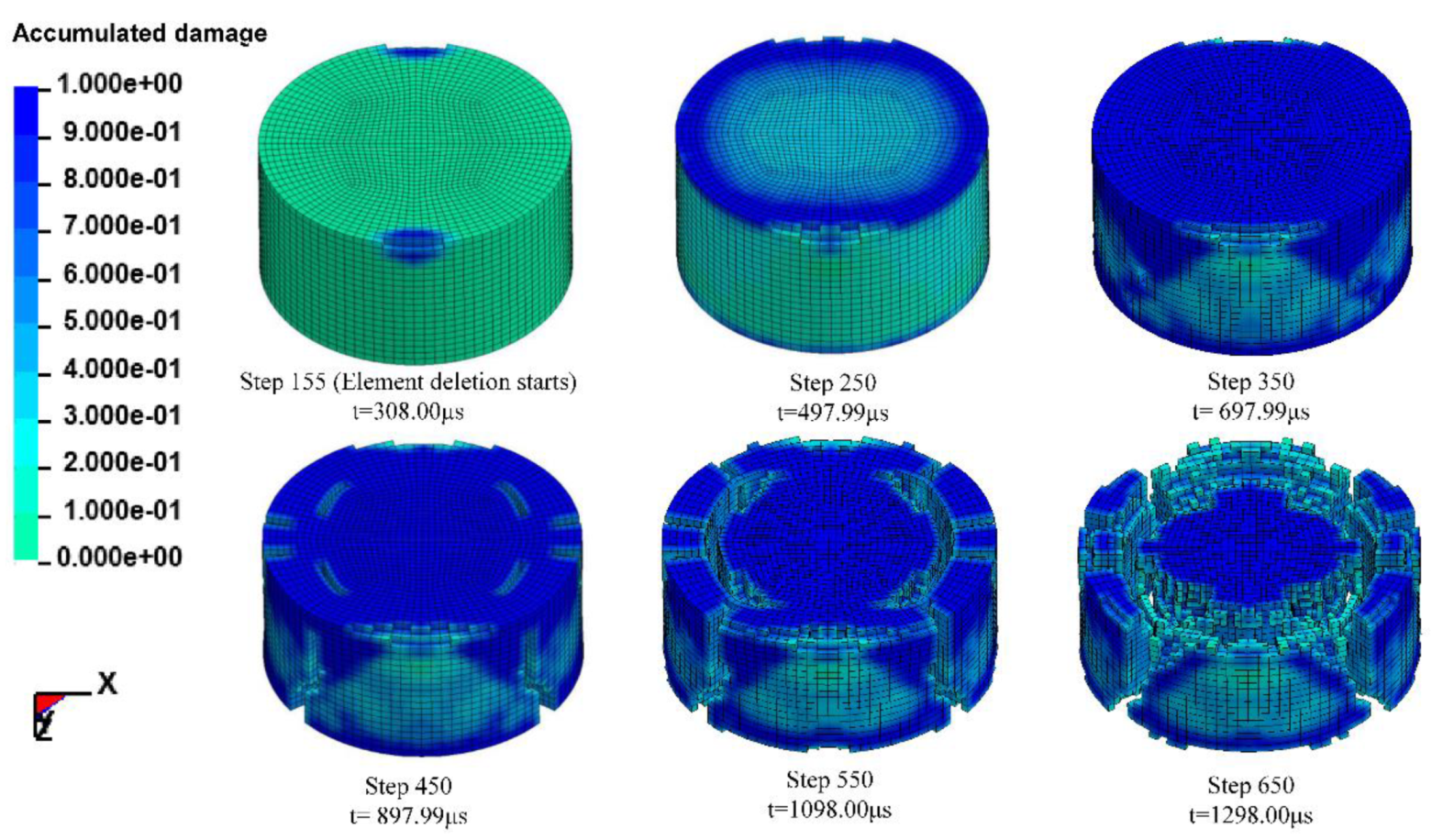

4.3. Failure Criterion and the Damage Mode

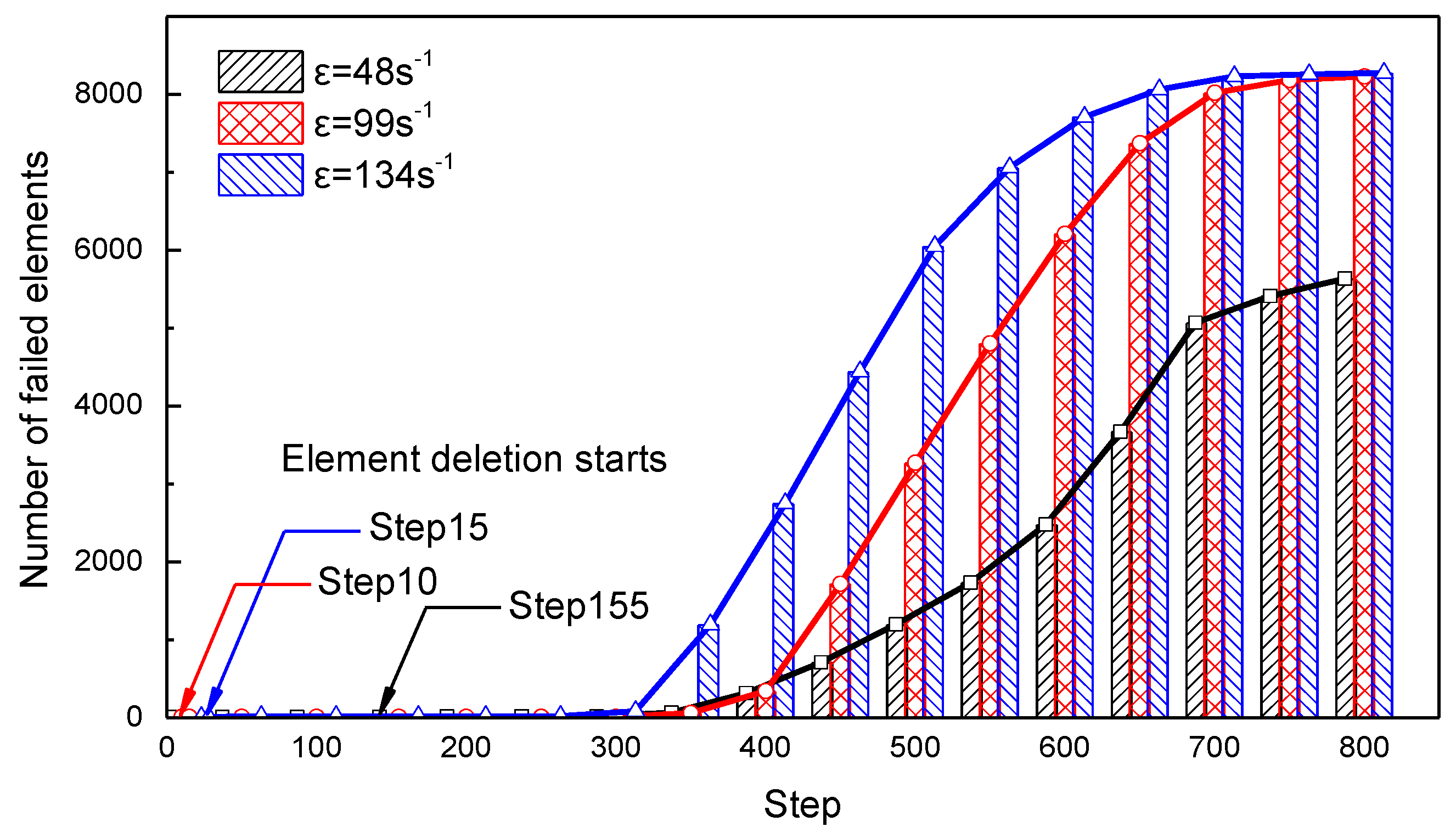

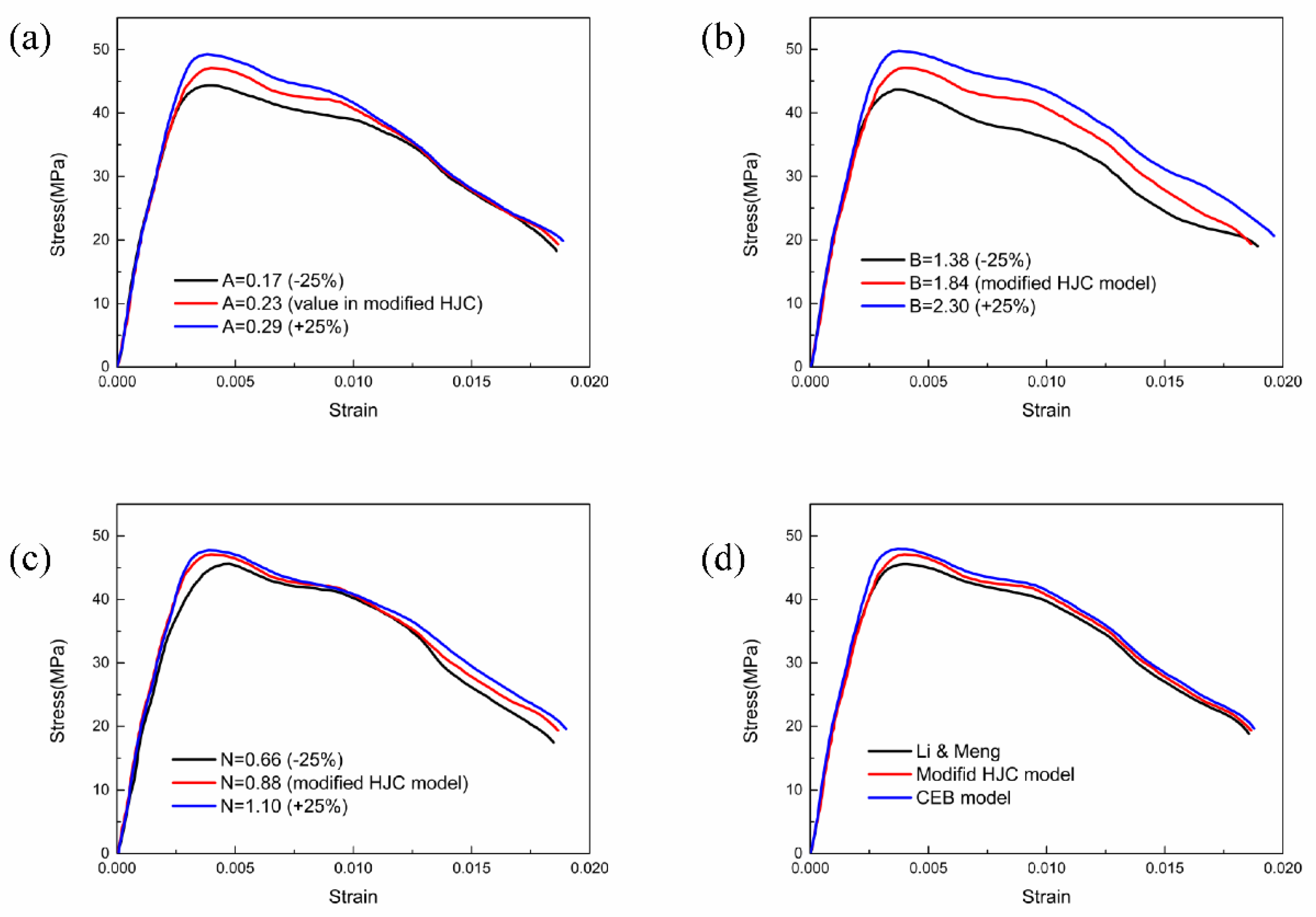

5. Parameter Studies

6. Conclusions

- (1)

- The triaxial compressive test and SHPB experimental results of RCC are provided as the basis of the modified HJC model. Then, the strength yield surface and the strain rate effect represented in the HJC model are modified by combining the triaxial compressive test results of concrete (including RCC and normal concrete for the limitation of the effective experimental data) and the SHPB experimental data of RCC, while the maximum principal strain failure criterion is adopted to describe the crushing and fracture properties of RCC. Parameters in the modified HJC model are obviously different from the values in the original model, and these corrections contribute to a more credible and accurate constitutive model to predict the dynamic mechanical characteristics of RCC.

- (2)

- The improved simulation method is established by the parameters obtained from the modified HJC model. The custom-shaped punch is replaced by loading a half-sine stress wave at the front surface of the incident bar, and contact of the eroding surface to the surface is employed, which shows great consistency with the SHPB experiment.

- (3)

- An improvement in the simulation with the parameters obtained from the modified HJC model is demonstrated compared to the test data. Stress–strain curves from the SHPB simulation results agree well with the experimental results, and the typical element at different parts of the specimen shows a similar stress–strain law to that of the results from the three-wave method.

- (4)

- The influence of the failure criterion, normalized parameters, pressure hardening exponent and strain rate effect on the dynamic compressive characteristics of RCC are analysed. The parameters referred to on the yield surface mainly affect the ascending section of the stress–strain curve, while the failure criterion basically controls the unloading section. Adopting the maximum principal strain failure criterion can better depict the specimen failure than the shear strain failure criterion, and is recommended for RCC so that the failure process of the RCC specimen simulated via the modified HJC model is consistent with the results captured by the high-speed camera. The results of the dynamic mechanical behaviour of RCC specimens obtained from the SHPB experiment and simulation are reliable and effective and agree well with each other.

Author Contributions

Funding

Conflicts of Interest

References

- Wang, C.; Chen, W.; Hao, H.; Zhang, S.; Song, R.; Wang, X. Experimental investigations of dynamic compressive properties of roller compacted concrete (RCC). Constr. Build. Mater. 2018, 168, 671–682. [Google Scholar] [CrossRef]

- Chi, M.; Huang, R. Effect of circulating fluidized bed combustion ash on the properties of roller compacted concrete. Cem. Concr. Compos. 2014, 45, 148–156. [Google Scholar] [CrossRef]

- Atiş, C.D. Strength properties of high-Volume fly ash roller compacted and workable concrete, and influence of curing condition. Cem. Concr. Res. 2005, 35, 1112–1121. [Google Scholar] [CrossRef]

- Cui, J.; Hong, H.; Shi, Y.C. Discussion on the suitability of concrete constitutive models for high-Rate response predictions of RC structures. Int. J. Impact Eng. 2017, 106, 202–216H. [Google Scholar] [CrossRef]

- Hao, Y.F.; Hao, H.; Jiang, G.P.; Zhou, Y. Experimental confirmation of some factors influencing dynamic concrete compressive strengths in high-Speed impact tests. Cem. Concr. Res. 2013, 52, 63–70. [Google Scholar] [CrossRef]

- Li, Q.B.; Zhang, C.H.; Wang, G.L. Dynamic damage constitutive model of concrete in uniaxial tension. Eng. Fract. Mech. 1996, 53, 449–455. [Google Scholar]

- Holmquist, T.J.; Johnson, G.R. A computational constitutive model for glass subjected to large strains, high strain rates and high pressures. J. Appl. Mech. 2011, 78, 051003. [Google Scholar] [CrossRef]

- Riedel, W.; Kawai, N.; Kondo, K.I. Numerical assessment for impact strength measurements in concrete materials. Int. J. Impact Eng. 2009, 36, 283–293. [Google Scholar] [CrossRef]

- Huang, F.L.; Wu, H.J.; Jin, Q.K.; Zhang, Q.M. A numerical simulation on the perforation of reinforced concrete targets. Int. J. Impact Eng. 2005, 32, 173–187. [Google Scholar] [CrossRef]

- Wu, Y.; Crawford, J.E.; Magallanes, J.M. Performance of LS-DYNA concrete constitutive models. In Proceedings of the 12th International LS-DYNA Users Conference, Detroit, MI, USA, 3–5 June 2012; pp. 3–5. [Google Scholar]

- Malvar, L.J.; Crawford, J.E.; Wesevich, J.W.; Simons, D. A plasticity concrete material model for DYNA3D. Int. J. Impact Eng. 1997, 19, 847–873. [Google Scholar] [CrossRef]

- Whirley, R.G.; Englemann, B.E. DYNA3D: A Nonlinear Explicit Three-Dimensional Finite Element Code for Solid and Structural Mechanics—User’s Manual; Report, UCRL-MA-107254 Revision 1; Lawrence Livermore National Laboratory: Livermore, CA, USA, 1991.

- Murray, Y.D.; Abu-Odeh, A.Y.; Bligh, R.P. Evaluation of LS-DYNA concrete material model 159 (No. FHWA-HRT-05-063). 2007. [Google Scholar]

- Polanco-Loria, M.; Hopperstad, O.S.; Børvik, T.; Berstad, T. Numerical predictions of ballistic limits for concrete slabs using a modified version of the HJC concrete model. Int. J. Impact Eng. 2008, 35, 290–303. [Google Scholar] [CrossRef]

- Nanni, A. Properties and design of fiber reinforced roller compacted concrete. Transp. Res. Rec. 1989, 1226, 61–68. [Google Scholar]

- Jowkarmeimandi, R.; Aslani, F. Stress–Strain model for concrete under cyclic loading. Mag. Concr. Res. 2012, 64, 673–685. [Google Scholar]

- Wang, X.H.; Zhang, S.R.; Wang, C.; Song, R.; Shang, C.; Fang, X. Experimental investigation of the size effect of layered roller compacted concrete (RCC) under high-Strain-Rate loading. Constr. Build. Mater. 2018, 165, 45–57. [Google Scholar] [CrossRef]

- Zhang, S.R.; Wang, X.H.; Wang, C.; Song, R.; Huo, H.Y. Compressive behavior and constitutive model for roller compacted concrete under impact loading: Considering vertical stratification. Constr. Build. Mater. 2017, 151, 428–440. [Google Scholar] [CrossRef]

- Wang, X.H.; Zhang, S.R.; Wang, C.; Song, R.; Shang, C.; Cao, K.L. Fragmentation-Based dynamic size effect of layered roller compacted concrete (RCC) under impact loadings. Constr. Build. Mater. 2018, 192, 58–69. [Google Scholar] [CrossRef]

- Zhang, S.R.; Song, R.; Wang, C.; Wang, X.H. Experimental Investigation of the Compressive Behavior of RCC under High Strain Rates: Considering the Rolling Technique and Layered Structure. J. Mater. Civ. Eng. 2018. [Google Scholar] [CrossRef]

- Ross, C.A.; Tedesco, J.W. Split-Hopkinson pressure-Bar tests on concrete and mortar in tension and compression. Mater. J. 1989, 86, 475–481. [Google Scholar]

- Le Nard, H.; Bailly, P. Dynamic behaviour of concrete: The structural effects on compressive strength increase. Mech. Cohesive-Frict. Mater. 2000, 5, 491–510. [Google Scholar] [CrossRef]

- Hao, Y.F.; Hao, H. Numerical evaluation of the influence of aggregates on concrete compressive strength at high strain rate. Int. J. Prot. Struct. 2011, 2, 177–206. [Google Scholar] [CrossRef]

- Holmquist, T.J.; Johnson, G.R.; Cook, W.H. A computational constitutive model for concrete subjected to large strains, high strain rates, and high pressures. In Proceedings of the 14th International Symposium on Ballistics, Québec City, QC, Canada, 26–29 September 1993; pp. 591–600. [Google Scholar]

- Lu, G.; Li, X.B.; Wang, K.J. A numerical study on the damage of projectile impact on concrete targets. Comput. Concr. 2012, 9, 21–33. [Google Scholar] [CrossRef]

- Ren, G.M.; Wu, H.; Fang, Q.; Kong, X.Z. Parameters of Holmquist-Johnson-Cook model for high-Strength concrete-Like materials under projectile impact. Int. J. Prot. Struct. 2017. [Google Scholar] [CrossRef]

- Deng, R.G. Mechanical properties of roller compacted concrete. J. Southwest Jiaotong Univ. 2002, 37, 19–25. [Google Scholar]

- Yan, D.; Lin, G.; Xu, P. Dynamic strength and deformation of concrete in triaxial stress states. Eng. Mech. 2007, 24, 58–64. [Google Scholar]

- Hou, Z.G. Research on concrete strength under triaxial strength. Master’s Thesis, Hebei University of Technology, Tianjin, China, 2006. [Google Scholar]

- Hao, Y.; Hao, H.; Li, Z.-X. Numerical analysis of lateral inertial confinement effects on impact test of concrete compressive material properties. Int. J. Prot. Struct. 2010, 1, 145–167. [Google Scholar] [CrossRef]

- Xu, H.; Wen, H.M. A computational constitutive model for concrete subjected to dynamic loadings. Int. J. Impact Eng. 2016, 91, 116–125. [Google Scholar] [CrossRef]

- CEB-FIP, MC90. Design of Concrete Structures; CEB-FIP Model Code 1990; British Standard Institution: London, UK, 1993. [Google Scholar]

- Li, Q.M.; Meng, H. About the dynamic strength enhancement of concrete-Like materials in a split Hopkinson pressure bar test. Int. J. Solids Struct. 2003, 40, 343–360. [Google Scholar] [CrossRef]

- Tedesco, J.W.; Ross, C.A. Strain-Rate-Dependent constitutive equations for concrete. J. Press. Vessel Technol. 1998, 120, 398–405. [Google Scholar] [CrossRef]

- Malvern, L.E.; Jenkins, D.A.; Tang, T.; Ross, C.A. Dynamic compressive testing of concrete. In Proceedings of the 2nd Symposium on the Interaction of Non-Nuclear Munitions with Structures, Panama City Beach, FL, USA, 15–18 April 1985; pp. 194–199. [Google Scholar]

- ACI Committee. Building Code Requirements for Reinforced Concrete and Commentary; American Concrete Institute: Detroit, MI, USA, 2002. [Google Scholar]

- Beshara FBA. Smeared crack analysis for reinforced concrete structures under blast-Type loading. Eng. Fract. Mech. 1993, 45, 119–140. [Google Scholar] [CrossRef]

- Bittencourt, T.N.; Wawrzynek, P.A.; Ingraffea, A.R.; Sousa, J.L. Quasi-Automatic simulation of crack propagation for 2D LEFM problems. Eng. Fract. Mech. 1996, 55, 321–334. [Google Scholar] [CrossRef]

- Grote, D.L.; Park, S.W.; Zhou, M. Dynamic behavior of concrete at high strain rates and pressures: I. experimental characterization. Int. J. Impact Eng. 2001, 25, 869–886. [Google Scholar] [CrossRef]

- Manual, LS-DYNA Keyword User’s; Volume, I. Version 971; Livermore Software Technology Corporation: Livermore, CA, USA, 2007; Volume 7374, p. 354.

- Zhang, S.R.; Li, H.B.; Wang, G.H.; Kong, Y. Comparative analysis of mesh size effects on numerical simulation of shock wave in air blast and underwater explosion. J. Hydraul. Eng. 2015, 46, 298–309. [Google Scholar]

- Kong, X.Z.; Fang, Q.; Li, Q.M.; Hao, W.; John, E.C. Modified K&C model for cratering and scabbing of concrete slabs under projectile impact. Int. J. Impact Eng. 2017. [Google Scholar] [CrossRef]

- Meng, H.; Li, Q.M. Correlation between the accuracy of a SHPB test and the stress uniformity based on numerical experiments. Int. J. Impact Eng. 2003, 28, 537–555. [Google Scholar] [CrossRef]

| W/C | Sand Ratio (%) | Fly Ash Content (%) | Water Reducing Agent (%) | Air Entraining Agent (%) | Material Consumption (kg/m3) | Air Content (%) | Wet Density (kg/m3) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Water | Cement | Fly Ash | Sand | Aggregate | |||||||

| 0.50 | 31 | 60 | 0.8 | 0.05 | 88 | 70 | 106 | 672 | 1507 | 3.8 | 2453 |

| Peak Additional Axial Stress | Peak Axial Strain | Peak Lateral Strain | ||

|---|---|---|---|---|

| 0 | 0 | 14.9 | 0.411 | −0.237 |

| 5 | 0.34 | 26.1 | 0.625 | −0.490 |

| 10 | 0.67 | 37.3 | 1.578 | −0.760 |

| 15 | 1.01 | 41.9 | 2.270 | −1.279 |

| 20 | 1.34 | 50.3 | 3.078 | −2.228 |

| 25 | 1.68 | 54.1 | 3.630 | −2.849 |

| 30 | 2.01 | 60.1 | 4.516 | −3.478 |

| Fundamental Parameters | Yield Surface | Damage Parameters | EOS Parameters | ||||

|---|---|---|---|---|---|---|---|

| 2350 kg·m−3 | 0.23 | 0.04 | 7.0 MPa | ||||

| 10.63 GPa | 1.84 | 1.00 | 0.005 | ||||

| 20.68 MPa | 0.88 | 0.01 | 800 MPa | ||||

| 2.80 MPa | 7.00 | 0.12 | |||||

| 85 GPa | |||||||

| −171 GPa | |||||||

| 208 GPa | |||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Song, R.; Wang, G.; Zhang, S.; Cao, X.; Wei, P. Modifications of the HJC (Holmquist–Johnson–Cook) Model for an Improved Numerical Simulation of Roller Compacted Concrete (RCC) Structures Subjected to Impact Loadings. Materials 2020, 13, 1361. https://doi.org/10.3390/ma13061361

Wang C, Song R, Wang G, Zhang S, Cao X, Wei P. Modifications of the HJC (Holmquist–Johnson–Cook) Model for an Improved Numerical Simulation of Roller Compacted Concrete (RCC) Structures Subjected to Impact Loadings. Materials. 2020; 13(6):1361. https://doi.org/10.3390/ma13061361

Chicago/Turabian StyleWang, Chao, Ran Song, Gaohui Wang, Sherong Zhang, Xuexing Cao, and Peiyong Wei. 2020. "Modifications of the HJC (Holmquist–Johnson–Cook) Model for an Improved Numerical Simulation of Roller Compacted Concrete (RCC) Structures Subjected to Impact Loadings" Materials 13, no. 6: 1361. https://doi.org/10.3390/ma13061361

APA StyleWang, C., Song, R., Wang, G., Zhang, S., Cao, X., & Wei, P. (2020). Modifications of the HJC (Holmquist–Johnson–Cook) Model for an Improved Numerical Simulation of Roller Compacted Concrete (RCC) Structures Subjected to Impact Loadings. Materials, 13(6), 1361. https://doi.org/10.3390/ma13061361