The Radial Piezoelectric Response from Three-Dimensional Electrospun PVDF Micro Wall Structure

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Electrospinning Solution Preparation

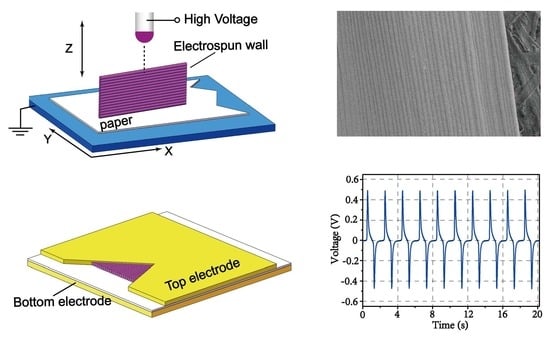

2.3. Three-Dimensional Electrospinning for Fabrication of Micro Wall

2.4. Characterization and Measurements

3. Results and Discussion

3.1. Fabricaition and Characterization

3.2. Piezoelectric Performance

3.3. Enhancement of Electrical Outputs

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Brown, L.F. Design considerations for piezoelectric polymer ultrasound transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Contr. 2000, 47, 1377–1396. [Google Scholar] [CrossRef] [PubMed]

- Ramadan, K.S.; Sameoto, D.; Evoy, S. A review of piezoelectric polymers as functional materials for electromechanical transducers. Smart Mater. Struct. 2014, 23, 033001. [Google Scholar] [CrossRef]

- Bowen, C.R.; Kim, H.A.; Weaver, P.M.; Dunn, S. Piezoelectric and ferroelectric materials and structures for energy harvesting applications. Energy Environ. Sci. 2013, 7, 25–44. [Google Scholar] [CrossRef] [Green Version]

- Vicente, J.; Costa, P.; L-Mendez, S.; Abete, J.M.; Iturrospe, A. Electromechanical properties of PVDF-based polymers reinforced with nanocarbonaceous fillers for pressure sensing applications. Materials 2019, 12, 3545. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cui, Z.; Drioli, E.; Lee, Y.M. Recent progress in fluoropolymers for membranes. Prog. Polym. Sci. 2014, 39, 164–198. [Google Scholar] [CrossRef]

- Esfahani, H.; Jose, R.; Ramakrishna, S. Electrospun ceramic nanofiber mats today: Synthesis, properties, and applications. Materials 2017, 10, 1238. [Google Scholar] [CrossRef] [Green Version]

- Xue, J.; Wu, T.; Dai, Y.; Xia, Y. Electrospinning and Electrospun nanofibers: Methods, materials, and applications. Chem. Rev. 2019, 119, 5298–5415. [Google Scholar] [CrossRef]

- Fang, J.; Zhu, Y.; Lin, T. Electrical power generator from randomly oriented electrospun poly (vinylidene fluoride) nanofibre membrabes. J. Mater. Chem. 2011, 21, 11088–11091. [Google Scholar] [CrossRef] [Green Version]

- Chang, C.; Tran, V.H.; Wang, J.; Fuh, Y.K.; Lin, L. Direct-write piezoelectric polymeric nanogenerator with high energy conversion efficiency. Nano Lett. 2010, 10, 726–731. [Google Scholar] [CrossRef]

- Mandal, D.; Yoon, S.; Kim, K.J. Origin of piezoelectricity in an electrospun poly (vinylidene fluoride-trifluoroethylene) nanofiber web-based nanogenerator and nano-pressure sensor. Macromol. Rapid Commun. 2011, 32, 831–837. [Google Scholar] [CrossRef]

- Yu, H.; Huang, T.; Lu, M.; Mao, M.; Zhang, Q.; Wang, H. Enhanced power output of an electrospun PVDF/MWCNTs-based nanogenerator by tuning its conductivity. Nanotechnology 2013, 24, 405401. [Google Scholar] [CrossRef] [PubMed]

- Pu, J.; Yan, Y.; Jiang, Y.; Chang, C.; Lin, L. Piezoelectric actuaton of direct-write electrospun fibers. Sens. Actuators A 2010, 164, 131–136. [Google Scholar] [CrossRef]

- Ren, G.; Cai, F.; Li, B.; Zheng, J.; Xu, C. Flexible pressure sensor based on a poly(VDF-TrFE) nanofiber web. Macromol. Mater. Eng. 2013, 298, 541–546. [Google Scholar] [CrossRef]

- Zhu, J.; Niu, X.; Hou, X.; He, J.; Chou, X.; Xue, X.; Zhang, W. Highly reliable real-time self-powered vibration sensor based on enhanced piezoelectric nanogenerator. Energy Technol. 2017, 6, 781–789. [Google Scholar] [CrossRef]

- Gui, J.; Zhu, Y.; Zhang, L.; Shu, X.; Liu, W.; Guo, S.; Zhao, X. Enhanced output-performance of piezoelectric poly(vinylidene fluoride trifluoroethylene) fibers-based nanogenerator with interdigital electrodes and well-ordered cylindrical cavities. Appl. Phys. Lett. 2018, 112, 072902. [Google Scholar] [CrossRef]

- Fuh, Y.K.; Chen, S.Y.; Ye, J.C. Massively parallel aligned microfibers-based harvester deposited via in situ, oriented poled near-field electrospinning. Appl. Phys. Lett. 2013, 103, 033114. [Google Scholar] [CrossRef]

- Luo, G.; Teh, K.S.; Liu, Y.; Zang, X.; Wen, Z.; Lin, L. Direct-write, self-aligned electrospinning on paper for controllable fabrication of three-dimensional structures. ACS Appl. Mater. Interfaces 2015, 7, 27765–27770. [Google Scholar] [CrossRef] [Green Version]

- Gregorio, R.; Ueno, E.M. Effect of crystalline phase, orientation and temperature on the dielectric properties of poly(vinylidene fluoride) (PVDF). J. Mater. Sci. 1999, 34, 4489–4500. [Google Scholar] [CrossRef]

- Fang, J.; Niu, H.; Wang, H.; Wang, X.; Lin, T. Enhanced mechanical energy harvesting using needleless electrospun poly(vinylidene fluoride) nanofibre webs. Energy Environ. Sci. 2013, 6, 2196–2202. [Google Scholar] [CrossRef]

- Fuh, Y.K.; Wang, B.S. Near field sequentially electrospun three-dimensional piezoelectric fibers arrays for self-powered sensors of human gesture recognition. Nano Energy 2016, 30, 677–683. [Google Scholar] [CrossRef]

- Cai, X.; Lei, T.; Sun, D.; Lin, L. A critical analysis of the α, β, and γ phases in poly(vinylidene fluoride) using FTIR. RSC Adv. 2017, 7, 15382–15389. [Google Scholar] [CrossRef] [Green Version]

- Yang, R.; Qin, Y.; Li, C.; Dai, L.; Zhang, Z.L. Characteristics of output voltage and current of integrated nanogenerators. Appl. Phys. Lett. 2009, 94, 022905. [Google Scholar] [CrossRef]

- Yang, R.; Qin, Y.; Dai, L.; Wang, Z.L. Power generation with laterally packaged piezoelectric fine wires. Nat. Nanotechnol. 2009, 4, 34–39. [Google Scholar] [CrossRef] [PubMed]

- Fan, F.R.; Tian, Z.Q.; Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, G.; Luo, Y.; Zhang, Q.; Wang, S.; Wang, L.; Li, Z.; Zhao, L.; Teh, K.S.; Jiang, Z. The Radial Piezoelectric Response from Three-Dimensional Electrospun PVDF Micro Wall Structure. Materials 2020, 13, 1368. https://doi.org/10.3390/ma13061368

Luo G, Luo Y, Zhang Q, Wang S, Wang L, Li Z, Zhao L, Teh KS, Jiang Z. The Radial Piezoelectric Response from Three-Dimensional Electrospun PVDF Micro Wall Structure. Materials. 2020; 13(6):1368. https://doi.org/10.3390/ma13061368

Chicago/Turabian StyleLuo, Guoxi, Yunyun Luo, Qiankun Zhang, Shubei Wang, Lu Wang, Zhikang Li, Libo Zhao, Kwok Siong Teh, and Zhuangde Jiang. 2020. "The Radial Piezoelectric Response from Three-Dimensional Electrospun PVDF Micro Wall Structure" Materials 13, no. 6: 1368. https://doi.org/10.3390/ma13061368